Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9 results about "Epichlorohydrin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epichlorohydrin (abbreviated ECH) is an organochlorine compound and an epoxide. Despite its name, it is not a halohydrin. It is a colorless liquid with a pungent, garlic-like odor, moderately soluble in water, but miscible with most polar organic solvents. It is a chiral molecule generally existing as a racemic mixture of right-handed and left-handed enantiomers. Epichlorohydrin is a highly reactive electrophilic compound and is used in the production of glycerol, plastics, epoxy glues and resins, and elastomers.

Endotoxin adsorption medium based on magnetic chitosan microballoon and its application method

InactiveCN102350309AHigh selectivitySimple and fast operationOther chemical processesAlkali metal oxides/hydroxidesCross linkerAcetic acid solution

The invention discloses an endotoxin adsorption medium based on magnetic chitosan microballoon and an application method, wherein the preparation method of endotoxin adsorption medium comprises the following steps: (1) dispersing a magnetic material in an acetic acid solution, adding chitosan to prepare water phase I, transferring water phase I to liquid paraffin containing span 80, taking glutaraldehyde as a cross-linking agent, preparing chitosan microballoon by using an anti-phase suspension method; (2) dispersing magnetic chitosan microballoon in a mixed solution of dimethyl sulfoxide and sodium hydroxide, adding chloropropylene oxide for activating, washing by deionized water till neutralizing to obtain an activated product; (3) placing the activated product in an endotoxin affinity ligand solution for immobilizing to obtain the endotoxin adsorption medium based on the magnetic chitosan microballoon. The endotoxin adsorption medium of the present invention has high selectivity of endotoxin and simple operation, and can be used for removing the endotoxin in a plurality of biological products.

Owner:ZHEJIANG UNIV OF TECH

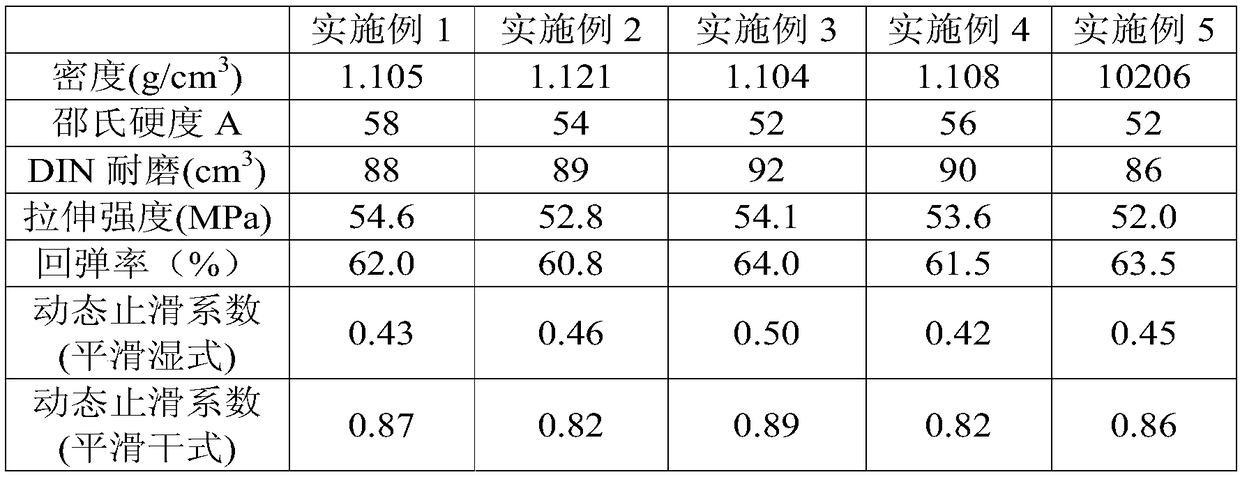

Fireproof anti-abrasion rubber shoe sole material and preparation method thereof

InactiveCN109354817AImprove wear resistanceGood mechanical propertiesSolesPolymer scienceMechanical property

Owner:JINJIANG XINQIMEI SHOES MATERIAL DEV

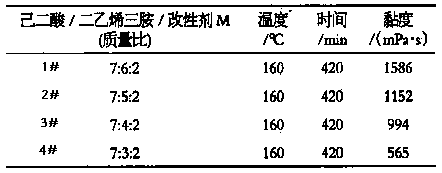

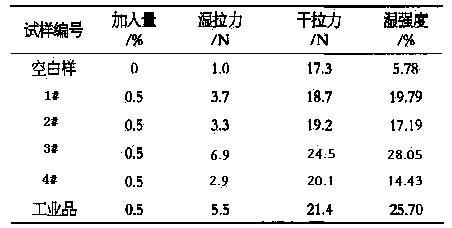

Papermaking wet strengthening agent preparation method

InactiveCN103806337AEnhancement effect is goodLow priceReinforcing agents additionPolyamideWastewater

Owner:王慧

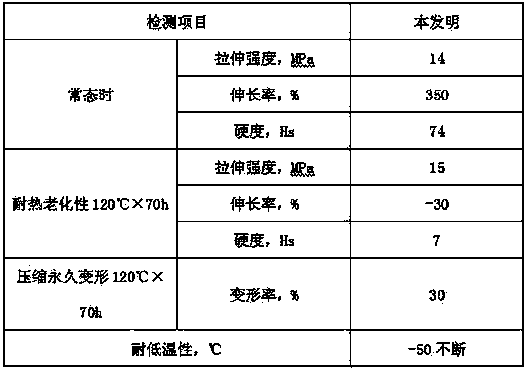

Rubber tube and preparation method thereof

ActiveCN104072973AImprove high temperature resistanceImprove low temperature resistancePolymer scienceAntimony trioxide

Owner:LIUZHOU YINGHANG AUTO PARTS

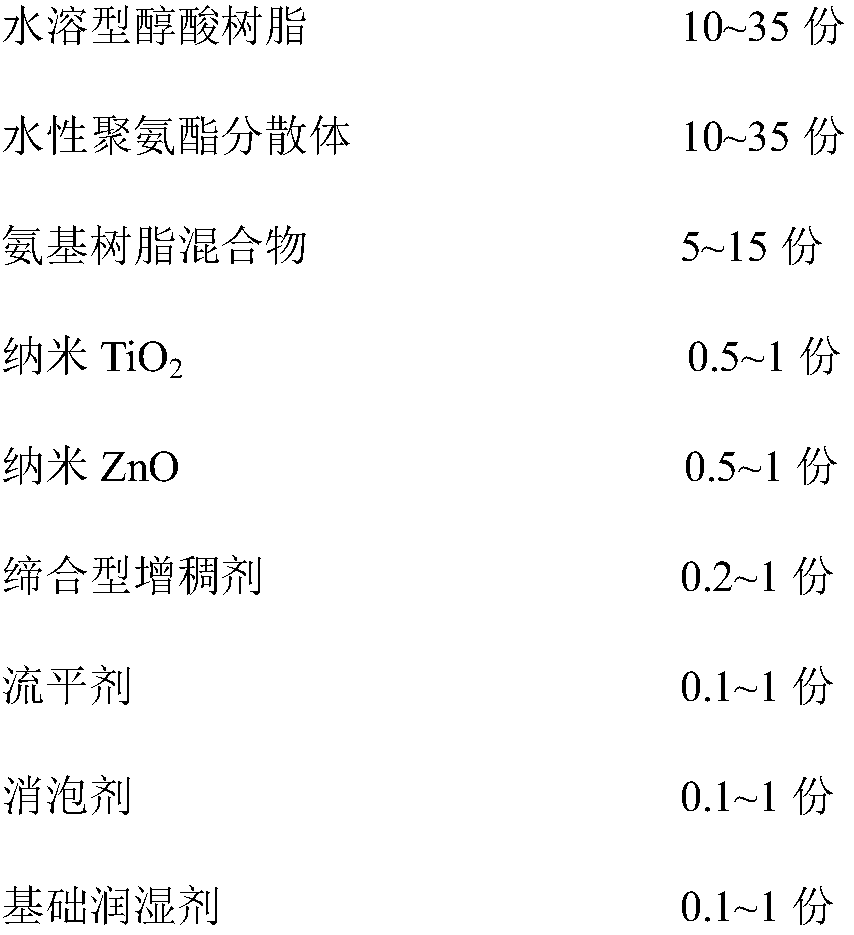

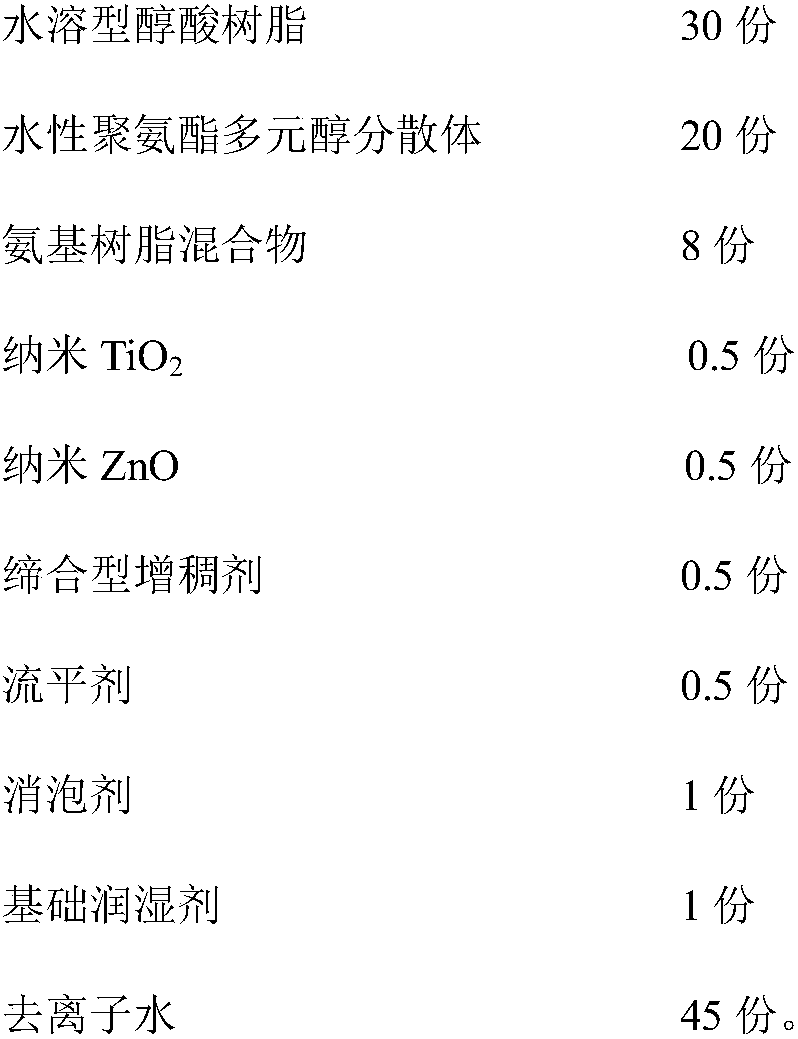

Durable antibacterial waterborne woodenware coating and preparation method thereof

ActiveCN108165146AImprove antibacterial propertiesOvercoming volatileAntifouling/underwater paintsPaints with biocidesAssociation typePolyamide

Owner:肇庆易涂宝涂料有限公司

A process for preparation of an aromatic n-glycidylamine

A process for preparing an aromatic N-glycidylamine comprising a step of heating a mixture of an amine having at least one aromatic aminohydrogen atom with at least 0.7 equivalent of epichlorohydrin per aminohydrogen equivalent of the amine in presence of a catalyst dissolved in an inert organic solvent, at a pressure in a range of 200 mbar to 600 mbar; and adding a base to the mixture at a pressure in a range of 200 mbar to 600 mbar to facilitate dehydrochlorination of product of the previous step to obtain the aromatic N-glycidylamine.

Owner:GRASIM IND LTD

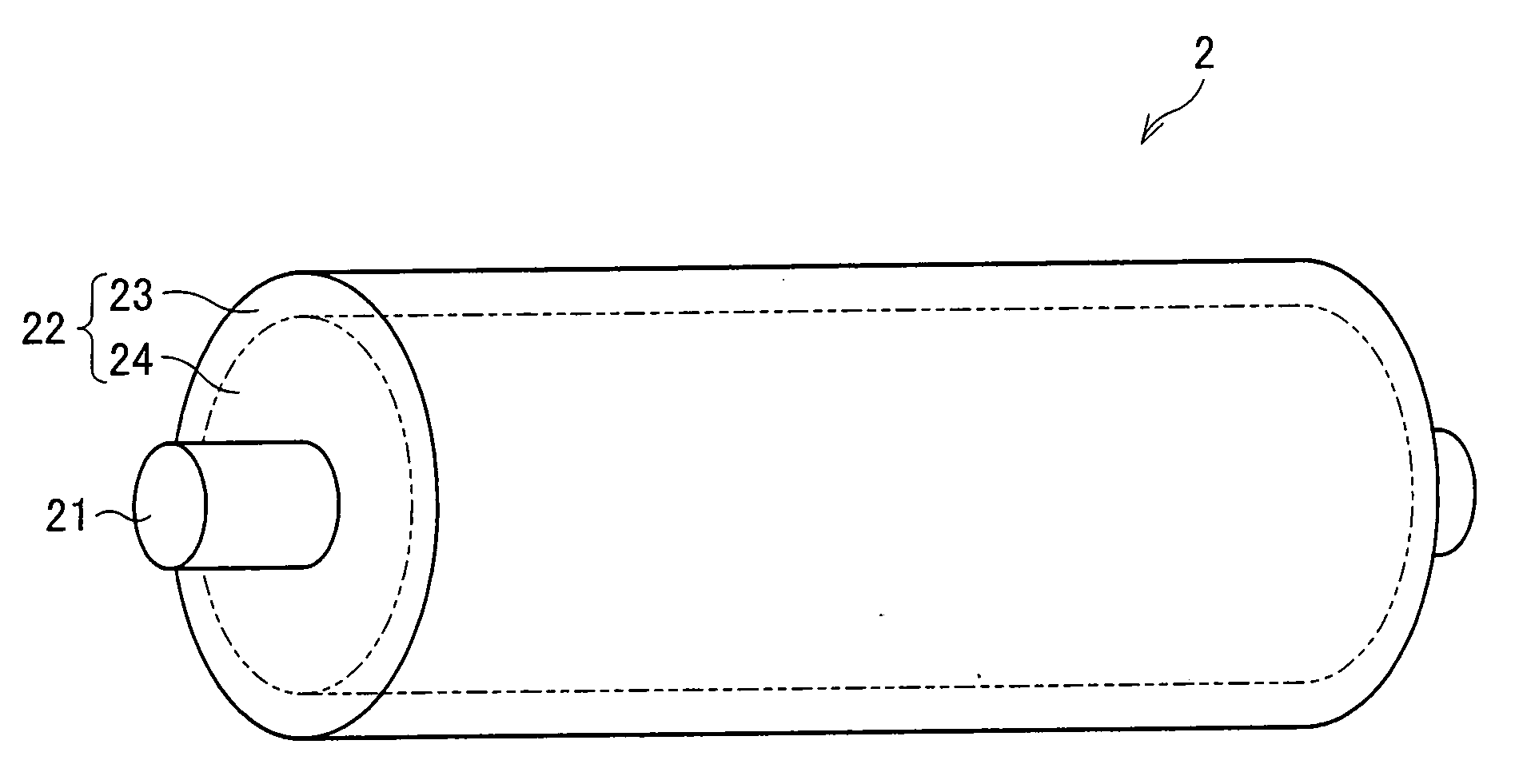

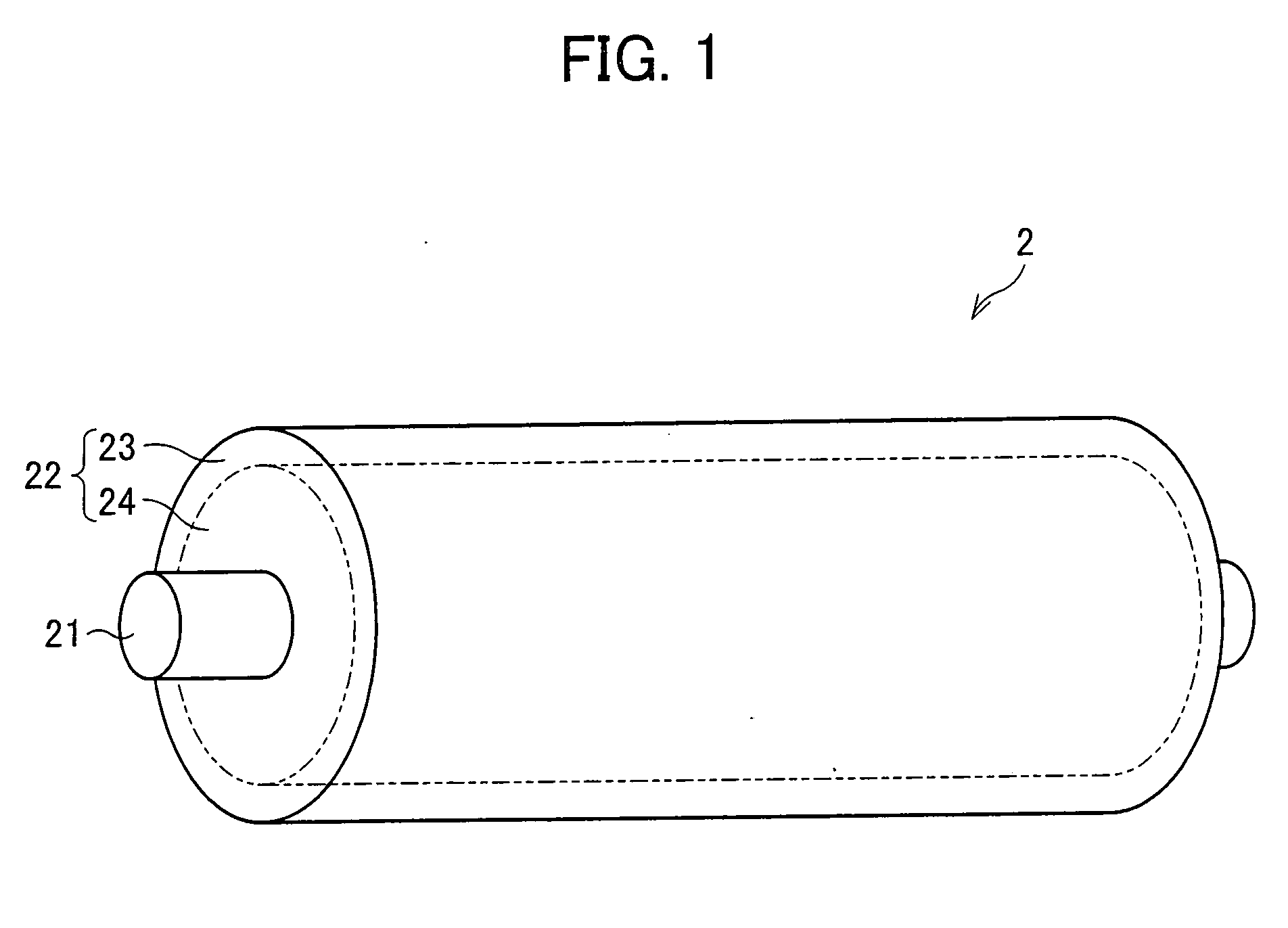

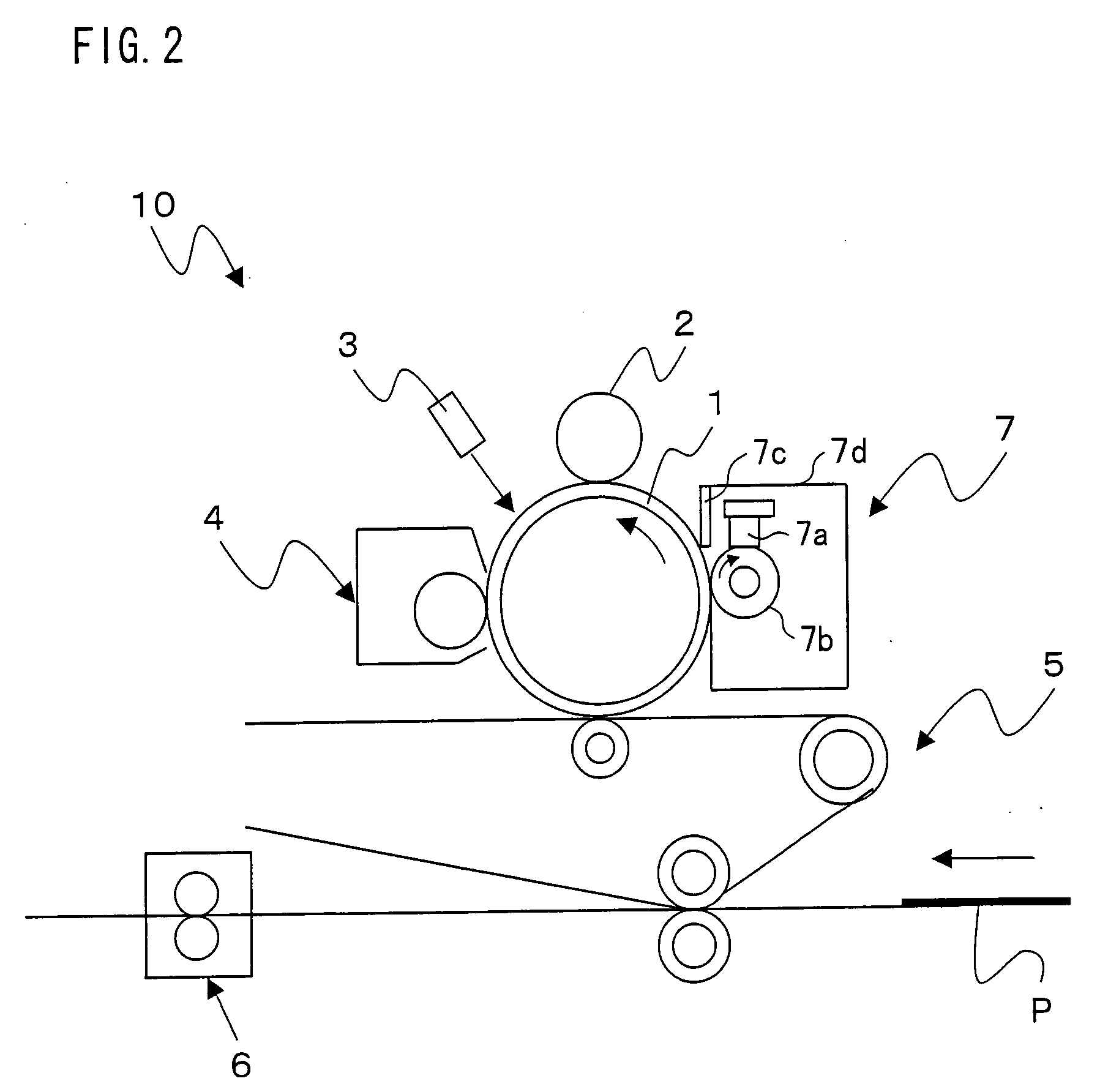

Charging roller and image forming apparatus incorporating same

InactiveUS20070253737A1Stable conductionElectrographic process apparatusCorona dischargeImage formationEngineering

Owner:SHARP KK

Method for purifying epoxy chloropropane

The invention relates to a method for purifying epoxy chloropropane, in particular to a refining method for preparing high-purity epoxy chloropropane. A rectifying tower with a side liquid-phase extraction function is used as a finished product tower for refining the epoxy chloropropane, and finished epoxy chloropropane is extracted from a rectifying section in a side liquid-phase manner. Tower top distillate contains more water and light components and is conveyed to a dehydrating tower top, and heavy components are discharged from a tower pot. The finished product tower with the side liquid-phase extraction function is used for replacing a conventional tower, on one hand, harsh requirements of the finished product tower on water content and light components of feed are lowered, so that energy consumption in the refining process of the epoxy chloropropane is reduced; and on the other hand, the high-purity (99.99%) finished epoxy chloropropane is easily obtained by extracting the epoxy chloropropane in the side liquid-phase manner.

Owner:CHANGZHOU UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap