Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11 results about "Sodium benzoate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium benzoate is a substance which has the chemical formula C₆H₅COONa. It is a widely used food preservative, with an E number of E211. It is the sodium salt of benzoic acid and exists in this form when dissolved in water. It can be produced by reacting sodium hydroxide with benzoic acid.

High-strength environment-friendly composite board and preparation method thereof

InactiveCN104690805AHigh strengthImprove toughnessNon-macromolecular adhesive additivesProtein adhesivesEnvironmental resistanceFiber

Owner:安徽忠盛新型装饰材料有限公司

Green pepper preservative solution

InactiveCN102696753AExtended storage timeGuaranteed tasteFruit and vegetables preservationChemistrySodium benzoate

The invention provides a green pepper preservative solution. The green pepper preservative solution comprises the following components in parts by weight: 0.4-0.6 parts of sodium benzoate, 0.5-1.5 parts of sodium alginate, 0.5-1 parts of sodium thiosulfate, 1-2 parts of ascorbic acid, 0.1-0.3 parts of calcium phosphate, 0.3-0.5 parts of ferrous sulfate and 100-120 parts of water. A preparation method comprises the following steps of taking the components in the parts by weight, adding the components into a container, and then adding a small quantity of water to the container, uniformly mixing the components and the water so as to obtain the green pepper preservative solution, and further diluting the green pepper preservative solution to a desired concentration during using. By using the green pepper preservative solution provided by the invention, the storage time of green peppers can be prolonged and mouth feel, color and hardness of green peppers can be guaranteed.

Owner:柳迪

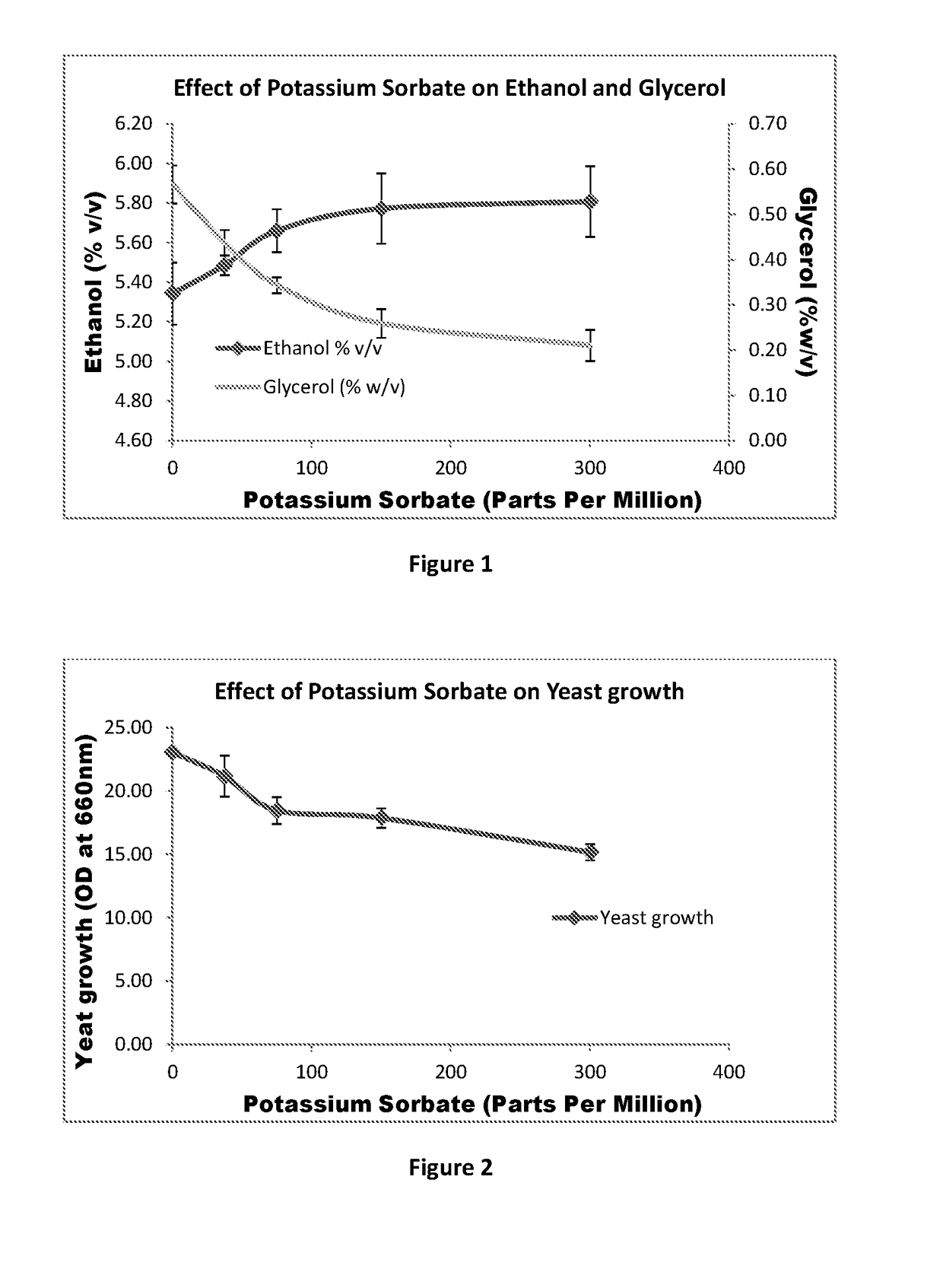

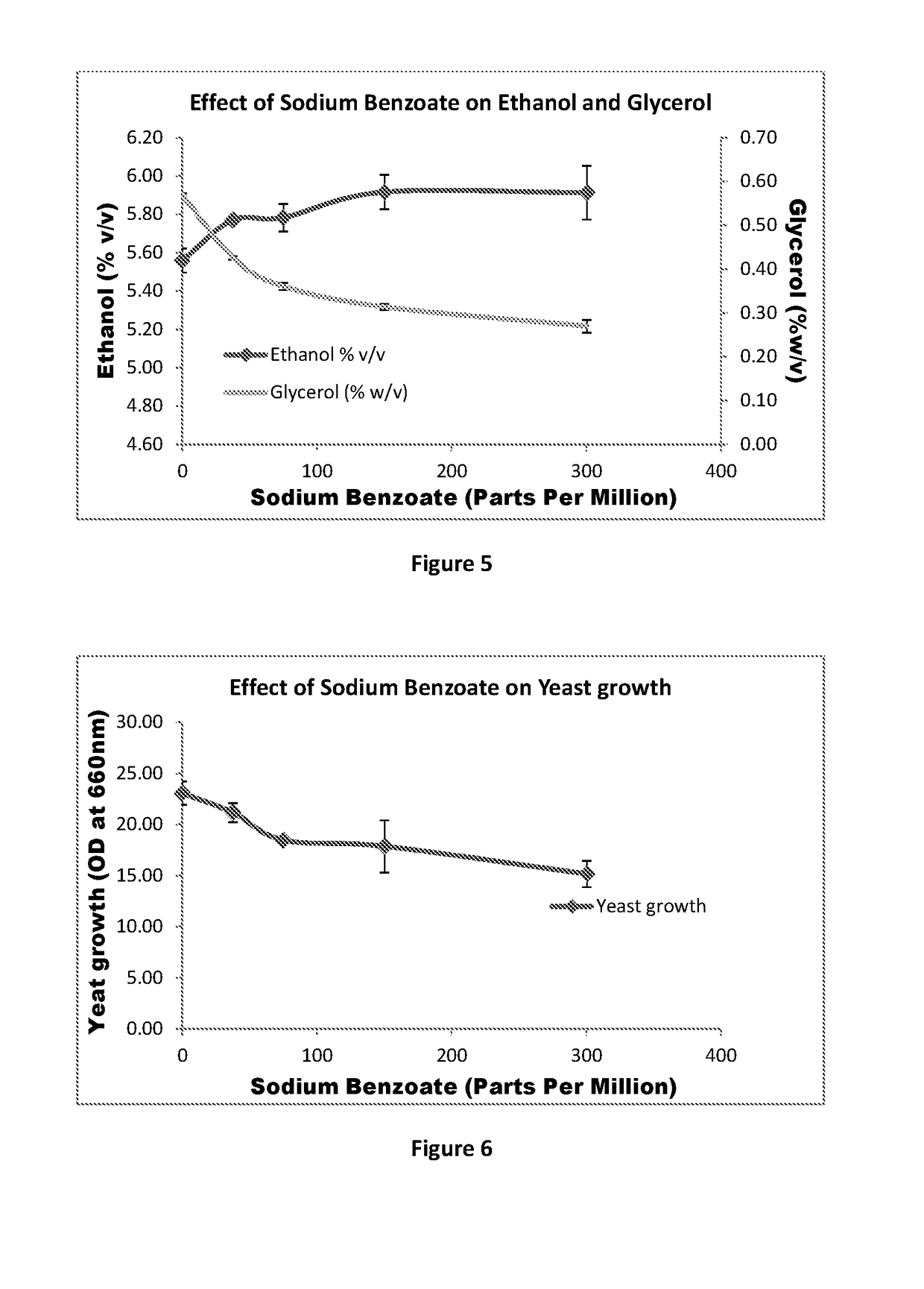

Process for production of bio-alcohol

InactiveUS20180030483A1Increase alcohol productionReduced unproductive yeast productionFungiBiofuelsAlcohol productionGlycerol

Owner:DANISCO CHINA HLDG CO LTD +2

Processing process of fragrant and crispy sliced garlic

InactiveCN104366338ADetoxificationTo promote metabolismFood ingredient functionsFood preparationBiotechnologyNutrition

Owner:彭超昀莉

Preparation methods of olive essential oil facial masks

InactiveCN107550758ARealize pure manual preparationCosmetic preparationsToilet preparationsWater bathsAdditive ingredient

The invention discloses preparation methods of olive essential oil facial masks. The preparation method of a peel-off type skin-moistening facial mask comprises the following steps: taking polyvinyl alcohol, adding alcohol into polyvinyl alcohol, and adding the obtained solution into water containing sodium alginate, carboxymethylcellulose, sodium benzoate and olive oil; carrying out heating to 60-80 DEG C, carrying out constant-temperature water bath, carrying out stirring so that the mixing is uniform, and carrying out standing overnight; on the next day, adding glycerol, propylene glycol, silicon latex and an appropriate amount of essence, and carrying out sufficient and uniform stirring. The preparation method of a non-woven facial mask comprises the following steps: carrying out heating so that sodium hyaluronate, EDTA-2Na and water are dissolved, and adding olive oil; then adding tween-80, bisabolol and an appropriate amount of essence into glycerol and butanediol, carrying out mixing with the obtained water solution, and adding an appropriate amount of a preservative. Different plant extract ingredients such as witch hazel extraction liquid, rosemary extract and ginkgol biloba extract can be added into the product, and thus different kinds of facial masks with different functions can be prepared. The method is easy and convenient to operate, the utilization ratio of theraw materials is high, and the ratio of the raw materials, ingredients and pigment varieties can be changed according to requirements.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Production method of white sugar garlic

InactiveCN104351697AUnique flavorAdapt to tasteFood preparationSodium acetrizoateMonosodium glutamate

The invention relates to a production method of white sugar garlic. The process sequence comprises the following steps: raw material selection, cleaning, soaking and salting, preserving, re-cleaning, batching, impregnating, draining, packaging, sterilizing, air drying and boxing, wherein for the soaking and salting step, fresh garlic, water and salt are mixed in a mass ratio of 15:10:1 and soaked and salted for 4-8 days, and water in the bottom of a pit is pumped to the upper part for exchange in a soaking and salting process; for the batching step, 60 kg of garlic is added with 40 kg of water, 9-11 kg of white sugar, 1.5-2.5 kg of monosodium glutamate, 2-3 kg of vinegar, 100-200 g of acetic acid, 80-100 g of citric acid, 46-54 g of sodium cyclamate, 10-15 g of acesulfame potassium, 5-7 g of saccharin, 46-54 g of aspartame, 18-22 g of ethylene diamine tetraacetic acid disodium salt, 7-9 g of sodium dehydroacetate, 22-26 g of sodium benzoate and 46-54 g of D-sodium erythorbate. The white sugar garlic is fresh and sweet, is not greasy, has slight sour taste, is unique in flavor, and adapts to the taste of eaters in vast regions.

Owner:朱兴初

Lubricating oil for oil field operation drill pipe

InactiveCN108300549AExtensive sources of raw materialsWide variety of sourcesDrilling compositionLubricant compositionEthyl acetateSodium sulfate

Owner:NANTONG JINNIU MACHINERY MFR

Ready-to-eat euphausia pacifica sauce for bibimbap and making method of ready-to-eat euphausia pacifica sauce

InactiveCN107212363AFull of nutritionAnti agingLipidic food ingredientsFood ingredient functionsReady to eatEuphausia pacifica

Owner:MAANSHAN SHIYUEFENG FOOD

Weeding and insect killing high-efficiency mildew-proof material

Owner:常熟市胜阳干燥剂贸易有限公司

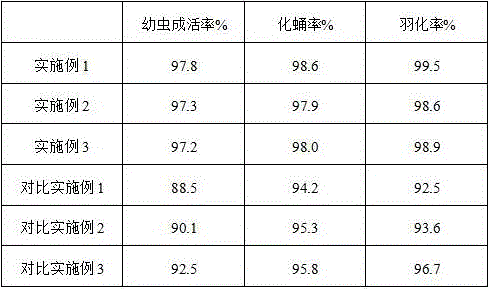

Fodder for improving breeding efficiency of beet armyworm

InactiveCN106306389AImprove reproductive efficiencyImprove immunityAnimal feeding stuffAccessory food factorsBiotechnologyVitamin C

Owner:华巧波

Broken-peel pickled pepper red sour soup and manufacture method thereof

InactiveCN112753983ASave time and costLow pollution rateFood scienceBiotechnologyMonosodium glutamate

The invention discloses a broken-peel pickled pepper red sour soup, which comprises the following raw materials in parts by weight: 10-70% of Lycopersicon esculentum, 10-70% of broken-peel pickled peppers, 10-15% of colleseed oil, 1-4% of Zingiber officinale Roscoe, 1-4% of Allium sativum L. and 5-8% of added water. All the raw materials are grinded into a paste, and then, according to parts by weight of the raw material paste, 1-2% of chicken powder, 1-3% of monosodium glutamate, 0.5-2% of lactic acid, 0.5-1% of citric acid, 2-5% of white sugar, 0.5-1% of Litsea pungens Hemsl. oil and 0.1-0.5g / kg of sodium benzoate are added. The manufacture method of the broken-peel pickled pepper red sour soup comprises the following steps of: 1) taking food materials: breaking the Lycopersicon esculentum and the broken-peel pickled peppers for standby, and taking bruised ginger and minced garlic; 2) evenly mixing the food materials, adding the colleseed oil and the water, grinding into an even paste, and heating the even paste at the temperature of 80 DEG C for 7 minutes; 3) seasoning by adding the chicken powder, the monosodium glutamate, the lactic acid, the citric acid, the white sugar and the Litsea pungens Hemsl. oil in sequence; 4) adding the sodium benzoate for corrosion prevention; and 5) after filling is carried out, sterilizing by heating at the temperature of 75 DEG C for 15min, cooling to be 40 DEG C or below, and then, packaging in a box. The invention has a simple technology, waste resources are reasonably utilized, and cost is low.

Owner:GUIZHOU MEITAN FUYING FOOD DEV CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap