Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Cement mortar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

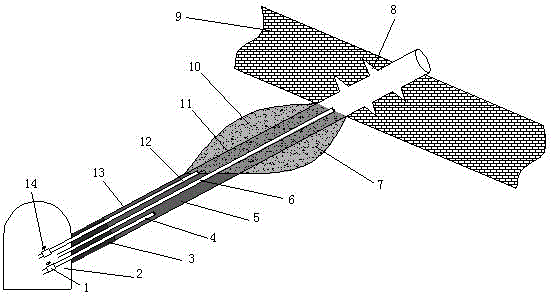

Method for fracturing coal seam by employing high-pressure gas

ActiveCN104405358ASolve the problem of air leakageGuaranteed gas pressureFluid removalSealing/packingParticulatesProduct gas

Owner:TAIYUAN UNIV OF TECH

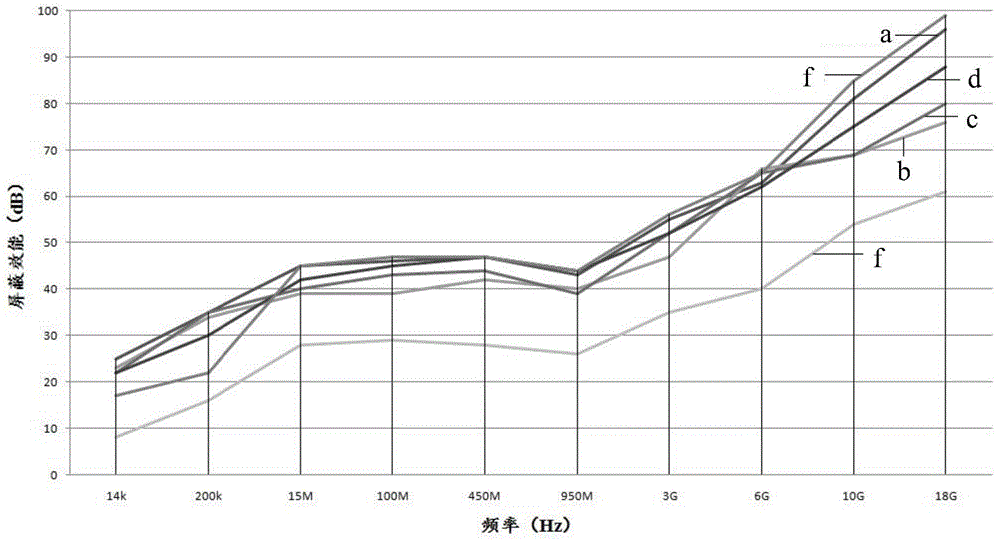

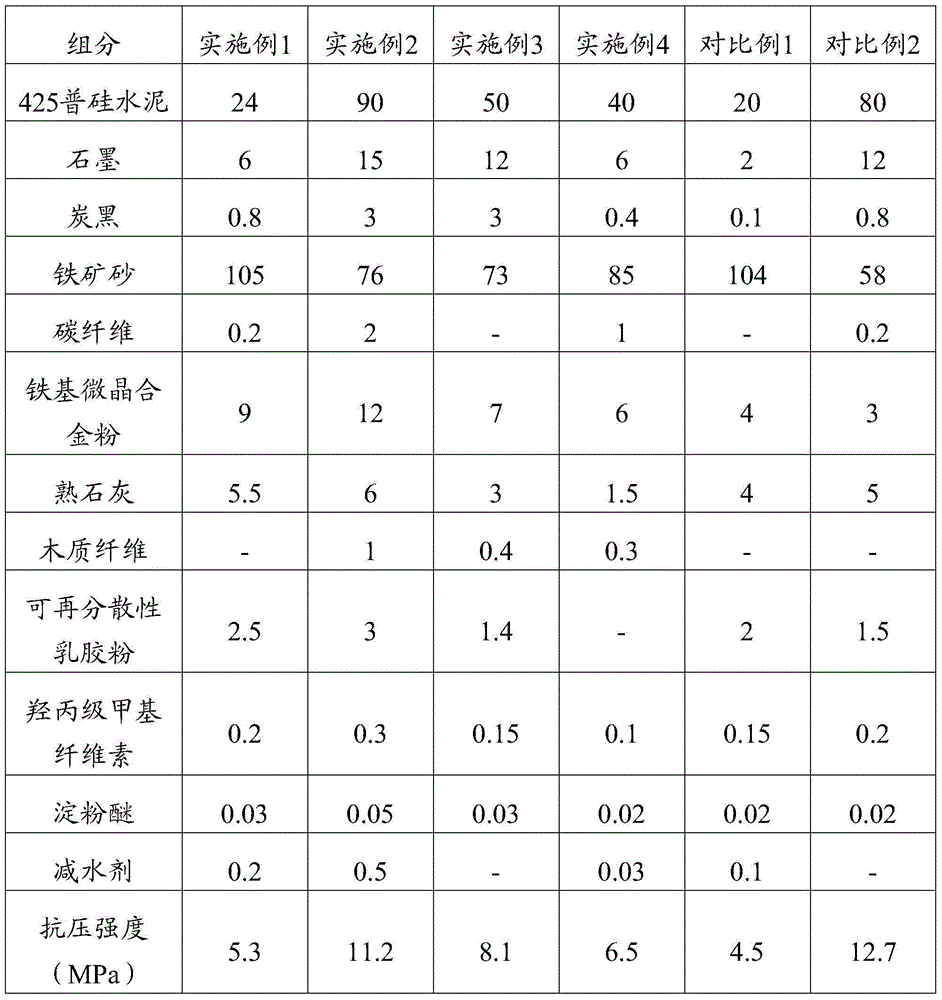

Cement mortar

Owner:ANFANG HI TECH ELECTROMAGNETIC SAFETY TECHN BEIJING

Pre-laying waterproof coiled material construction process for welding and adhesive bonding combined construction

Owner:KESHUN WATERPROOF TECH CO LTD

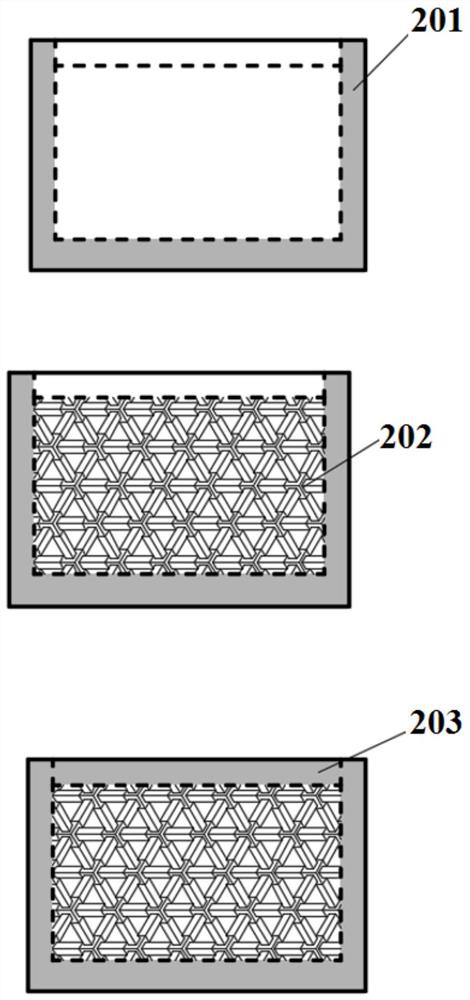

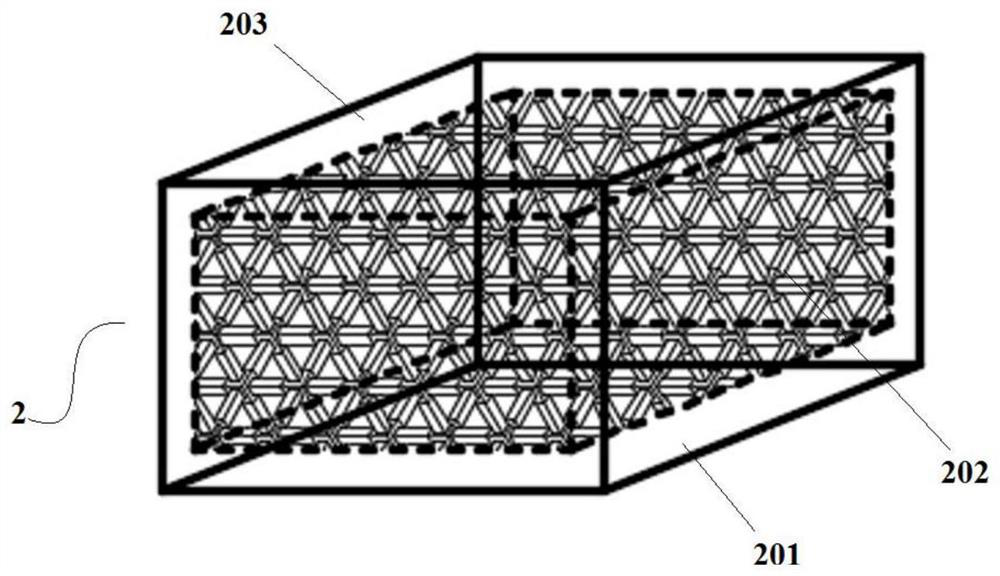

Testing method for determining stress and damage mechanism of columnar jointed rock mass

InactiveCN107271276ASolving Research Questions for StabilityAvoid cumbersomenessPreparing sample for investigationMaterial strength using tensile/compressive forcesTest sampleAxial pressure

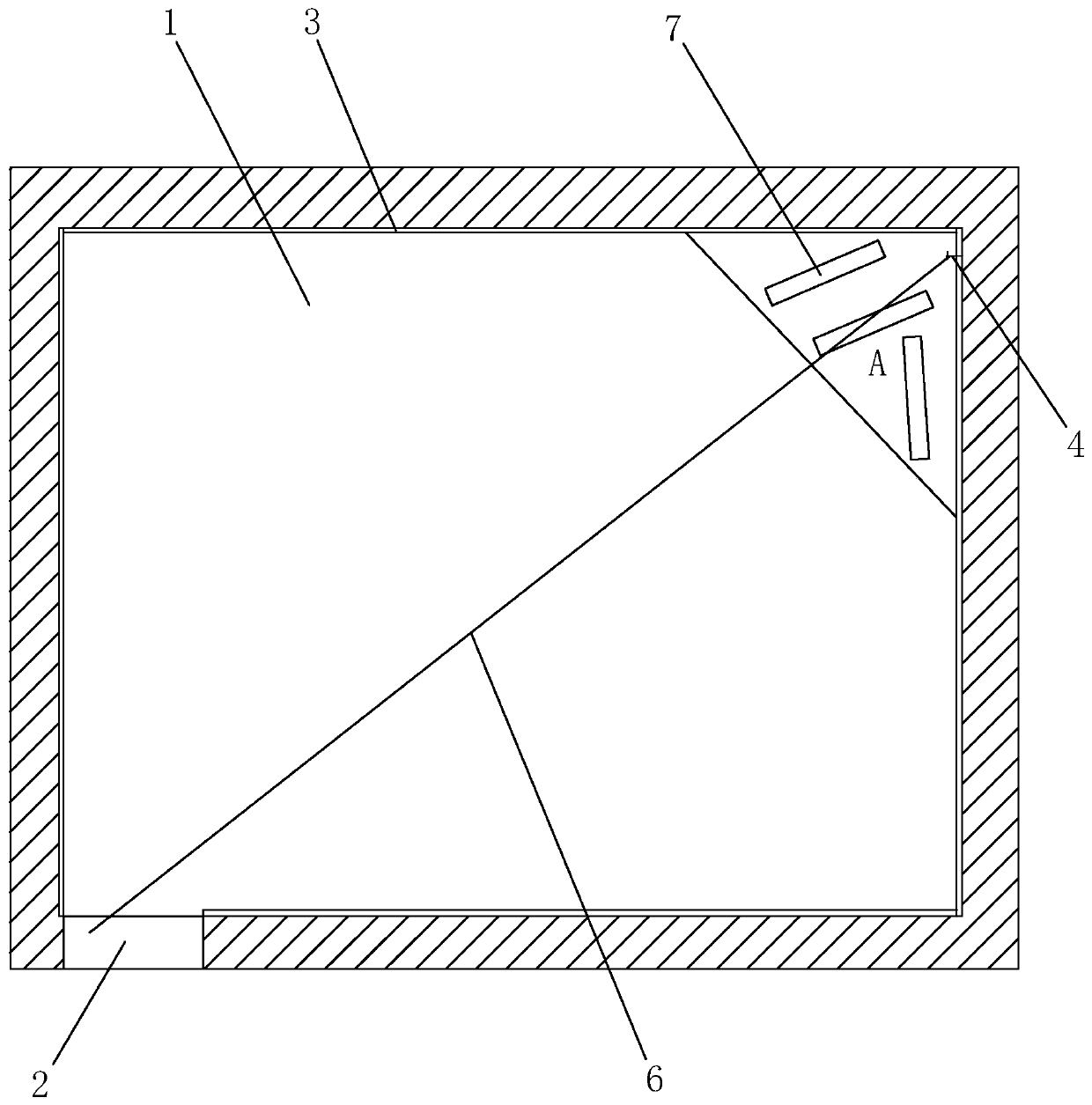

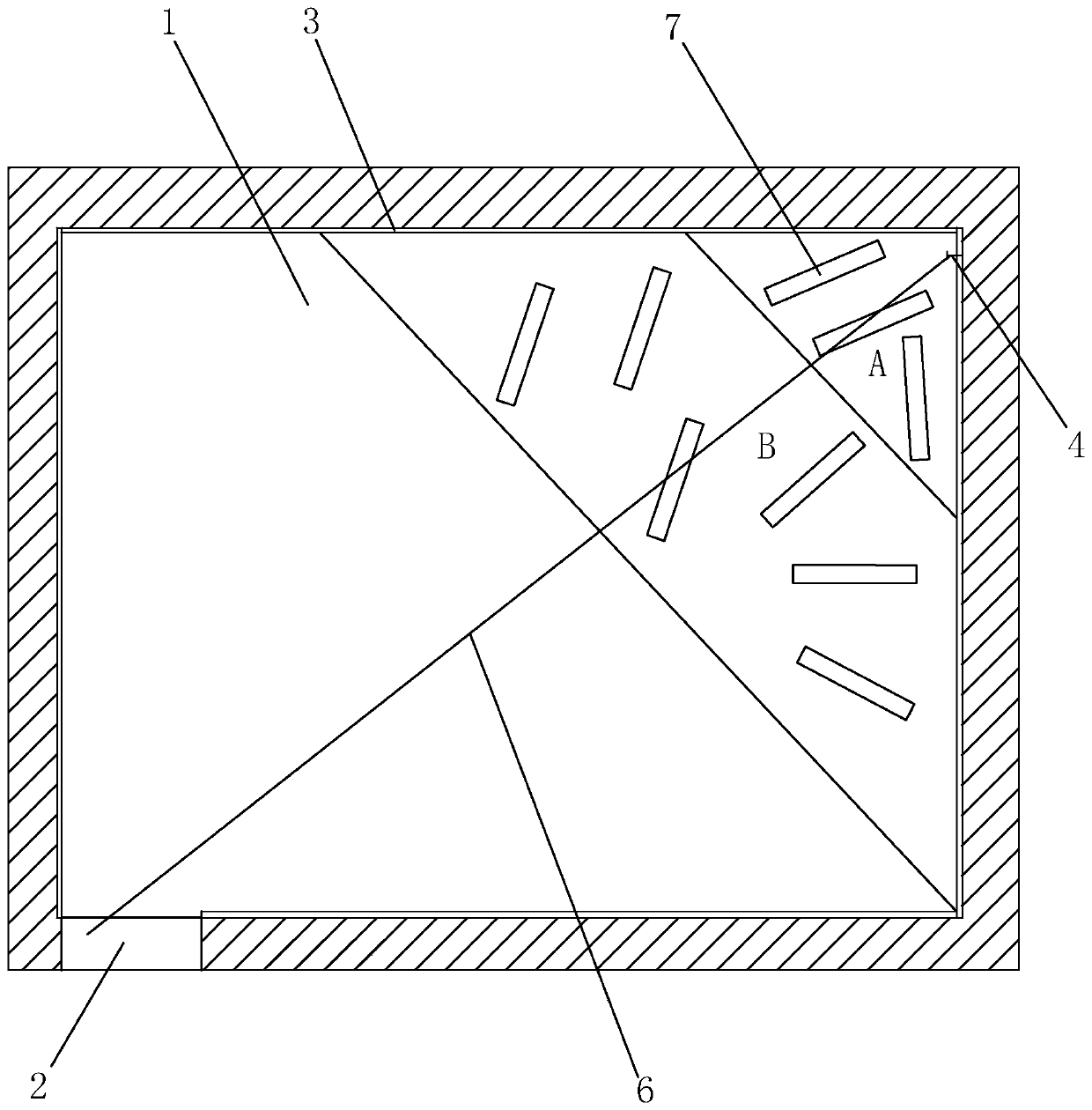

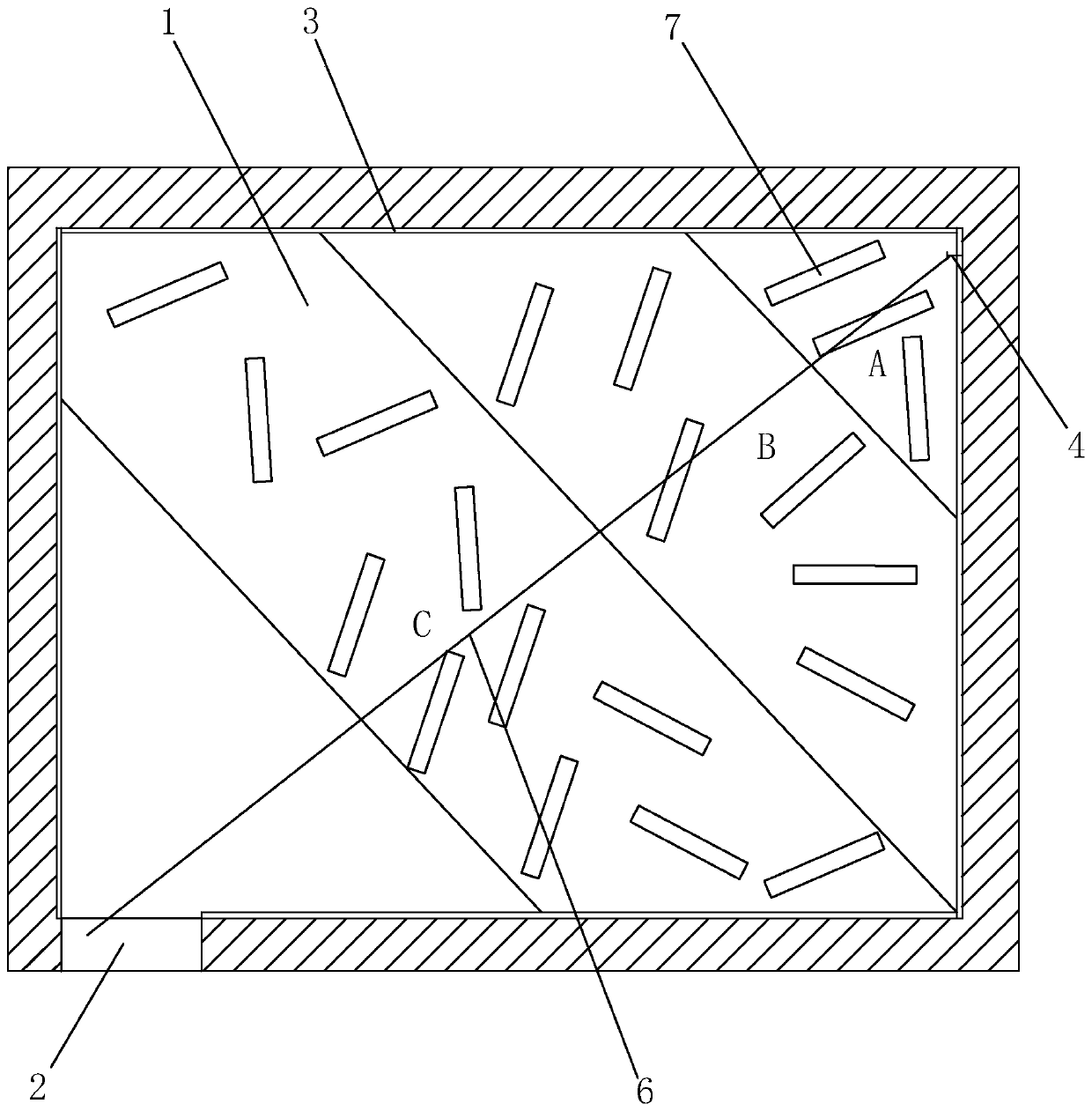

The invention discloses a testing method for determining a stress and damage mechanism of a columnar jointed rock mass. The testing method comprises the following steps: 1) preparing cement mortar according to mechanical characteristics of an actual rock mass to prepare a regular hexagonal prism-shaped test sample; 2) splicing the regular hexagonal prism-shaped test samples to form a cuboid-shaped columnar jointed rock mass test sample model; curing, cutting and polishing to prepare cube-shaped columnar jointed rock mass test pieces with different inclined angles; 3) putting the columnar jointed rock mass test pieces into a rock rheometer; fixing the rock rheometer in the horizontal direction and slowly applying axial pressure until the test pieces are damaged; recording stress and strain data in a testing process; 4) processing recorded testing data to obtain a stress-strain relation of the columnar jointed rock mass, wherein the stress-strain relation reflects the stress and damage mechanism of the rock mass. According to the testing method disclosed by the invention, stress and damage conditions of the columnar jointed rock mass are demonstrated by a model testing method; the testing method has the advantages of low construction price, high simulation degree, simplicity in operation and the like.

Owner:HOHAI UNIV

Epoxy resin-containing cement mortar

Owner:GUILIN JIEYU ENVIRONMENTAL PROTECTION SCI & TECH

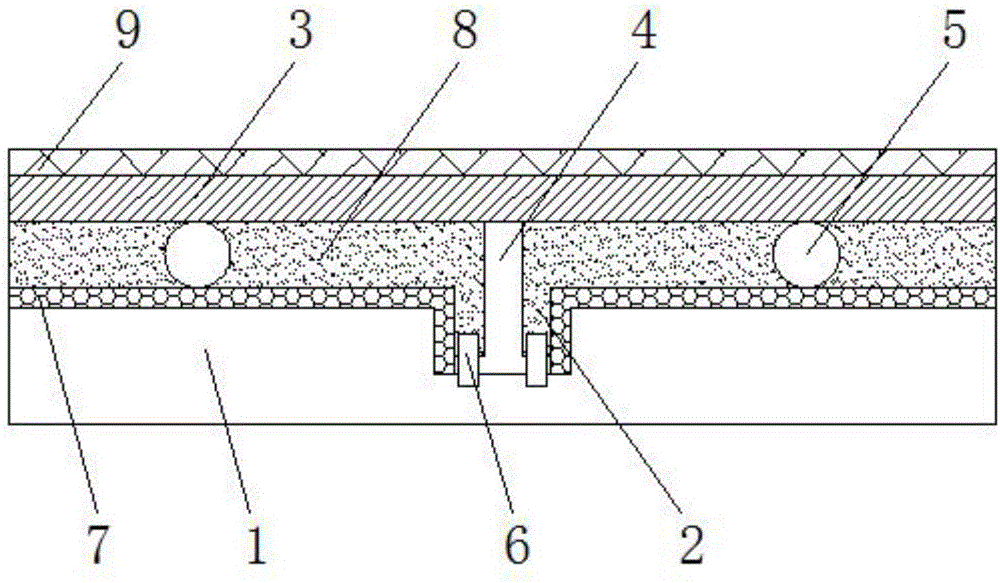

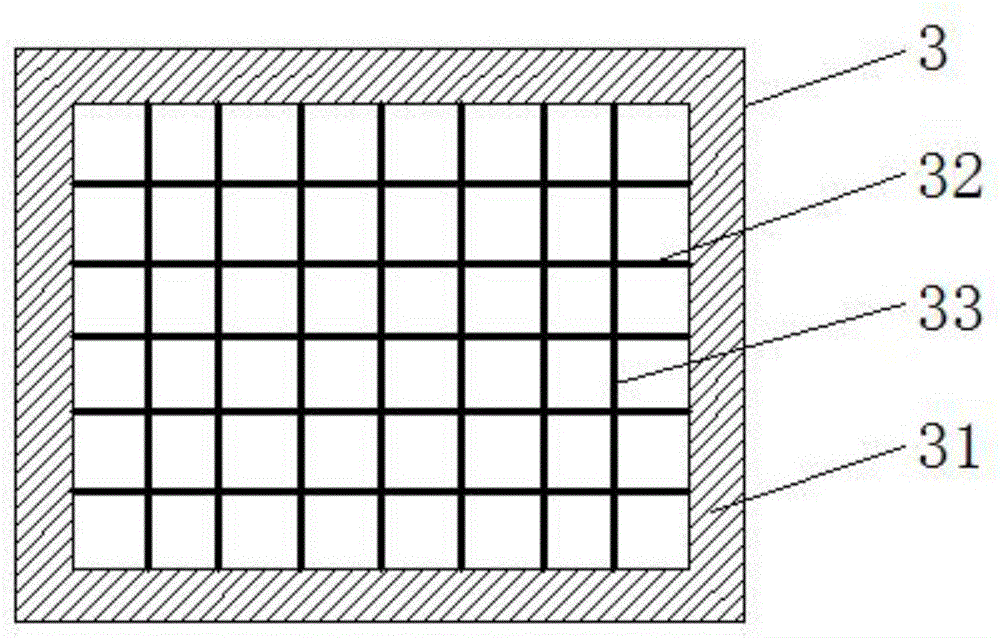

Polymer modified cement mortar steel fabric surface layer reinforcing structure

InactiveCN106639350AEnsure stabilityImprove practicalityBuilding repairsSurface layerPolymer modified

Owner:天津大盛基业新材料科技股份有限公司

Method and structure for co-processing waste incineration fly ash underground in mine

ActiveCN114160542AAlleviate resource constraintsAlleviating the Nowhere to Dispose ProblemSolid waste disposalTransportation and packagingEnvironmental engineeringCement mortar

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Ground fine leveling technology

Owner:江苏尚瑞鸿涛建设工程有限公司

High-bearing-capacity pavement structure and paving construction method

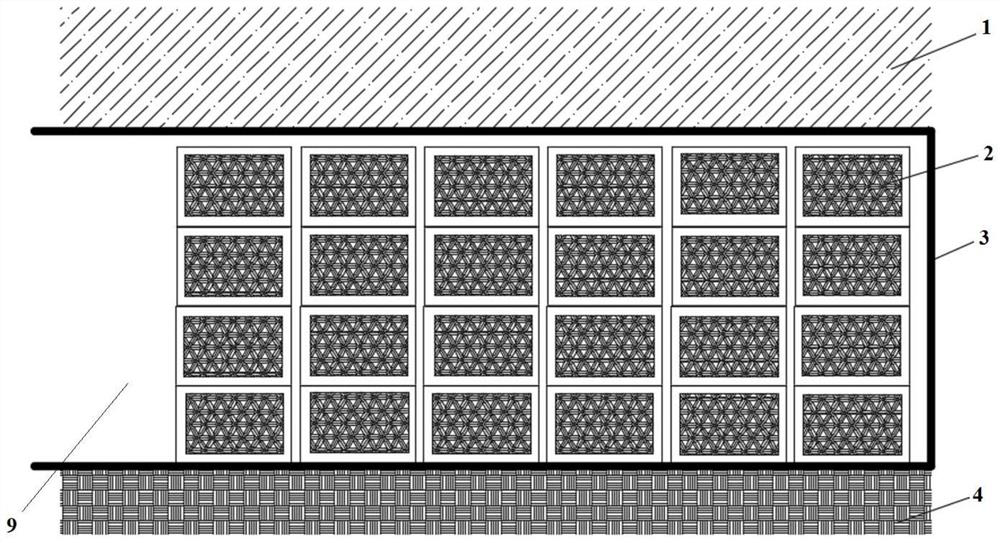

PendingCN114575212AGuaranteed filling densityAchieving uniformity of distributionPaving reinforcementsIn situ pavingsScreedCrushed stone

The high-bearing-capacity pavement structure comprises a graded broken stone layer, a mortar layer is laid on the graded broken stone layer, a bonding layer is laid on the mortar layer, and an asphalt concrete overlay layer is laid on the bonding layer; a reinforcement cage is arranged in the bonding layer, outer ribs are arranged on the upper side and the lower side of the reinforcement cage, and the outer ribs extend into the mortar layer and the asphalt concrete overlay layer. The paving construction method of the high-bearing-capacity pavement structure comprises the following steps: 1) leveling a site and erecting a template; (2) paving a large-particle-size gravel layer; (3) paving a small-particle-size gravel layer; (4) rolling to form a graded broken stone layer; the construction method comprises the following steps of (1) paving cement mortar to form a gravel grouting layer, (2) mounting a reinforcement cage, (3) paving a bonding layer, (4) paving a bonding layer, and (5) paving cement mortar to form a gravel grouting layer, (6) mounting a reinforcement cage, (7) paving a mortar layer, (8) paving a bonding layer, and (9) paving an asphalt concrete overlay layer.By adopting the structure and the method, the pavement structure is optimized, the stability between layers of pavements is enhanced, the slippage risk of the pavement is reduced, and reliable environmental conditions are provided for normal operation of roads.

Owner:CHINA RAILWAY BEIJING ENG GRP CO LTD

Anti-seepage method for deepwater hard rock steel sheet pile cofferdam

ActiveCN113982006AImprove anti-seepage performanceImprove construction efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesProtective foundationSoil scienceCofferdam

The invention discloses an anti-seepage method for a deepwater hard rock steel sheet pile cofferdam, which comprises the following steps of: drilling a hole guide groove in a field rock-soil layer by using a hole guide machine so as to insert and fix the lower end of a steel sheet pile; after the hole guide groove is formed, throwing coarse sand for filling the groove hole firstly, and then throwing clay for filling the hole guide groove till a groove opening is filled; driving a steel sheet pile which is manufactured in advance and provided with a grouting pipe into the throwing and filling soil of the hole guide groove till the built-in depth which is designed in advance is reached, and after the steel sheet pile enters the position, injecting cement mortar into the hole guide groove through a grouting pipe with a hole; before the cement mortar is solidified, arranging an ultrasonic density sensor in the groove to monitor the density change of the soil body in the groove in real time, continuing grouting when the density of the soil body does not reach a design value, and stopping grouting once the density of the soil body reaches the requirement; and pumping water from the inner side of the steel plate cofferdam after the cement mortar is solidified. Most double-wall steel cofferdam construction schemes can be replaced, the number of temporary cofferdam projects is greatly reduced, and the application range of the steel sheet pile cofferdam technology is greatly expanded.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap