Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Waste product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste (or wastes) are unwanted or unusable materials.Waste is any substance which is discarded after primary use, or is worthless, defective and of no use. A by-product by contrast is a joint product of relatively minor economic value. A waste product may become a by-product, joint product or resource through an invention that raises a waste product's value above zero.

Dry recycling technology for MOX fuel pellet waste

ActiveCN106782736AHigh recovery rateShort recycling processRadioactive decontaminationLiquid wasteCombustion

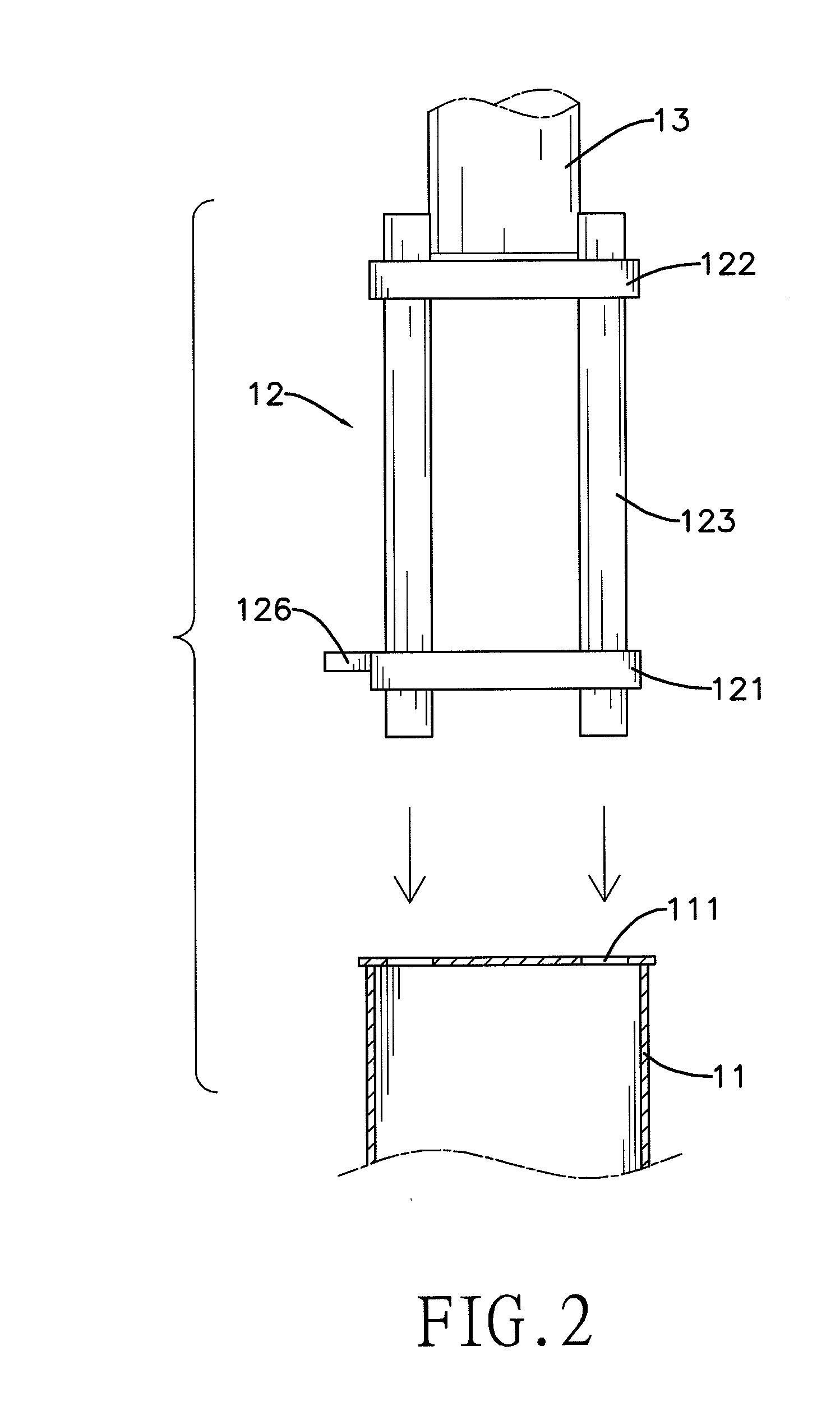

The invention belongs to the field of nuclear fuel. In order to solve the problem that an MOX fuel pellet waste wet recycling technology has many defects, the invention provides a dry recycling technology for MOX fuel pellet waste. The technology comprises the following steps of 1, burning MOX fuel pellet waste; 2, crushing by using a crusher; 3, screening; 4, ball milling; and 5 recycling. According to the technology provided by the invention, powdering of the MOX fuel pellet waste is achieved by crushing-ball milling technologies, so that the technology is fundamentally different from a dry recycling technology for UO2 fuel pellet waste using an oxidized crushing technology. Practical application shows that the MOX fuel pellet waste wet recycling technology provided by the invention has the advantages of high recycling rate, short recycling technical process, high in speed, simple in equipment, low in cost, and being free from generating radioactive liquid waste, and can be recycled in an MOX combustion manufacturer; the recycled power has similar sintering performance with the common MOX raw material powder, and can be mixed with common raw materials for preparing MOX fuel pellets.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Oil expeller

Owner:GOLDEN FLOWER TEA OIL PRODN

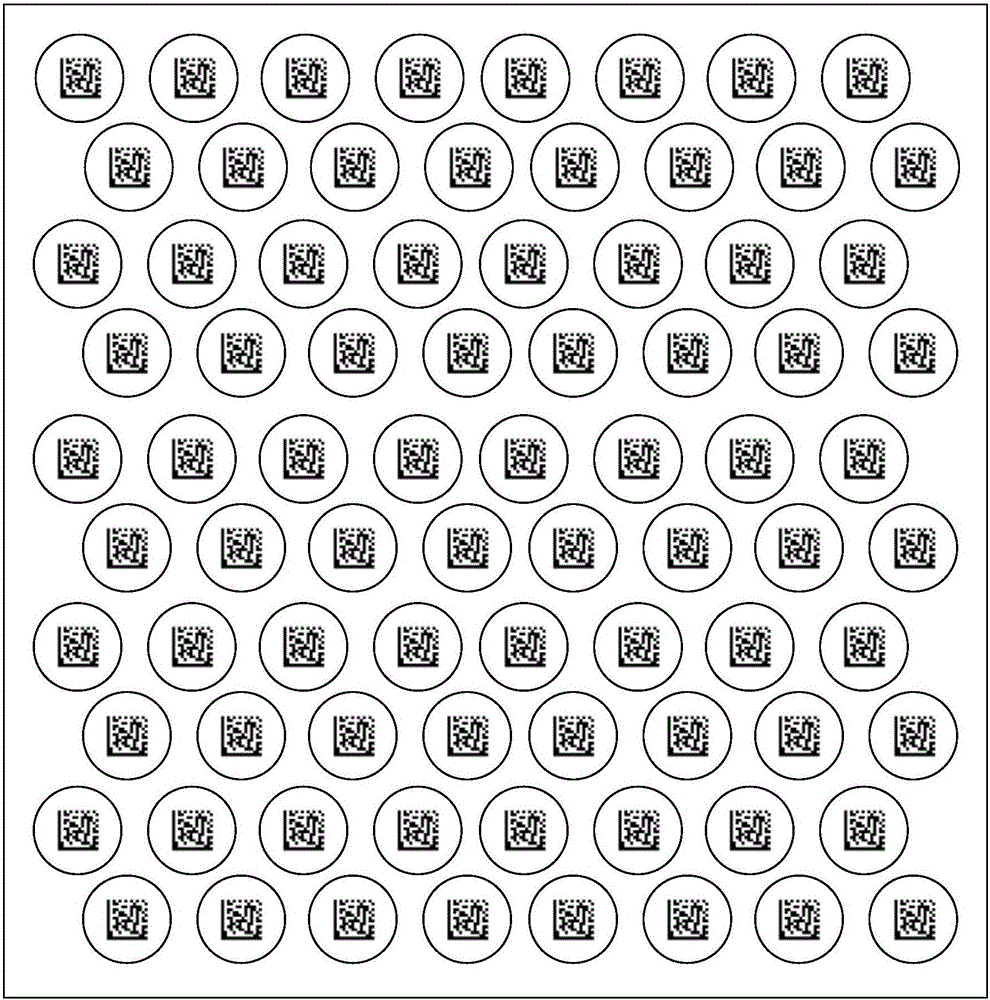

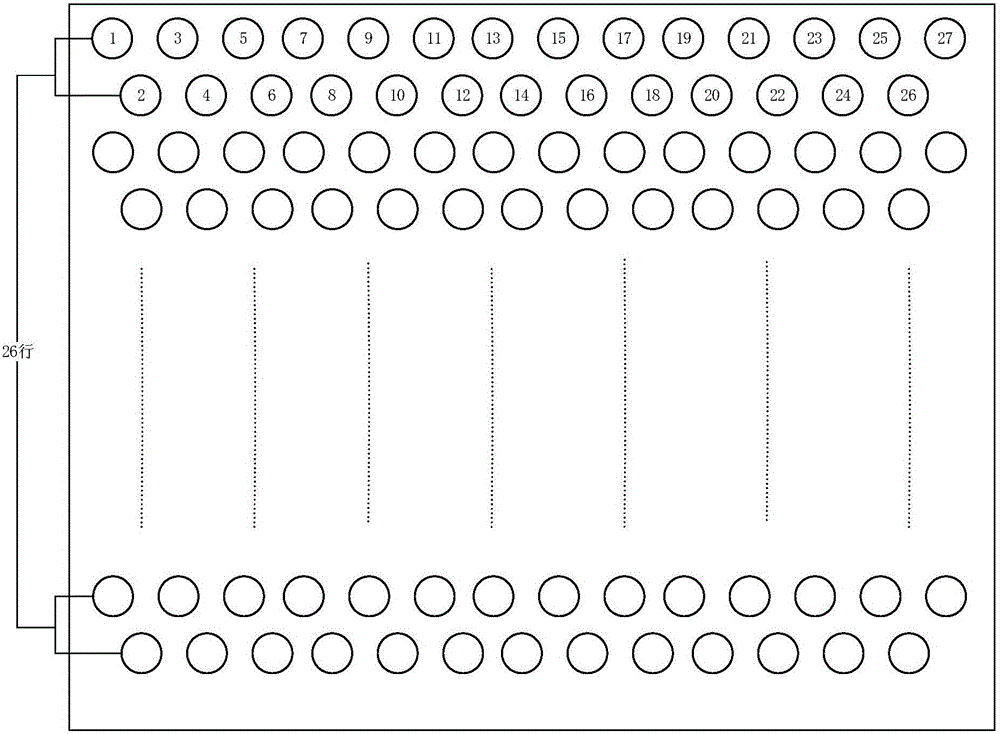

Method for detecting identification code tagging quality of large-breadth printing material

Owner:SIGMATRIX TECH CO LTD

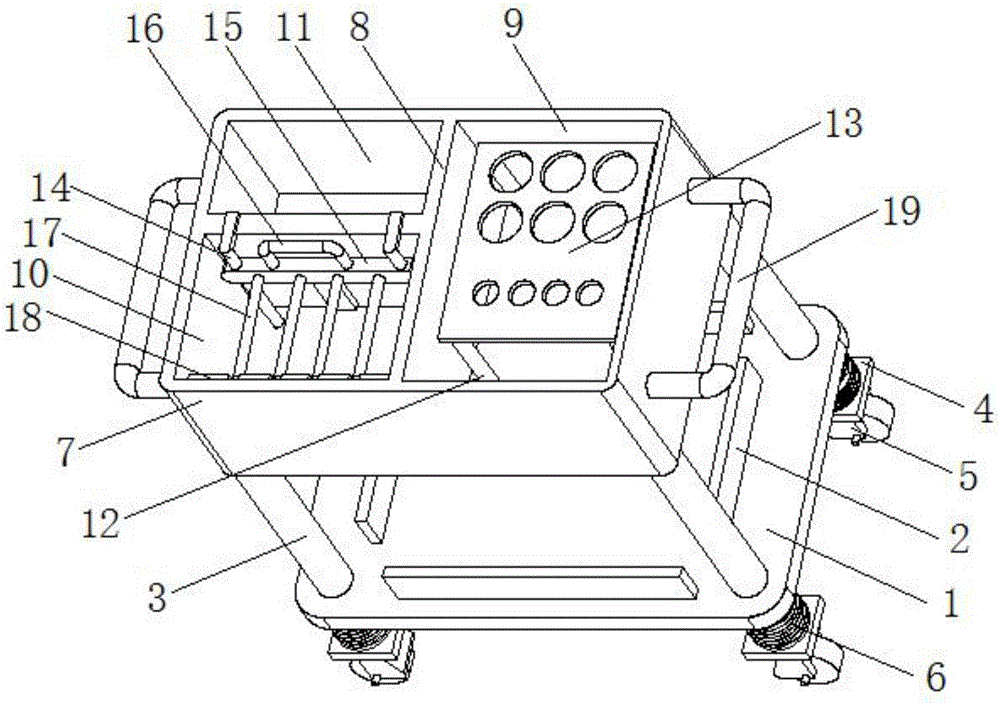

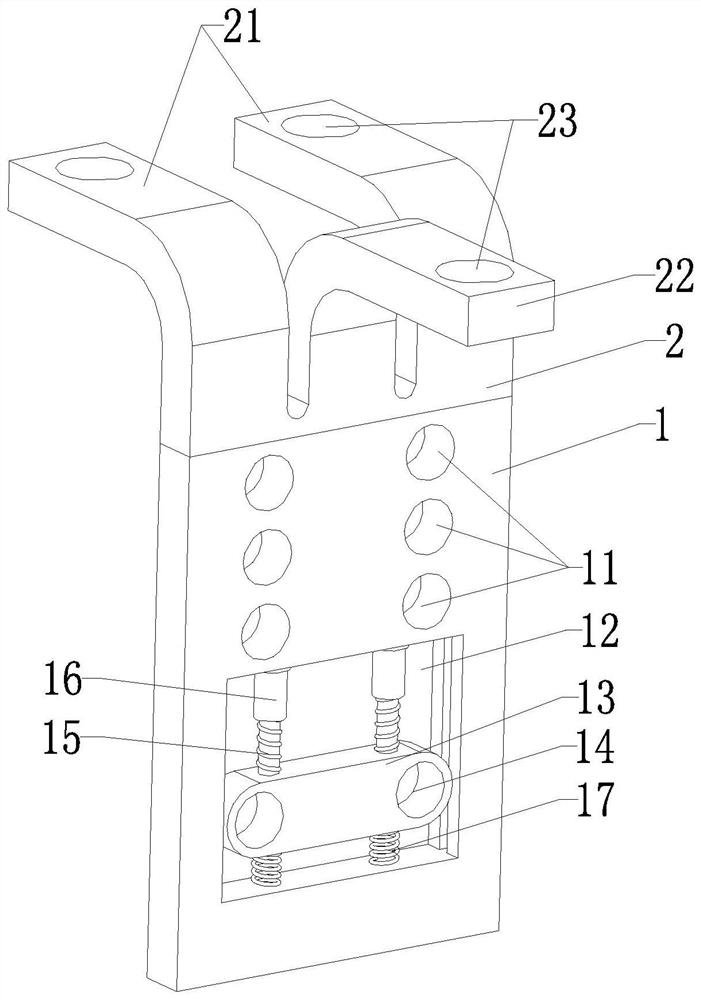

Tool conveying device for anesthesia department

InactiveCN106074058AEasy to placeEasy to transportNursing accommodationAmbulance serviceMedical wasteWaste product

Owner:齐志温

Steel plate straightening method

The invention provides a steel plate straightening method. The steel plate straightening method comprises the steps that whether a rolled steel plate is abnormal or not is judged, if the rolled steelplate is abnormal, steel plate parameters of the steel plate are input, new straightening parameters are obtained through calculation according to the steel plate parameters, the new straightening parameters are sent to a basic automatic control system, and the basic automatic control system controls a straightener to straighten according to the new straightening parameters. According to the steelplate straightening method, calculating the steel plate parameters of the abnormal steel plate is carried out to obtain the new straightening parameters, the straightener is controlled to straightenaccording to the new straightening parameters, and the straightened abnormal steel plate is obtained, so that the shape of the steel plate is guaranteed, and the waste quantity is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

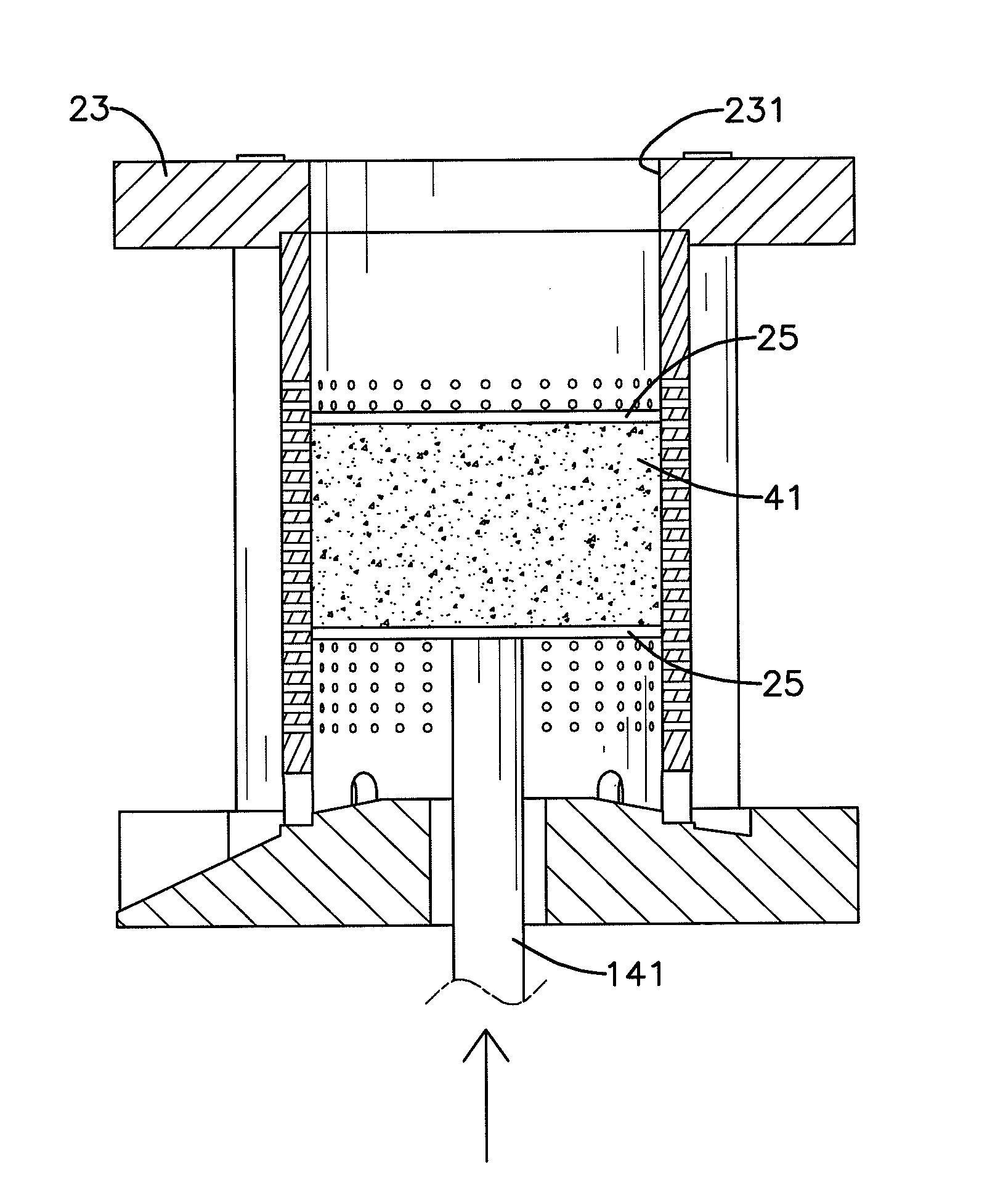

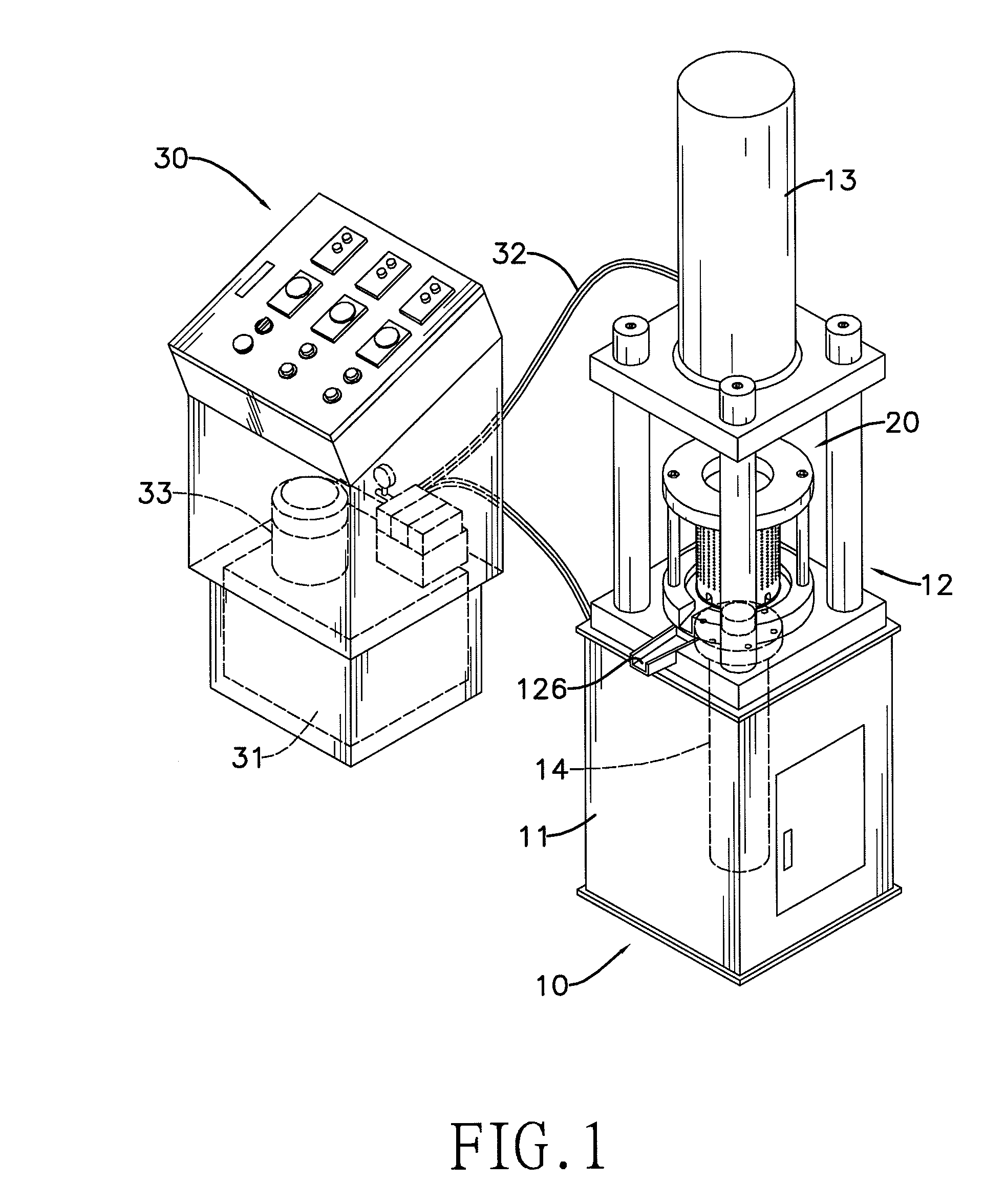

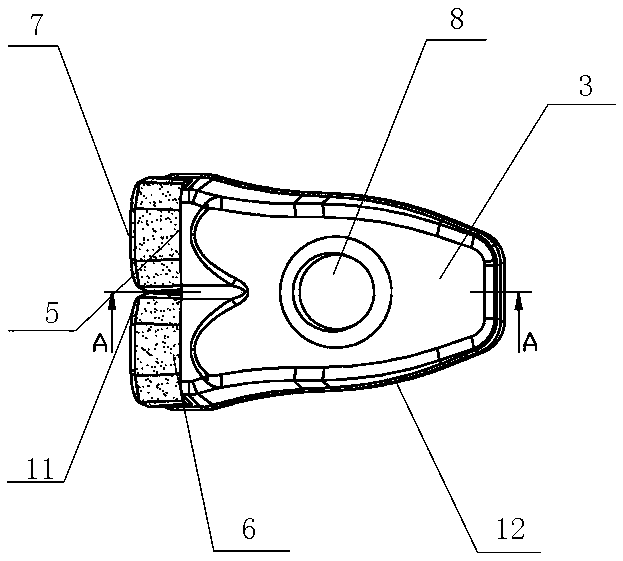

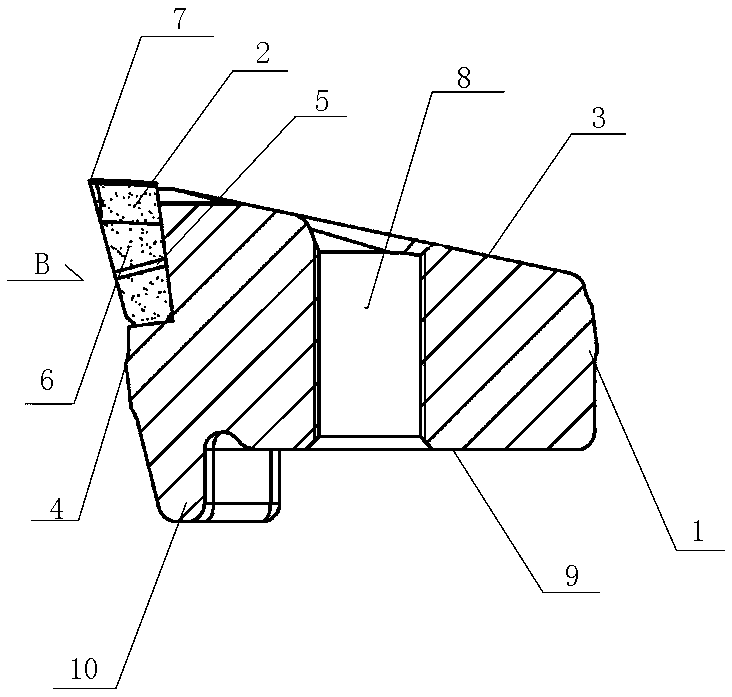

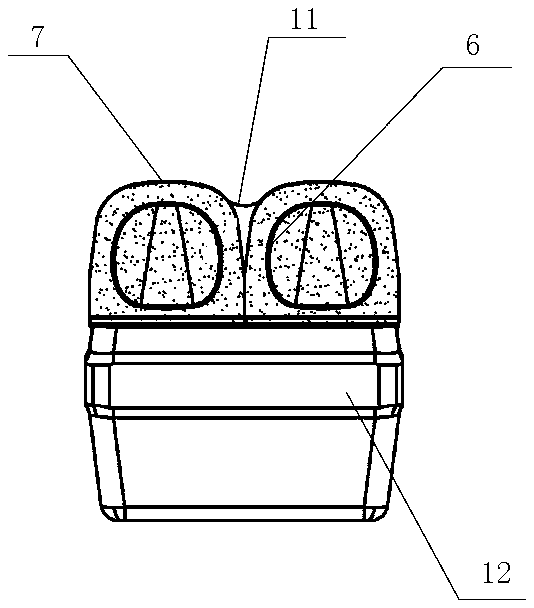

Smashing machine and mechanical teeth for waste product treatment

PendingCN108855418AGood structural firmnessReasonable structureGrain treatmentsWaste productSharp angle

Owner:德清爱得机械有限公司

Preparation process before silicon wafer cutting

InactiveCN111070447AReduce incidenceReduce manufacturing costFine working devicesWaste productSilicon chip

Owner:江阴苏阳电子股份有限公司

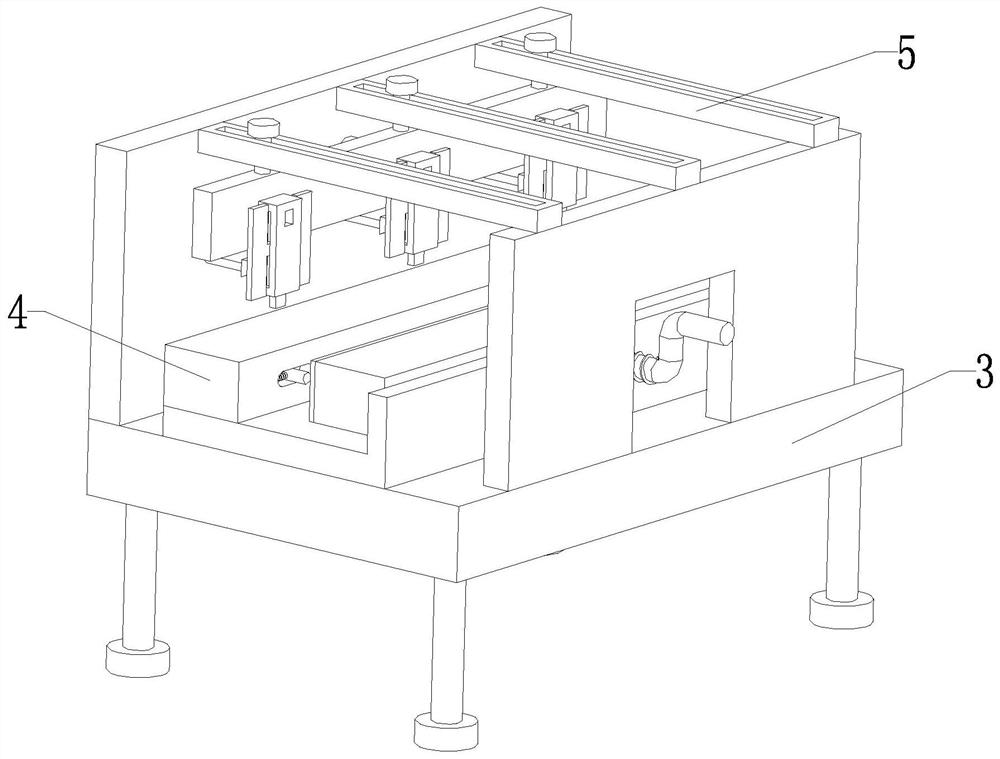

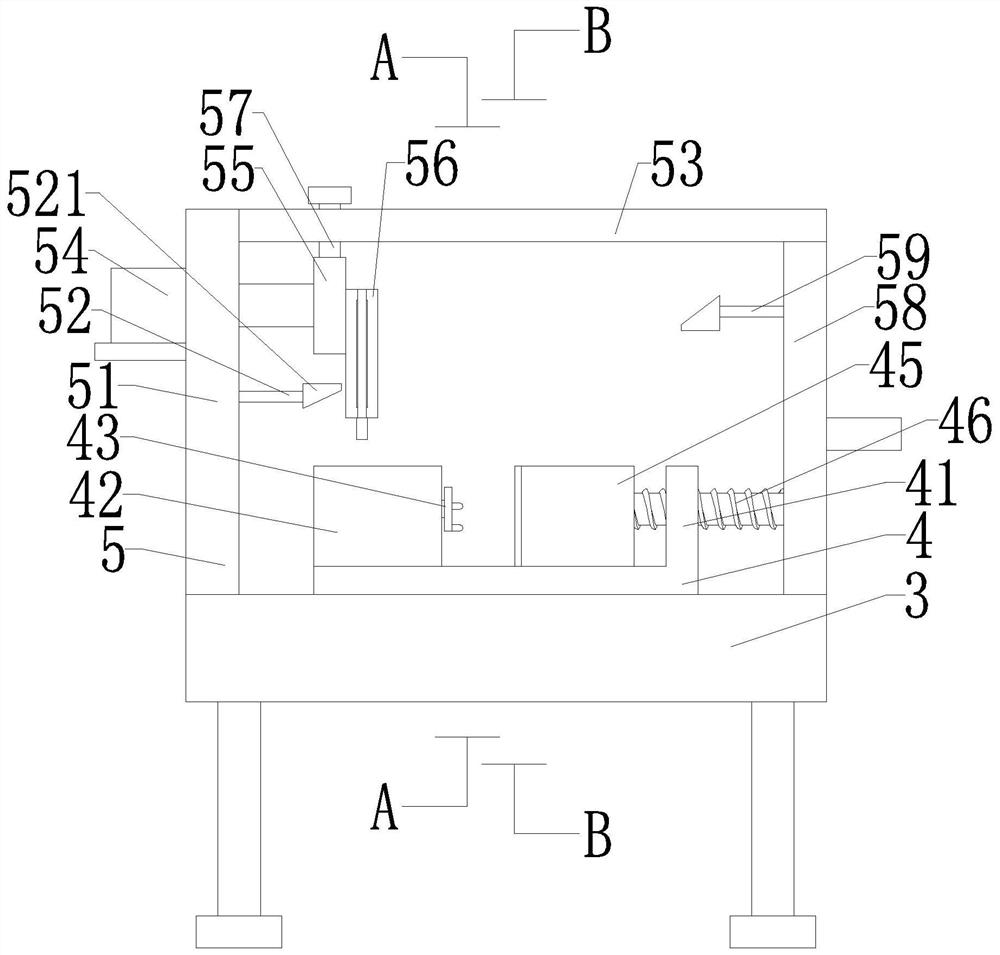

Dry-hanging stone curtain wall connecting piece and manufacturing machine thereof

InactiveCN113464526AIncrease diversityReduce installation difficultyWallsSheet joiningWaste productIndustrial engineering

Owner:武汉大帝豪建筑装饰工程有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap