System and method for liquid treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

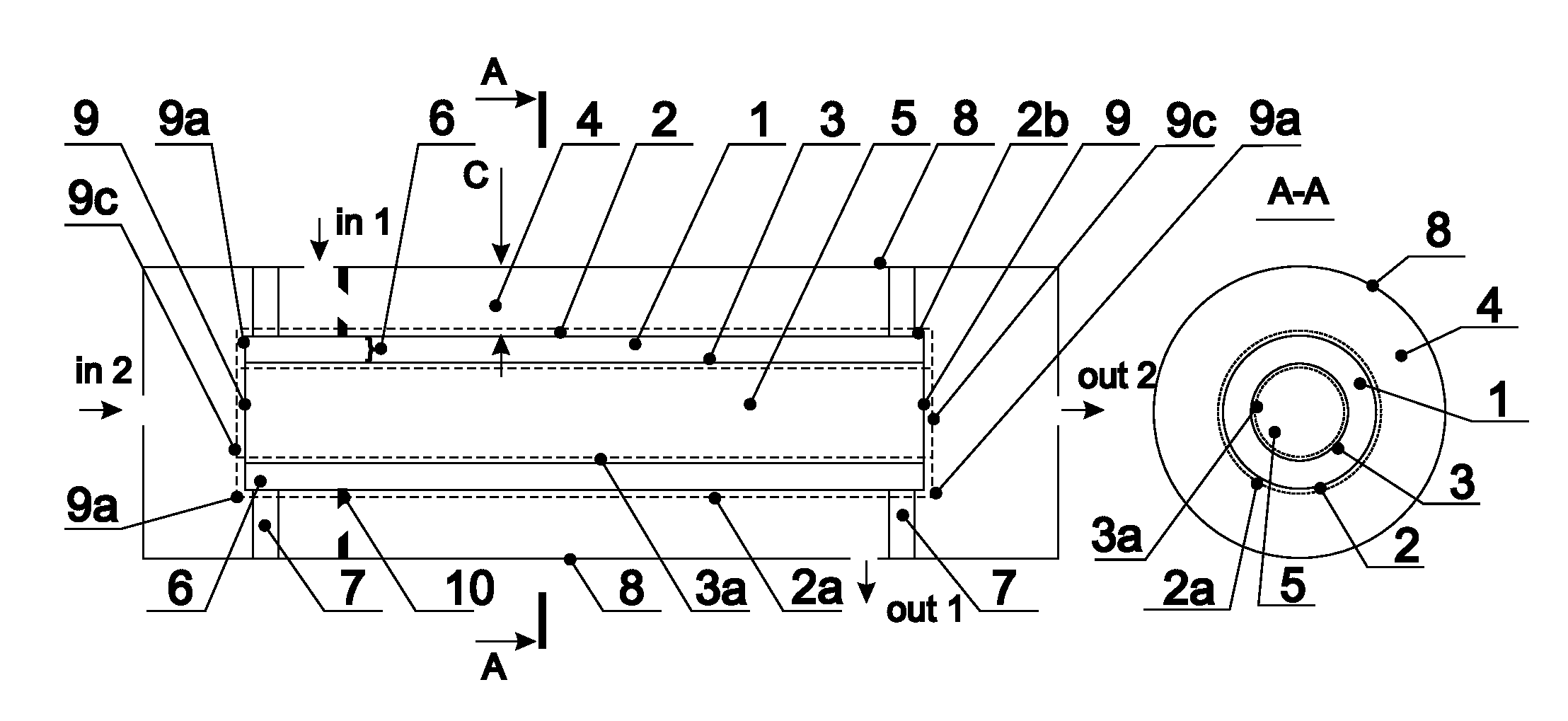

[0118]As shown in FIG. 1 and FIG. 3, in the first embodiment, the liquid to be treated may get inside space 5 of lamp 1 through inlet “in2”, and after radiation, exit reactor 21 through outlet “out2”. The gas mixture (ambient air or oxygen) for generation of oxidizing agents (ozone, singlet oxygen, hydroxyl radical, and others) enters through inlet “in1”. The oxidizing agents-containing mixture exits housing of reactor 8 through outlet “out1”.

second embodiment

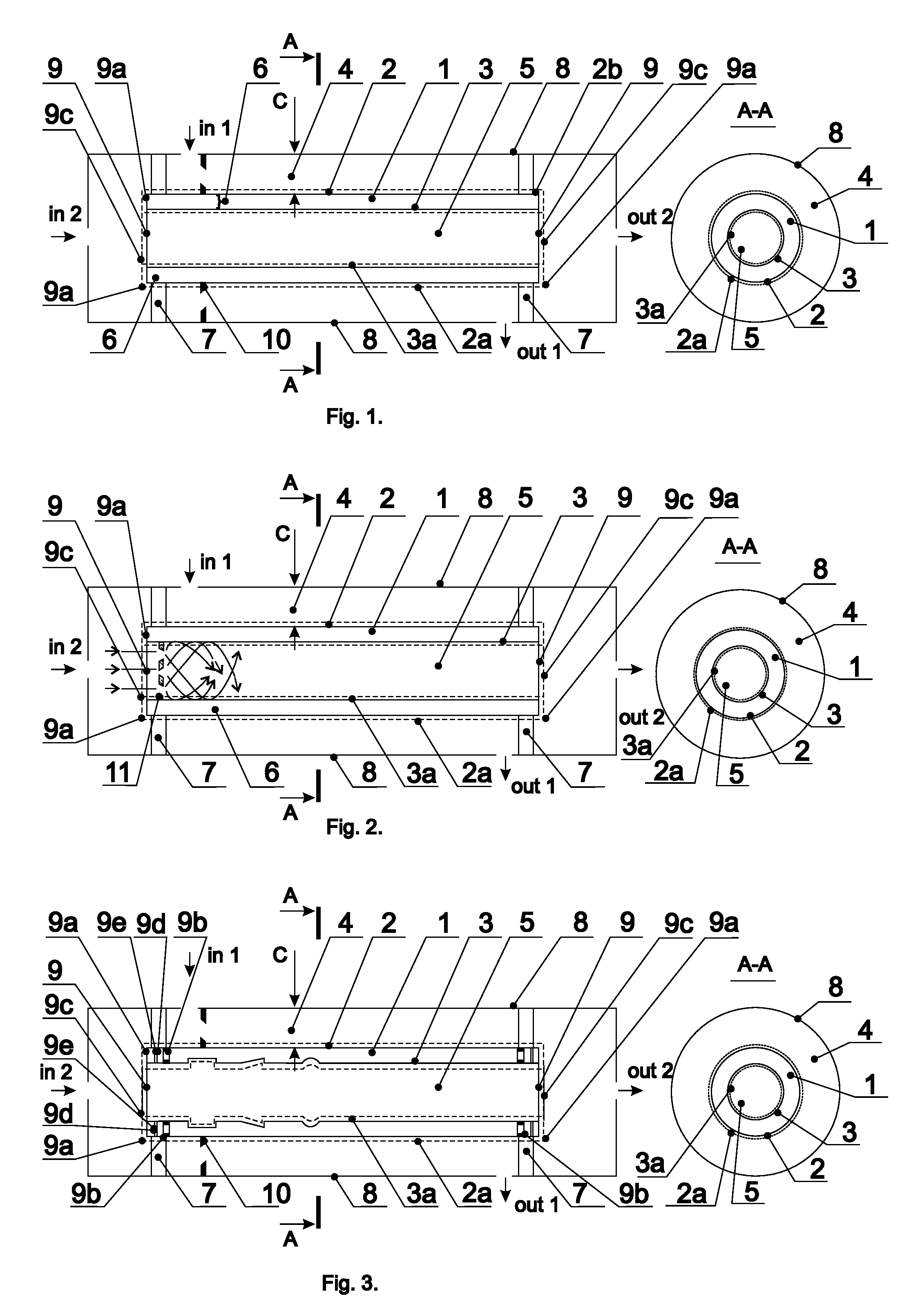

[0119]As shown in FIG. 2, in the second embodiment, the liquid to be treated may get inside housing of reactor 8 through inlet “in1”, and after radiation, exit through outlet “out1”. The gas mixture (ambient air or oxygen) for generation of oxidizing agents (ozone, singlet oxygen, hydroxyl radical, and others) generation enters housing of reactor 8 through inlet “in2”. After UV exposure, the oxidizing agents-containing mixture exits the apparatus through outlet “out2”.

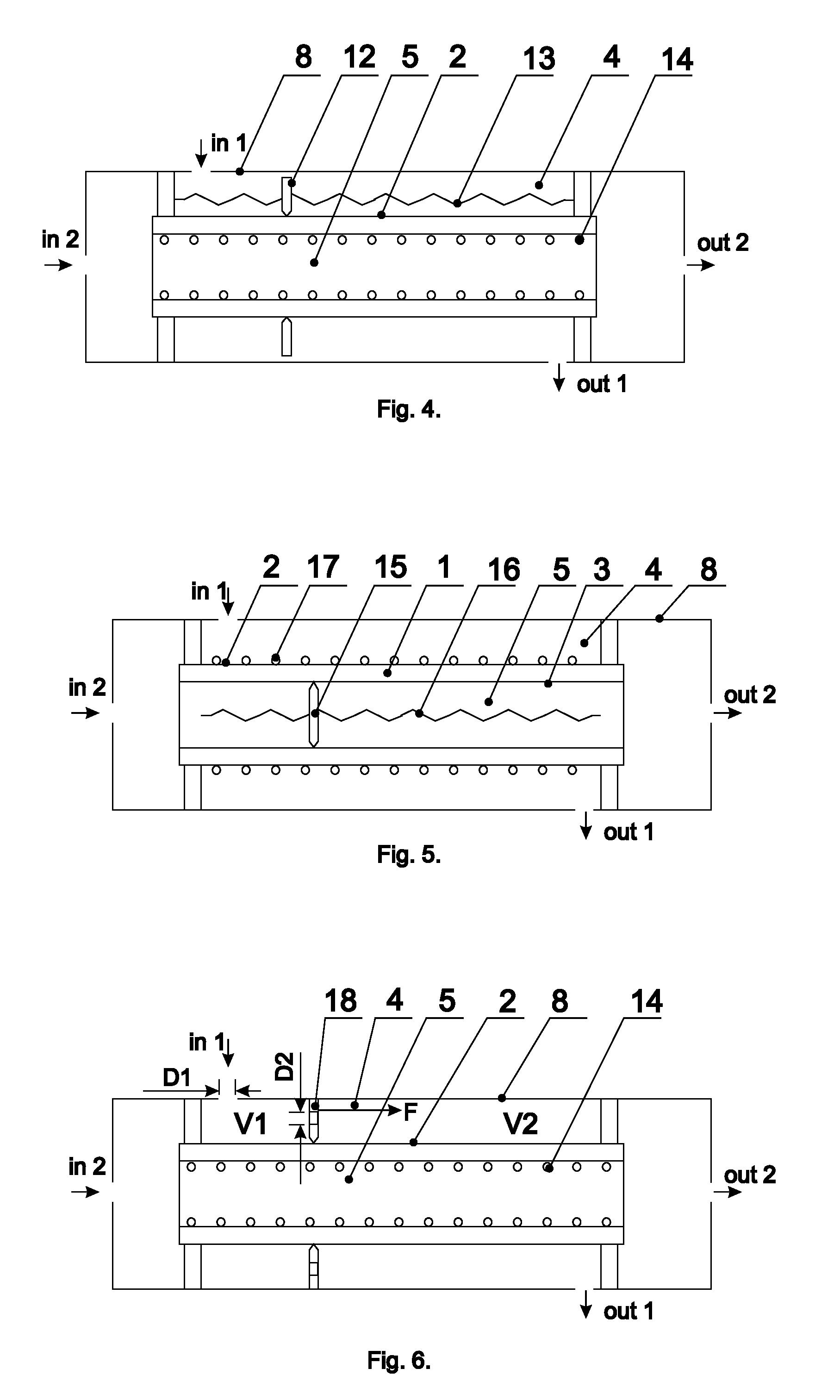

[0120]System for Cleaning the Emitting Active Surfaces of the Lamp

[0121]The lamp cleaning system comprises a set of activities aimed at removing contaminants from the emitting surface of the lamp (a sleeve adjoining the liquid being emitted. The implementation of the cleaning system may employ chemical, abrasive, or mechanical approaches.

[0122]Under the chemical approach repeated with a certain periodicity, a chemical (or a mixture of chemicals) dissolvable in the liquid and capable of removing contaminants from the em...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap