Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Stamping process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

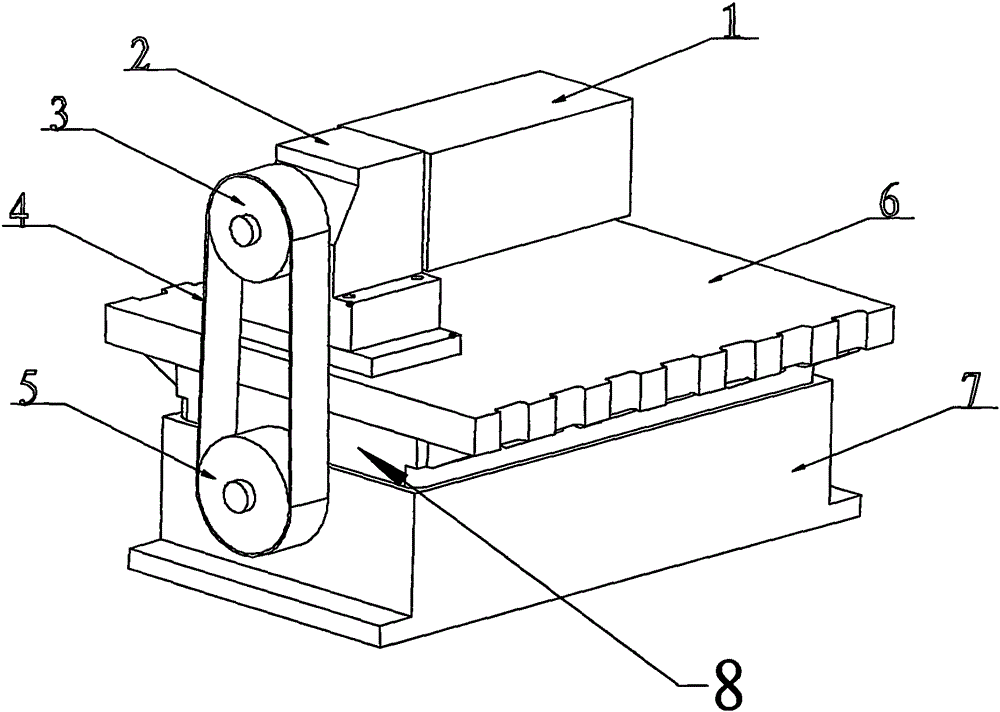

Device and method for measuring heat exchange coefficient of interface in hot stamp process

ActiveCN103033530ARealize the test of interface heat transfer coefficientAvoid incomingMaterial heat developmentSheet steelMeasurement device

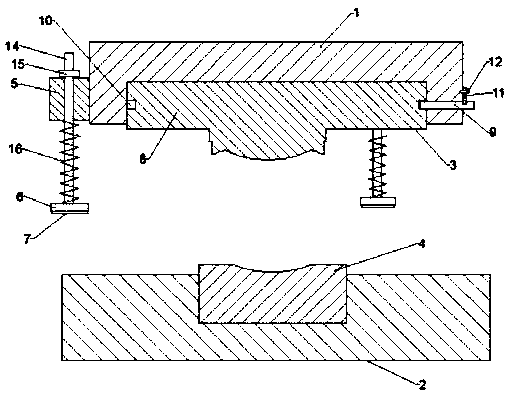

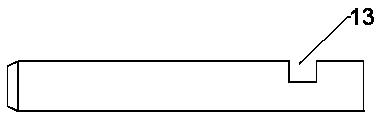

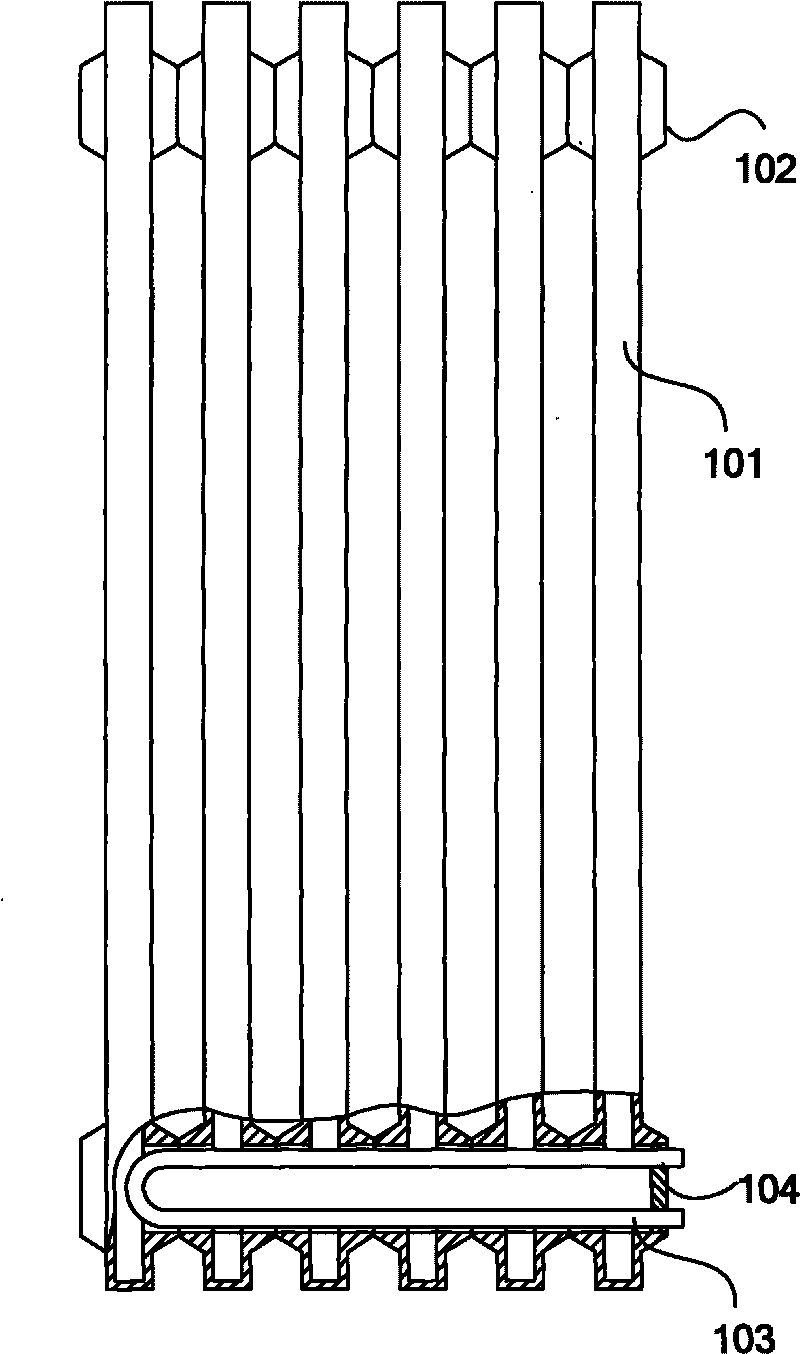

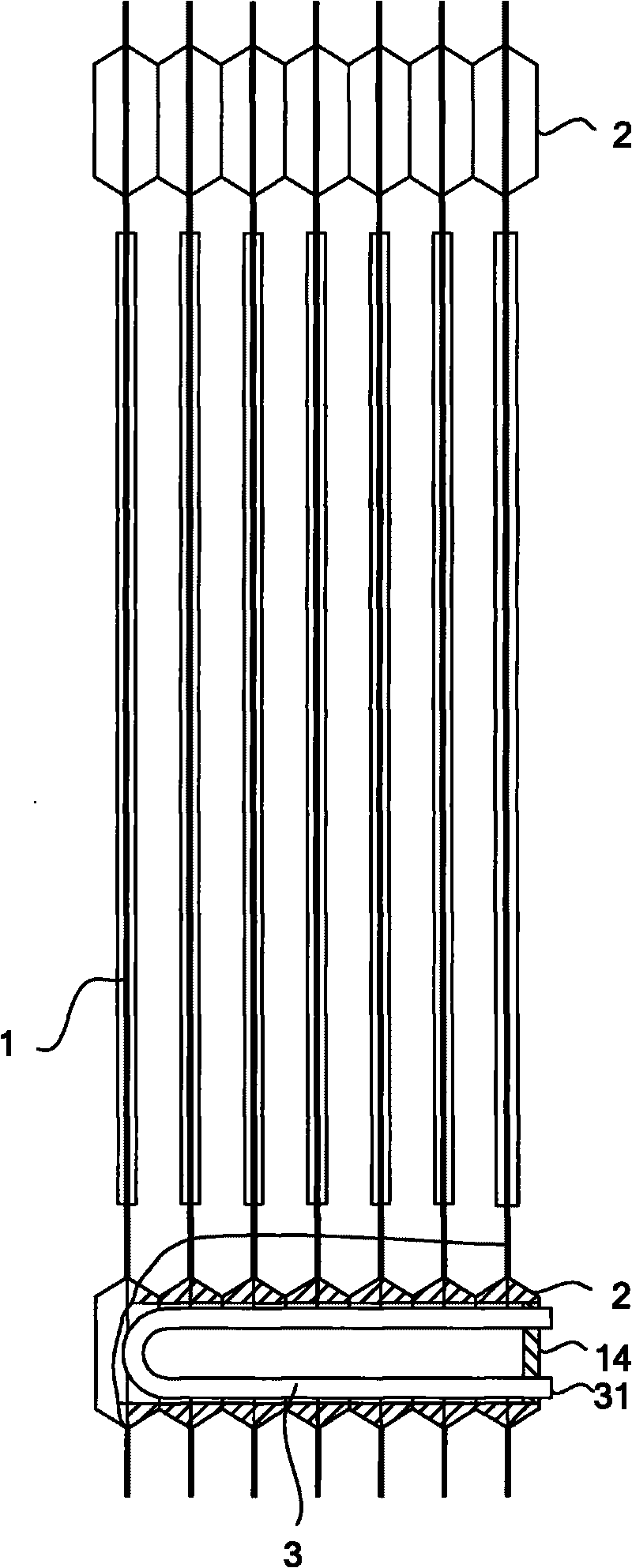

The invention discloses a device for measuring a heat exchange coefficient of an interface between a high-temperature steel plate and a die in a hot stamp process. The device comprises a pressure applying device and a measurement device, wherein the pressure applying device comprises a pressurization device, an upper workbench and a lower workbench, wherein the pressurization device is connected with the upper workbench and the lower workbench respectively; the measurement device comprises an upper fixture, a lower fixture and a test sample fixing fixture; the upper fixture is fixed on the upper workbench; the lower fixture is fixed on the lower workbench; and the test sample fixing fixture is arranged between the upper fixture and the lower fixture. The invention also discloses a method for measuring the heat exchange coefficient of the interface between the high-temperature steel plate and the die in the hot stamp process. By the device and the method, the limitation to samples with the thickness being more than 30mm in the prior art is avoided; the heat exchange coefficient of the interface between the steel plate and the die in the hot stamp process can be measured; and by an elastic energy storage element, stabilization of interface pressures between a boron steel test sample and an upper die and between the boron steel test sample and a lower die can be guaranteed.

Owner:TENGZHOU PROD QUALITY SUPERVISION & INSPECTION INST

Watercolor block printing blanked stamping process

InactiveCN103587328AImprove the three-dimensional effectDecorative surface effectsPattern printingStamping processComputer engineering

The invention discloses a watercolor block printing blanked stamping process, which comprises the following steps of 1) preparing watercolor block printing base timber; 2) drawing needed patterns on the upper surface of the watercolor block printing base timber; 3) etching to remove the surface base timber except the lines of patterns; 4) cutting the surplus base timber of the base timber with the three-dimensional patterns obtained in step 3) along the outer edge of each pattern to the position which is 1cm away from the outer edge of the pattern, thus obtaining a watercolor block printing version; 5) selecting the needed watercolor block printing version from step 4), printing colors corresponding to the patterns on the watercolor block printing version, and covering the watercolor block printing version by utilizing a piece of wetted Chinese art paper; 6) covering the Chinese art paper in step 5) by utilizing a felt, and brushing the felt for 3 to 5 times along a single oblique direction by utilizing a brush rake; 7) removing the felt in the step 6), lifting the Chinese art paper to be away from the watercolor block printing version, and airing the Chinese art paper for three hours; 8) mounting. The pattern indentation on the watercolor block printing version is pressed onto the wetted Chinese art paper through the brush rake, so that the colorful and fluctuated patterns can be formed.

Owner:HANGZHOU SHIZHUZHAI PRINT ART

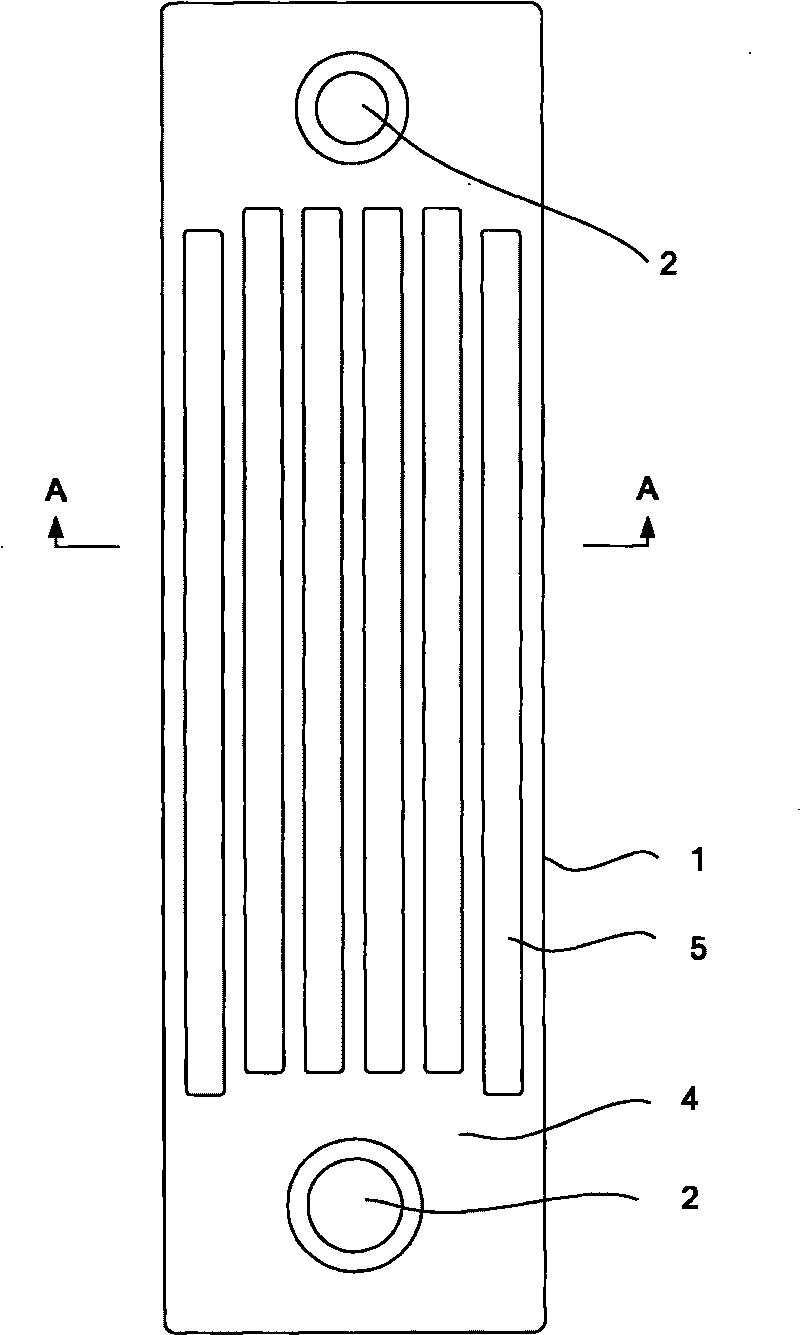

Stamping die capable of keeping pressing leftover material parts of plates

Owner:天津市武清区环球锌业有限公司

Working method of mobile phone lens support frame continuous punching die

Owner:SUZHOU WUZHONG ECONOMIC DEV ZONE BOYU MOLD PROCESSING FACTORY

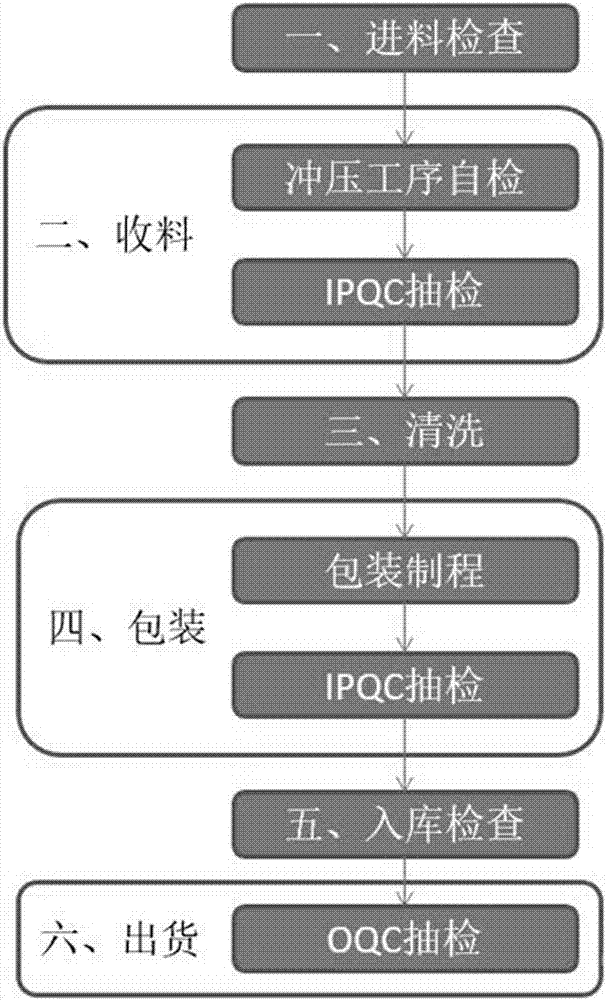

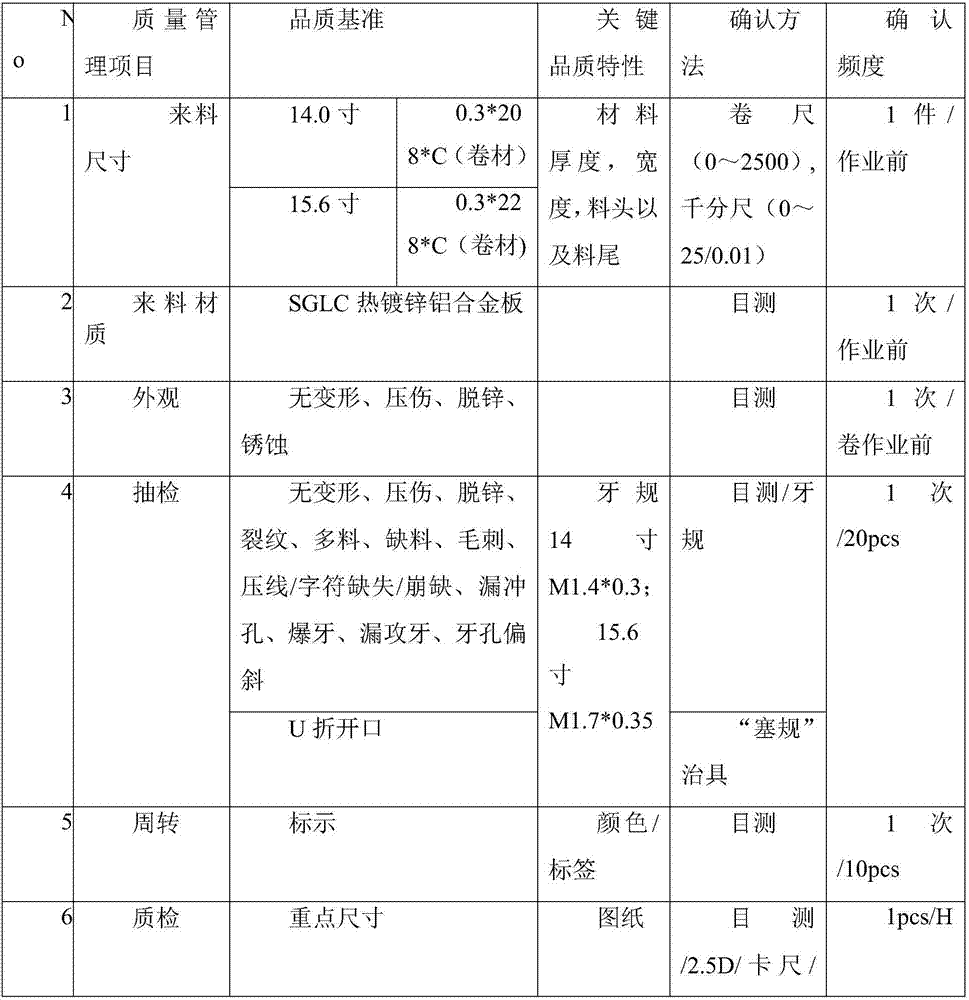

Backplane quality control method

Owner:重庆通灿电子有限公司

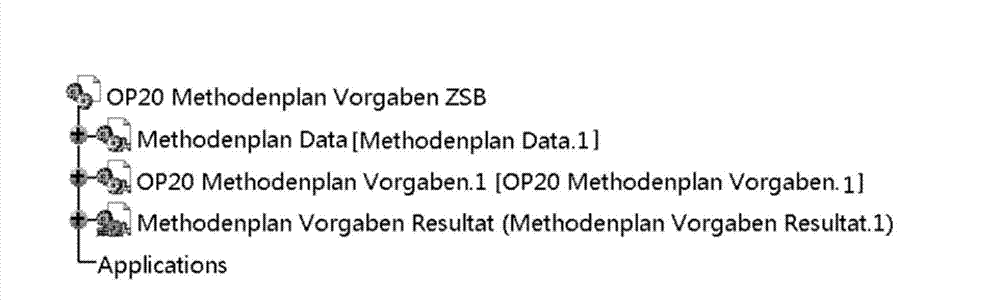

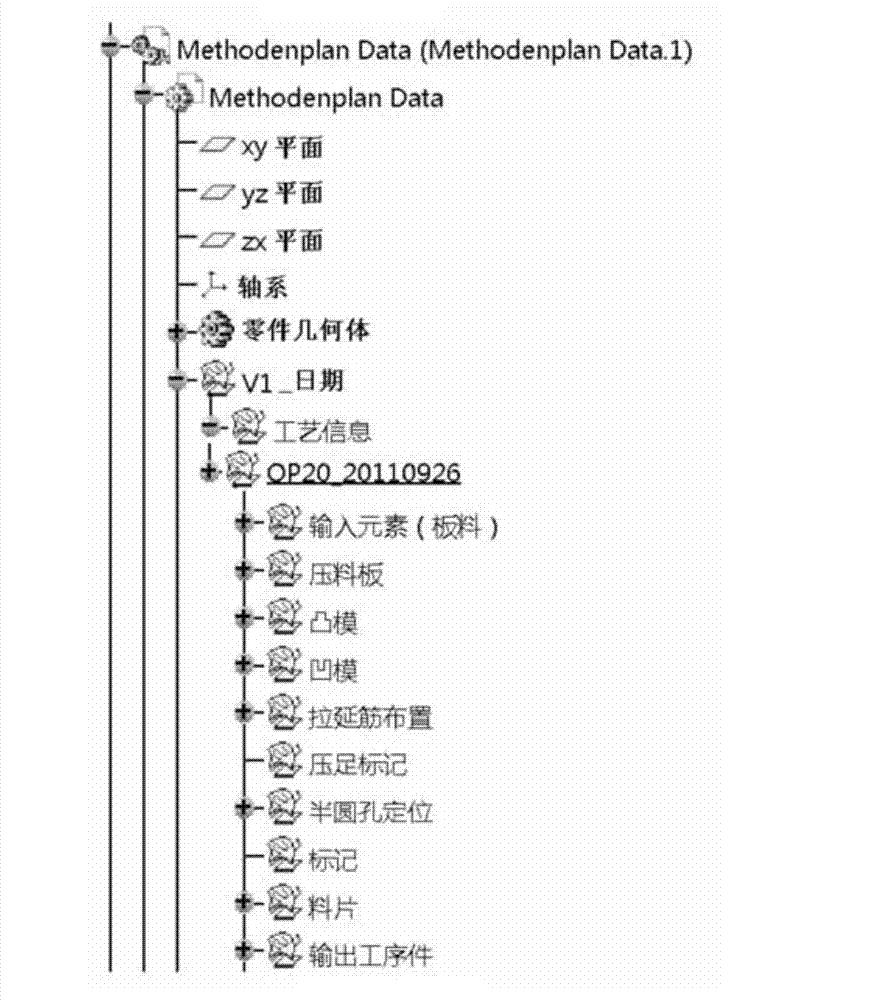

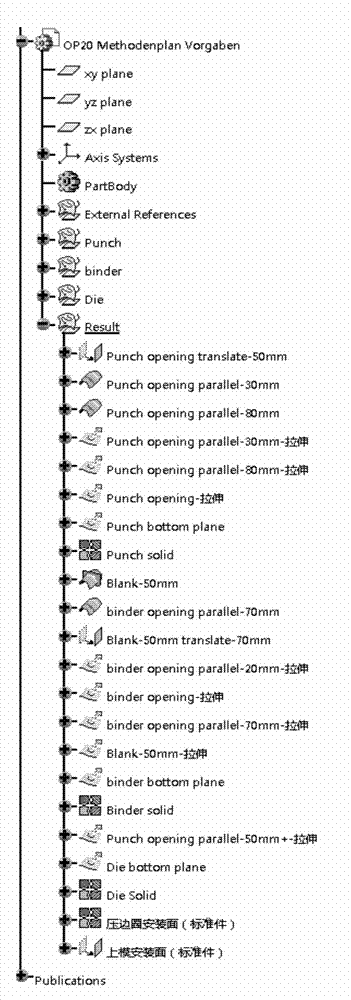

Fully parametric drawing mould design method

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

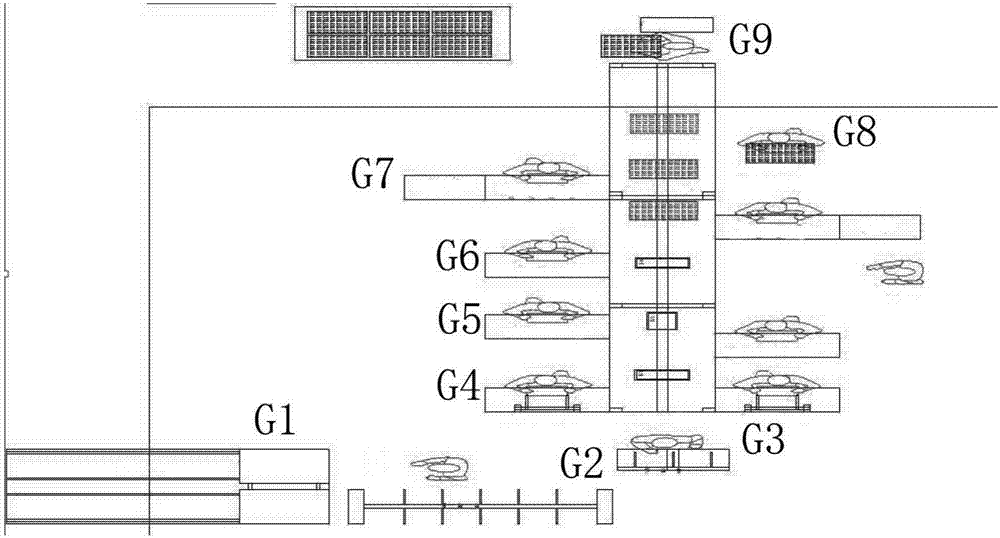

Stamping process for large-table-board stamping device of metal sheet stamping and cutting automation equipment

Owner:LUOYANG YOUNENG AUTOMATION EQUIP CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap