Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Basalt fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Basalt fiber is a material made from extremely fine fibers of basalt, which is composed of the minerals plagioclase, pyroxene, and olivine. It is similar to fiberglass, having better physicomechanical properties than fiberglass, but being significantly cheaper than carbon fiber. It is used as a fireproof textile in the aerospace and automotive industries and can also be used as a composite to produce products such as camera tripods.

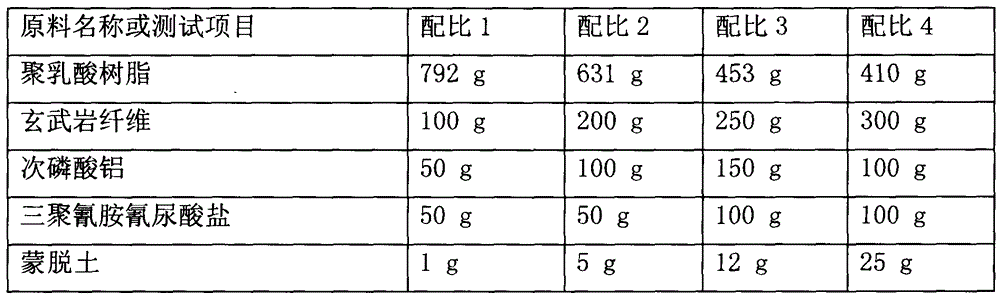

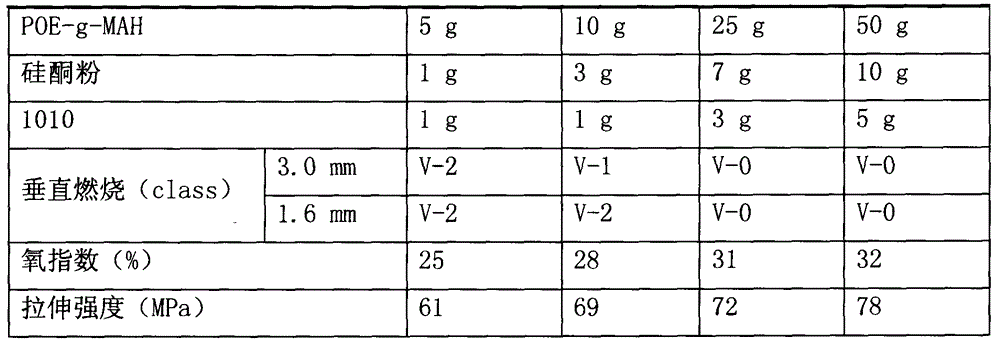

Halogen-free flame-retardant basalt fiber reinforced polylactic acid composite material and preparation method thereof

InactiveCN104312118AImprove flame retardant performanceImprove heat resistancePolymer scienceNitrogen

Owner:HEFEI UNIV

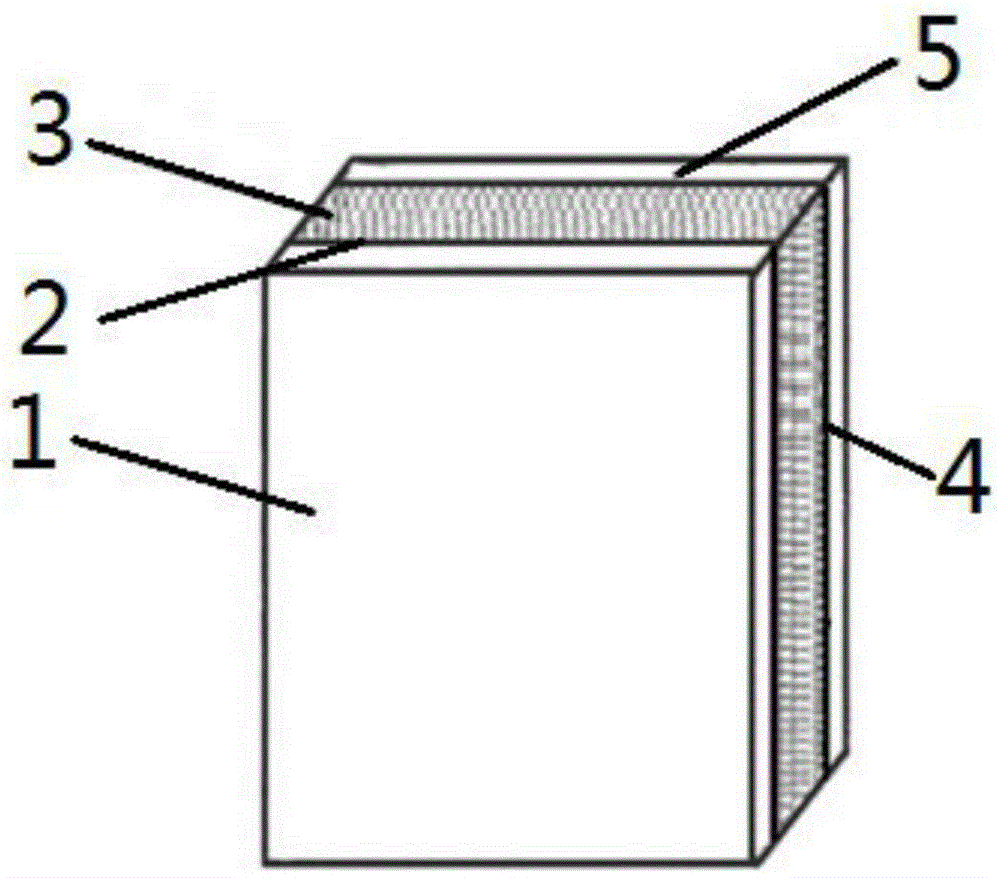

Composite material for producing PVC plastic steel section and preparation method thereof

InactiveCN107266823AImprove mildew resistanceImprove high temperature resistancePlasticizerMagnesium stearate

The invention belongs to the technical field of door and window materials, and provides a composite material for producing PVC plastic steel sections and a preparation method thereof, wherein the composite material comprises the following raw materials in parts by weight: 160-190 parts of PVC, 2-6 parts of magnesium stearate, 11-13 parts of Phenolic Resin, 15-25 parts of polyethylene wax,-2-9 parts of sodium silicate, 1-4 parts of basalt fiber, 1.2-3.5 parts of forsterite powder, 2-4 parts of an anti-aging agent, 0.2-3.1 parts of a plasticizer, 0.4-2 parts of an additive and 1-2 parts of nano silver. The composite material uses the PVC as a main material, the anti-aging agent is compounded to improve the anti-aging properties of the material, the nano silver is compounded to improve the mildew resistance of the material, the basalt fiber is compounded to improve the mechanical properties and the anti-aging properties of the material, the forsterite powder is compounded to improve the high-temperature resistance, the plasticizer is compounded to make the mechanical properties of the material good, and the aging rate is reduced.

Owner:HEFEI YIZHI DOORS & WINDOWS CO LTD

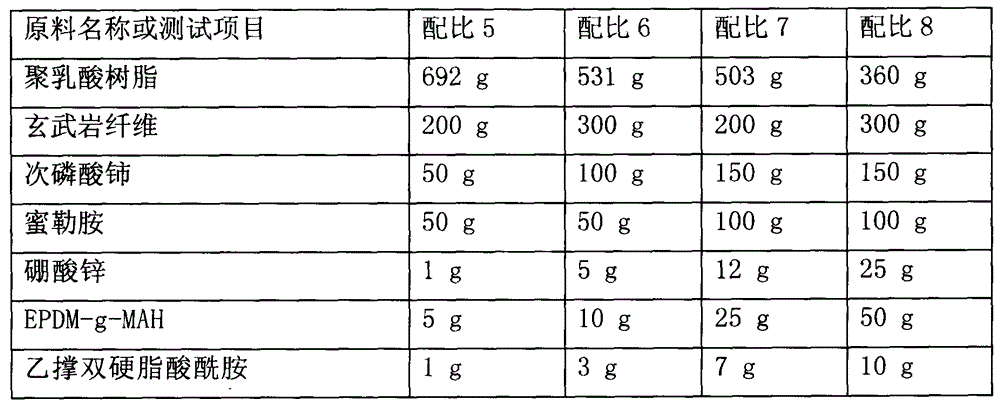

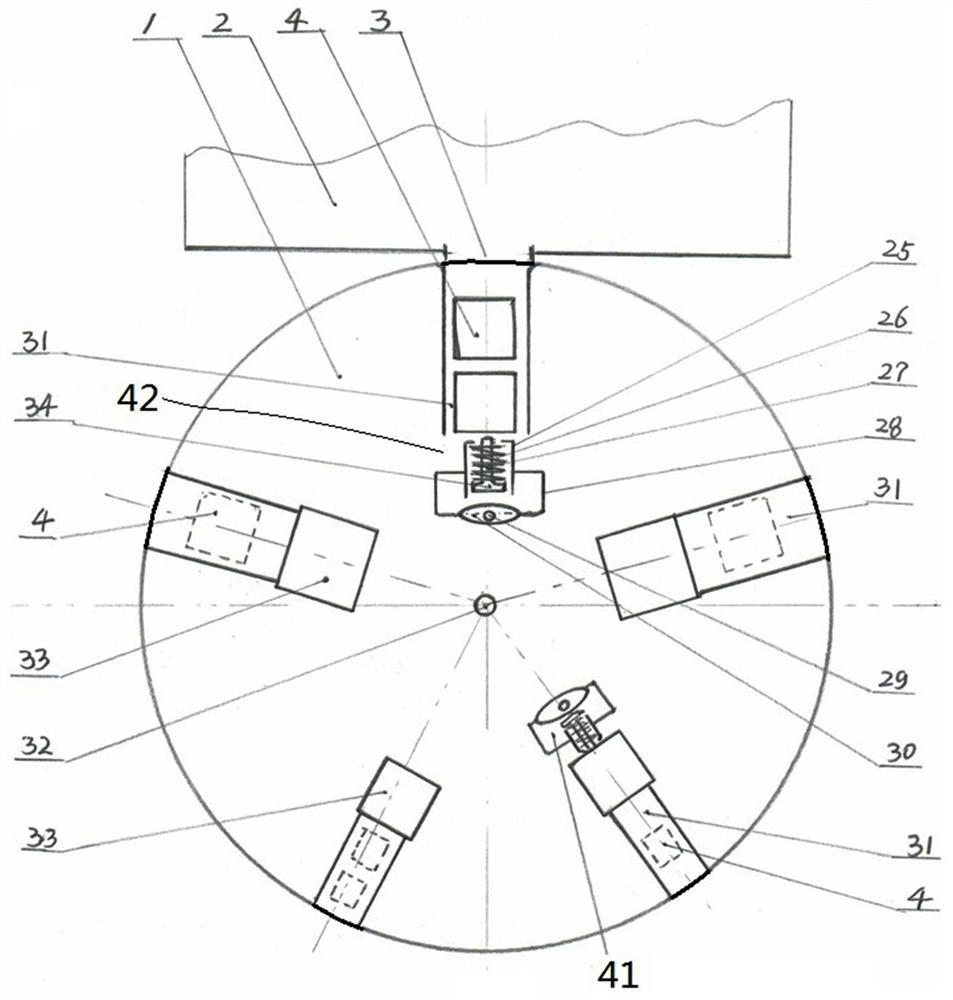

Rotating disc type automatic basalt fiber feeding device

PendingCN112047080AAutomatic and accurate deliveryReduce labor intensityConveyor partsEngineeringBasalt fiber

Owner:HENAN VOCATIONAL & TECHN COLLEGE OF COMM +1

A kind of carbon fiber composite bulletproof plate and preparation method thereof

ActiveCN104197786BShorten the timeIncrease productivityLaminationLamination apparatusEnergy absorptionFiber-reinforced composite

Owner:SHANDONG UNIV

Preparation method for temperature-resistant reinforced wood-plastic composite material

InactiveCN108948763AHigh tensile strengthHigh modulus of elasticity in tensionUltimate tensile strengthBasalt fiber

The invention discloses a preparation method for a temperature-resistant reinforced wood-plastic composite material. The preparation method comprises the following steps: (1) preparation of reinforcedbasalt fiber; (2) weighing and mixing of raw materials for a wood-plastic composite material; and (3) extrusion molding. Through special improvement treatment, the preparation method for the wood-plastic composite material provided by the invention significantly improves mechanical properties like tensile strength, tensile elastic modulus, bending strength, bending modulus and impact strength ofa material, reinforces corrosion resistance, temperature resistance and aging resistance of the material, and has good comprehensive use quality, long service life and great promotion and applicationvalues and market competitiveness.

Owner:王伟

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap