Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Nitrogen oxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrogen Oxide. Definition - What does Nitrogen Oxide mean? Nitrogen oxide is a common term for mono-nitrogen oxides viz. nitric oxide (NO) and nitrogen dioxide (NO 2). Its chemical formula is (NOx). It is formed when nitrogen (N 2) comes in contact or reacts with oxygen (O 2).

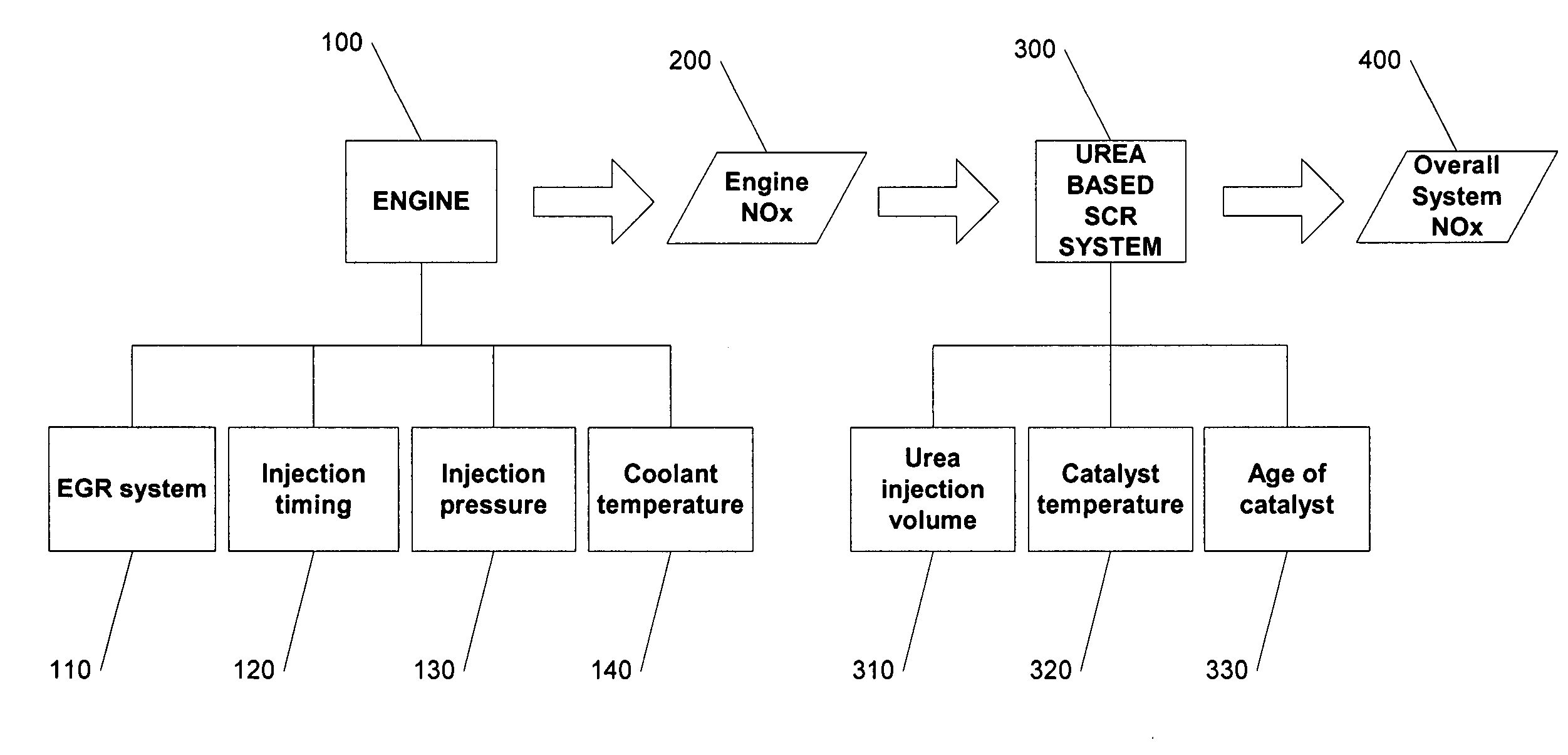

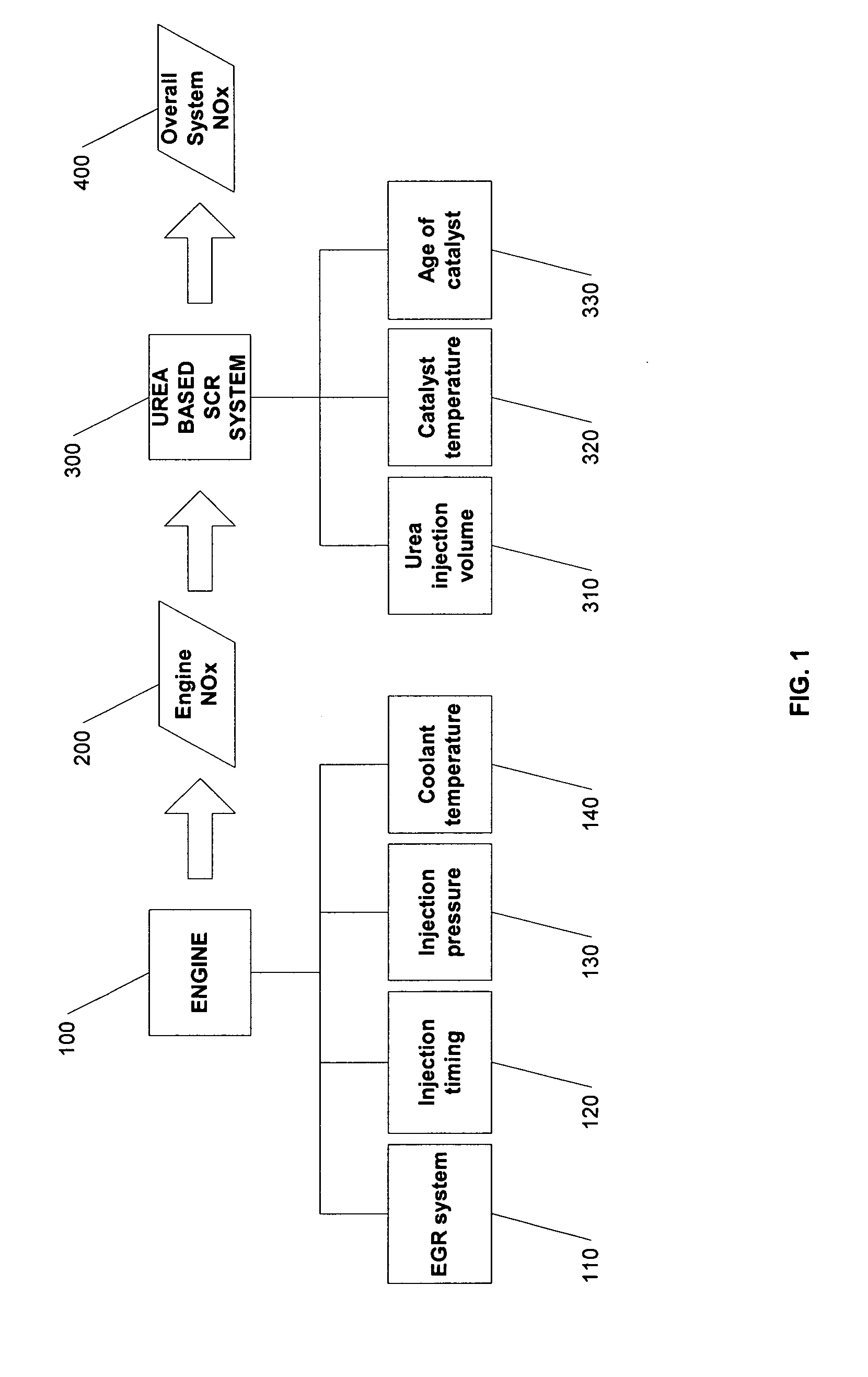

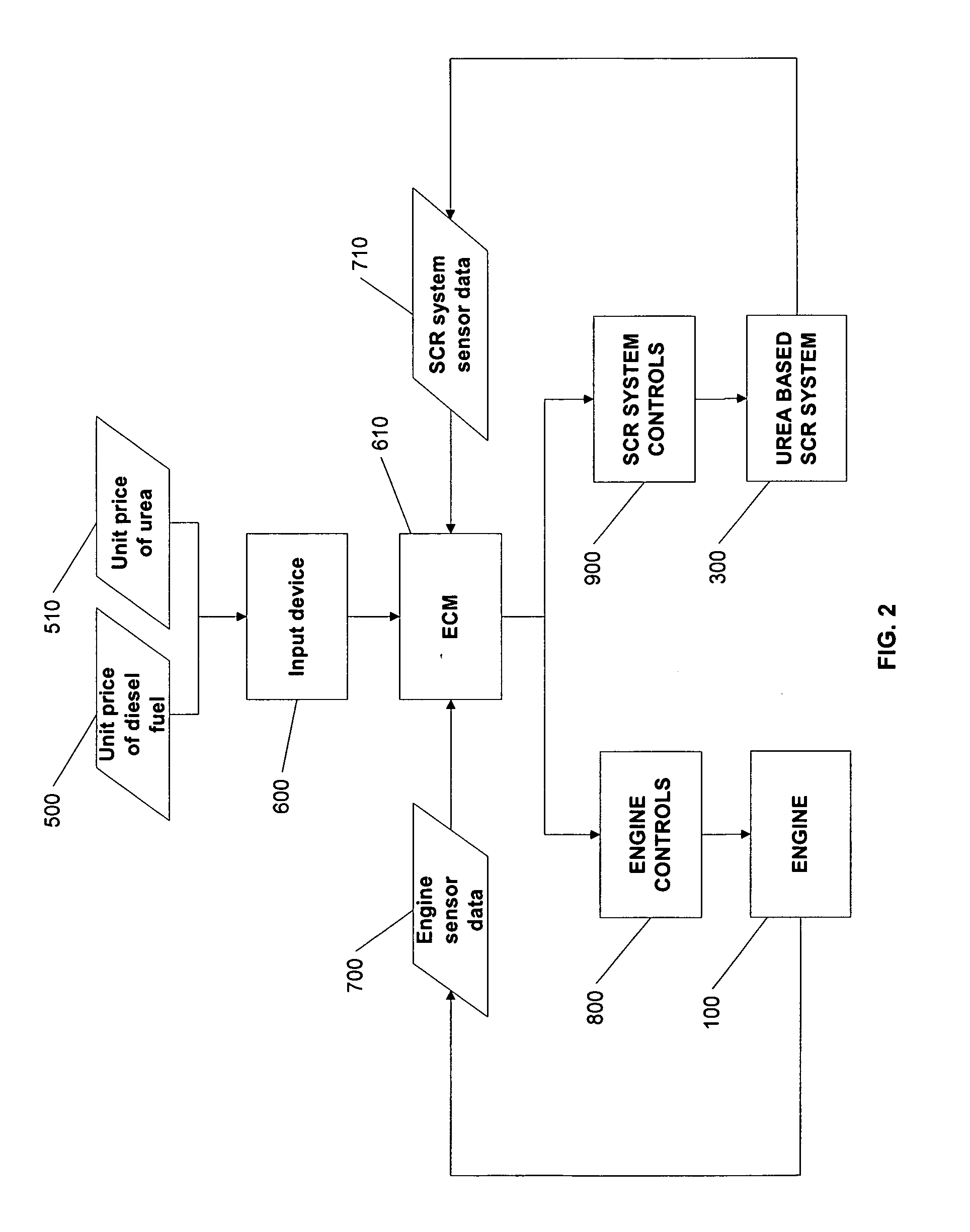

System and method for NOx reduction optimization

ActiveUS20070163244A1Reduced fuel efficiencyReduce nitrogen oxide contentAnalogue computers for vehiclesElectrical controlExhaust gas recirculationDiesel engine

Owner:CUMMINS INC

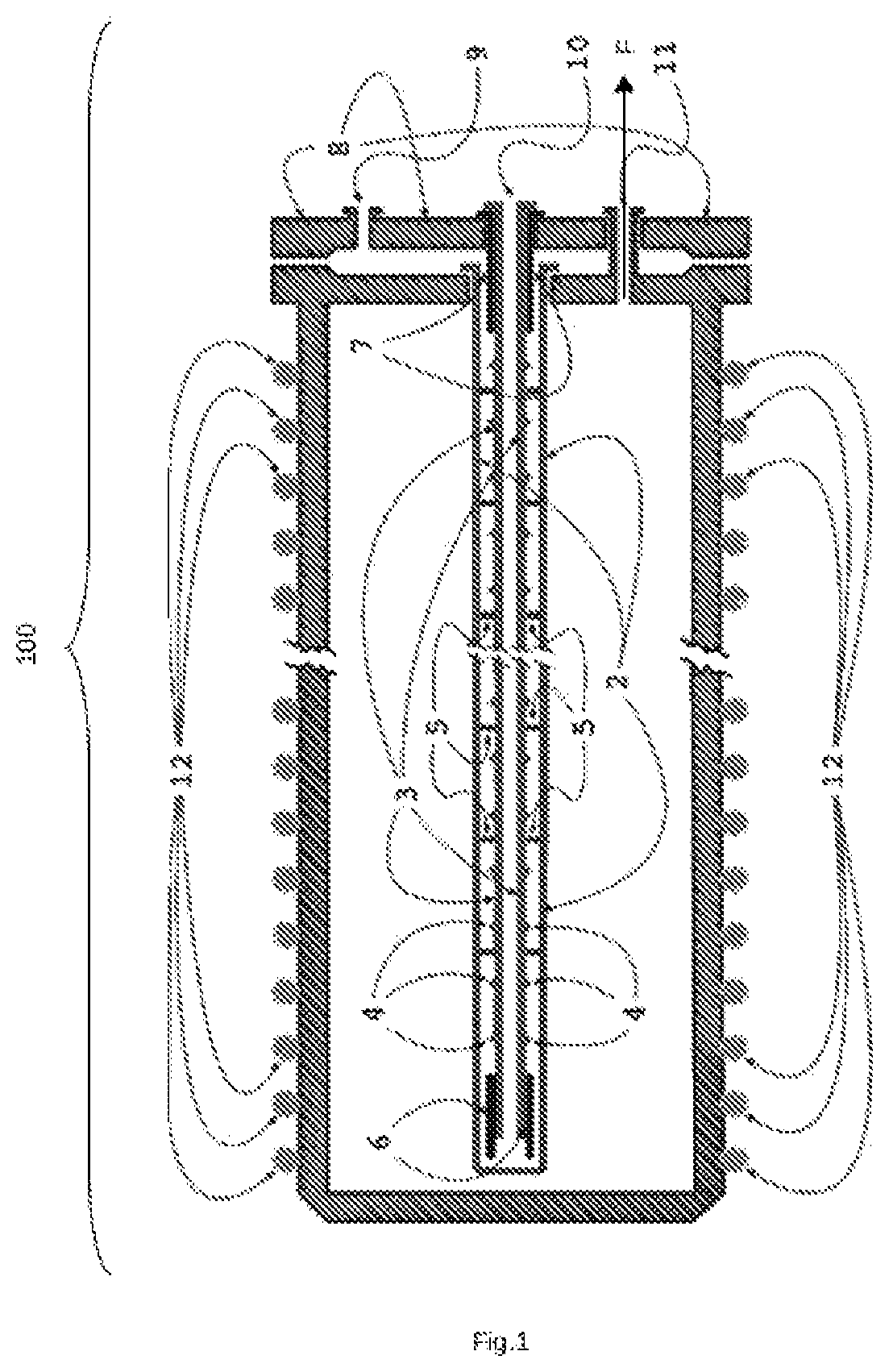

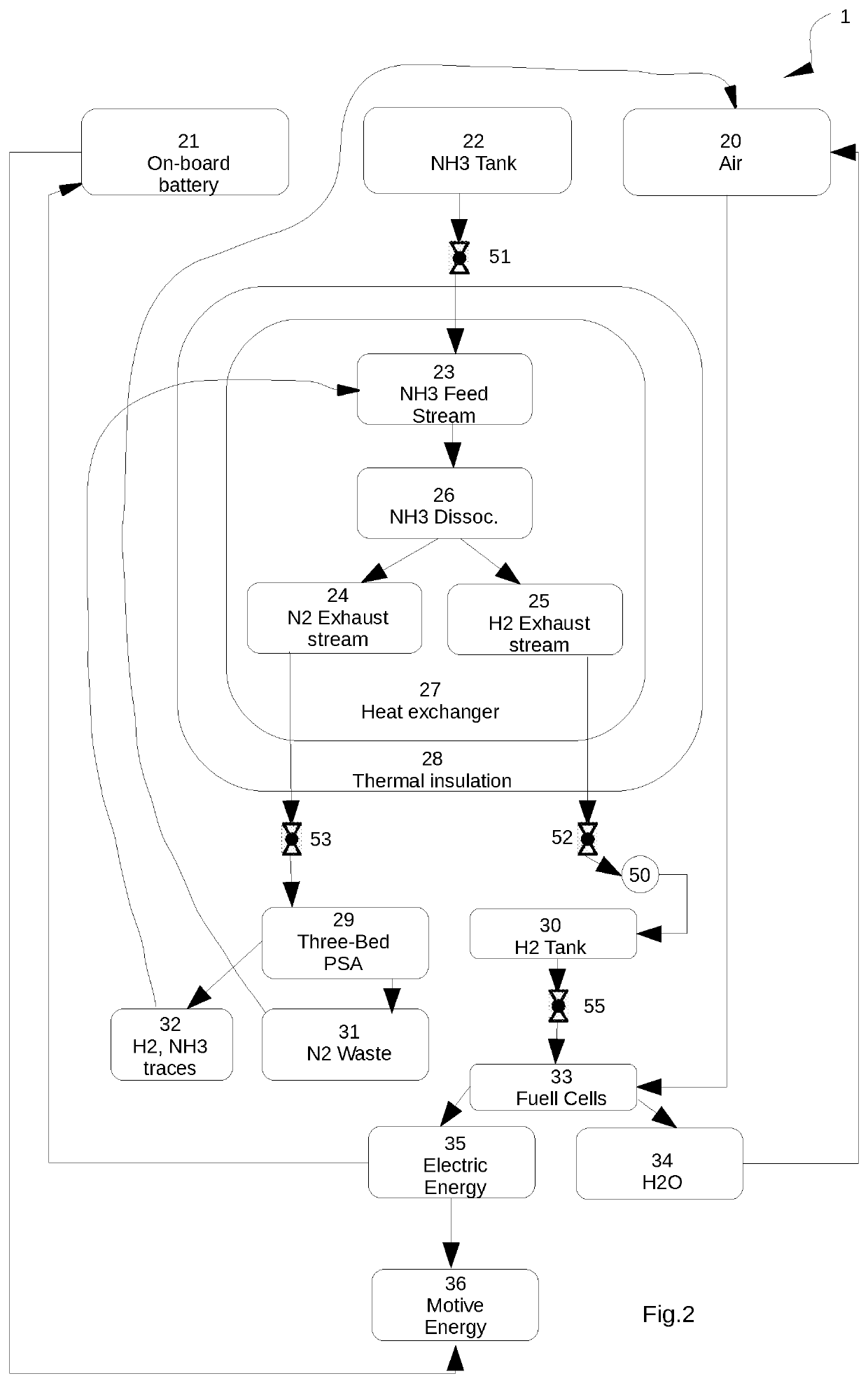

Separation system

ActiveUS20200388869A1Low costReduce thicknessReactant parameters controlHydrogen productionNitrogen oxidesNitrogen dioxide

Owner:GALBIATI CRISTIANO

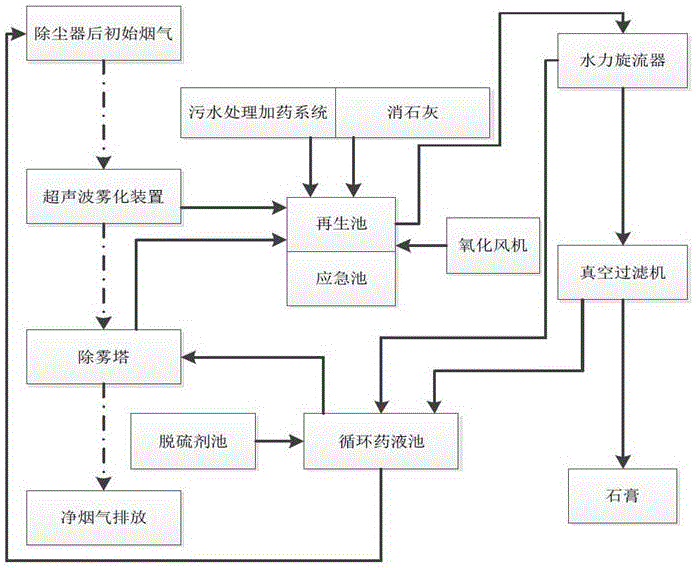

Thermal power plant ultrasonic atomization desulfurization-dust removal-ammonia escape prevention integrated system

InactiveCN107433115ALow concentration of sulfur dioxideReduce dust contentCombination devicesGas treatmentAutomatic controlEngineering

Owner:陈佐会

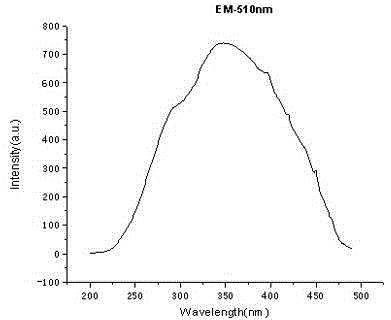

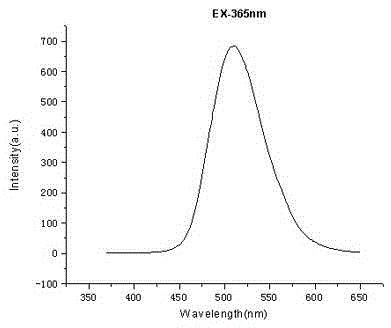

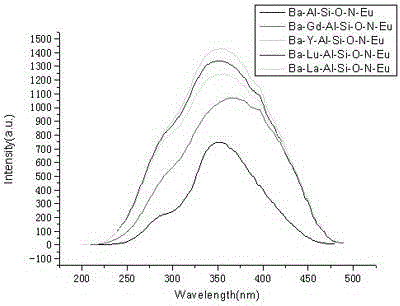

Rare-earth-doped nitrogen oxide green fluorescent powder and preparation method thereof

InactiveCN104610967AImprove luminosityWide effective excitation rangeLuminescent compositionsNitrogen oxidesRare earth ions

Owner:JIANGXI UNIV OF SCI & TECH

Automobile exhaust system diagnosis and repair method

InactiveCN106870081AInternal combustion piston enginesExhaust treatment electric controlExhaust gasNitrogen oxides

Owner:宿迁薪融智能科技有限公司

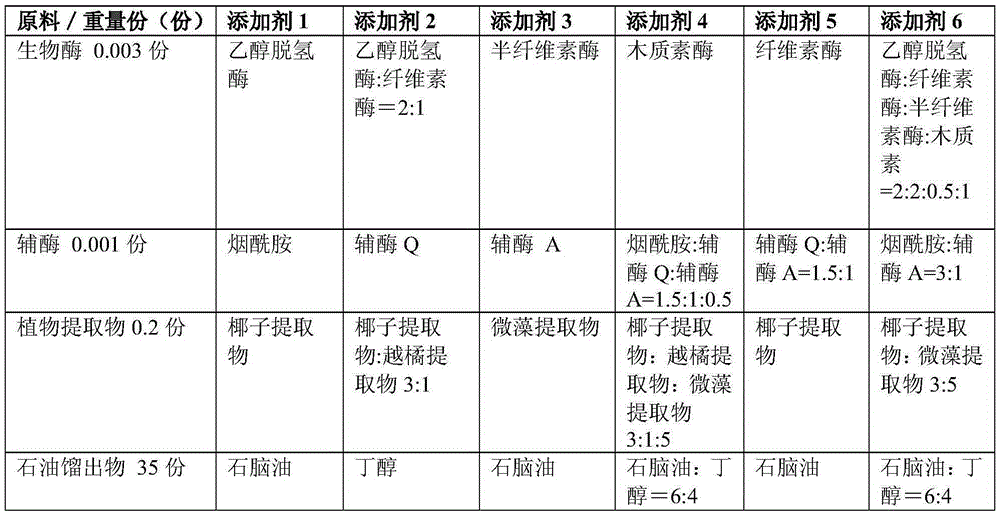

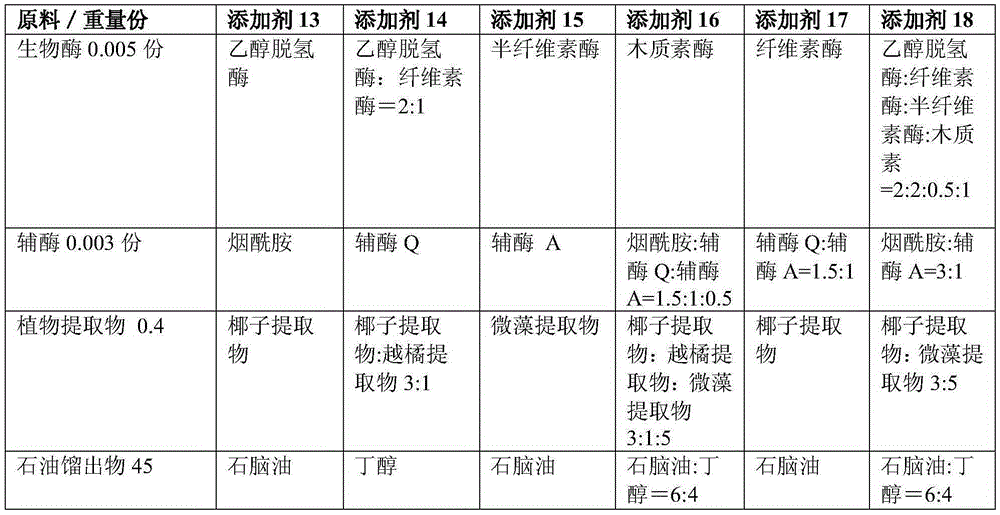

Gasoline environmental-protection and energy-saving additive and environmental-protection and energy-saving gasoline

InactiveCN106590775AReduce consumptionImprove synchronous combustionLiquid carbonaceous fuelsEngineeringPetroleum

Owner:国科蓝天清洁能源技术有限公司

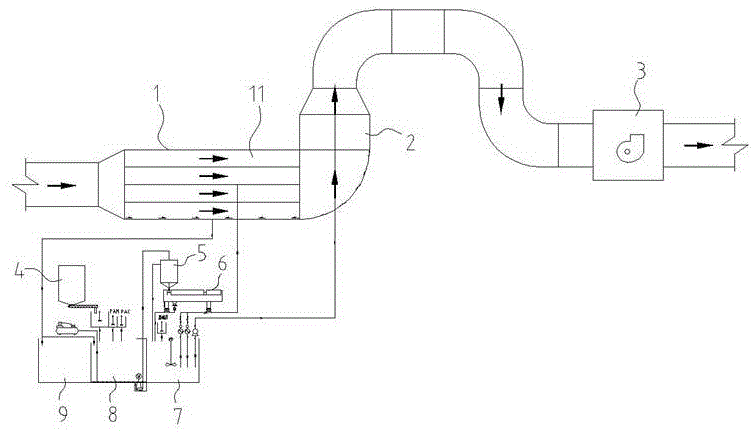

Emission technology of vapor containing nitrogen oxide and tar

ActiveCN108854458AImprove the efficiency of absorbing harmful components in exhaust gasPrevent control failure problems caused by errorsGas treatmentDispersed particle separationAtmospheric airExhaust gas emissions

The invention discloses an emission technology of vapor containing nitrogen oxide and tar. The emission technology comprises the following steps: opening a cutoff valve, a circulating water pump and an exhaust fan, wherein the circulating water pump starts a water circulation process; opening a discharging valve and releasing calcium hydroxide into water in a stepped overflow pool, and opening thedischarging valve when the pH value of the water in the stepped overflow pool is smaller than or equal to 8.0; closing the discharging valve when the pH value of the water in the stepped overflow pool is greater than or equal to 8.7; when an adjustment target is to prevent haze and the temperature of exhaust gas is greater than or equal to 90 DEG C, stopping the temperature-regulating operation;opening the temperature-regulating operation again when the temperature of the exhaust gas is smaller than 80 DEG C; stopping the temperature-regulating operation again when the adjustment target is to prevent thermal pollution and the difference value between the temperature of the exhaust gas and the atmospheric temperature is smaller than 3 DEG C; opening the temperature-regulating operation when the difference value between the temperature of the exhaust gas and the atmospheric temperature is greater than 6 DEG C. The emission technology disclosed by the invention can efficiently remove sulfur dioxide and nitrogen oxide from water, the weak alkalinity of water is maintained on the premise of ensuring safety and the emission temperature of the exhaust gas is correspondingly controlled according to different adjustment targets.

Owner:HENAN SONGYUE CARBON

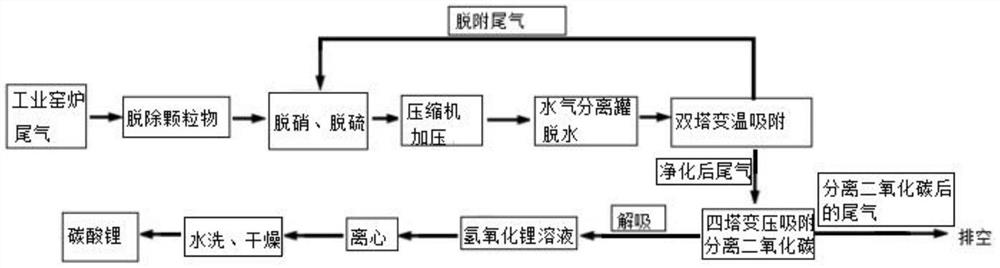

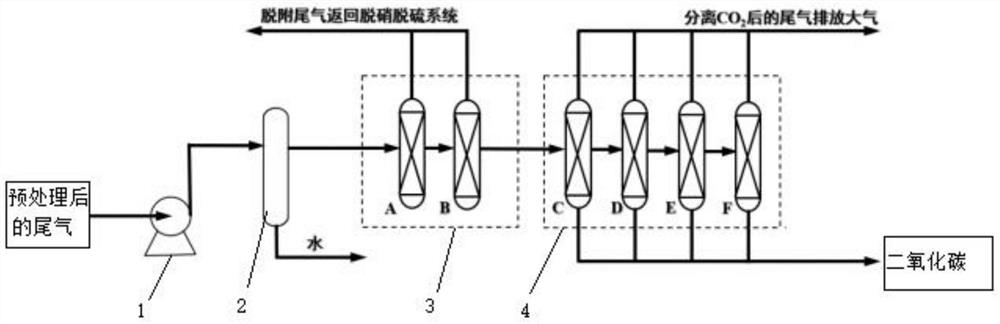

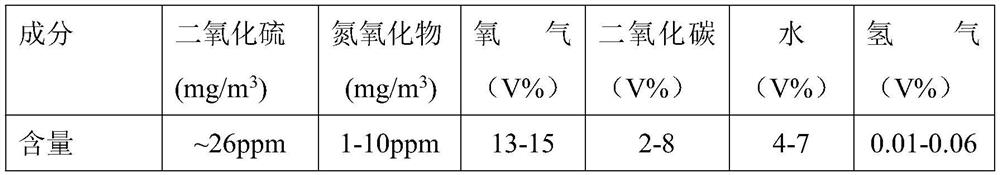

Method for recovering carbon dioxide from tail gas of industrial kiln and producing lithium carbonate

ActiveCN114835142AHigh gas purityHigh recovery rateProductsCarbon compoundsParticulatesLithium hydroxide

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap