Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Fiberboard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fiberboard (or fibreboard) is a type of engineered wood product that is made out of wood fibers. Types of fiberboard (in order of increasing density) include particle board or low-density fiberboard (LDF), medium-density fiberboard (MDF), and hardboard (high-density fiberboard, HDF).

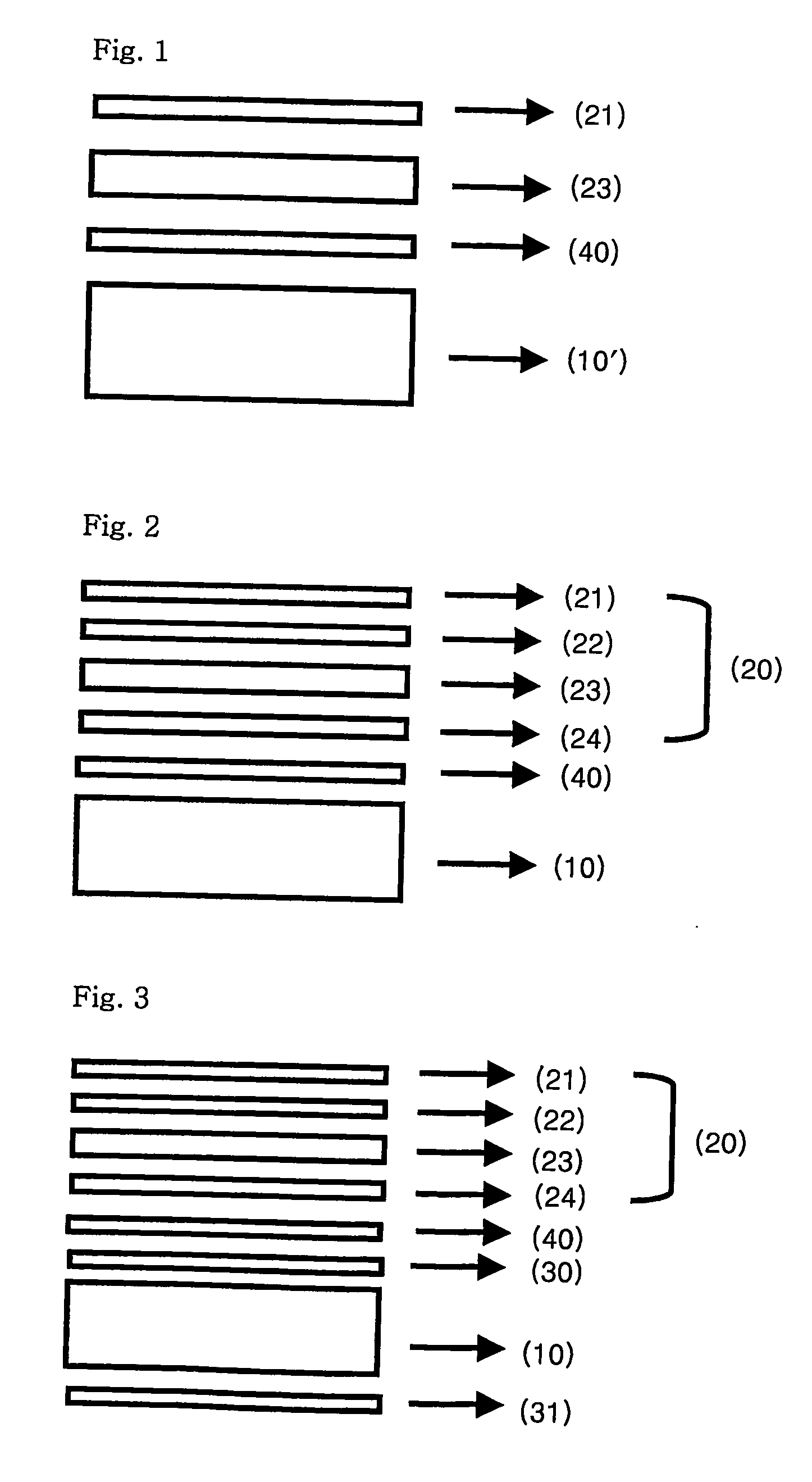

Wood flooring composed of wpl, base and soundproof layer

InactiveUS20060172118A1Improve surface strengthEnhance natural textureCovering/liningsLighting and heating apparatusWood veneerHigh density

Owner:LG CHEM LTD

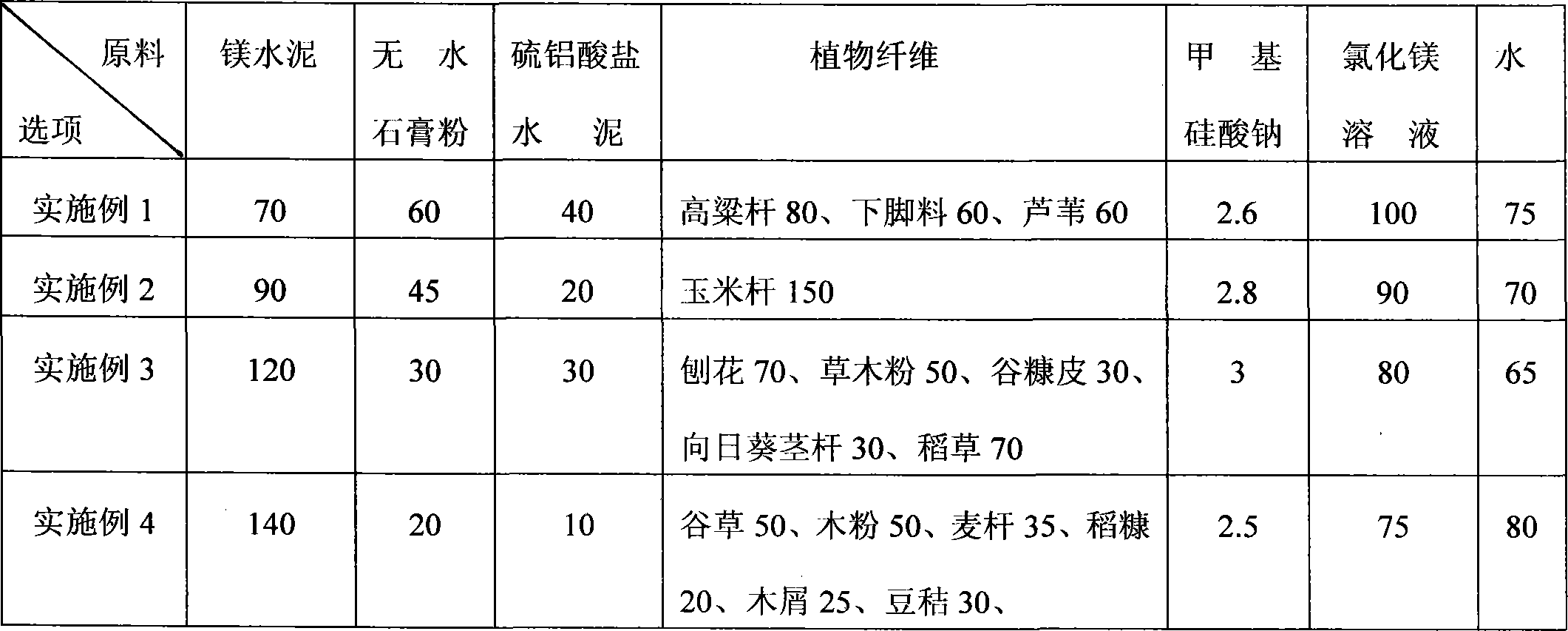

Magnesium-calcium pyrophyte pressed-fibre board and method of manufacturing the same

InactiveCN101172825AObvious beneficial effectGood effectSolid waste managementWeather resistancePlant fibre

Owner:谢涛

Construction method for concrete shear wall

InactiveCN103741846AReduce construction costsShort construction periodWallsHeat proofingFiberCalcium silicate

Owner:山西省第二建筑工程公司

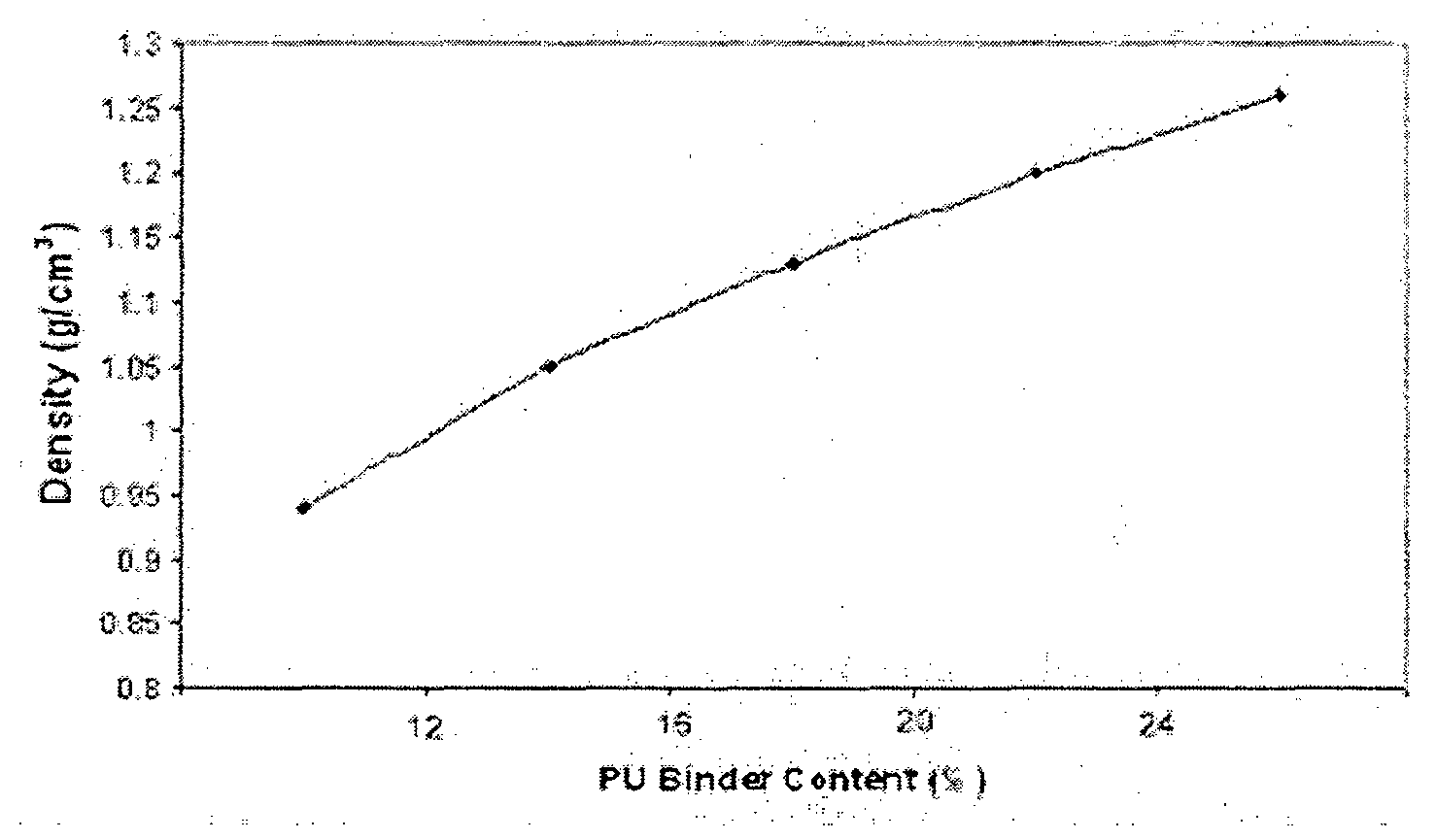

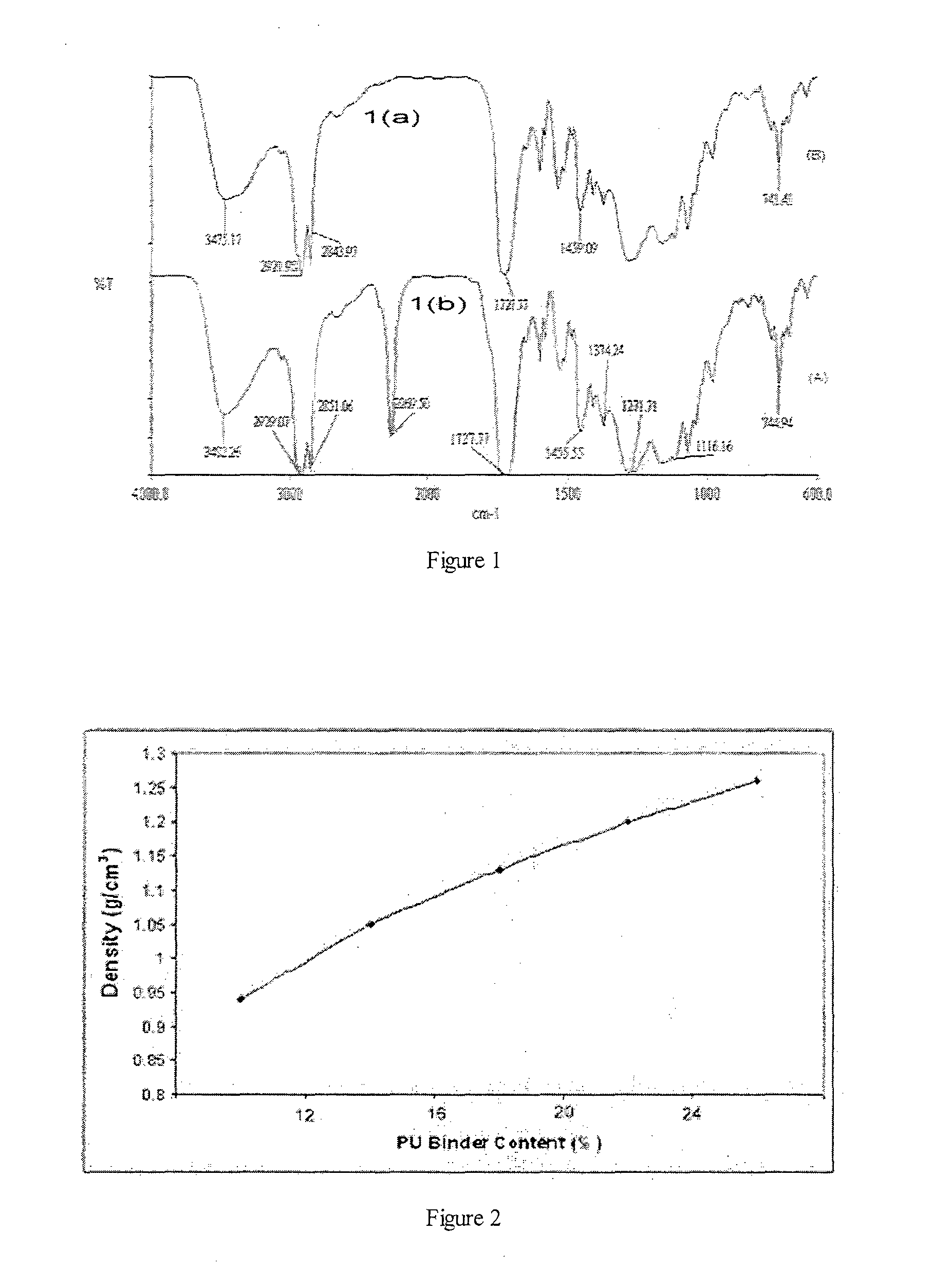

Fibreboard from agricultural wastes and a method for manufacturing the same

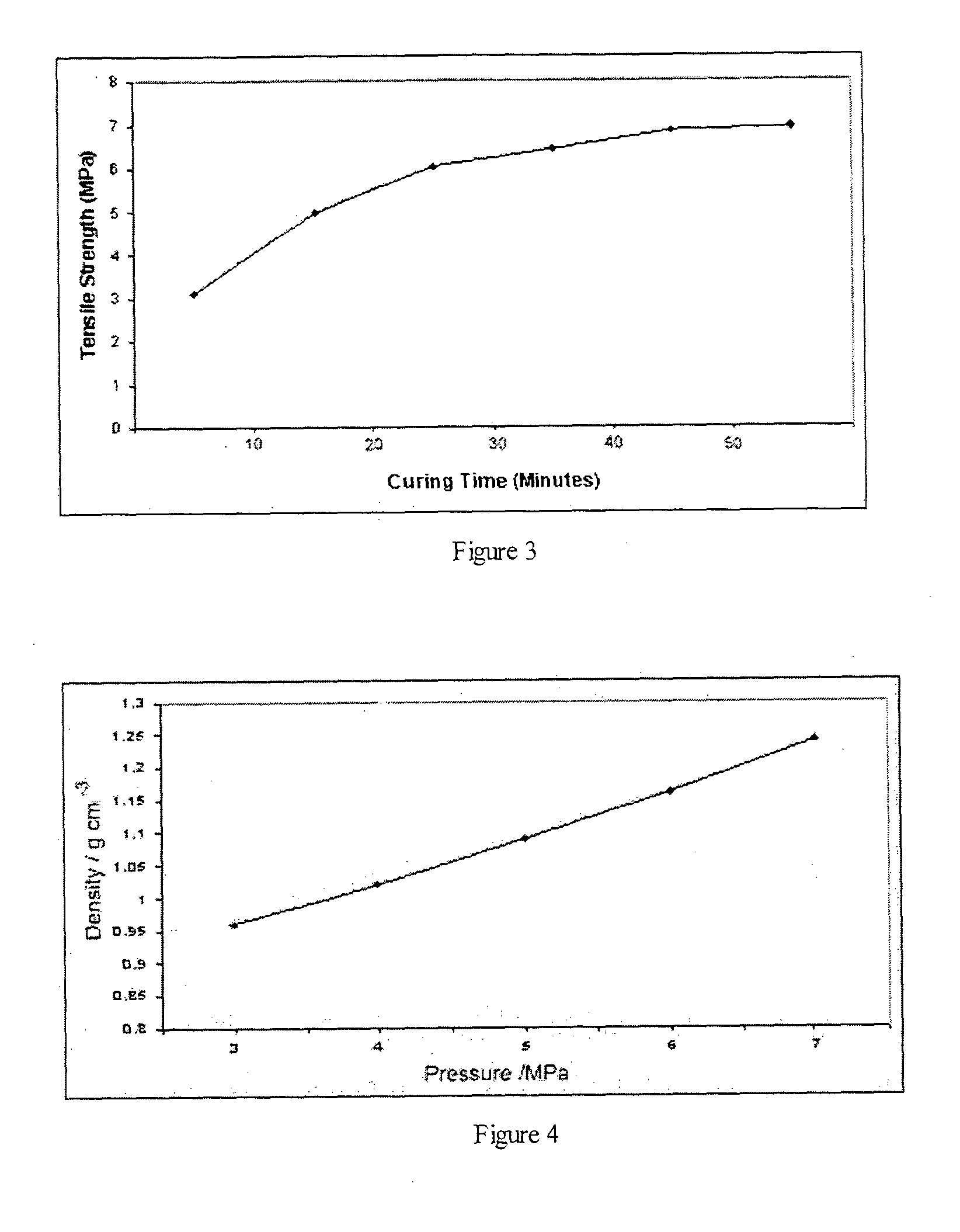

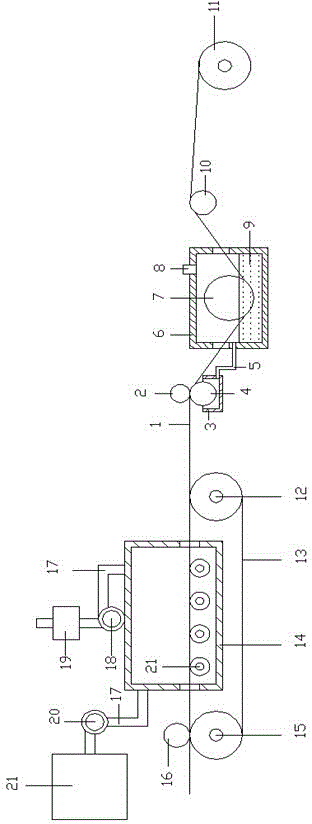

InactiveUS20120296014A1Low costEasy to usePolyureas/polyurethane adhesivesWood working apparatusPolyolPlant fibre

Owner:UNIVERSITI MALAYA +1

Completely-asbestos-free environment-friendly sealing plate and method for preparation thereof

Owner:浙江国泰萧星密封材料股份有限公司

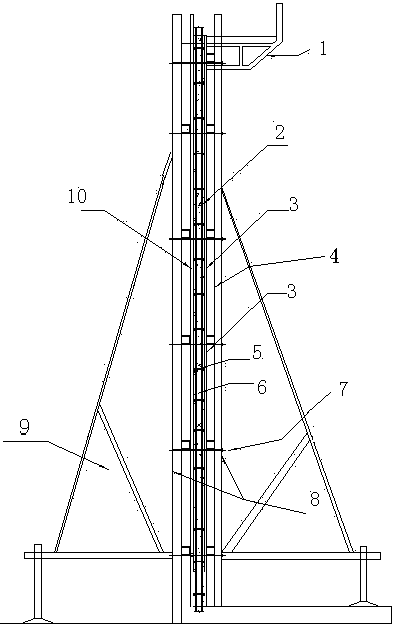

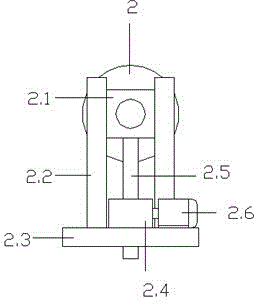

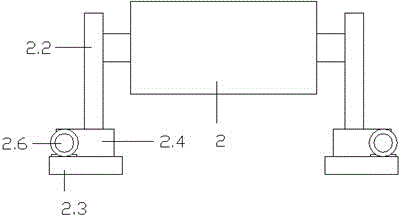

Resin coating and curing device for production of glass fiber board

Owner:SUQIAN TIANCAI GLASS FIBER

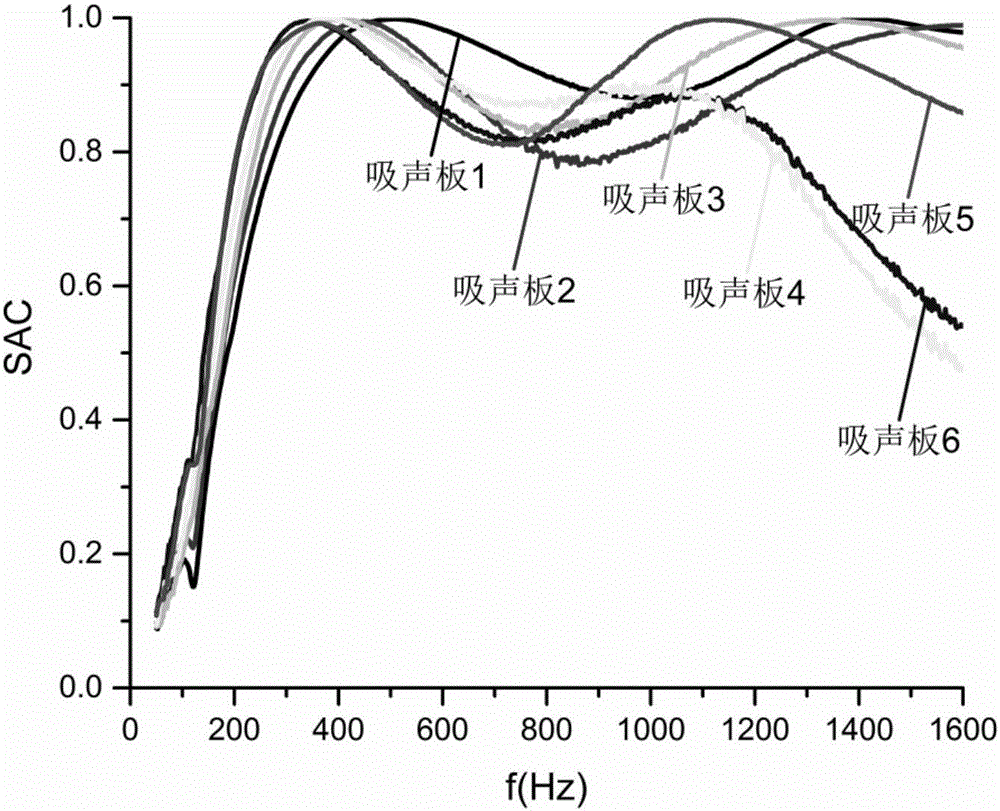

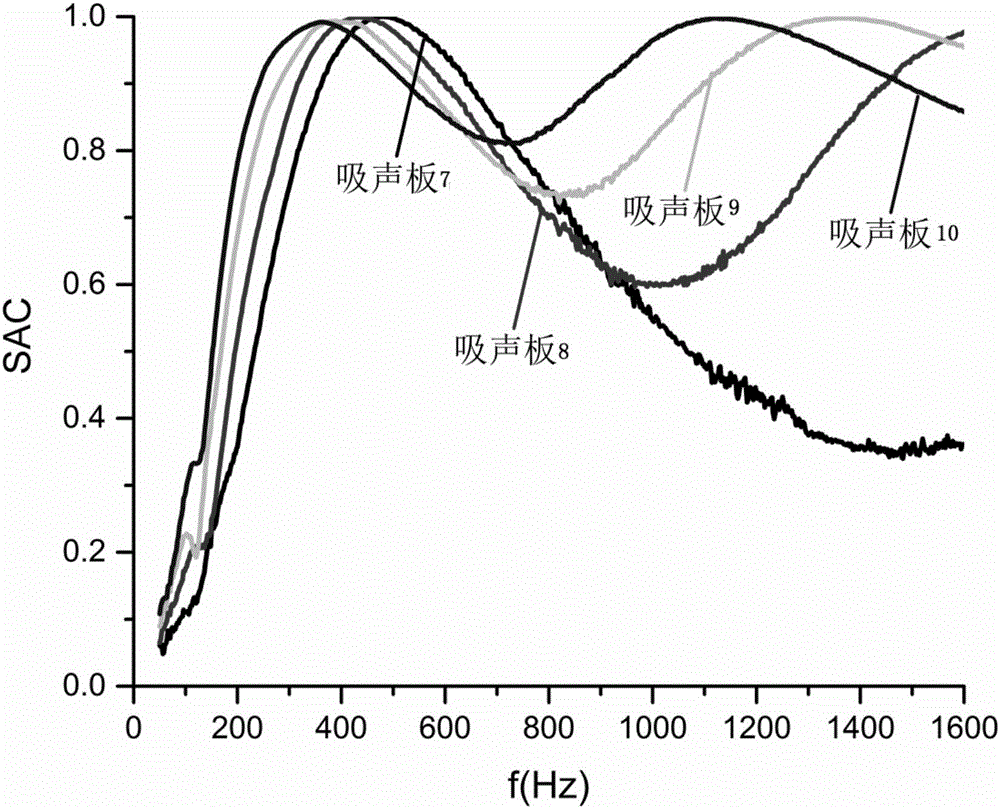

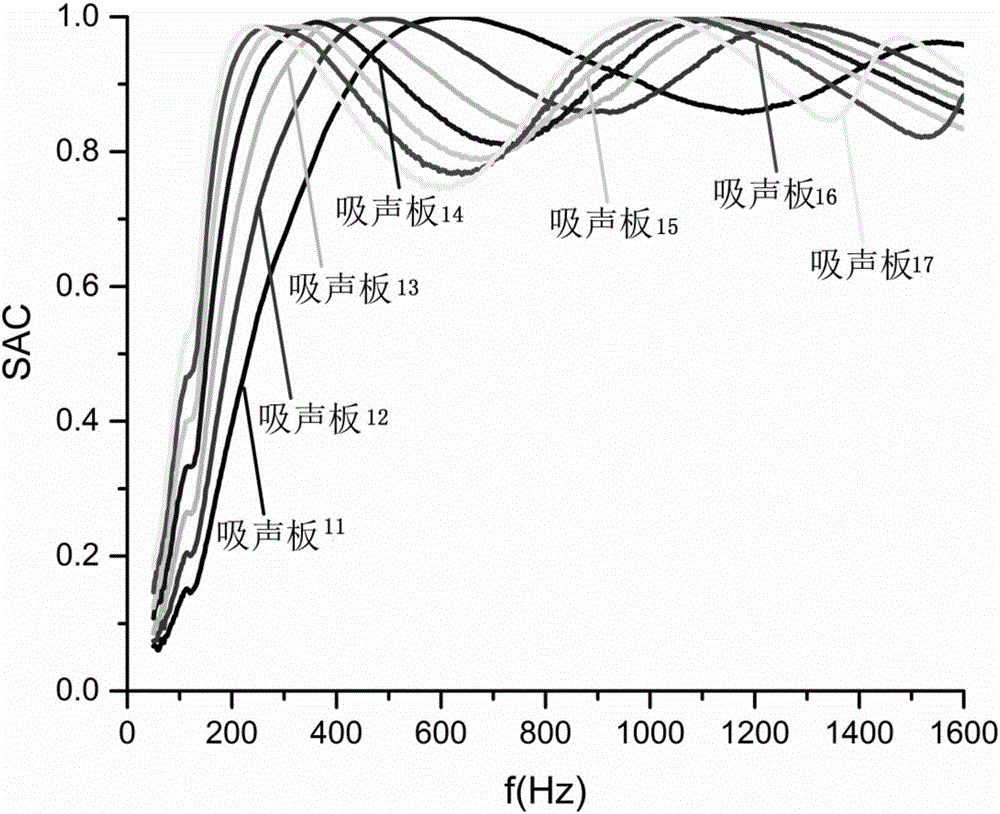

Resistance-double resonance composite sound absorbing profile

InactiveCN106703234AGood effectAdjustable acoustic performanceSound proofingFrequency spectrumResonance

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

An adhesive used for moisture-proof fiberboards

InactiveCN106554737AShort curing timeImprove waterproof and water resistanceNon-macromolecular adhesive additivesStarch adhesivesAdhesiveMoisture

Owner:SHIFANG MIDEE WOOD IND

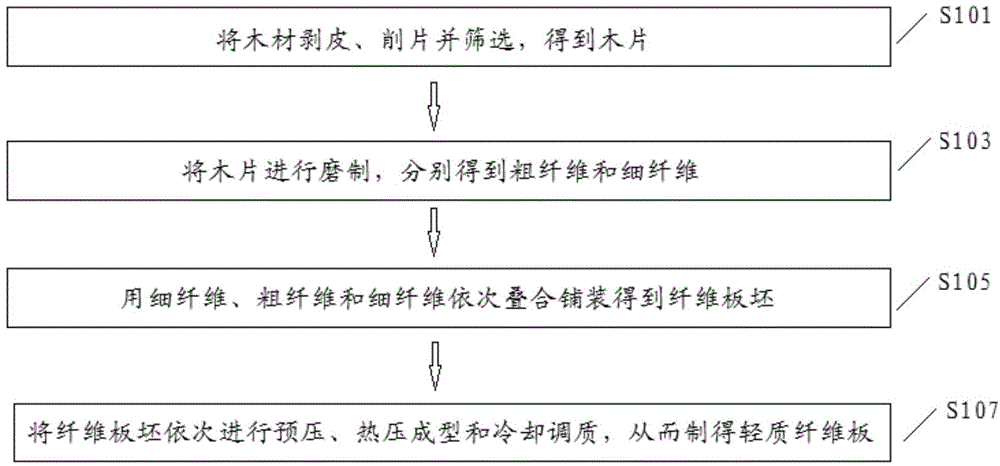

Method for manufacturing light-weight fiberboard

InactiveCN104669394AImprove mechanical propertiesLow densityWood working apparatusFlat articlesFiberSurface layer

Owner:CHINA FOMA GROUP

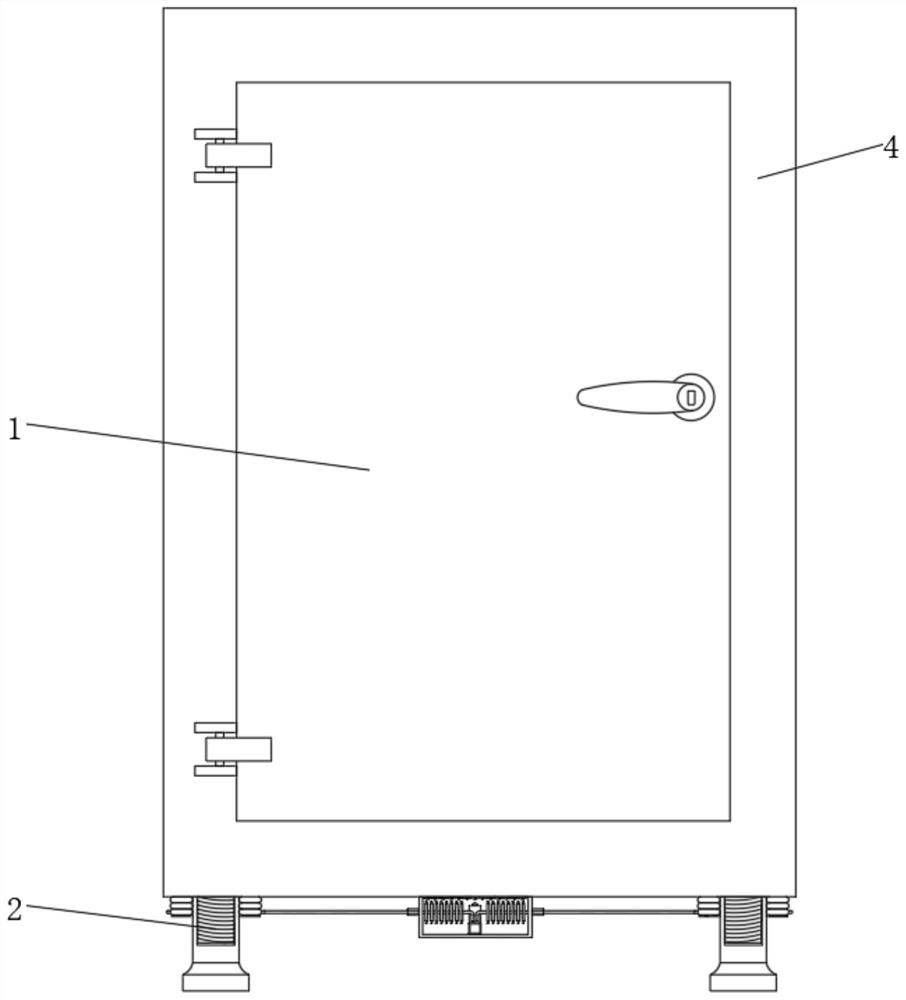

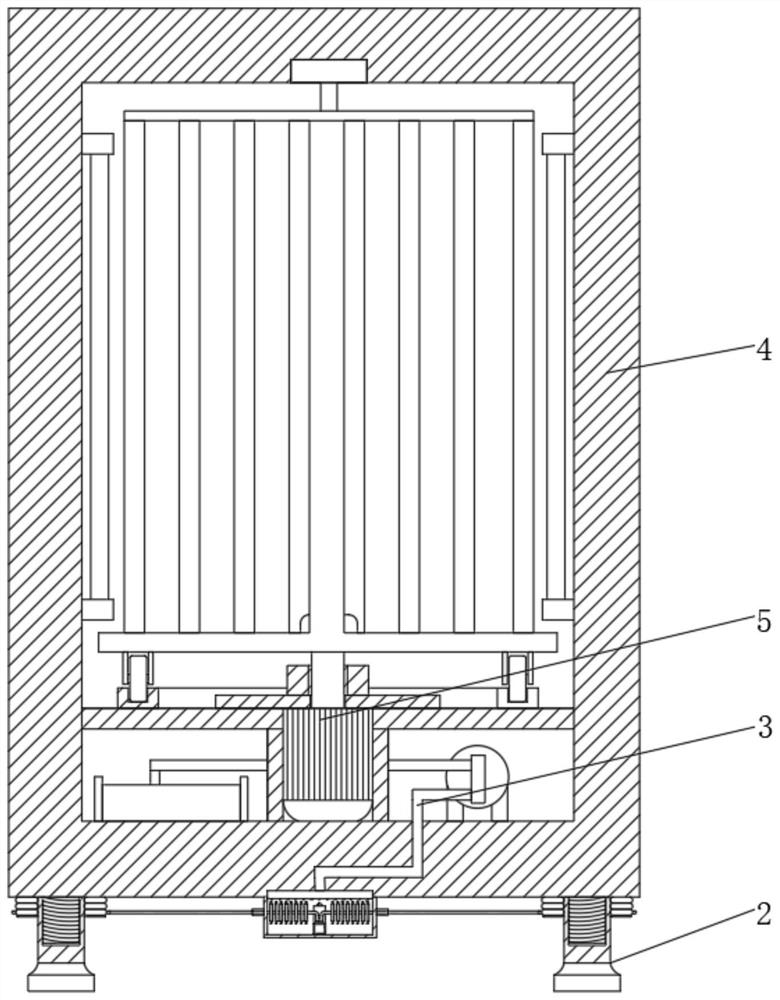

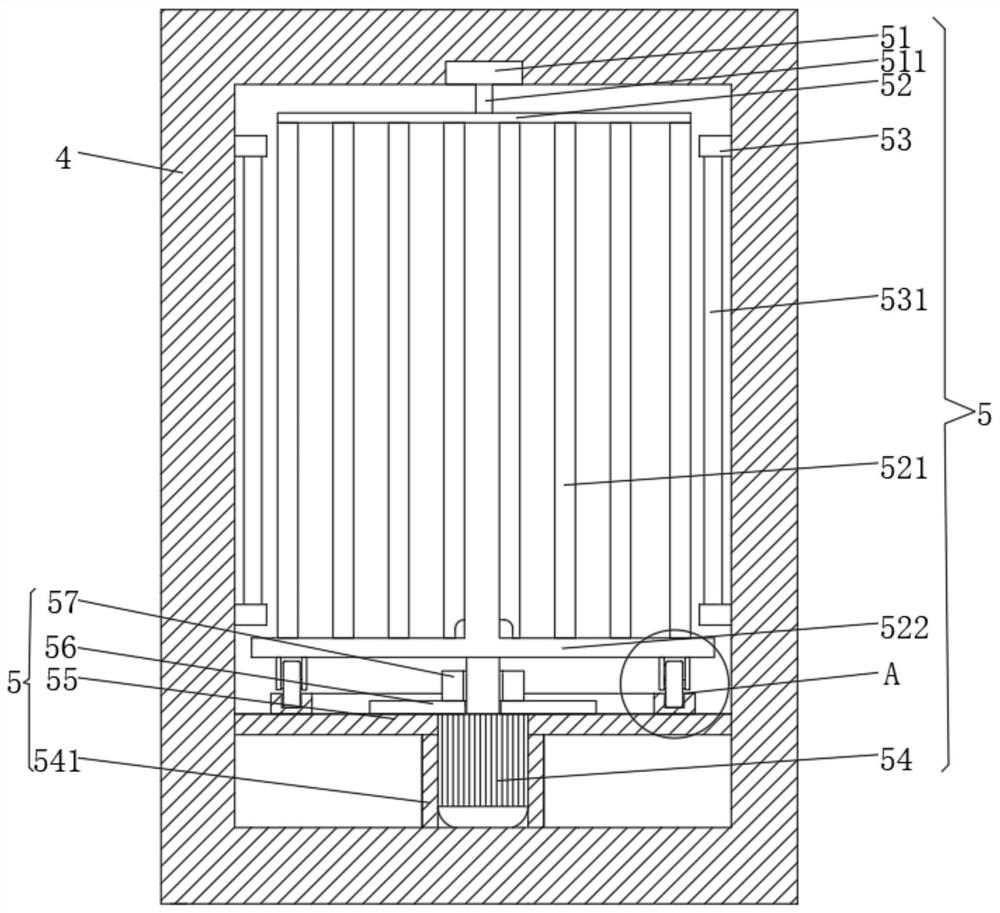

Heating fiber box type resistance furnace with rotating disc

InactiveCN112414117ASolve the problem of not being able to effectively achieve all-round heatingHeating evenlyFurnace typesFiberElectric machine

Owner:浙江德清蓝雅晶体纤维有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap