Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11 results about "Atmospheric air" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

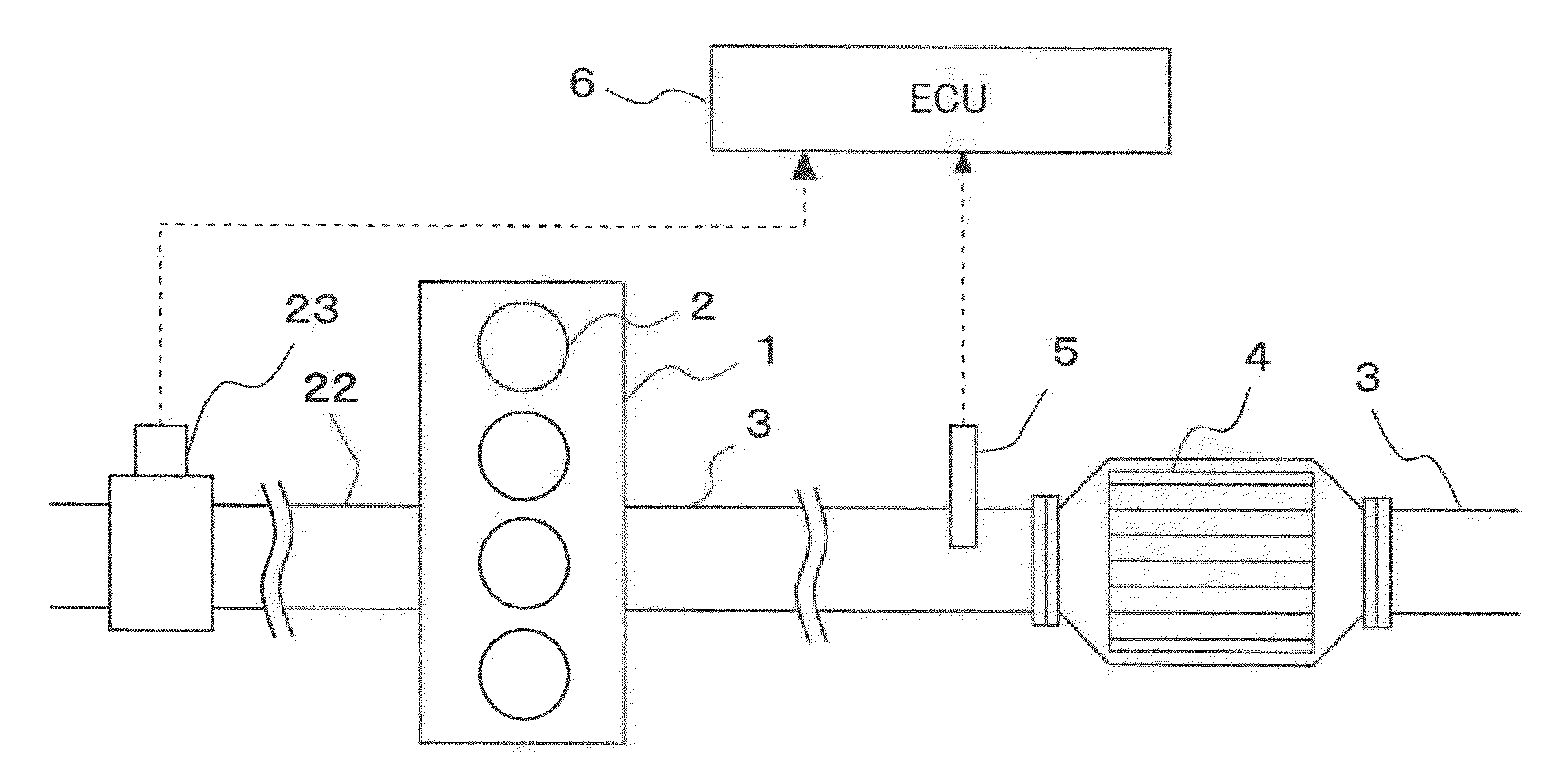

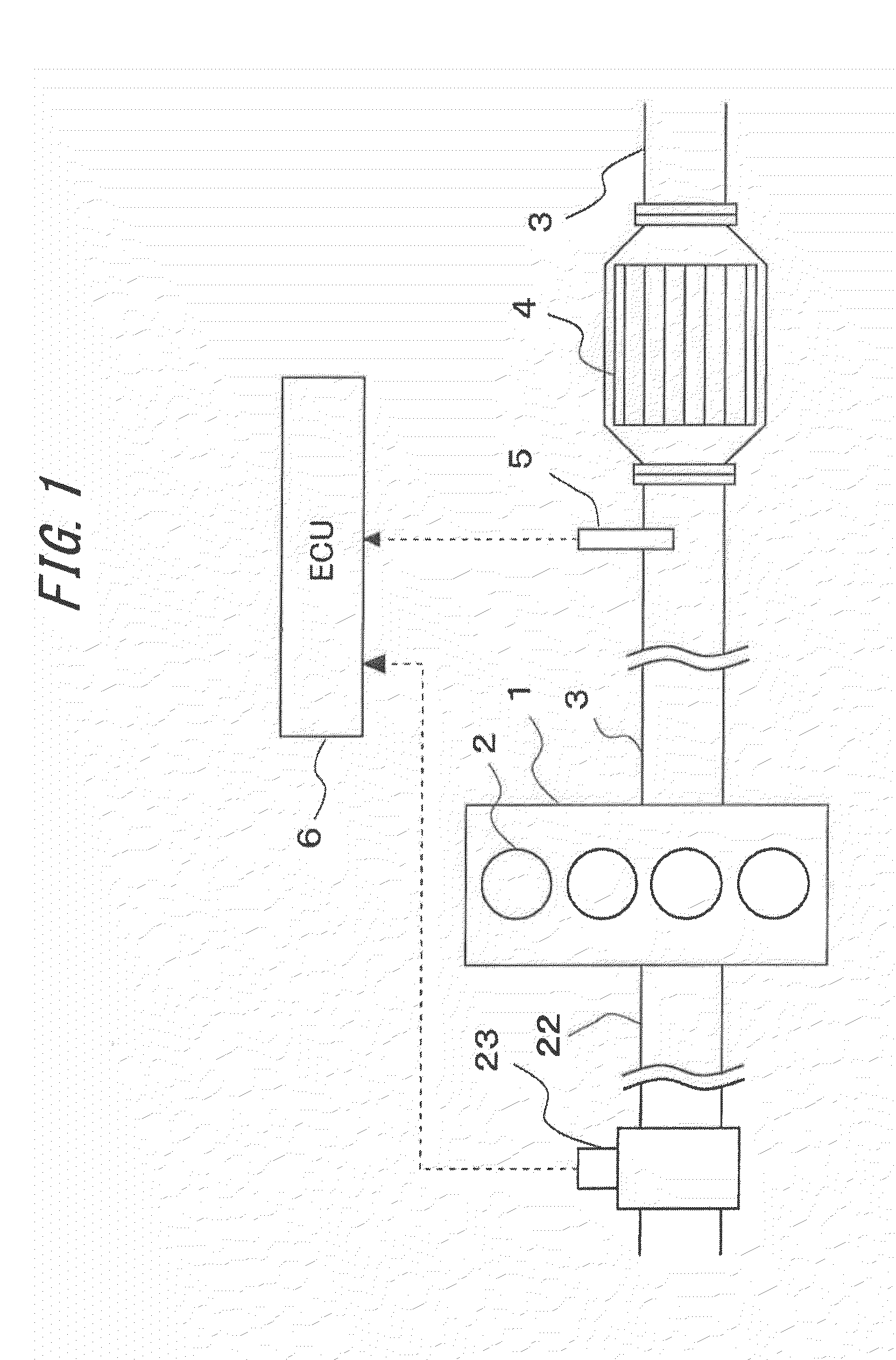

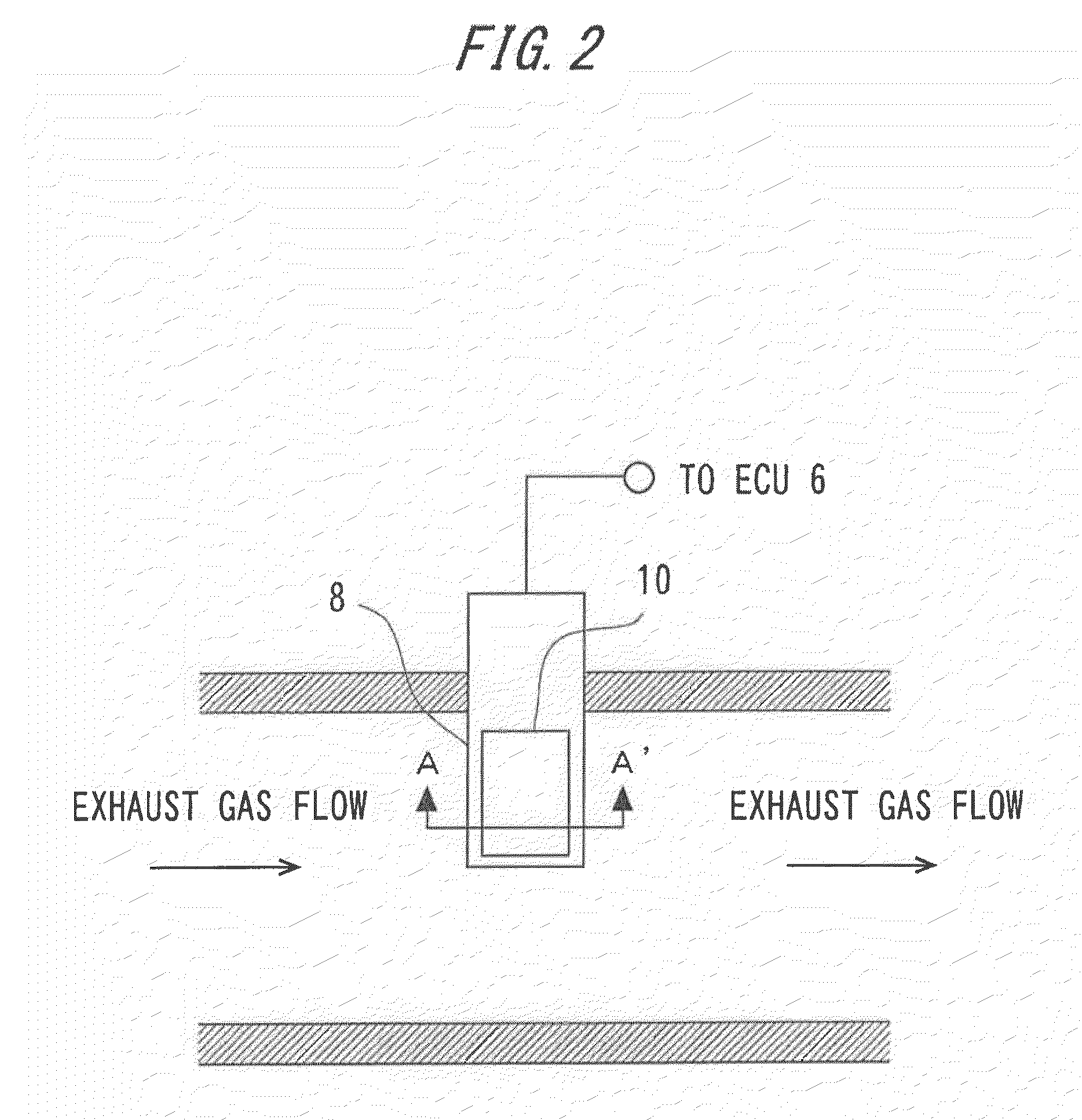

Air-fuel ratio sensor and control apparatus for internal combustion engine

InactiveUS20100300418A1Improve responsivenessElectrical controlExhaust apparatusControl layerAtmospheric air

Owner:TOYOTA JIDOSHA KK

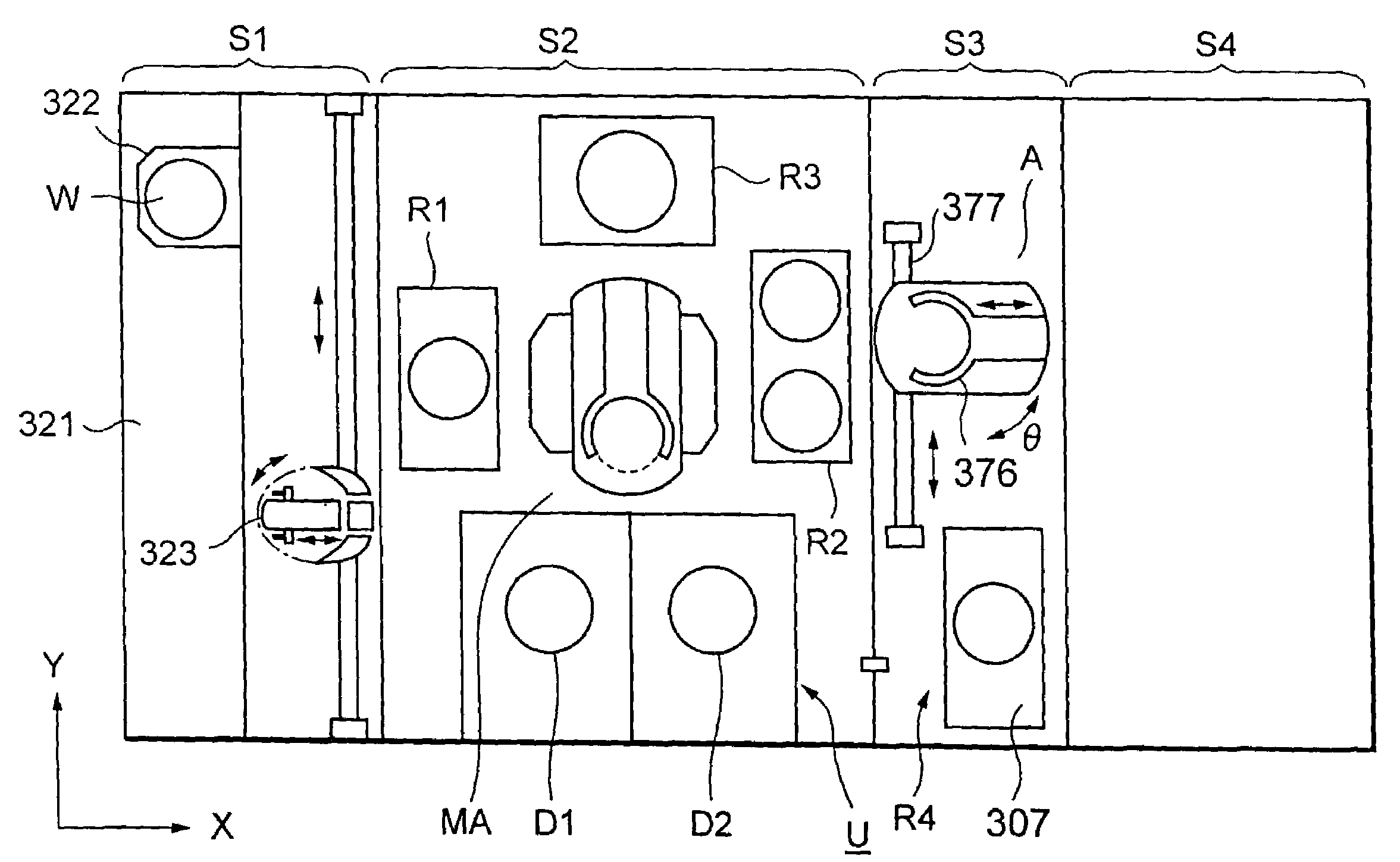

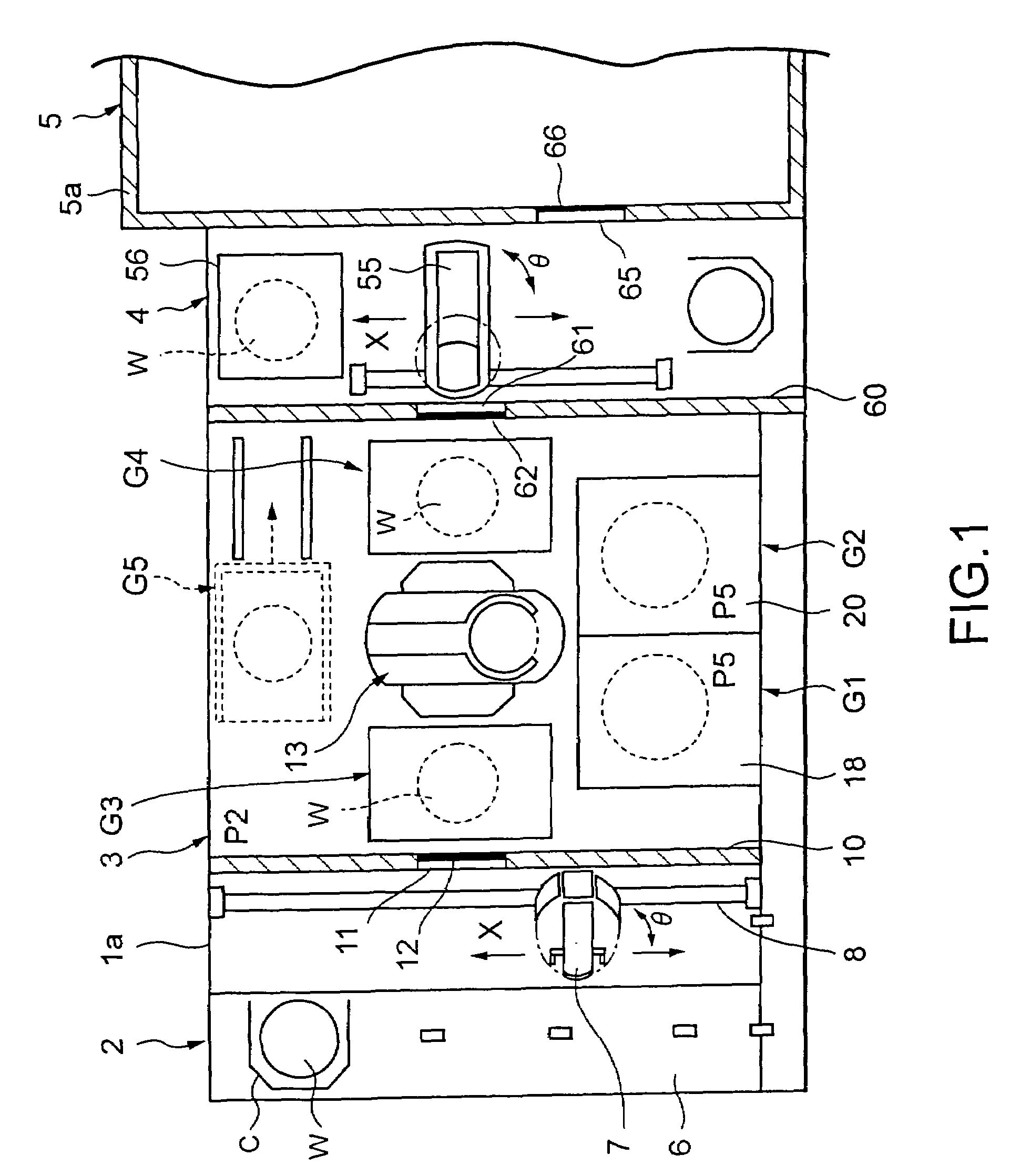

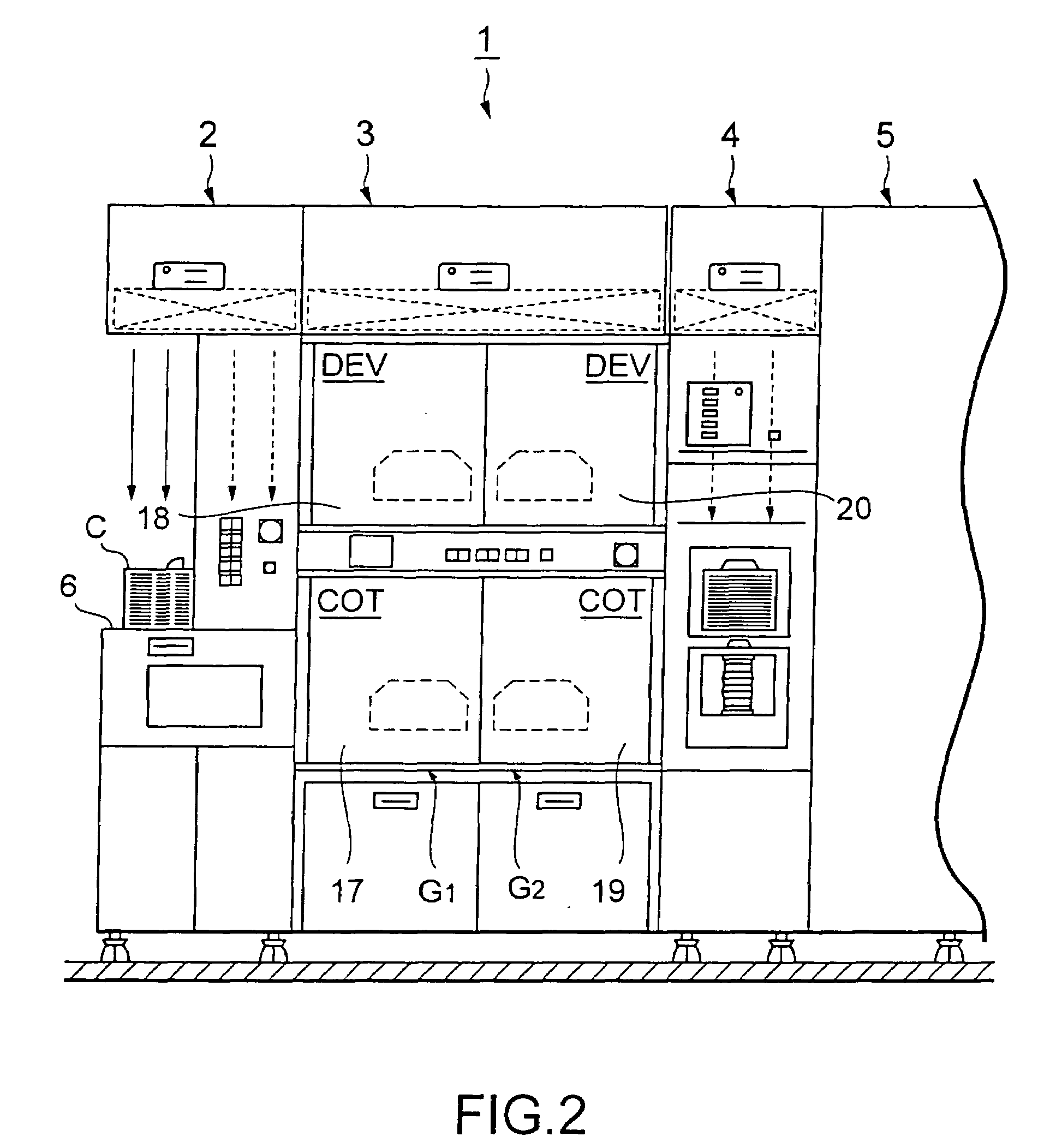

Substrate processing apparatus and substrate processing method

InactiveUS7208066B2Avoid levelingLiquid surface applicatorsPhotomechanical apparatusAtmospheric airEngineering

Owner:TOKYO ELECTRON LTD

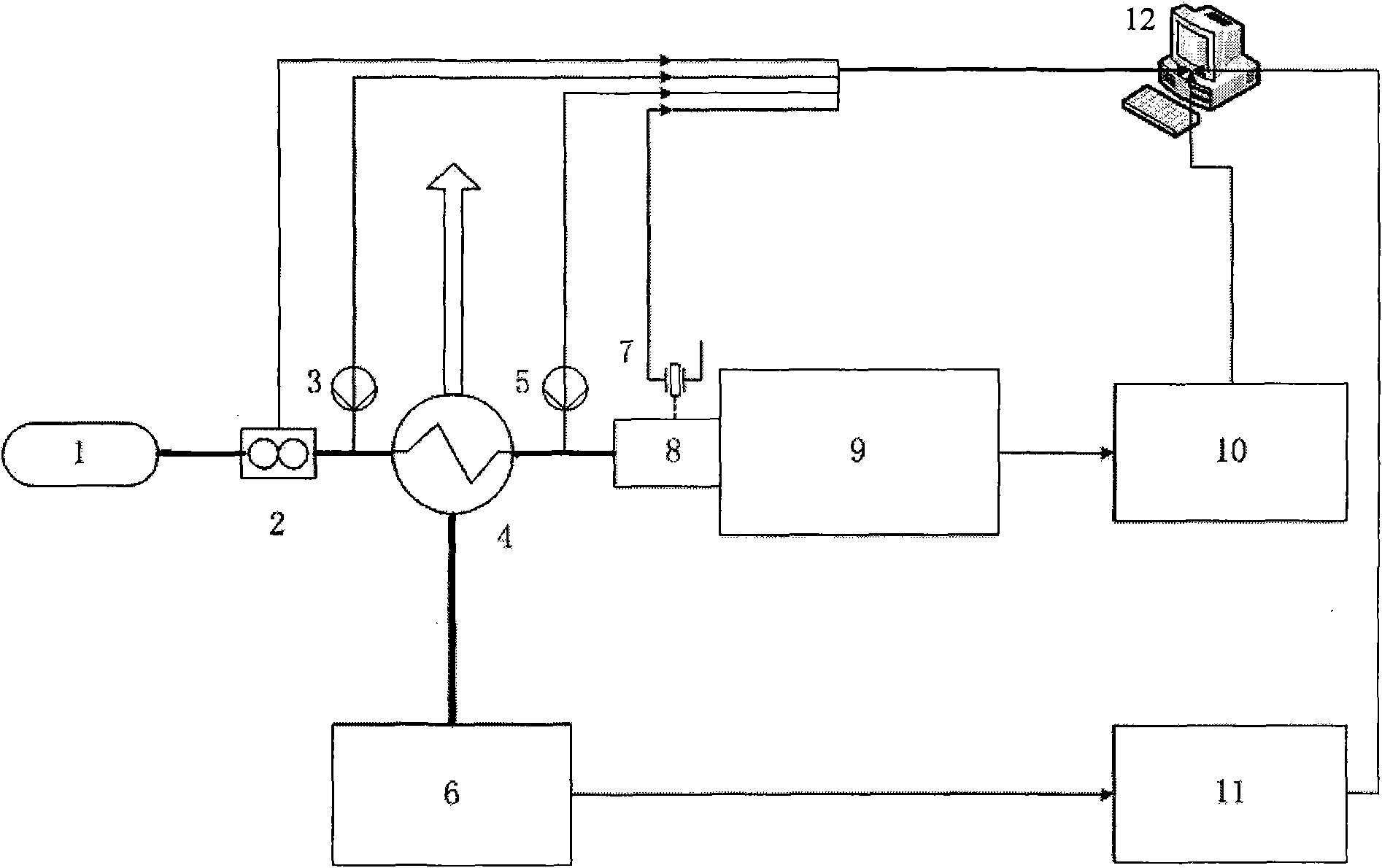

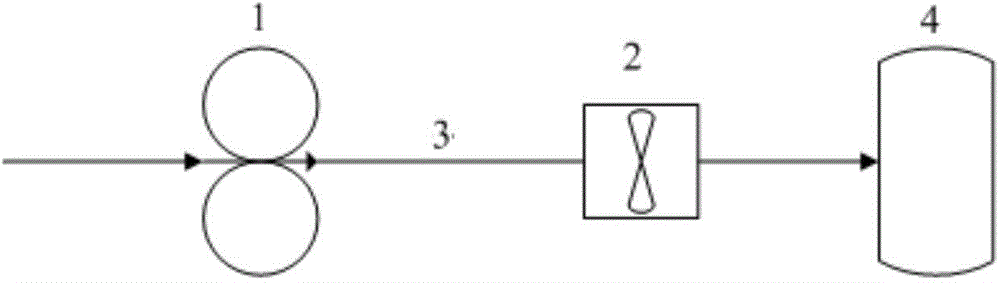

Air-fuel mixed power test system

InactiveCN101551298AReliable Experimental ParametersEngine testingPilot systemAtmospheric air

Owner:ZHEJIANG UNIV

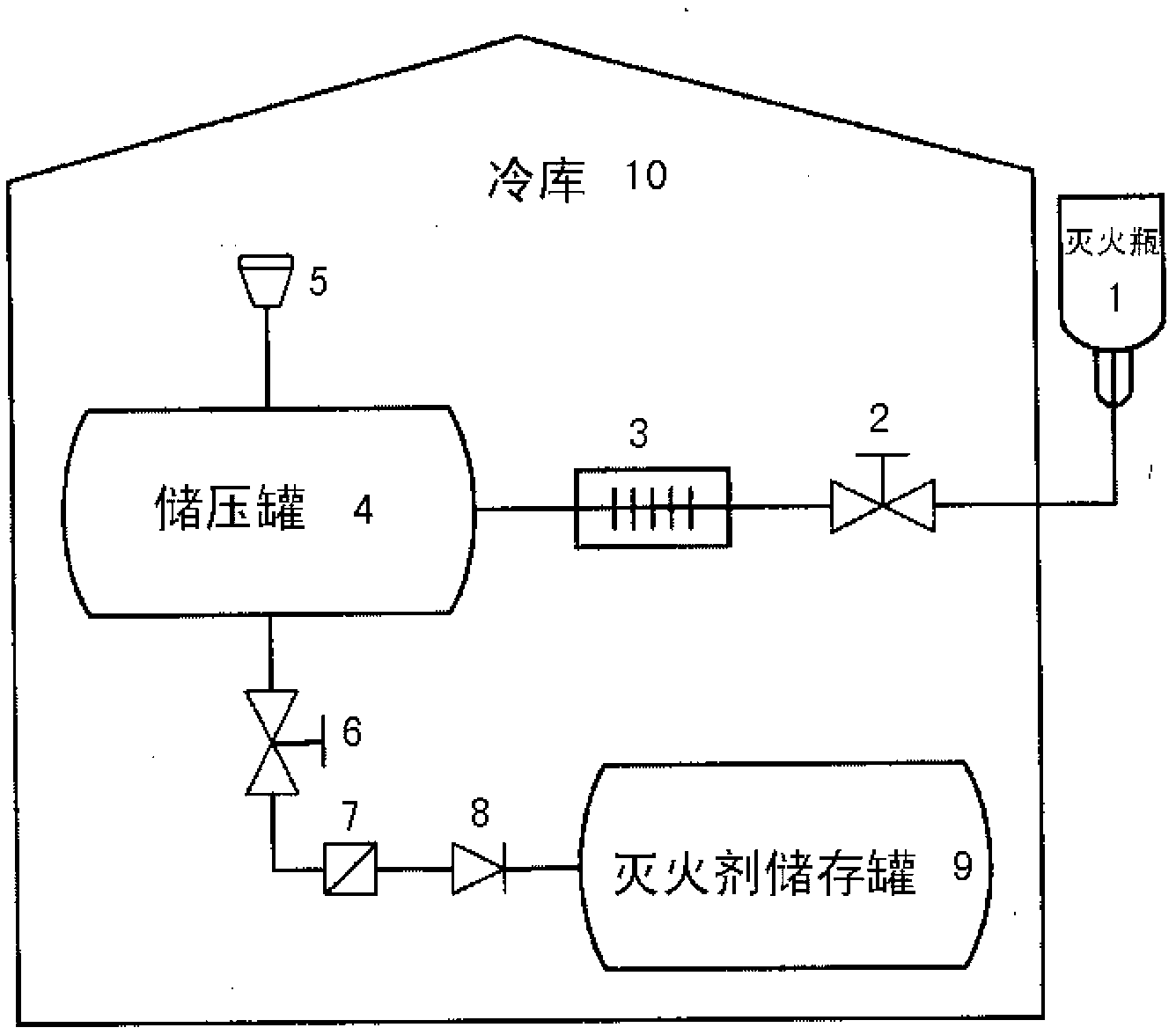

Recovery method of alkyl-halide fire extinguishing agent in fire extinguishing bottle for aviation

Owner:北京丰荣航空科技股份有限公司

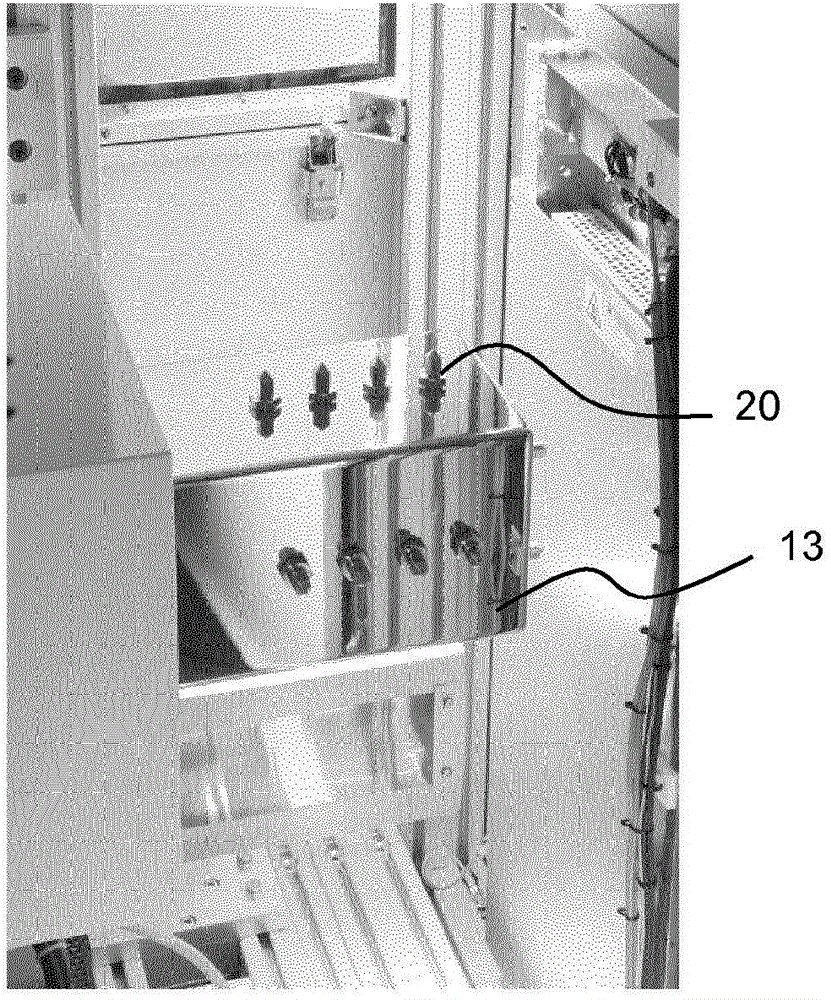

Oil-air separator driven by engine oil scavenging pump

InactiveCN104594976AReduce pollutionReduce consumptionMachines/enginesCrankcase ventillationAtmospheric airFuel tank

Owner:CHINA NORTH ENGINE INST TIANJIN

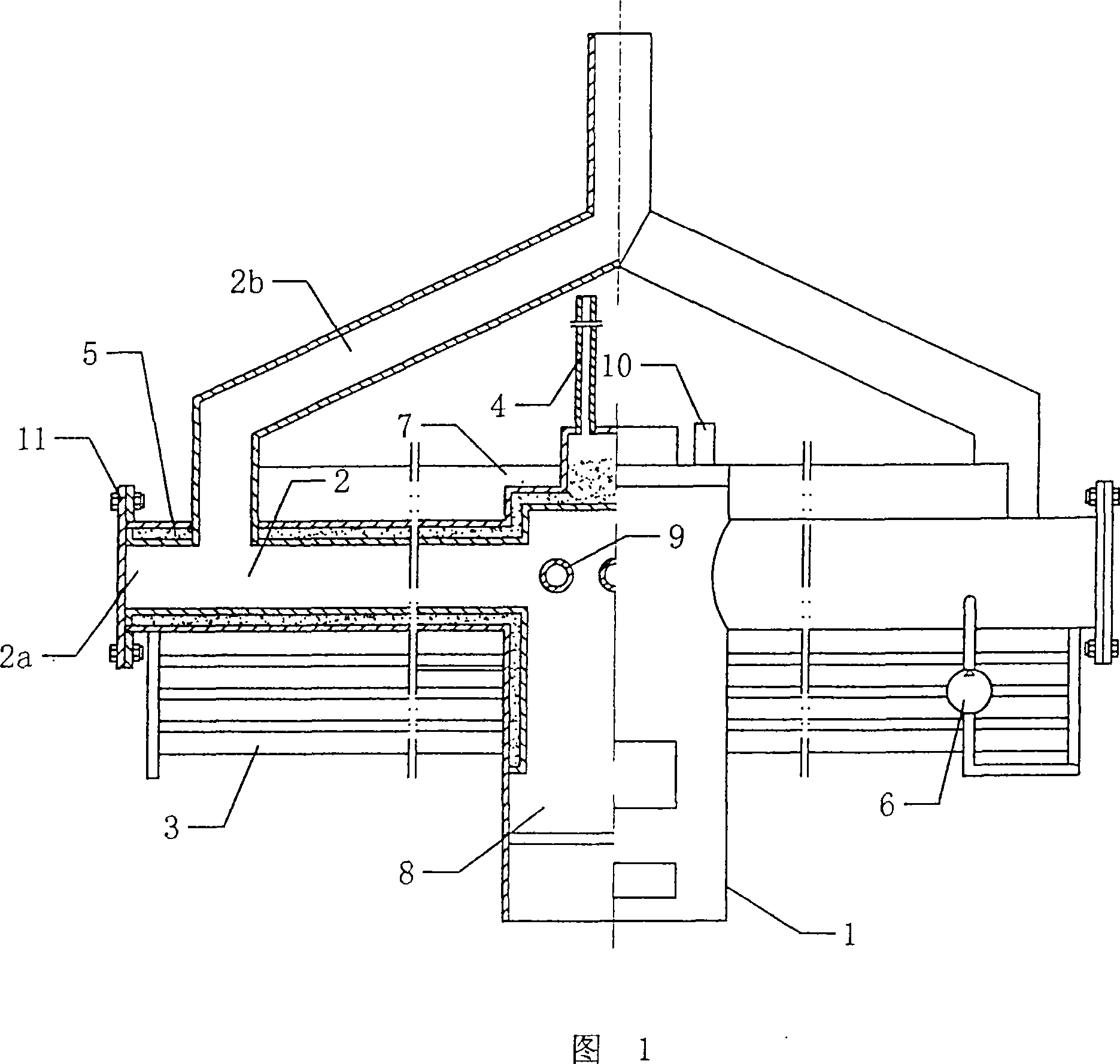

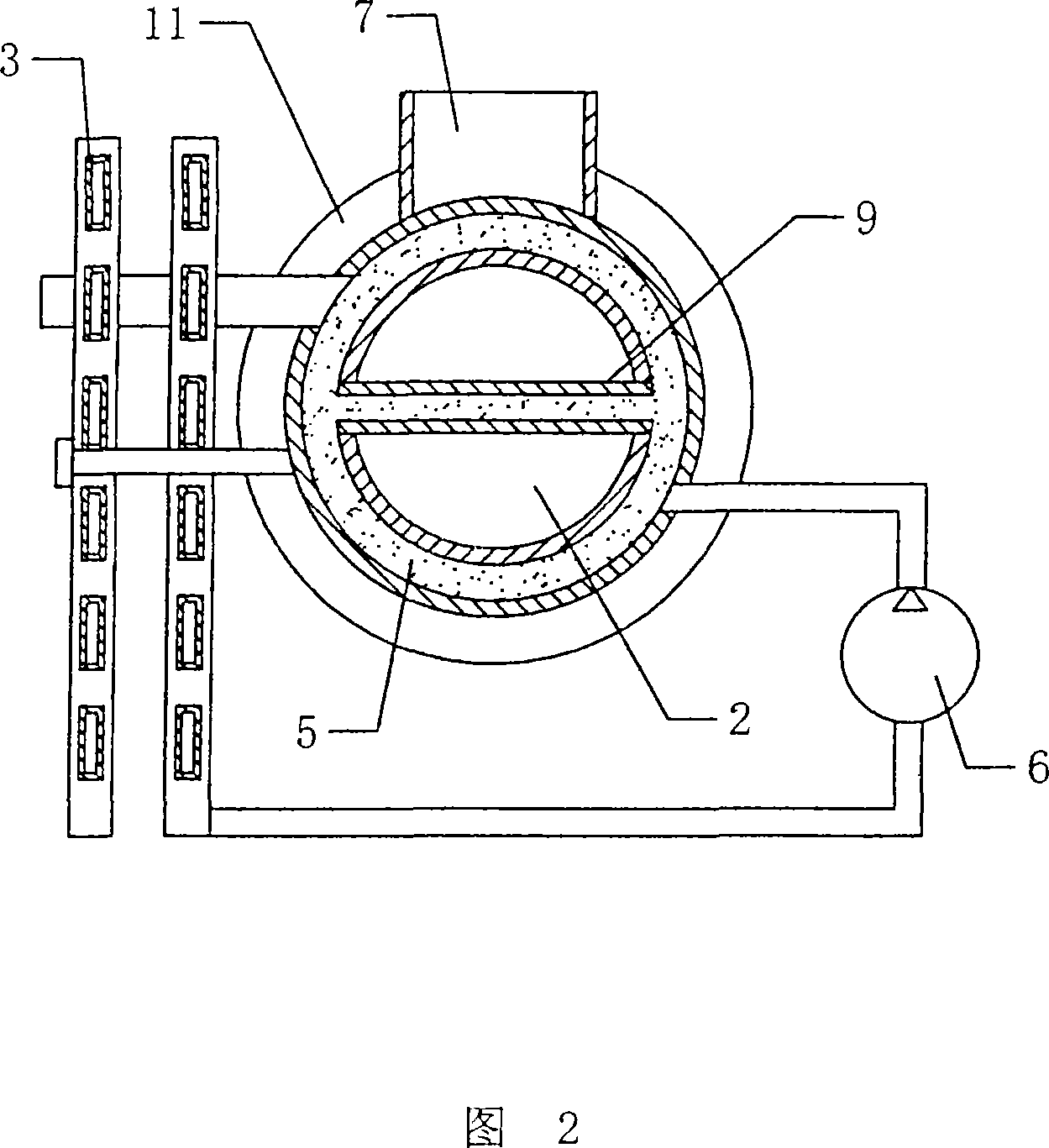

Lumber drying kiln

InactiveCN101144685AImprove thermal conductivityTemperature safetyHeating arrangementCombustion chamberHeat conducting

Owner:李祥文

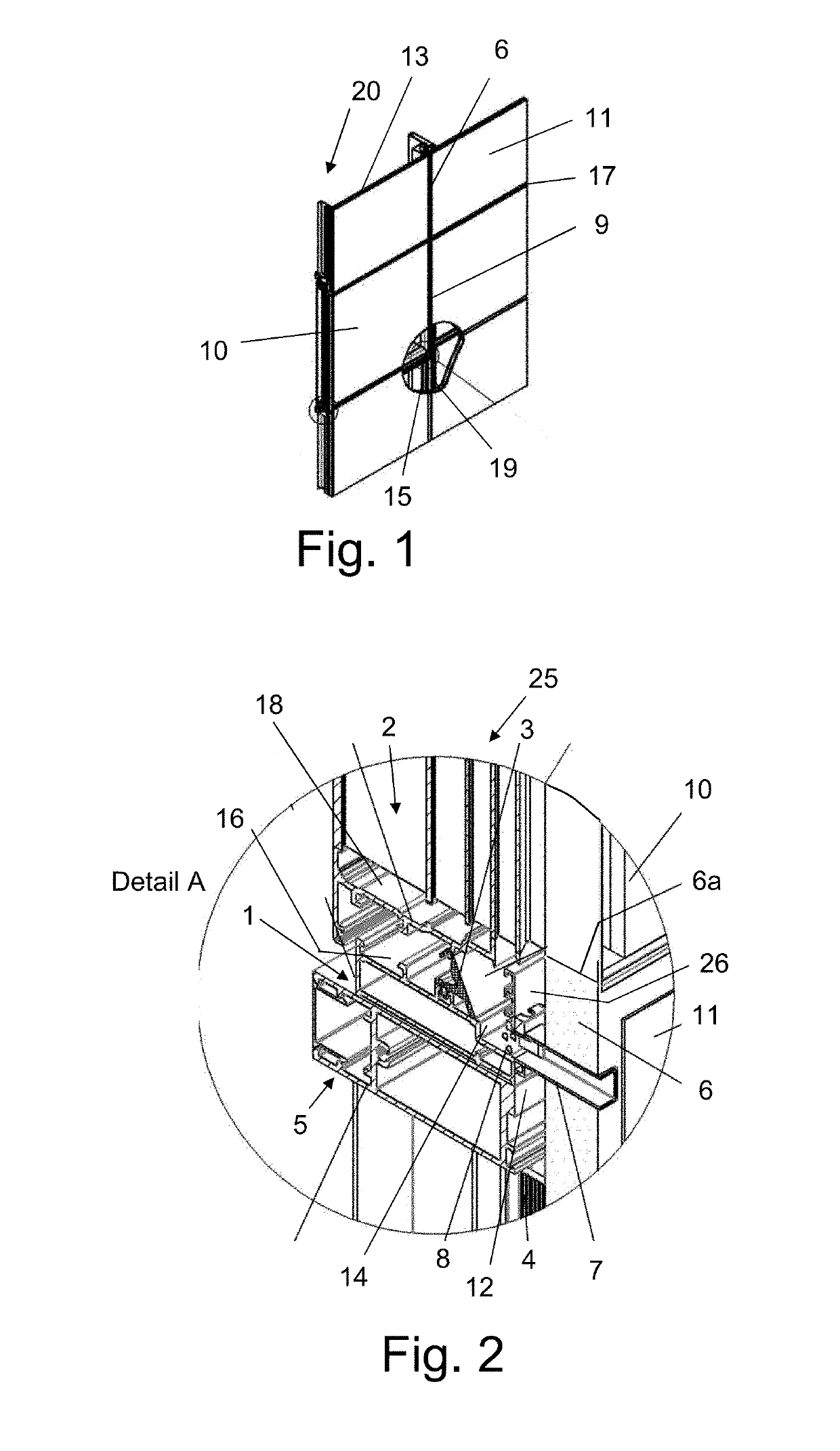

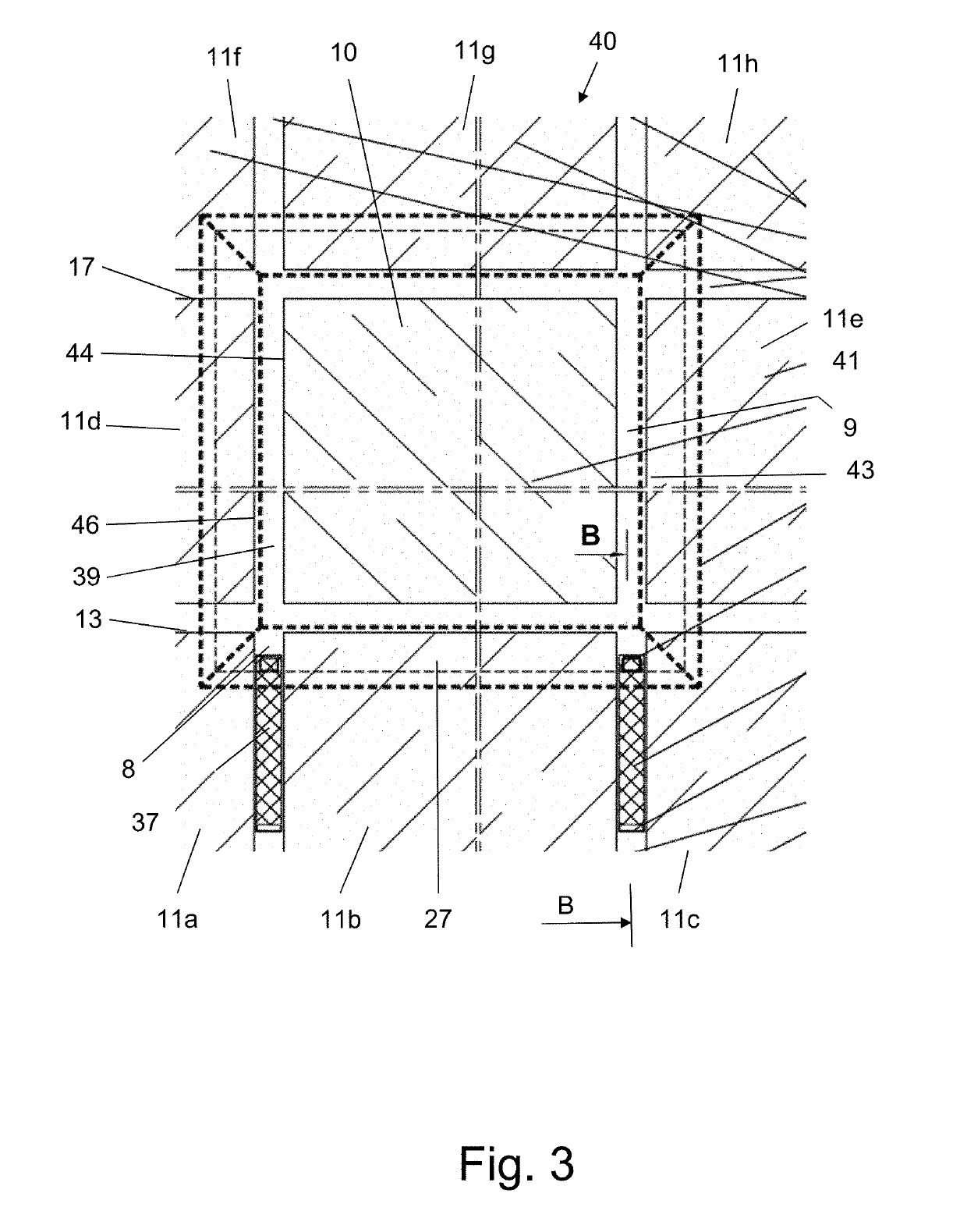

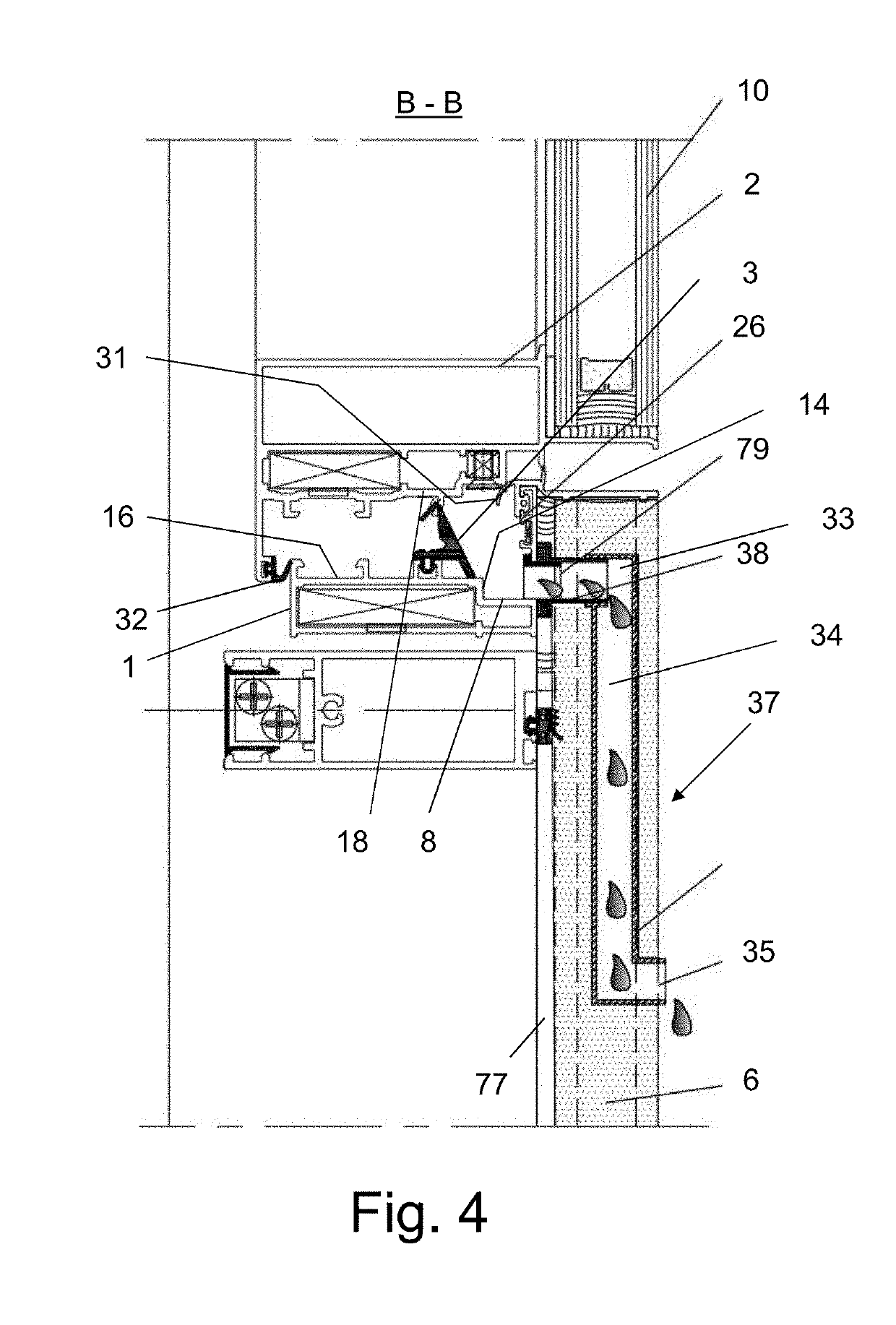

Curtain wall drain opening apparatus

Owner:EXTAL LTD

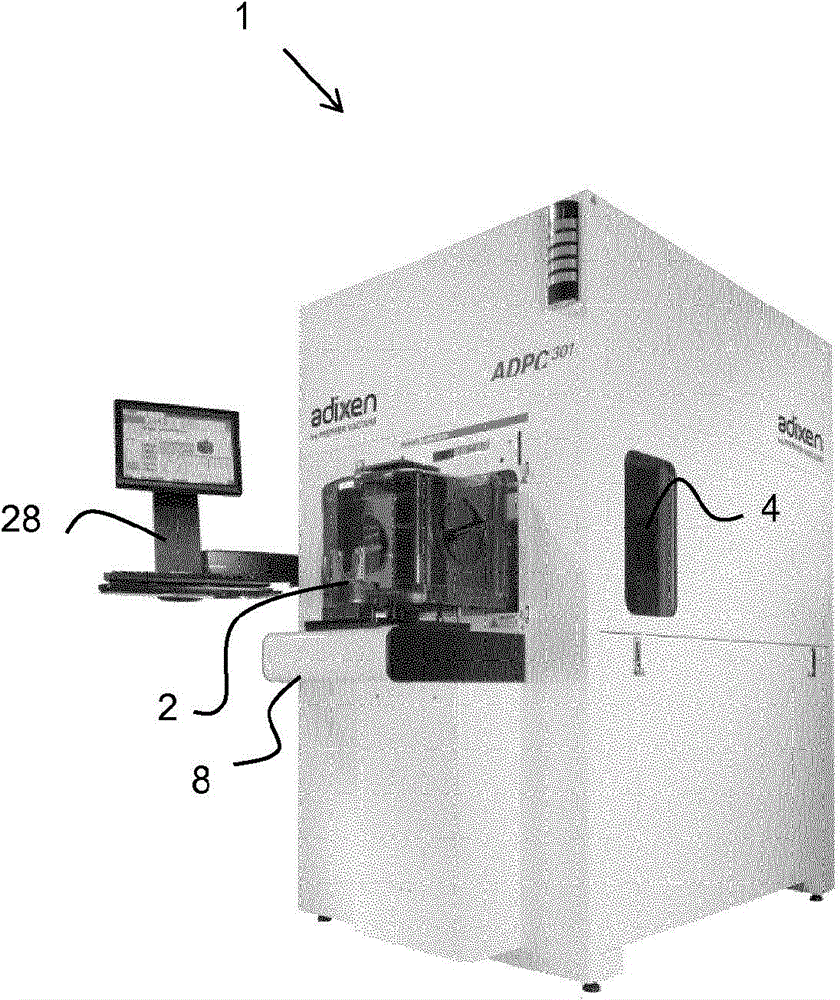

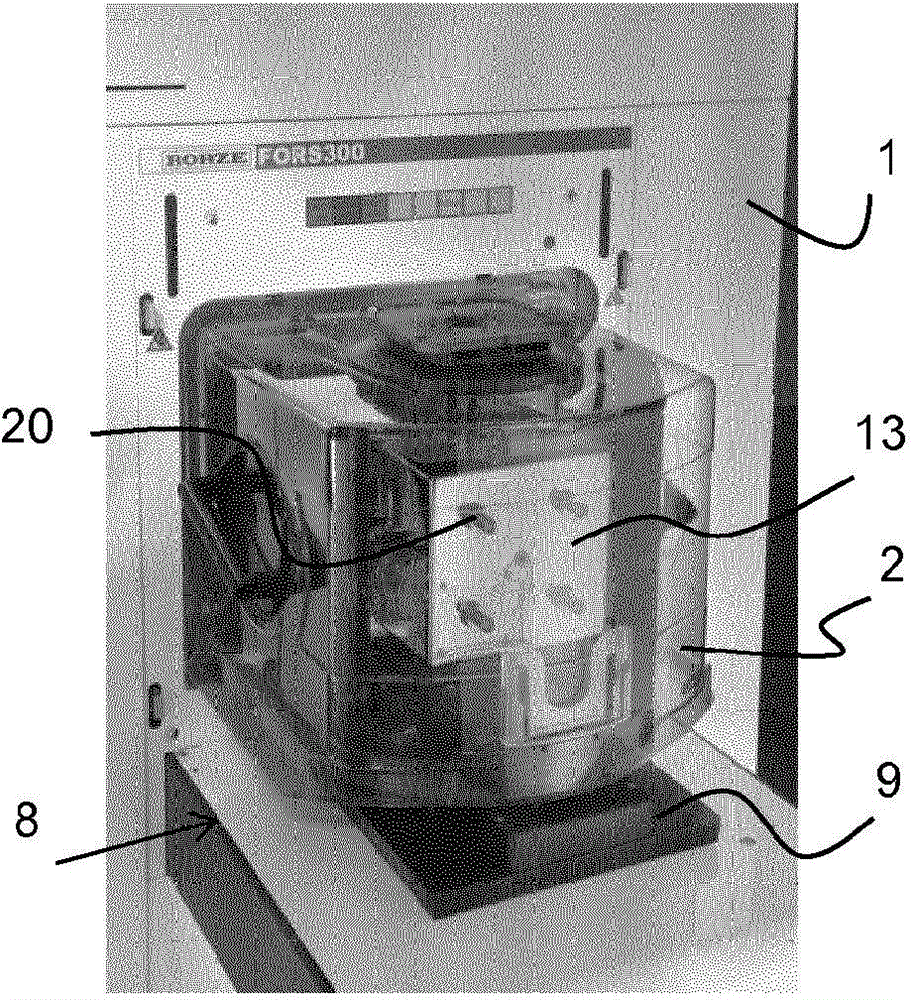

Station and method for measuring particulate contamination of a transport chamber for conveying and atmospherically storing semiconductor substrates

ActiveCN104813461ASemiconductor/solid-state device manufacturingIndividual particle analysisAtmospheric airProduct gas

Owner:PFEIFFER VACUUM GMBH

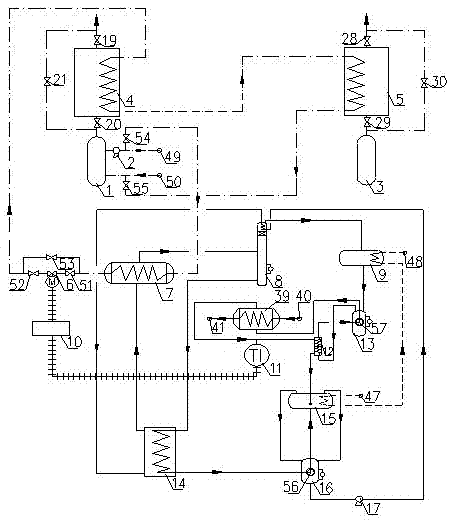

Ammonia-water absorption type refrigerator driven by oilfield waste heat and used for recycling light hydrocarbon

InactiveCN105444456AReduce loadSolve the problem of high exhaust heat and air pollutionClimate change adaptationEnergy efficient heating/coolingBinding equilibriumAtmospheric air

Owner:TAISHAN GROUP

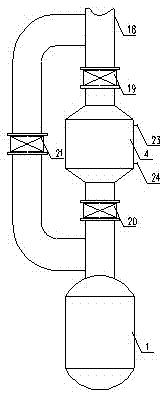

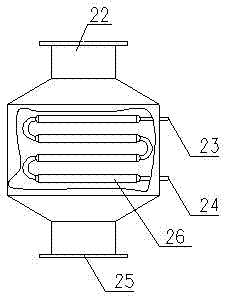

Emission technology of vapor containing nitrogen oxide and tar

ActiveCN108854458AImprove the efficiency of absorbing harmful components in exhaust gasPrevent control failure problems caused by errorsGas treatmentDispersed particle separationAtmospheric airExhaust gas emissions

The invention discloses an emission technology of vapor containing nitrogen oxide and tar. The emission technology comprises the following steps: opening a cutoff valve, a circulating water pump and an exhaust fan, wherein the circulating water pump starts a water circulation process; opening a discharging valve and releasing calcium hydroxide into water in a stepped overflow pool, and opening thedischarging valve when the pH value of the water in the stepped overflow pool is smaller than or equal to 8.0; closing the discharging valve when the pH value of the water in the stepped overflow pool is greater than or equal to 8.7; when an adjustment target is to prevent haze and the temperature of exhaust gas is greater than or equal to 90 DEG C, stopping the temperature-regulating operation;opening the temperature-regulating operation again when the temperature of the exhaust gas is smaller than 80 DEG C; stopping the temperature-regulating operation again when the adjustment target is to prevent thermal pollution and the difference value between the temperature of the exhaust gas and the atmospheric temperature is smaller than 3 DEG C; opening the temperature-regulating operation when the difference value between the temperature of the exhaust gas and the atmospheric temperature is greater than 6 DEG C. The emission technology disclosed by the invention can efficiently remove sulfur dioxide and nitrogen oxide from water, the weak alkalinity of water is maintained on the premise of ensuring safety and the emission temperature of the exhaust gas is correspondingly controlled according to different adjustment targets.

Owner:HENAN SONGYUE CARBON

Inert gas system for floating type oil storage-and-discharge device

The invention relates to an inert gas system for a floating type oil storage-and-discharge device. The inert gas system for the floating type oil storage-and-discharge device comprises an exhaust gas and diesel oil mode inert gas unit, a sensor, an oil storage cabin and a control unit. The exhaust gas and diesel oil mode inert gas unit comprises an inert gas main pipe, an exhaust gas and diesel oil mode inert gas generation device, an oxygen analyzer, a deck water seal, a main pipe pressure adjusting valve, a main pipe pressure transmitter, a normally-opened shutoff valve and an oil cabin pressure adjusting valve. The inert gas main pipe communicated with the inert gas generation device is communicated with the oil storage cabin sequentially through the deck water seal, the main pipe pressure adjusting valve, the normally-opened shutoff valve and the oil cabin pressure adjusting valve. The exhaust gas and diesel oil mode inert gas generation device, the main pipe pressure adjusting valve and the oil cabin pressure adjusting valve are respectively and electrically connected with the control unit. The oxygen analyzer and the main pipe pressure transmitter arranged on the inert gas main pip are respectively and electrically connected with the control unit. The inert gas main pipe is provided with two branches, the first branch is communicated with the atmosphere through a control valve electrically connected with the control unit, and the second branch is provided with a pressure vacuum shutoff valve.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap