Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Electric furnaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Far infrared Nixing pottery product and preparation method thereof

The invention discloses a far infrared Nixing pottery product and a preparation method thereof. The far infrared Nixing pottery finished product, far infrared Nixing pottery powder and far infrared Nixing pottery slurry is prepared by adding the metal oxides Cr2O3, MgO, MnO2 and ZrO2 and other compounds serving as auxiliary raw materials into Nixing pottery which is made in Qinzhou, Guangxi, and has the advantages of more cheap chemical components, high content and high quality and serves as a main raw material and roasting the mixture at the temperature of between 1,000 and 1,200 DEG C in a high-temperature electric furnace or a high-temperature roasting furnace or a high-temperature burning kiln according to the pottery. The far infrared Nixing pottery product transmits a far infrared ray with the wavelength of 6 to 23 mu m at the normal temperature and can be applied to the industry, medical care and living goods in the fields such as medical care, energy conservation and environment protection, building materials, heat insulating materials, water quality improvement, paper making plastic, fiber weaving, food preservation, food roasting, wine making industry, pharmaceutical industry and the like. The preparation method has the advantages of simple process, low energy consumption, low cost, high benefit and good product quality.

Owner:李建洪

Small-dimension British standard deformed steel bar B500B and manufacturing technology thereof

The invention discloses a small-dimension British standard deformed steel bar B500B and a manufacturing technology thereof. The chemical component requirements of the small-dimension British standard deformed steel bar B500B are: C: 0.19-0.22 wt%, Si: 0.20-0.60 wt%, Mn: 0.70-0.90 wt%, Cr: 0.5-0.8%, P, S: less than or equal to 0.035 wt%, Ni, Cu: less than or equal to 0.25 wt%, Mo, Al: less than or equal to 0.10 wt%, and N: less than or equal to 0.011 wt%; the balance is Fe; carbon equivalent Ceq is less than or equal to 0.50%. The technology comprises converter or electric furnace smelting, LF refining or argon blowing refining, CCM bloom or billet continuous casting, bar controlled rolling, and controlled cooling. The component design takes chromium to replace expensive vanadium for alloying, is matched with reasonable-design controlled rolling temperature and air cooling temperature, realizes production of the small-dimension British standard deformed steel bar B500B with qualified performance in low cost, and acquires favorable economical and social benefits.

Owner:NANJING IRON & STEEL CO LTD

Processing technology of iron-chromium-aluminum resistance wire

InactiveCN104637640AResistor manufactureElectric furnacesResistance wire

Owner:DANYANG ZHISHENG ALLOY

Low-aluminum and low-silicon welding wire steel low-sulfur-control smelting method

ActiveCN111979374AReduce sulfur contentPrevent slagSteelmakingSlag (welding)

Owner:NANJING IRON & STEEL CO LTD

Method for producing environmentally friendly high-temperature fold-resistant high-strength high purity corundum bricks

InactiveCN105237003ASurprised by high temperature flexural performanceReduce dosageBrickMixed materials

Owner:长兴宏泰耐火器材有限公司

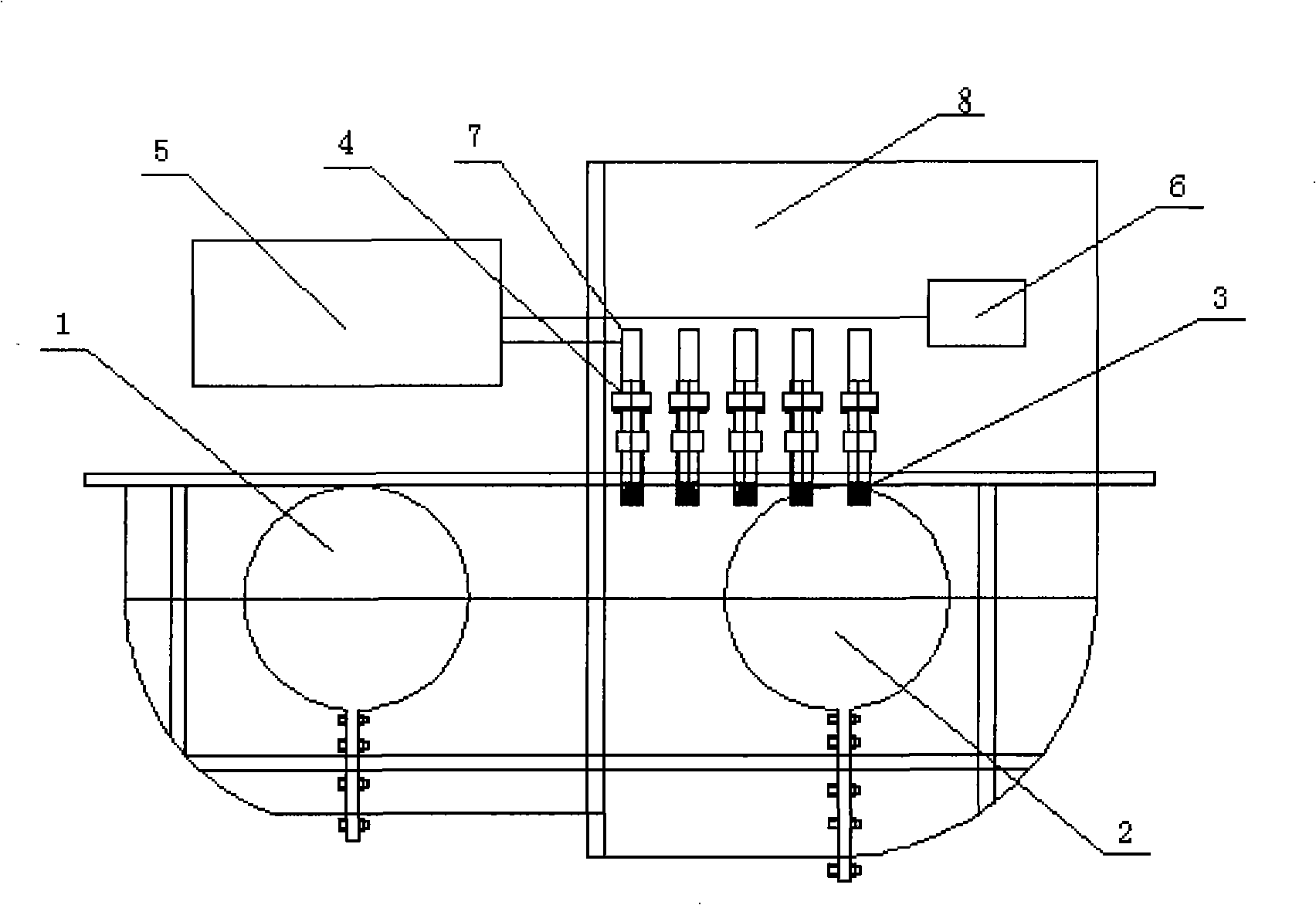

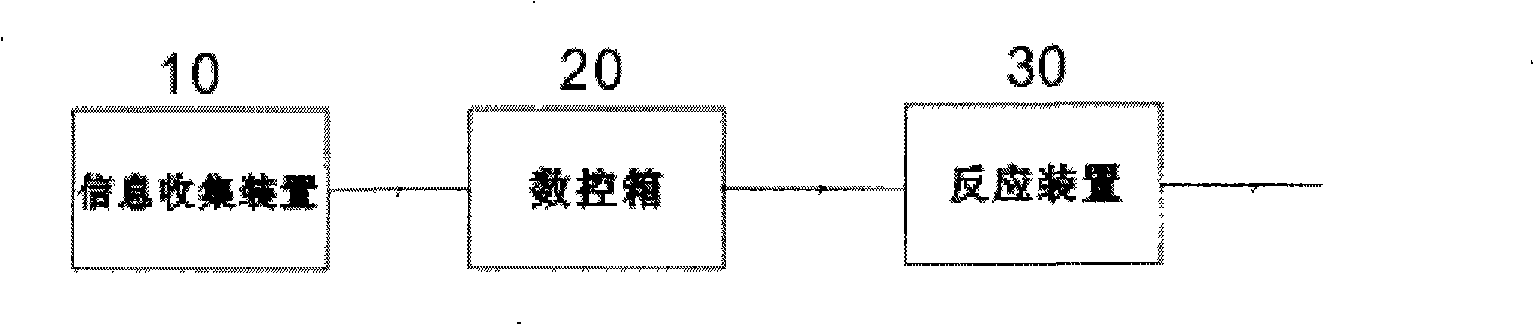

Smelting furnance of copper tube

Owner:青岛宏奥铜管有限公司

Full-tooth continuous quenching method for slewing bearing

PendingCN114317906AHigh hardnessImprove mechanical propertiesFurnace typesIncreasing energy efficiencyRare-earth elementKerosene

Owner:安徽省宁国顺昌机械有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap