Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

21 results about "Bottle cap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bottle cap seals the top opening of a bottle. A cap is typically colourfully decorated with the logo of the brand of beverage. Plastic caps are used for plastic bottles, while metal with plastic backing is used for glass; the metal is usually steel. Plastic caps may have a pour spout. Flip-Top caps like Flapper closures provide controlled dispensing of dry products. Caps for plastic bottles are often made of a different type of plastic from the bottle.

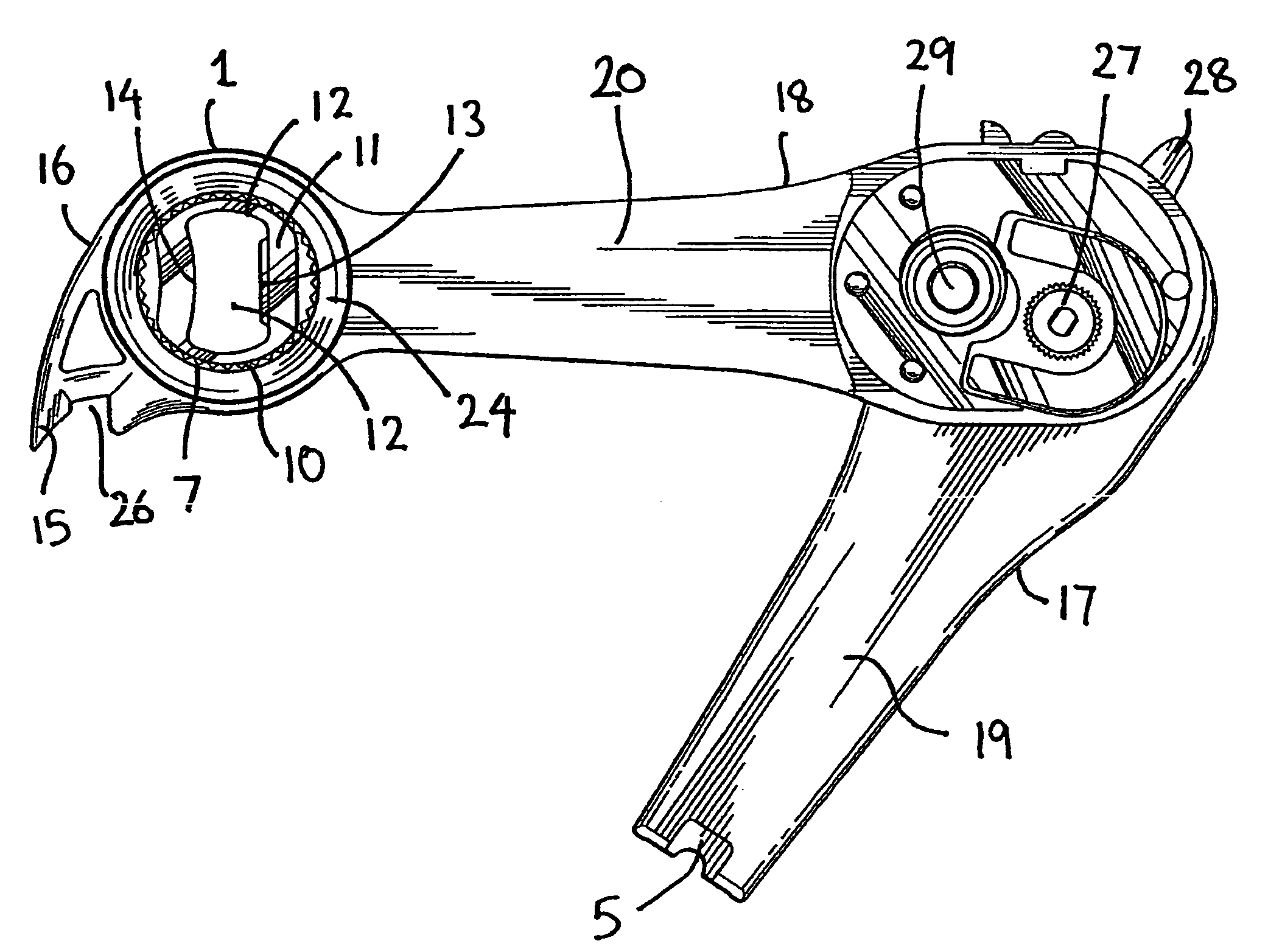

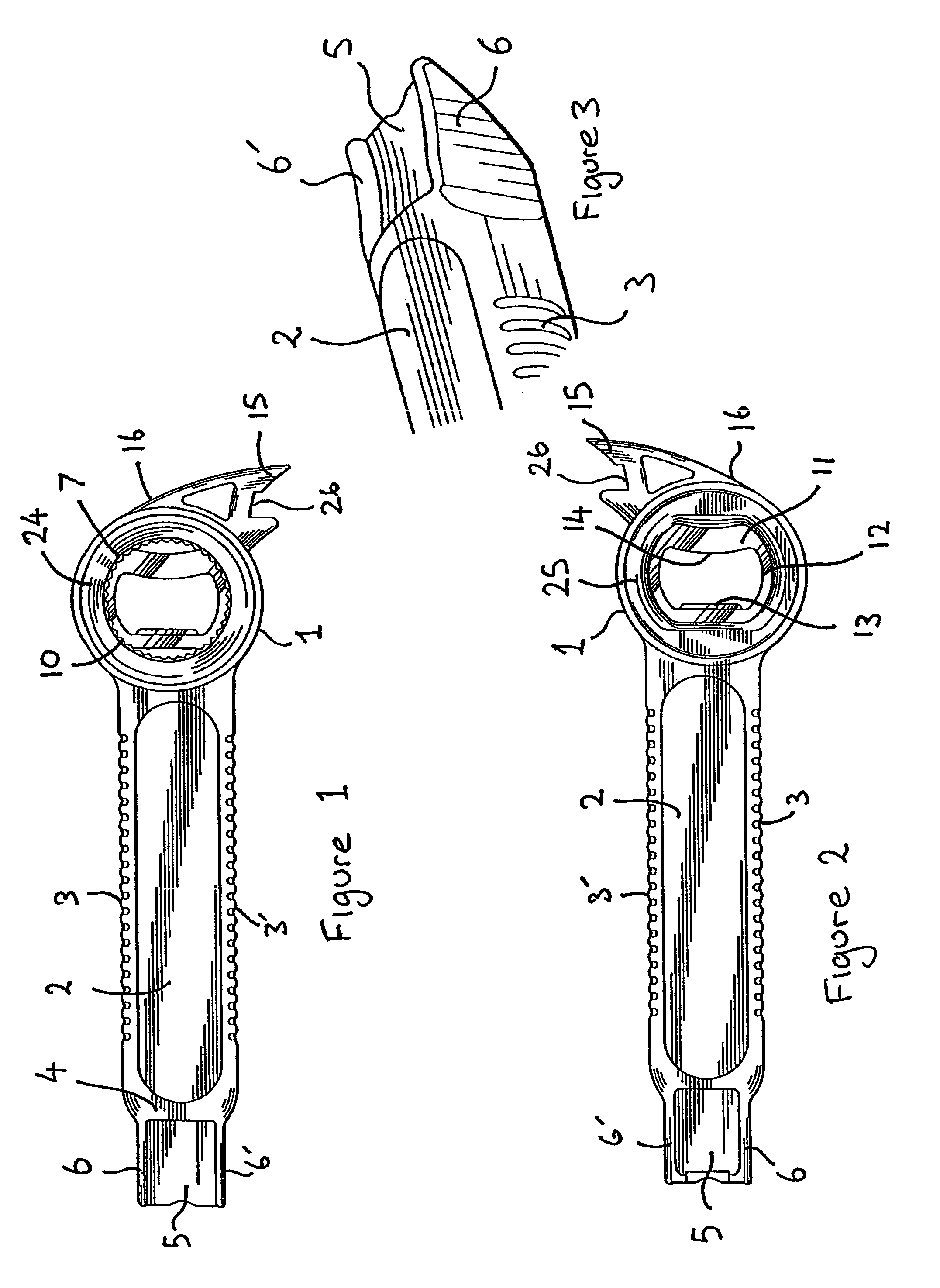

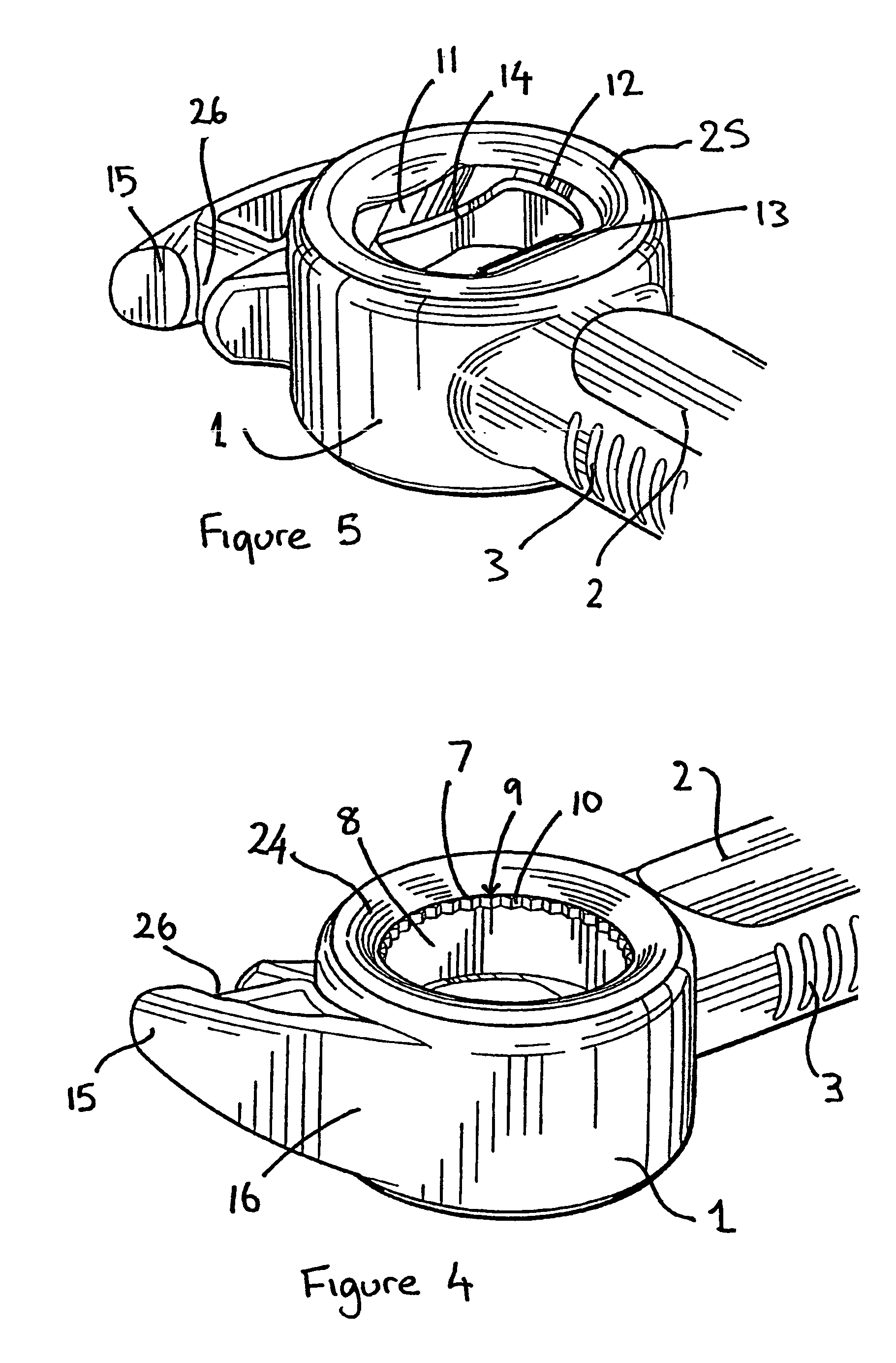

Multi-purpose opener

ActiveUS7004049B2Bottle/container closurePower operated devicesScrew capBottle cap

A multi-purpose opener for removing a closure from a variety of containers has a sleeve having a first end with an opening for receiving a screw cap within the sleeve. The sleeve has an internal wall with one or more projections for engaging the screw cap, and a second end with a slot having a blade for engaging a bottle cap. A handle is integral with the sleeve and extends radically there from. The distal end of the handle has a taper for engaging under the lift tab of drink can. A claw for engaging a ring pull tab of a can is integral with the sleeve and extends tangentially from the sleeve diametrically opposite the handle.

Owner:UNION LUCKY IND LTD

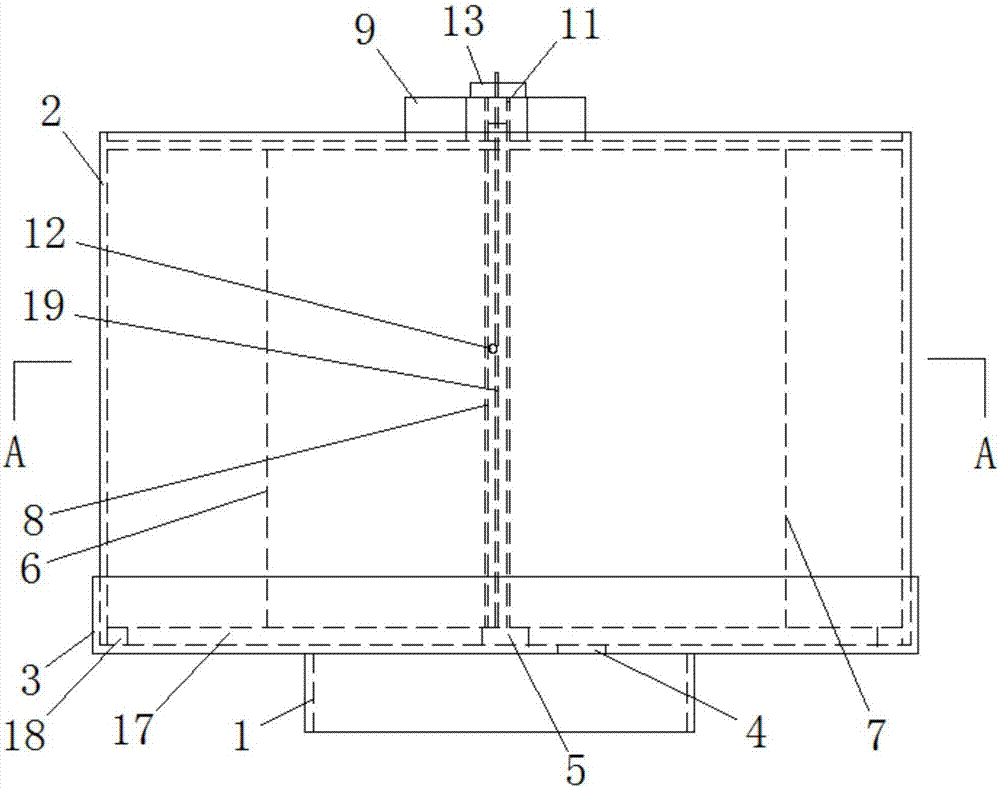

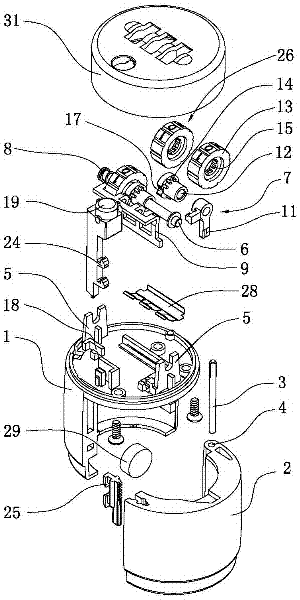

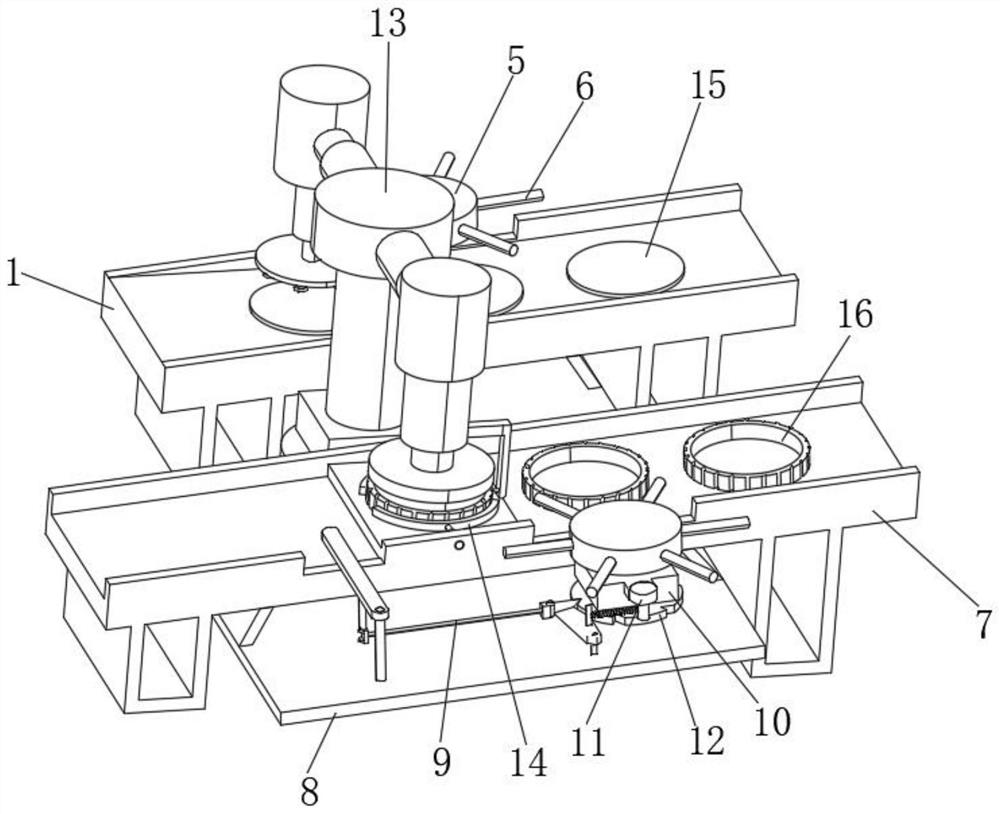

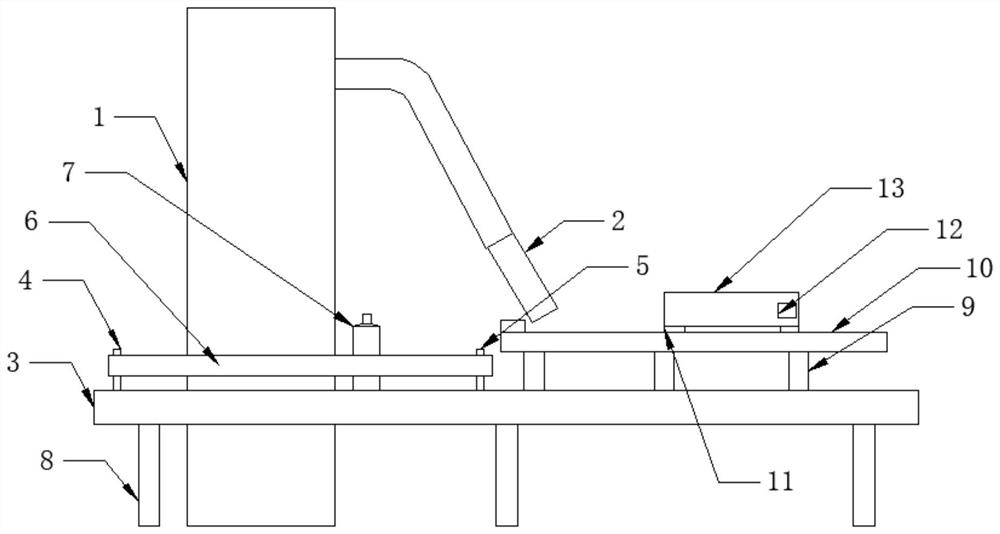

Traditional Chinese medicine tablet filling device

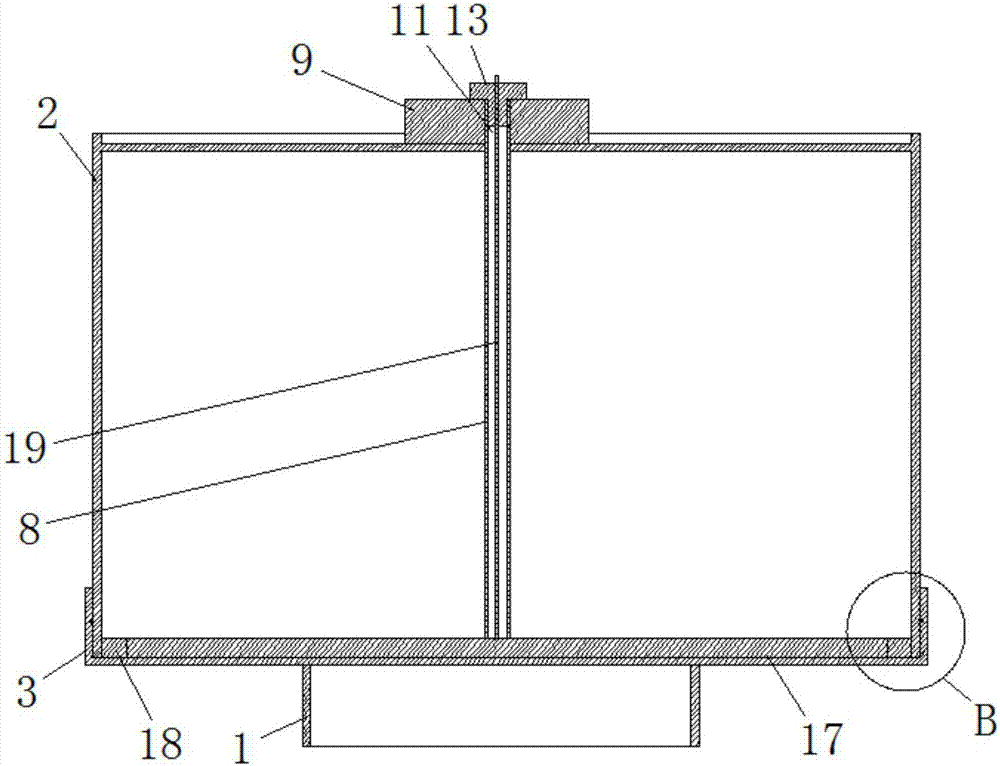

ActiveCN112960201AGuaranteed storage securityGuaranteed sealing performanceCapsThreaded caps applicationSolenoid valveEngineering

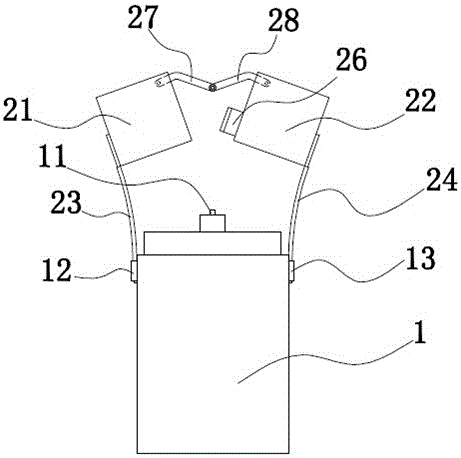

The invention relates to the technical field of traditional Chinese medicine processing, in particular to a traditional Chinese medicine tablet filling device which comprises an X-axis conveying mechanism, a filling mechanism, medicine bottles and bottle caps, wherein the filling mechanism and a Z-axis conveying mechanism are installed above the X-axis conveying mechanism; the filling mechanism comprises a first supporting frame, and a tablet tank is fixed to the top end of the first supporting frame; a solenoid valve is fixed to the bottom end of the tablet tank, and the Z-axis conveying mechanism comprises a second supporting box; a second conveyor belt is movably connected to the interior of the second supporting box, and the bottle caps are evenly distributed on the second supporting box; an X-axis driving mechanism is arranged behind the right side of the Z-axis conveying mechanism, and comprises a second supporting frame; and an X-axis sliding table is fixed to the top end of the second supporting frame, and the front end of the X-axis sliding table is slidably connected with a Y-axis driving mechanism. According to the filling device, a screw cap and sealing detection integrated structure is adopted, therefore the sealing detection can be carried out while the caps are sealed, and the storage safety of tablets is ensured.

Owner:YANTAI KANGGUTANG MEDICAL TECH CO LTD

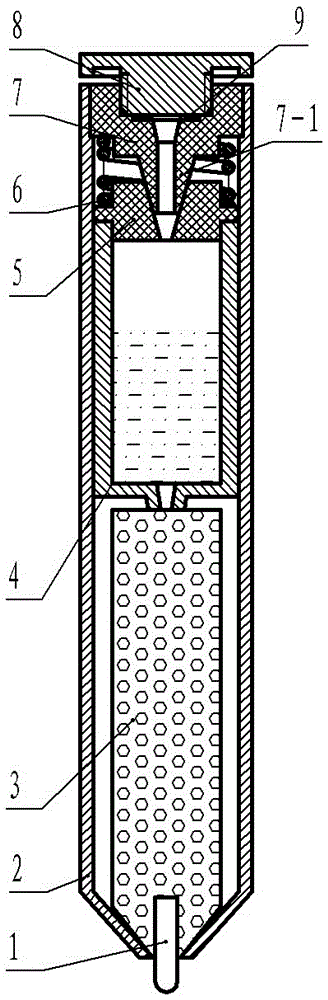

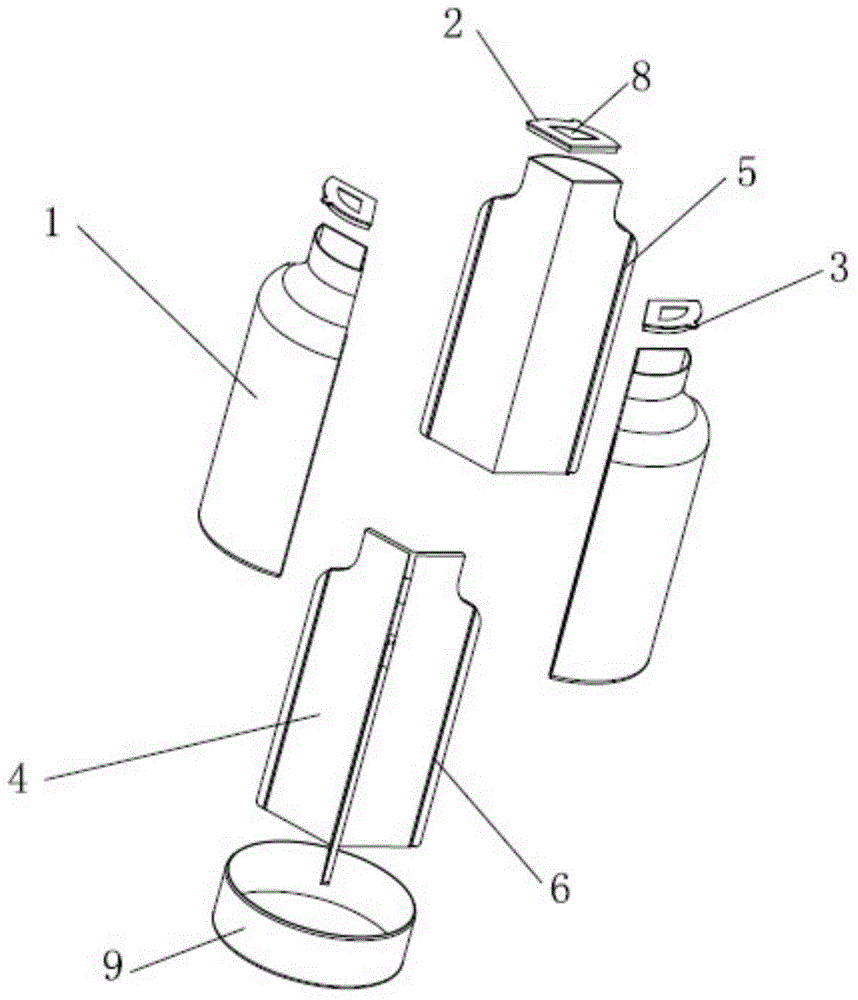

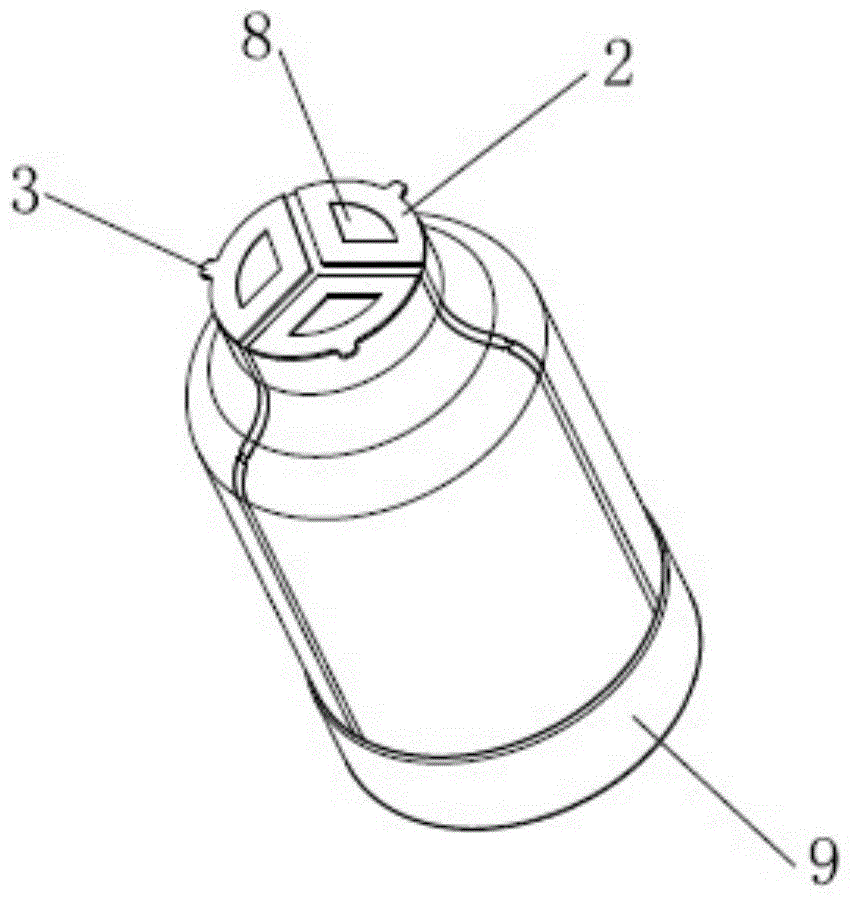

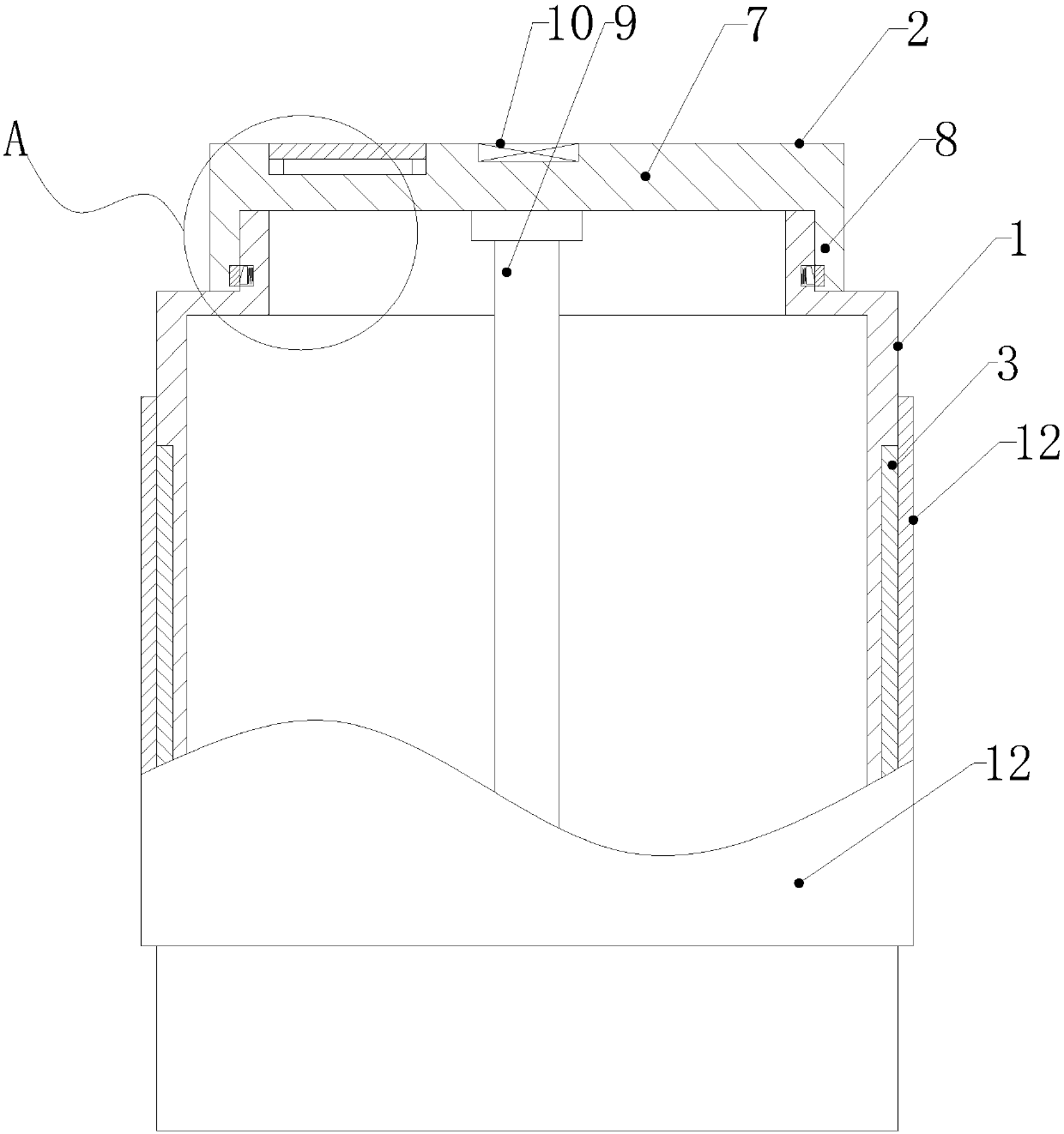

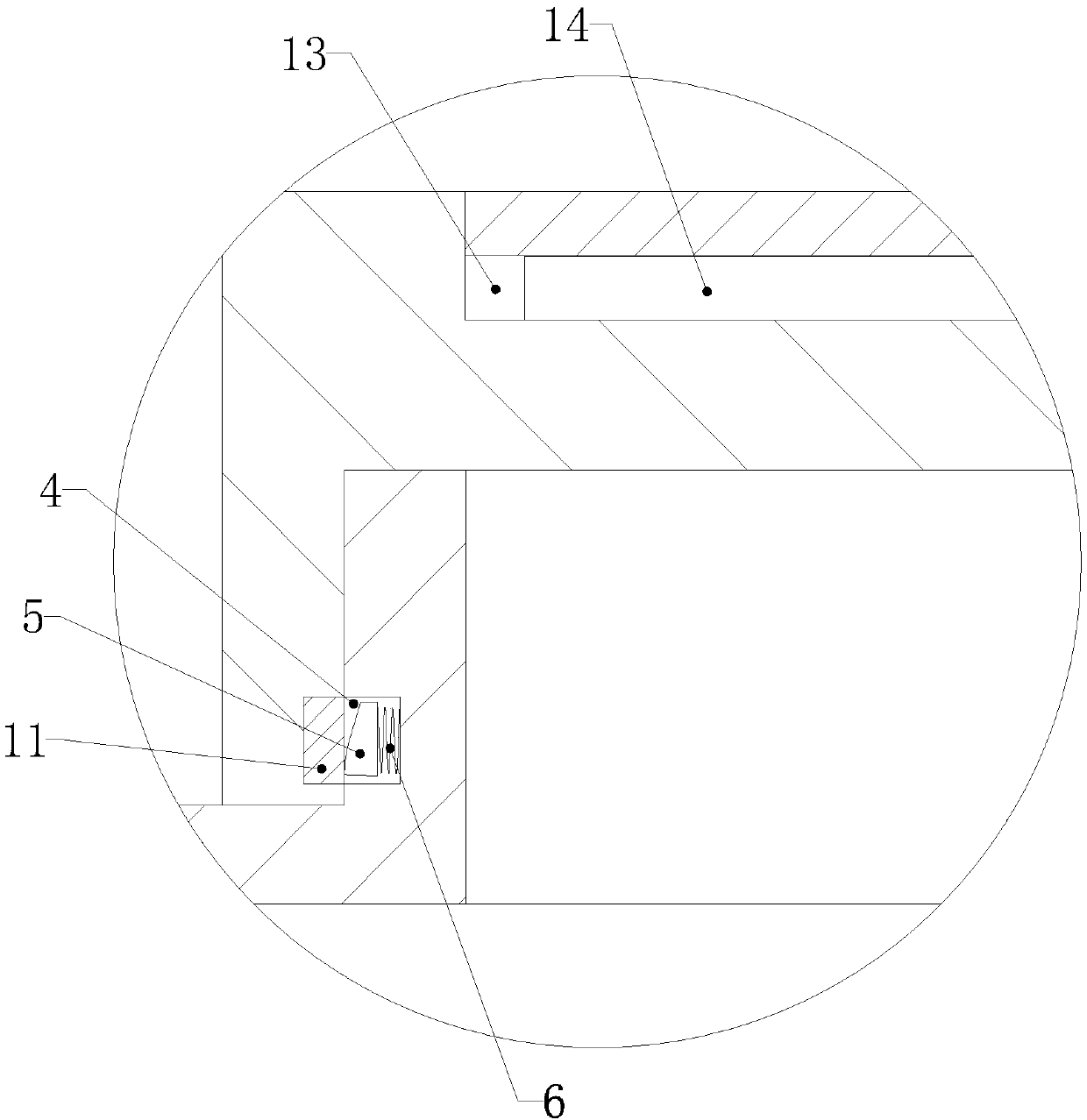

Quantitative liquid outlet bottle cover

The invention provides a quantitative liquid outlet bottle cover. The quantitative liquid outlet bottle cover comprises a bottle cover body and a cylinder, wherein the upper end of the bottle cover body is rotatably connected with the lower end of the cylinder through a connection cap; a liquid outlet hole penetrating through the upper end of the bottle cover body and the connection cap is formed in the bottle cover body and the connection cap; a baffle plate is arranged at the bottom of the cylinder; a sealing ring is arranged between the baffle plate and the cylinder; a liquid inlet hole is also formed in the position, corresponding to the liquid outlet hole, of the baffle plate; a fixed blocking piece, a sliding blocking piece and a rotating shaft arranged in the length direction of the cylinder are arranged in the cylinder; the rotating shaft adopts a hollow structure, and a position adjusting rod is arranged in the rotating shaft; the lower end of the position adjusting rod is fixed to the baffle plate, the upper end of the position adjusting rod extends out to the outer side of the end of the rotating shaft, and the upper end of the rotating shaft penetrates through the upper end of the cylinder and extends to the outer side of the cylinder; and a rotary knob with a pointer is arranged at the upper end of the rotating shaft. The quantitative liquid pouring is realized by taking the bottle cover as a starting point, and the bottle cover can realize standardized production and can be repeatedly used for many times for different bottles. The quantitative liquid outlet bottle cover belongs to the field of quantitative fluid obtaining.

Owner:GUIZHOU UNIV

Residual-prevention yoghourt bottle

Owner:顾钰锋

Method for locking/unlocking bottle cap

Owner:YIFENG MFG

Bottle cap component and container bottle with same

InactiveCN103434743AAffect flavorImpact costClosure with auxillary devicesContainers with multiple articlesEngineeringBottle cap

Owner:ZHUHAI ZHONGFU IND GRP

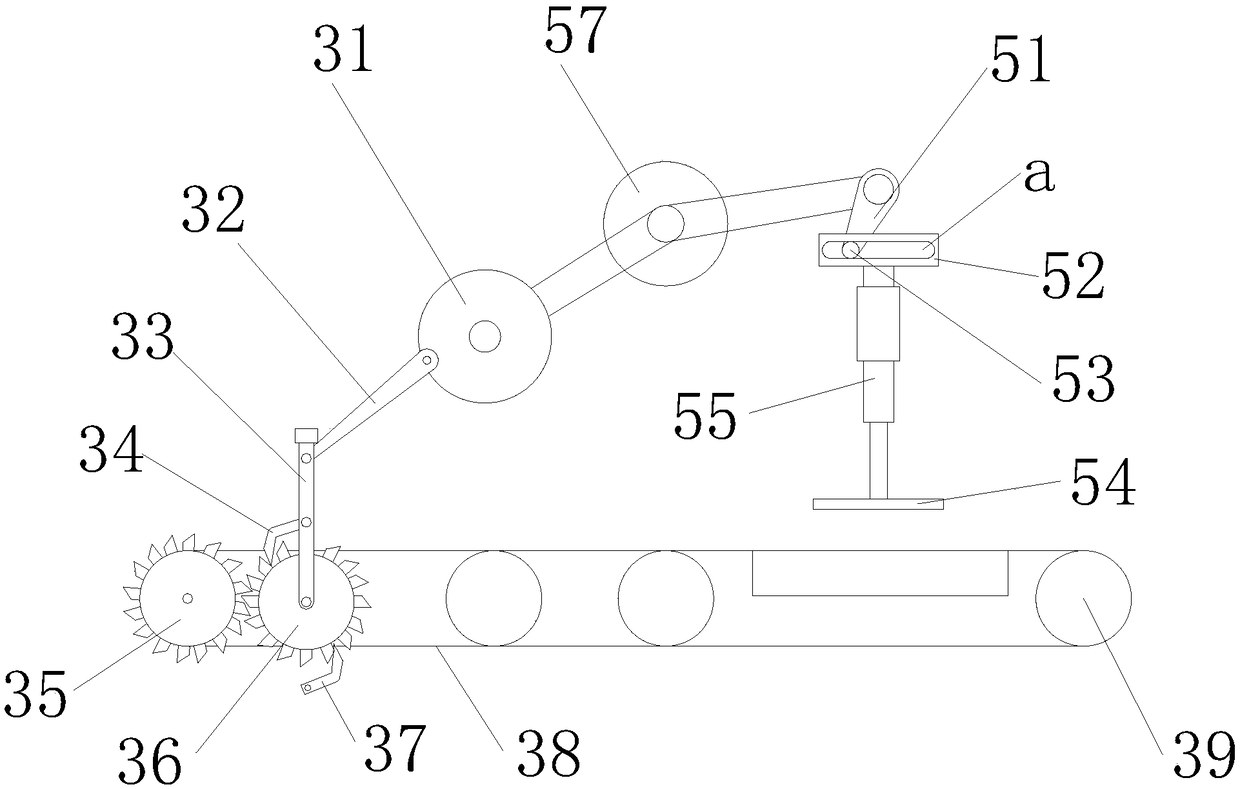

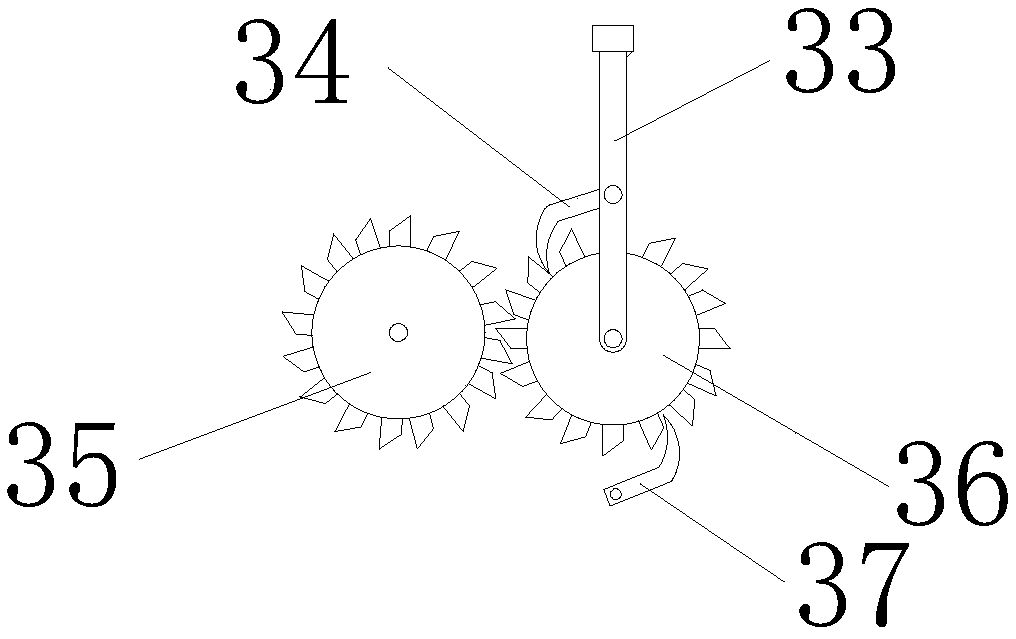

Continuous feeding and stamping apparatus for bottle cap production

InactiveCN109127940AHighly corporatedImprove stamping effectMetal-working feeding devicesClosure capsDrive shaftEngineering

Owner:安徽省潜山县包装制品有限公司

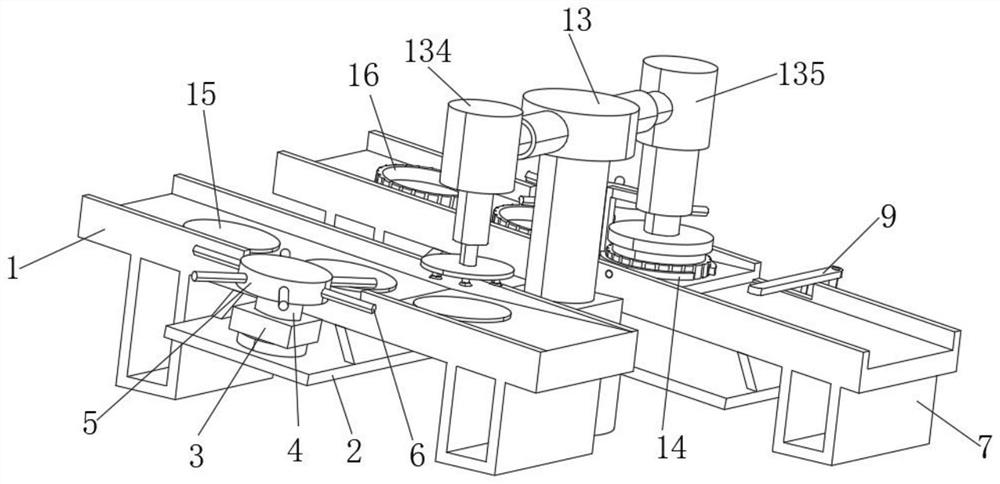

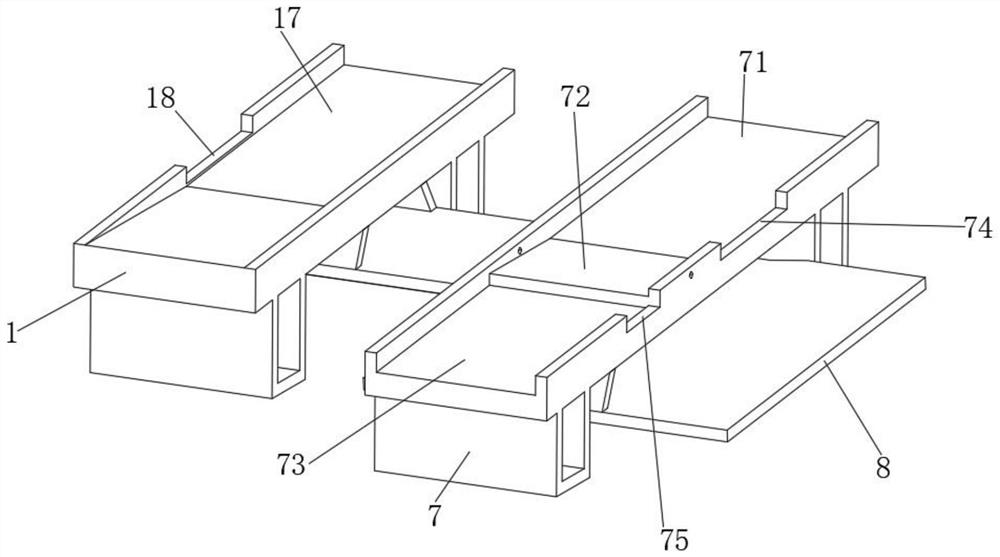

Bottle cap gasket plugging machine

PendingCN114751001ASmooth transmissionProduction rhythm is tightPackagingElectric machineControl engineering

Owner:HEFEI UNIV OF TECH

Eyedrop bottle

Owner:陈伟群

Device for collecting and measuring expiration

ActiveCN101988871AEliminate on-site dilutionEliminate the problems caused by sub-packagingWithdrawing sample devicesPreparing sample for investigationEngineeringBottle cap

Owner:SHENZHEN SEEKYA BIO SCI & TECH CO LTD

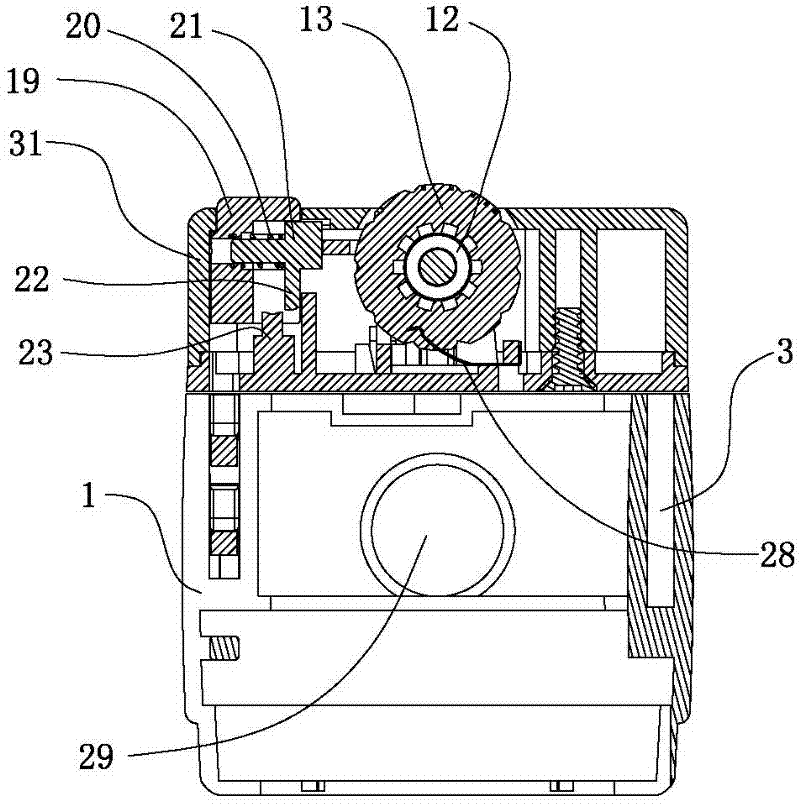

Bottle cap assembly dislocation auxiliary device

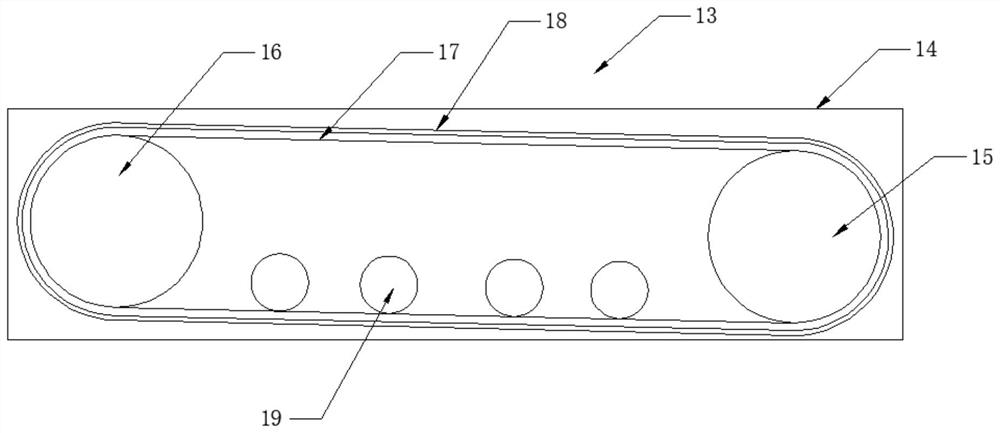

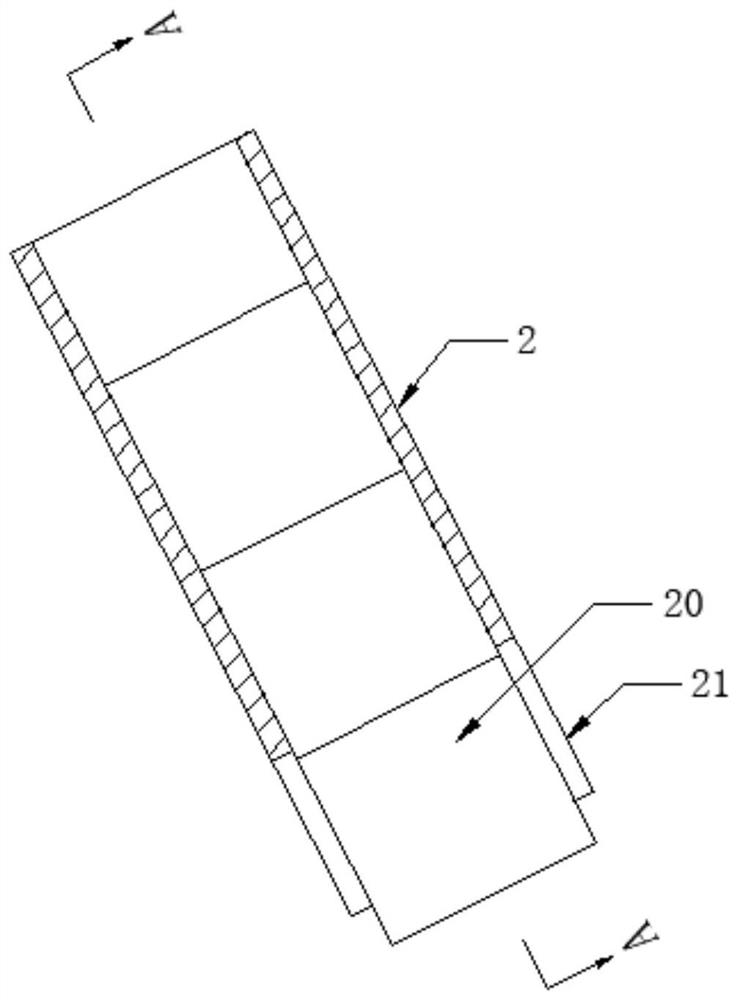

The invention provides a bottle cap assembly dislocation auxiliary device which comprises an assembling machine working table and an upper fixed plate, wherein an principle axis is arranged on the working table, a driven wheel is arranged at the lower end of the principle axis and meshed with a driving wheel, a large guide sleeve body, a small guide sleeve body and a tray are arranged on the principle axis, a lower guide sleeve is arranged on the large guide sleeve body, an upper guide sleeve and an internal plastic piece drive plate are arranged on the small guide sleeve body, reciprocating levers are arranged on the upper guide sleeve and the lower guide sleeve, rollers are arranged at the lower ends of the reciprocating levers, cams are arranged at the lower ends of the rollers and fixedly arranged on the working table, the tray is provided with a piece supporting tray and an upper drive plate, a guide seat is arranged on the tray and internally provided with a lifting lever and a thrust bearing, a spring is arranged on the lifting lever, a soft sleeve is arranged at the lower end of the lifting lever, and a steel ball is arranged in a groove at the upper end of the guide seat and contacted with a tooth surface cam plate. The bottle cap assembly dislocation auxiliary device solves the problem that raised teeth of a plastic inner assembly and positioning grooves of an outer cover can not accurately correspond to one another when an automatic assembling machine is in assembling, improves the production efficiency and lowers the production cost.

Owner:LIPENG PACKING YANTAI CITY

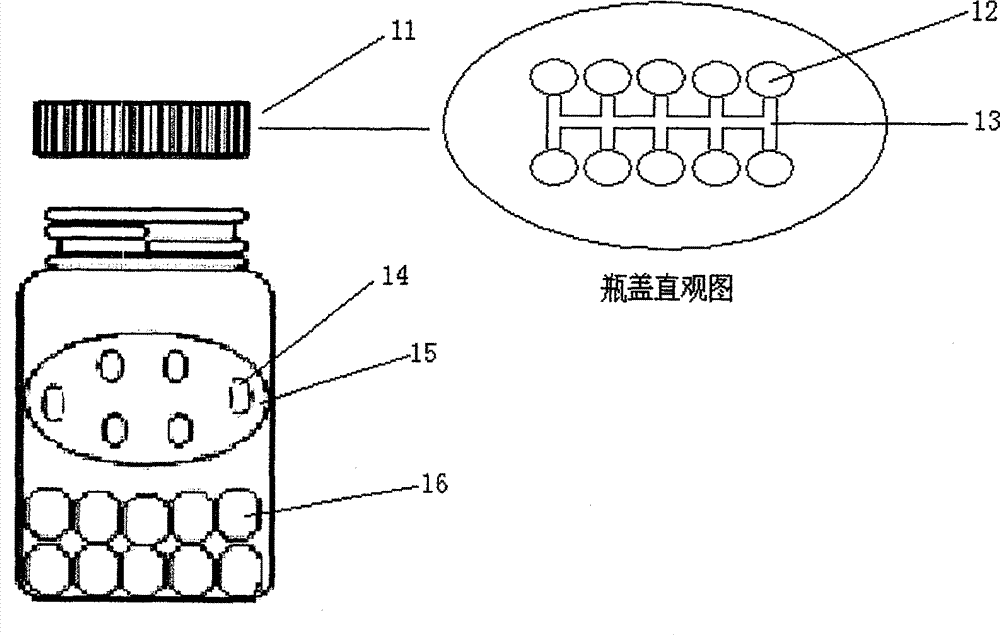

Multifunctional combination bottle

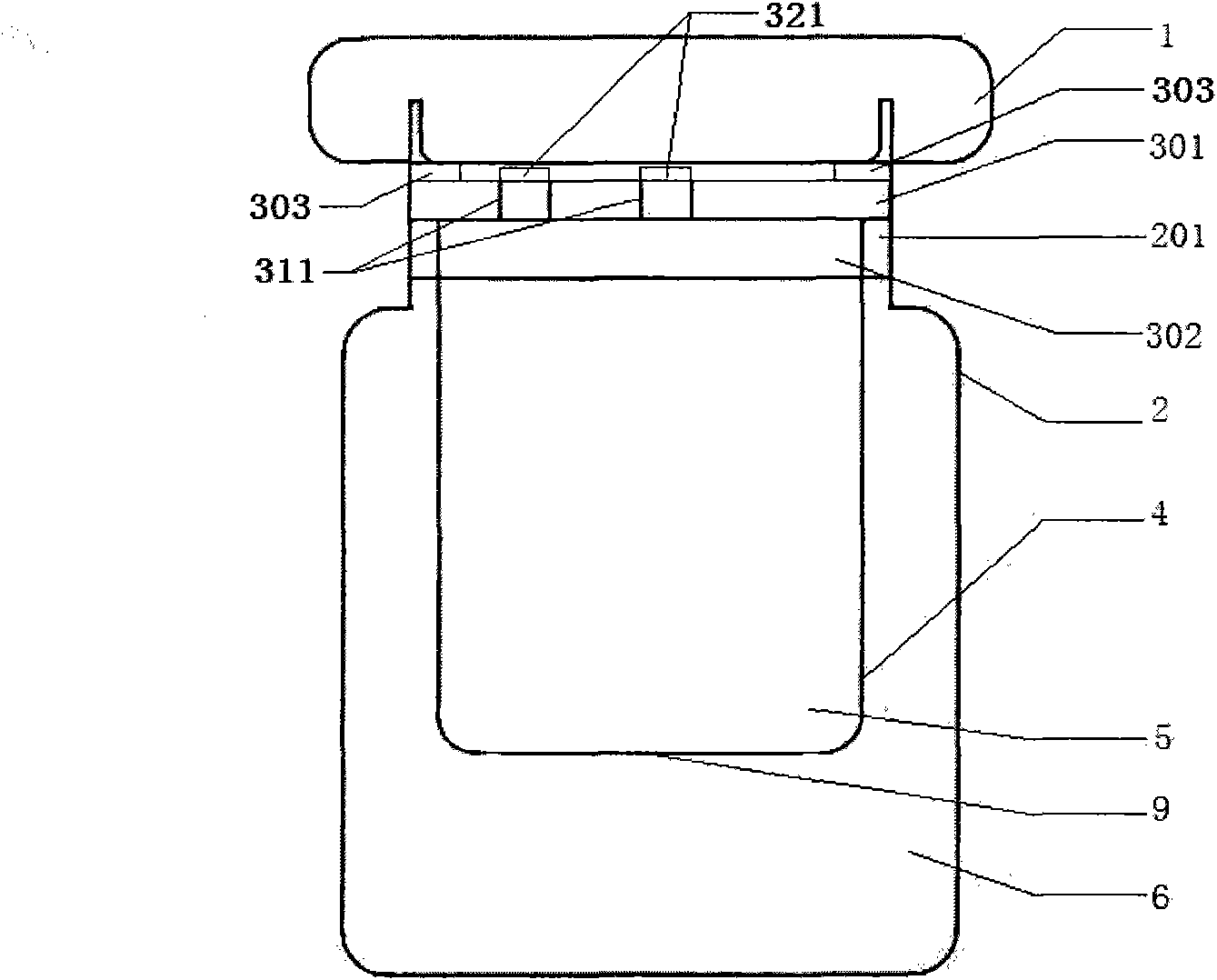

The invention discloses a multifunctional combination bottle, and relates to the field of containing containers. The problem that an existing bottle can only contain a single substance is solved. The combination bottle comprises an upper bottle body, a middle bottle body and a lower bottle body which are independent from one another and are vertically and sequentially connected into a whole in a screwed mode. A first inward-concave screw connector is arranged on the bottom of the upper bottle body. A middle bottle opening which is in screw-thread fit with the first screw connector is arranged on the top of the middle bottle body. A second inward-concave screw connector is arranged on the bottom of the middle bottle body. A lower bottle opening which is in screw-thread fit with the second screw connector is arranged on the top of the lower bottle body. An upper bottle opening is arranged on the top of the upper bottle body. An upper bottle cap which is in threaded connection with the upper bottle opening is arranged on the upper bottle opening. The middle bottle opening, the lower bottle opening and the upper bottle opening are each provided with aluminum-foil paper capable of being torn off. The bottom of the first screw connector and the bottom of the second screw connector are sleeved with sealing gaskets. The multiple bottle bodies are combined and connected together to form a bottle capable of containing different substances independently, and the bottle is multifunctional, simple and practical.

Owner:周建行

Device for rapid dehydration and of fixing biological molecule detection sample and method

Owner:银丰低温医学科技有限公司

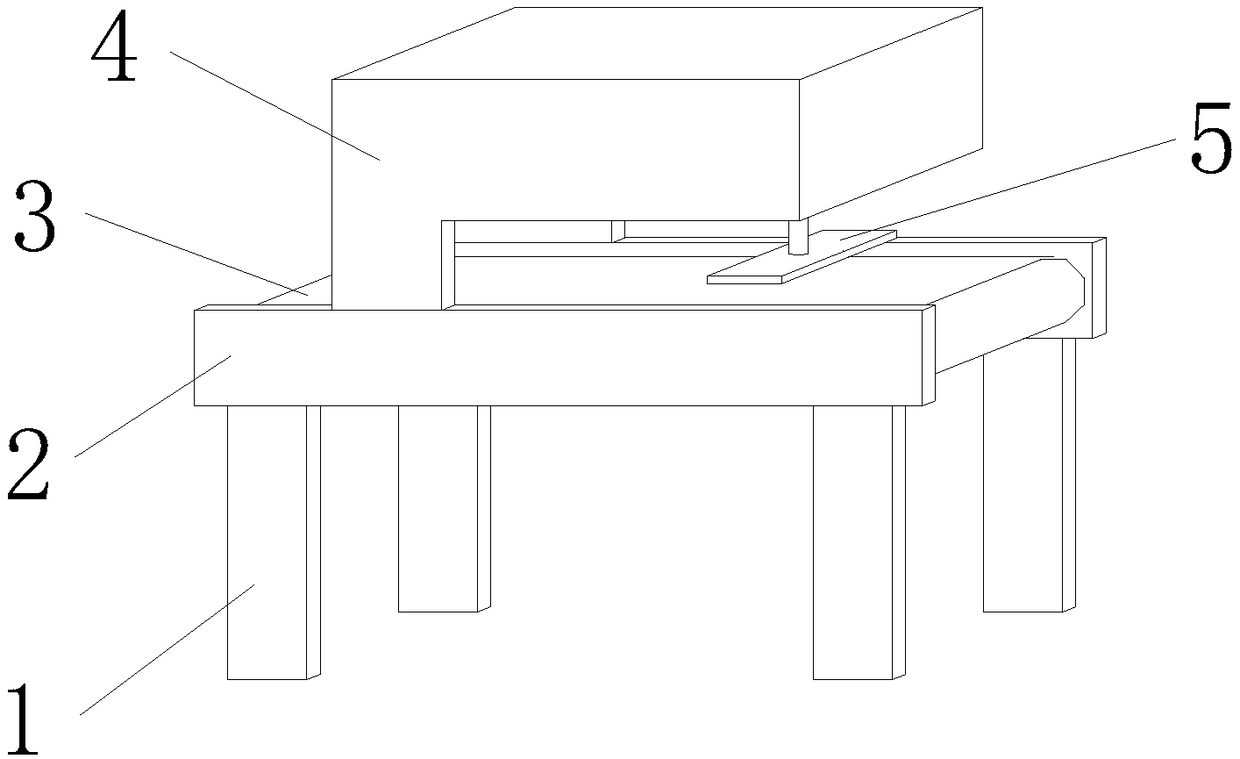

Capping machine

InactiveCN112250006AAvoid damageEasy to compressConveyorsFlanged caps applicationElectric machineryBottle cap

Owner:苏州仁宇机械有限公司

Nail polish bottle allowing colors to be distinguished

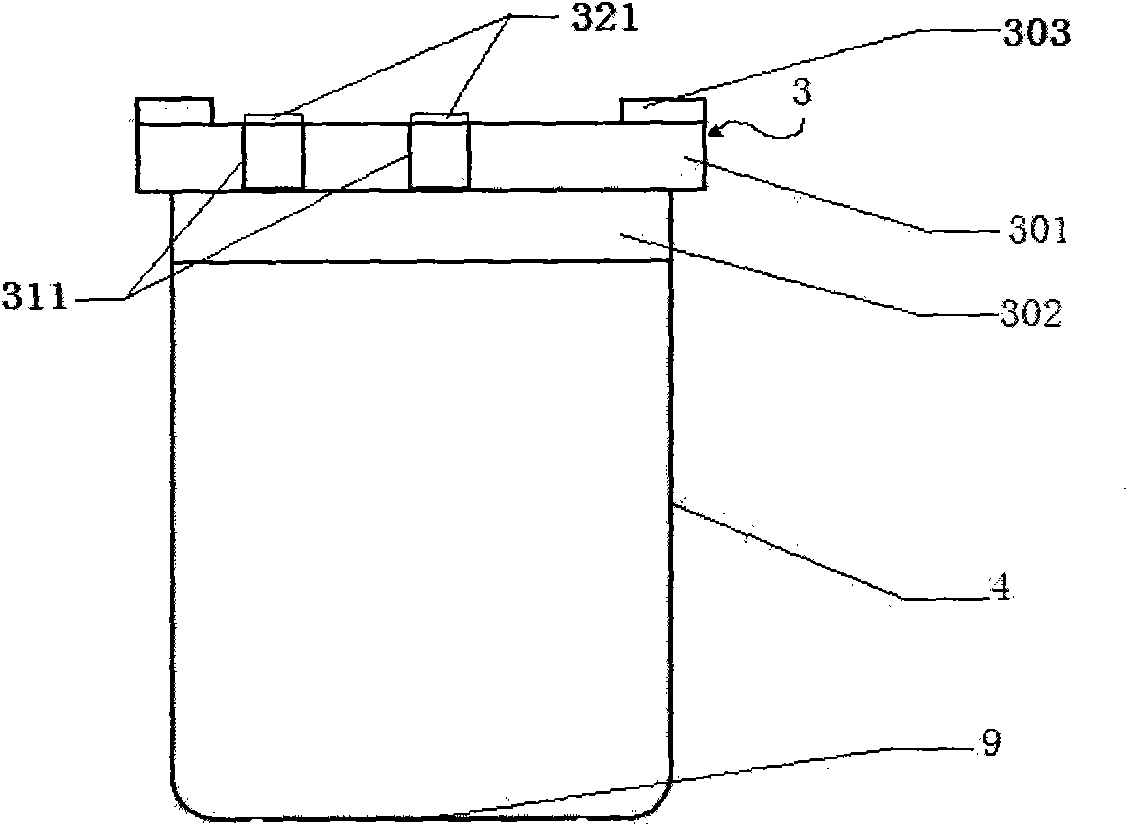

The invention discloses a nail polish bottle allowing colors to be distinguished. The nail polish bottle comprises a bottle body (1) and a bottle cap (2), wherein the bottle cap is colorized and the same as nail polish in color, in this way, people can purchase the nail polish on selection conveniently, and the nail polish bottle is practical and attractive.

Owner:郇丽霞

Combined bottle with base

Owner:WUXI WEISHUN METAL PROD

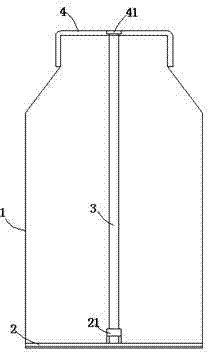

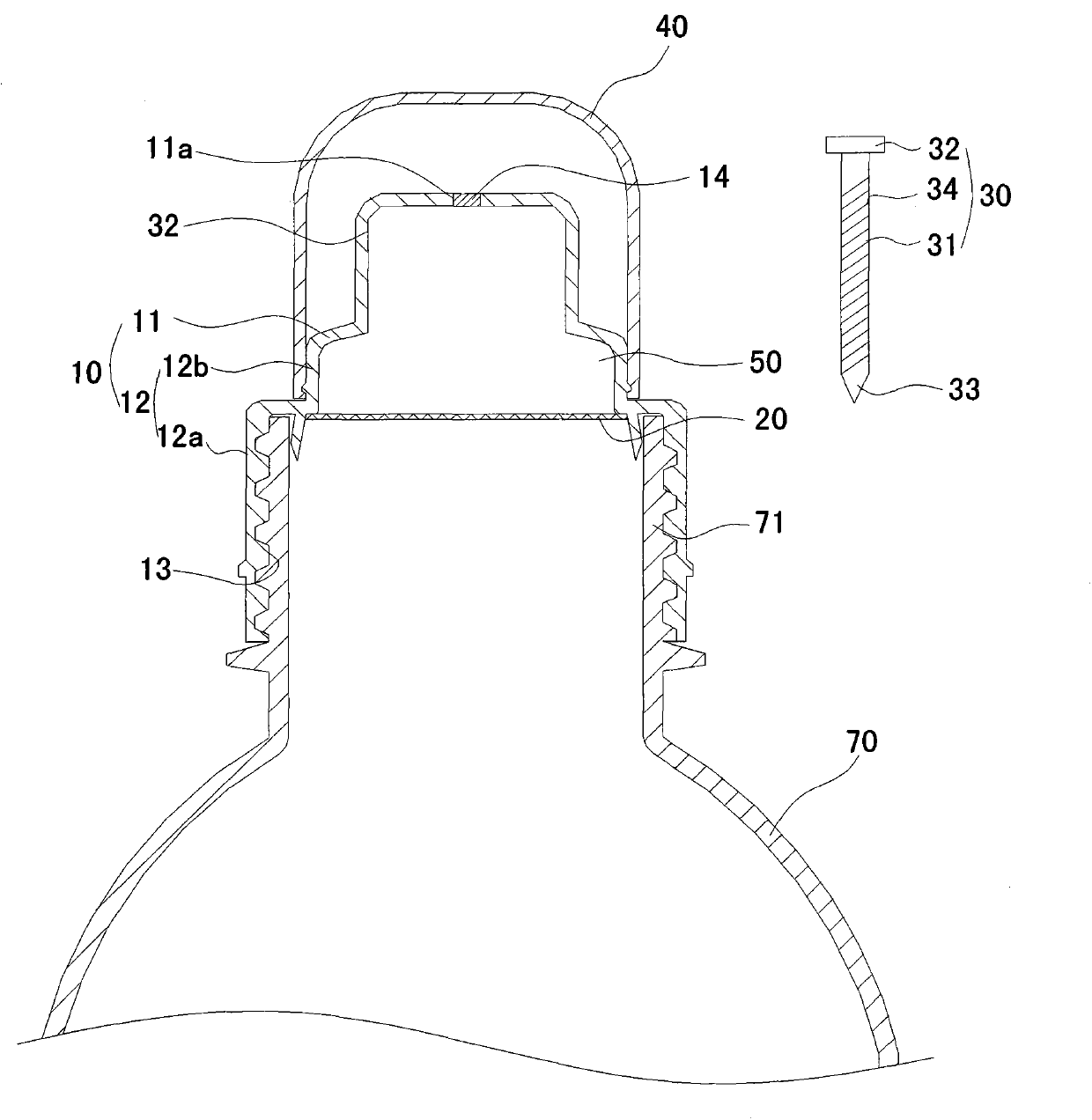

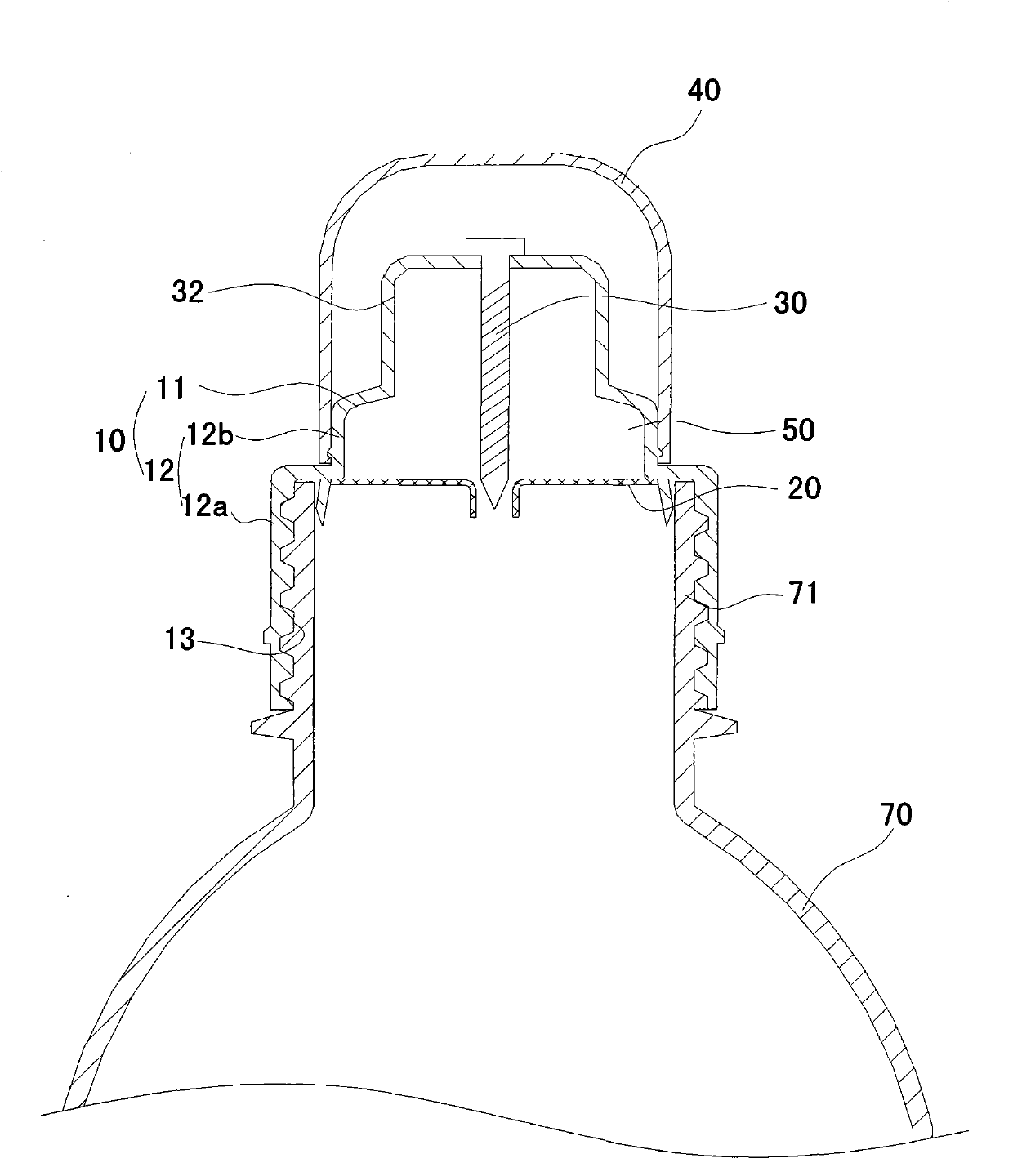

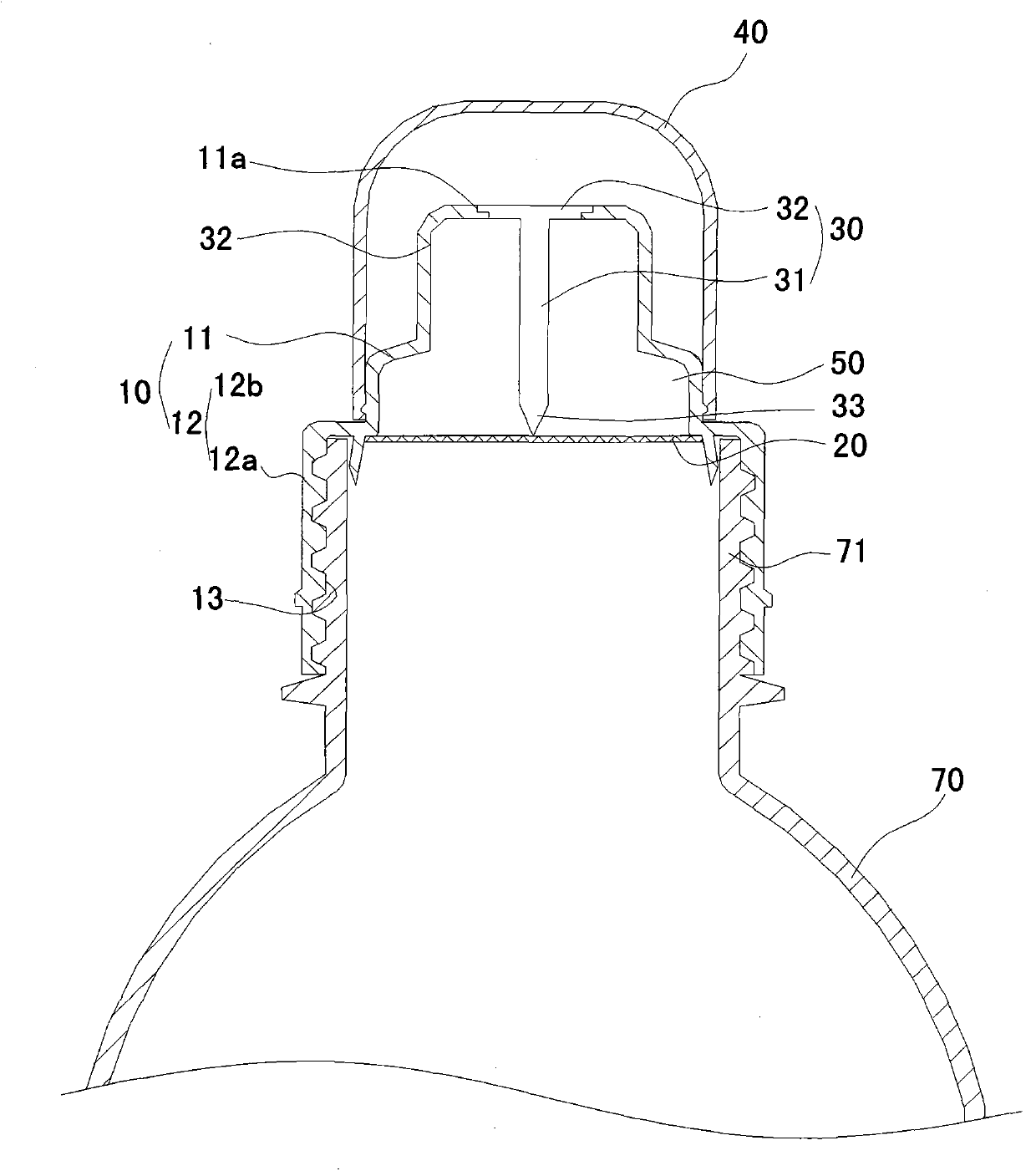

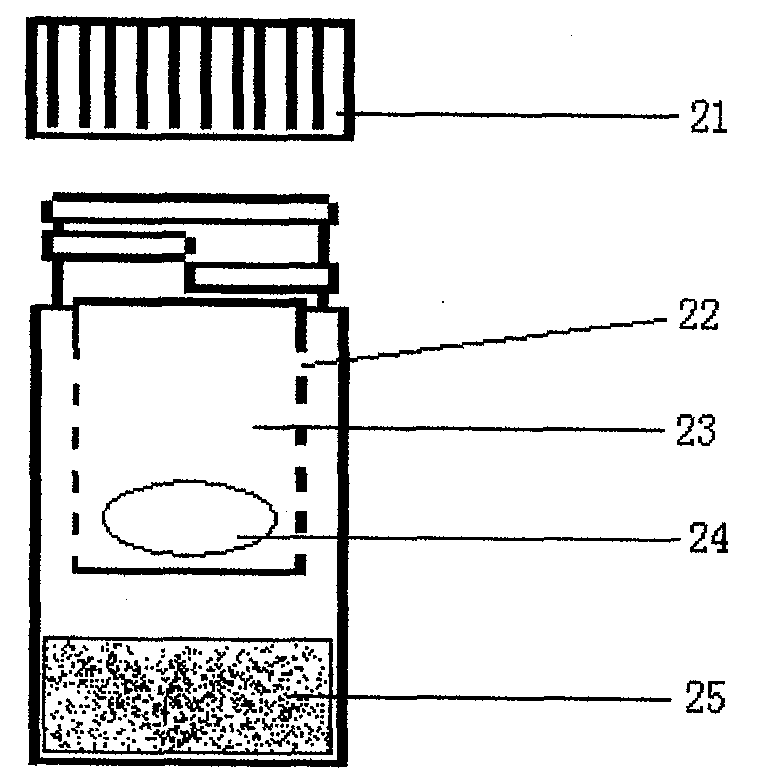

Baby bottle

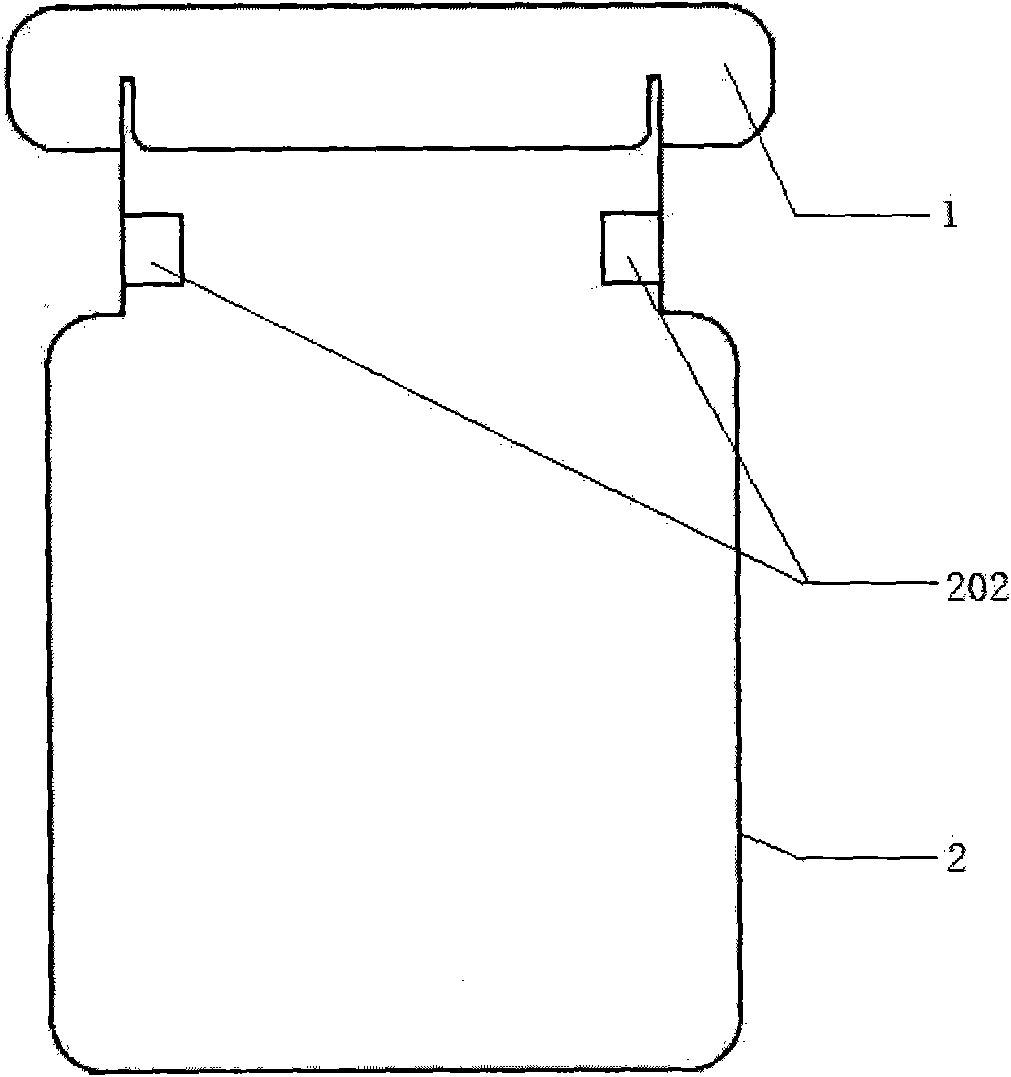

The invention discloses a baby bottle which comprises a bottle body, a bottle cap and a nipple, wherein the bottle body is flared; the diameter of the top of the bottle is greater than the diameter of the bottom of the bottle; the bottle cap is fixedly connected to the bottle body; the bottle cap is connected with a flow adjustment mechanism; the nipper is connected with the flow adjustment mechanism. According to the baby bottle, the shape of the bottle body is changed to be flared, so that the liquid in the bottle body can flow out completely when the bottle body is in a horizontal state, a baby is not required to raise his head; therefore, the problem of choking in a head raising state is solved; the liquid flowing speed can be adjusted by the arrangement of the flow adjustment mechanism, so that the baby can use the bottle more comfortably.

Owner:陈小英

Honey storage bottle

Owner:SUZHOU SHANDING BEE PROD CO LTD

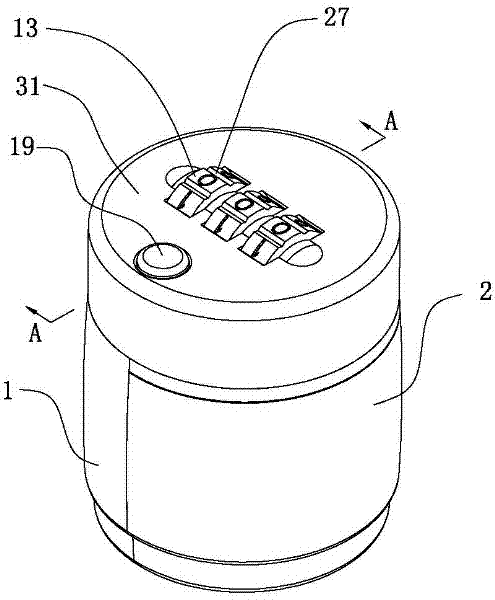

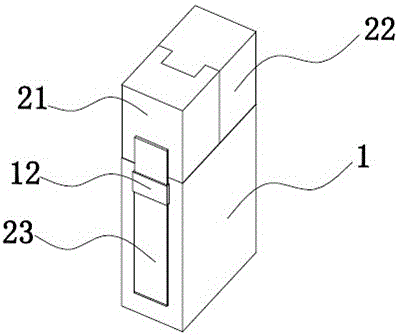

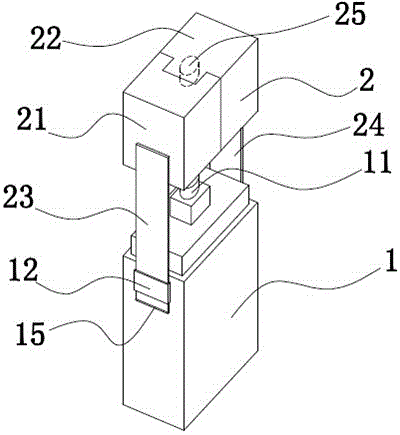

Cover screwing device for filling machine

PendingCN107954385AWith shock absorbing effectReduce impactCapsThreaded caps applicationEngineeringPumping vacuum

The invention discloses a cover screwing device for a filling machine. The cover screwing device is used for screwing bottle covers on bottles and comprises a mounting seat, a rotating piece, a coverscrewing mould and a driving mechanism for driving the mounting seat to move. A cavity is formed between the mounting seat and the rotating piece; an upper magnetic ring, a lower magnetic ring and a magnetic conduction ring with the same size are arranged in the cavity, the upper magnetic ring and the lower magnetic ring are fixedly connected with the mounting seat, and the magnetic conduction ring is fixedly connected with the rotating piece; suction cups are embedded in the lower end face of the cover screwing mould, and a ventilation pipe communicating with the suction cups is arranged in the rotating piece; and reinforcing ribs for reinforcing the firmness of the suction cups are arranged at the connecting positions of the suction cups and the cover screwing mould. Air pumping is conducted on the ventilation pipe through vacuum extraction equipment on the filling machine, thus the suction cups can adsorb the bottle covers of different specifications, the situation that an originalcover screwing mould can only deal with screwing of bottle covers of the single specification is broken, meanwhile, the suction cups are reinforced, and thus in the screwing process, the suction cupscan provide sufficient torque to screw the bottle covers.

Owner:ZHANGJIAGANG KING MASCH MFR CO LTD

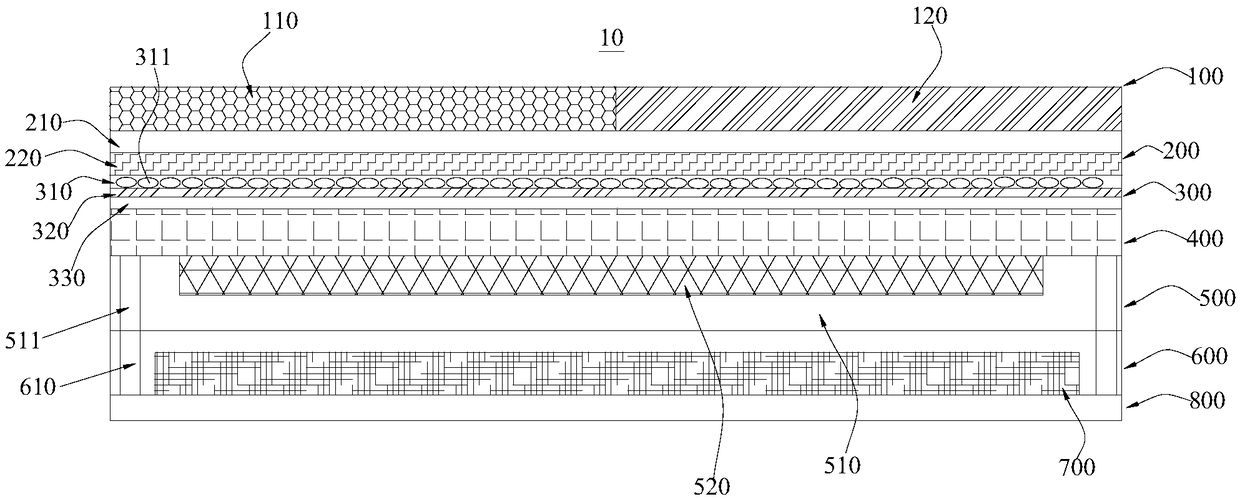

Anti-counterfeit wine bottle label structure

InactiveCN109272857AImprove waterproof performancePrevent counterfeitingStampsRecord carriers used with machinesAlcoholBiochemical engineering

Owner:HUIZHOU HAOMING SCI & TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap