Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Fiber reinforcement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reinforcement fibers are designed for specific and unique applications, ranging from micro synthetic fibers to reduce shrinkage and settlement cracking formed when concrete is still in the plastic state, to macro synthetic fibers as an alternative to traditional steel reinforcement for secondary reinforcement applicarions.

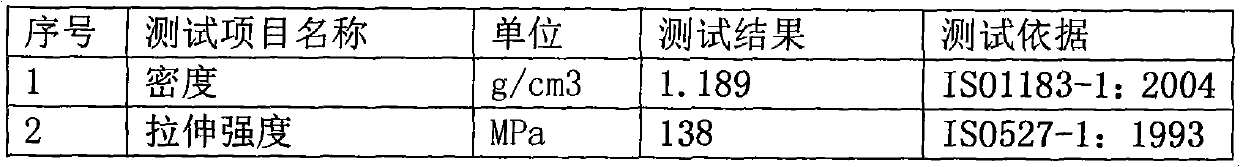

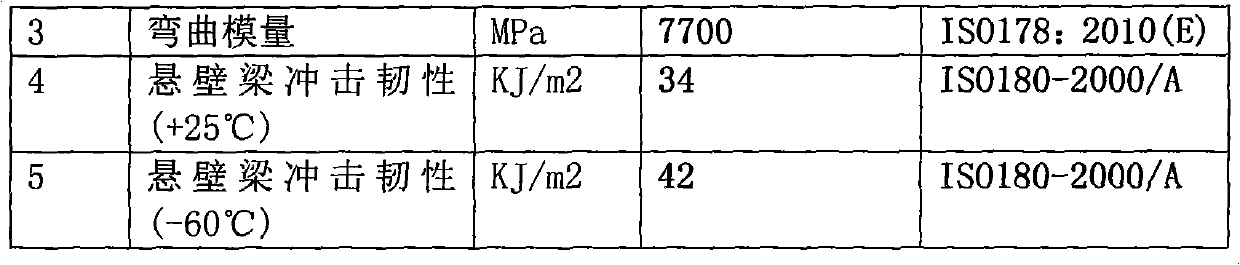

Long-fiber enhanced thermoplastic composite material vane used for wind energy generator

InactiveCN102675740ALow shrinkageLow temperature impact resistanceFinal product manufactureMachines/enginesGlass fiberPhoto aging

Owner:BEIJING NASHENGTONG ADVANCED MATERIAL & TECH CO LTD

Fiber reinforced ceramic-based composite material antenna cover for wave band W and preparation method thereof

ActiveCN109400194AReduce penetration rateReduce penetrationRadiating element housingsElectricitySilicon dioxide

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

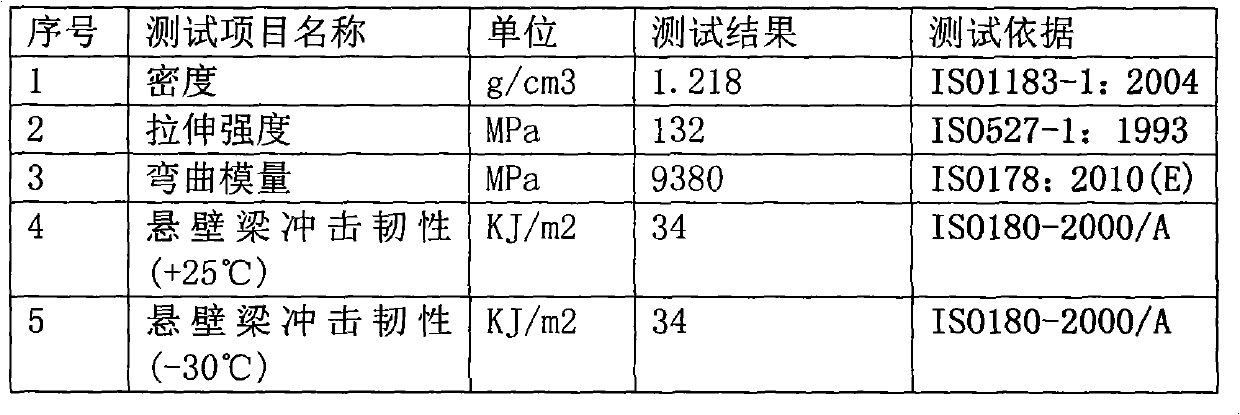

Wind resistant concrete roof component and system and method for forming same

A roof system includes a roof panel formed of concrete and an architectural surface such as a corrugated surface. A first layer of reinforcing material is disposed along and spaced inwardly from a first surface of the roof panel, and an optional second layer of reinforcing material is disposed along and spaced inwardly from a second surface of the roof panel. The first layer of reinforcing material is spaced from the second layer of reinforcing material. The reinforcing material may be formed of fiber-reinforced polymer mesh, made with carbon fibers or glass fibers. FRP rebar may be used in conjunction with FRP mesh to provide added structural strength. The roof panel may include one or more elongated ribs having a thickness greater than adjacent portions of the roof panel. In other aspects, concrete structures with reinforcing material may be used for either roof panels or wall applications.

Owner:FLORIDA INTERNATIONAL UNIVERSITY

Molybdenum fibre reinforced resin concrete material

InactiveCN101759397AGood physical and mechanical propertiesHigh compressive strengthKinetosomesResin-Based Composite

Owner:SHANDONG UNIV

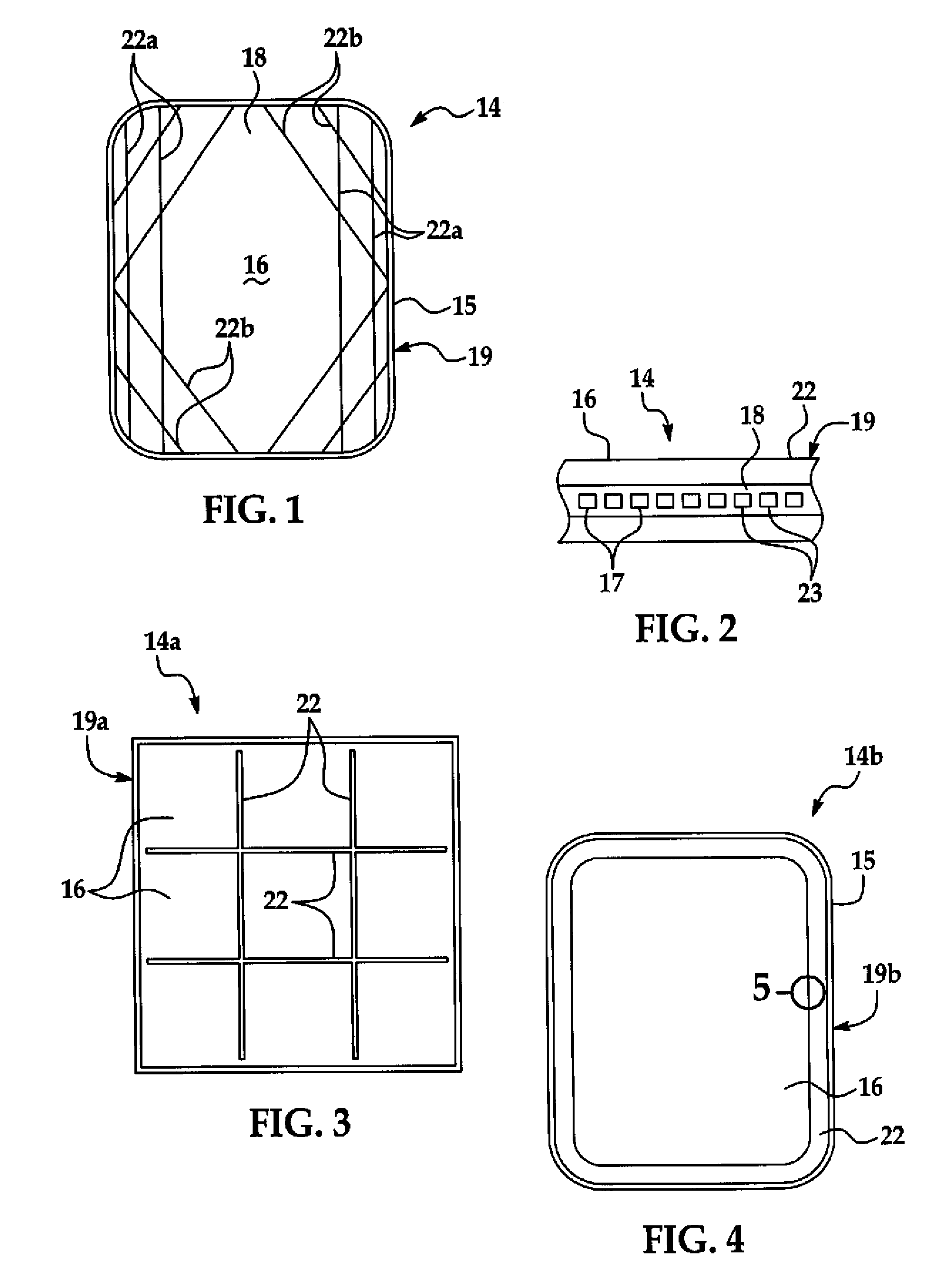

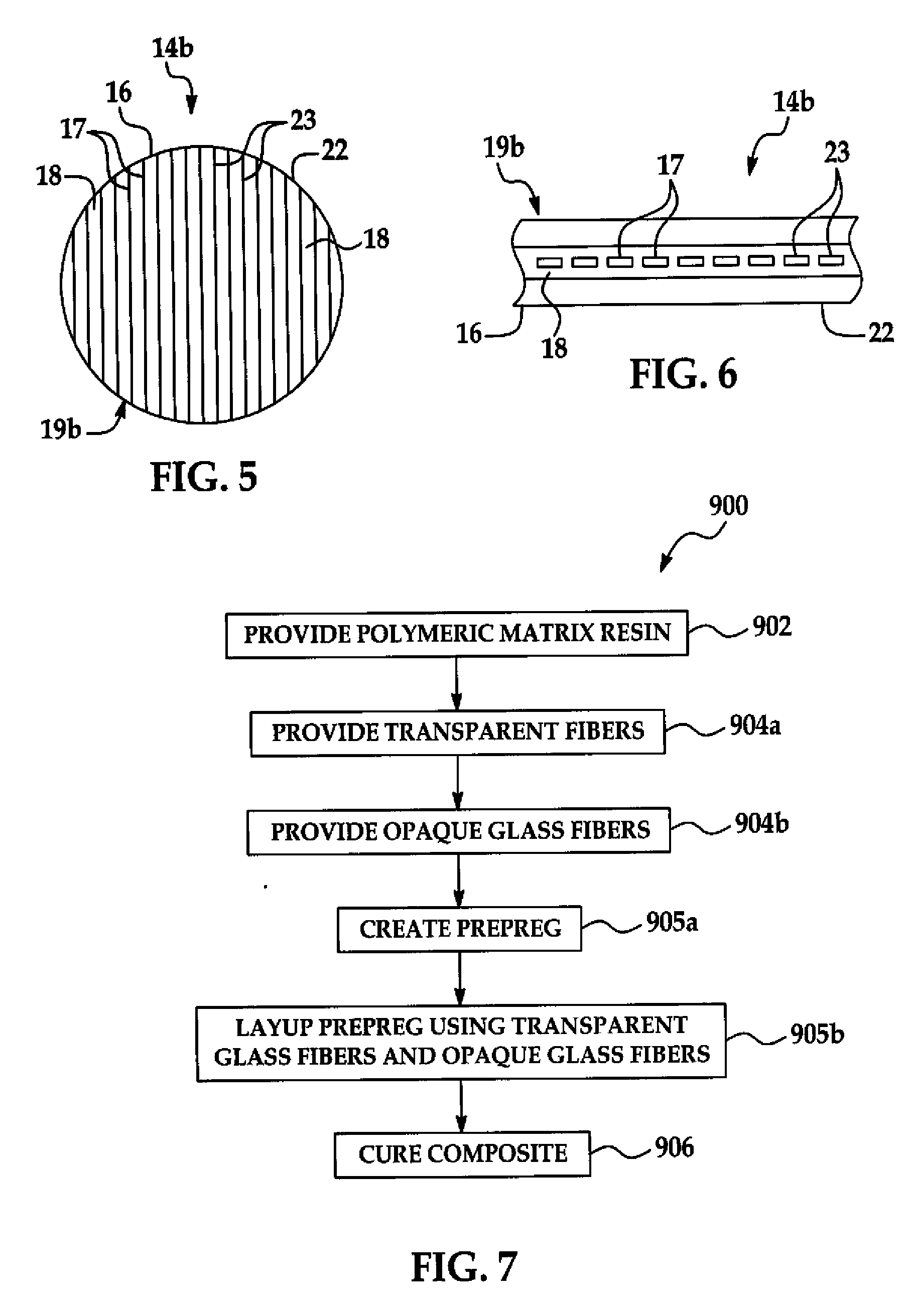

Opaque fiber reinforcement of composites

ActiveUS20100011702A1Synthetic resin layered productsEfficient propulsion technologiesFiber reinforcementPolymeric matrix

Owner:THE BOEING CO

Method for preparing composite type fracturing propping agent by utilizing gold ore tailings and zirconium oxide

InactiveCN102718493AImprove microstructureOvercoming brittlenessSolid waste disposalFluid removalZirconium hydrideExpanded clay aggregate

The invention discloses a method for preparing a composite type fracturing propping agent by utilizing gold ore tailings and zirconium oxide. The method comprises the steps of mixing the gold ore tailings, alumina powders and high-temperature zirconium oxide chopped fibers, then adding gum water solution, mixing uniformly, conducting wet grinding and then pelleting; putting particles into alumina crucible and arranging into a silicon carbide rod resistor furnace, heating to 1230 DEG C from the room temperature at the heating speed being 5 DEG C / min-10 DEG C / min, keeping the temperature for 0.5h-1h, heating to 1350 DEG C-1400 DEG C at the heating speed being 5 DEG C / min-7 DEG C / min, keeping the temperature for 2h-3h; and cooling the particles in the furnace and then taking out the particles, and screening the particles by a 20-40 meshes sieve so as to obtain the composite type fracturing propping agent. According to the method, fibers (crystal whiskers) necessary for enhancing the strength and toughness is provided by integrating the concept of composite materials integrated with a non-compact ceramic propping agent and adopting the high-temperature reaction self generation mode, and the composite type fracturing propping agent with high strength, high toughness, low density and low damage rate is prepared by two measures, namely fiber reinforcement and particle reinforcement.

Owner:SHAANXI UNIV OF SCI & TECH

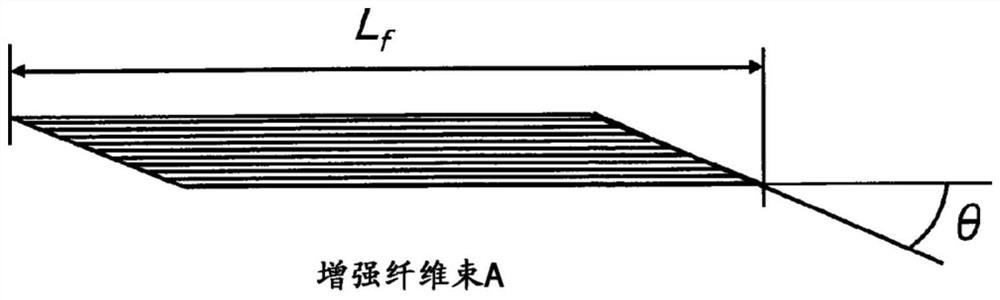

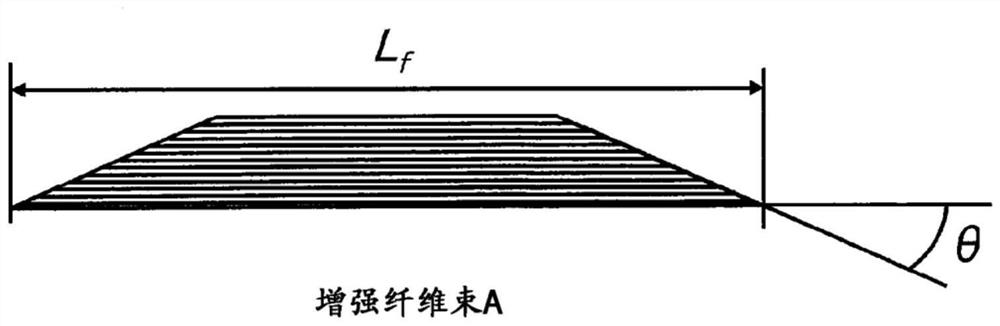

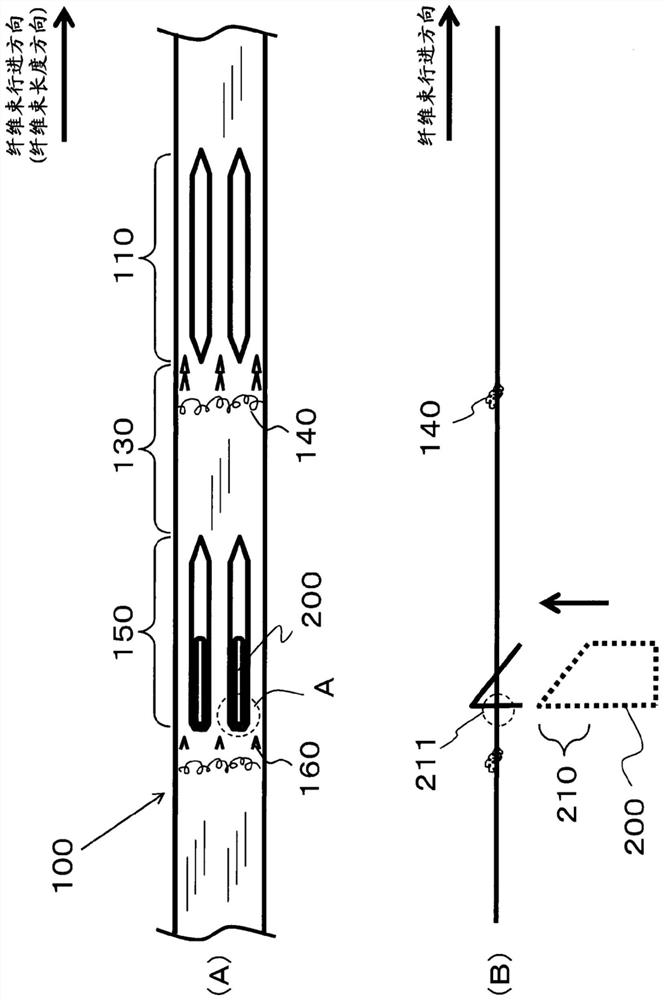

Fiber-reinforced resin material and production method therefor

PendingCN112955496AExcellent mechanical propertiesImprove productivityCoatingsPolymer scienceFiber bundle

Owner:TORAY IND INC

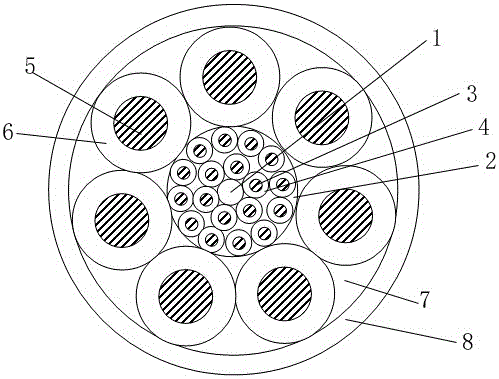

Composite type reel cable

InactiveCN105118555AFlexible cablesFlexible conductorsElectrical and Electronics engineeringFiber reinforcement

Owner:JIANGSU ZHONGMEI CABLE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap