Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Ingot casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength Mg-Y-Ni-Mn alloy and manufacturing method thereof

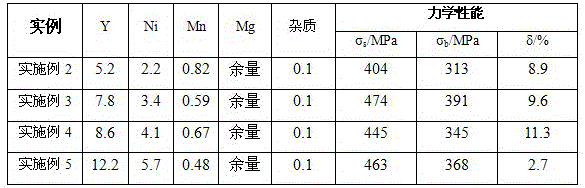

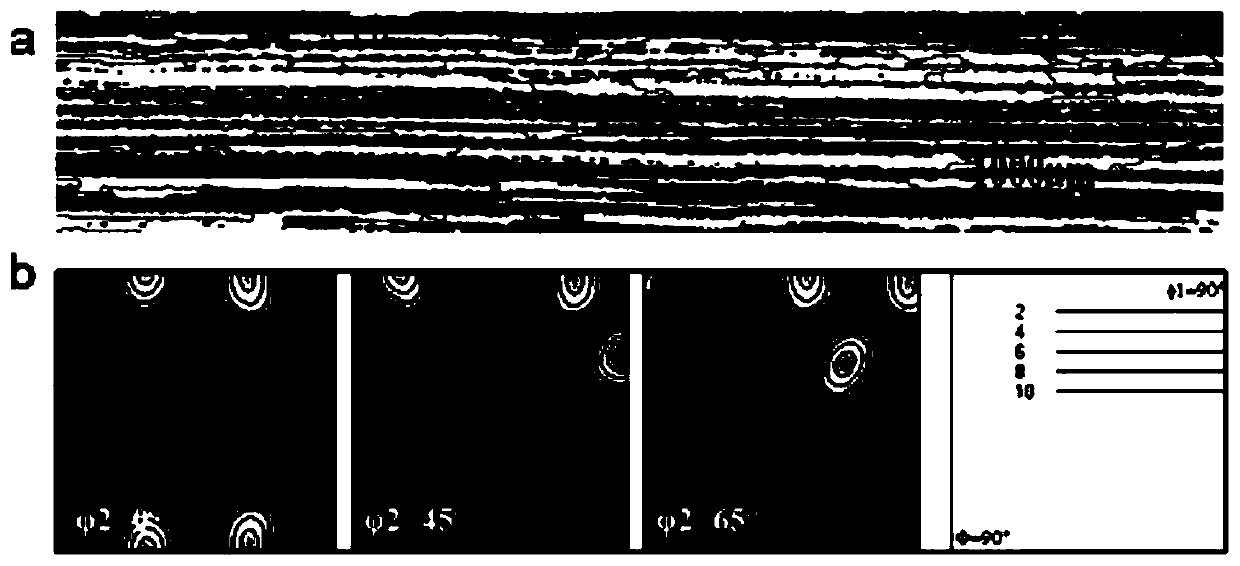

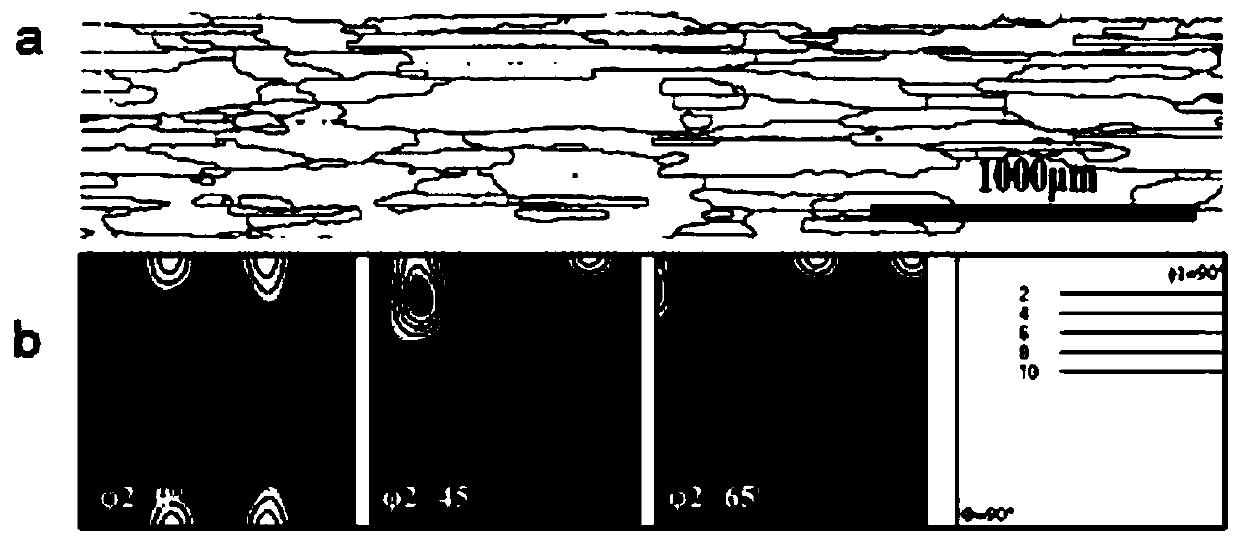

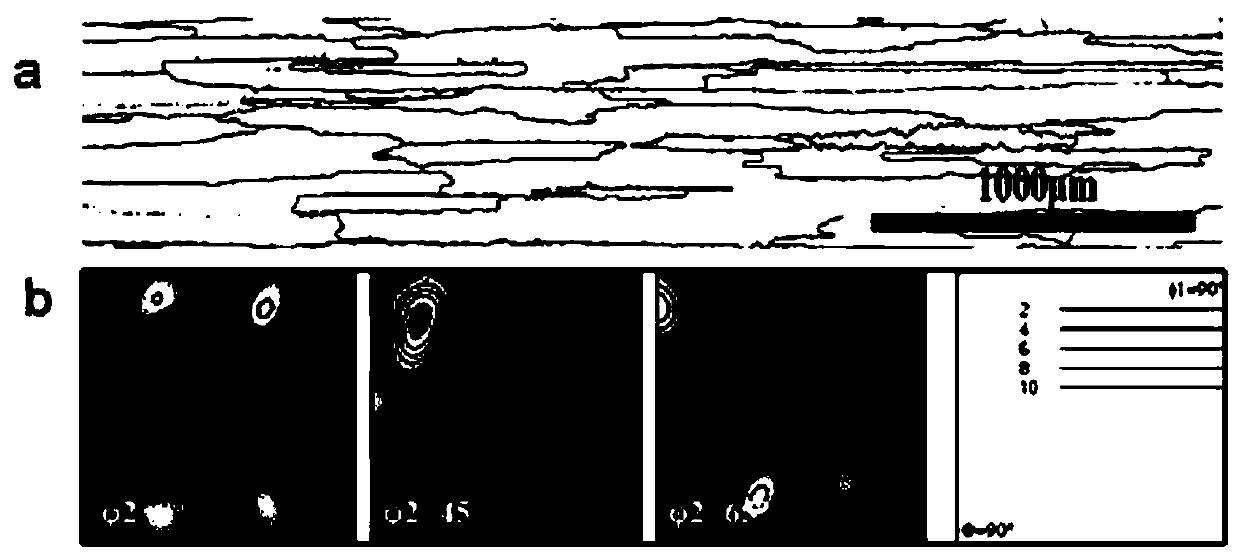

ActiveCN105543605ASignificant diffusion strengthening effectImprove acceleration performanceIngot castingRoom temperature

Owner:CHONGQING UNIV

Processing method for inhibiting recrystallization of aluminum lithium alloy

ActiveCN110791720ASolution treatmentIngot casting

Owner:CHONGQING UNIV OF ARTS & SCI

Rolling-cut type bilateral scissors and manufacturing method thereof

ActiveCN104233101AMeet normal cutting needsFurnace typesHeat treatment furnacesThick plateIngot casting

Owner:TAIER HEAVY IND

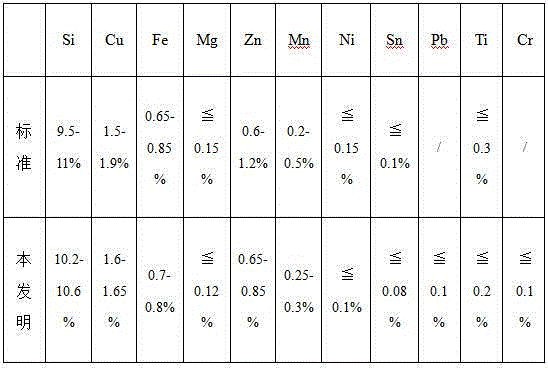

Method for improving performance of AlSi9Cu2 aluminum alloy ingot

Owner:帅翼驰新材料集团有限公司

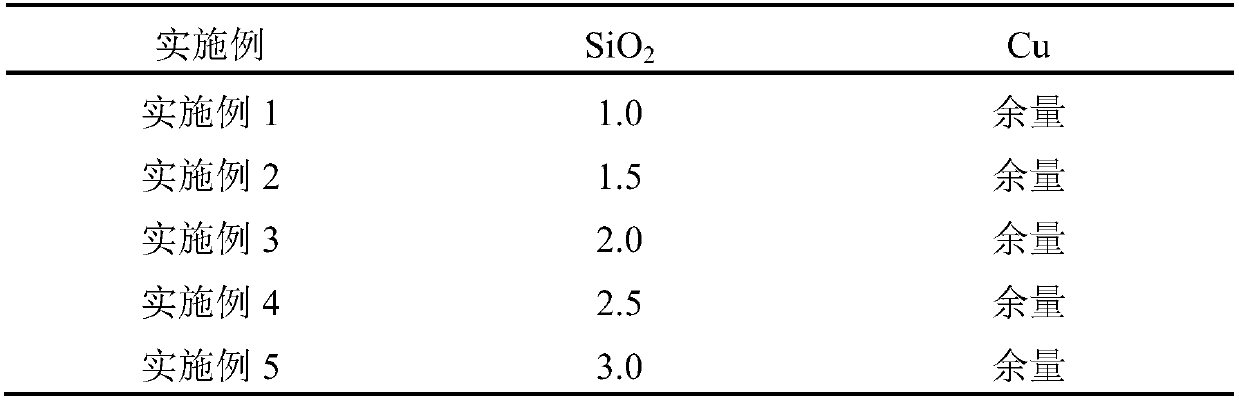

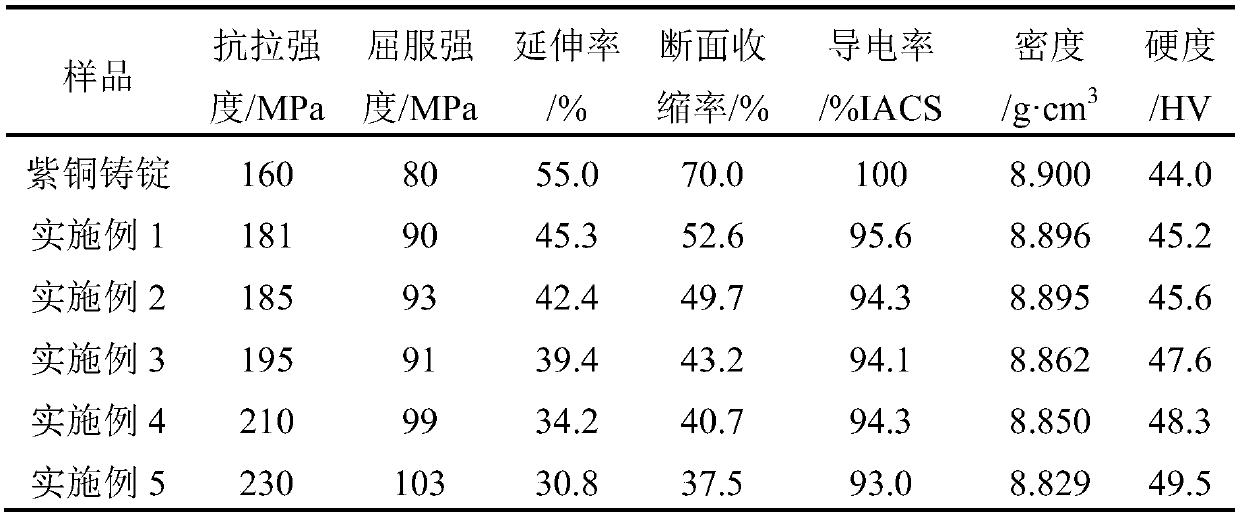

Silicon dioxide aerogel reinforced copper-based composite material and preparation method thereof

ActiveCN111378863ASilicon oxideIngot casting

Owner:GRIMAT ENG INST CO LTD

High-strength electric conduction copper rod material and preparation method

InactiveCN108950293AHigh strengthImprove conductivityConductive materialMetal/alloy conductorsNitrogen gasChromium

The invention discloses a high-strength electric conduction copper rod material and a preparation method. The preparation method comprises the following steps of selecting high-purity copper, iron, silicon, chromium, aluminum, silver, sodium, zinc, lead and nickel with the purities being 99.9% or more, and putting the raw materials into a melting furnace to be molten at the melting temperature being 1100 DEG C-1200 DEG C; continuously blowing nitrogen into the raw materials and stirring the raw materials for 25-35 min to change the raw materials into molten copper; pouring molten alloy into acasting mold cavity to conduct casting; taking out the cast raw materials from the casting mold cavity and cooling the raw materials through a cooling system to form an ingot casting; and conducting secondary heating on the cooled ingot casting and conducting thermal plastic deformation on the ingot casting. According to the preparation method the raw materials are selected and are subjected to smelting, pouring and quenching treatment to be manufactured into a high-strength electric conduction copper rod, and the problem that normal use of an instrument is affected due to the fact that most of copper rods in precise instruments are common copper rods is solved.

Owner:WUHU HAIYUAN COPPER IND CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap