Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Tube furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tube furnace is an electric heating device used to conduct syntheses and purifications of inorganic compounds and occasionally in organic synthesis. One possible design consists of a cylindrical cavity surrounded by heating coils that are embedded in a thermally insulating matrix. Temperature can be controlled via feedback from a thermocouple. More elaborate tube furnaces have two (or more) heating zones useful for transport experiments. Some digital temperature controllers provide an RS232 interface, and permit the operator to program segments for uses like ramping, soaking, sintering, and more. Advanced materials in the heating elements, such as molybdenum disilicide offered in certain models can now produce working temperatures up to 1800 °C. This facilitates more sophisticated applications. Common material for the reaction tubes include alumina, Pyrex, and fused quartz.

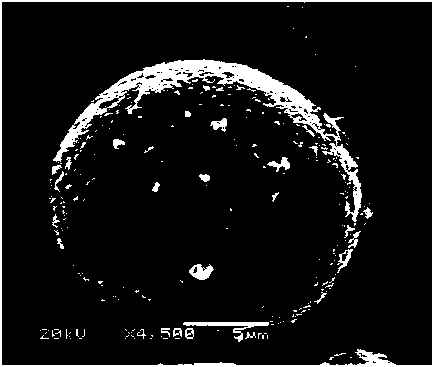

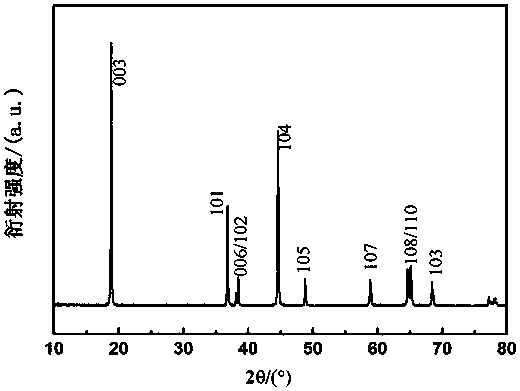

Lithium silicate-coated Ni-Co lithium aluminate positive electrode material and preparation method thereof

InactiveCN107910539AImprove cycle stabilityImprove high rate discharge performanceCell electrodesSecondary cellsLithium aluminateSilicon dioxide

Owner:CENT SOUTH UNIV

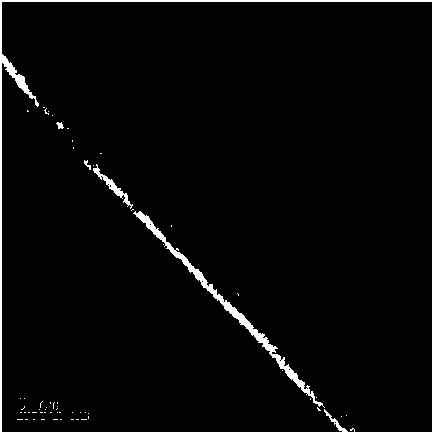

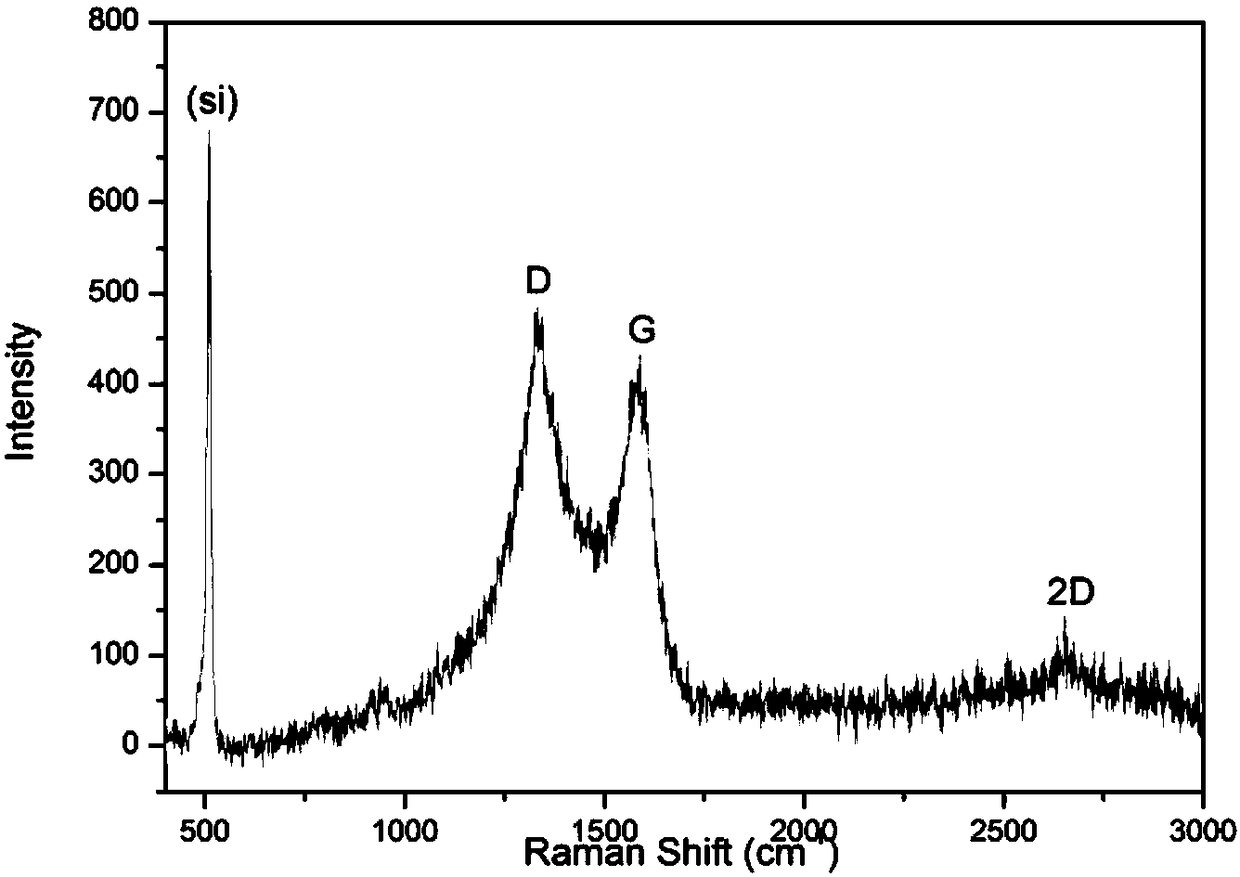

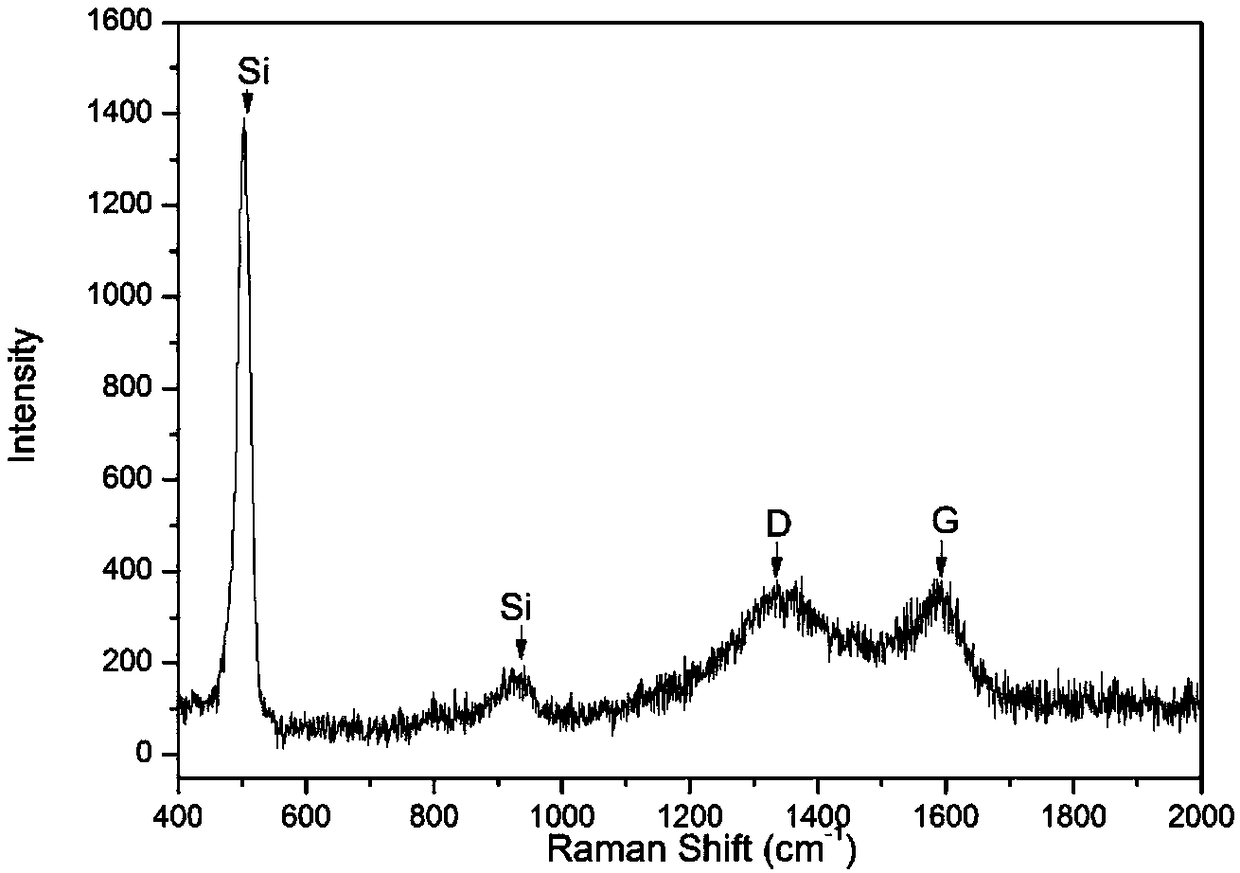

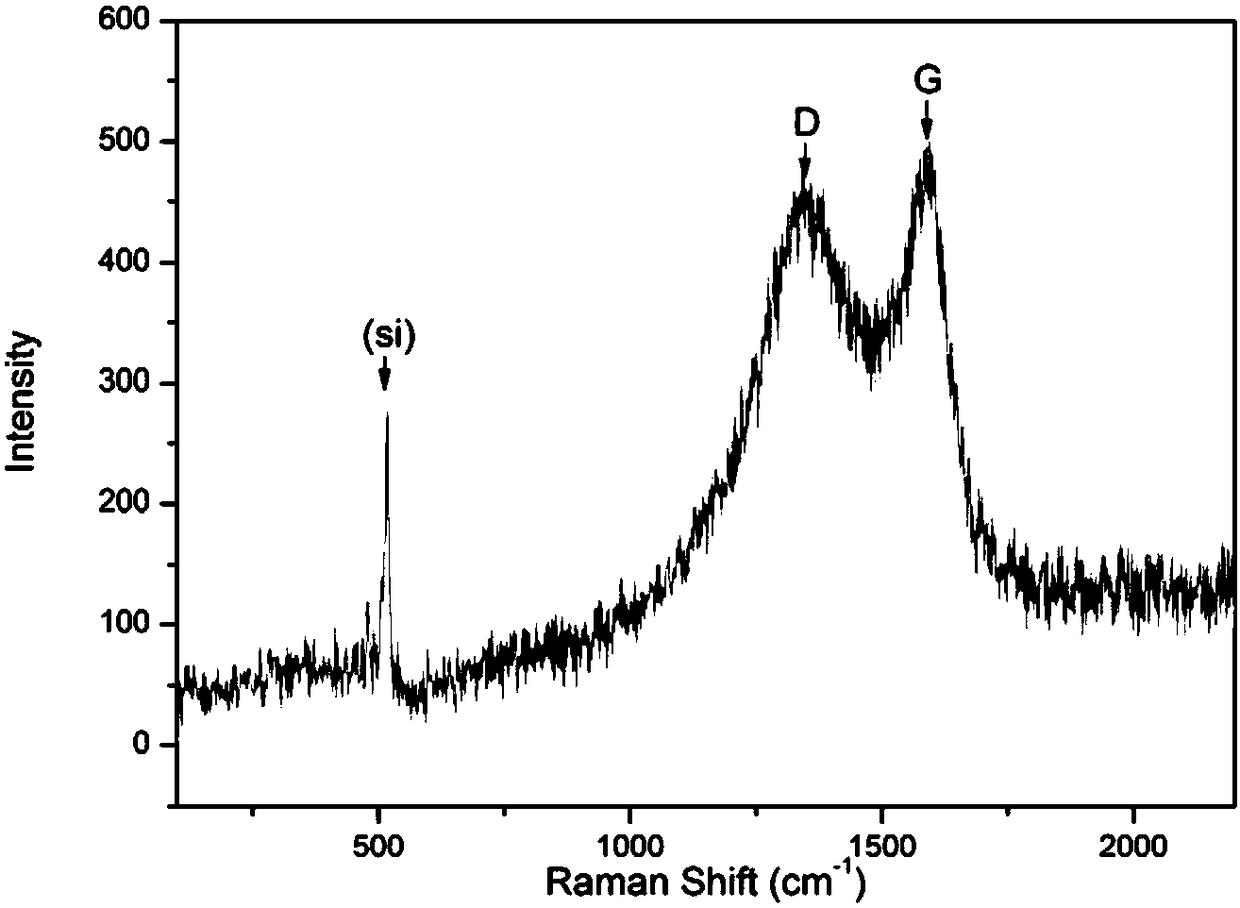

In-situ preparation method of carbon nano-sheet-coated nano-silicon composite material

Owner:XUCHANG UNIV

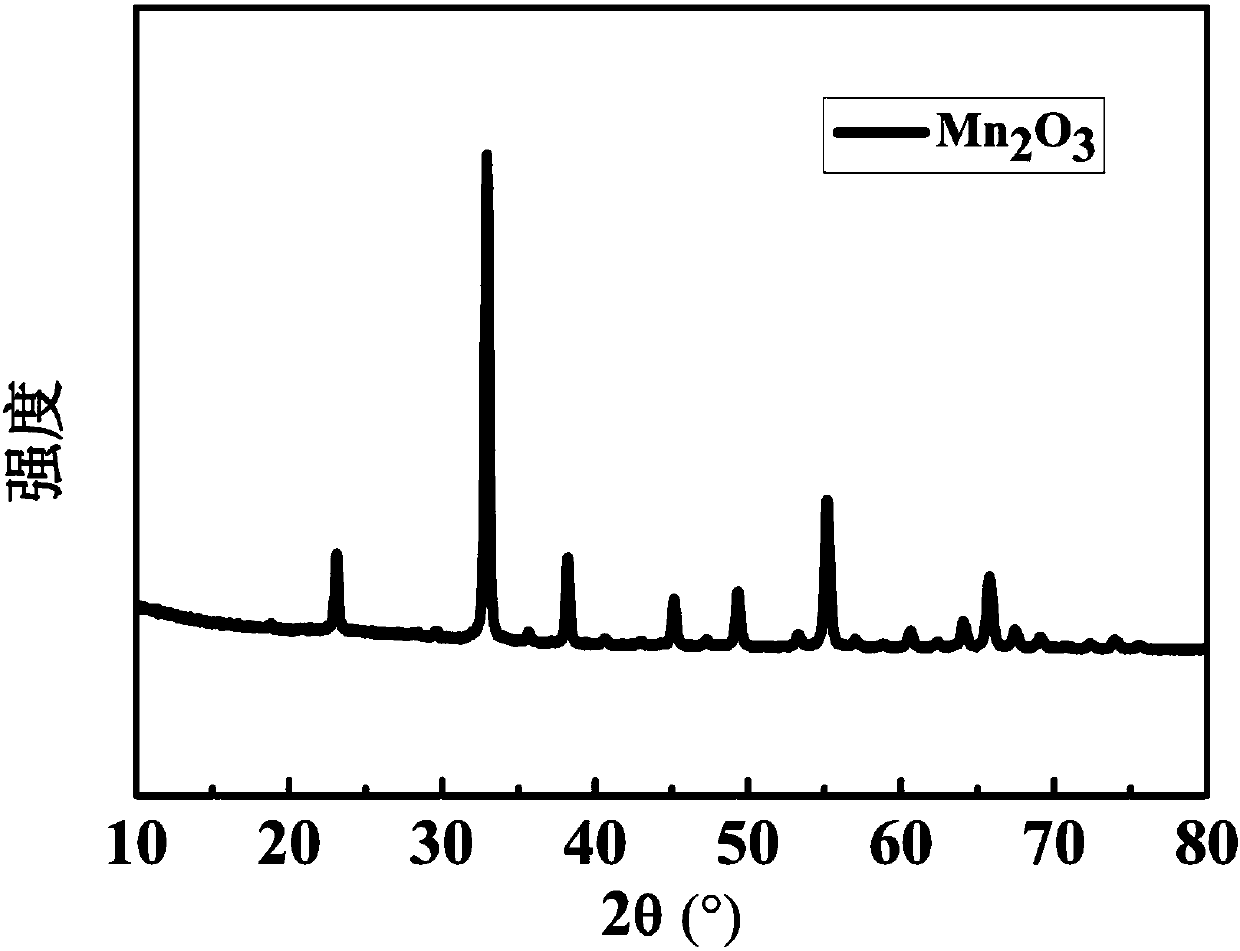

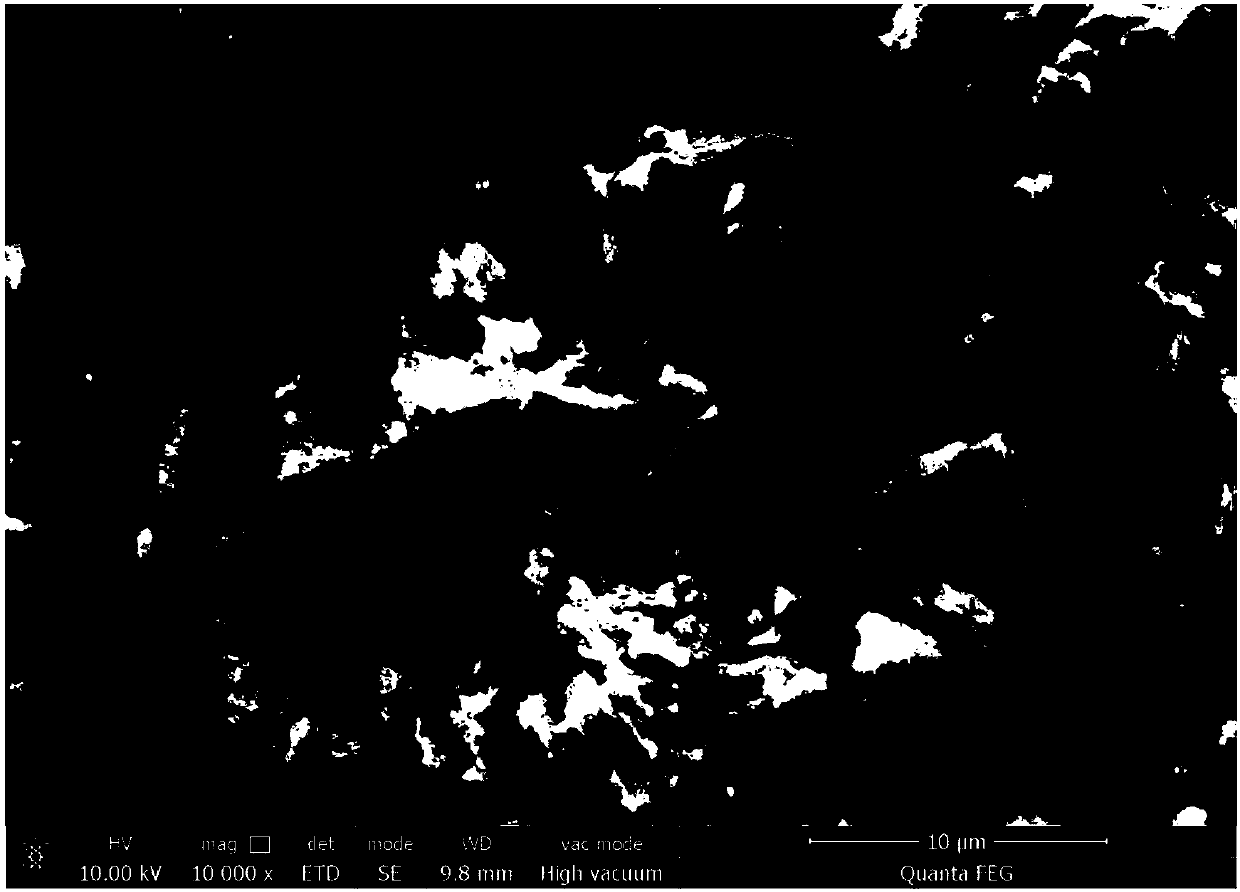

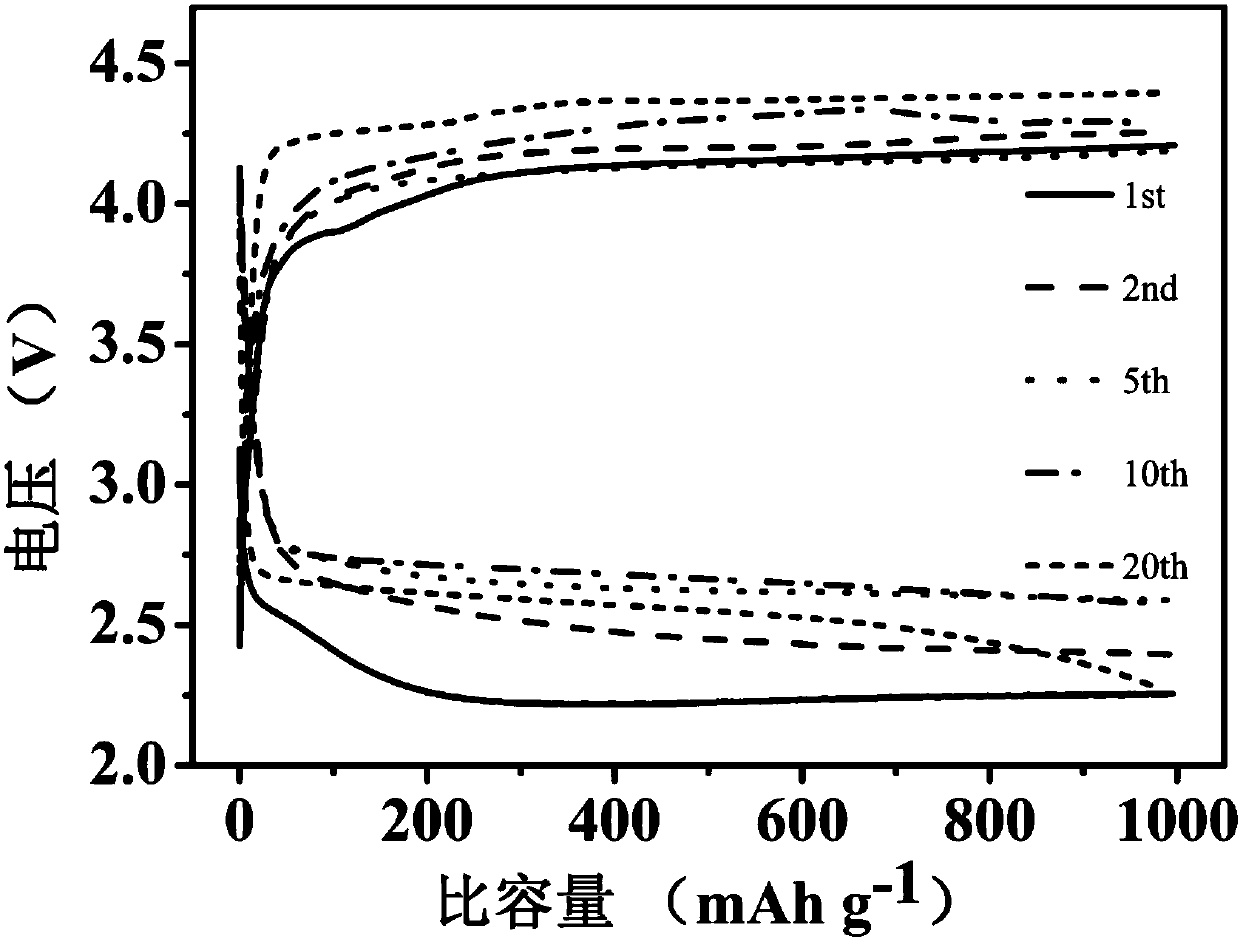

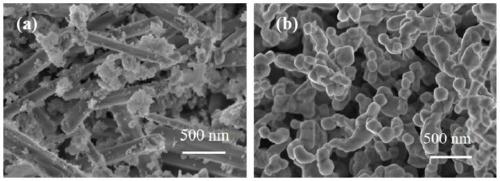

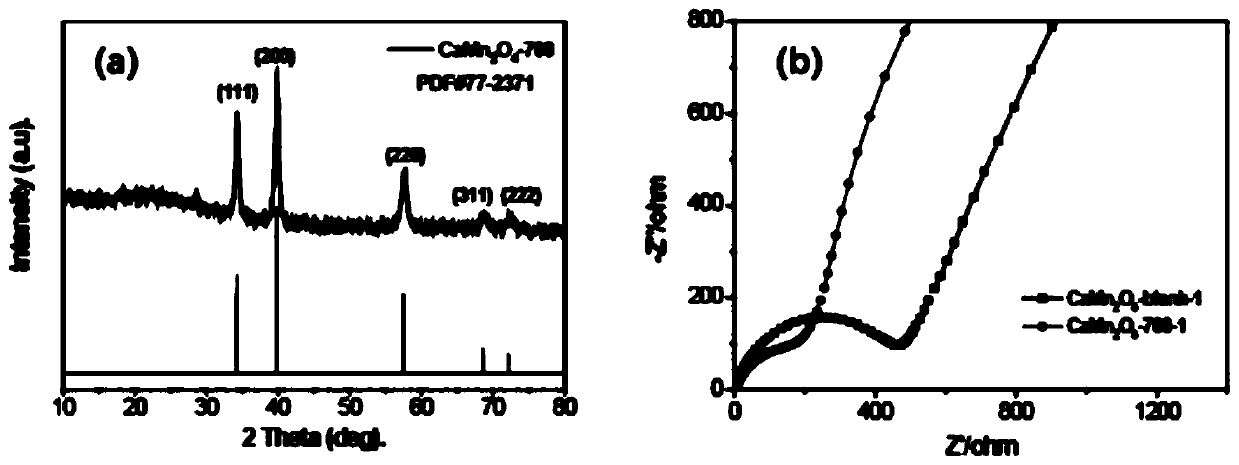

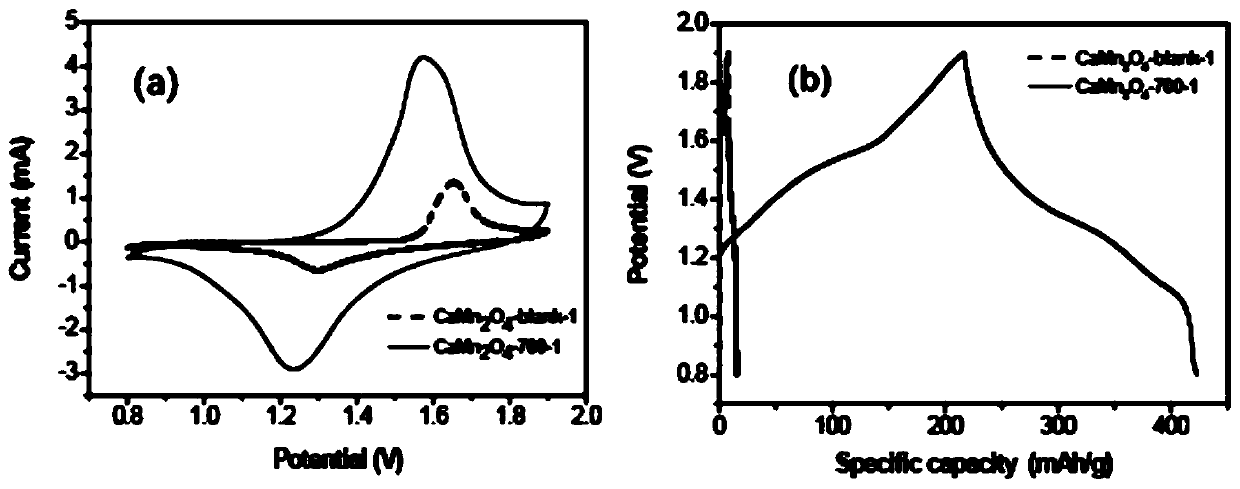

Preparation method of positive electrode catalyst Mn2O3 of lithium carbon dioxide battery

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

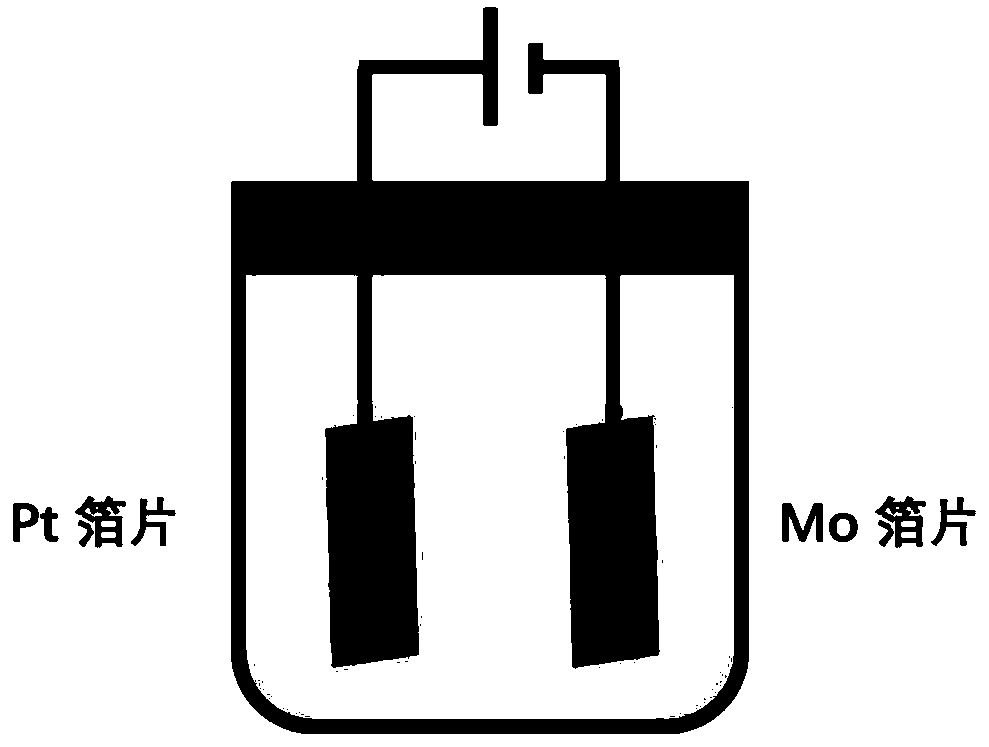

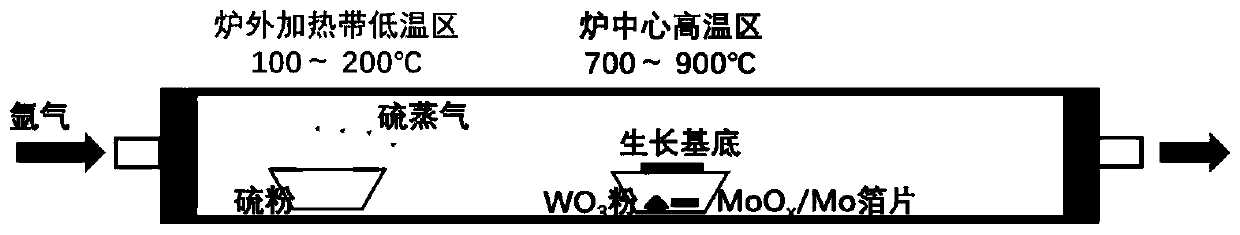

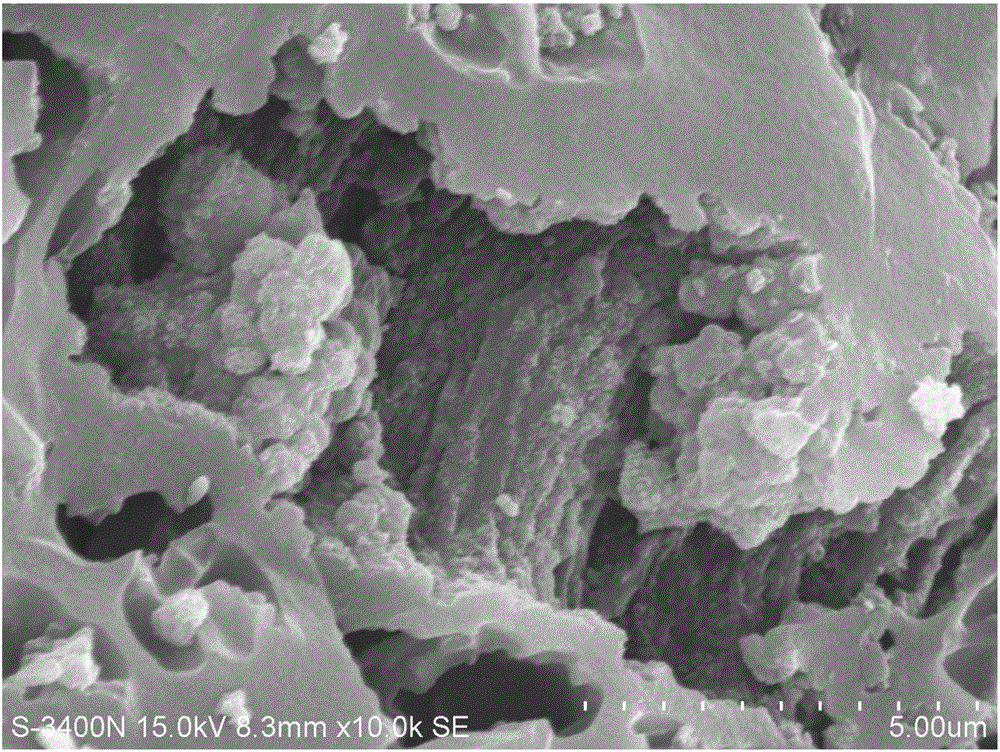

Preparation method for single-layer MoS2-WS2 transverse heterojunction

PendingCN110808281ASimple methodStrong controllabilitySemiconductor/solid-state device manufacturingSemiconductor devicesTube furnaceTungsten

The invention discloses a preparation method for a single-layer MoS2-WS2 transverse heterojunction, which belongs to the field of nano material growth. Electrochemical oxidation treatment is carried out on selected precursor sources to volatilize the precursor sources corresponding to molybdenum and tungsten at different temperatures, and the transverse heterojunction with the micron-sized clear interface is prepared in one step by a chemical vapor deposition method. According to the method of growing the transverse heterojunction, in a tubular furnace capable of accurately controlling the temperature, inert gas is used as transport gas of reaction sources (a molybdenum source, a tungsten source and a sulfur source), and different chemical vapor deposition reactions are controlled to occurto form the transverse heterojunction. The single-layer MoS2-WS2 transverse heterojunction prepared by the method has a micron-scale clear heterojunction boundary, and the transverse size can reach 100 microns or above. According to the method, the controllability of the growth process is high, a growth temperature window can be effectively widened, the growth temperature is reduced, and size andinterface controllable growth is achieved.

Owner:BEIJING UNIV OF TECH

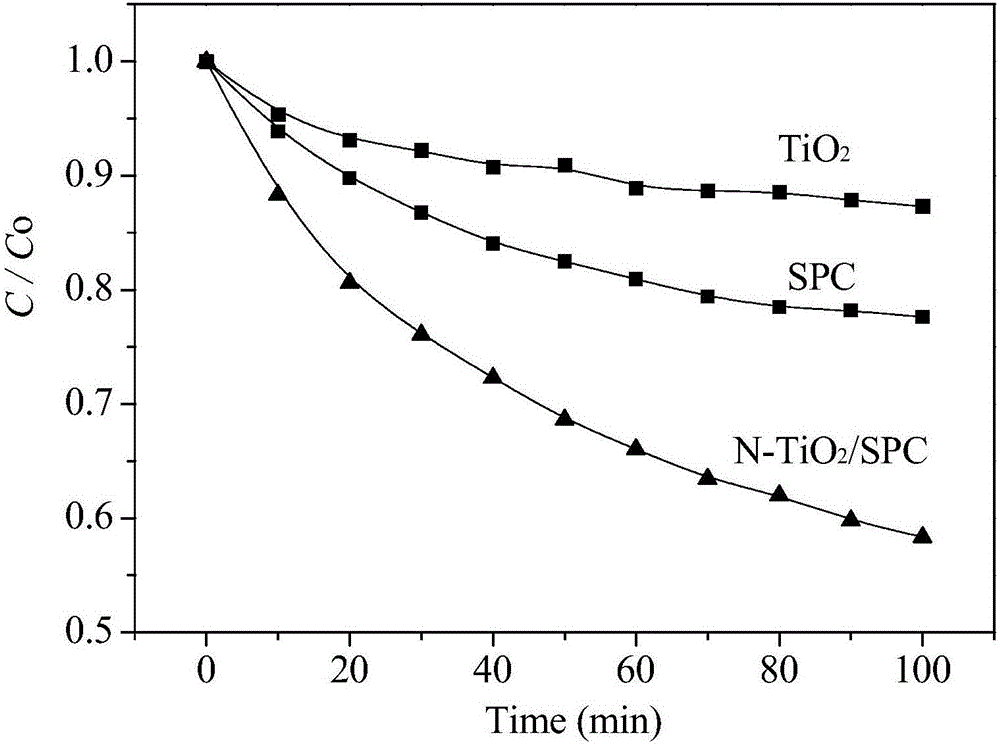

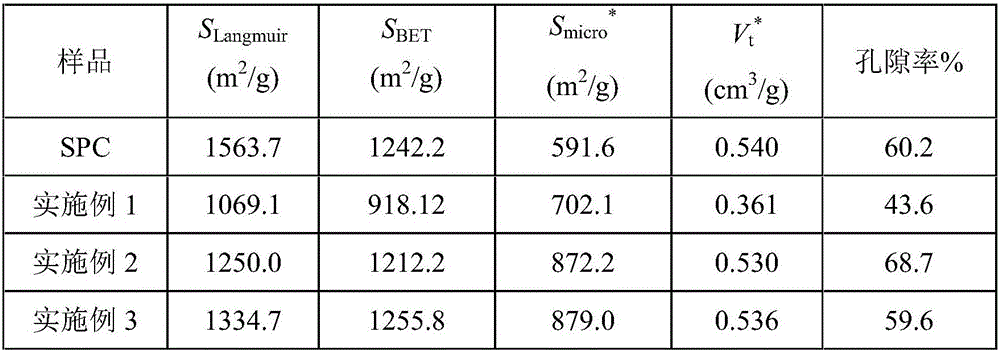

Bifunctional adsorbent of N-TiO2 silkworm-excrement porous carbon and preparation method of bifunctional adsorbent

InactiveCN106268641AGood dispersionHigh reactivityGas treatmentPhysical/chemical process catalystsPorous carbonShielding gas

Owner:GUANGXI UNIV

Preparation method for zeolite-activated carbon composite adsorbent

InactiveCN107876009AIncrease the areaLarge adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesSorbentCarbonization

Owner:SHAANXI SHENGMAI PETROLEUM

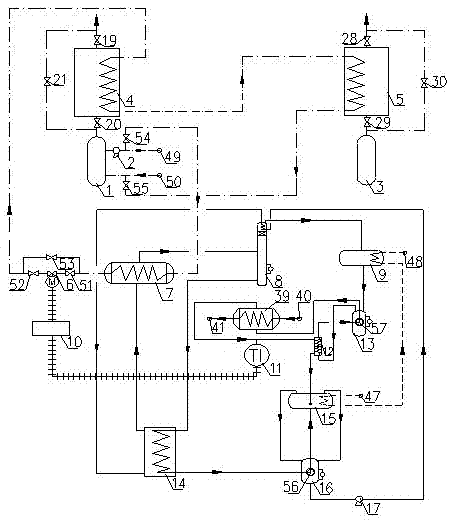

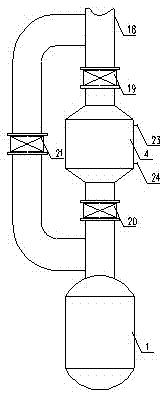

Ammonia-water absorption type refrigerator driven by oilfield waste heat and used for recycling light hydrocarbon

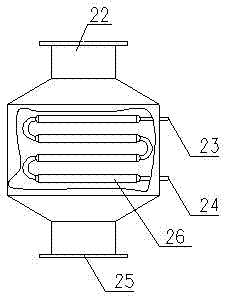

InactiveCN105444456AReduce loadSolve the problem of high exhaust heat and air pollutionClimate change adaptationEnergy efficient heating/coolingBinding equilibriumAtmospheric air

Owner:TAISHAN GROUP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap