Preparation method of silver electrochemical modified microorganism fuel cell active carbon air cathode

An air cathode and fuel cell technology, applied in battery electrodes, electrical components, circuits, etc., to achieve the effects of low production cost, improved performance, and enhanced ability to catalyze oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

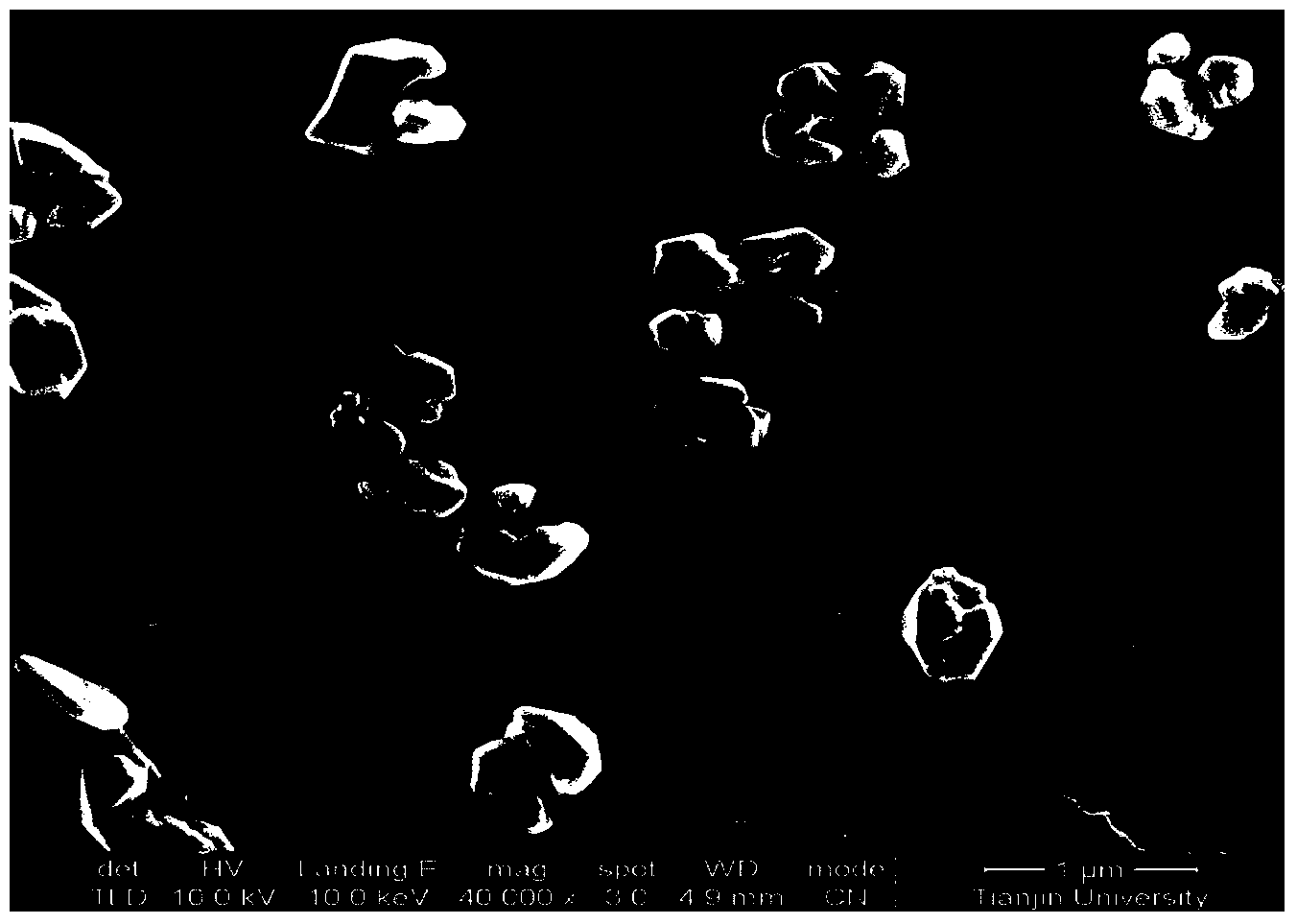

[0032] Step 1: Preparation and Characterization of Silver Electrochemically Modified Activated Carbon Air Cathode

[0033] The conductive graphite and PTFE are rolled on the stainless steel side according to the weight ratio of 1:3, and calcined at 340°C for 20 minutes. Activated carbon and PTFE were mixed at a weight ratio of 6:1 and pressed onto the other side of the stainless steel mesh to prepare an activated carbon air cathode.

[0034] Put the prepared activated carbon air cathode into the electrodeposition device, use 2.2mM silver nitrate as the electrolyte, and use Ag / AgCl as the reference electrode, 1cm 2 The platinum sheet was used as the reference electrode, and a three-electrode system was formed with the working electrode. Connect the system to an electrochemical workstation, and conduct electrodeposition at an external voltage of -0.8V for 50s.

[0035] After the deposition, pour out the electrolyte, take out the deposited activated carbon air cathode, wash it ...

Embodiment 2

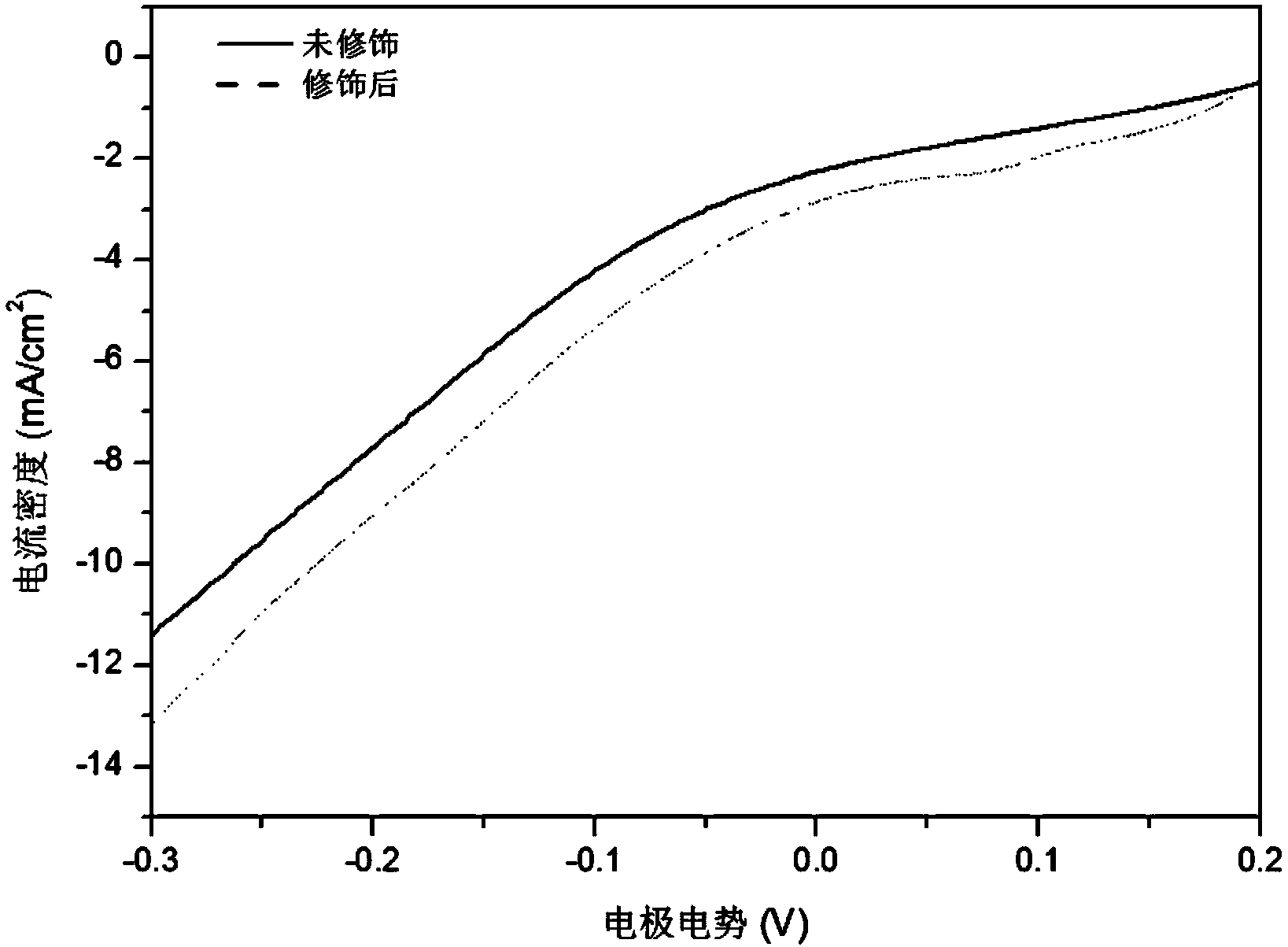

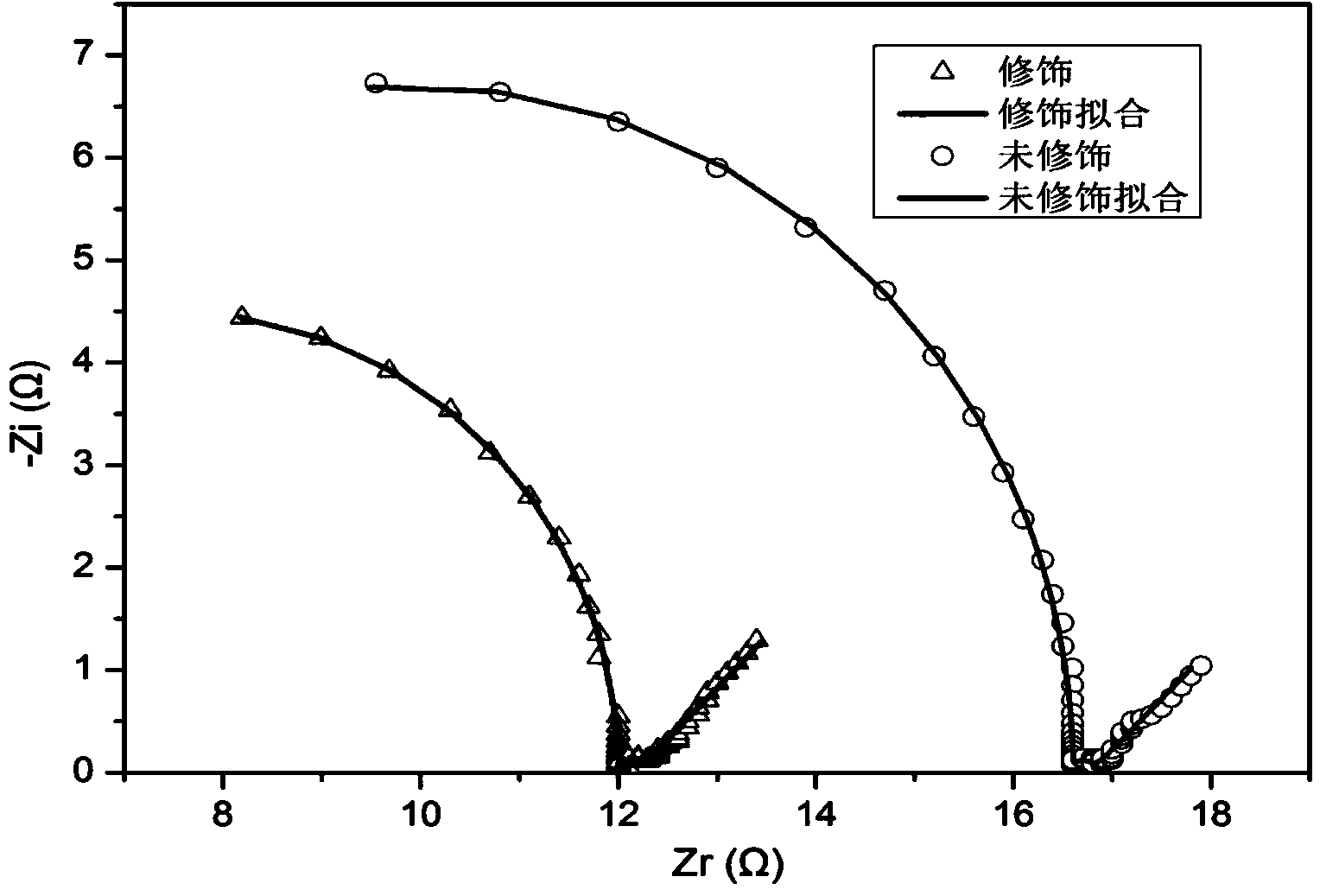

[0045] Under the same conditions as in Example 1, electrodeposition was carried out for 25 s. Battery performance has also been improved. Under the same external voltage, the current density of the activated carbon air cathode after silver deposition is higher than that of the blank activated carbon air cathode. The activated carbon air cathode after silver electrodeposition was loaded into the battery for cultivation. After the anode microorganisms matured, the measured maximum power density of the microbial fuel cell reached 927mW / cm 2 , the output power is improved relative to the blank activated carbon air cathode.

Embodiment 3

[0047] Under the same conditions as in Example 1, electrodeposition was carried out for 100 s. Battery performance has been improved. Under the same external voltage, the current density of the activated carbon air cathode after silver deposition is higher than that of the blank activated carbon air cathode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Effective area | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap