Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16 results about "Drying time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drying time(Noun) The time required for the loss of volatile components so that the material will no longer be adversely affected by weather conditions such as dew, rain or freezing.

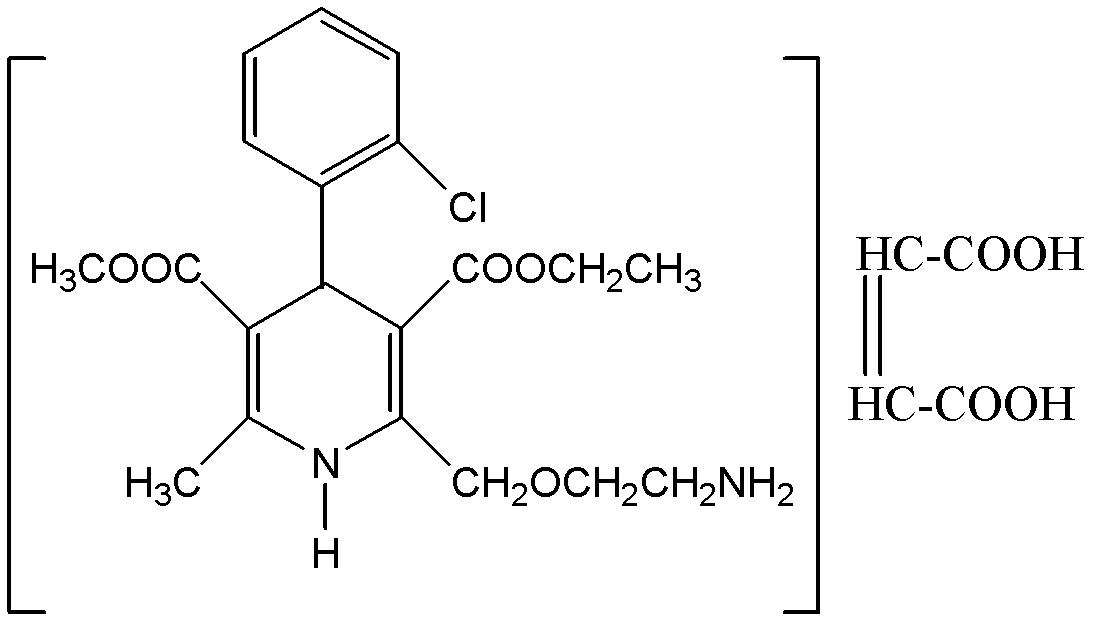

Preparation method of amlodipine maleate

Owner:NORTHEAST PHARMA GRP

Filtering method for suspended matters in water

InactiveCN104155204AExtended drying timeReduce drying timesWeighing by absorbing componentFiltrationDrying time

Owner:广州衡创测试技术服务有限公司

Novel magnesium oxysulfate cement-based fireproof coating and preparation and application methods thereof

Owner:UNIV OF SCI & TECH LIAONING

Microwave vibration bed drying method of medium moisture content granular grains

ActiveCN102524381ADry evenlyImprove efficiencySeed preservation by dryingEngineeringProcess engineering

Owner:JIANGNAN UNIV

Polyvinyl alcohol water-based architectural paint

Owner:苏州市超邦涂料有限公司

Novel ink

Owner:陈雁

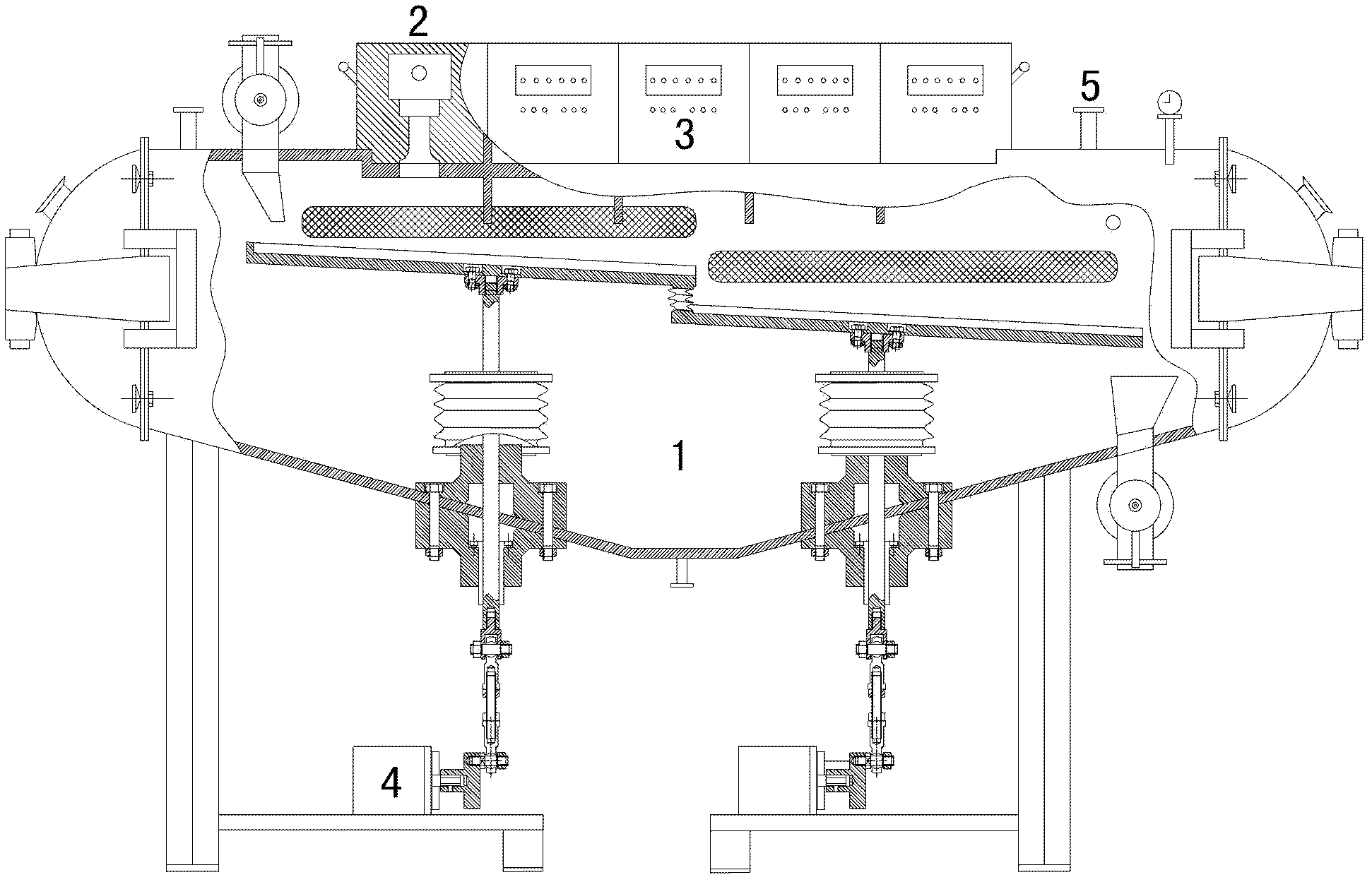

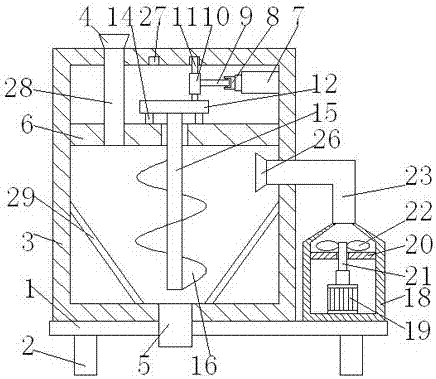

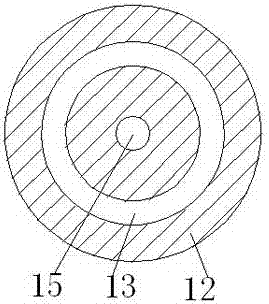

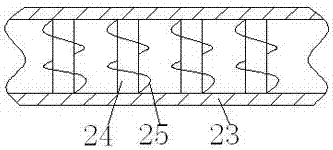

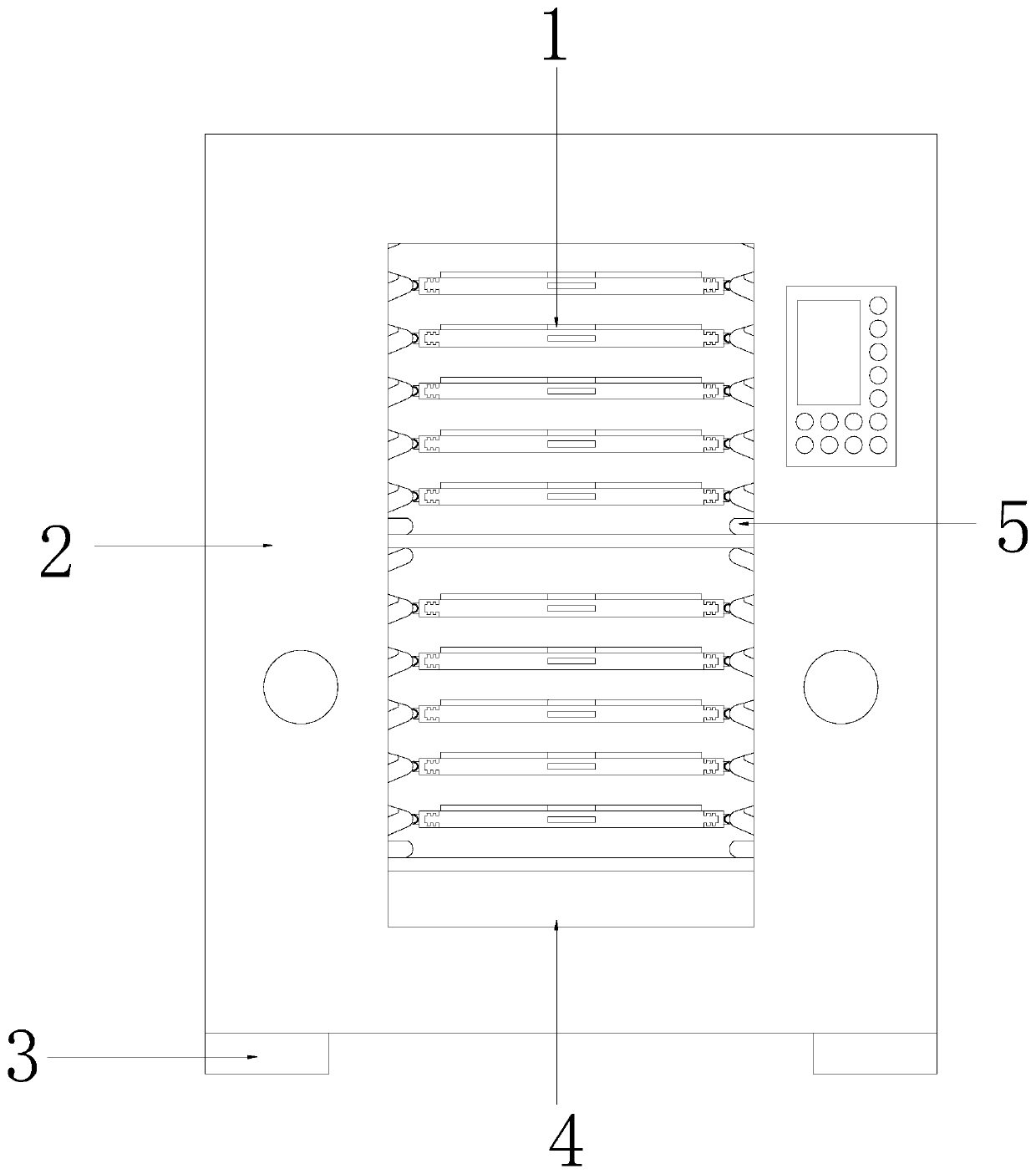

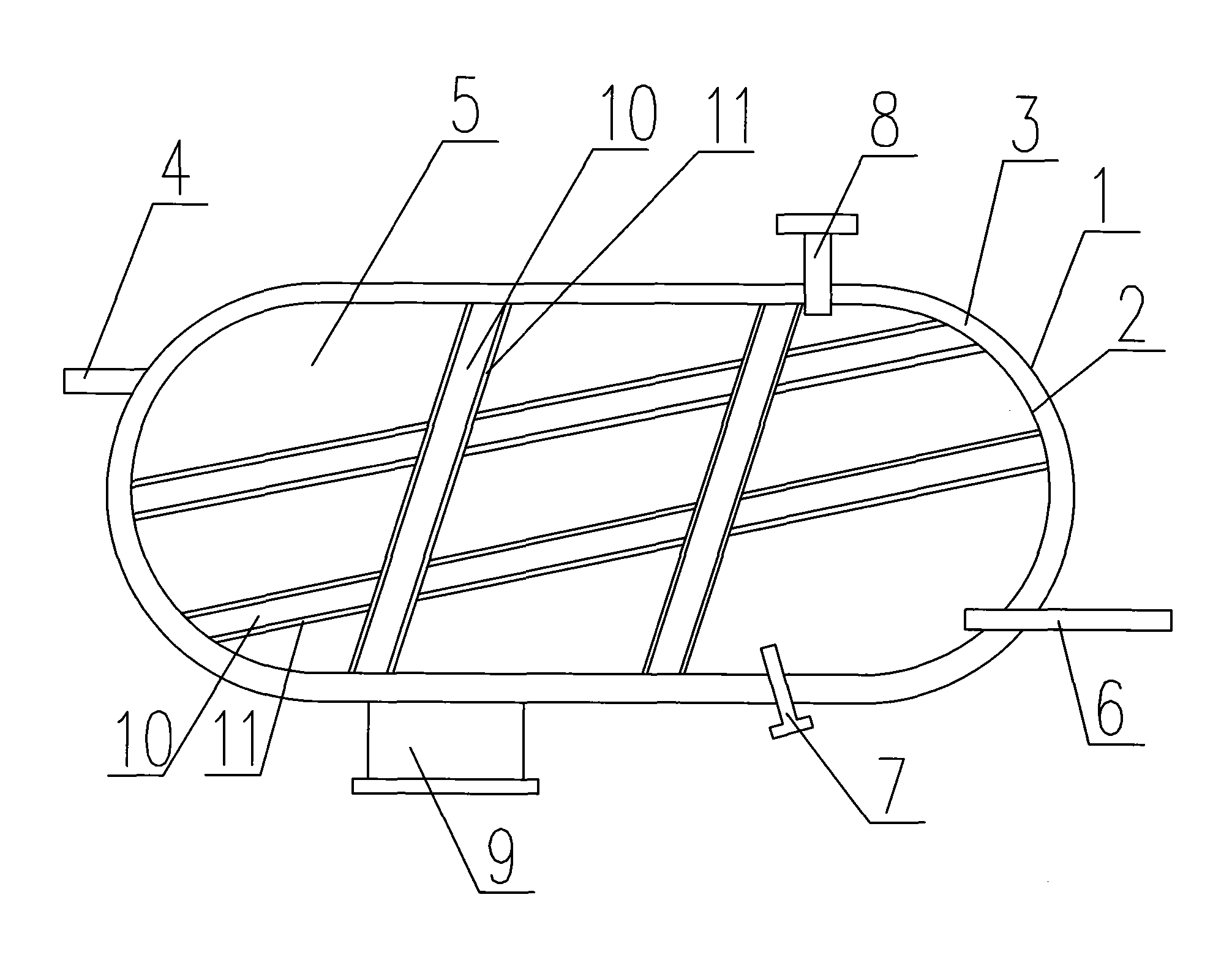

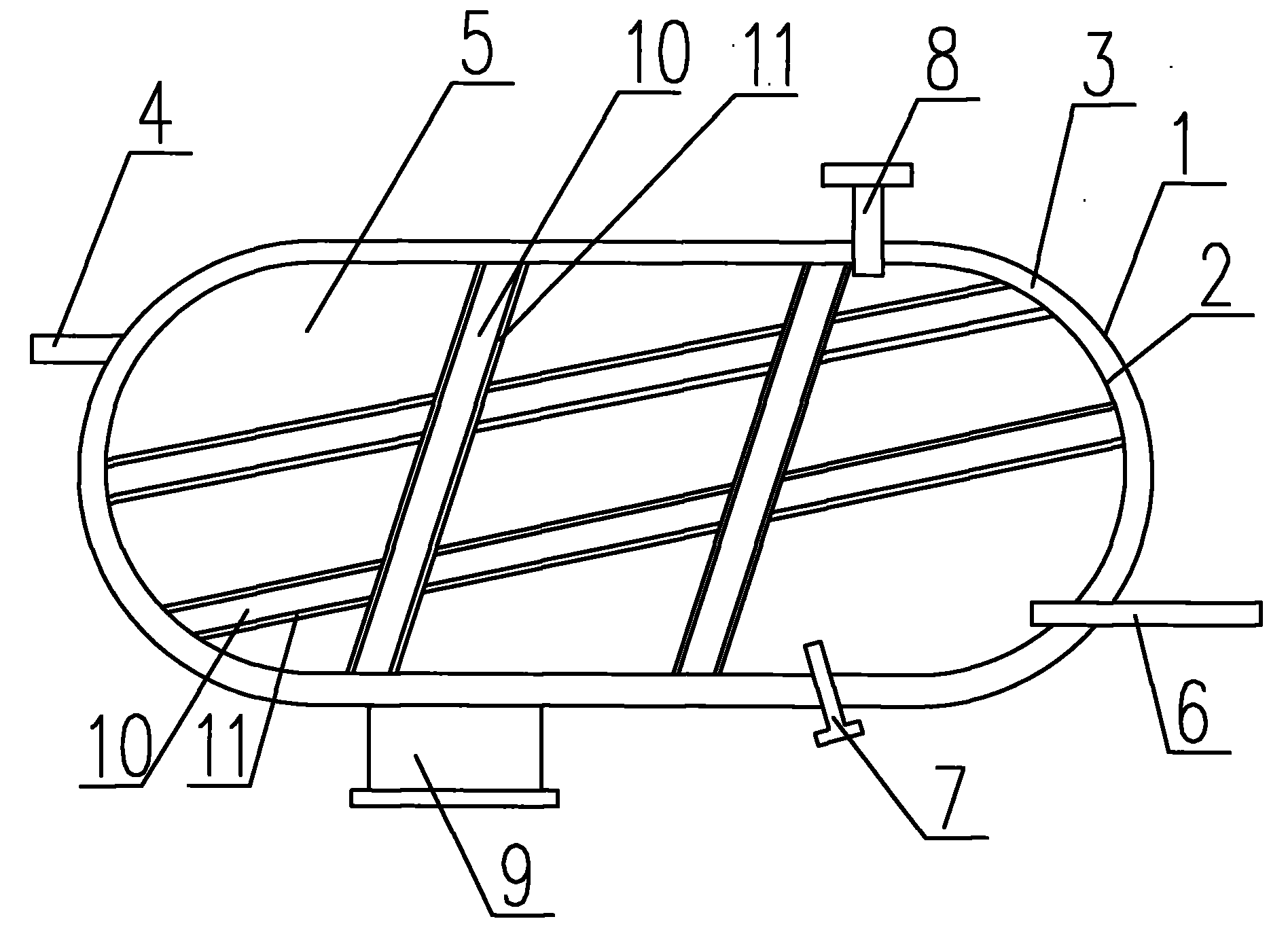

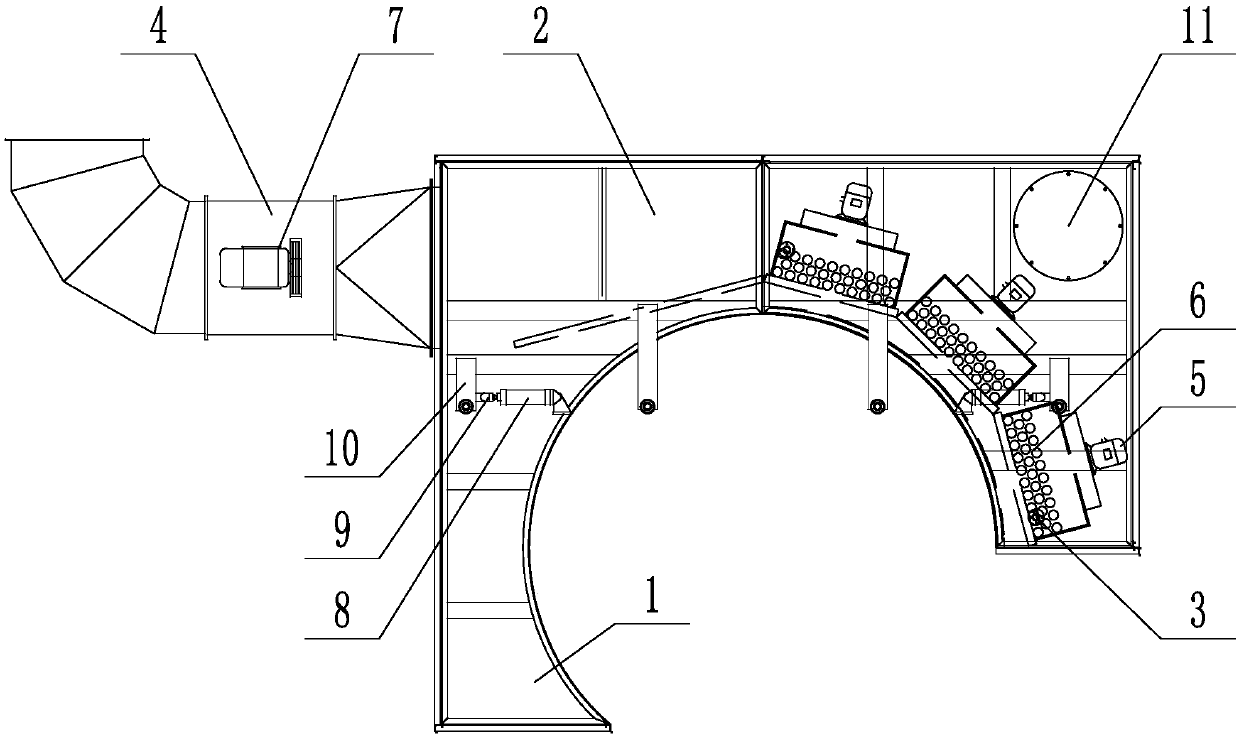

Crop uniform drying device

InactiveCN108007128ASolve the problem of not having uniform dryingDry evenlyDrying gas arrangementsDrying machines with non-progressive movementsEngineeringDrying time

Owner:王腾蛟

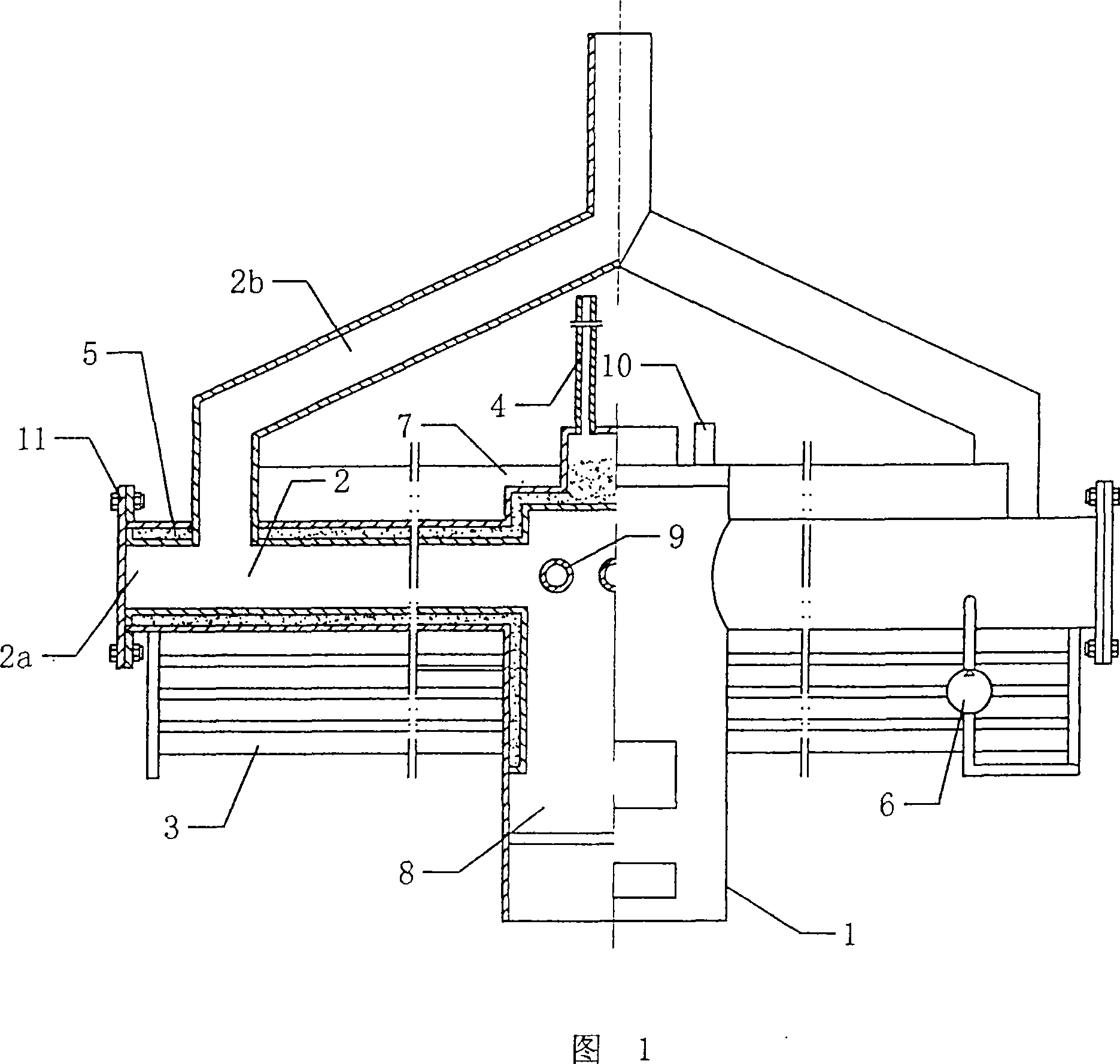

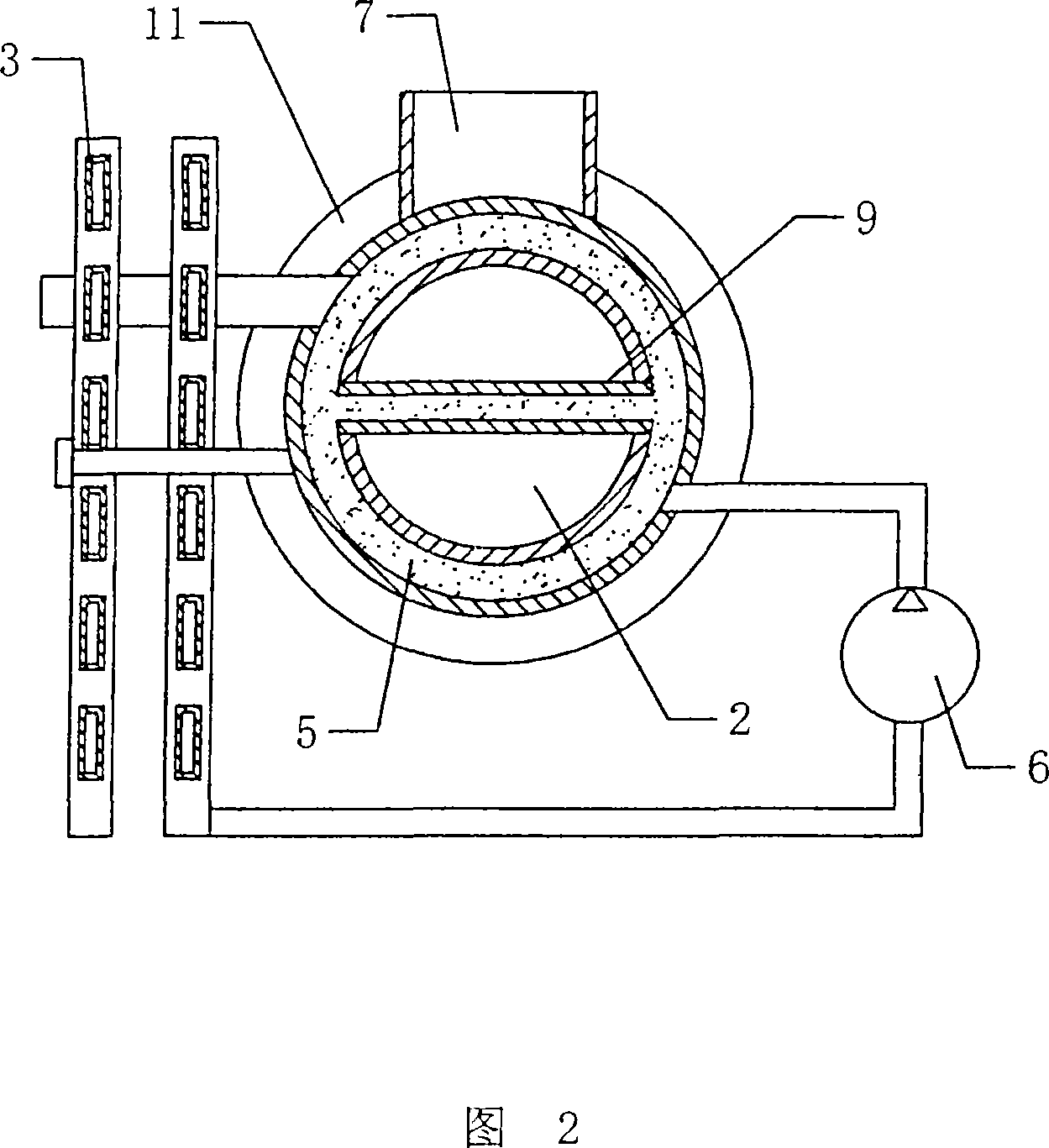

Lumber drying kiln

InactiveCN101144685AImprove thermal conductivityTemperature safetyHeating arrangementCombustion chamberHeat conducting

Owner:李祥文

Anti-corrosion acrylic acid epoxy resin powder paint for ceramic

ActiveCN104312235AWidely producedAnti-corrosive paintsPowdery paintsGlycidyl methacrylateDi-tert-butyl peroxide

Owner:SWANCOR JIANGSU NEW MATERIALS CO LTD

Rubber particle drying device

InactiveCN111520990AWith lifting functionEasy to put inDrying gas arrangementsDrying chambers/containersProcess engineeringDrying time

Owner:郑家强

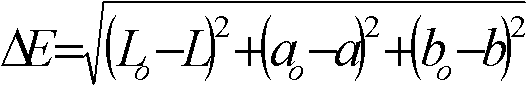

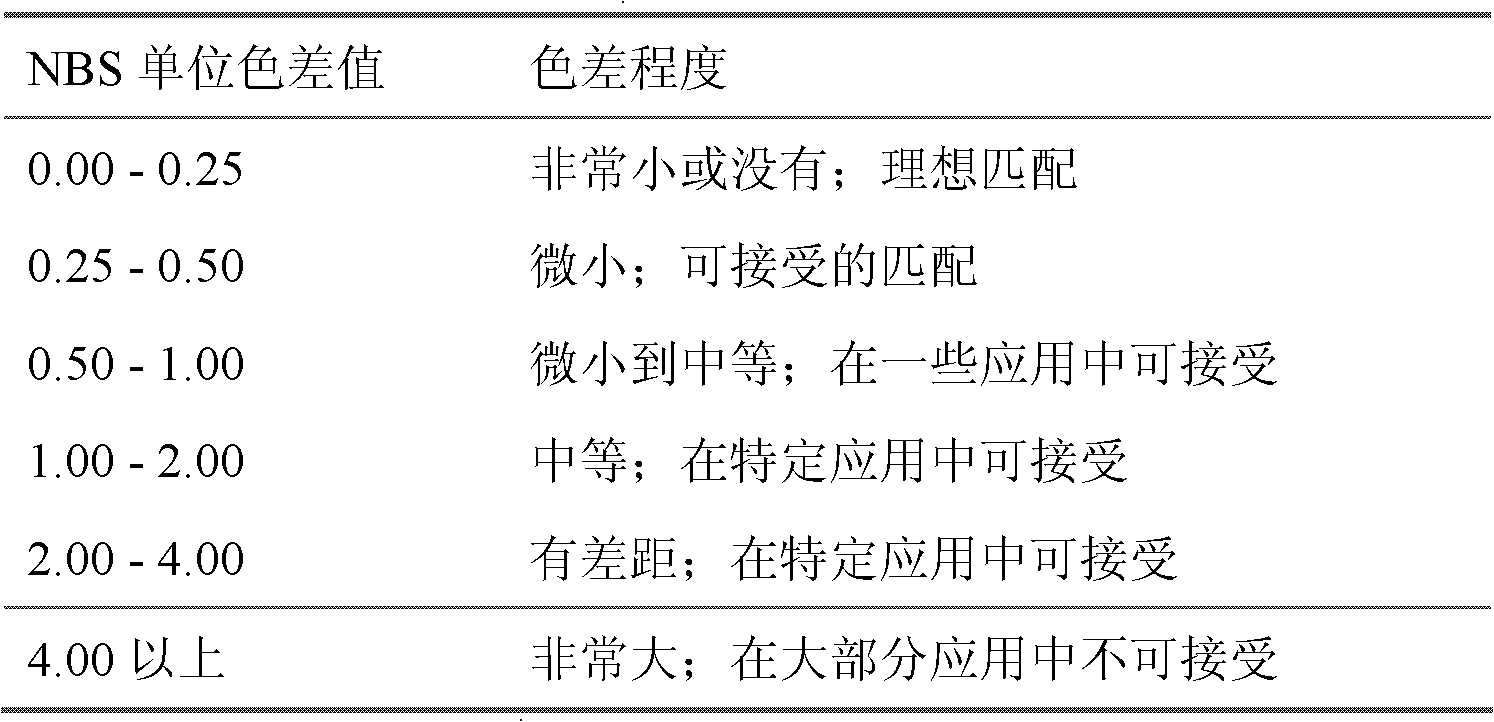

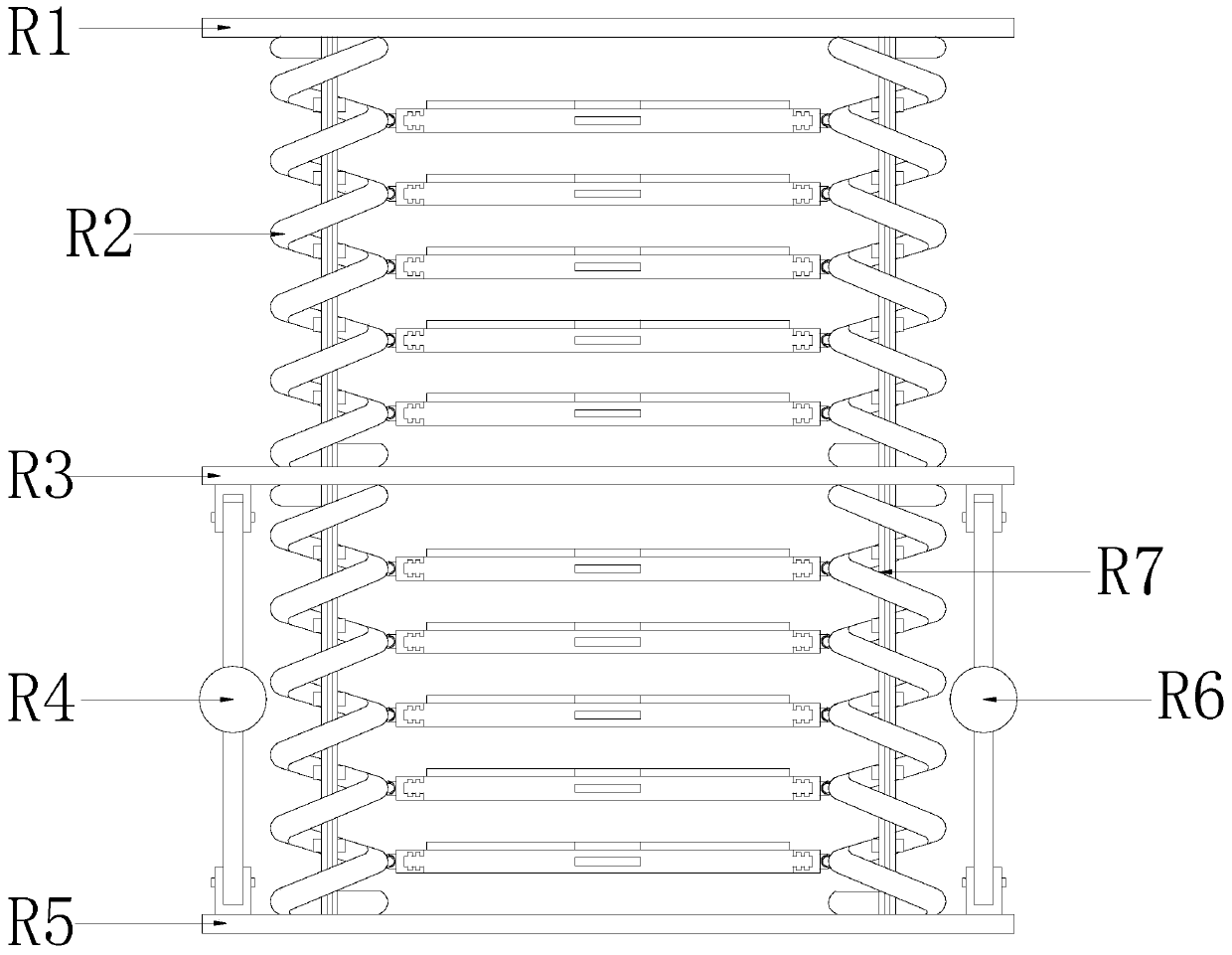

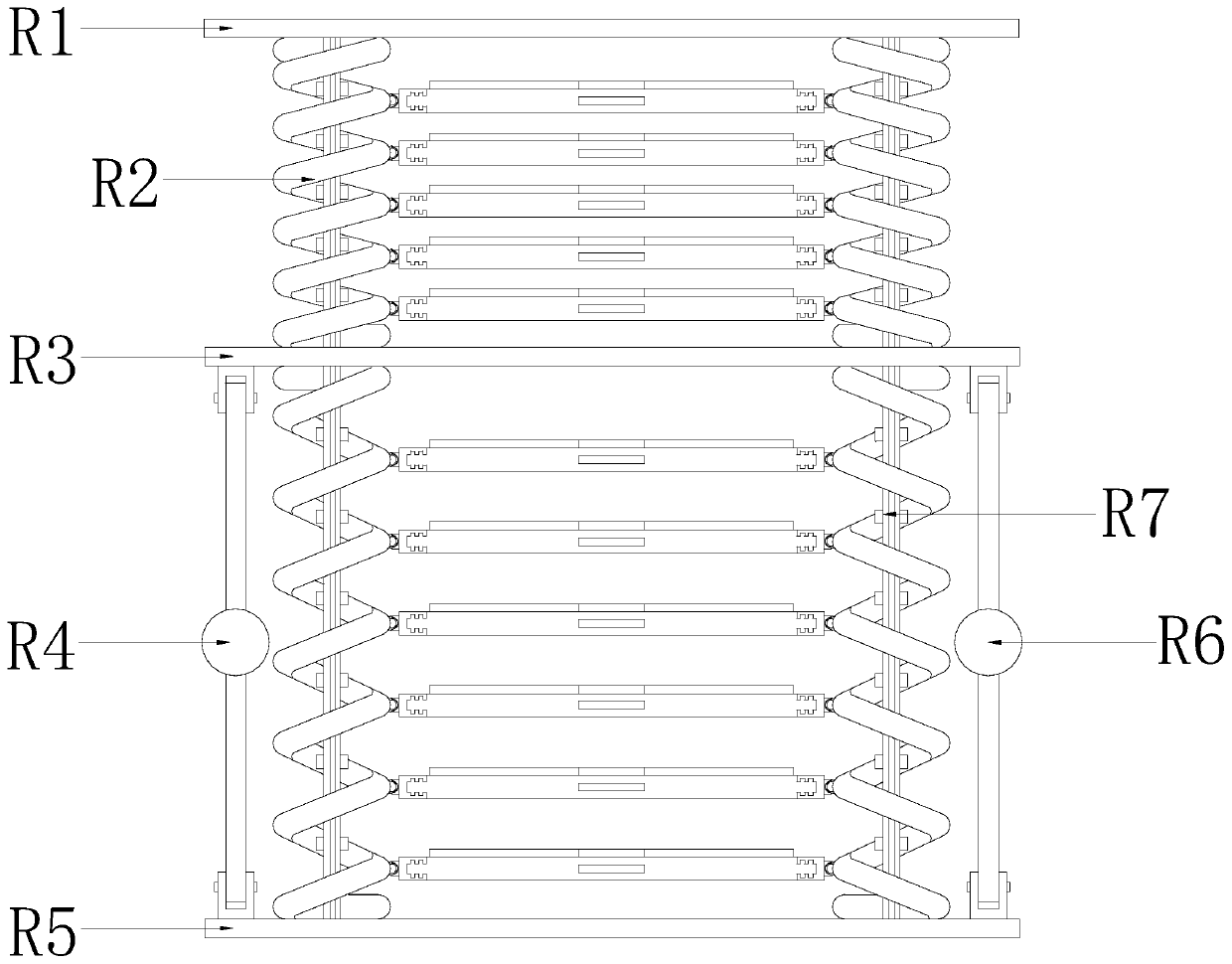

Rapid shunting drier for polyester raw material

InactiveCN101928991AWell mixedReduce color differenceMelt spinning methodsFilament-forming treatmentPolyesterEngineering

Owner:张家港保税区炬德化纤有限公司

Denim fabric printing and dyeing process

ActiveCN107254786AFast coloringNot easy to fadeLiquid/gas/vapor removalTextile treatment machine arrangementsSodium bicarbonateDenim

Owner:上海宛林服装有限公司

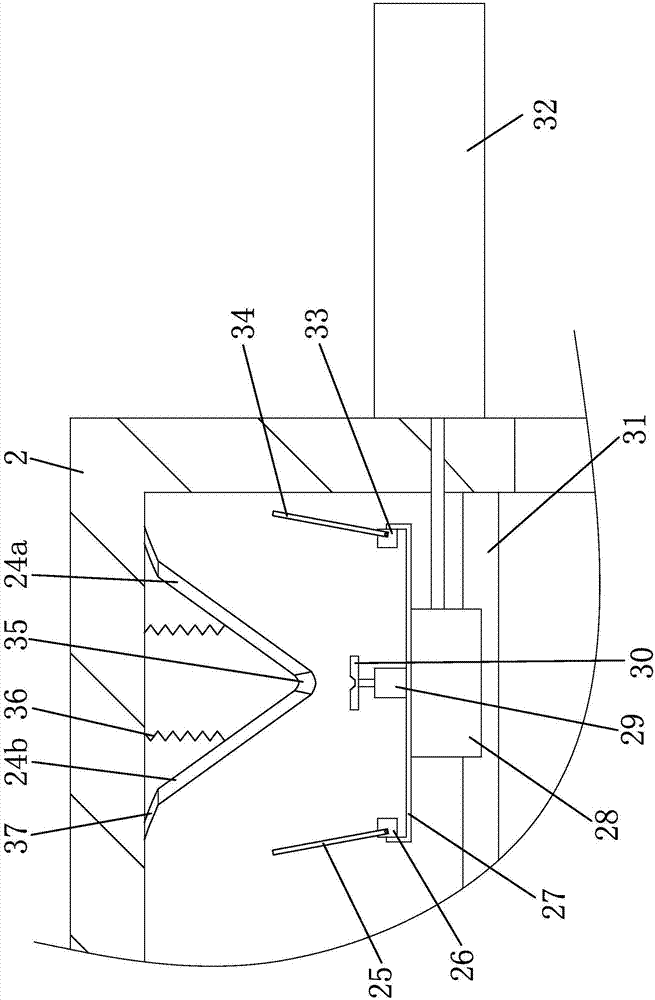

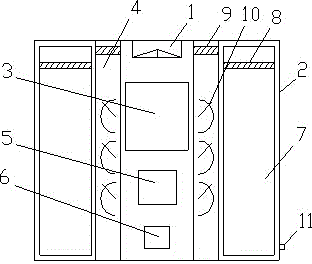

Flash drying device for paint applied to road marking

The invention discloses a flash drying device for a paint applied to road marking. The flash drying device comprises a drying box, a drier and a spray-washing head; a first fixing rod is welded at thetop end inside the drying box; a second fixing rod is welded at the bottom end inside the drying box; a second conveying belt is installed at the upper end of the second fixing rod through a fixing bolt; an inclined plate is arranged at one side of the first conveying belt and the second conveying belt; an arc-shaped passage is formed inside the inclined plate; the two sides of the arc-shaped passage are each provided with a storage groove; a fulcrum bar is welded inside one side of the inclined plate; one side of the fulcrum bar is fixedly arranged inside the sidewall of the drying box through a fixing plate; and one side of the internal upper end of the drying box is provided with the spray-washing head. The flash drying device disclosed by the invention can prolong the drying time of the paint inside the drying box, can accelerate drying of the paint and can also be conveniently provided with the spray-washing head in order to wash the inside of the drying box, thereby maintainingthe cleanness and preventing paint mud accumulation.

Owner:ANHUI JIASITE COATINGS CO LTD

Direct-blowing type drying cylinder cover welded assembly

InactiveCN107905015AReduce consumptionImprove drying efficiencyDryer sectionPulp and paper industryHeat sink

Owner:SHANDONG HANTONG AOTE MACHINERY

Adjustable hot air drying device

InactiveCN104567286ASimple structureEasy to operateDrying gas arrangementsDrying machines with local agitationRegulation temperatureWater vapor

Owner:霍山县叶王农机制造有限公司

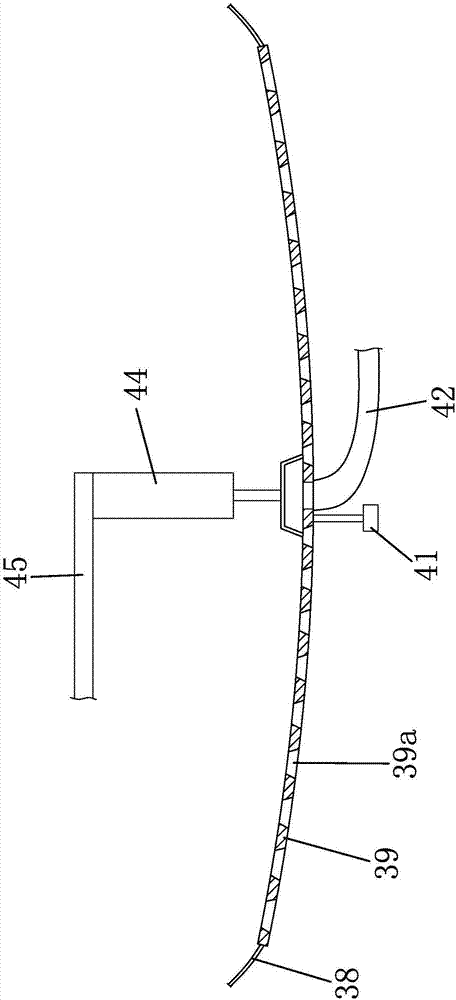

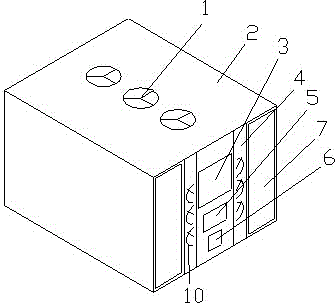

Clothes drying machine

InactiveCN108729169ASolve the situation prone to odorTextiles and paperLaundry driersEngineeringDrying time

The invention relates to the technical field of drying machines and discloses a clothes drying machine which comprises a drying machine body, wherein gas guide tubes are fixedly connected with the left side and the right side of the top of the drying machine body; a welding plate is fixedly connected with the inner wall of the back surface of the drying machine body; a convex block is fixedly connected with the front surface of the welding plate. By adopting the clothes drying machine, the problems that clothes can be smell in a too long drying time and may be not completely dried in a too short drying time can be solved; according to the scheme, a sleeve is connected with the back surface of the welding plate, a sleeve column is fixedly connected with the top of a gas outlet tank, the sleeve is matched with the sleeve column, the welding plate can be displaced up and down conveniently, that is, the welding plate can be adjusted, the convex block is fixedly connected with the front surface of the welding plate, and clothes can be placed by using a clothes hook which is fixedly connected with the bottom of the convex block.

Owner:杨宏华

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap