Method for producing wastewater treatment agent with weathered coal graft organic macromolecule

A technology of organic polymer and wastewater treatment agent, which is applied in the direction of flocculation/sedimentation water/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., and can solve the problems of high post-treatment costs, large energy consumption, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1-3

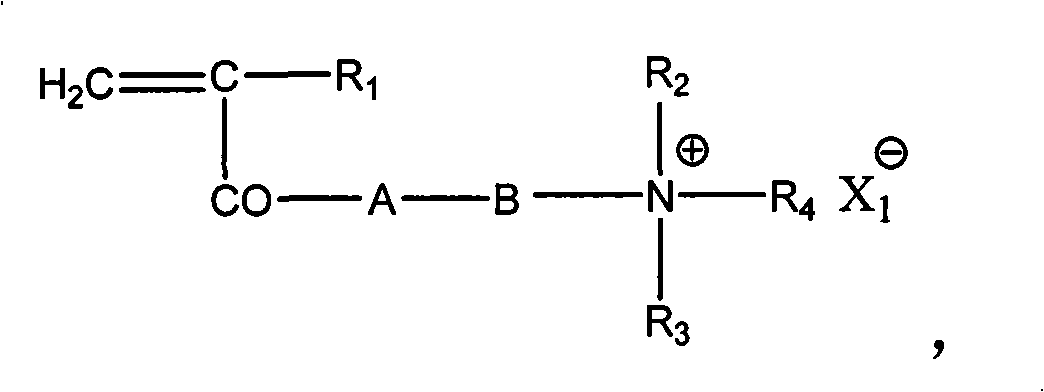

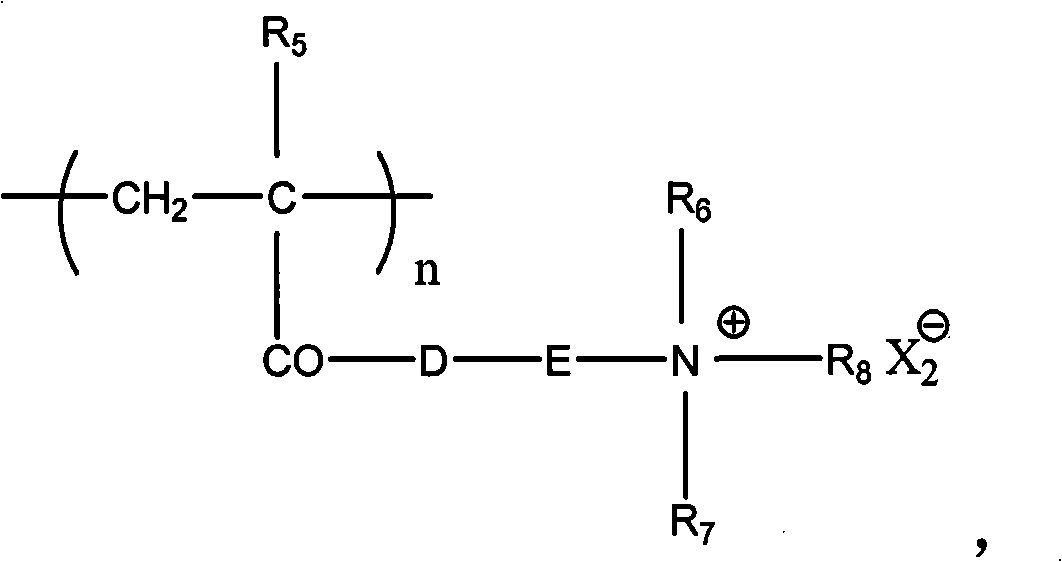

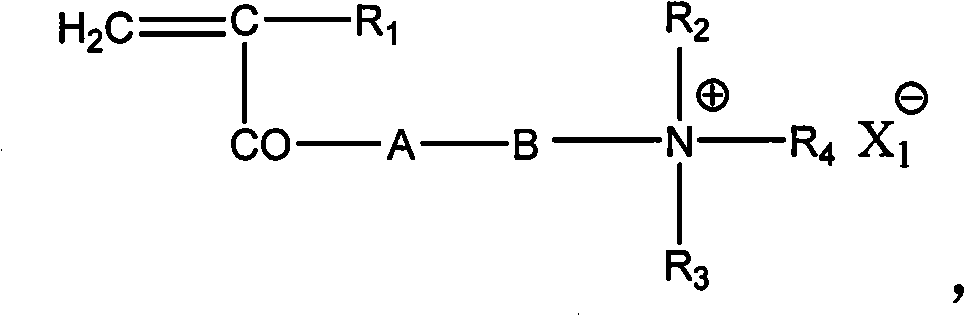

[0022] Synthesis Example 1-3: Synthesis Example of Cationic Addition Polymer Dispersant

[0023] Add 240g of deionized water to a 500mL reaction bottle, then add 60g of trimethylaminoethyl acrylate (DAC) (see NO.1 in Table 1), or 40g of trimethylaminoethyl acrylate and 80g of acrylamide (AM) The mixed monomer (see NO.2 in Table 1), or the mixed monomer of 20g trimethylaminoethyl acrylate and 100g acrylamide (see NO.3 in Table 1), add sulfuric acid dropwise to adjust the pH of the solution to 3. After raising the temperature to 42 degrees, pass nitrogen gas for about 30 minutes, then add 3g of 2% aqueous solution of V-50 to initiate the polymerization system. Heating was stopped after 15 hours of reaction to obtain dispersant synthesis examples No.1, No.2 and No.3. (See Table 1) Measure its weight-average molecular weight and cationicity respectively with static light scattering and colloid titration analysis.

Synthetic example 4-6

[0025] Add 240g of deionized water to a 500mL reaction bottle, then add 60g of trimethylaminoethyl methacrylate (DMC) (see NO.4 in Table 1), or 40g of trimethylaminoethyl methacrylate and 80g of propylene A mixed monomer of amide (AM) (see NO.5 in Table 1), or a mixed monomer of 20g trimethylaminoethyl methacrylate and 100g acrylamide (see NO.6 in Table 1), add sulfuric acid dropwise Adjust the pH of the solution to 3, heat up to 42 degrees, and pass nitrogen gas for about 30 minutes, then add 3g of 2% aqueous solution of V-50 to initiate the polymerization system. Heating was stopped after 15 hours of reaction to obtain dispersant synthesis examples No.4, No.5 and No.3. (See Table 1) Measure its weight-average molecular weight and cationicity respectively with static light scattering and colloid titration analysis.

[0026] The preparation example of the waste water treatment agent prepared by grafting weathered coal with organic polymer is introduced below.

Embodiment 1

[0028] In the 500 milliliters of 4 mouthfuls of round bottom flasks that are furnished with condensing tube, thermometer, nitrogen inlet and agitator, add the polymer NO-1 (20%) 25g that prepares in synthetic example 1, weathered coal 15g, 170.4g deionized Water, 115g of ammonium sulfate, 67.4g of 50% concentration of acrylamide, 115g of 80% trimethylethylamine acrylate chloride, heating up and keeping the temperature at 30-33°C to completely dissolve it. After 30 minutes of nitrogen gas, 1.9 g of 1% VA-044 aqueous solution was added to initiate the reaction. The viscosity of the reaction system began to increase 2.5 hours after the start of the reaction, and decreased after 25 minutes to form a dispersion. After reacting for 8 hours, 0.5 g of the above-mentioned initiator solution was added and the reaction was continued for 8 hours to obtain weathered coal grafted organic polymers to prepare wastewater treatment agents. The concentration, viscosity and particle size of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap