Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13 results about "Fixed bed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

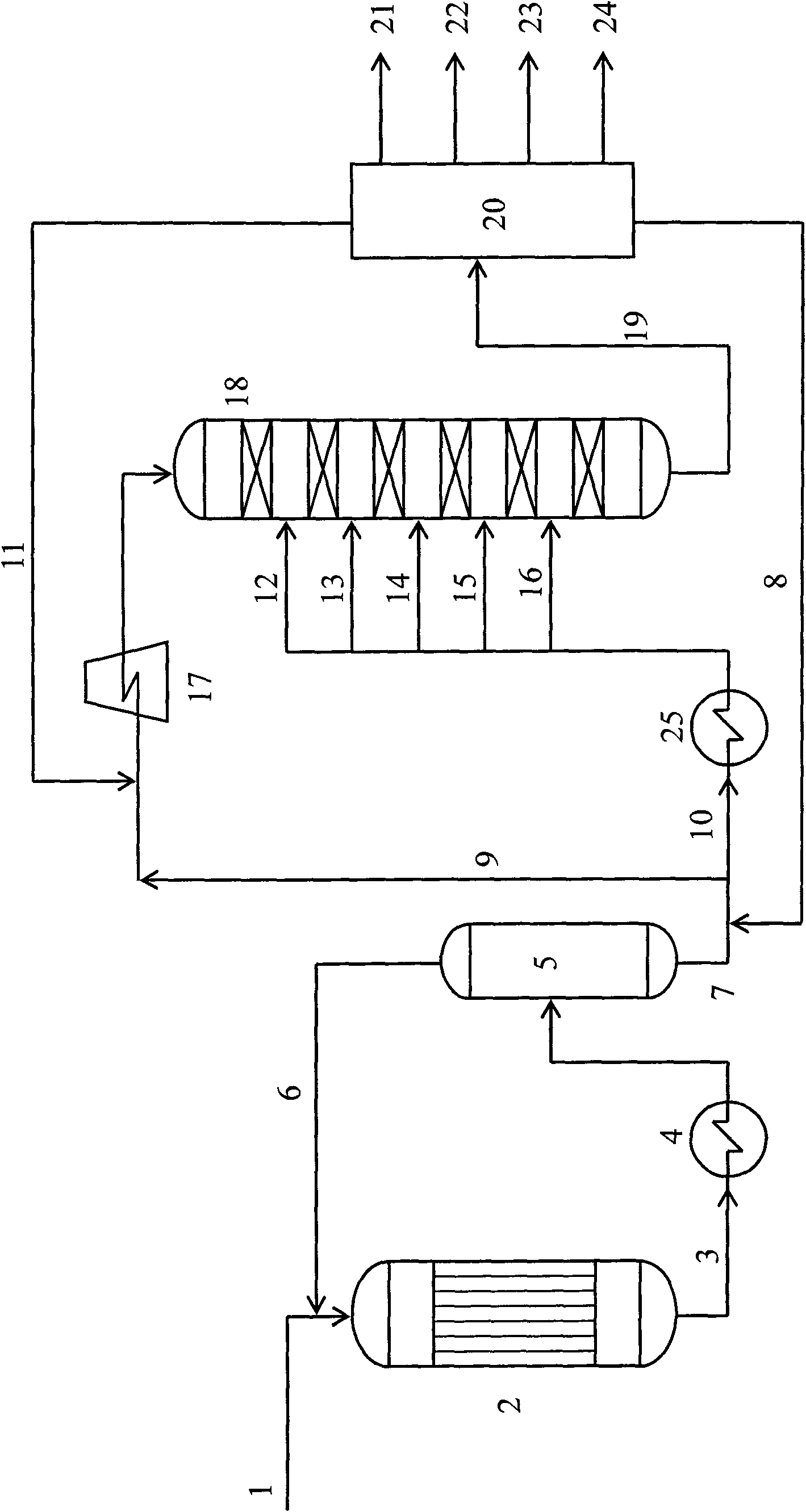

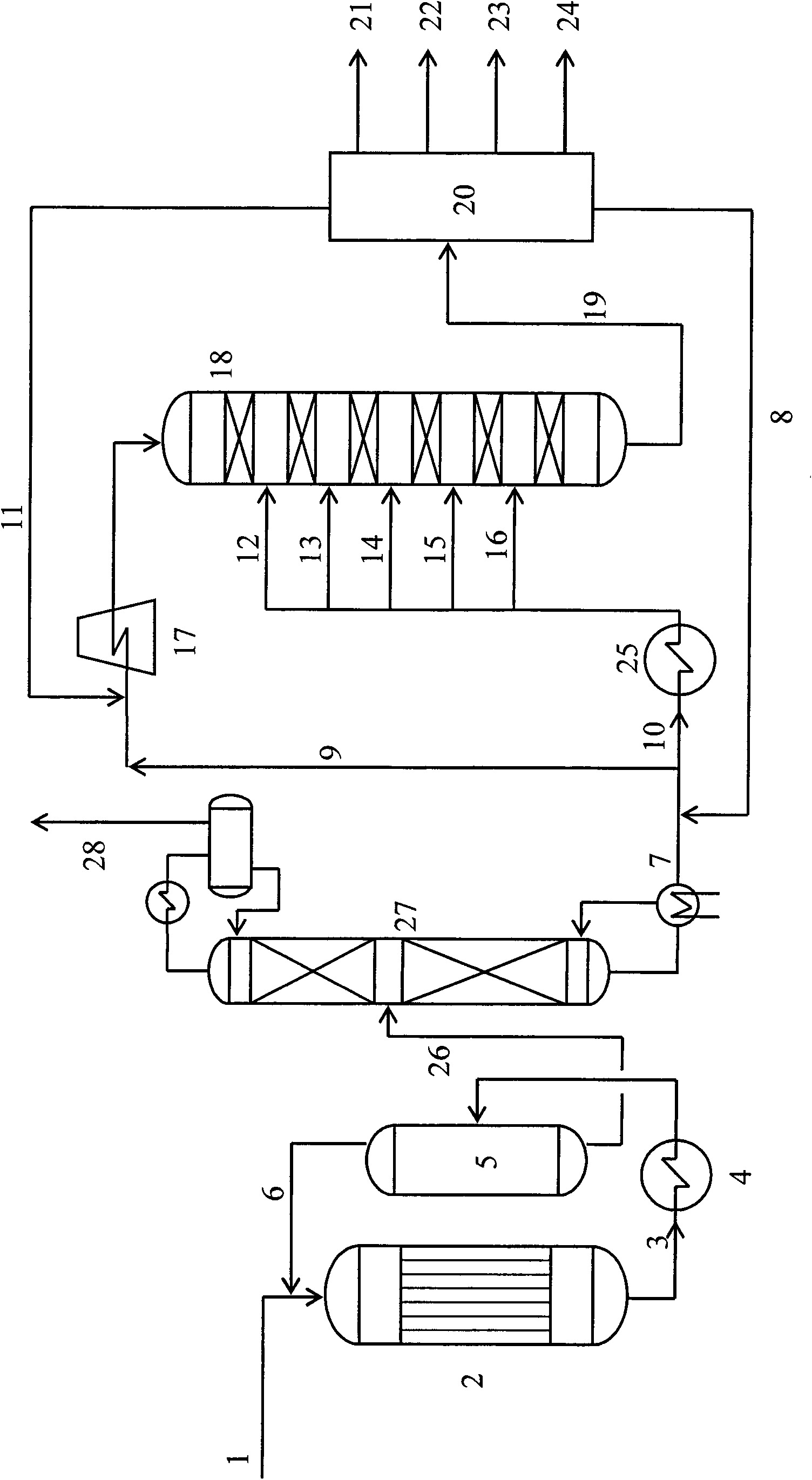

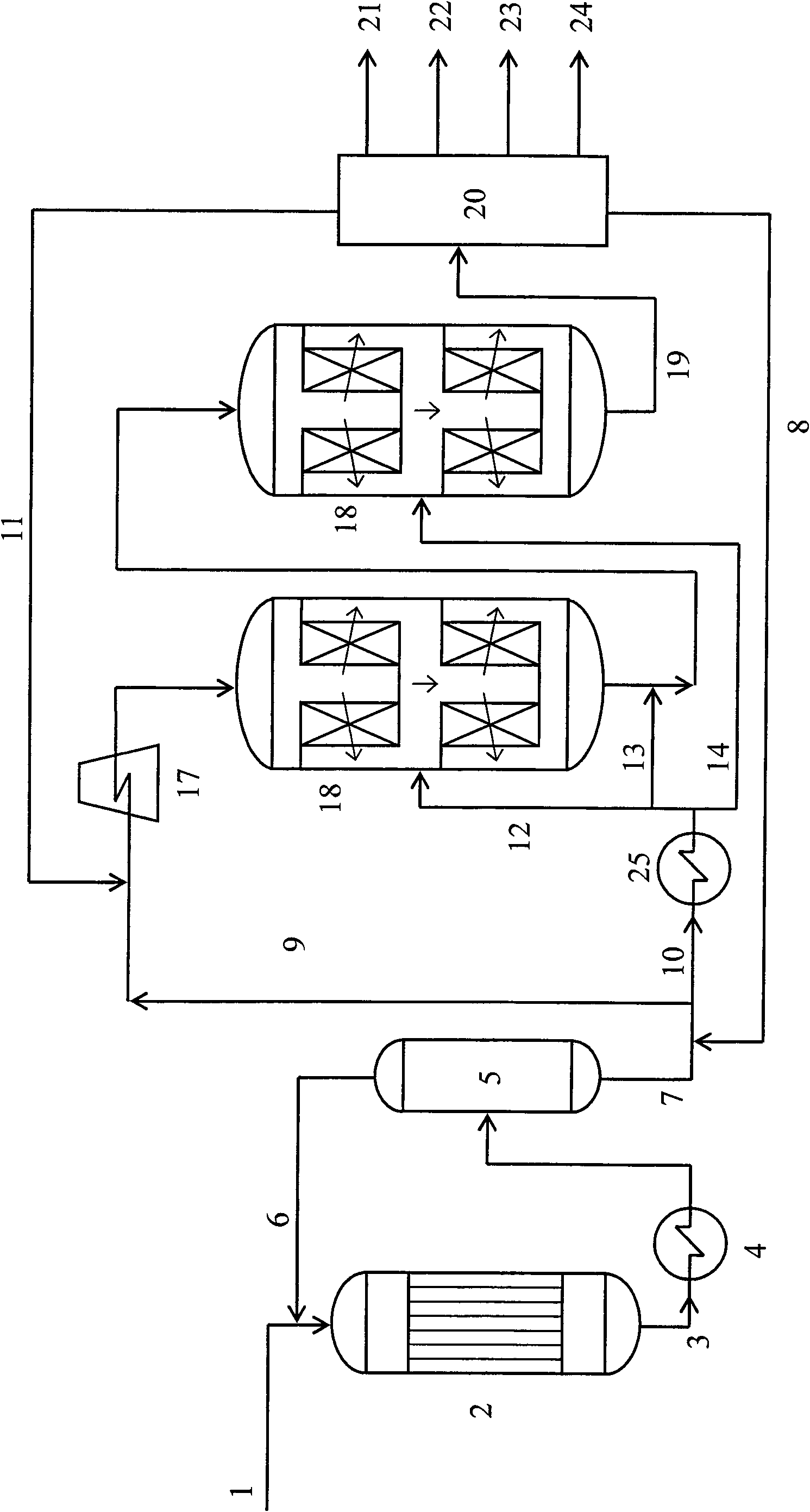

Method for directly preparing propylene from crude methanol

ActiveCN101659592ADistillation purification process omittedReduce energy consumptionHydrocarbon from oxygen organic compoundsEthylene productionMolecular sieveDiluent

Owner:WISON ENG

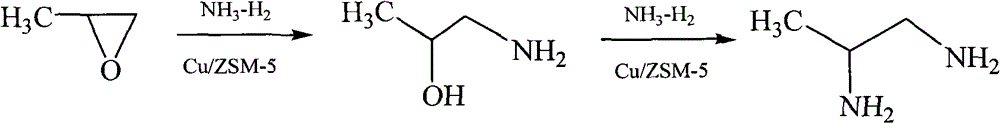

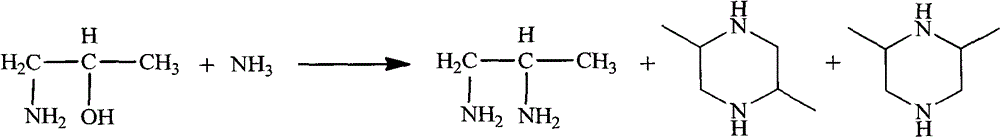

Coproduction method of 1, 2-propanediamine and dimethyl piperazine

InactiveCN102718661AReduce consumptionLow costOrganic compound preparationAmino compound preparationPorosityContact time

Owner:XIAN MODERN CHEM RES INST

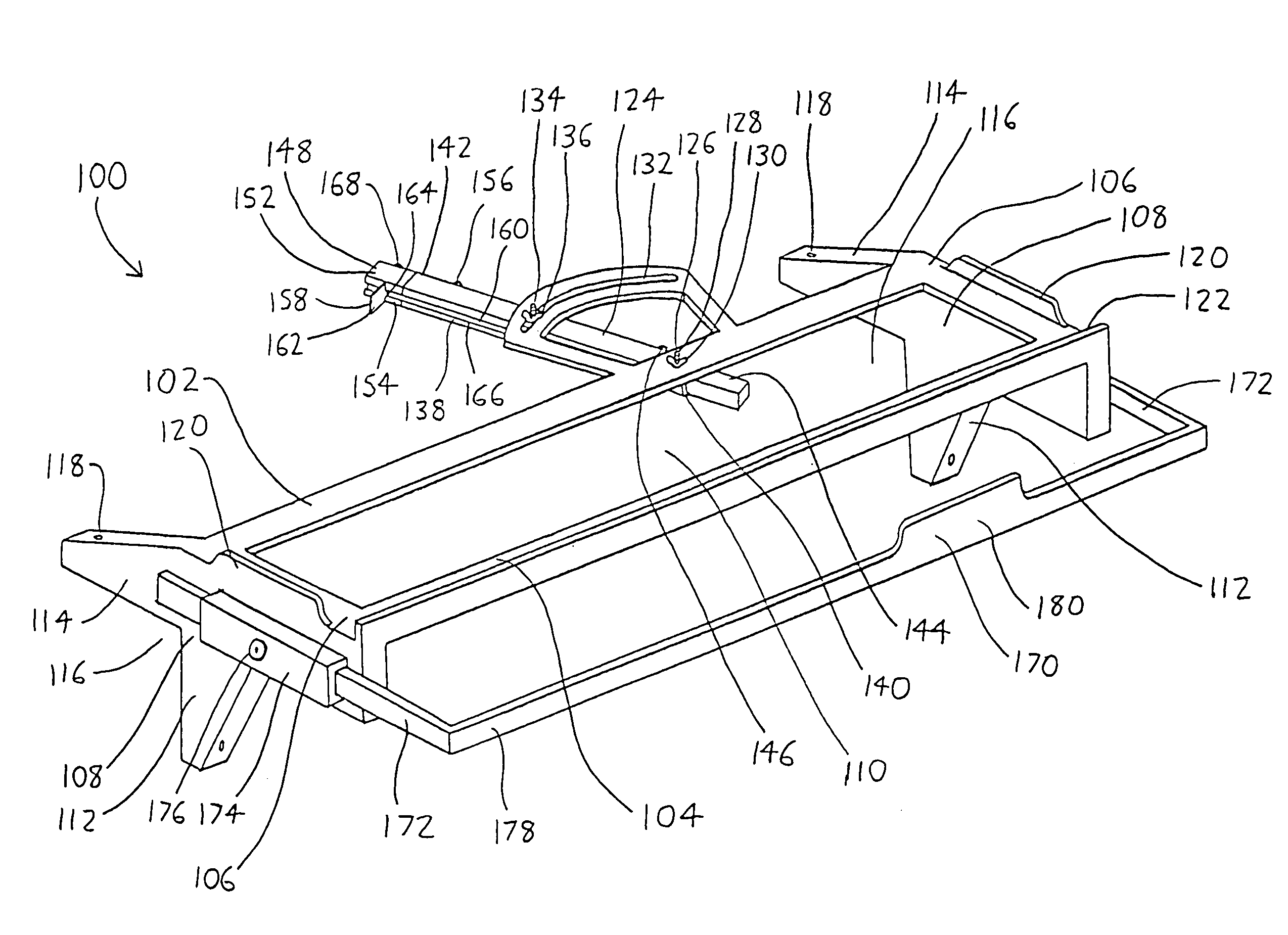

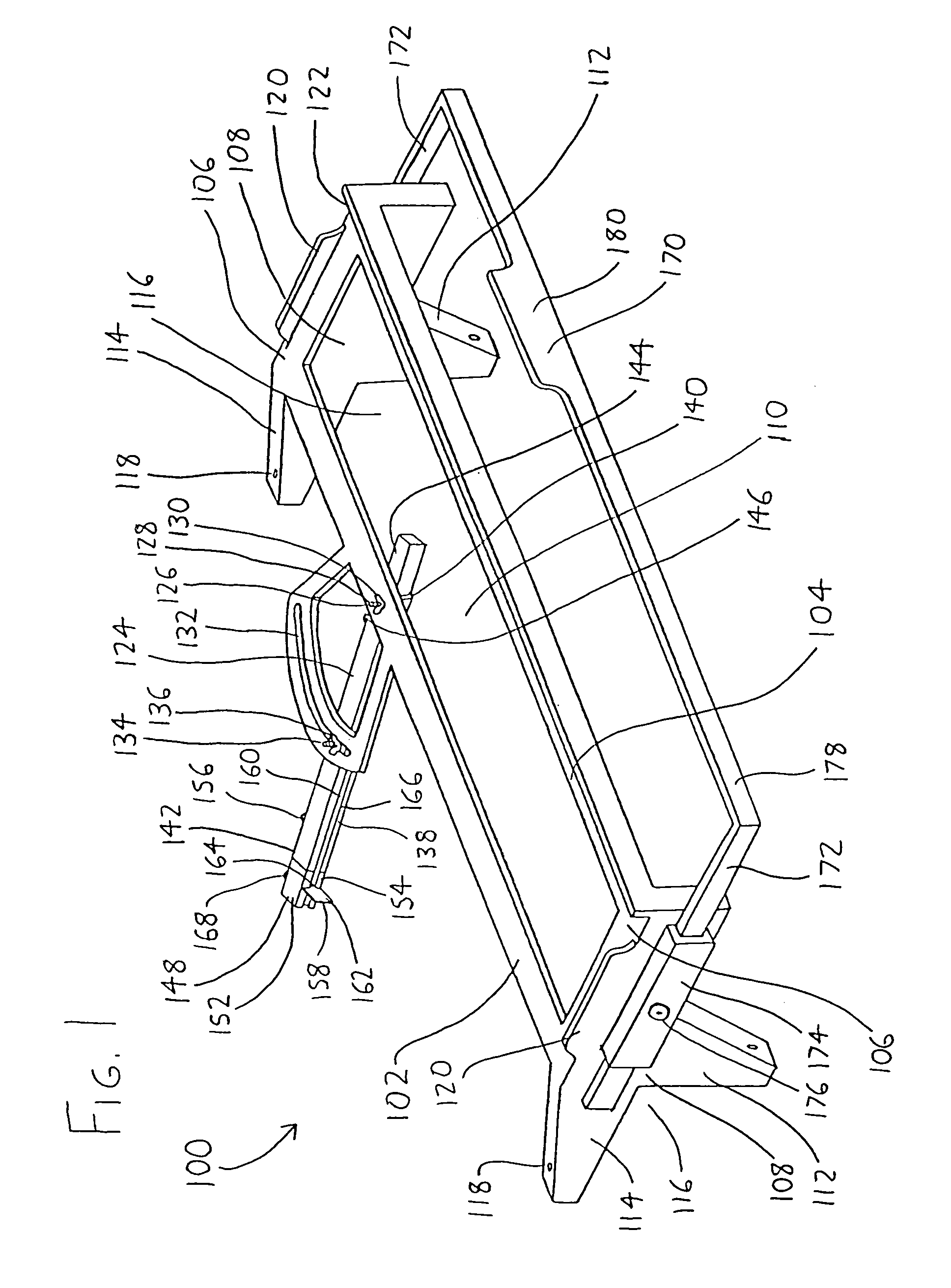

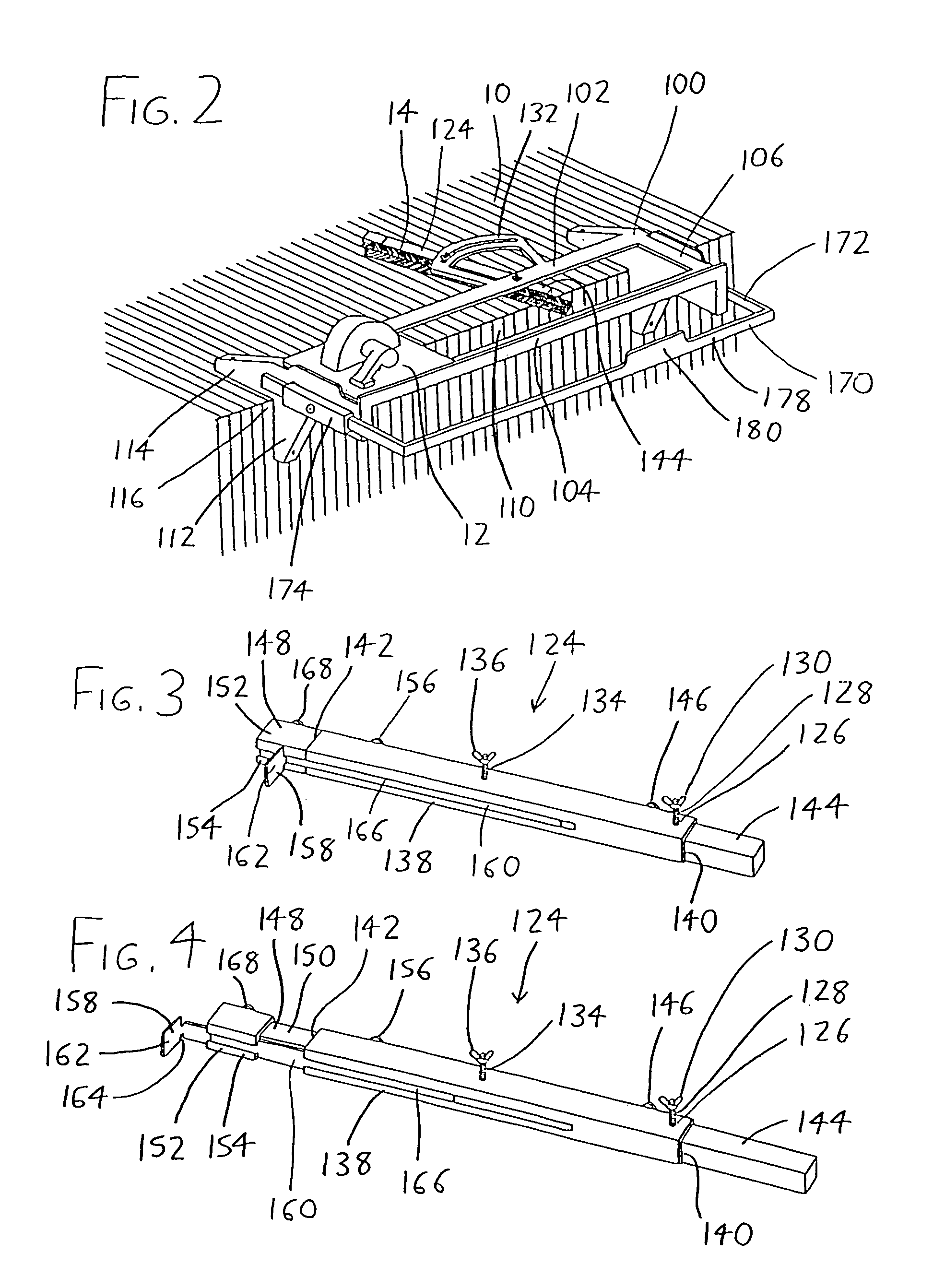

Work surface guide for power tools

InactiveUS6991009B1High precision cuttingGuide fencesMulti-purpose machinesPower toolFixed bed

Owner:SANDS WEDEWARD SUSAN A

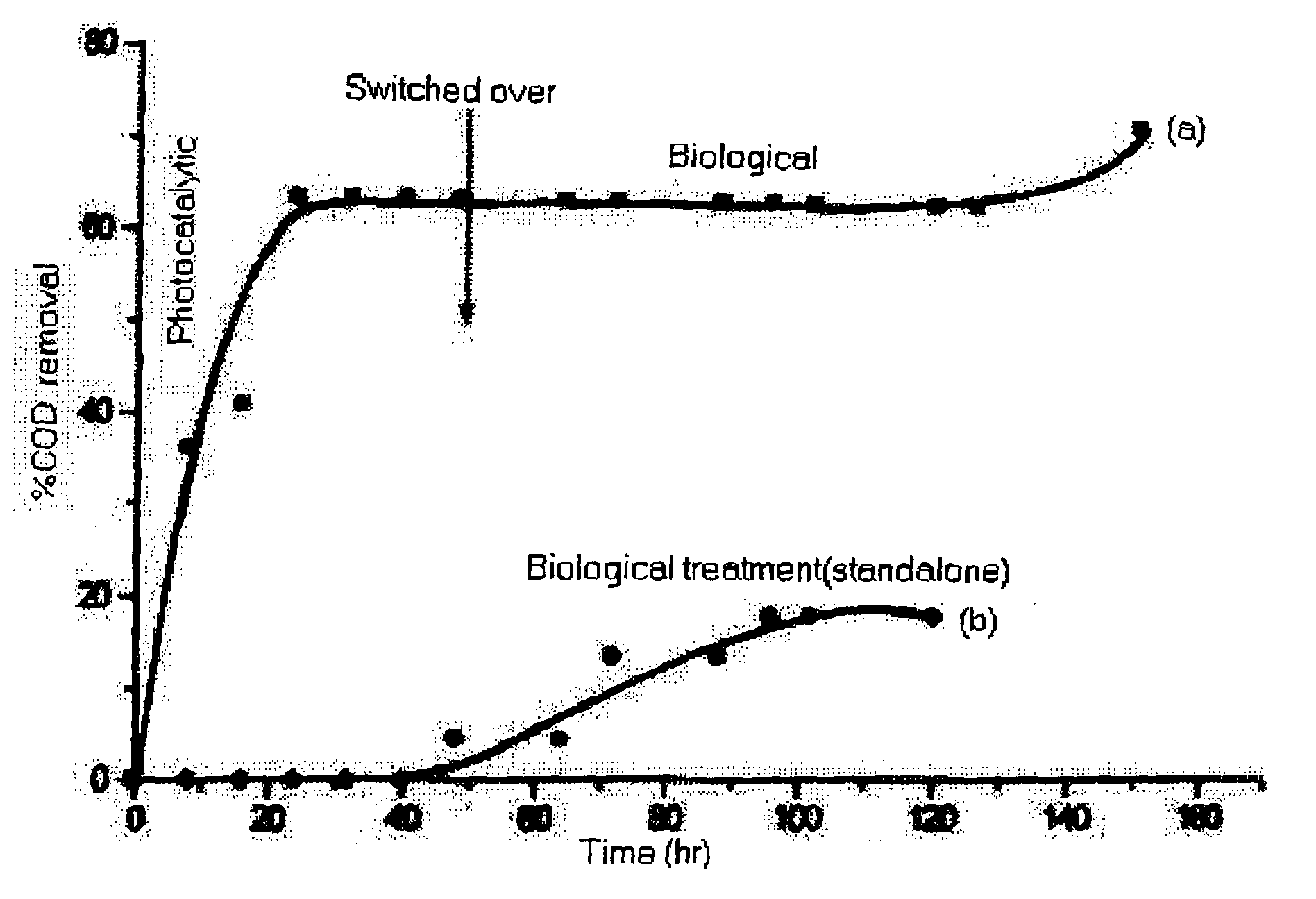

Apparatus for purification of industrial wastewater with thin film fixed bed TiO2 photocatalyst

InactiveUS20040182792A1Easy to disassembleEasy to recycleWater/sewage treatment by irradiationOther chemical processesIndustrial effluentSorbent

Owner:COUNCIL OF SCI & IND RES

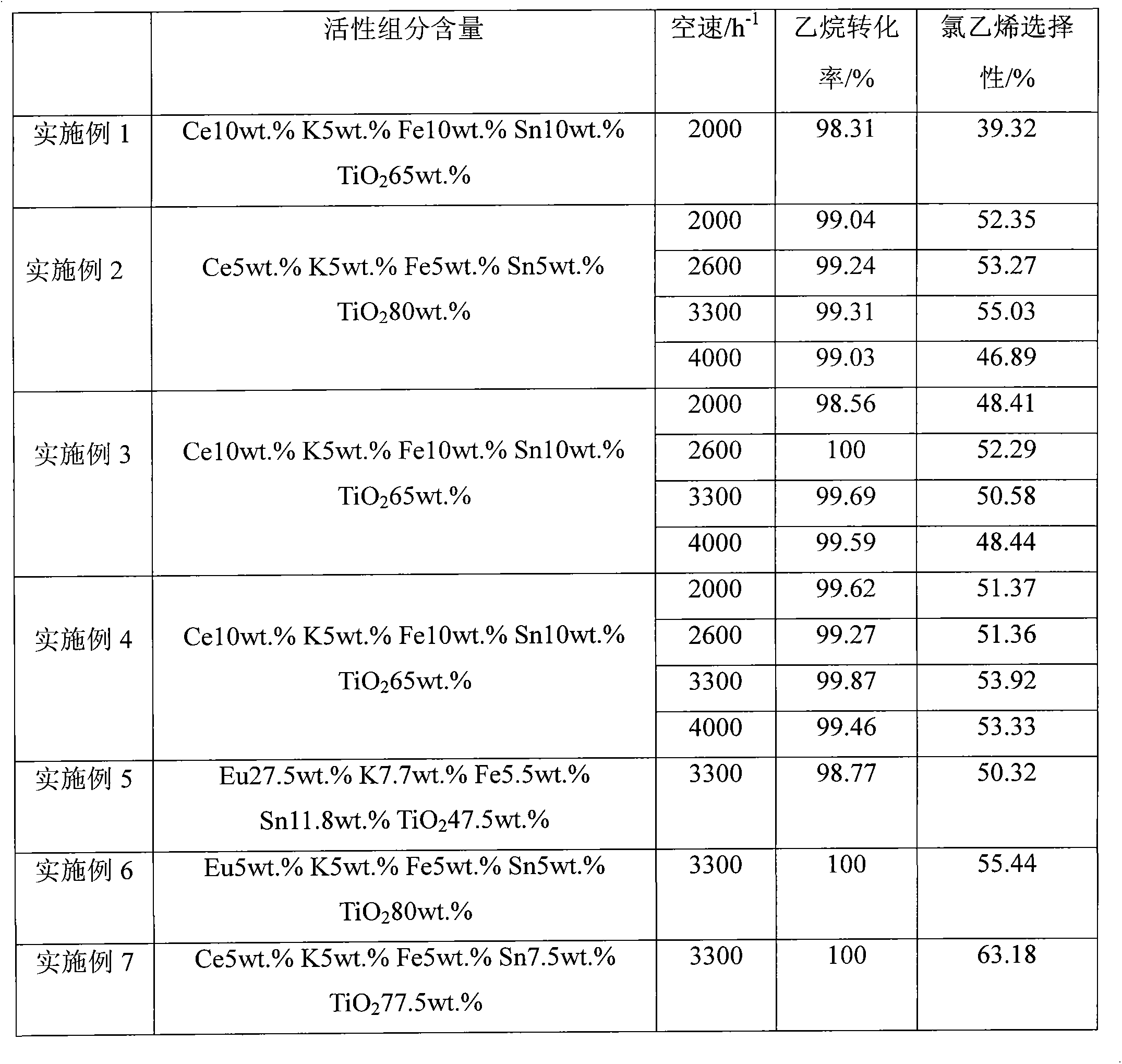

Preparation method for catalyst for preparing chloroethylene via ethane oxychlorination

InactiveCN103055877ASimple processLow reaction temperatureHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementReaction temperature

Owner:INNER MONGOLIA UNIVERSITY

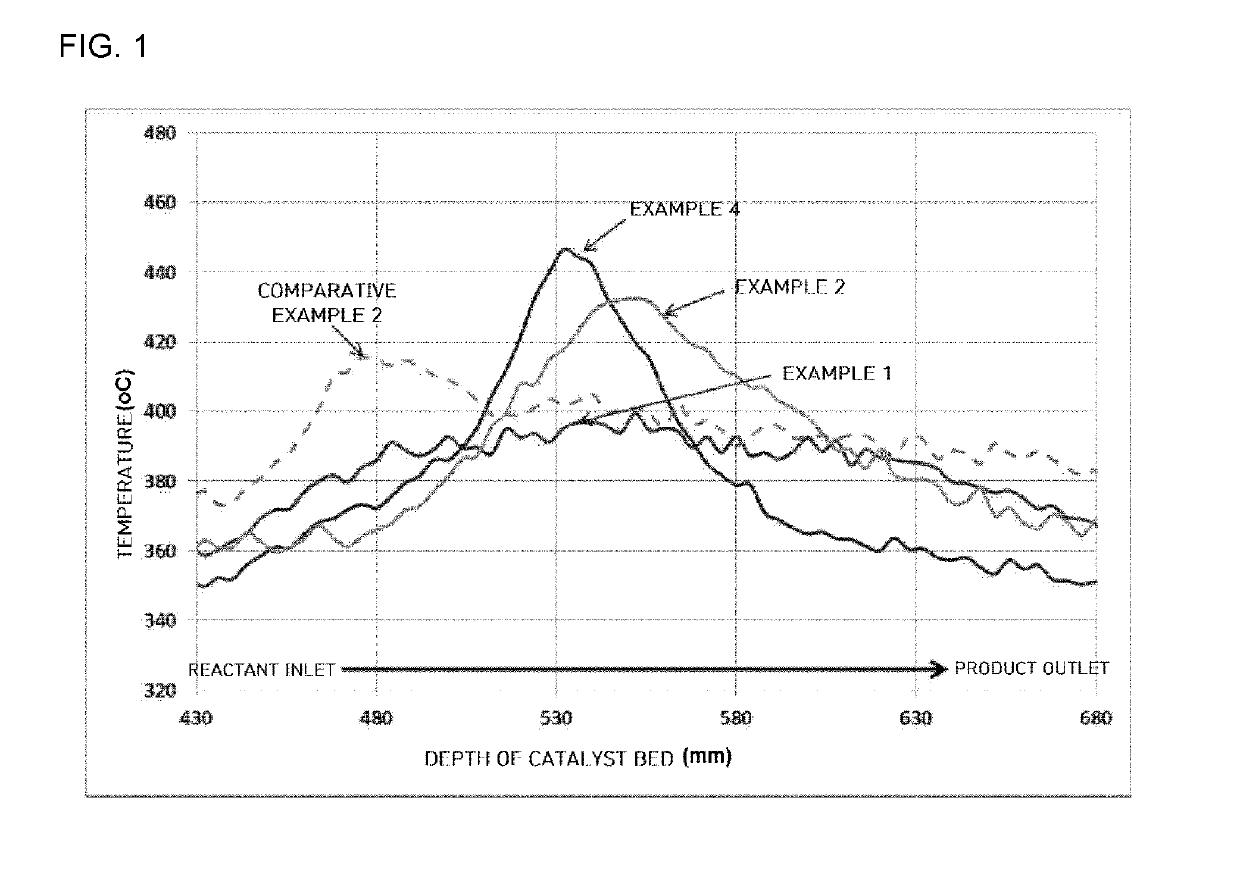

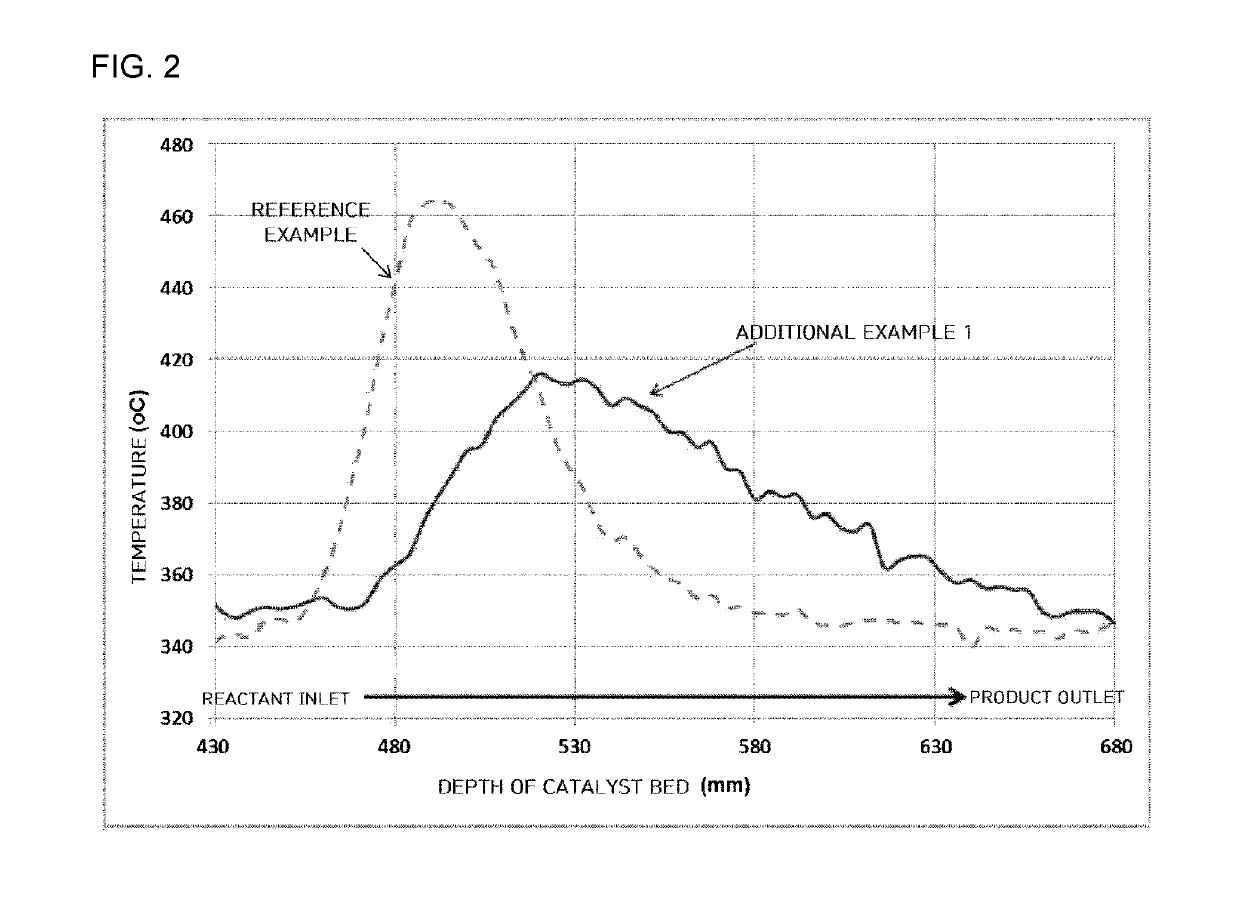

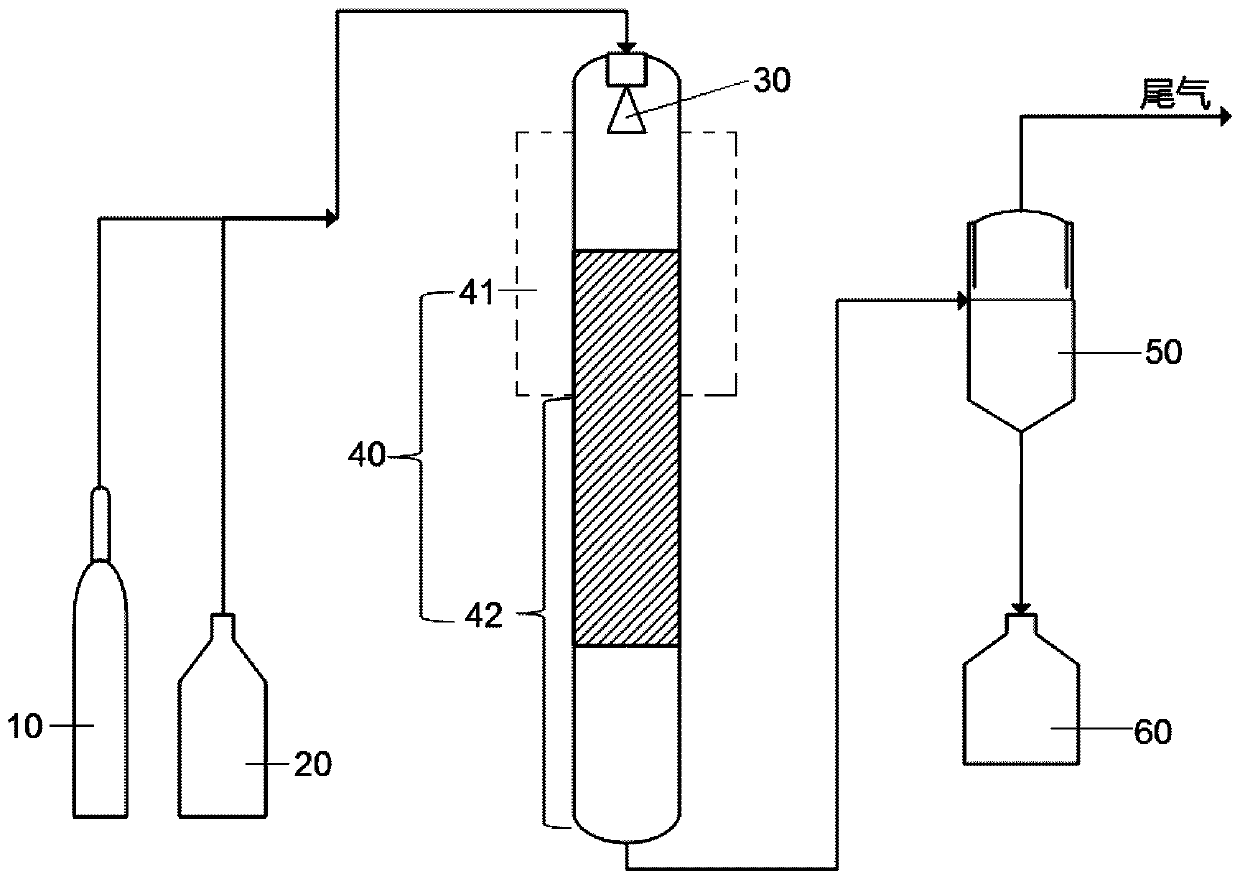

Catalyst system for oxidative dehydrogenation, reactor for oxidative dehydrogenation including catalyst system, and method of performing oxidative dehydrogenation using reactor

ActiveUS20190201876A1Effectively control generatedImprove conversion rateHydrocarbon preparation catalystsCatalystsFixed bedDehydrogenation

Owner:LG CHEM LTD

Catalyst and method for preparing p-methyl benzaldehyde from synthesis gas and toluene

ActiveCN111389454ALow costSimple process routeMolecular sieve catalystsOrganic compound preparationPtru catalystBenzaldehyde

Owner:SHAANXI YANCHANG PETROLEUM GRP

Method for producing ethylene raw material

ActiveCN112708439AExpand sourceAchieve reuseLiquid hydrocarbon mixture productionPolymer sciencePolyolefin

Owner:SINOCHEM QUANZHOU PETROCHEM CO LTD +1

Continuous hydrogenation method and application of ethyl pyrazine-2-carboxylate

ActiveCN111559983ARaise the degree of adequate responseShort reaction timeOrganic chemistryTemperature controlPyrazine

Owner:ASYMCHEM LIFE SCI TIANJIN

Preparation process of improved sulfur-resistant sintering flue gas decarburization catalyst

PendingCN114289041AIncrease the number ofEnhanced Surface AcidityPhysical/chemical process catalystsDispersed particle separationPtru catalystFlue gas

Owner:ANHUI XINCHUANG ENERGY SAVING & ENVIRONMENTAL PROTECTION SCI & TECH +1

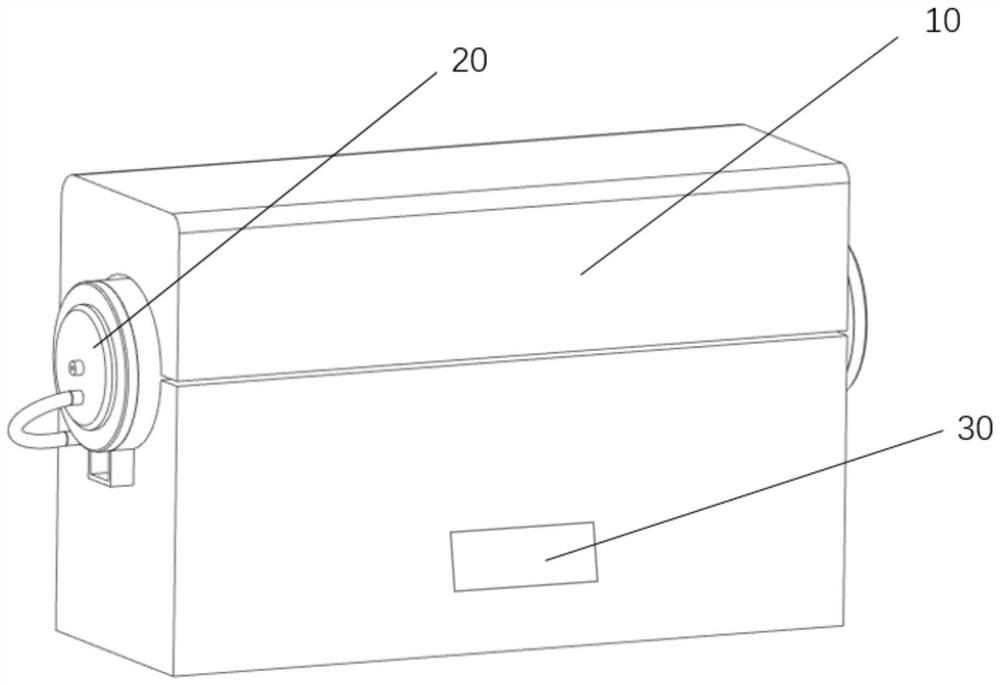

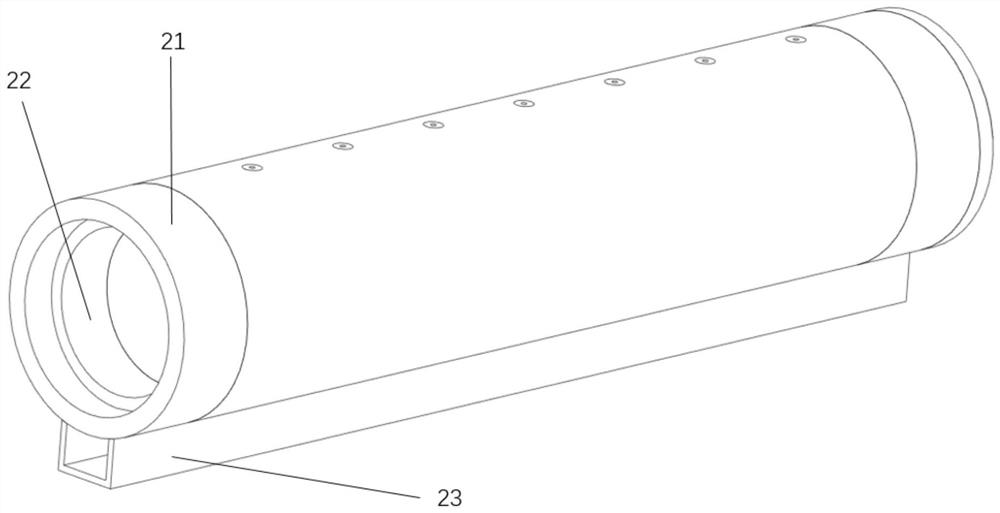

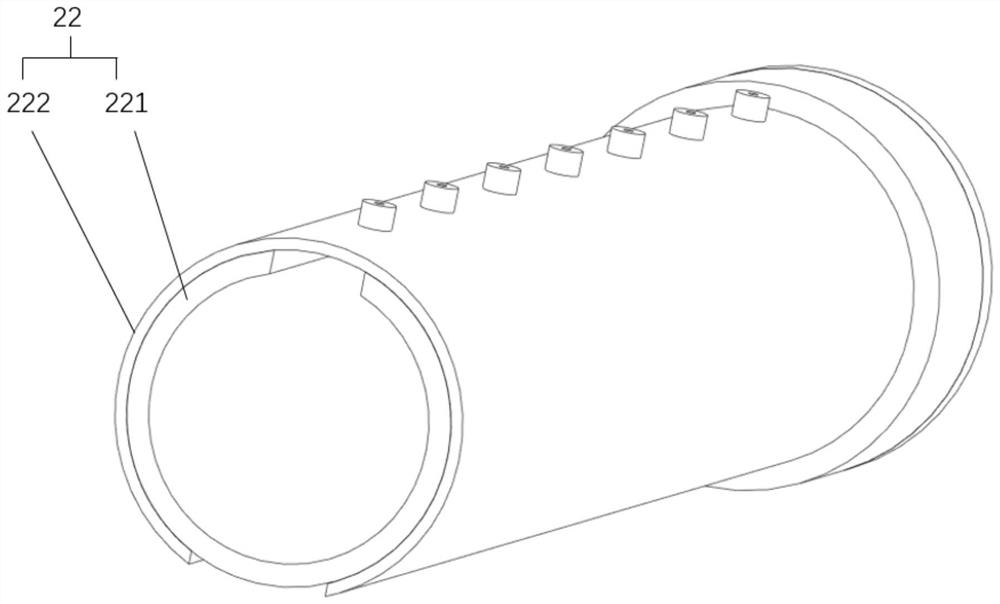

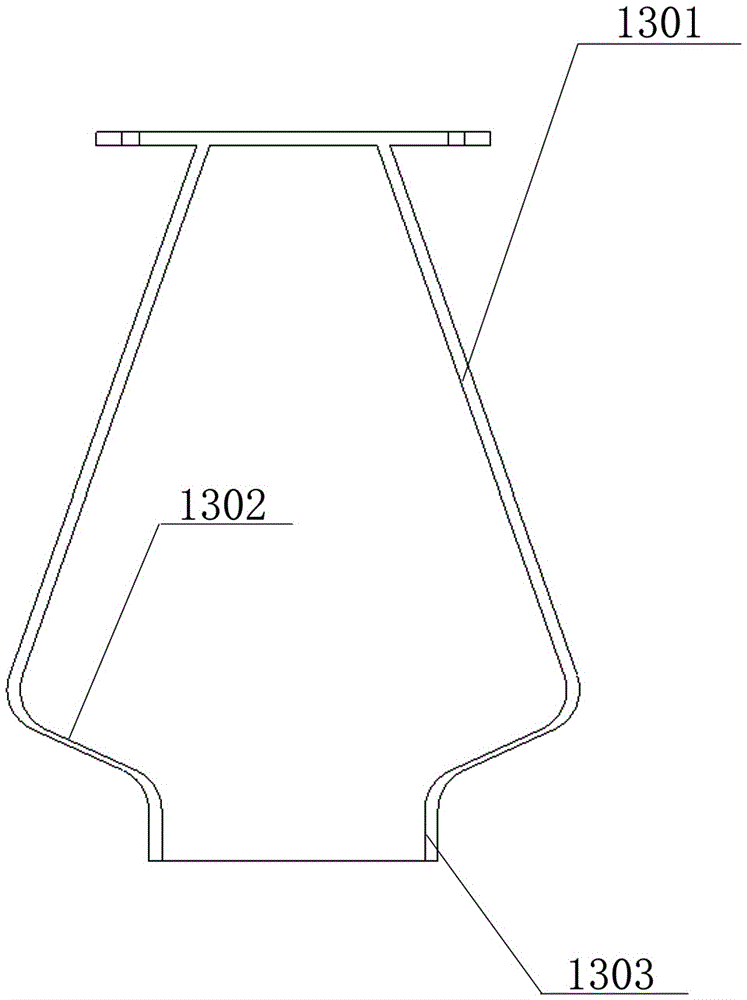

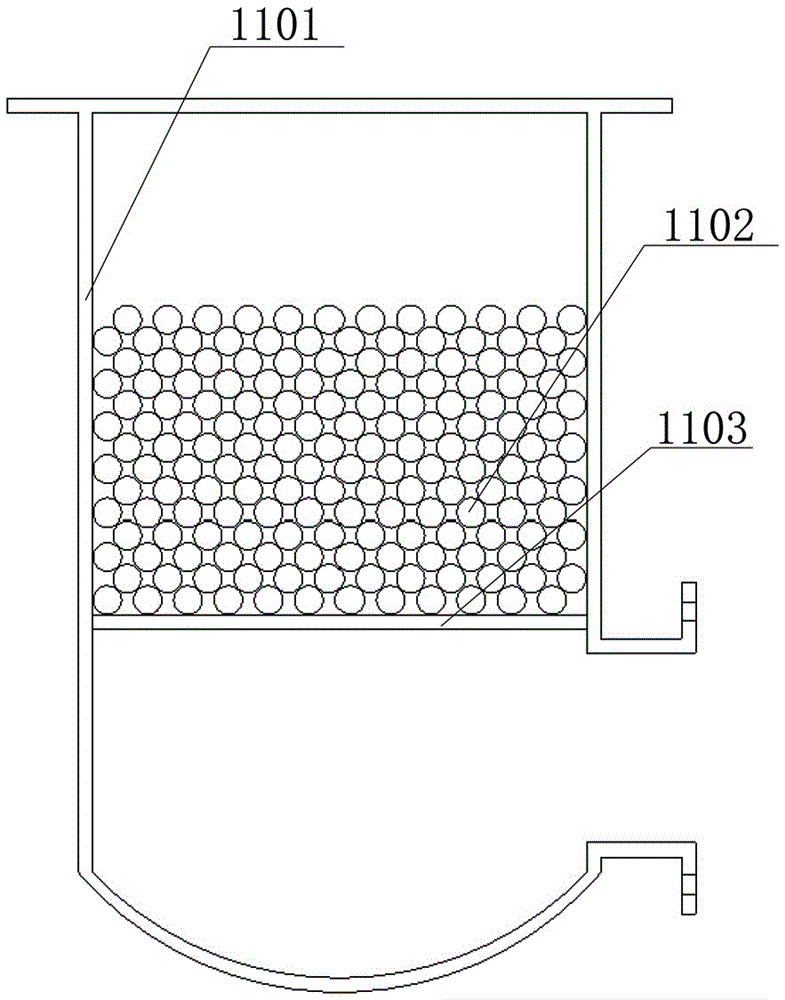

Circulating fixed bed

PendingCN113926392AAchieve recyclabilityEfficient secondary useGrapheneCarbon nanotubesEngineeringFixed bed

The invention discloses a circulating fixed bed. The circulating fixed bed is used for circularly producing a carbon material and comprises a temperature control body, at least one temperature control section reactor and a controller, the reactor is at least partially located in the temperature control body, and the temperature control body controls the temperature of each temperature control section reactor; the reactor comprises a rotating body and pipes AB, the pipes AB comprise a pipe A and a pipe B, and the pipe A and the pipe B are arranged in a sleeving mode and move relatively; and the controller controls materials to enter the A pipe and the B pipe to react to generate a carbon material, the controller controls the rotating body to rotate to drive the A pipe to rotate relative to the B pipe so as to feed and discharge the material, and the A pipe forms different angles relative to the B pipe in cycles so as to achieve cyclic production of the carbon material. The problems of energy conservation, environmental protection, high yield and homogenization in the prior art can be solved.

Owner:QINGDAO UNIV OF SCI & TECH

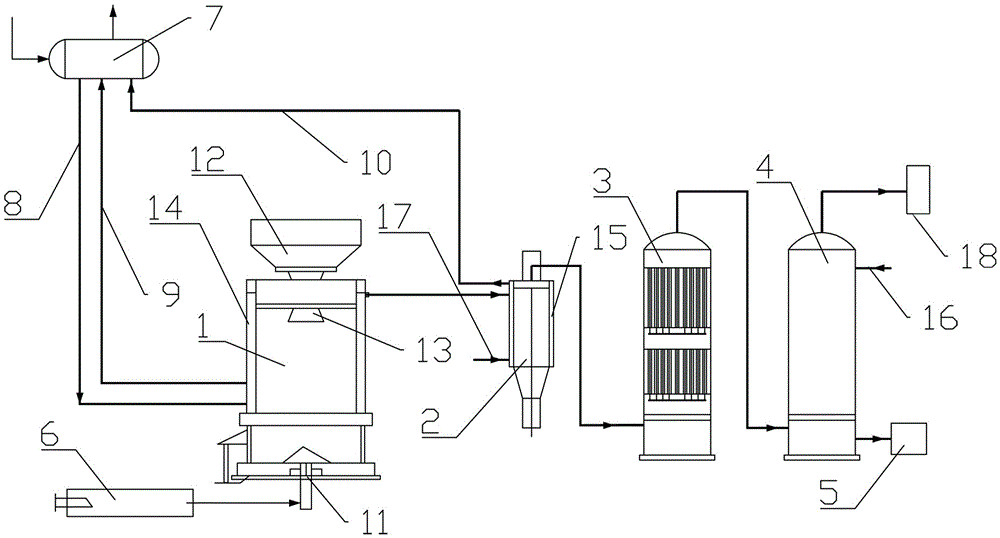

Fixed-bed pure-oxygen continuous gasification device and process adaptable to diversified coals

ActiveCN105542860AImprove decomposition rateHigh effective gas contentChemical industryGasification processes detailsAdditive ingredientFixed bed

Owner:河南顺达新能源科技有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap