Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15 results about "Manual handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

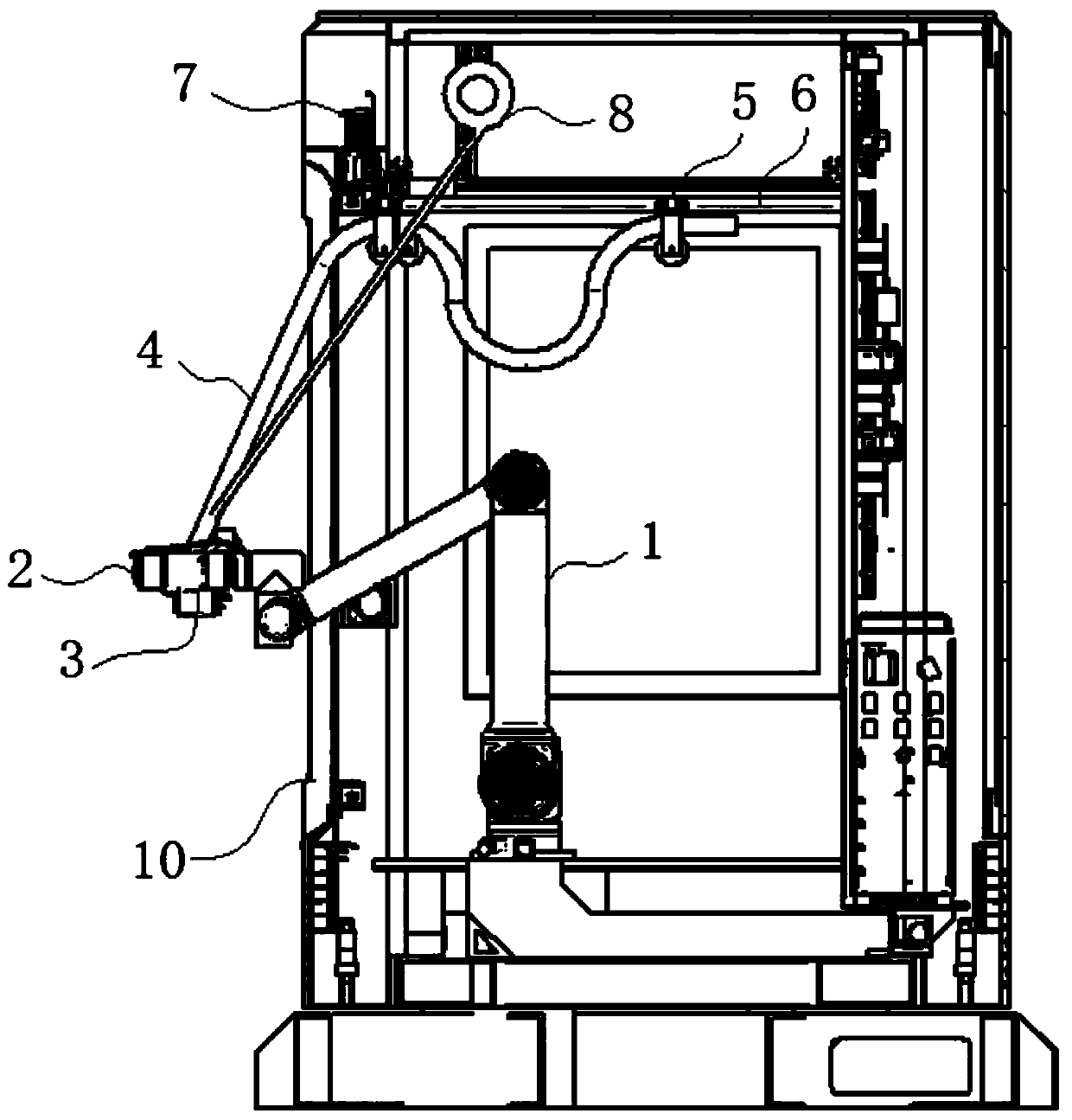

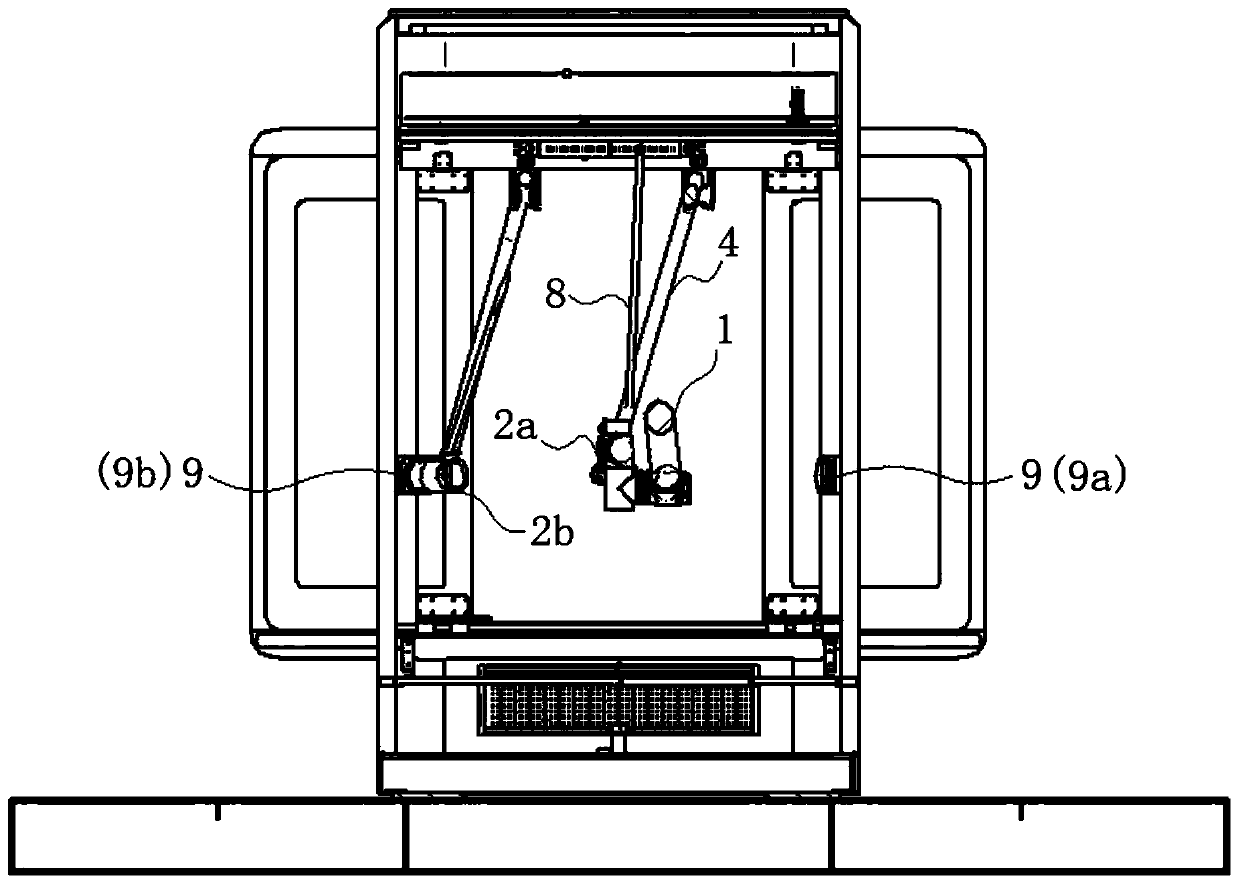

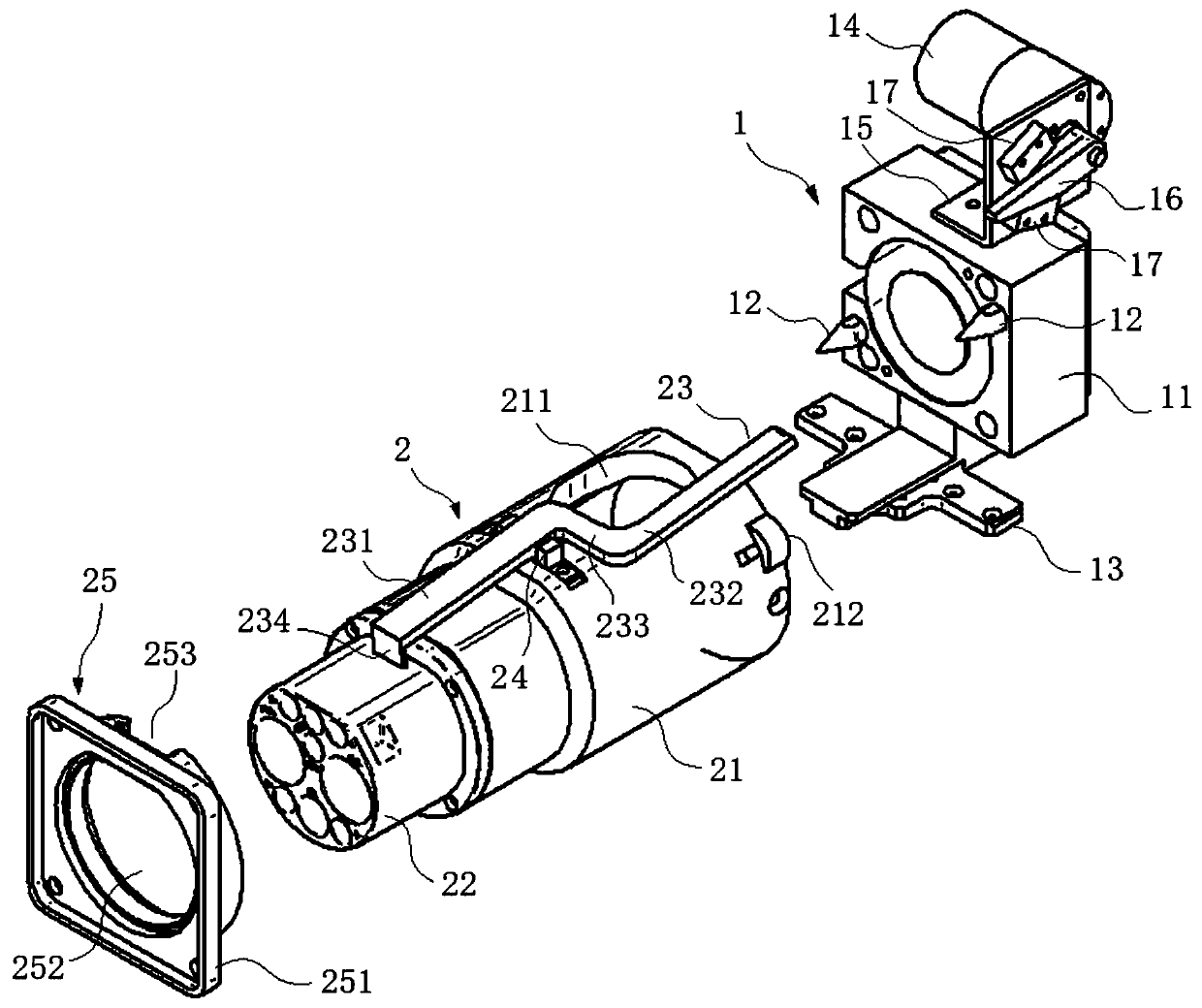

Full-automatic charging robot

PendingCN110696664ASolve charging problemsImprove securityCharging stationsElectric vehicle charging technologyRobotic armNew energy

Owner:BEIJING HUASHANG SANYOU NEW ENERGY TECH +1

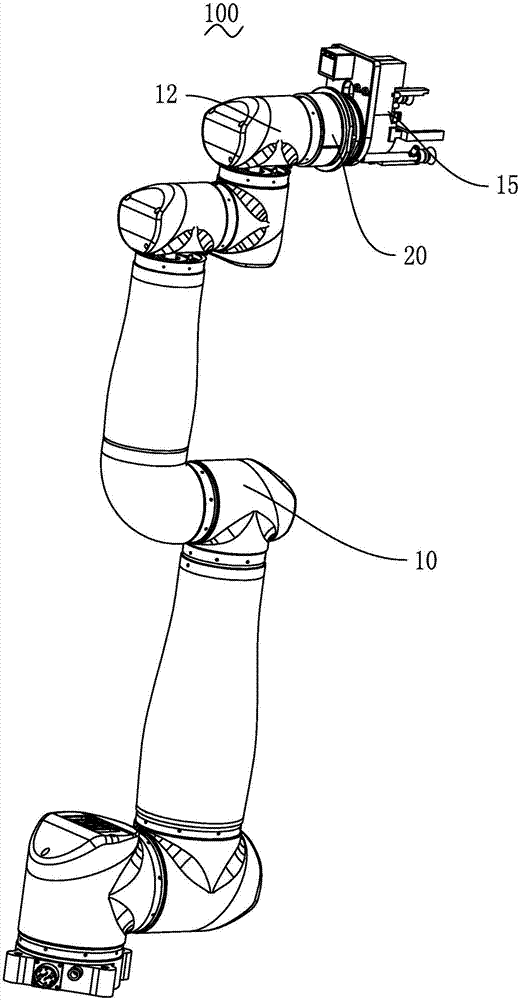

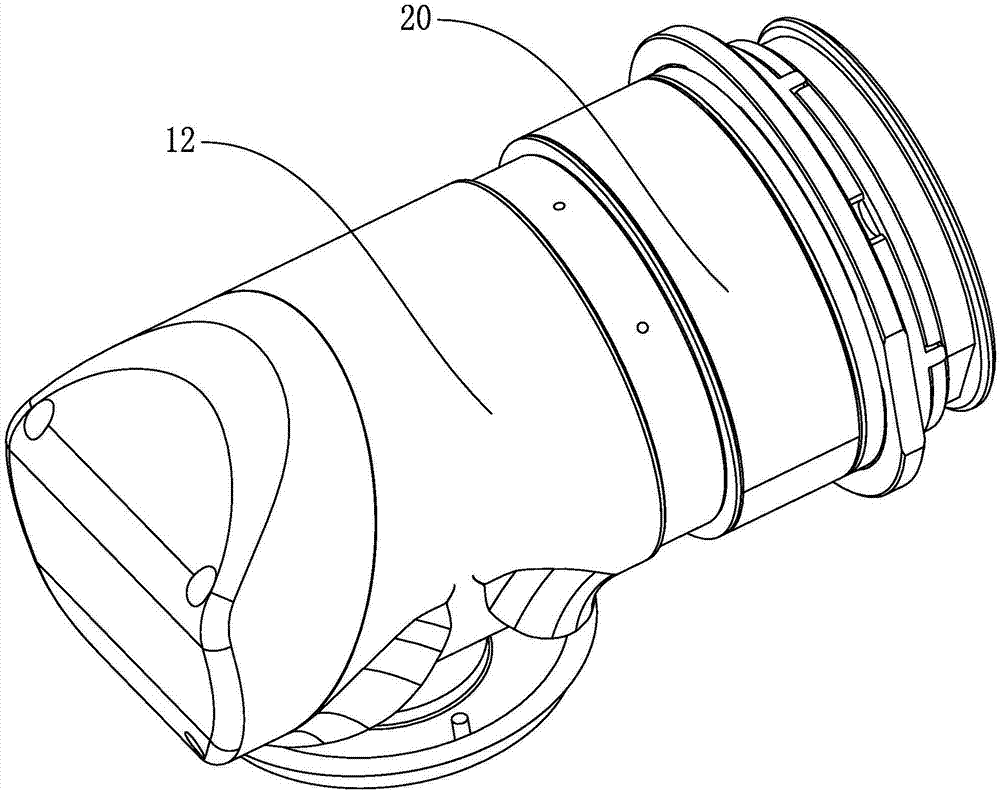

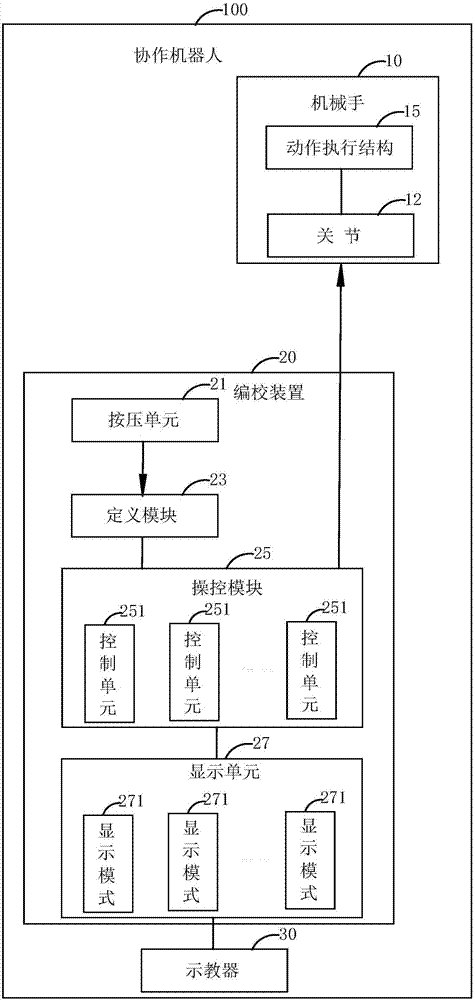

Collaborative robot

PendingCN107303671AReduce the intensity of manual operationImprove operational convenienceProgramme-controlled manipulatorRobot handMan machine

Owner:麦荷机器人(苏州)有限公司

Anchor structure for subsea tsunami detection easy to mount

InactiveCN108313209AReduce occupancyAvoid getting stuckAnchoring arrangementsContact failureEngineering

The invention discloses an anchor structure for subsea tsunami detection easy to mount, comprising a platform and a first cavity. The first cavity is arranged in the right of the platform. A motor ismounted in the first cavity. The bottom end of the motor is fitted with an output shaft. A first sleeve is welded to the bottom end of the platform. A first bevel gear is arranged on the right of theinner top end of the first sleeve. The anchor structure has the advantages that a second sleeve and a steel cable may cooperate such that the top end of the outer wall of an anchor is retracted into the second sleeve, space usage is greatly reduced, it is avoided that the anchor is jammed by foreign objects in water due to the failure of retraction, and manual handling the contact failure is omitted for workers; the motor and the first bevel gear may cooperate such that the motor is mounted in the platform to output transmission, and it is avoided that the motor mounted in the first sleeve isdamaged by invading water.

Owner:NANAN ZHINENGLAN IND DESIGN

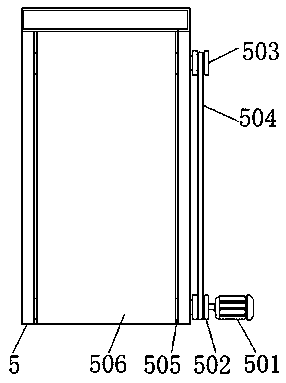

Flexible roll bending numerical control plate bending machine

PendingCN113458197AEasy to move up and downAvoid deformationMetal-working feeding devicesPositioning devicesNumerical controlHydraulic cylinder

The invention relates to the technical field of plate bending machines, in particular to a flexible roll bending numerical control plate bending machine. The machine comprises a base. A feeding box body and supporting columns are fixedly connected to the outer surface of the upper end of the base, the supporting columns are distributed behind the feeding box body in a bilateral symmetry manner, a driving roller and a driven roller are arranged between the two supporting columns, and the driving roller is located over the driven roller, and first hydraulic cylinders are fixedly connected to the outer surfaces of the upper ends of the supporting columns correspondingly. Plates with different diameters in the bending treatment process are lifted up through supporting blocks, the situation that the plates hang down and deform under the influence of gravity is avoided, the application range is widened, meanwhile, when the plates are fed, the plates with different widths are clamped and limited through limiting rollers on the two sides, the bending effect is prevented from being affected by position deviation generated during manual feeding, feeding is assisted through feeding rollers, the friction force is reduced, the pushing force of a worker for pushing a plate is conveniently reduced, and the overall working efficiency is improved.

Owner:汪新纪

A kind of operation method of robot flexible welding

InactiveCN102267027AWelding/cutting auxillary devicesAuxillary welding devicesEngineeringManual handling

Owner:CHANGZHI QINGHUA MACHINERY FACTORY

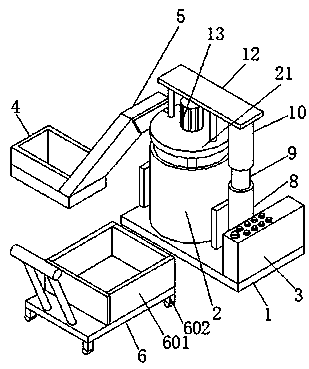

Intelligent building stone stirring device replacing manual operation and placement method

InactiveCN111468003AStir wellAvoid damageRotary stirring mixersTransportation and packagingElectric machineConstruction engineering

Owner:江苏枂硕电子科技有限公司

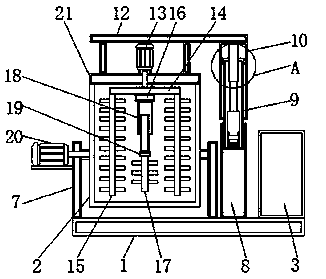

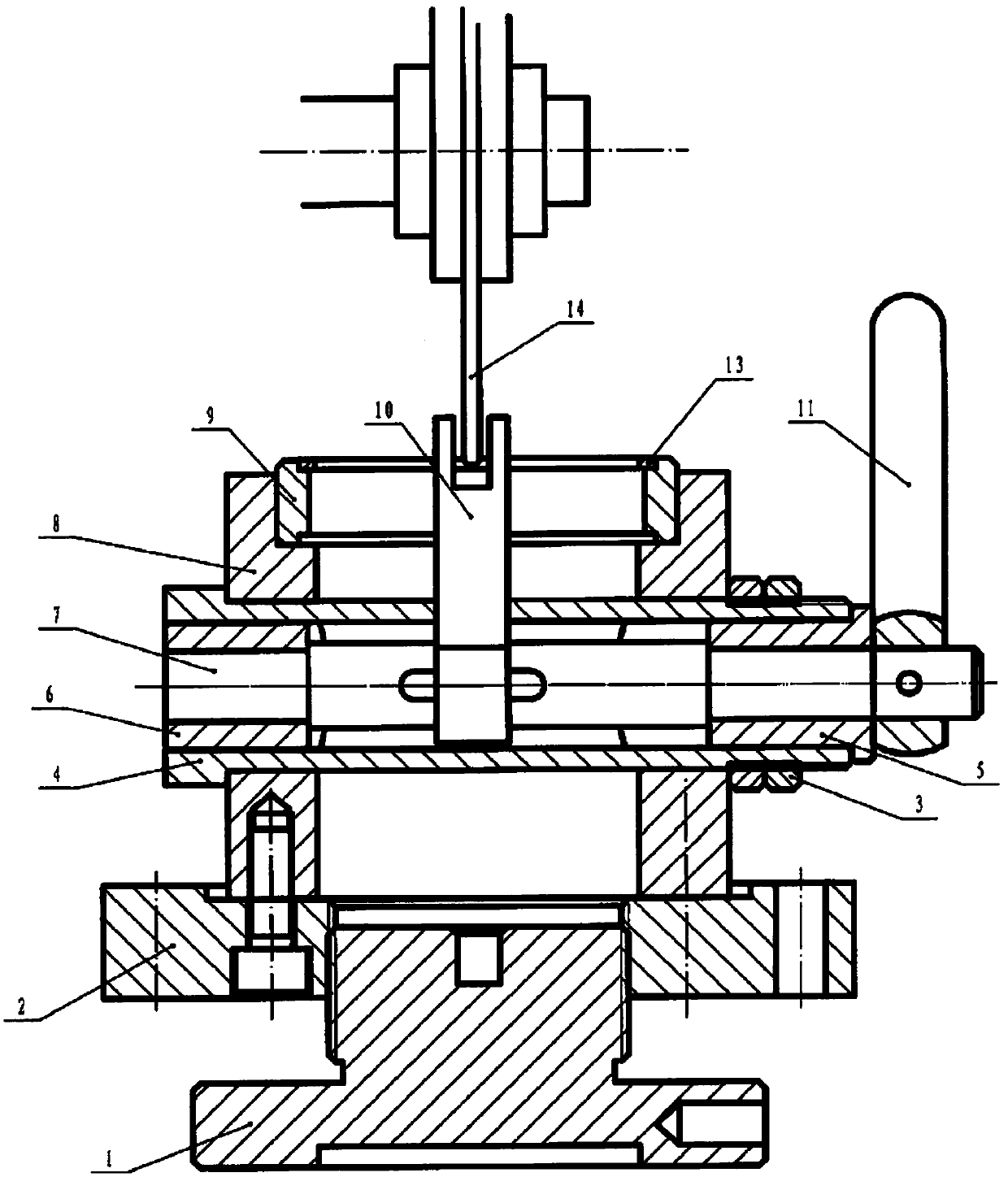

Quick clamping and grinding device for piston ring side positioning

PendingCN110814931AMeet processing needsPrecise positioningGrinding machinesGrinding work supportsPiston ringEngineering

Owner:无锡安尔达机械有限公司

Intelligent dismounting equipment for insert injection molding terminal

InactiveCN114801060ANo damageLocation does not affectDomestic articlesStructural engineeringExecution unit

The invention relates to an insert injection molding terminal dismounting technology, aims to solve the problems that an injection mold is difficult to separate from a terminal body and the terminal body is easily damaged by manual operation, and particularly relates to intelligent dismounting equipment for an insert injection molding terminal, which comprises the injection mold, an injection molding terminal shell, a terminal groove and the terminal body, the upper surface of the injection mold is connected with an injection molding terminal shell, and the upper surface of the injection molding terminal shell is provided with four terminal grooves. The lower surface of the injection molding terminal shell is knocked through the telescopic plate in the shrinkage box, generated vibration enables the injection molding terminal shell and the terminal body to be separated from each other, the terminal body cannot be damaged, and knocking cannot affect the position of an injection mold; through the data acquisition unit, the data processing unit and the data execution unit which are arranged in the connection box, the separation frame can accurately separate the injection molding terminal shell and the terminal body at the corresponding positions, the position movement of all the separation frames is not needed, and more electric power is saved.

Owner:ANHUI CISCO SAIDE ELECTRONIC TECH CO LTD

Production and processing equipment with automatic positioning and carving function for helmet pendants

InactiveCN112317968AEasy to passEasy accessWelding/cutting auxillary devicesAuxillary welding devicesLaser engravingManual handling

The invention discloses production and processing equipment with an automatic positioning and carving function for helmet pendants. The production and processing equipment comprises an operation case,and a laser engraving case is fixedly mounted on a right bolt of the top end surface of the operation case. According to the production and processing equipment, a pushing head and the laser engraving case are respectively arranged at the two ends of a guide groove in the top of the operation case; through the arrangement of the pushing head, a helmet can be conveniently pushed to the position below the laser engraving case when being conveyed to the front end of the pushing head through a conveying belt; through the arrangement of an inflation device and an air bag, the air bag can conveniently enter an inner cavity of the helmet to be attached to the helmet to form a clamping and fixing structure; through the arrangement of a rotating base and a laser head, the helmet can be driven to rotate while being engraved, and the helmet can be engraved at different portions; and through the arrangement of a feeding assembly, the helmet can be conveniently pushed out of the guide groove of the operation case after carving is finished, manual operation is avoided, operation steps are reduced, and therefore an automatic carving structure can be formed.

Owner:DONGGUAN UNIV OF TECH

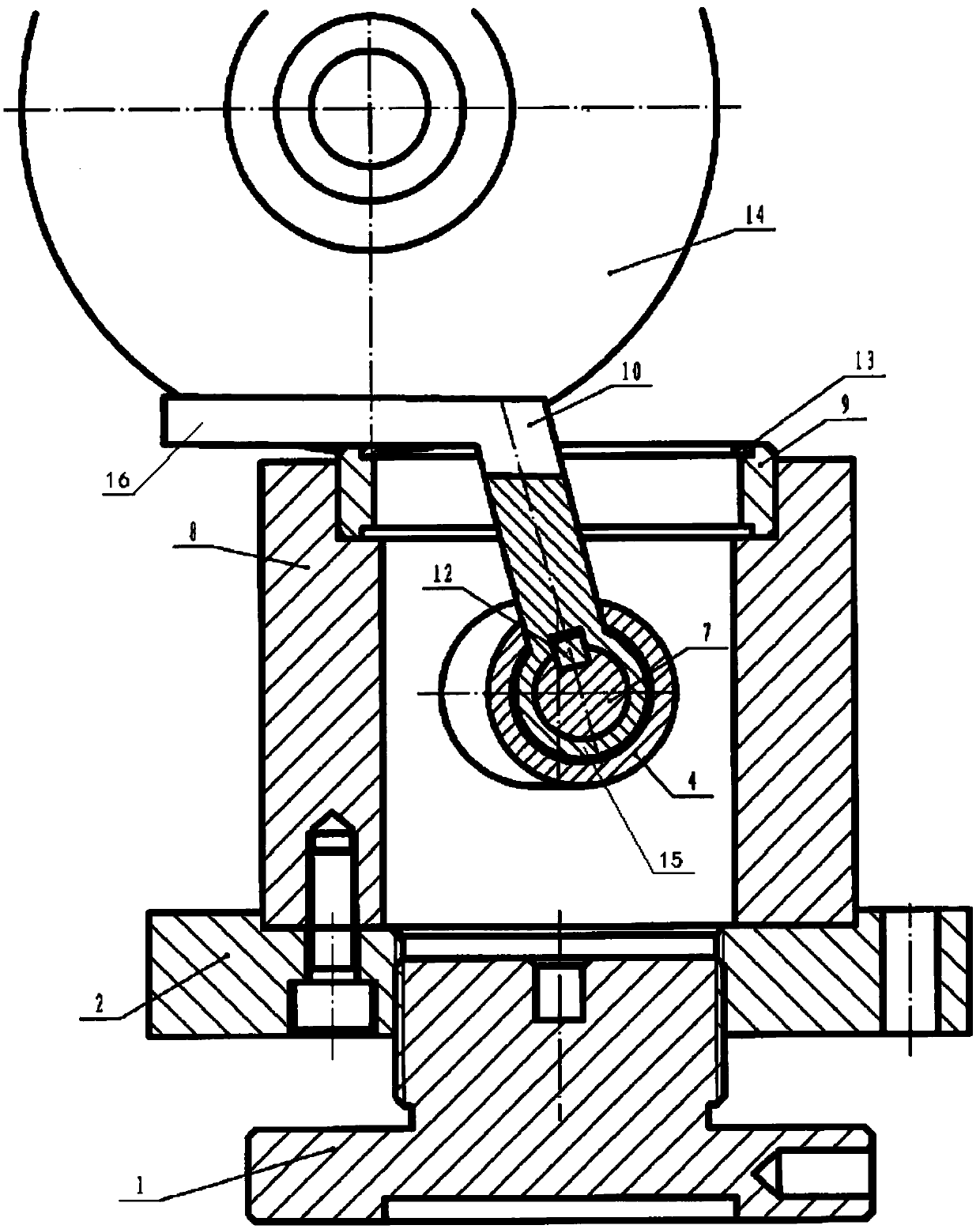

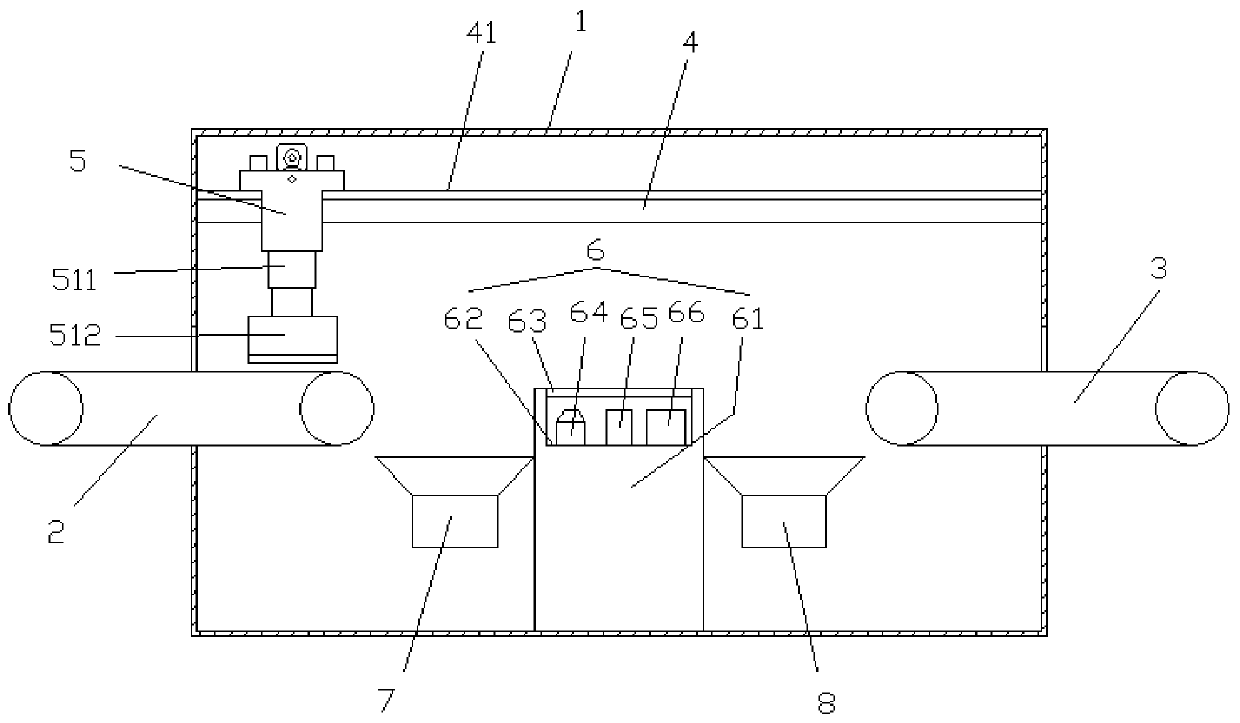

Full-automatic capsule aluminum plastic plate detecting equipment

PendingCN110882938AObserve workEasy for daily maintenanceSortingStructural engineeringTransfer mechanism

Owner:ZHEJIANG YALIDA CAPSULES

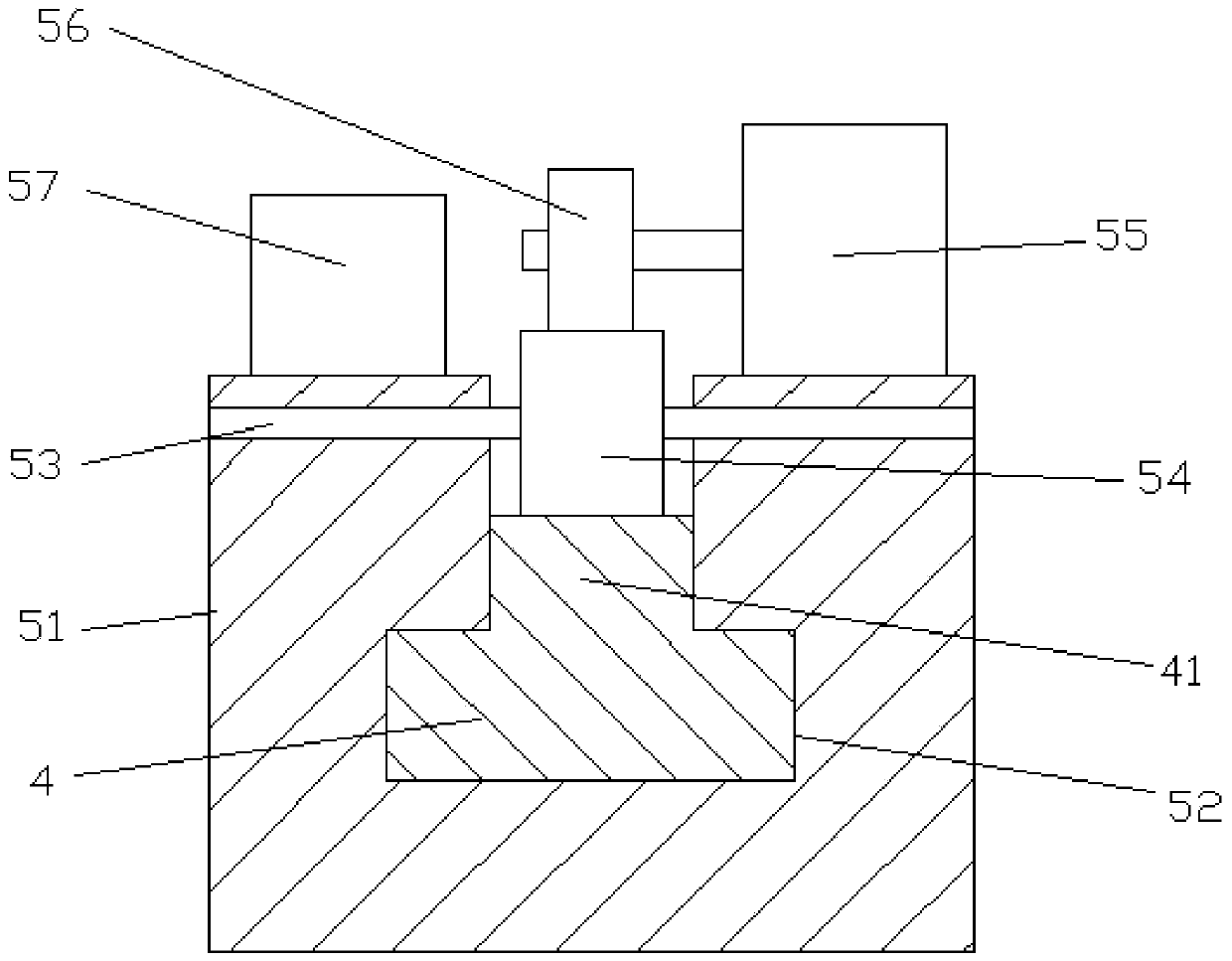

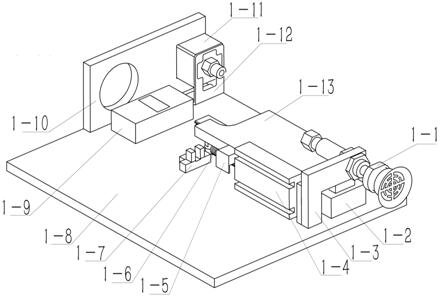

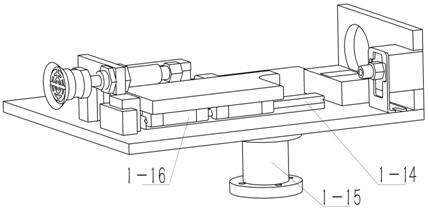

IGBT packaging pneumatic pressing riveting device

PendingCN113953803AThere will be no inconsistencies in the pressing stateSmall riveting forceSemiconductor/solid-state device manufacturingMetal working apparatusMechanical engineeringManual handling

Owner:ZHIHUIXUANTIAN INTELLIGENT SYST (HANGZHOU) CO LTD

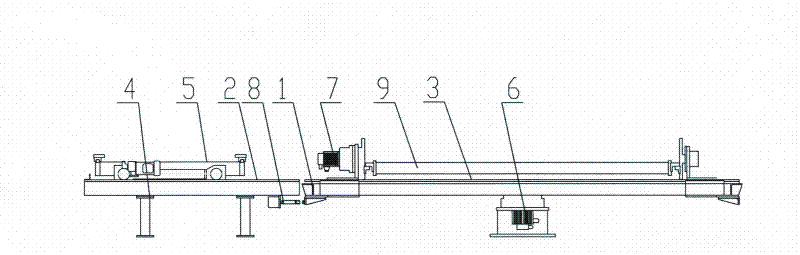

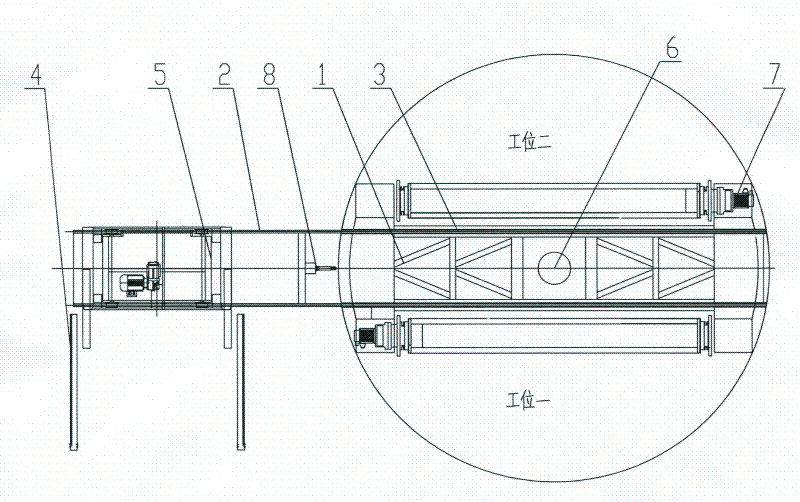

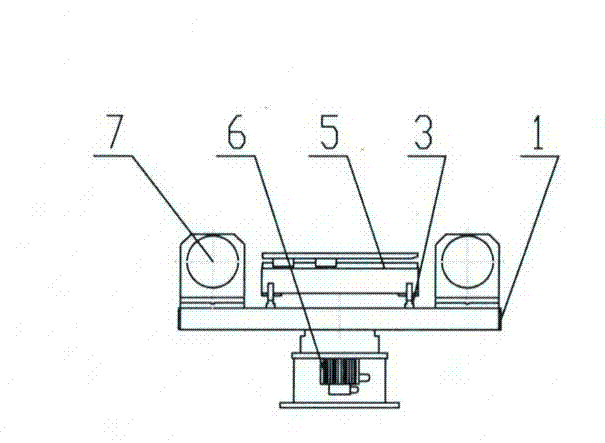

Traction device of material station for belt material processing

PendingCN111908220ANo manual operationIncrease productivityWebs handlingMaterials processingMechanical engineering

Owner:HENAN XINZHILIN ELECTROMECHANICAL DEVICE CO LTD

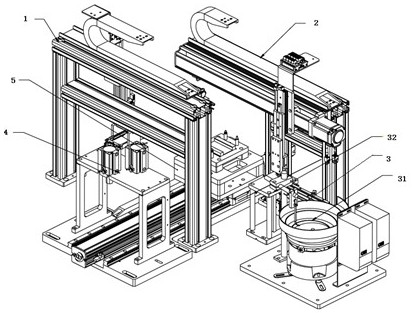

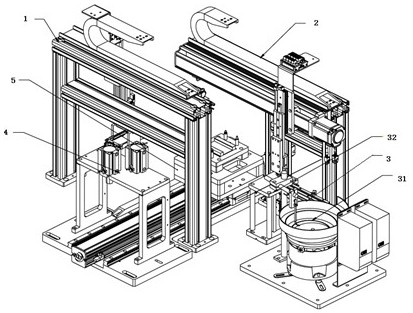

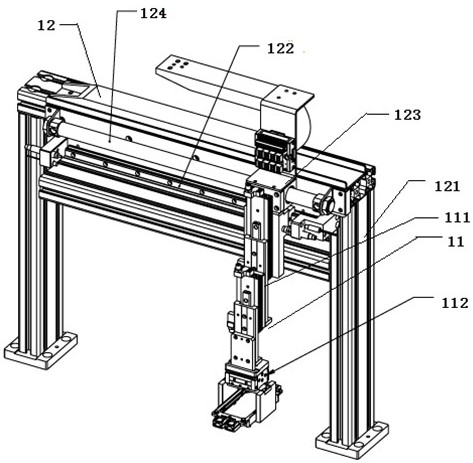

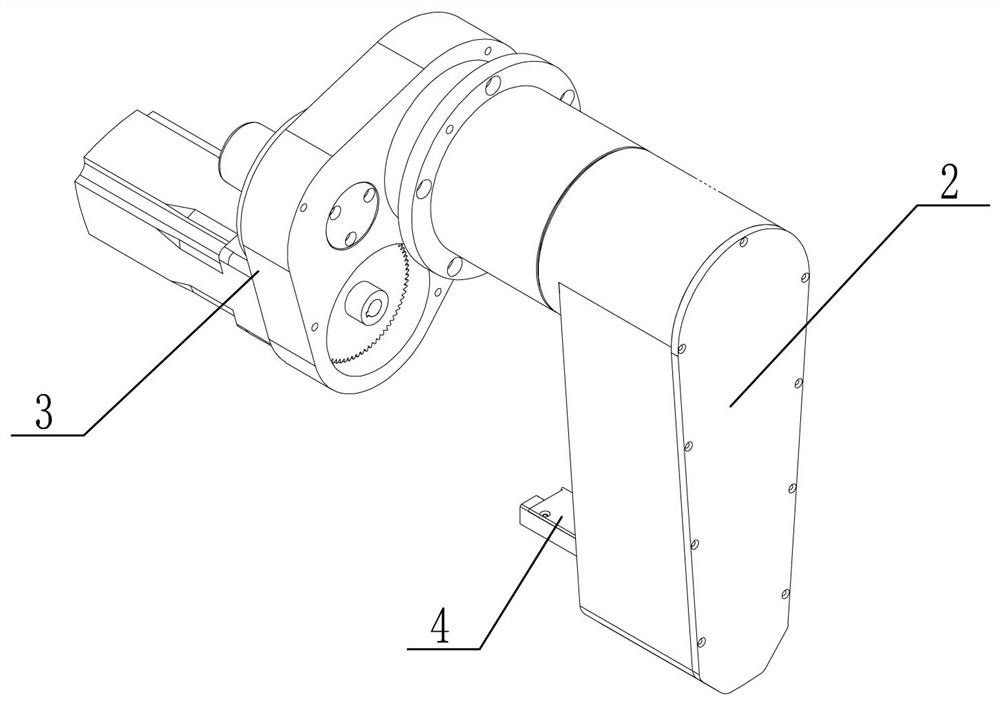

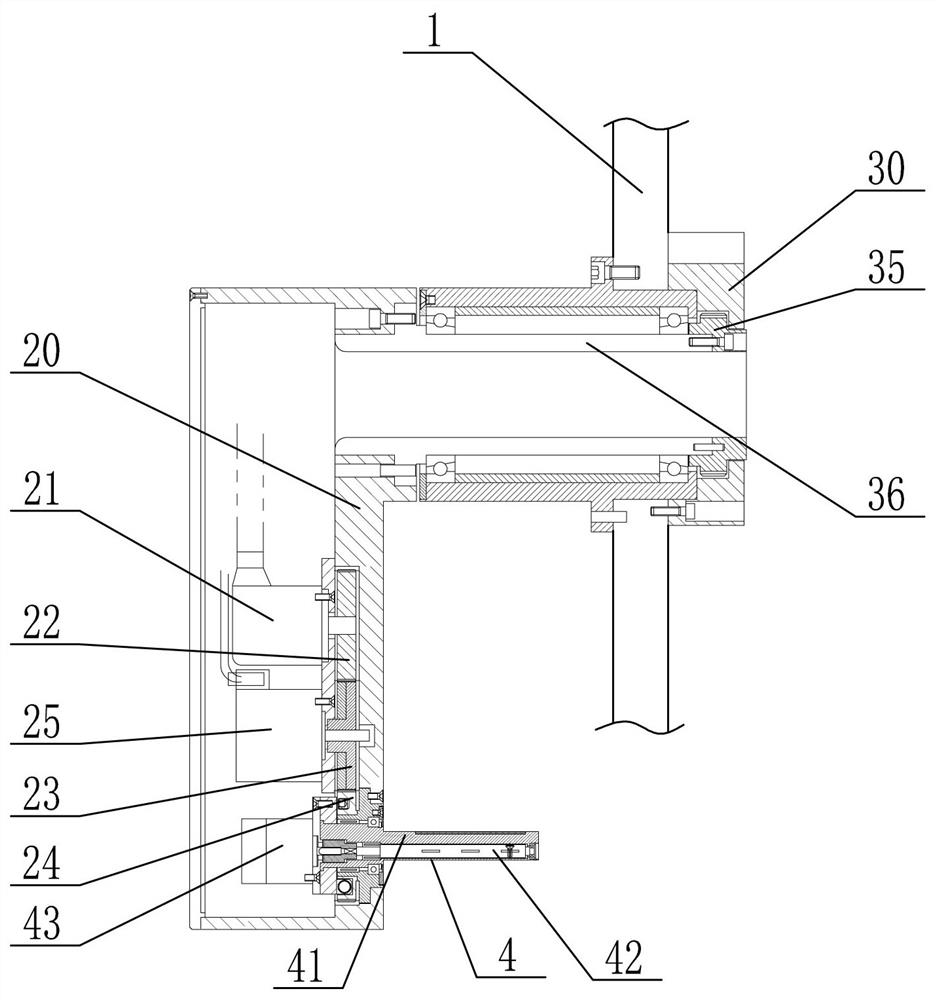

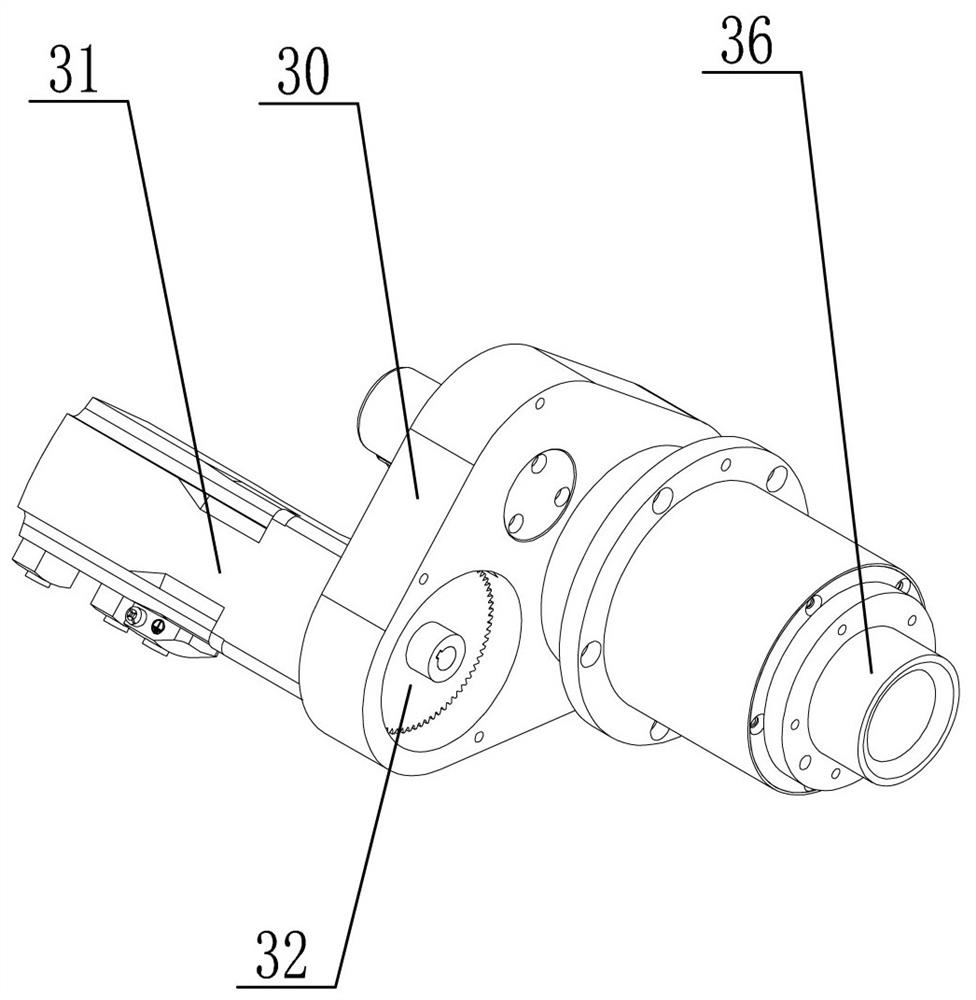

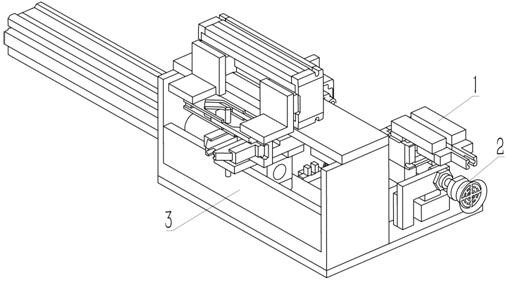

Label welding manipulator

ActiveCN113681211AImprove welding automation levelImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesRobot handIndustrial robotics

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Three-dimensional transport vehicle

PendingCN111762246AReduce manual operationsEasy and convenient position adjustmentSupporting partsHand carts with multiple axesVehicle frameManual handling

The invention provides a three-dimensional transport vehicle, and belongs to the technical field of vehicle manufacturing. The vehicle comprises a vehicle frame body, a hydraulic lifting mechanism, afirst bearing piece, a second bearing piece, and a plurality of rotating rollers, wherein the vehicle frame body includes a support frame, a first support plate arranged on the support frame, and a plurality of rolling wheels arranged on the support frame; the hydraulic lifting mechanism is arranged on the first supporting plate; the first bearing piece is arranged on the hydraulic lifting mechanism; the second bearing piece is arranged on the first bearing piece in a sliding manner; and the plurality of rotating rollers are rotatably arranged on the second bearing piece. Technical effects arethat a position of the transport vehicle can be adjusted through the rolling wheels; lifting of a first bearing part mounting part can be realized by utilizing the hydraulic lifting mechanism; translation of the installation part can be achieved through a sliding arrangement relation between the first bearing part and the second bearing part; and translation of the mounting part in the directionparallel to a sliding direction can be achieved through rotation of the rotating rollers so that position adjustment of the mounting part in three directions is achieved, multiple directions can be completed through the same transport vehicle, manual operation is reduced, installation and adjustment are easier and more convenient, and more time and labor are saved.

Owner:CRRC TANGSHAN CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap