Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Flexural strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexural strength, also known as modulus of rupture, or bend strength, or transverse rupture strength is a material property, defined as the stress in a material just before it yields in a flexure test. The transverse bending test is most frequently employed, in which a specimen having either a circular or rectangular cross-section is bent until fracture or yielding using a three point flexural test technique.

Door

The present invention discloses a door which has sufficient bending strength and is not damaged by moisture. The front panel 10 and the rear panel 20 of the door of the invention are made of glass fiber material. A pair of transverse frames 30a and 30b are made of synthetic resin, and a pair of longitudinal frames 40a and 40b made of wood comprising a plurality of veneers bonded together are fixed between edge portions of the front and rear panels. The upper and lower portions of the longitudinal frames are fixedly bonded to the lower and upper surfaces of each of the transverse frames so that the longitudinal frames are not exposed. In addition, a pair of cover plates 50 made of synthetic resin are attached to the outer side surfaces of the longitudinal frames so that the longitudinal frames are not exposed to the outside. The inner space defined by the frame between the front panel and the rear panel is filled with foaming liquid to form a foam layer.

Owner:TRINITY GLASS INT

Wear-resistant engineering plastic

InactiveCN107082933AImprove wear resistanceGood mechanical propertiesWear resistantEngineering plastic

Owner:东至县科创塑料制品有限公司

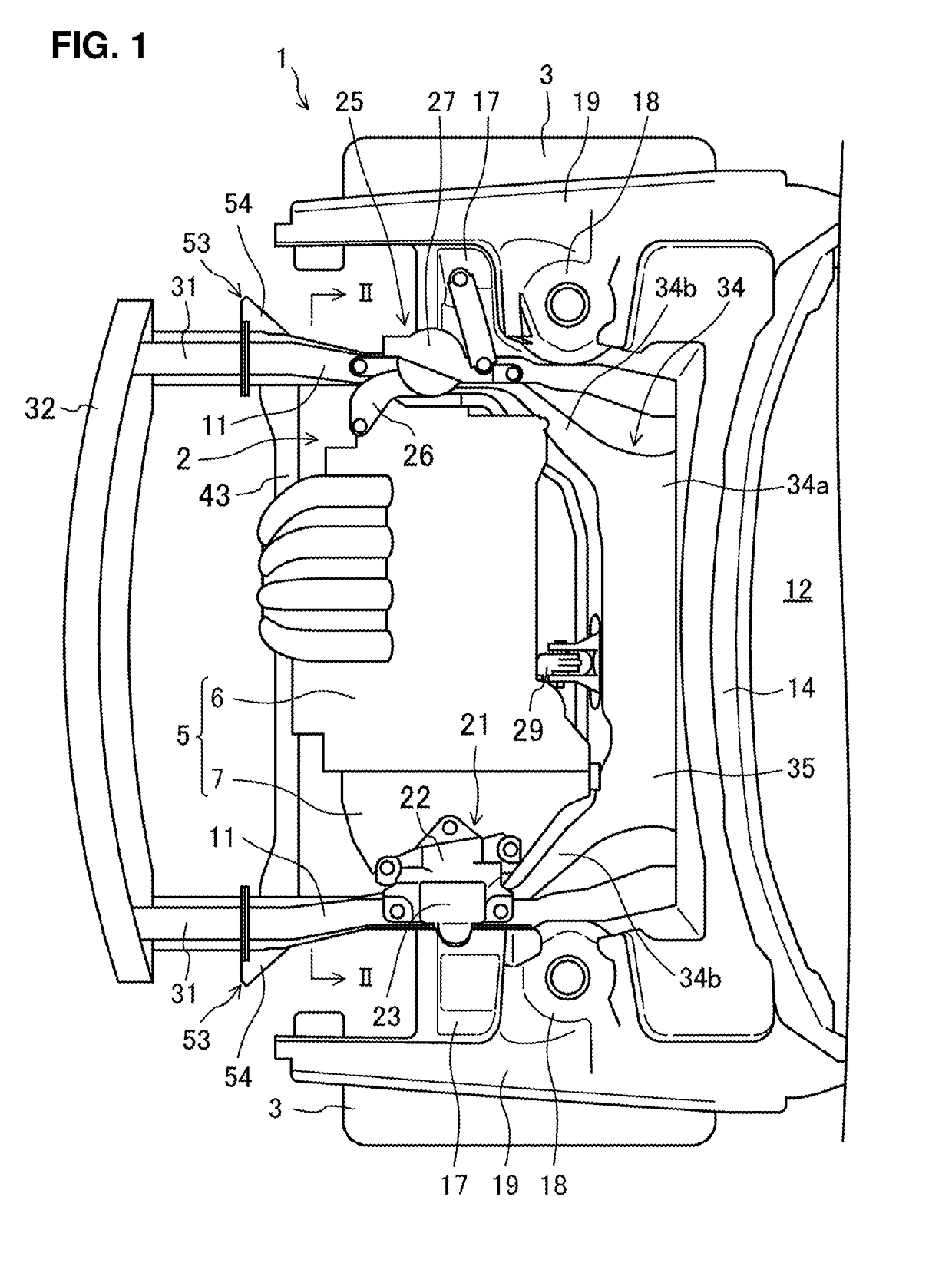

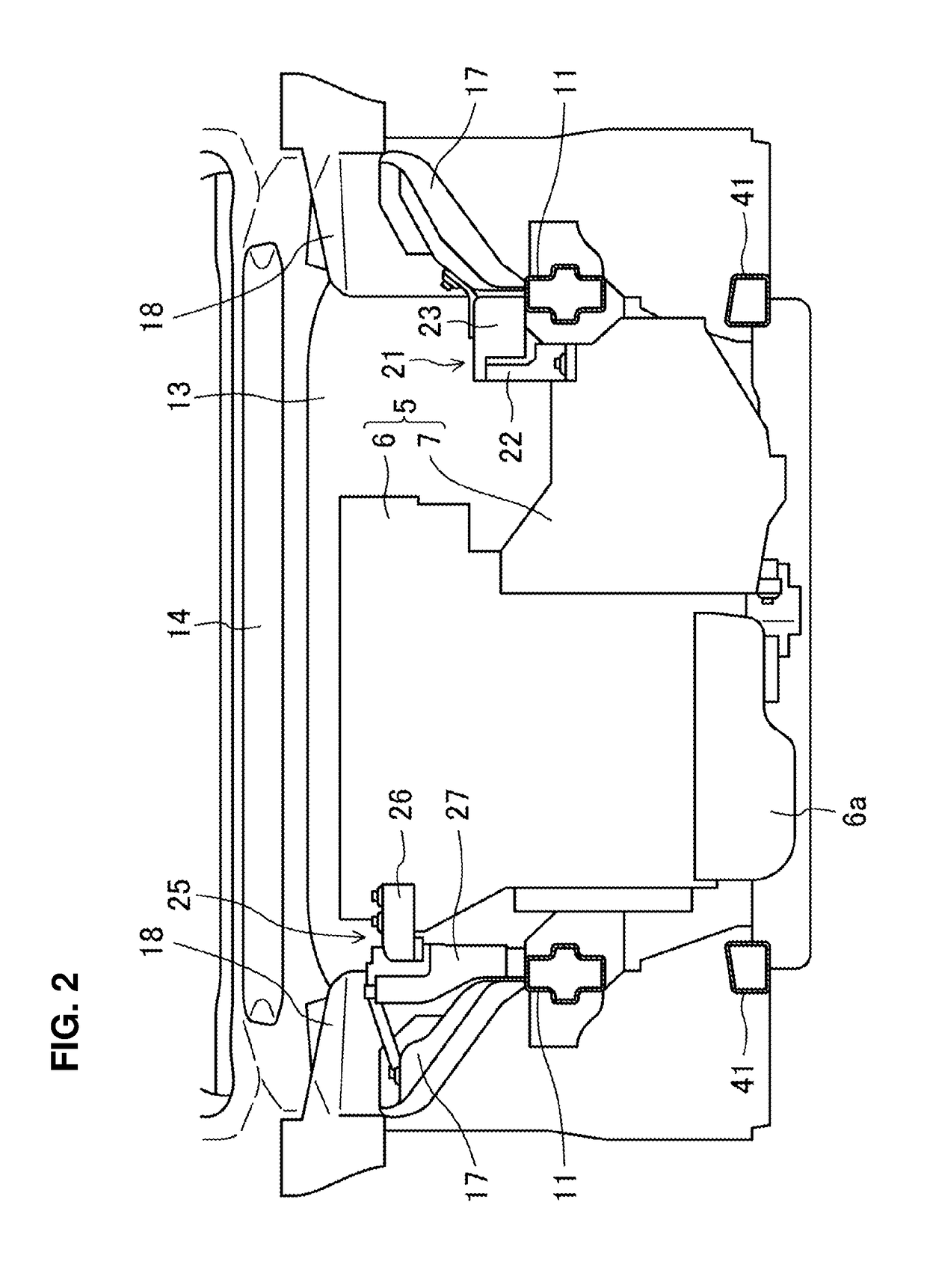

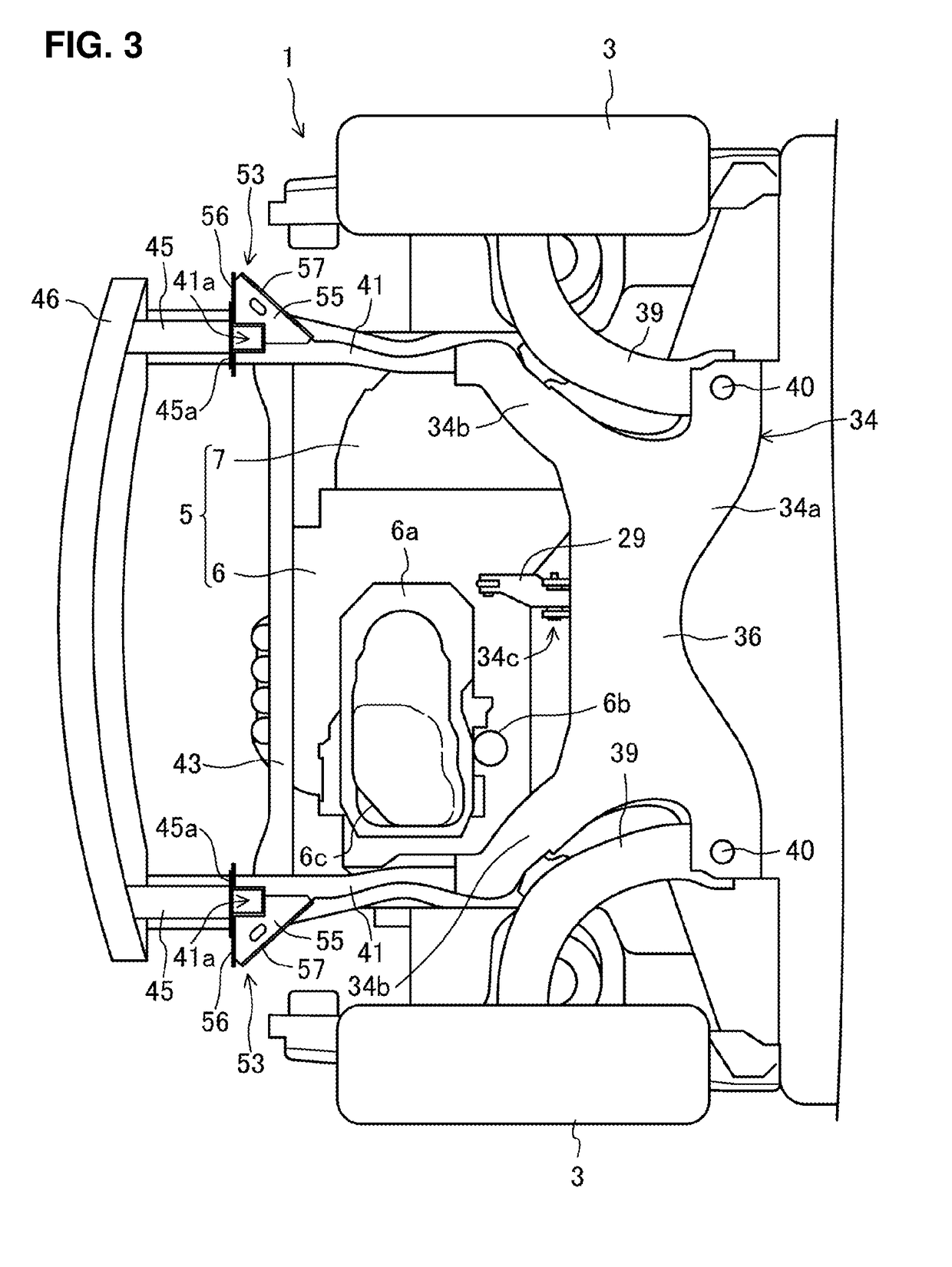

Vehicle

Owner:MAZDA MOTOR CORP

Production method of negative-ion chinlon short fibers

InactiveCN105671674ANegative ion function is goodGood effectMonocomponent polyamides artificial filamentArtifical filament manufactureFiberFlexural strength

The invention discloses a production method of negative ion nylon staple fiber, which comprises the following steps: 1) dropping 5-10 wt% sodium silicate aqueous solution into a suspension liquid of 300-400 mesh tourmaline fine powder with a solid content of 40-60% , keep the constant temperature at 50-70°C for 10-30 minutes, then separate the solid from the liquid and dry the solid to obtain anion particles; 2) mix nylon slices and anion particles at a weight ratio of 10-5:1, and heat up to a molten state , granulating to obtain the masterbatch; 3) spinning the masterbatch, cleaning, drying and winding the spinning to obtain far-infrared nylon staple fibers. Compared with the prior art, the nylon staple fiber obtained by the invention has good anion function, long-lasting effect, a tensile strength of more than 120Mpa, and a bending strength of more than 150Mpa.

Owner:ZHANGJIAGANG ANSHUN TECH DEV

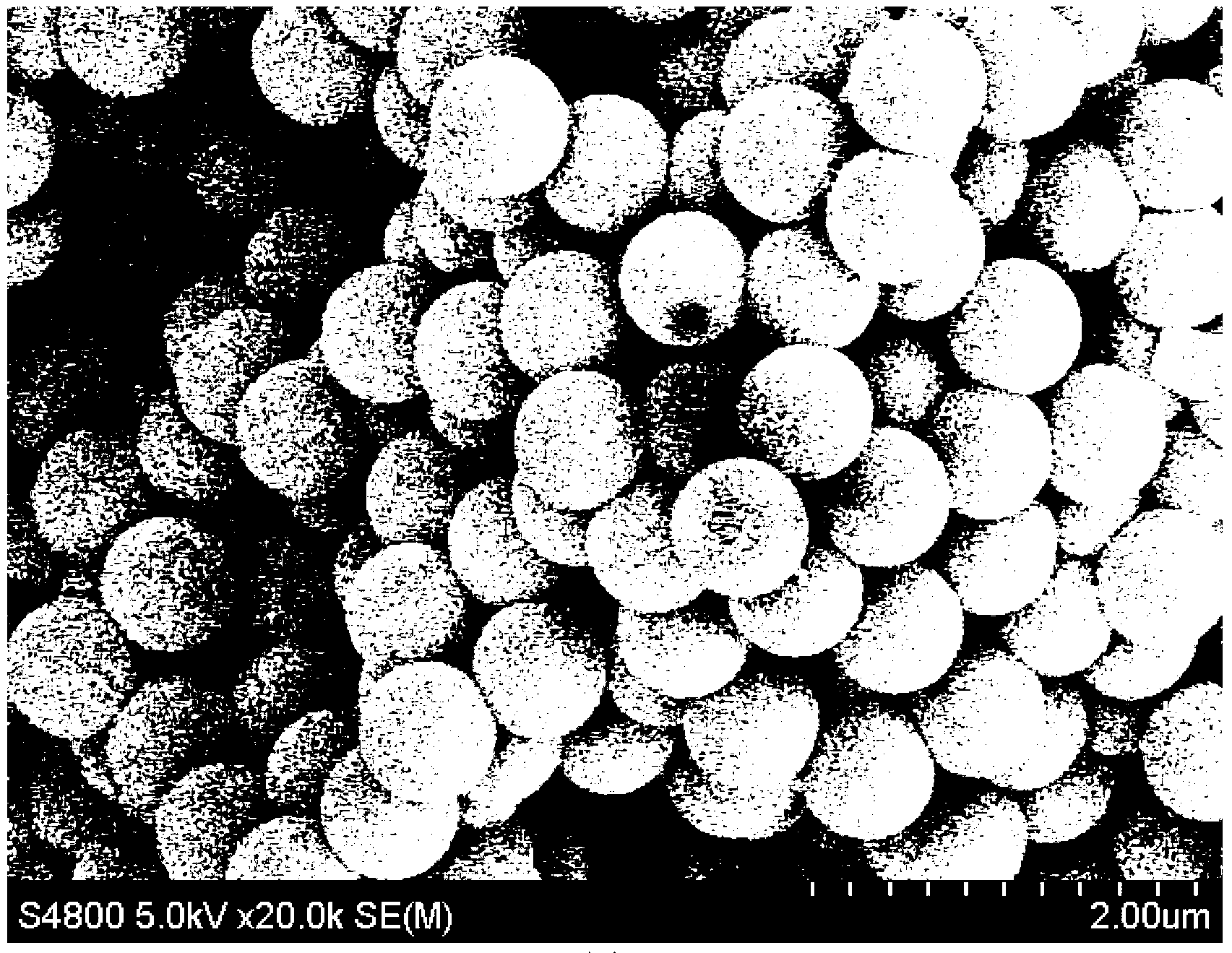

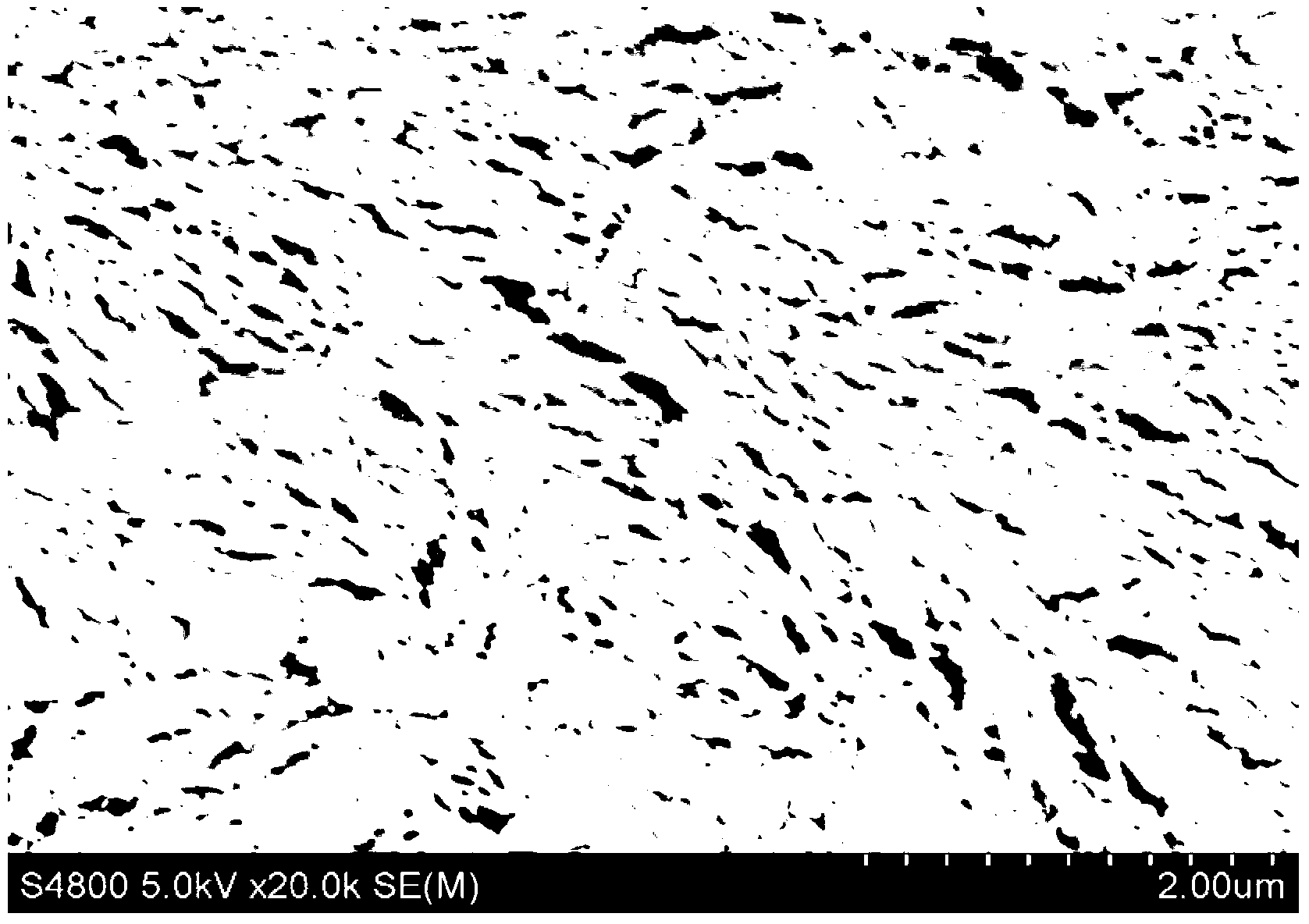

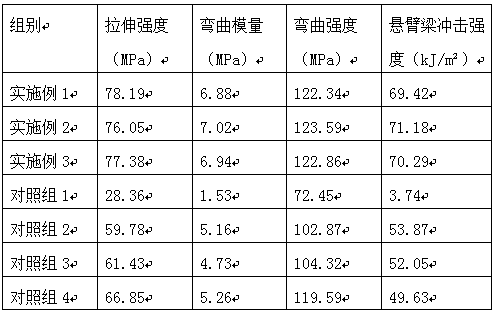

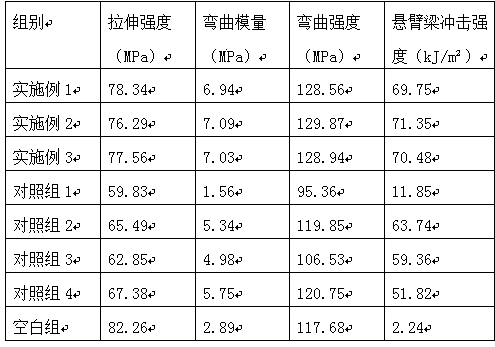

Preparation method of silicon dioxide microsphere/polyformaldehyde composite material

Owner:HEILONGJIANG UNIV

Anti-impact oil-resistant composite plastic used for automobile parts

InactiveCN108929535AHigh-density polyethyleneFlexural strength

Owner:界首市鑫一龙机械设备购销有限公司

High-modulus impact-resistant non-elastomer ternary blending composite pipe and processing technology thereof

InactiveCN112679848AImprove interfacial adhesionHigh tensile strengthTubular articlesElastomerPolymer science

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap