Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14 results about "Carbon fiber composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

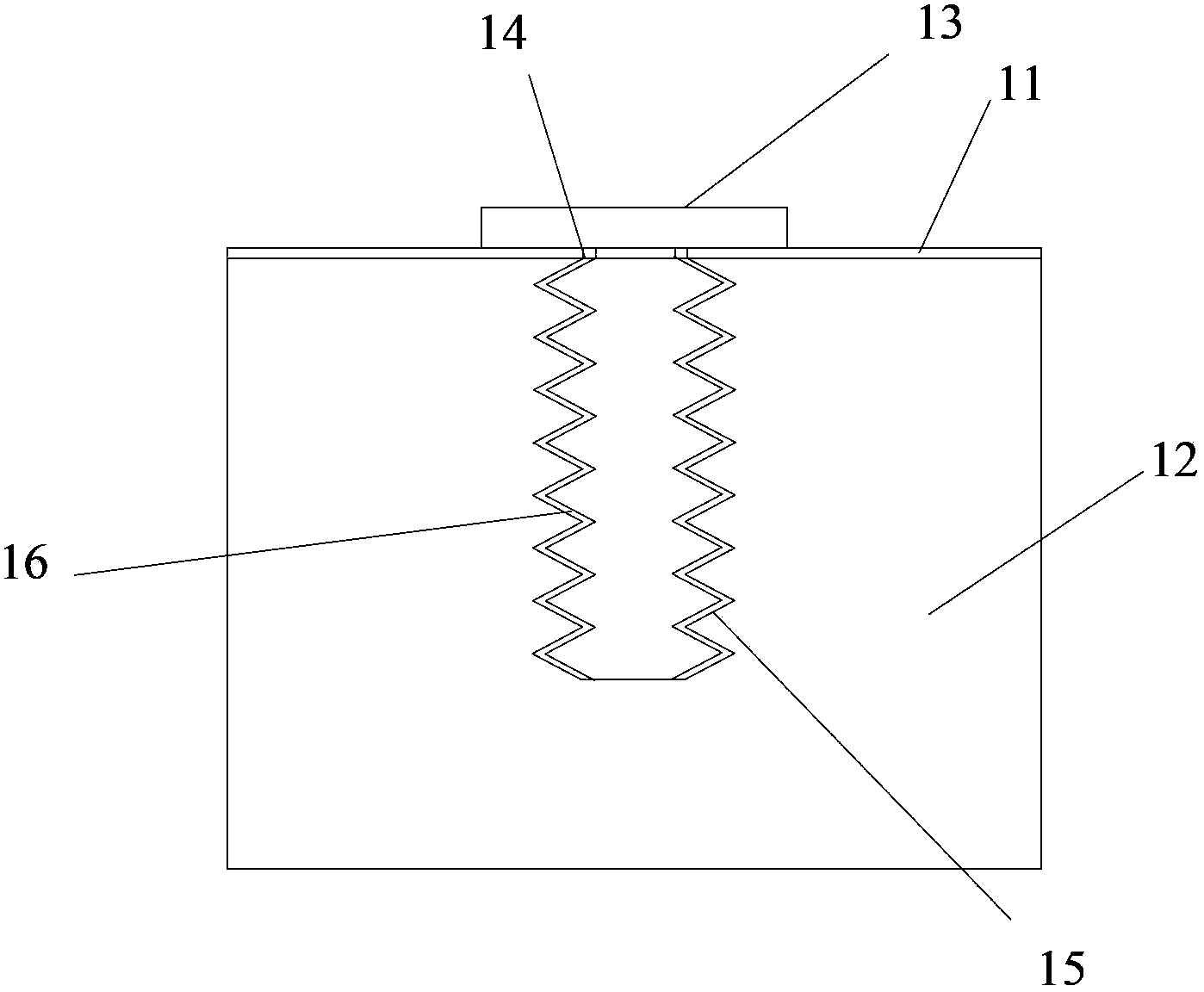

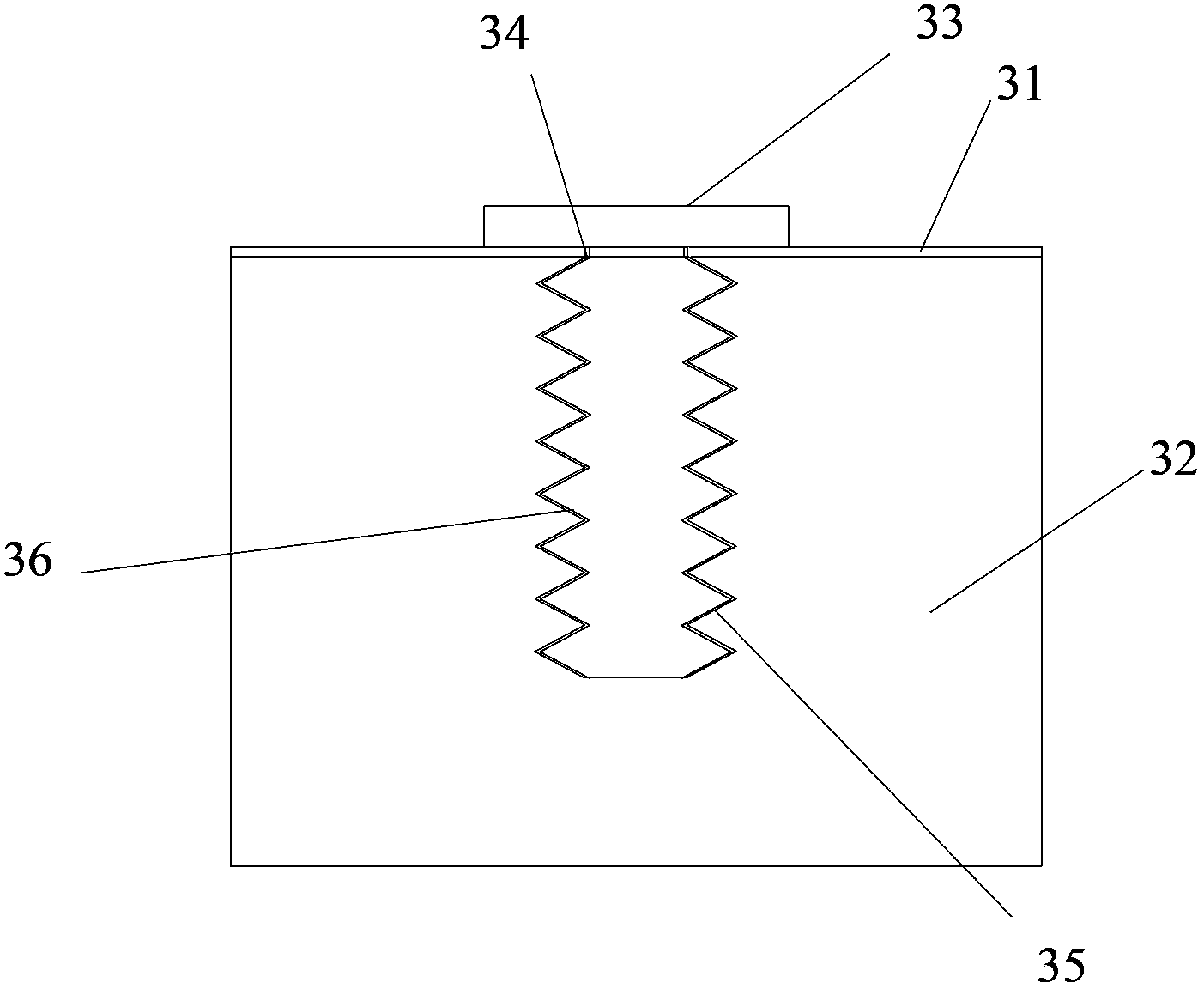

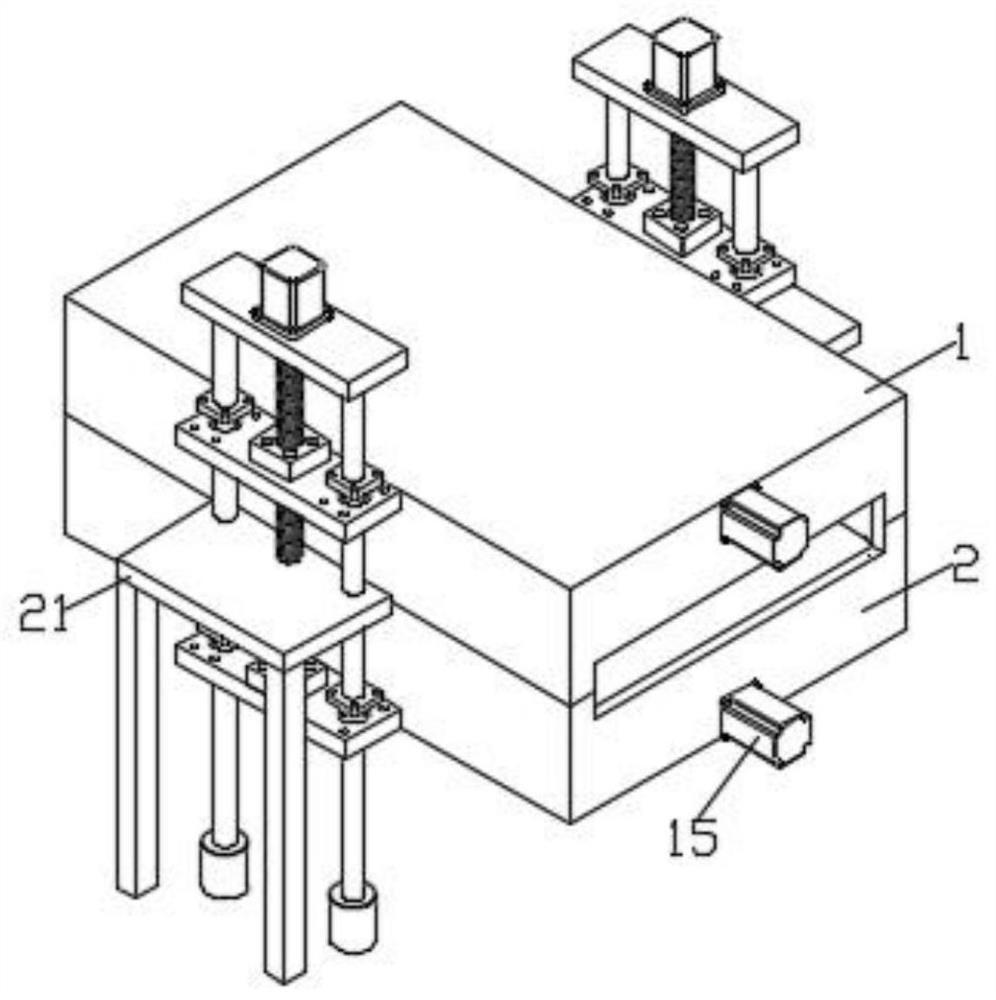

Device and method for detecting debonding defects of carbon fiber composite material

ActiveCN106596714AUniform excitation magnetic fieldAvoid missing detectionMaterial resistanceMaterial magnetic variablesMagnetic fieldCarbon fiber composite

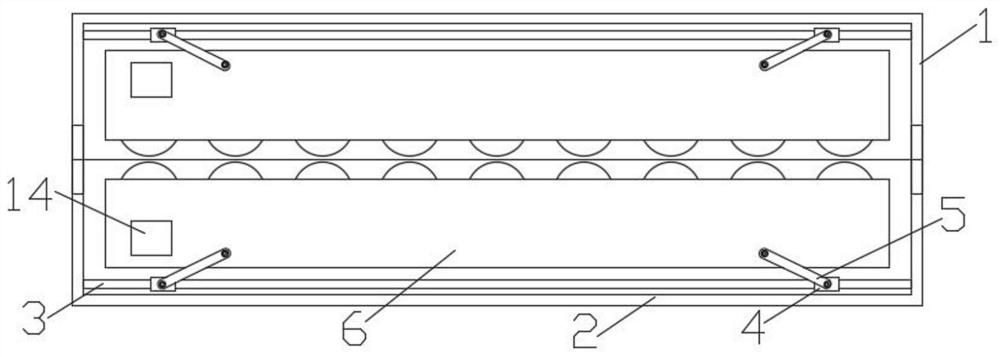

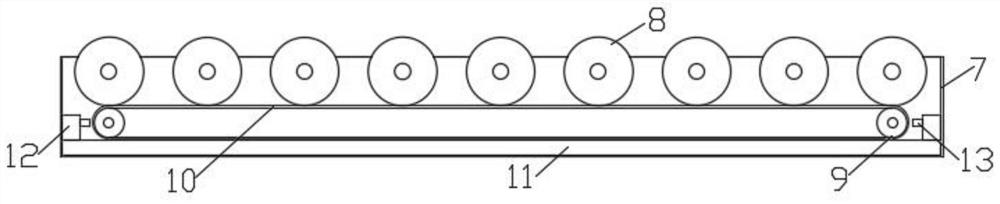

The invention discloses a device and a method for detecting debonding defects of a carbon fiber composite material. The device comprises a stimulating component and a plurality of detecting components, wherein the stimulating component is used for generating a stimulating magnetic field and comprises a cuboid magnetic core and an exciting coil winding the cuboid magnetic core; the detecting components are used for detecting induced magnetic fields influenced by a disturbed magnetic field and are uniformly arrayed below the stimulating component, the arraying direction of the detecting component is parallel with long sides of the cuboid magnetic core, and the detecting components are distributed opposite to the stimulating component; and a detecting coil is located between the exciting coil and a to-be-detected carbon fiber composite material during the detection. According to the detecting device and method provided by the invention, the rapid and real-time local detection can be realized, and furthermore, the detection range is not influenced by the space size of the detecting device.

Owner:NANCHANG HANGKONG UNIVERSITY

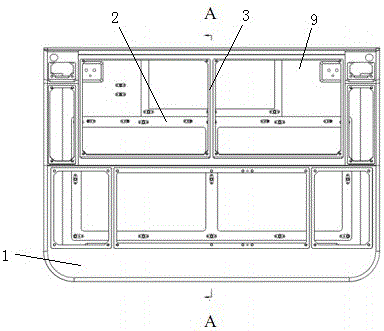

Intelligent carbon fiber composite board

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

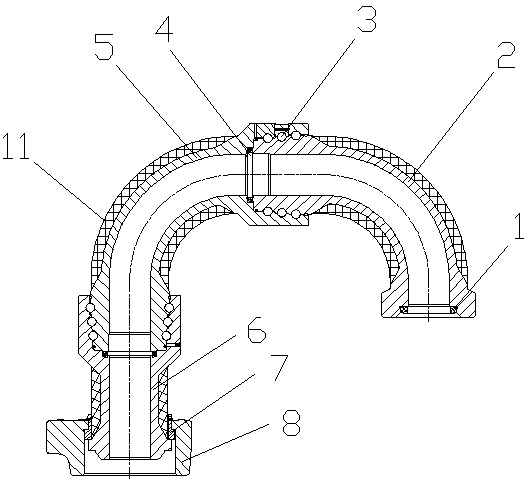

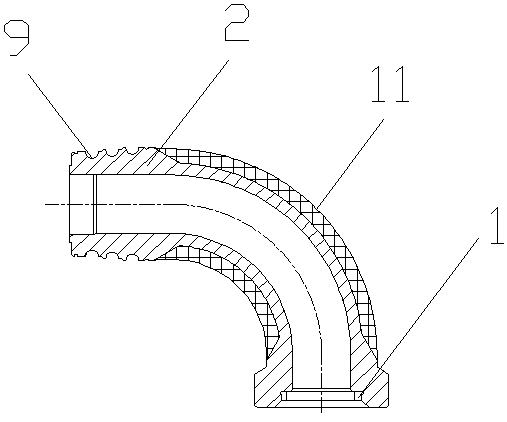

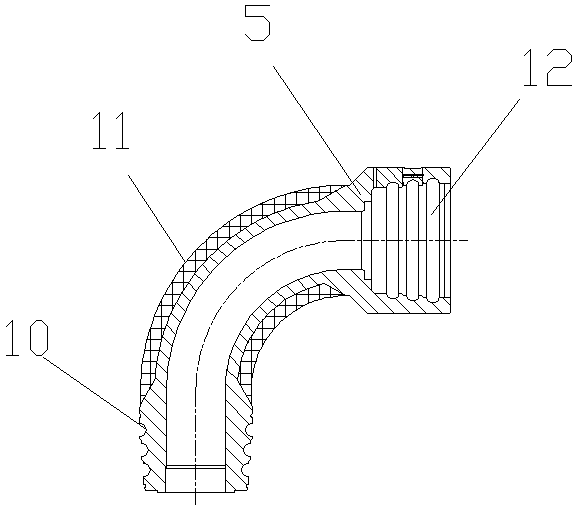

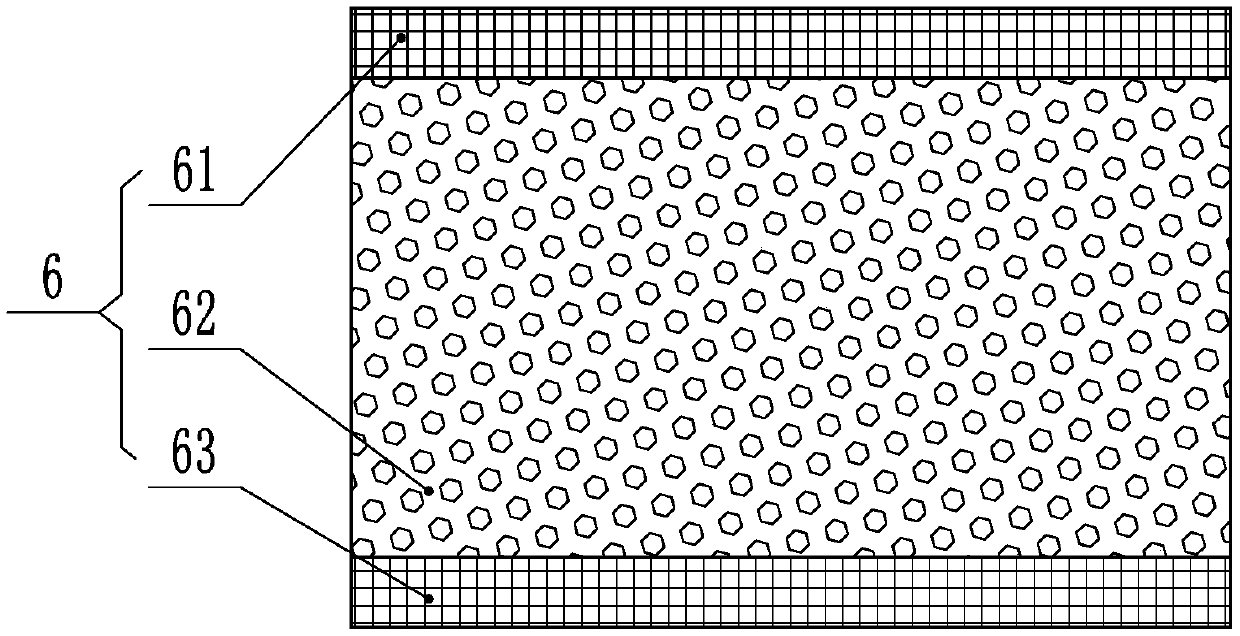

Carbon fiber composite material enhanced ultrahigh pressure movable bend

InactiveCN108050331AEasy to operateHigh tensile strengthCouplingsSiphonsUltra high pressureEngineering

Owner:中石化四机石油机械有限公司 +1

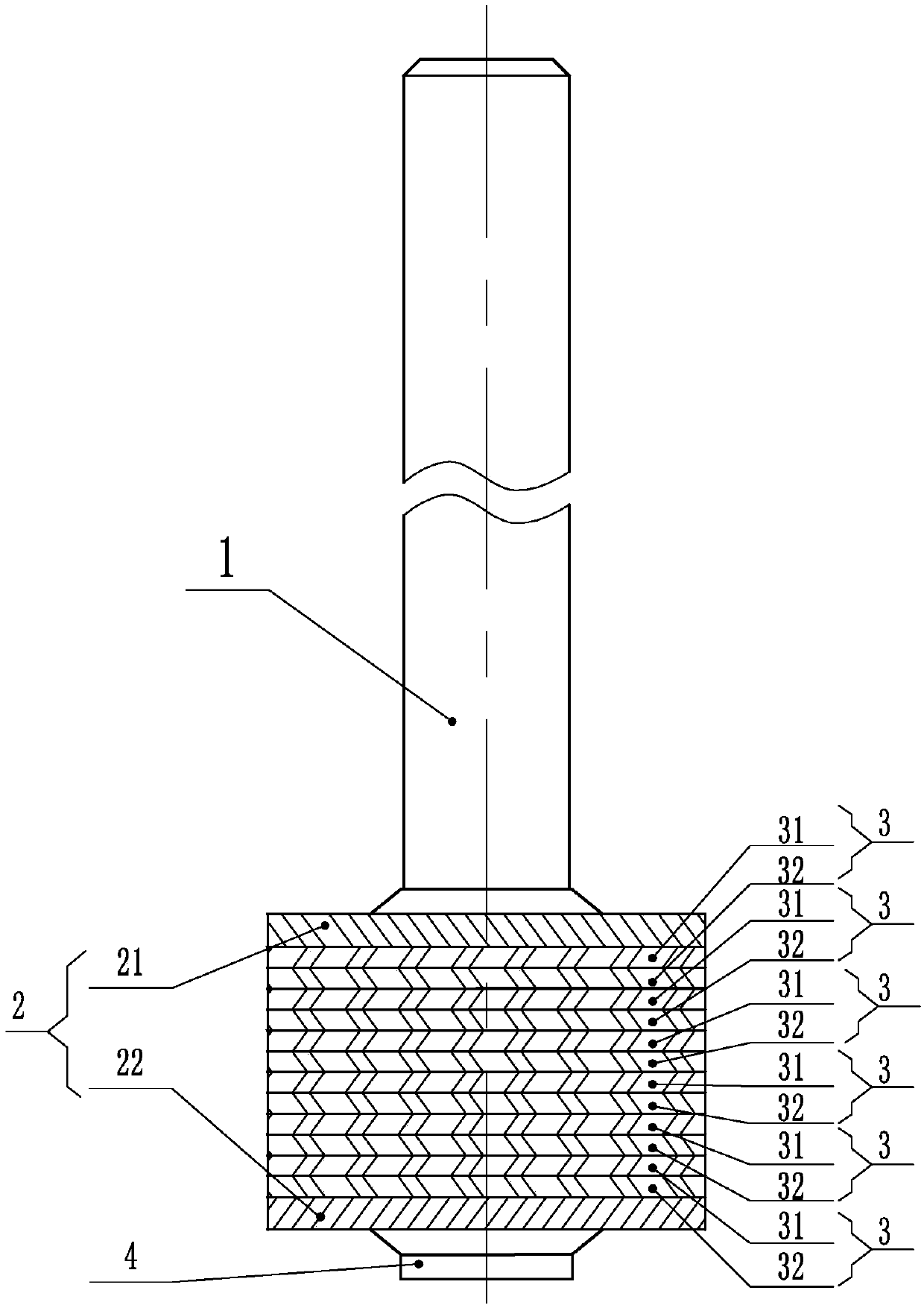

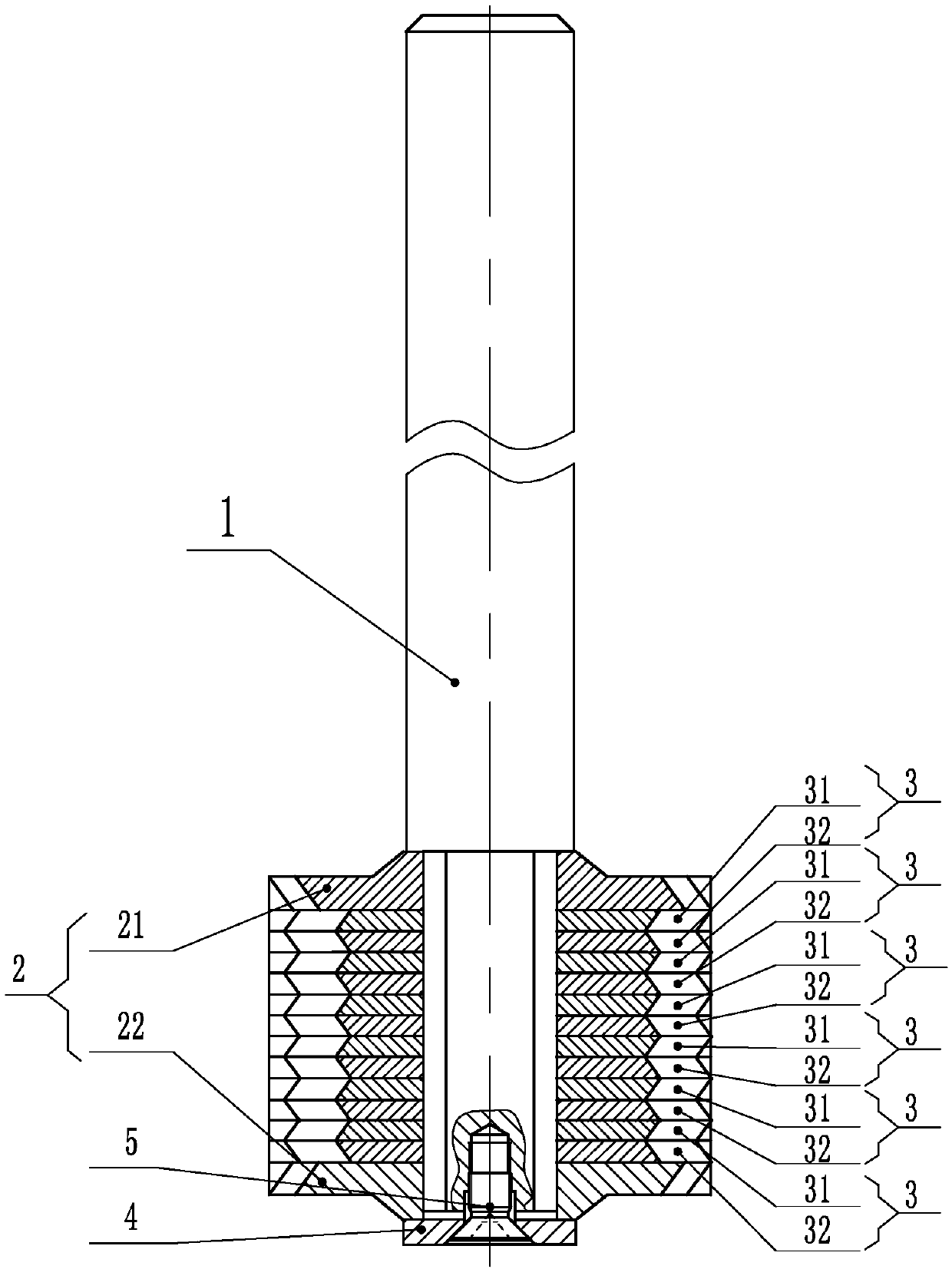

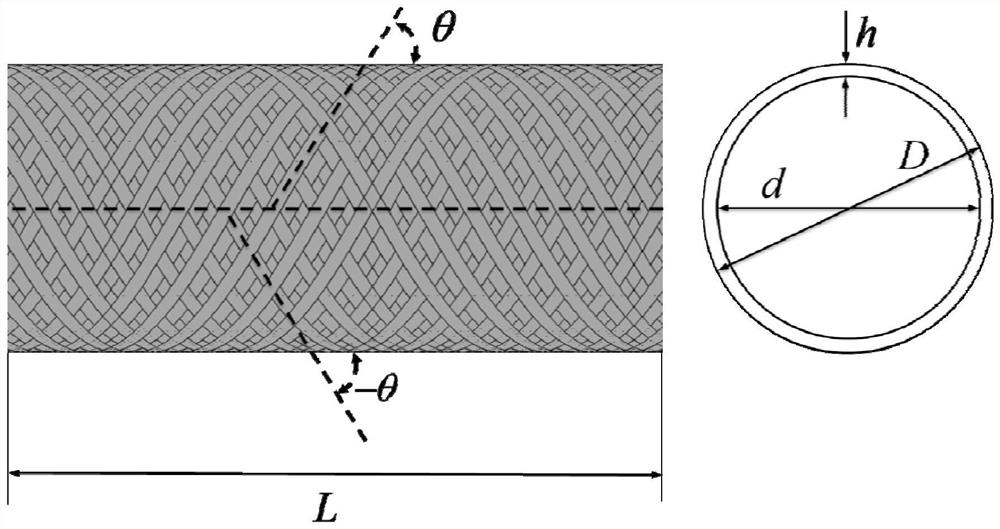

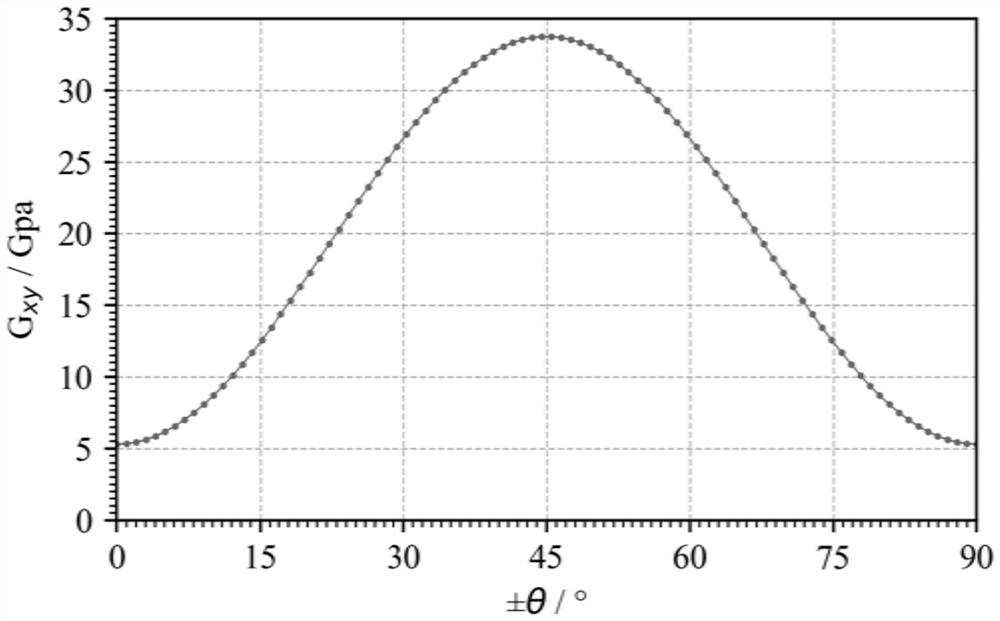

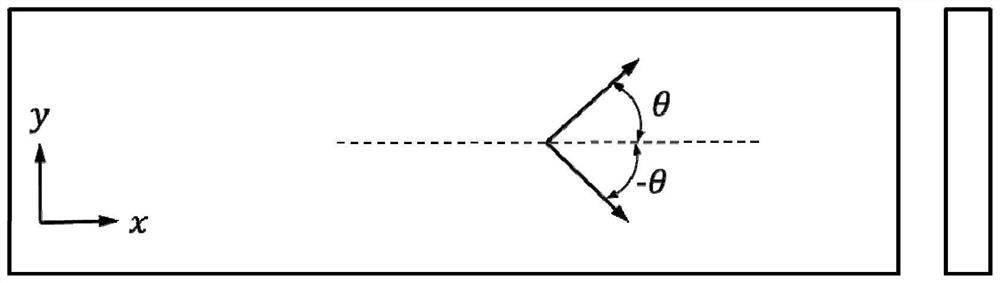

Method for designing and checking torsional rigidity of carbon fiber composite winding pipe fitting

PendingCN114297839ADesign optimisation/simulationComplex mathematical operationsCarbon fiber compositeTorsional rigidity

Owner:西安科为智通复合材料技术有限公司

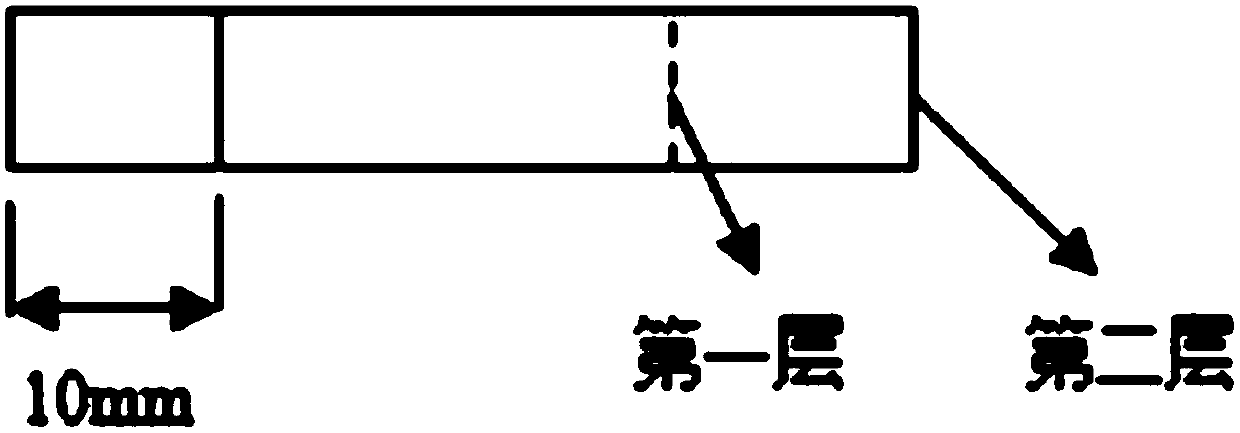

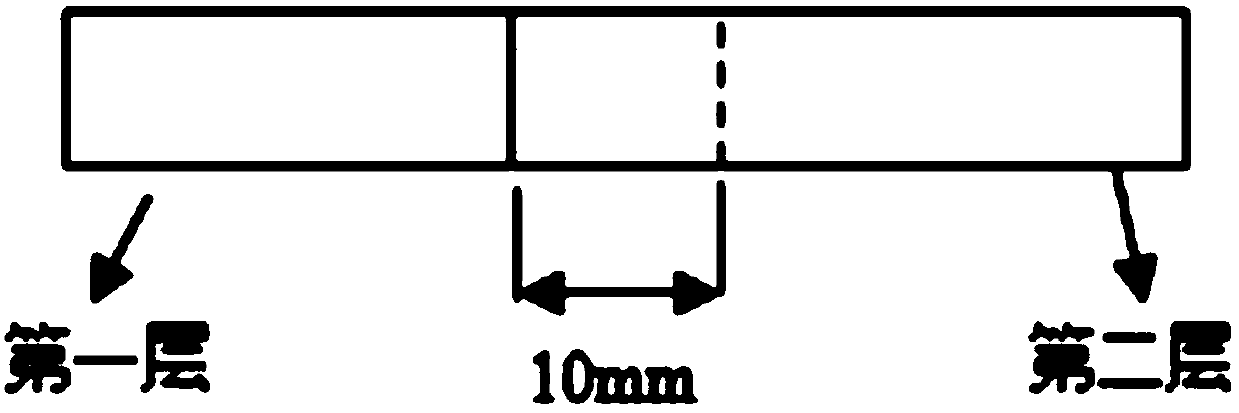

Carbon fiber cloth and pasting method of carbon fiber composite material composed of carbon fiber cloth

Owner:镇江兴谦新材料技术有限公司

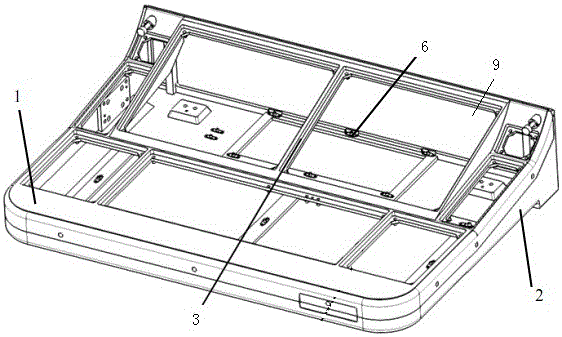

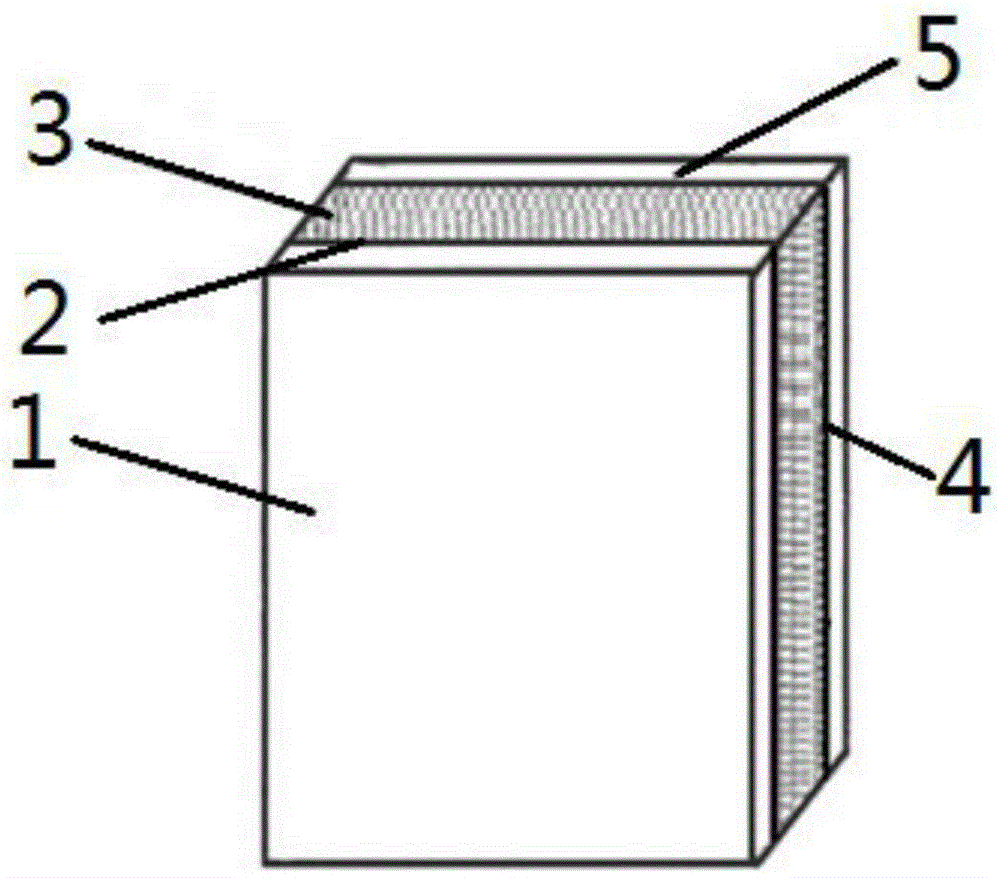

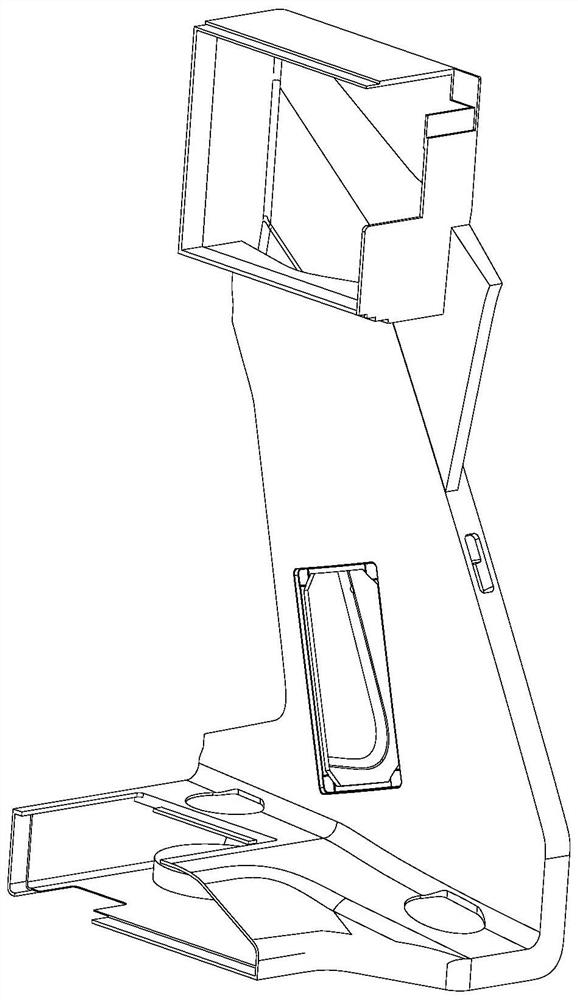

Carbon fiber composite operation skeleton of display and control console

InactiveCN106548810AMeet structural strengthMeet the stiffnessInstrument housingAdhesiveComputer module

Owner:HENGSHEN

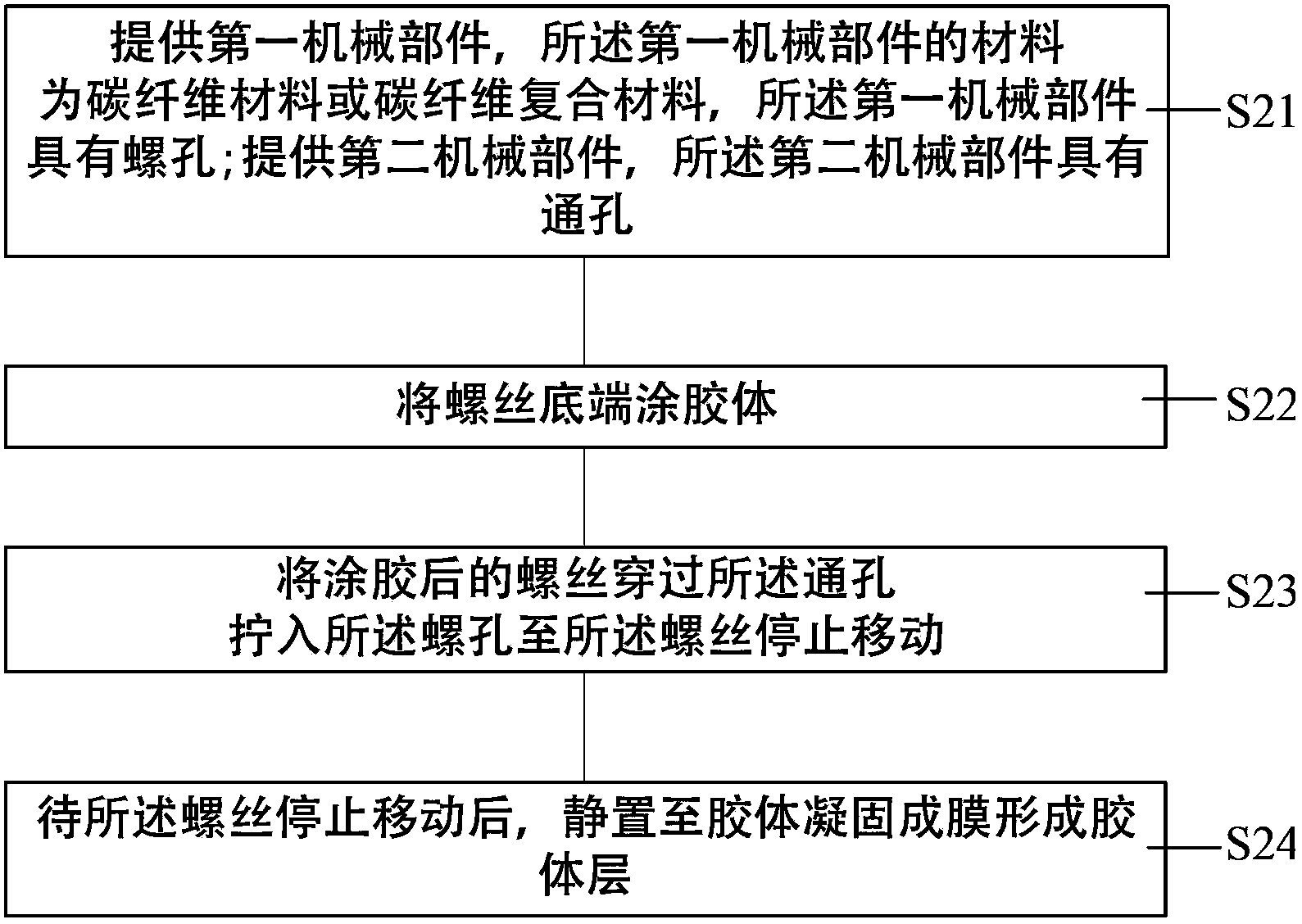

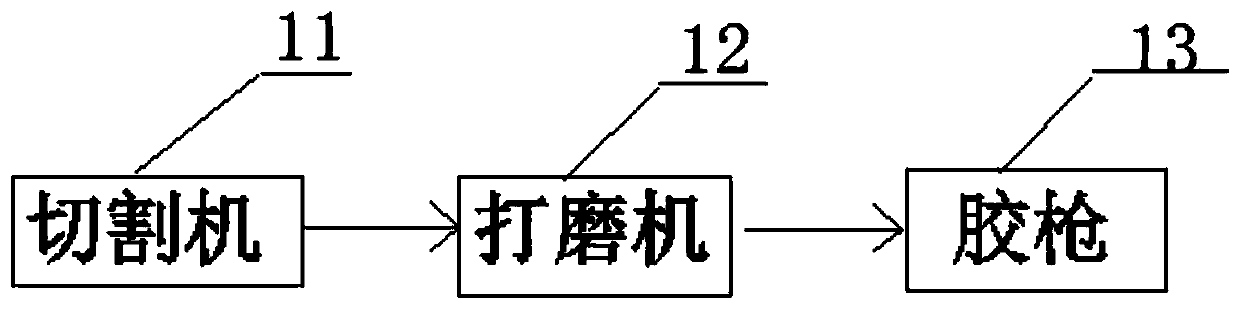

Assembling method of mechanical parts

Owner:宁波江丰复合材料科技有限公司

A kind of carbon fiber composite bulletproof plate and preparation method thereof

ActiveCN104197786BShorten the timeIncrease productivityLaminationLamination apparatusEnergy absorptionFiber-reinforced composite

Owner:SHANDONG UNIV

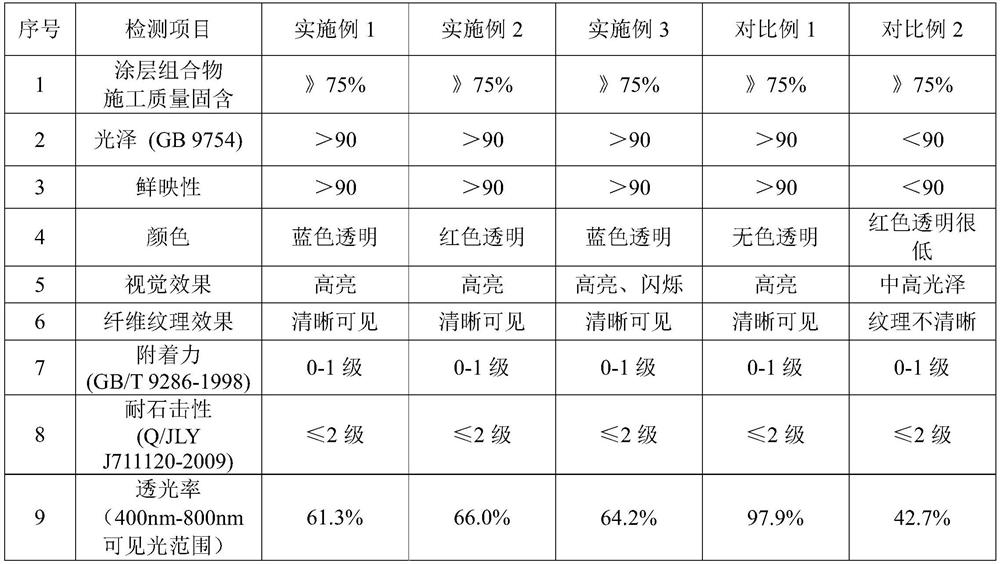

High-solid-content colored transparent coating composition as well as preparation method and application thereof

PendingCN113930143APolyurea/polyurethane coatingsSpecial surfacesWeather resistanceCarbon fiber composite

Owner:NIPPON PAINT CHINA

Carbon fiber composite material for main rotor of helicopter and preparation method of composite material

Owner:安徽省飞腾航空科技有限公司

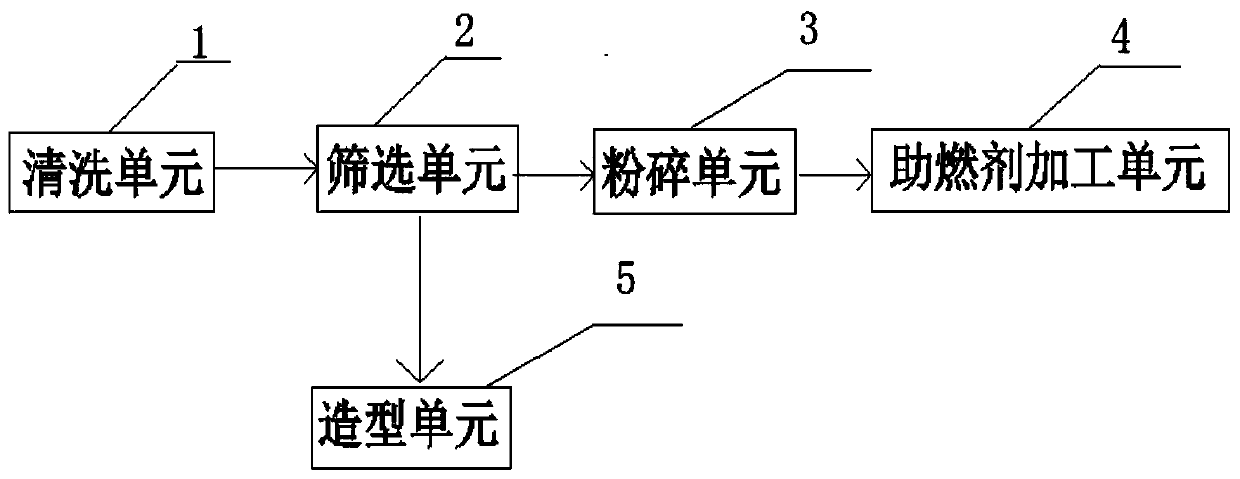

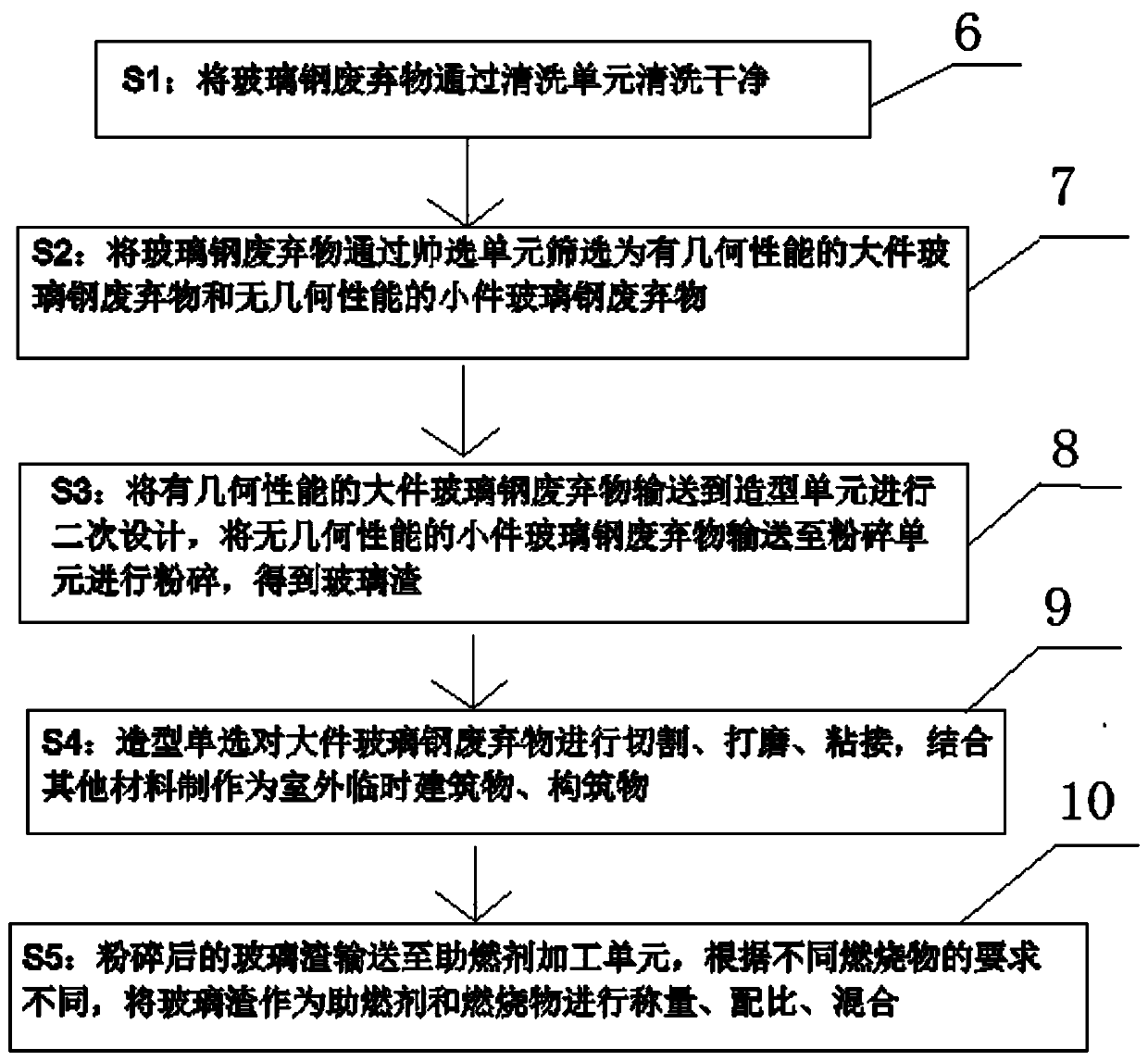

System and method for recycling fiberglass reinforced plastic or carbon fiber composite waste

Owner:益恒洁能(北京)科技有限公司

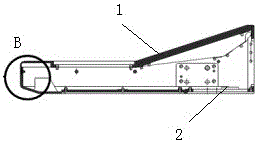

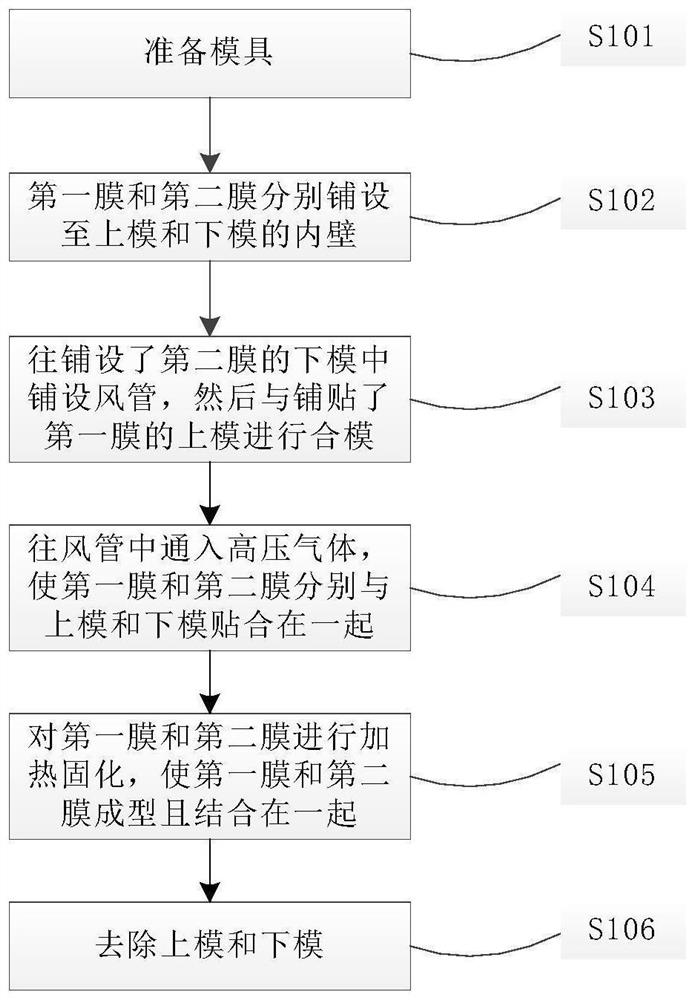

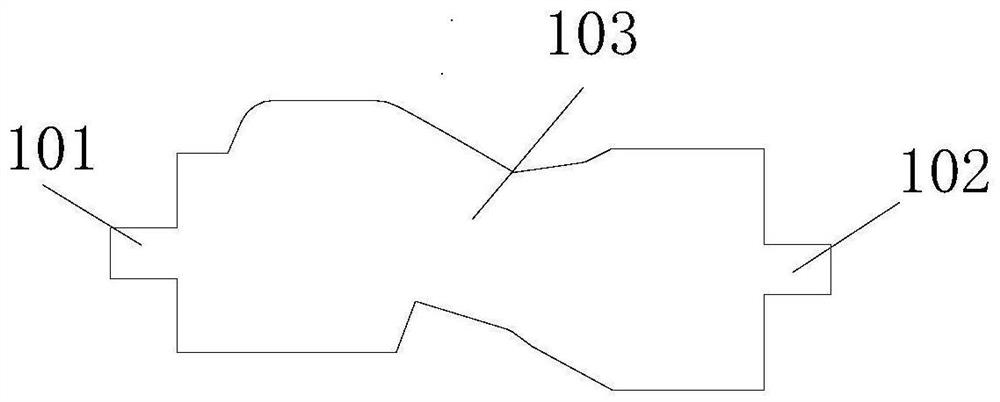

Display and control console support arm and forming method thereof

Owner:CETC WUHU DIAMOND AIRCRAFT MFG +1

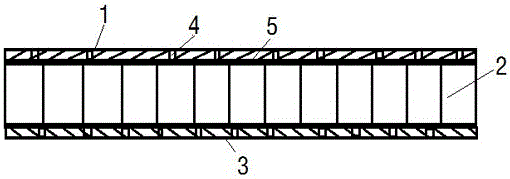

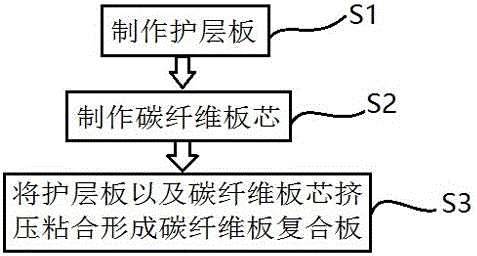

Carbon fiber composite plate and manufacturing method thereof

Owner:湖州优研知识产权服务有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap