Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15 results about "Microparticle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

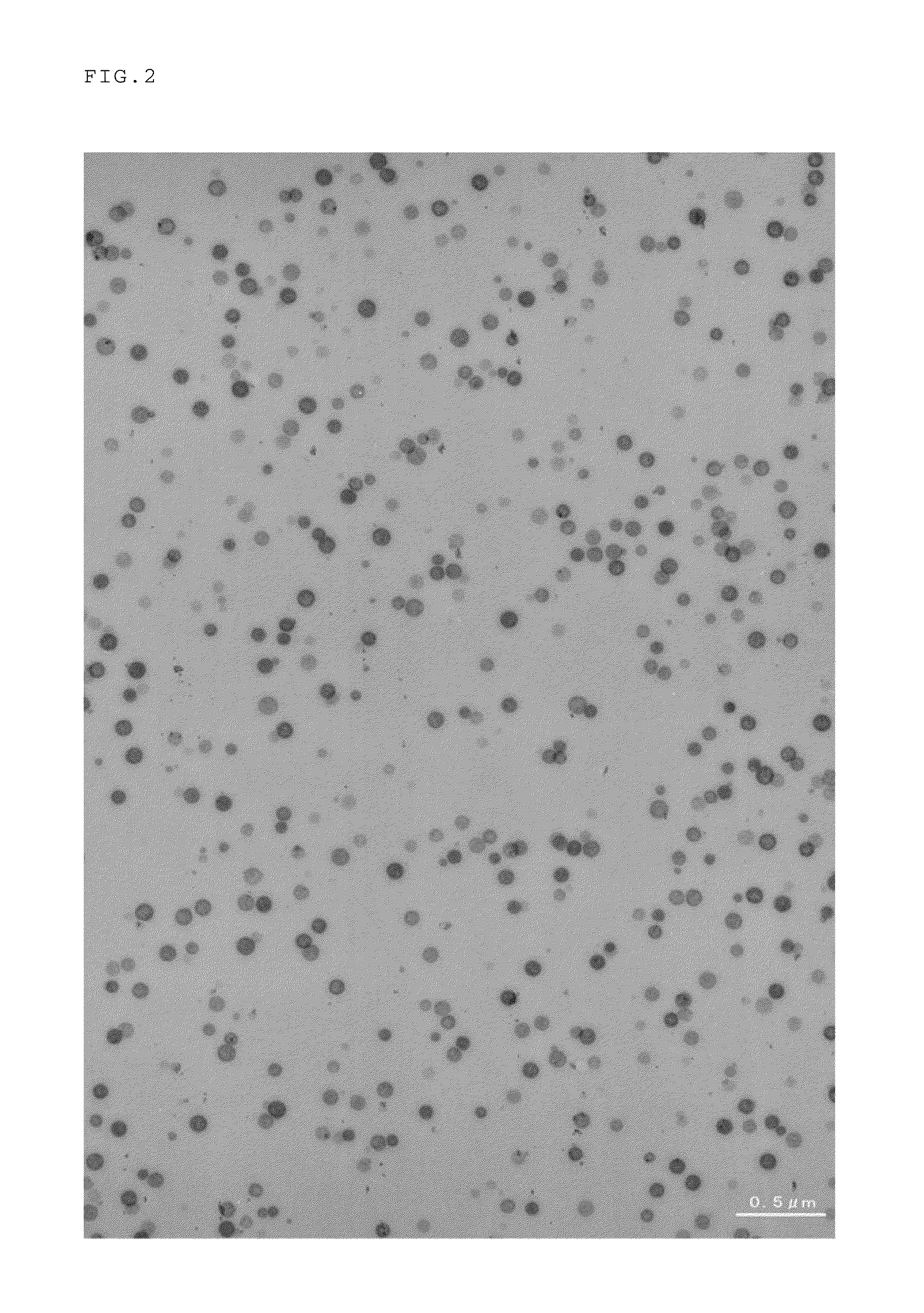

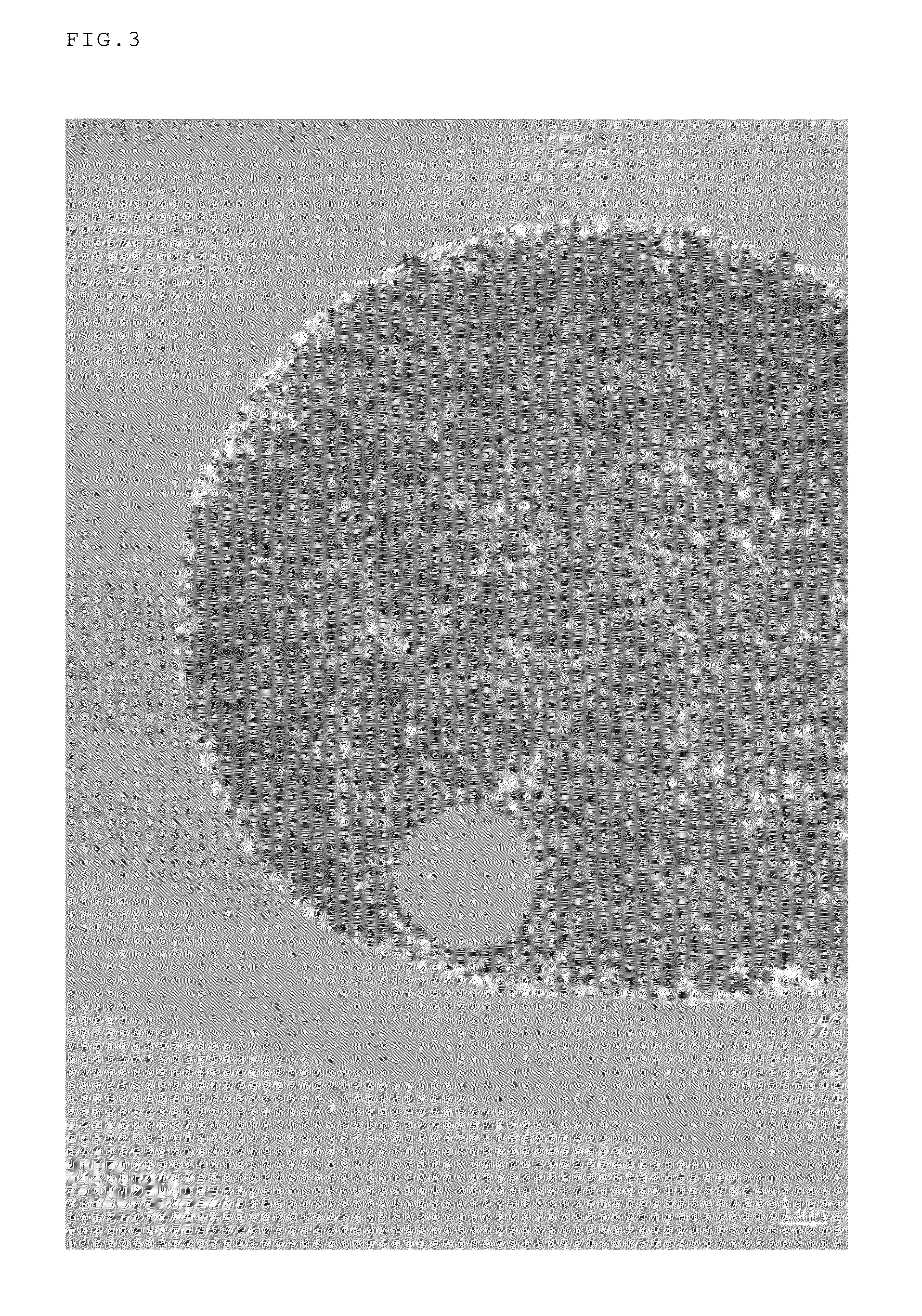

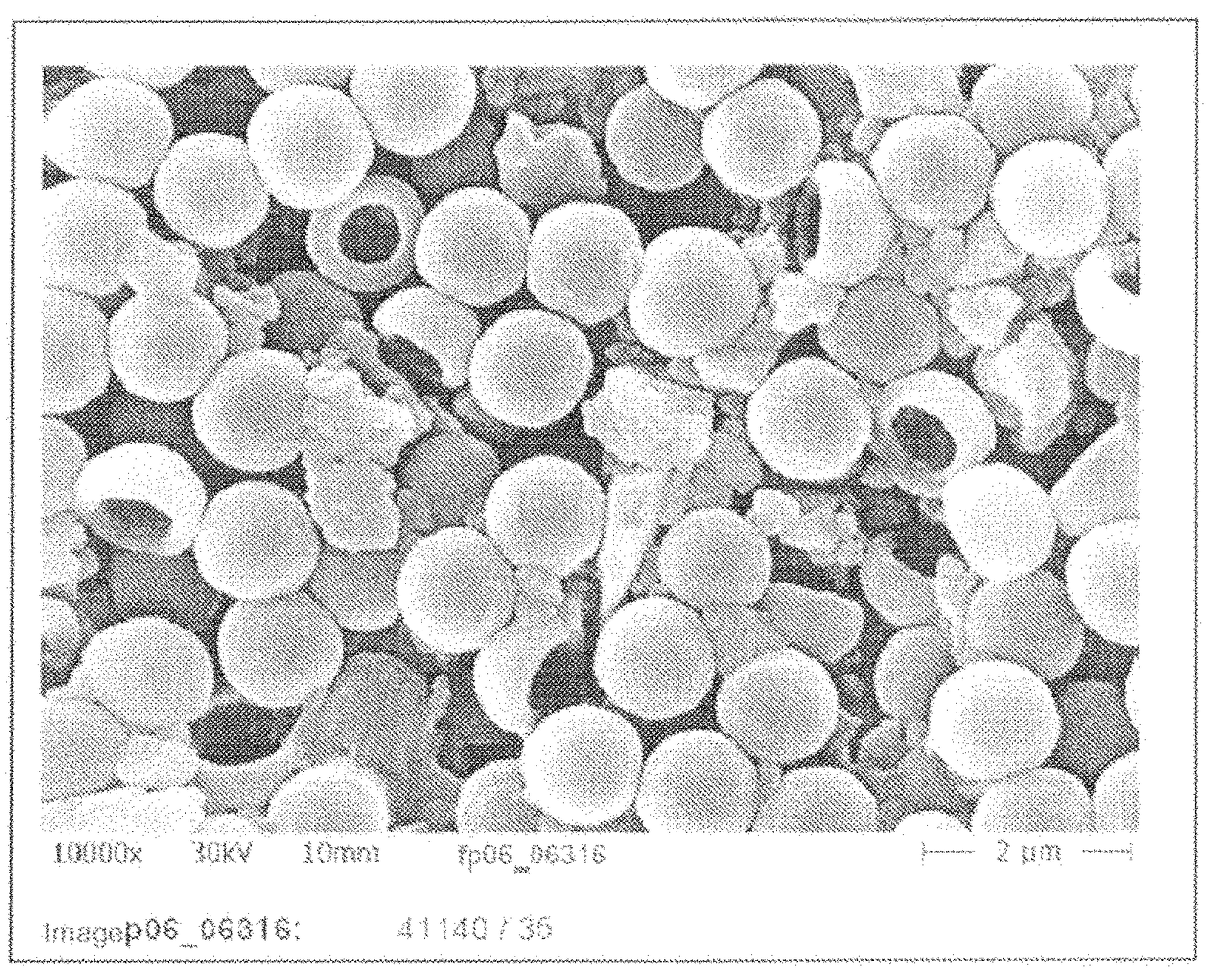

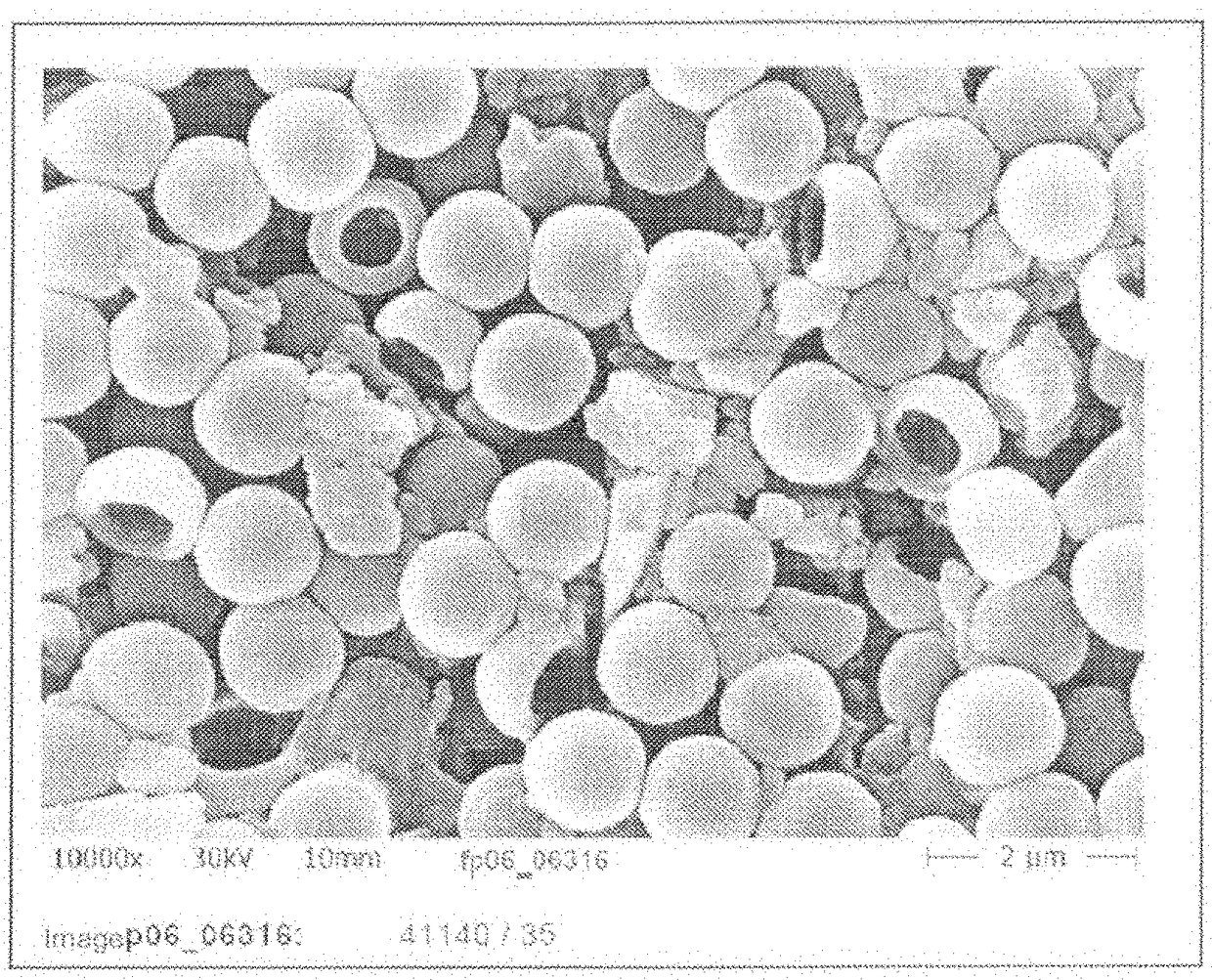

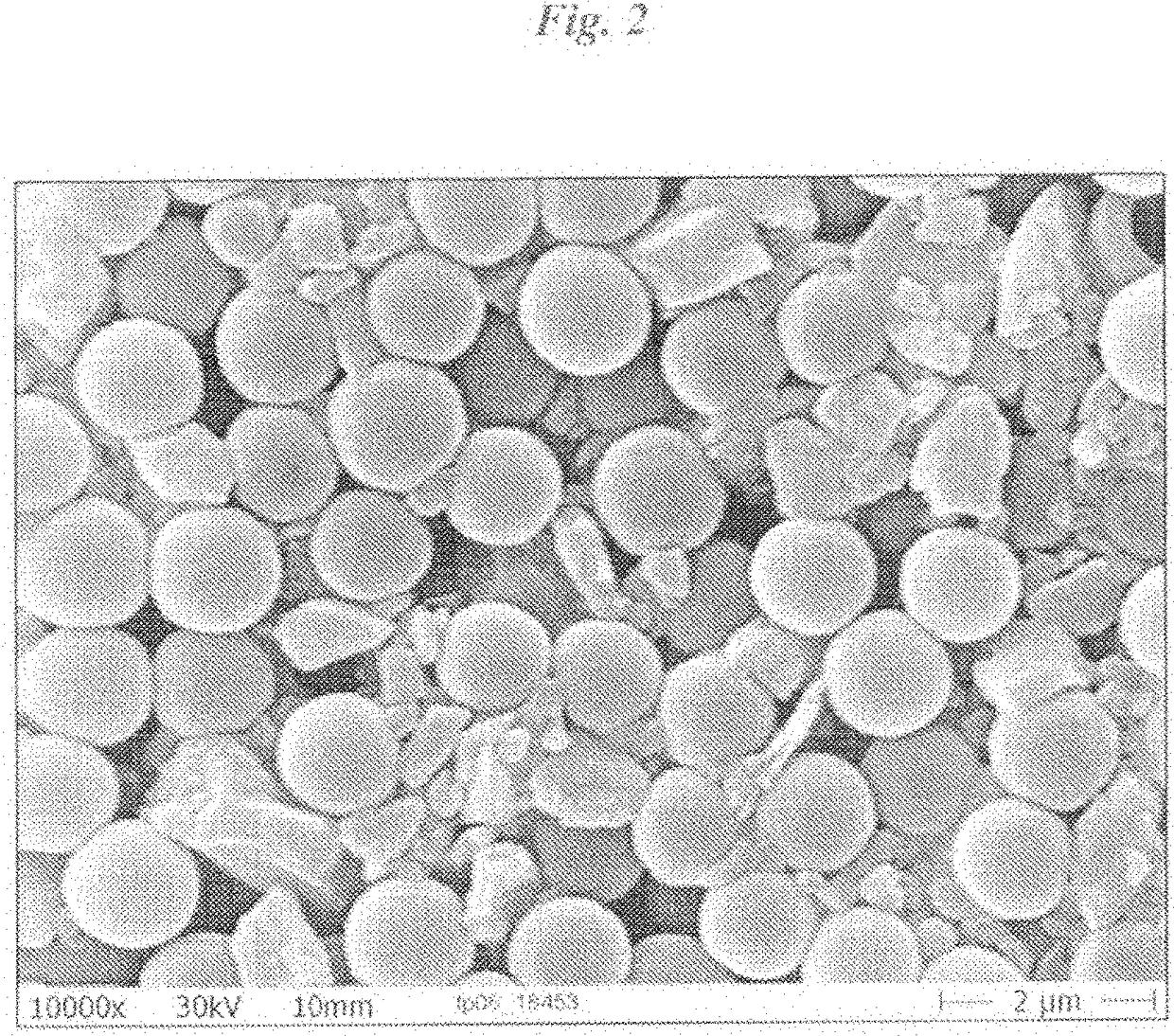

Microparticles are particles between 1 and 1000 μm in size. Commercially available microparticles are available in a wide variety of materials, including ceramics, glass, polymers, and metals. Microparticles encountered in daily life include pollen, sand, dust, flour, and powdered sugar.

Compositions and methods for treating conditions of the nail unit

InactiveUS20060275230A1Improve blood supplyPromote circulationBiocideCosmetic preparationsMicroparticlePhase change

Owner:TALIMA THERAPEUTICS INC

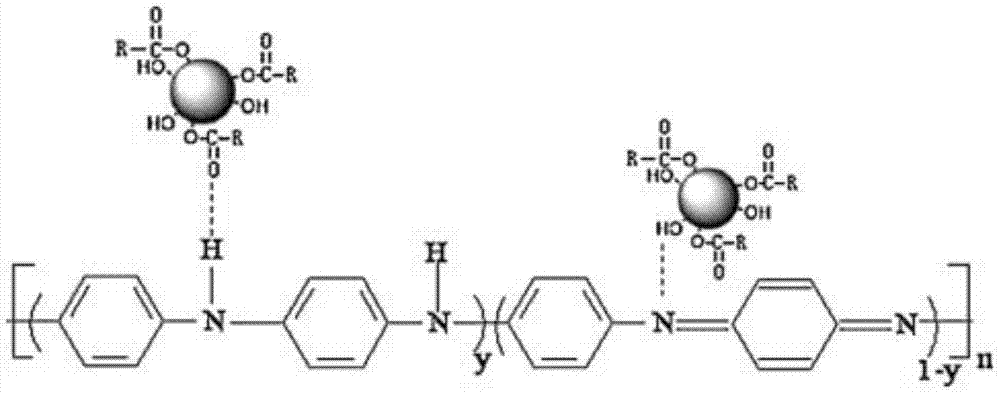

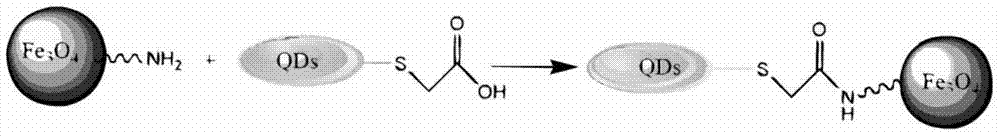

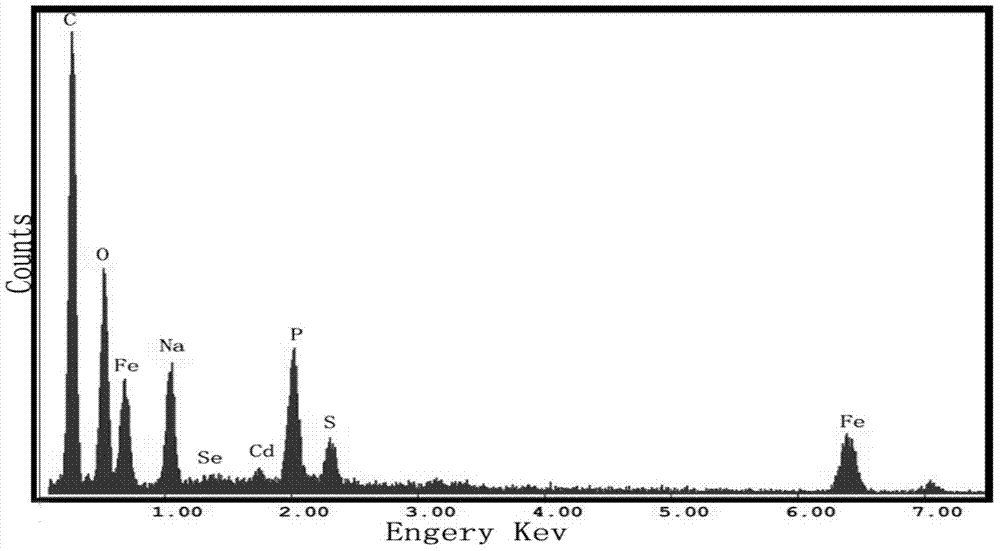

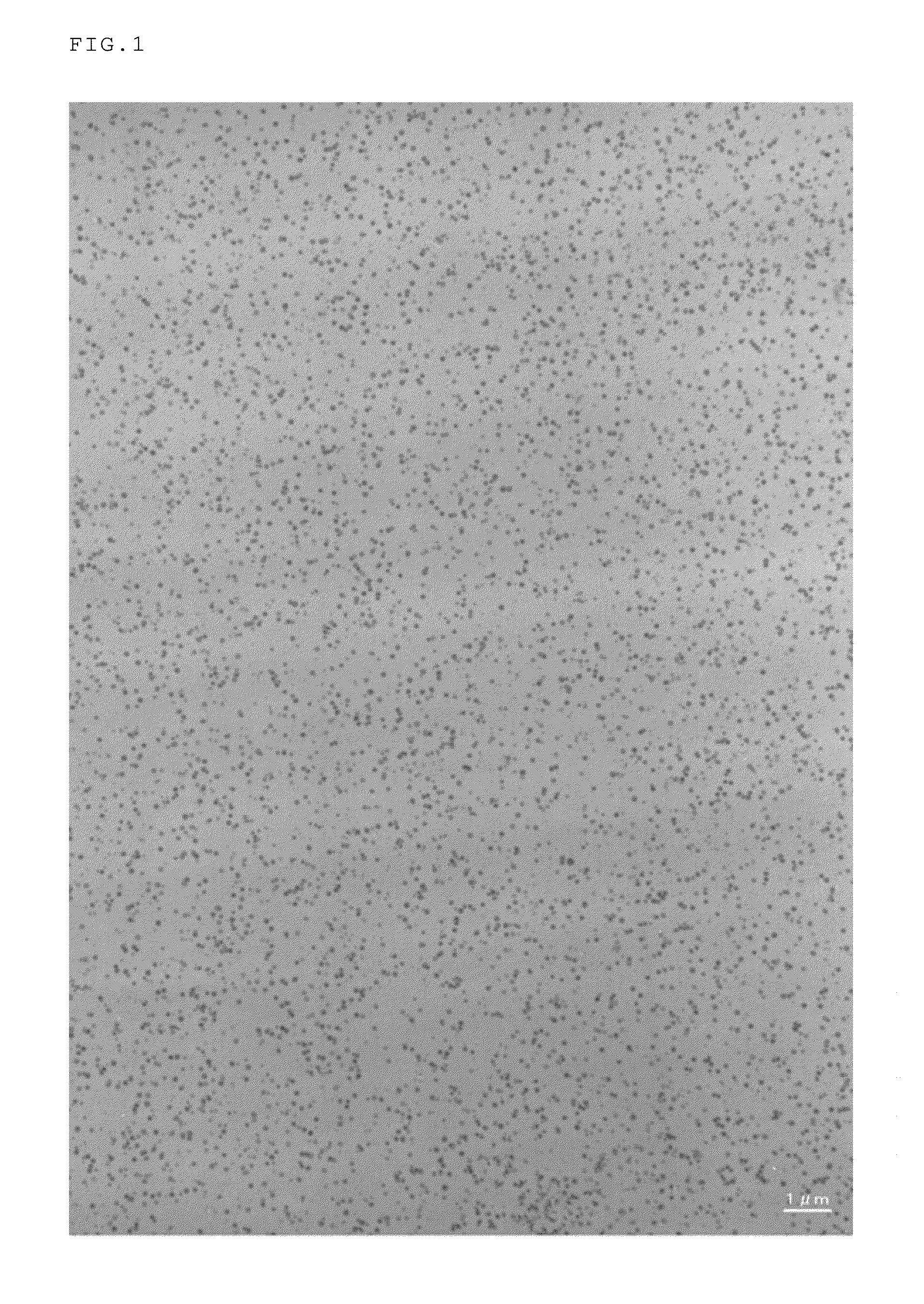

Magnetically fluorescent bifunctional microspheres prepared by connection of polyaniline magnetic microspheres and fluorescent quantum dots

InactiveCN103571493AWith magnetic and fluorescent dual functionsGood fluorescence propertiesMaterial nanotechnologyNanomagnetismMicrosphereBifunctional

Owner:SUZHOU UNIV OF SCI & TECH

Curable resin composition containing polymer microparticles

Owner:KANEKA NORTH AMERICA +1

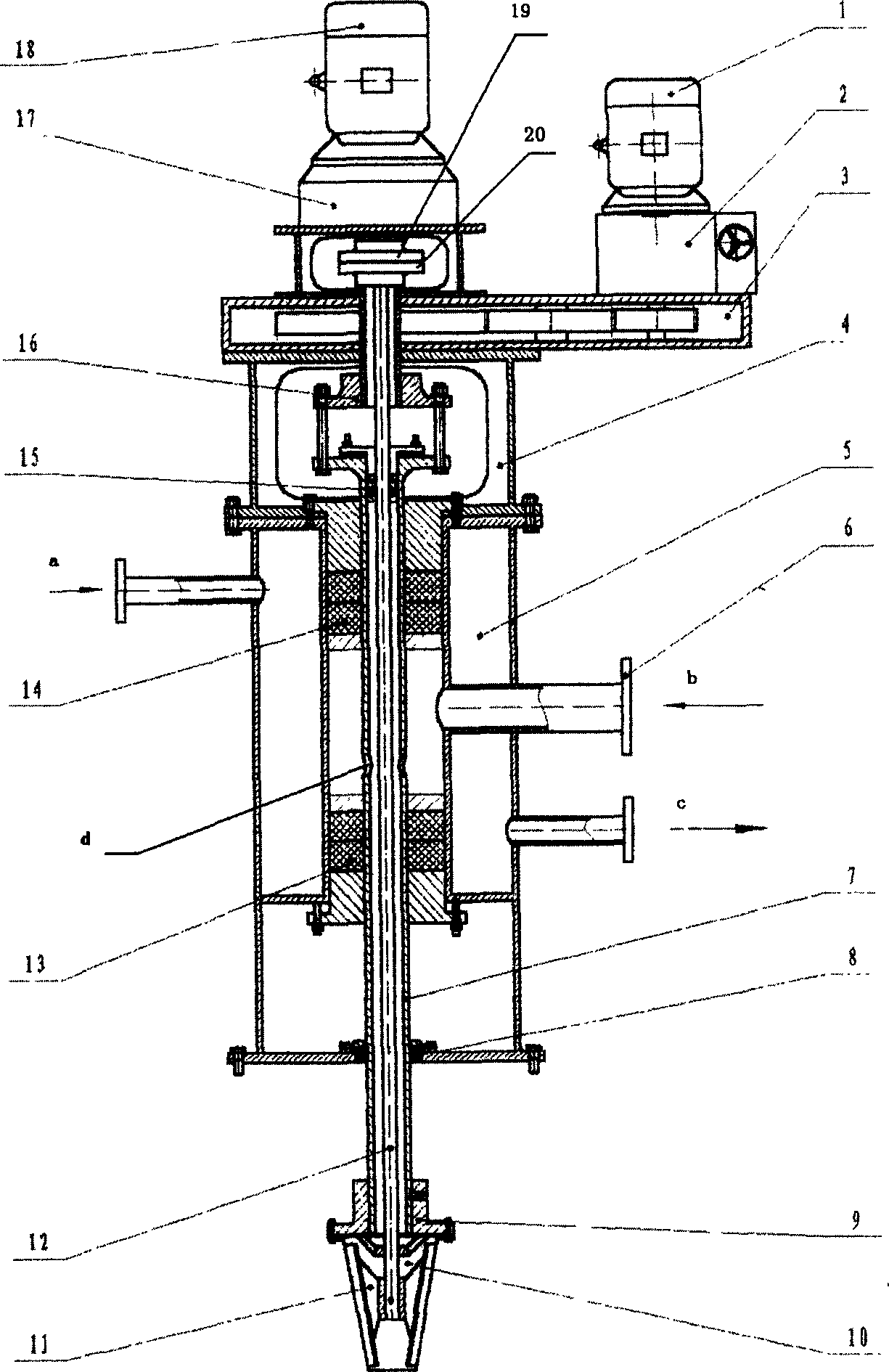

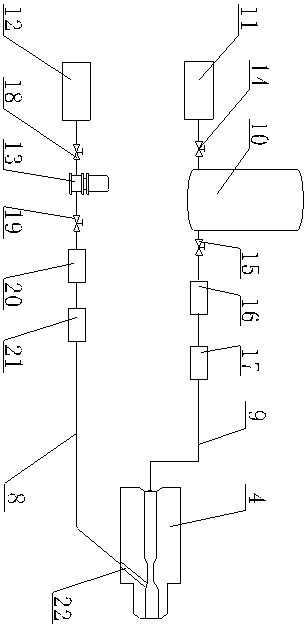

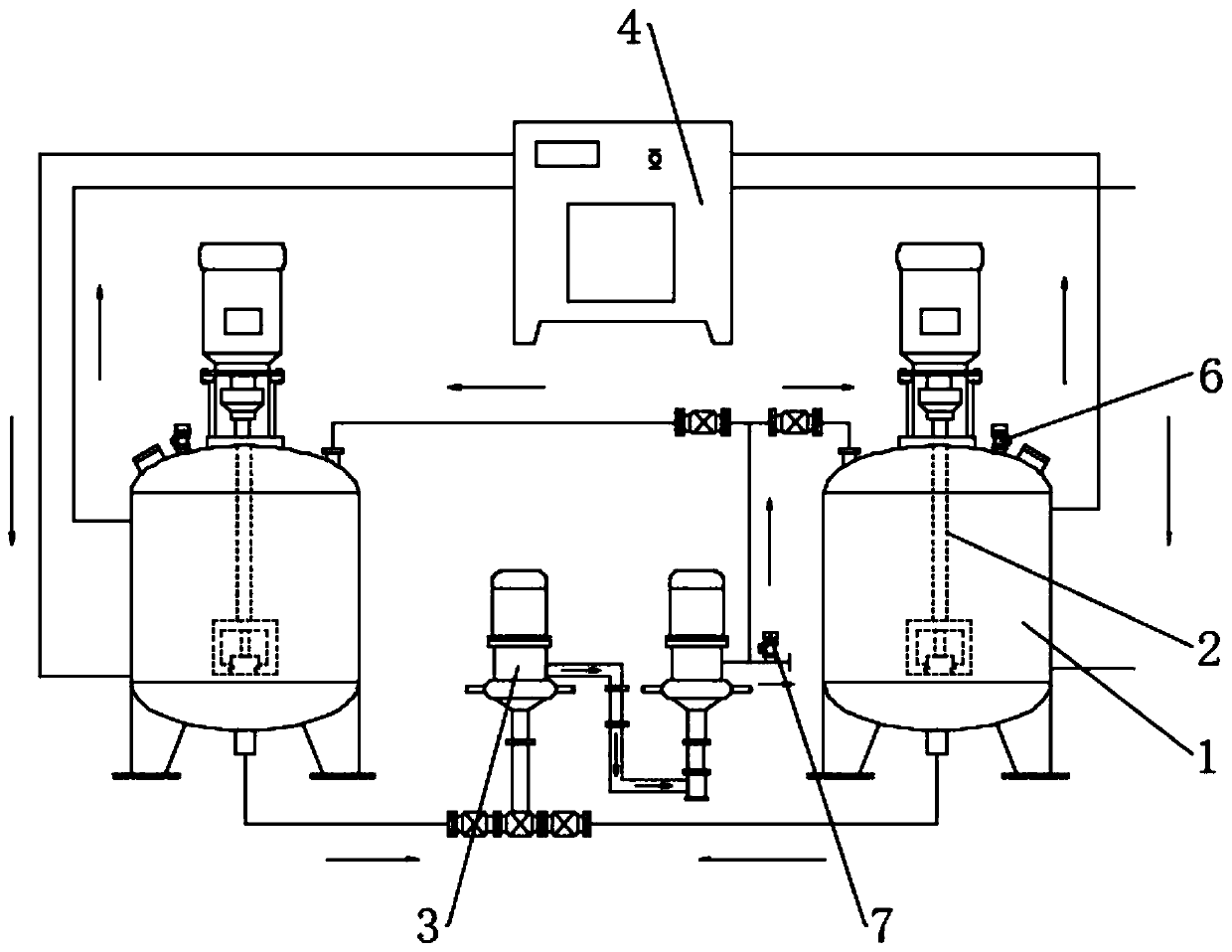

Applicator and method for transferring dispersion liquid

ActiveUS20080210160A1Bubble generating areReduce solubilityLiquid degasificationPressure pumpsBuffer tankDissolution

The present invention provides applicators reducing generating bubble. Dispersion liquid is supplied while the pressure of a circulation tank on the delivery side is lower than the atmospheric pressure but higher than the pressure of the space in buffer tanks. The dispersion liquid in the discharge chambers is recovered while the pressure in a circulation tank serving as recovery destination is lower than the atmospheric pressure. Gas dissolution can be reduced because the dispersion liquid does not come into contact with gases at pressures higher than the atmospheric pressure and engulffing gas or deformation of solid microparticles can be avoided because no pump is used.

Owner:ULVAC INC

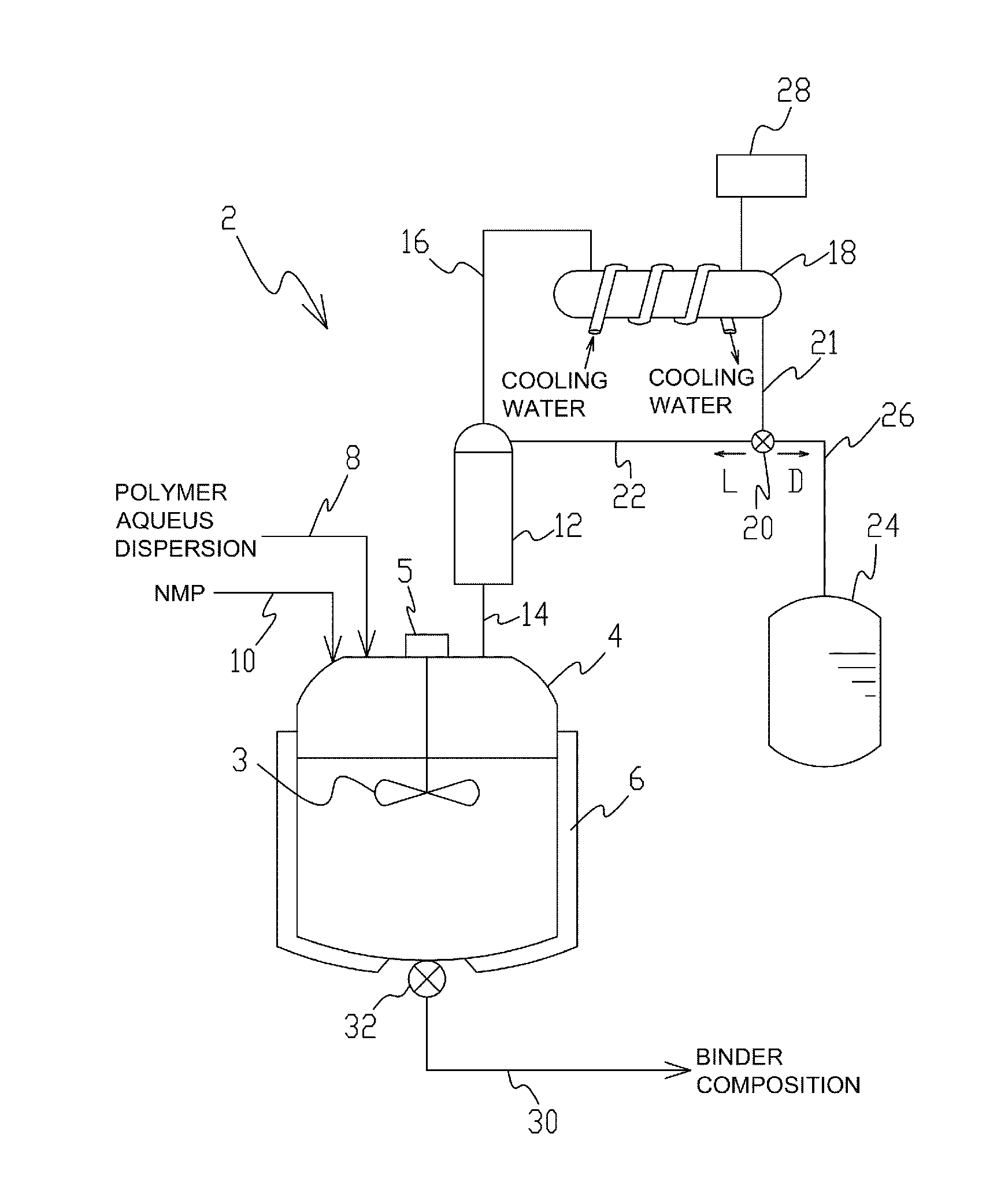

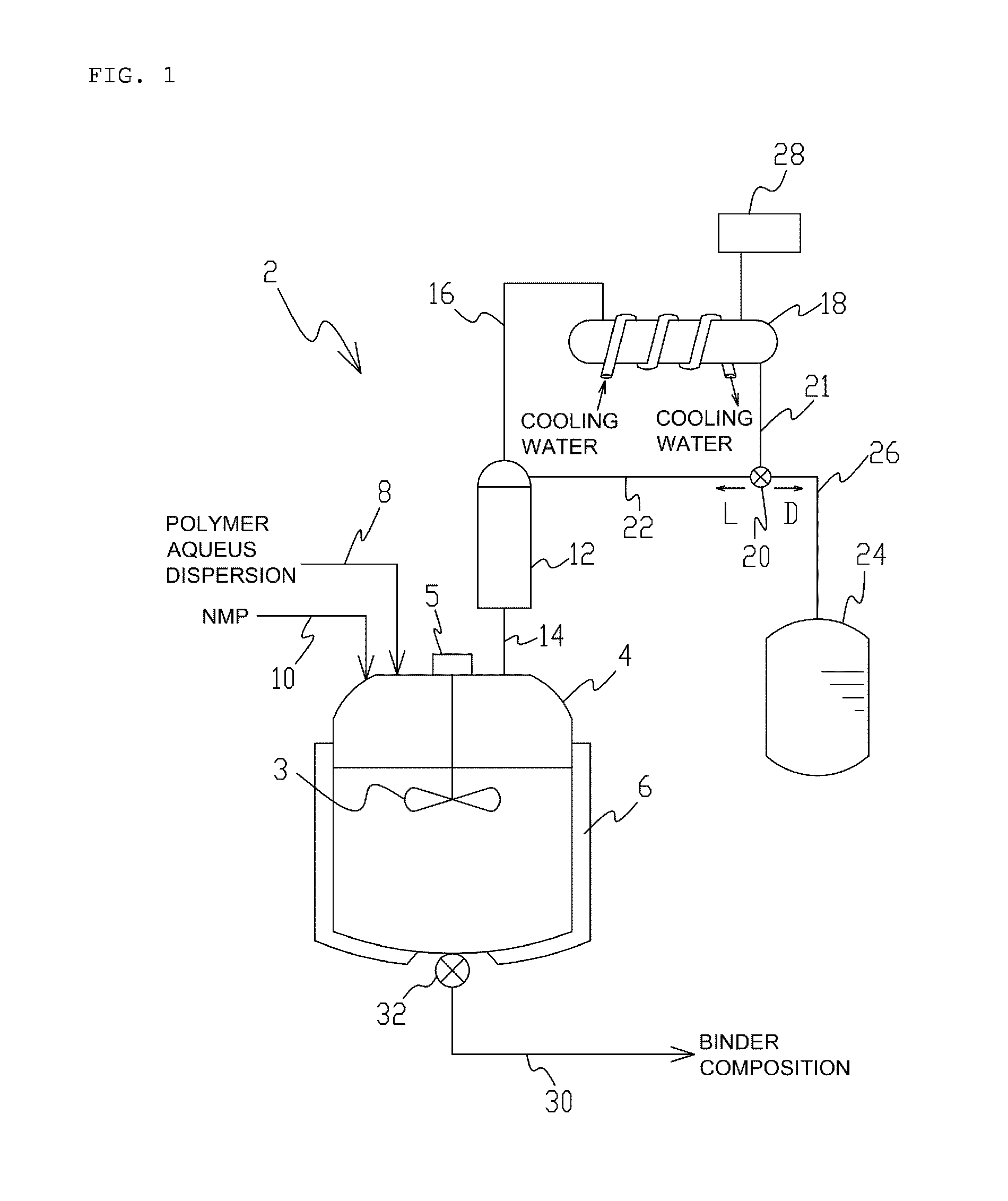

Method for producing slurry for heat-resistant layer for lithium ion secondary battery and method for producing electrode for lithium ion secondary battery

InactiveUS20140242296A1Reduce the amount of waterEfficiently obtainedElectrode manufacturing processesMixing methodsPolymer scienceDistillation

Owner:ZEON CORP

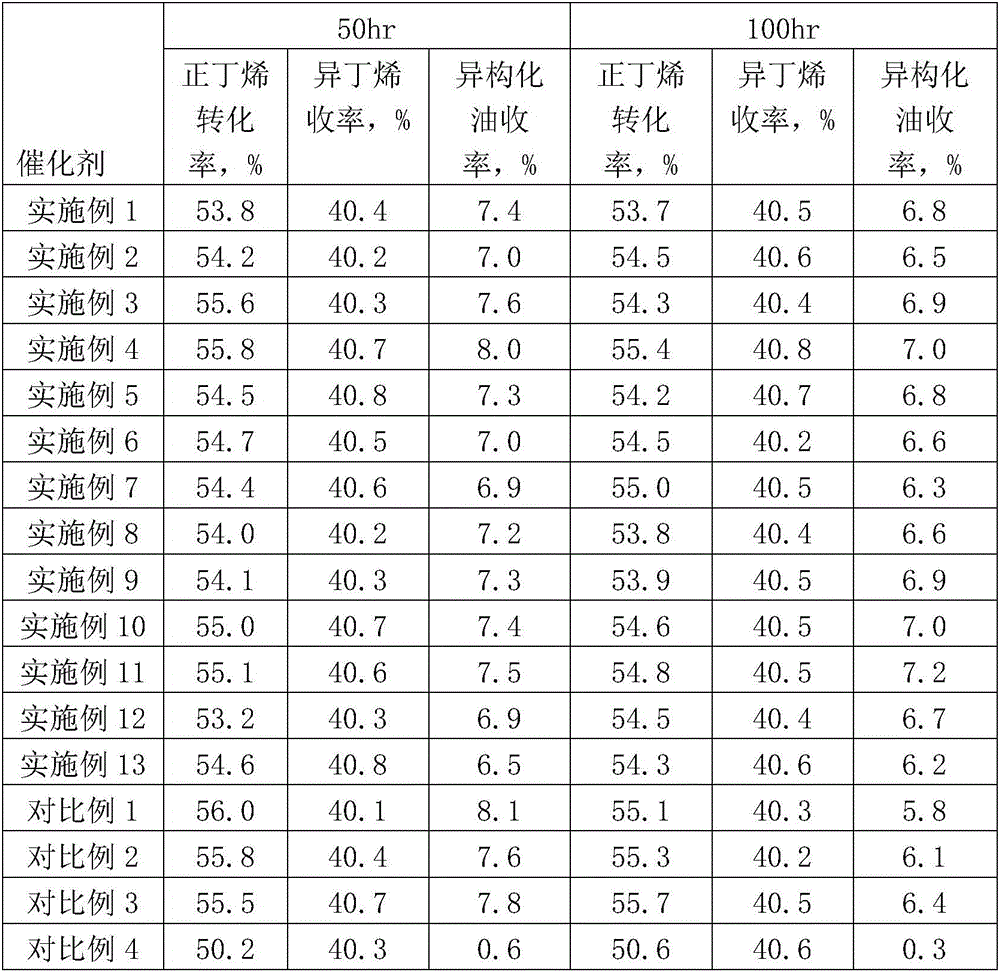

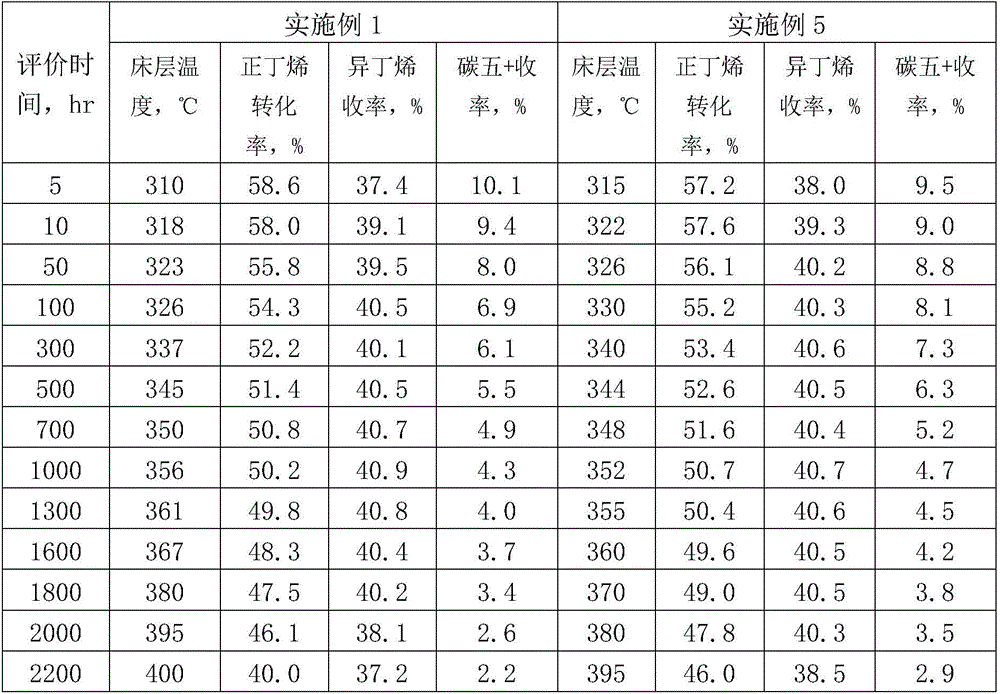

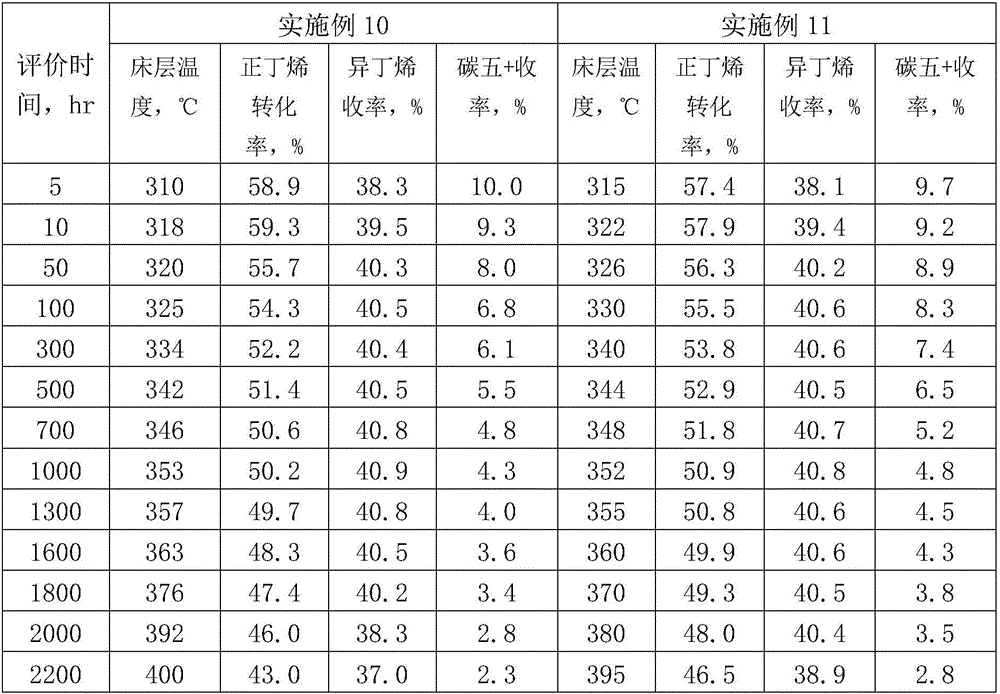

N-alkene isomerization catalyst and preparation method and application thereof

ActiveCN106076408AReduce in quantityReduce cokingHydrocarbon by isomerisationMolecular sieve catalystsButeneIsomerization

Owner:山东迅达化工集团有限公司

Clopidol controlled-release microparticle preparation and preparation method thereof

ActiveCN105168179AAvoid sudden releaseLess irritatingInorganic non-active ingredientsAntiparasitic agentsMicroparticleClopidol

Owner:ZHEJIANG ESIGMA BIOTECH CO LTD

Dental Polymerizable Core Build-Up Material of Separately Packed Type

ActiveUS20070249752A1Easy to operateImprove mechanical propertiesImpression capsTeeth fillingMethacrylateMeth-

Owner:KURARAY NORITAKE DENTAL

Sewage treatment agent and preparation method thereof

InactiveCN110422916AGood flocculation effectSmall frictional resistanceWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by flocculation/precipitationSodium BentoniteMicroparticle

Owner:合肥华威药业有限公司

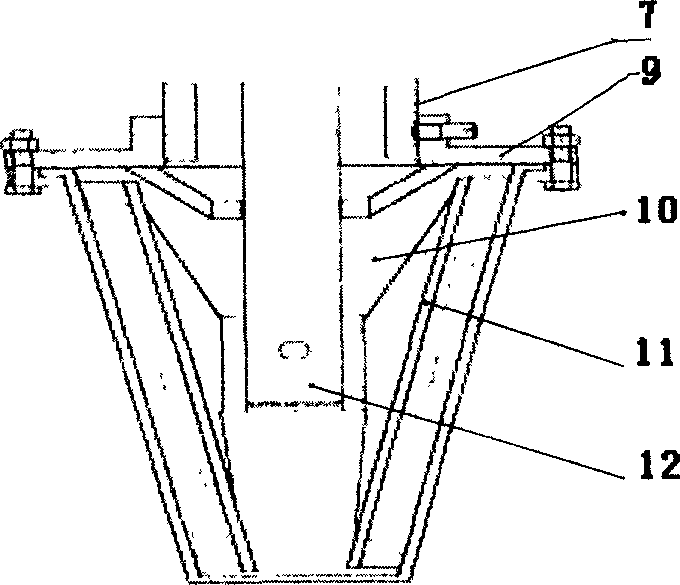

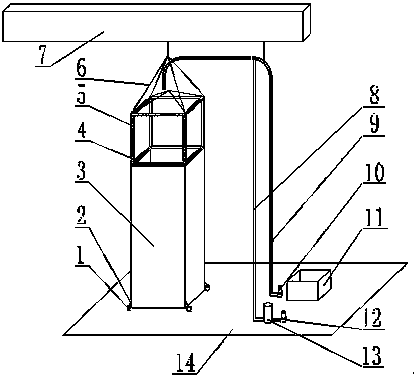

Continuous type solid liquid mixing granulation system

InactiveCN1562454AMeet different production requirementsGranulation by liquid drop formationMolten stateLiquid state

Owner:TIANJINSHI CHANGLUPRECISEBIOCHE MISTRY

Manual fogging device for high-voltage salt fog test

PendingCN108722711AQuick set upGood insulation properties in high voltage testWeather/light/corrosion resistanceLiquid spraying apparatusPotassiumMicroparticle

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID QINGHAI ELECTRIC POWER COMPANY +4

Composite of inorganic and/or organic microparticles and nano-dolomite particles

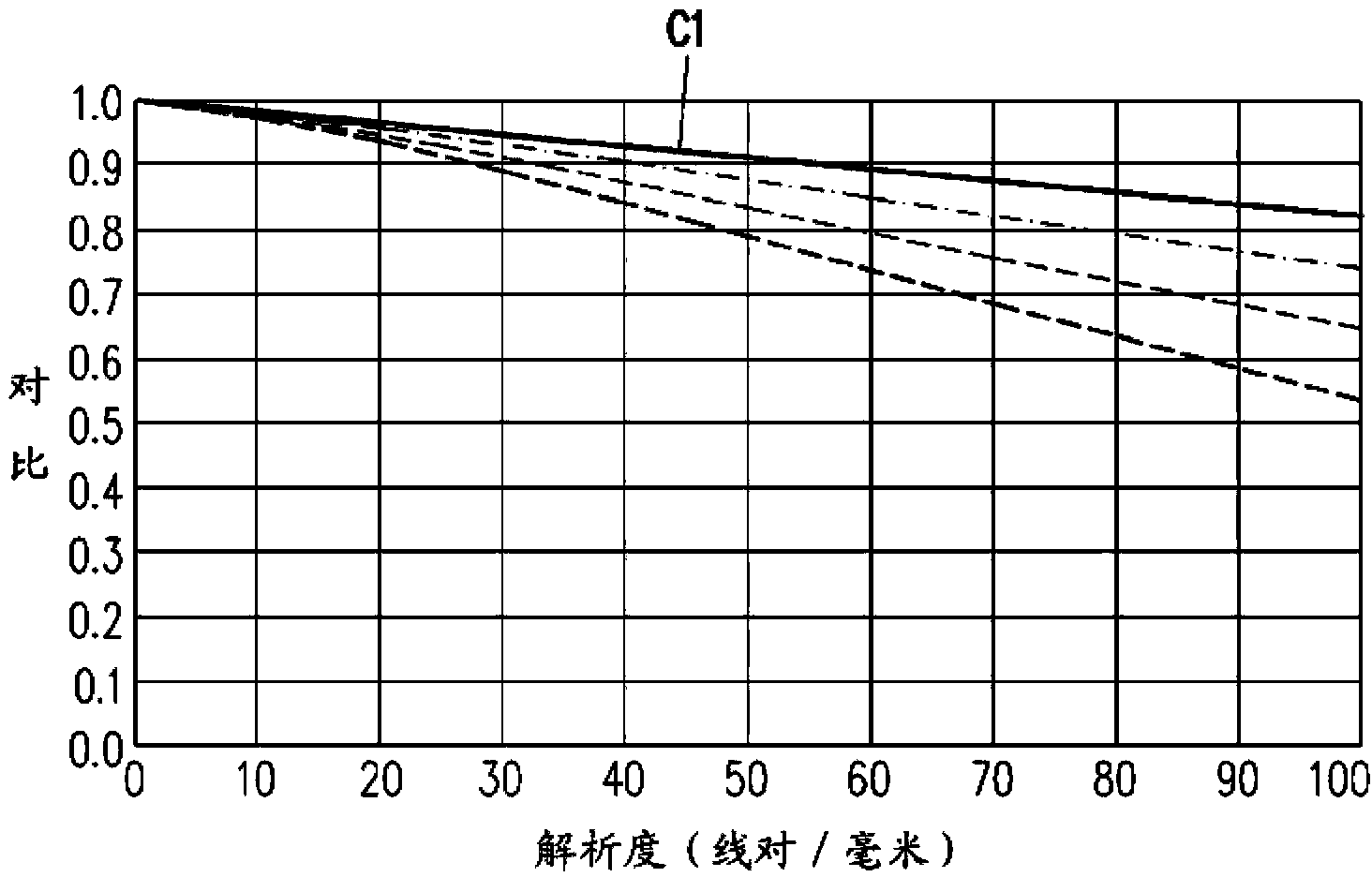

ActiveUS9944798B2Good optical performanceGood acid stabilityMaterial nanotechnologyNon-fibrous pulp additionNanoparticleSlurry

Owner:OMYA INT AG

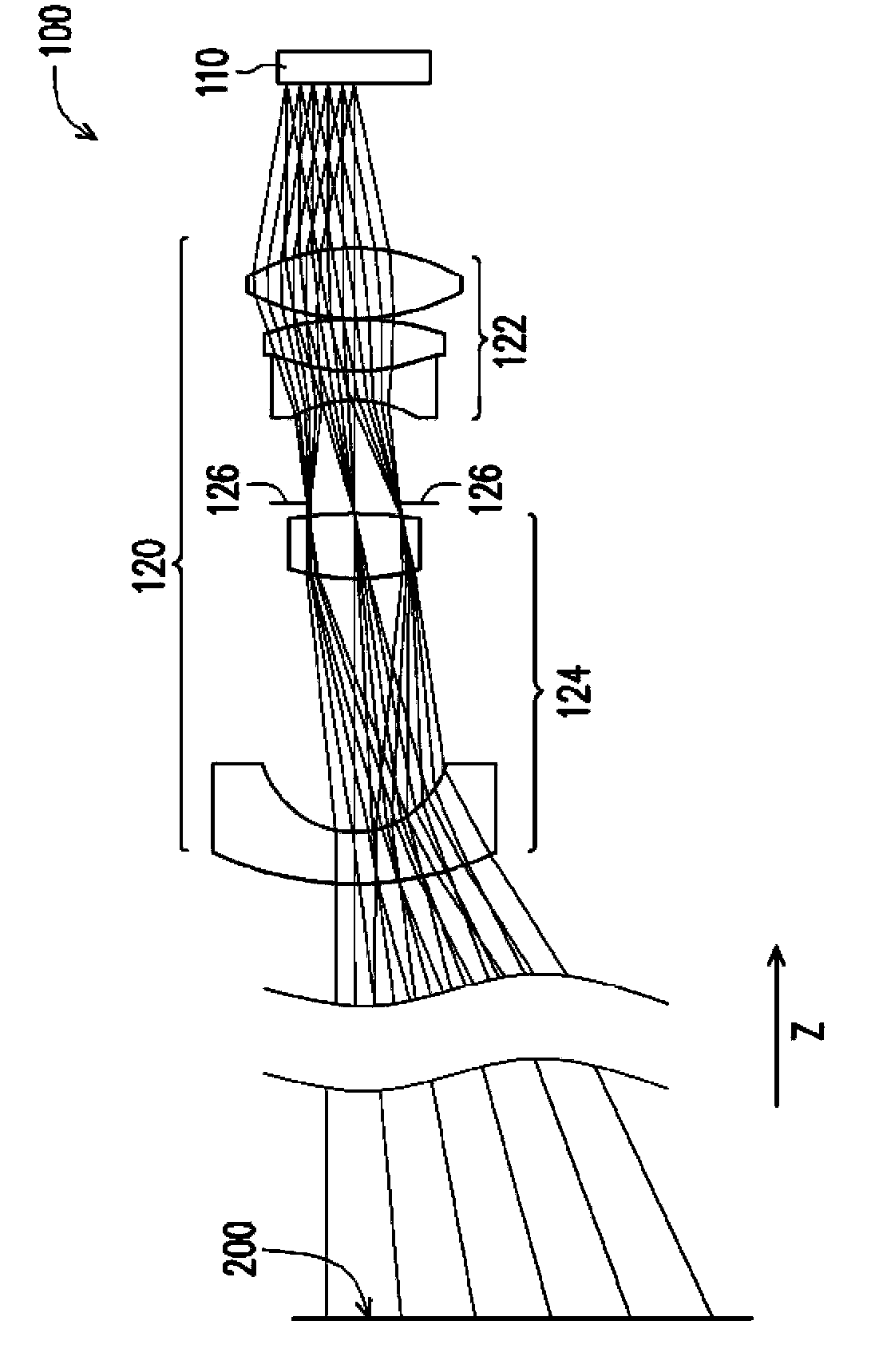

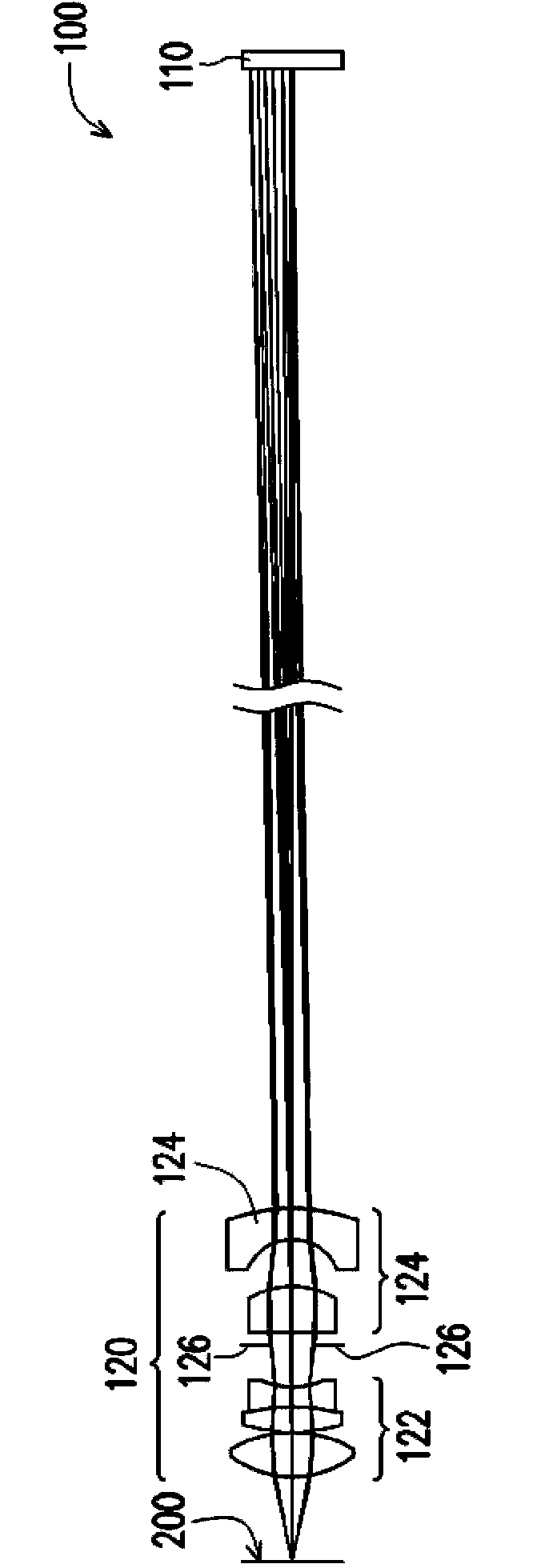

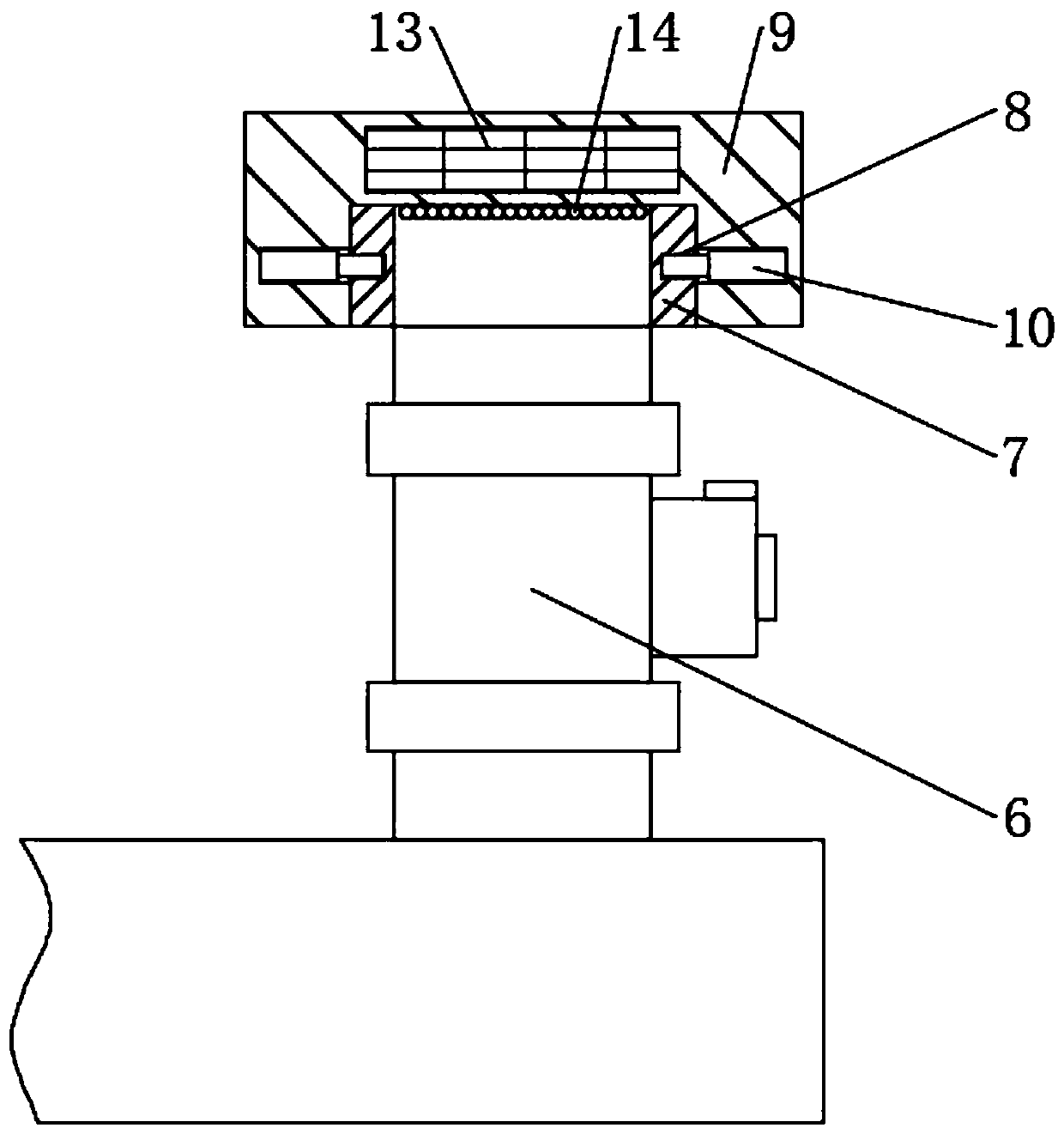

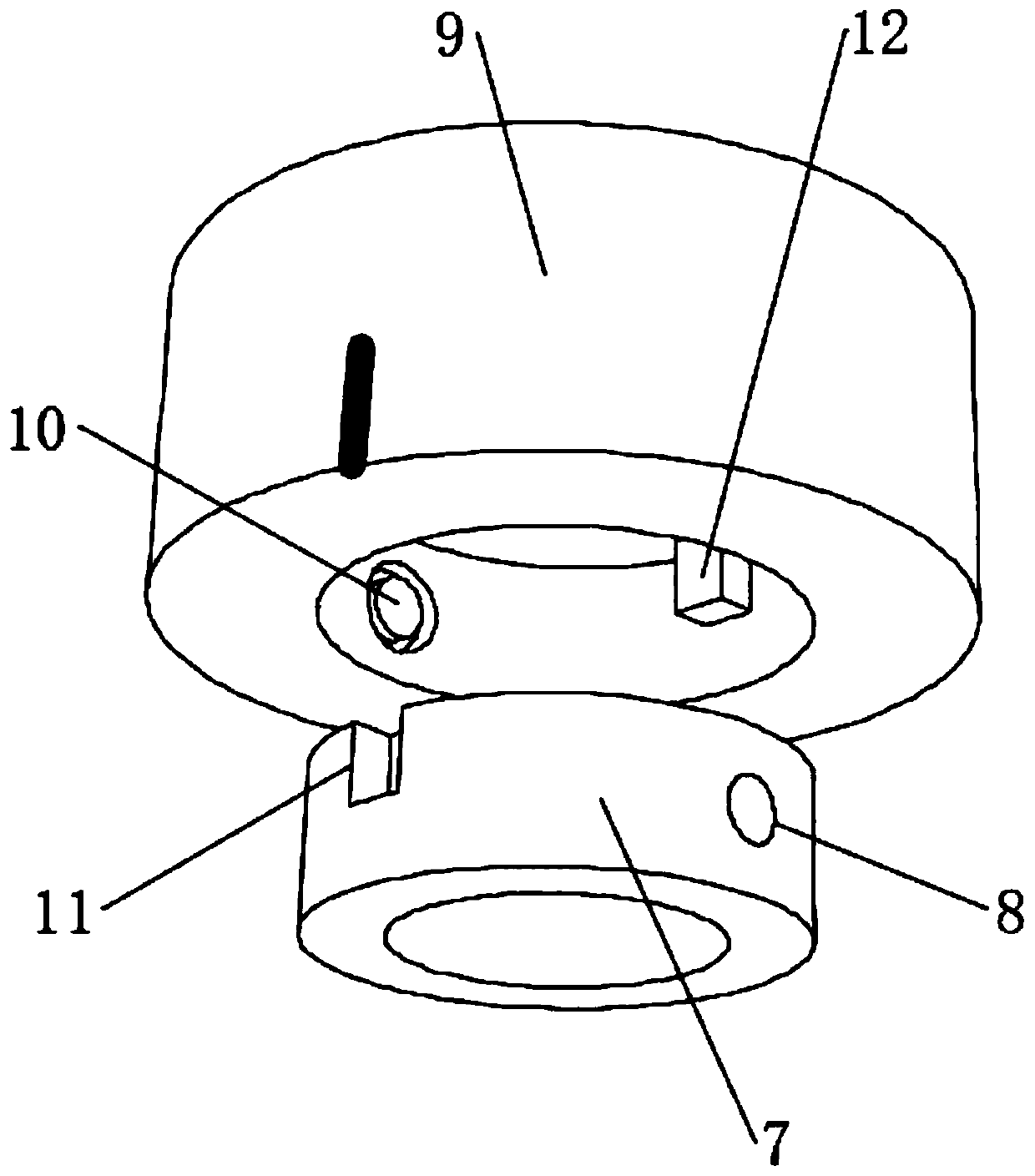

Projection lens, projection device and optically-induced microparticle device

Owner:IND TECH RES INST

Direct cooling type intelligent automation numerical control low-temperature dispersion smashing and grinding complete facility

PendingCN110681452AImprove frictional heating phenomenonImproved grinding and dispersion effectGrain treatmentsNumerical controlPharmacy

Owner:WENZHOU HAO STAR MACHINERY EQUIP MFG

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap