Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Monolayer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A monolayer is a single, closely packed layer of atoms, molecules, or cells. In some cases it is referred to as a self-assembled monolayer. Monolayers of layered crystals like graphene and molybdenum disulfide are generally called 2D materials.

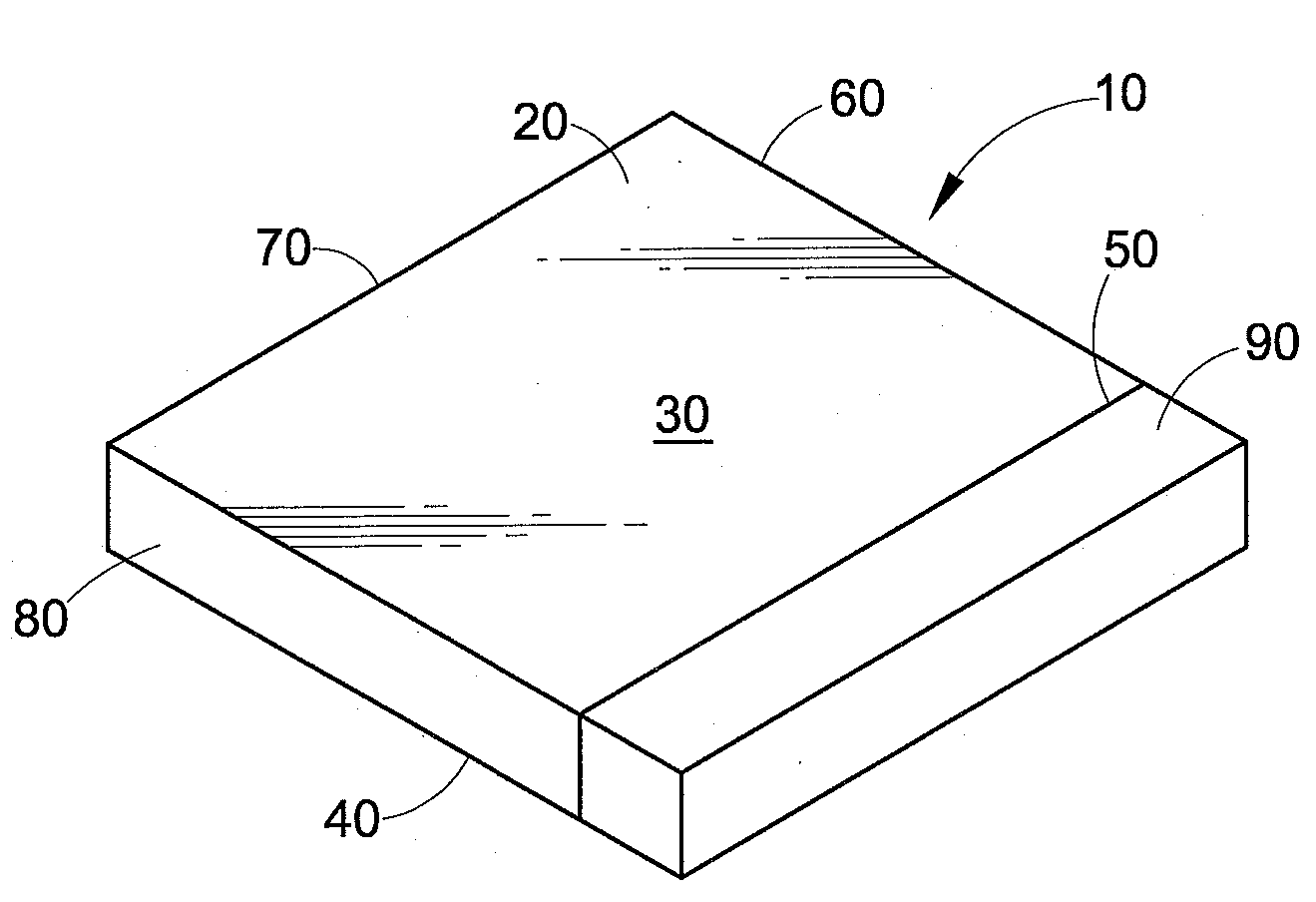

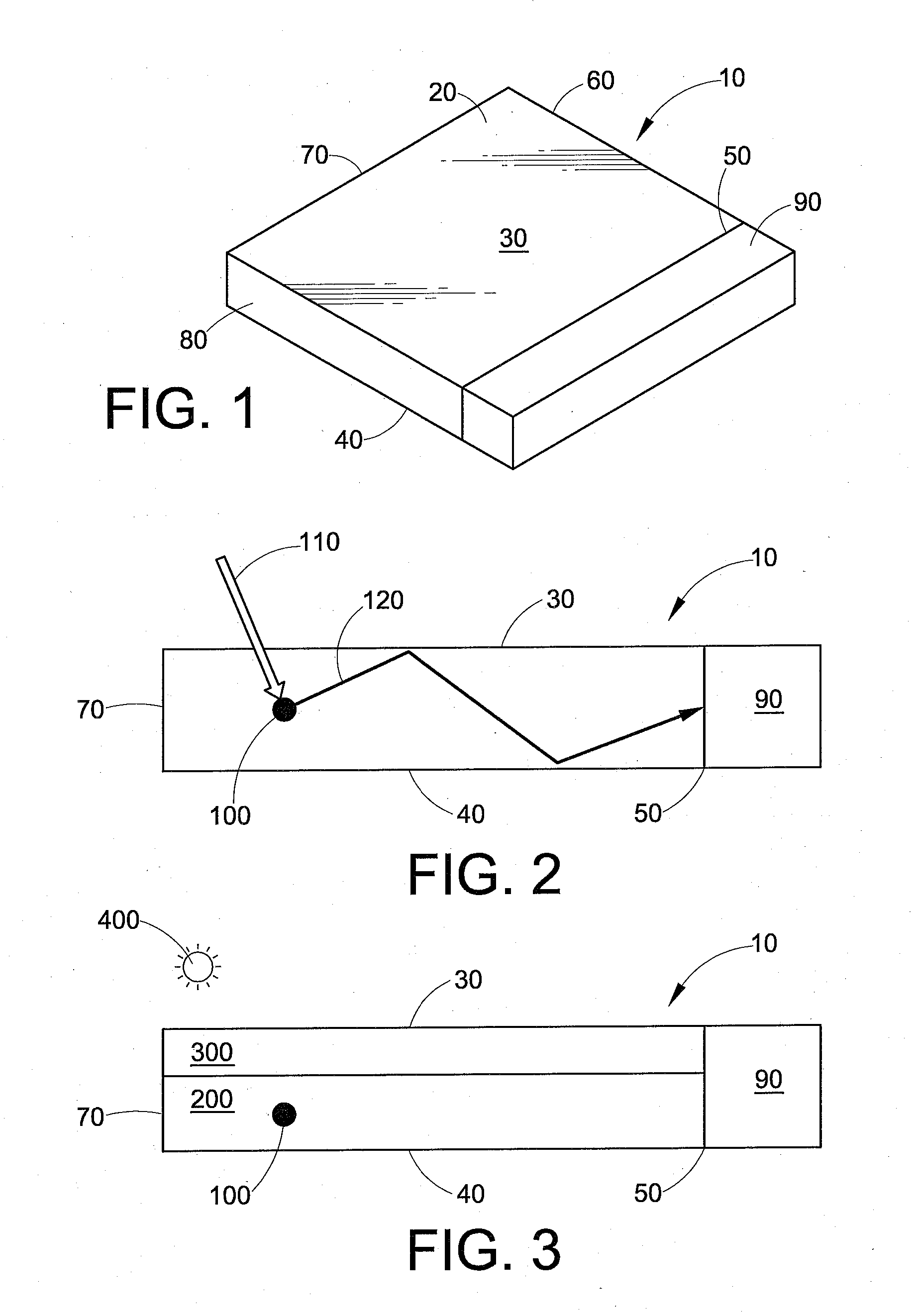

Luminescent solar collector

Owner:SABIC GLOBAL TECH BV

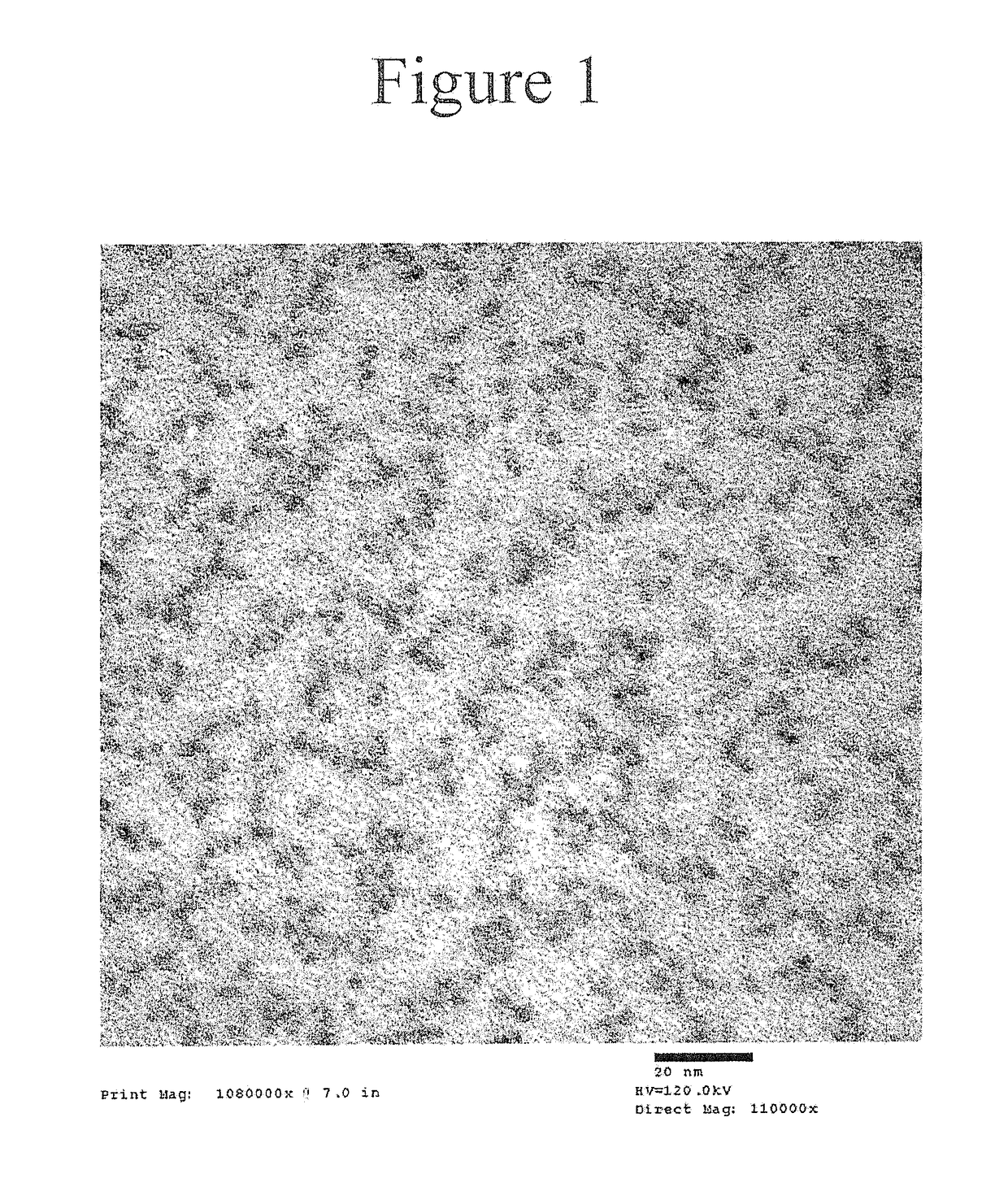

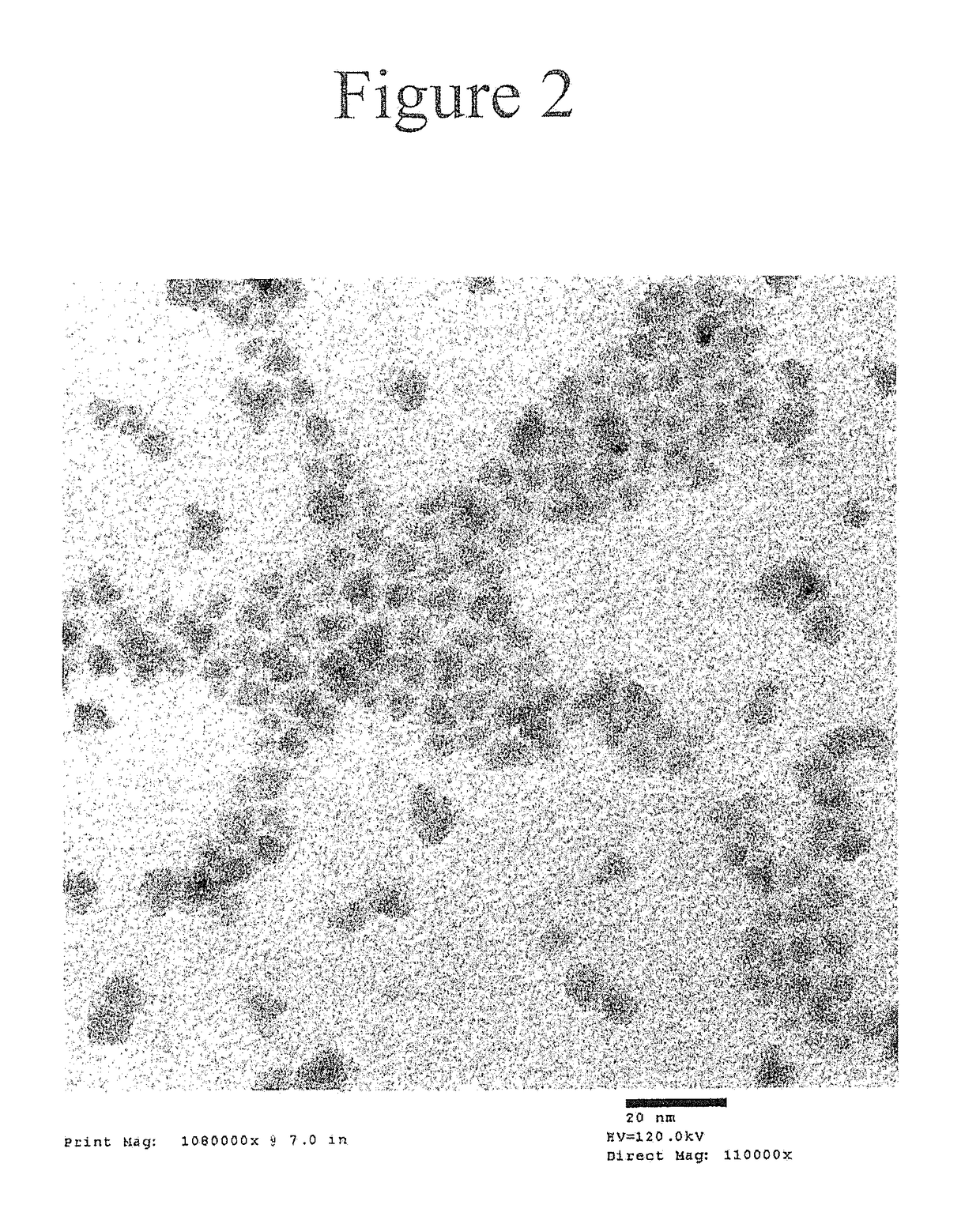

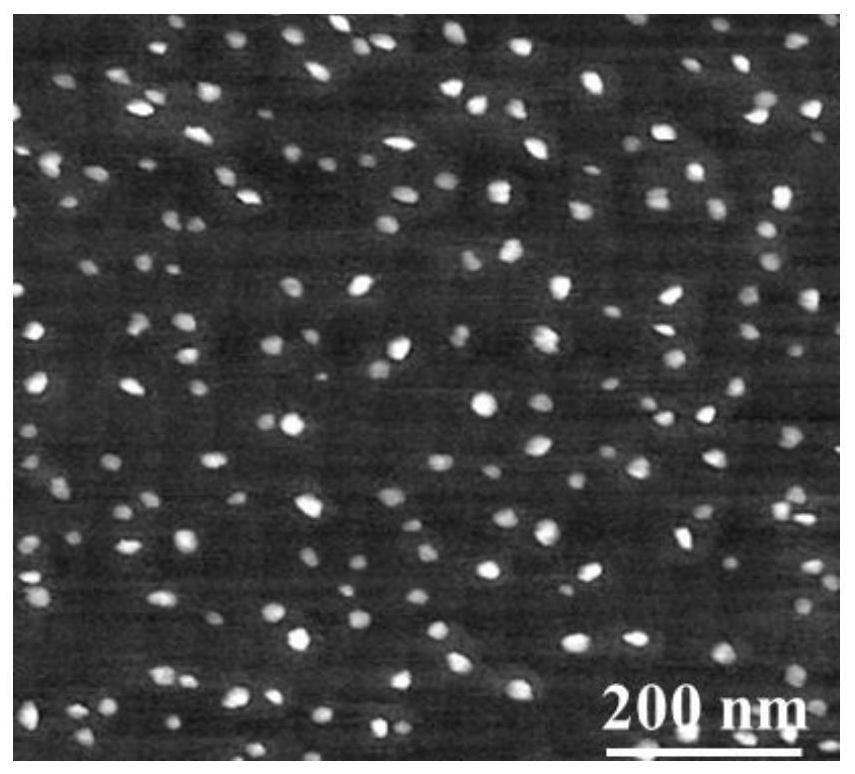

Stable inp quantum dots with thick shell coating and method of producing the same

InactiveUS20180119007A1Solid-state devicesSemiconductor/solid-state device manufacturingSynthesis methodsPhotoluminescence

Owner:NANOSYS INC

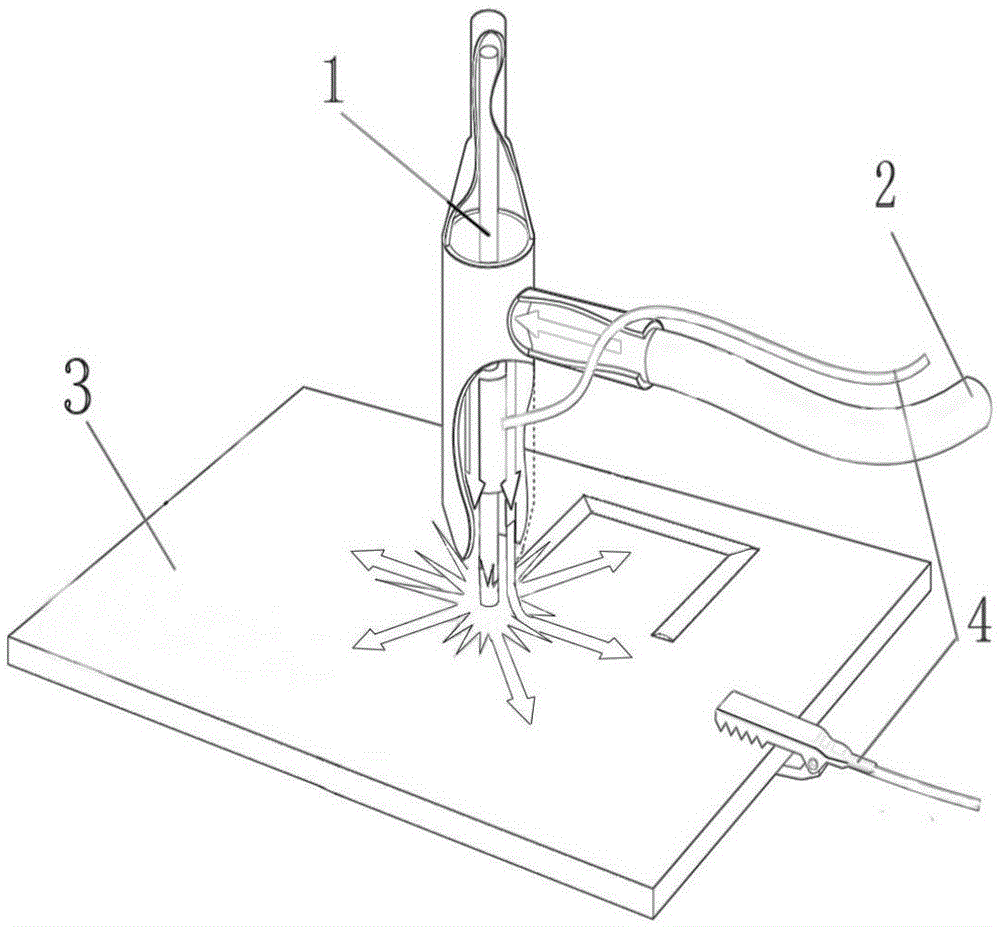

Consumable electrode gas shielded arc deposition three-dimensional printing method

InactiveCN105643053AHigh shape accuracyQuality improvementArc welding apparatusShielding gasEngineering

Owner:GUIZHOU NORMAL UNIVERSITY

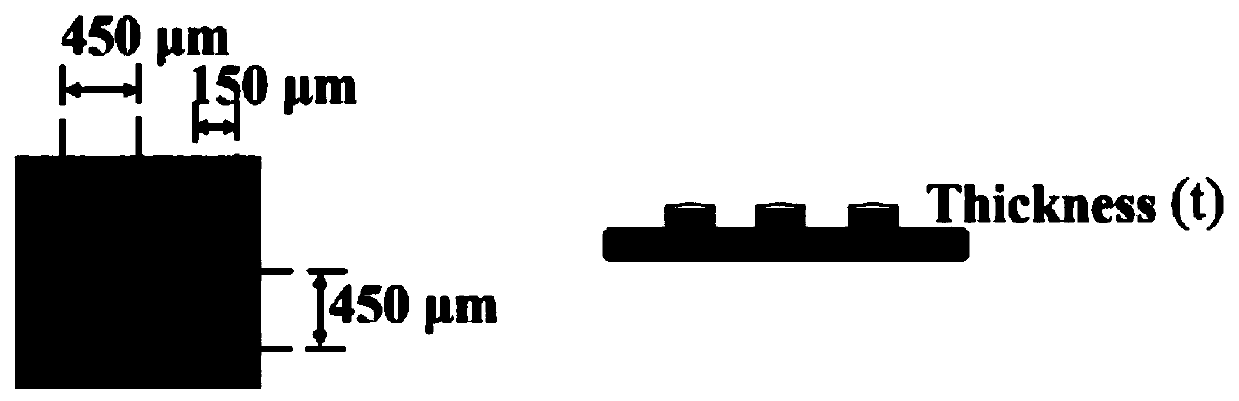

Cellulose nanosheet material and preparation method thereof

The invention discloses a cellulose nanosheet material. The thickness and the transverse size of the cellulose nanosheet material can be both adjusted and controlled, the thickness is 1-100 nm, the transverse size is 0.1-30 [mu] m, more than 80% of the cellulose nanosheet material is a single layer, the thickness of the single layer is 4 nm+ / -1 nm, in addition, the cellulose nanosheet material is smooth in surface, and the AFM (Atomic Force Microscope) measurement shows that the fluctuation of the surface is within 0.1 nm. The invention further discloses a preparation method of the cellulose nanosheet material. The preparation method comprises the following steps: firstly, performing mixed grinding on a cellulosic material and a lyophobic material so as to gradually separate cellulose into flakes, and further performing ultrasonic dispersion and separation to remove the lyophobic material, thereby obtaining the cellulose nanosheet material. The cellulose nanosheet material disclosed by the invention is of a layered, orientated and crystal structure, and is high in polydispersity in transverse size and morphology.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

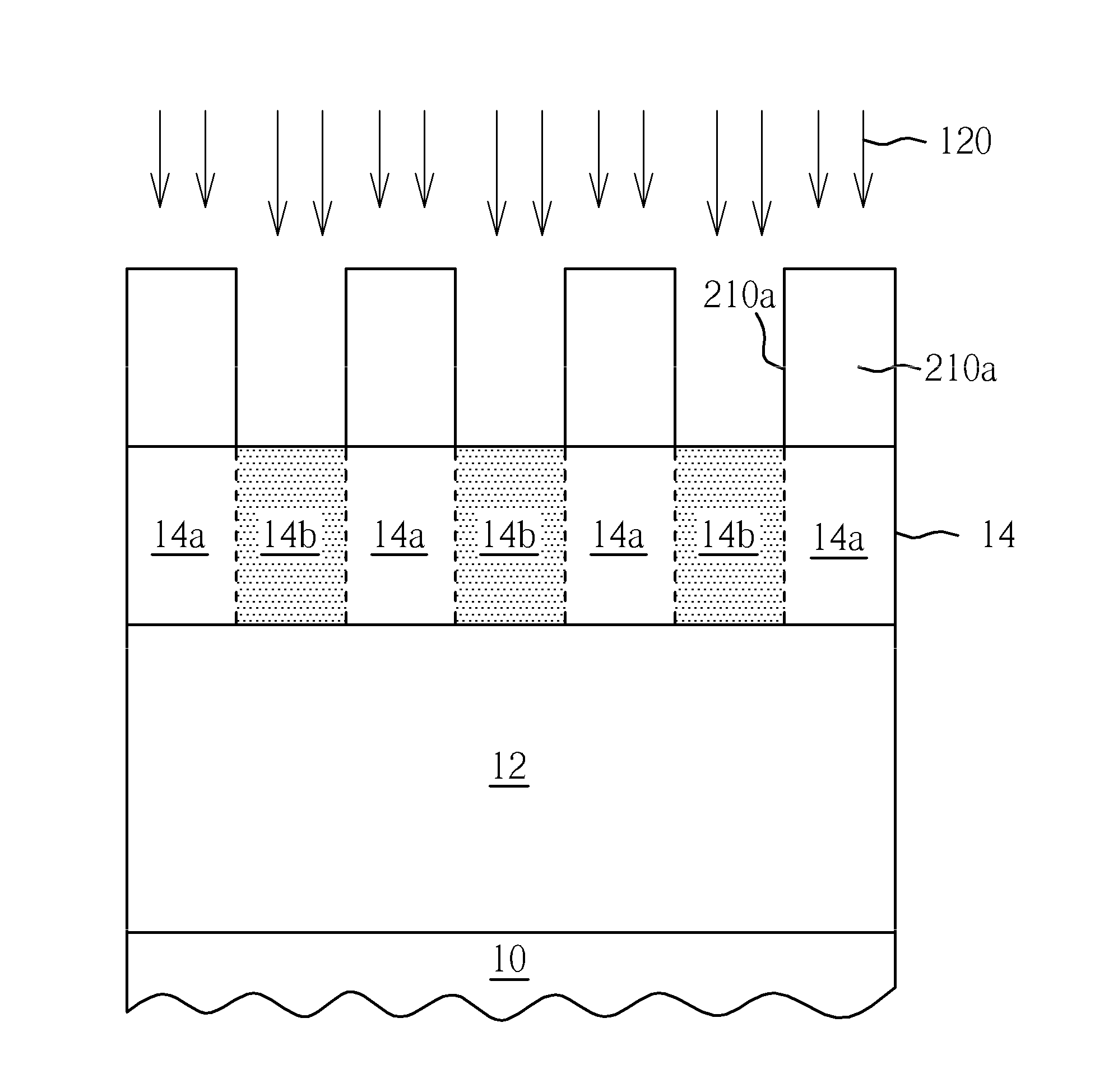

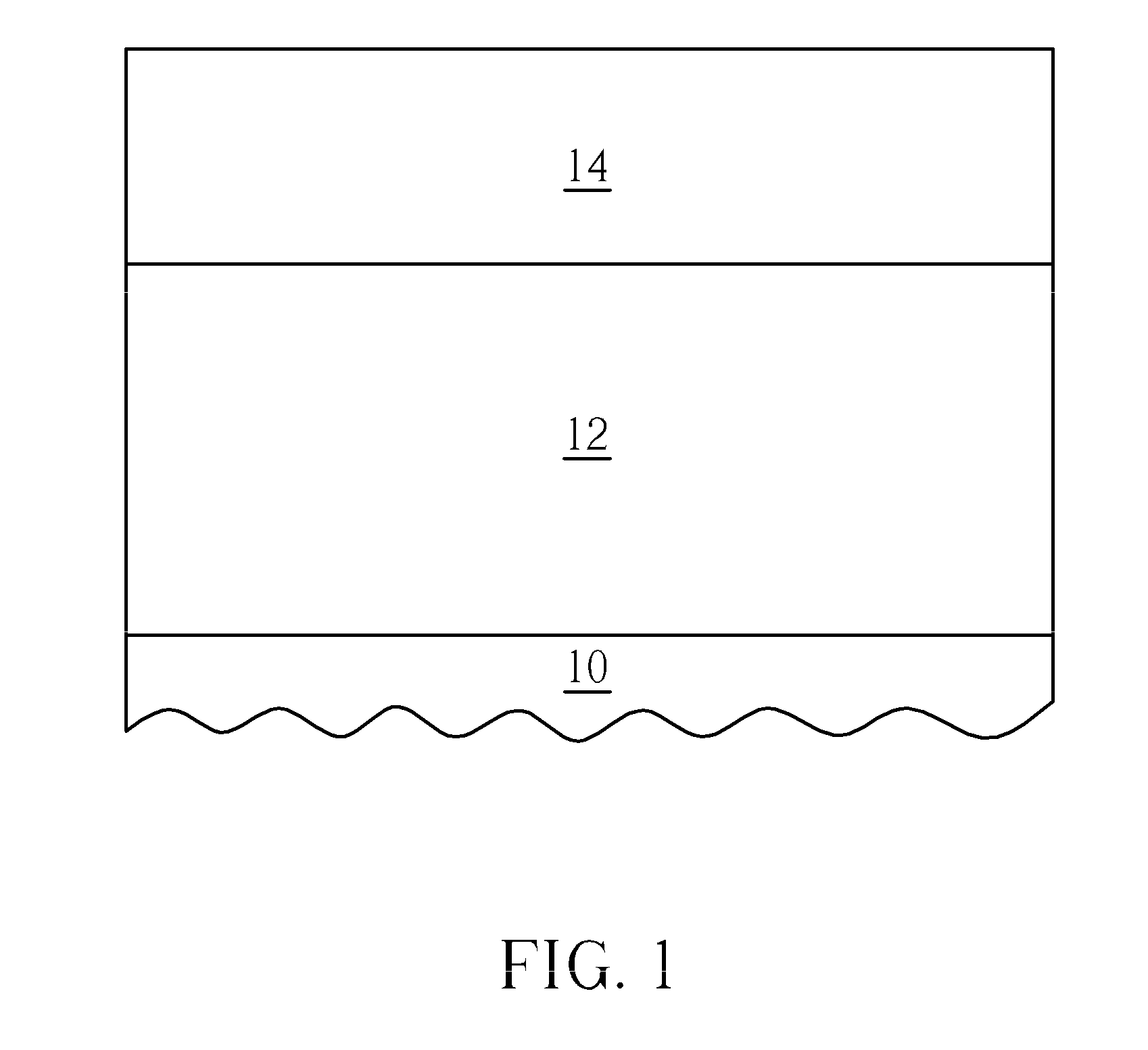

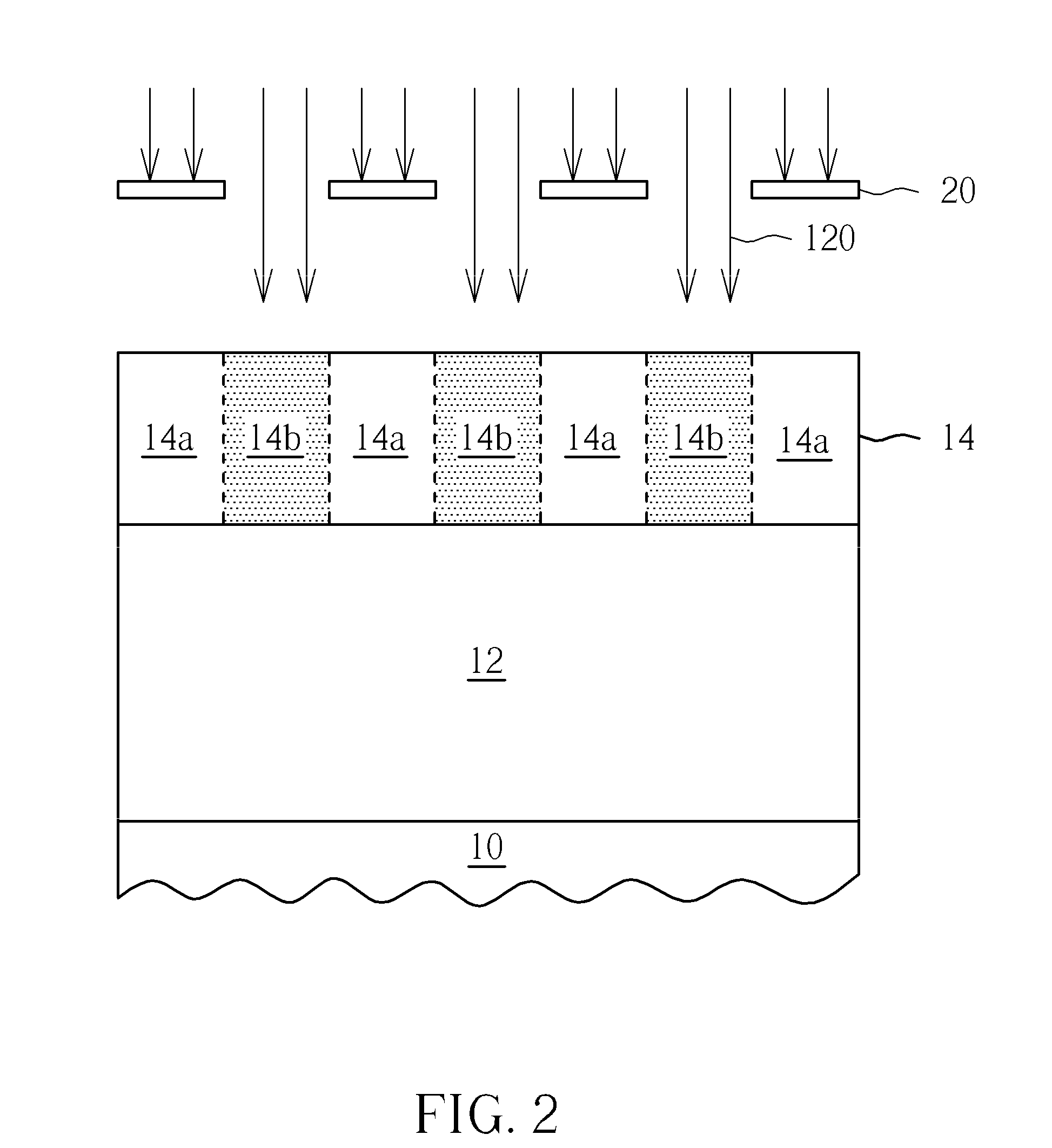

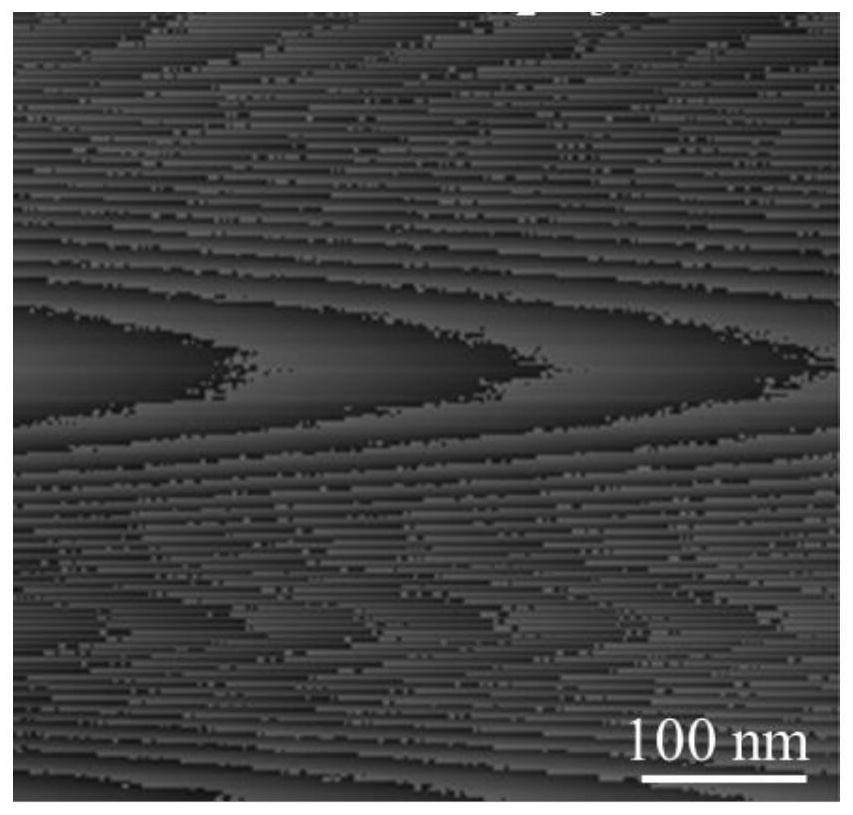

Method of forming an etch mask

ActiveUS20130071790A1Simple methodElectric discharge tubesSemiconductor/solid-state device manufacturingResistSolvent

Owner:NAN YA TECH

Near infrared blocking membrane and preparation method thereof

ActiveCN104327757AReduce light transmittanceGood light transmissionNon-macromolecular adhesive additivesFilm/foil adhesivesInfraredFilm coating

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

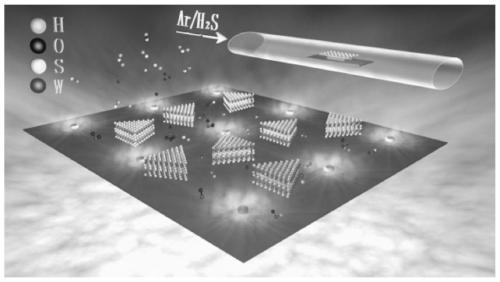

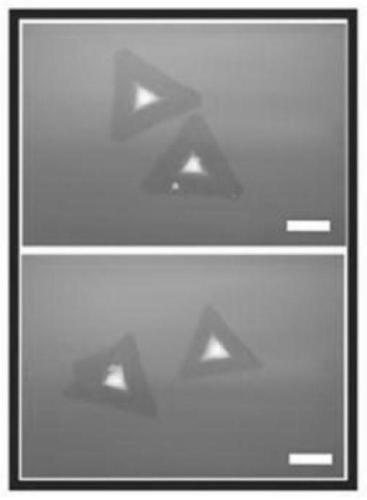

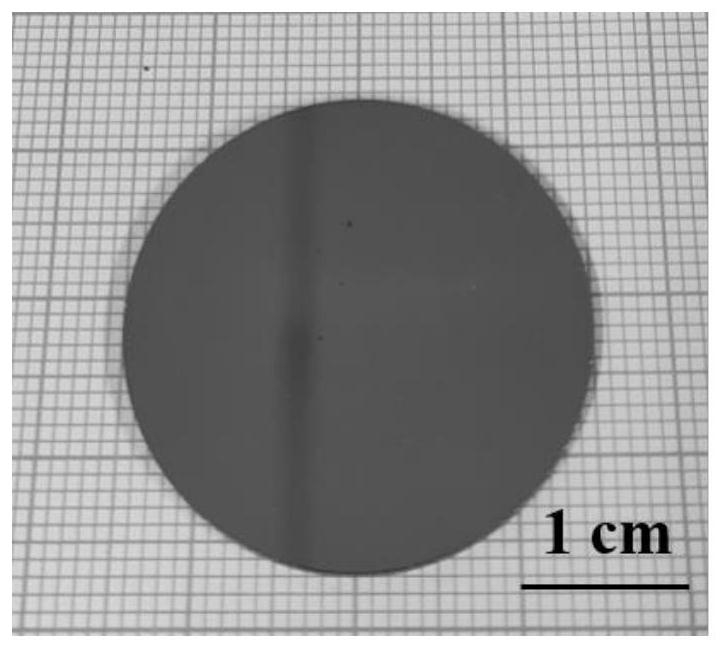

Preparation method and application of wafer-level absolute single-layer transition metal chalcogenide

ActiveCN113088922AImprove crystal qualityLarge single crystal sizeFinal product manufactureChemical vapor deposition coatingPhysical chemistrySingle crystal

Owner:NORTHWESTERN POLYTECHNICAL UNIV

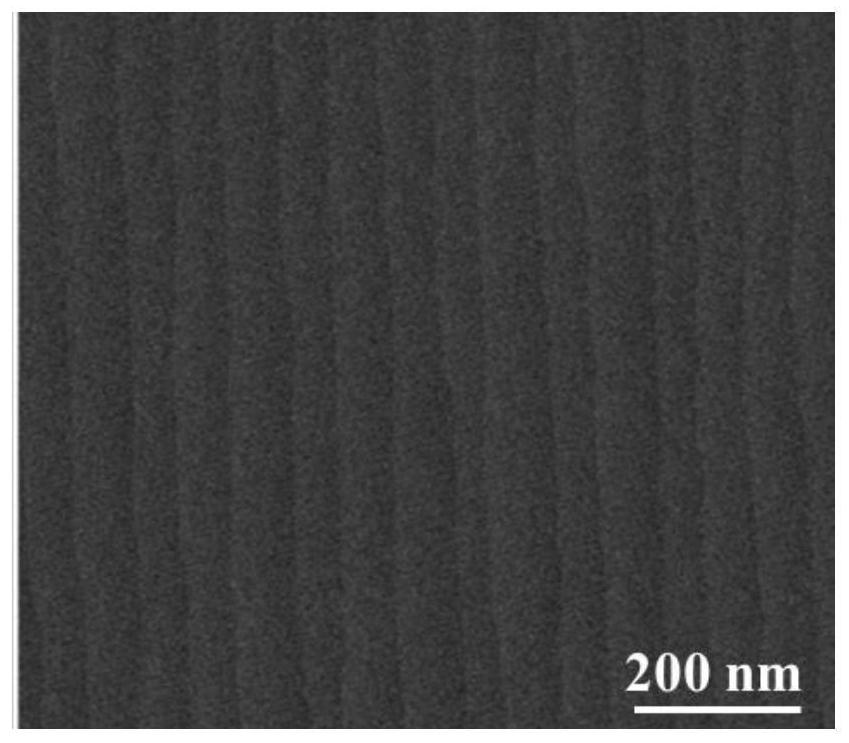

Preparation method of tungsten disulfide single crystal with controllable layer number

ActiveCN111472049AIncrease profitHigh repetition ratePolycrystalline material growthFrom chemically reactive gasesSingle crystalMaterials science

Owner:WENZHOU UNIVERSITY

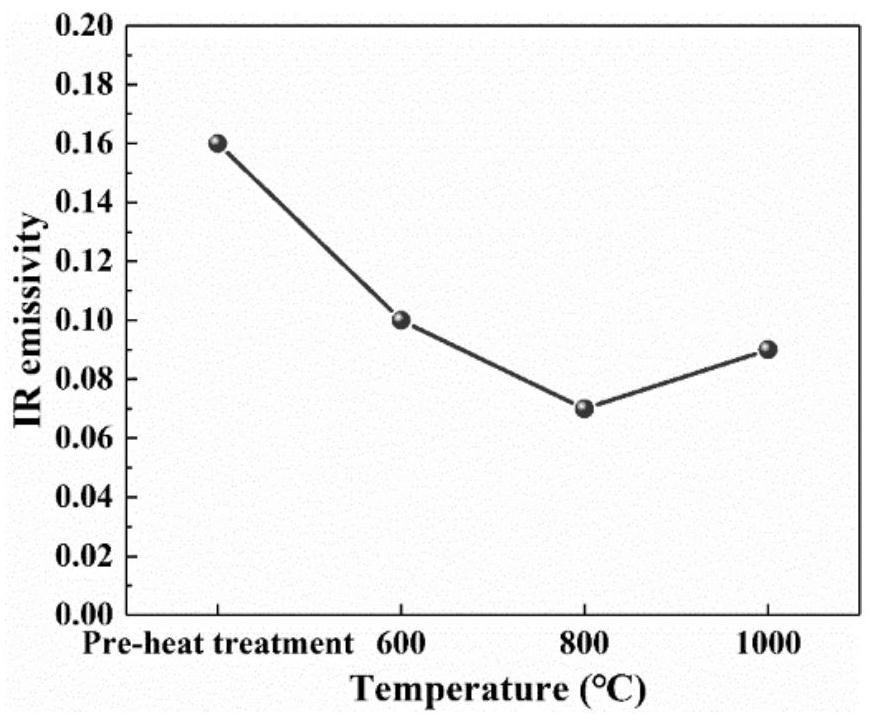

High-temperature-resistant, water-oxygen-resistant and low-infrared-emissivity composite film for ceramic-based composite material and preparation method

ActiveCN113403594AReduce IR emissivityEasy to useVacuum evaporation coatingSputtering coatingComposite filmLow emissivity

Owner:NORTHWESTERN POLYTECHNICAL UNIV

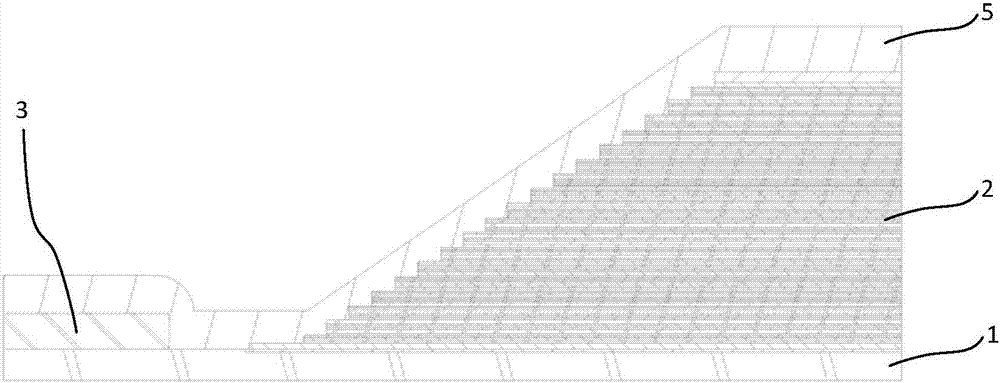

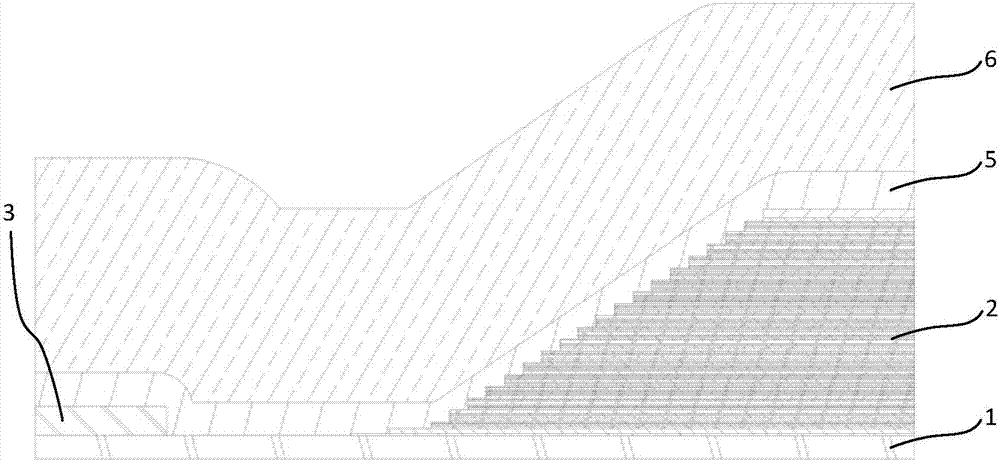

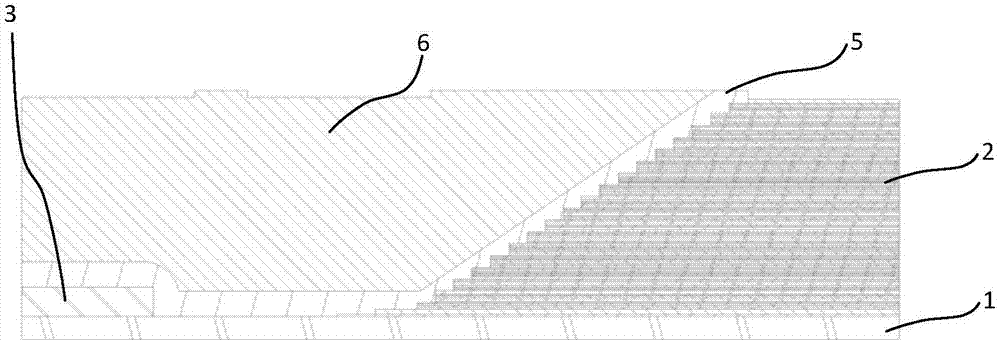

Method for forming multilayer composite film and three-dimensional memory device

ActiveCN107579074AIncreasing the thicknessSolve the problem of surface cracking under high stressSolid-state devicesSemiconductor devicesMemory chipComposite film

Owner:YANGTZE MEMORY TECH CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap