Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Polymer modified" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

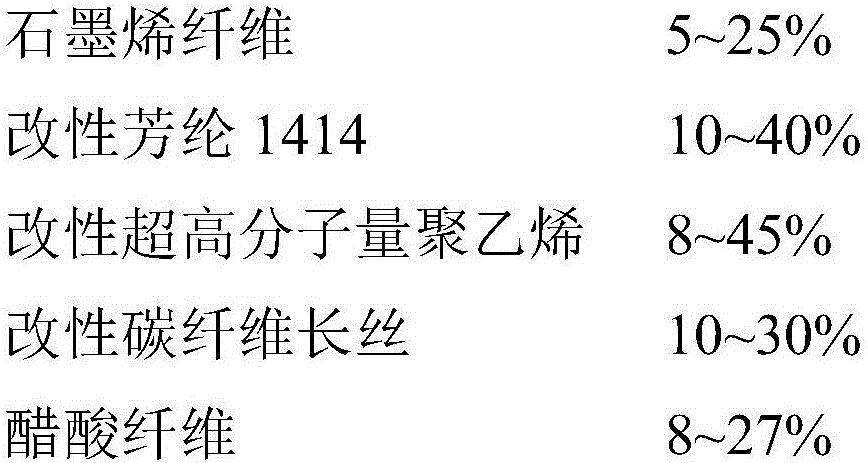

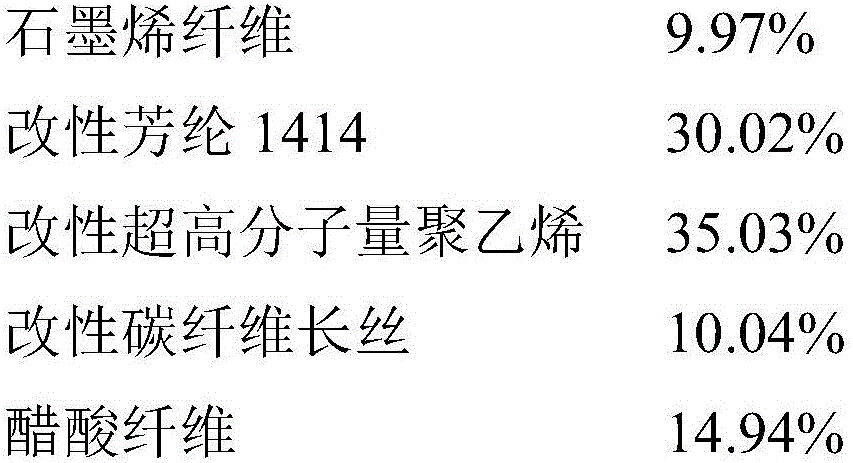

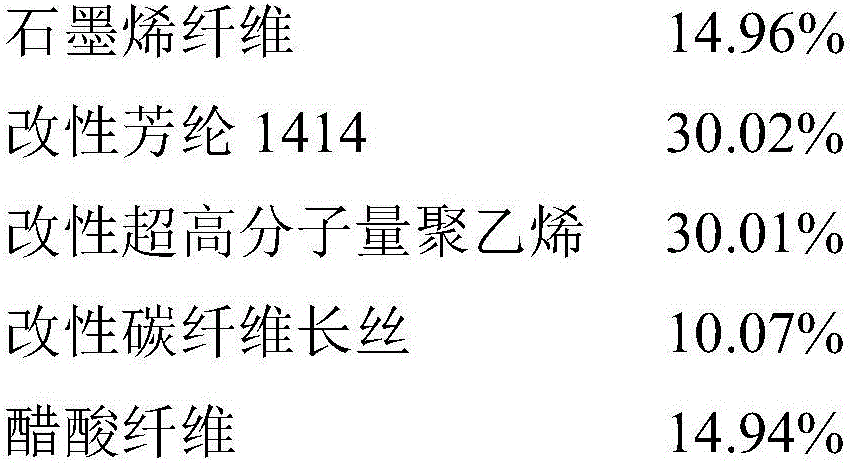

Ultralight bulletproof cloth and manufacture method thereof

Owner:广东军铠防护科技有限公司

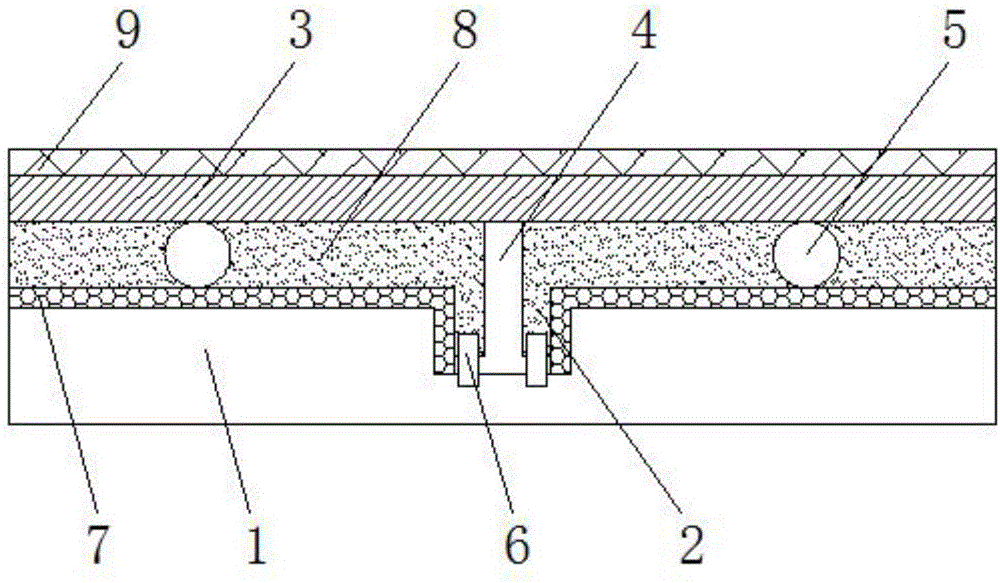

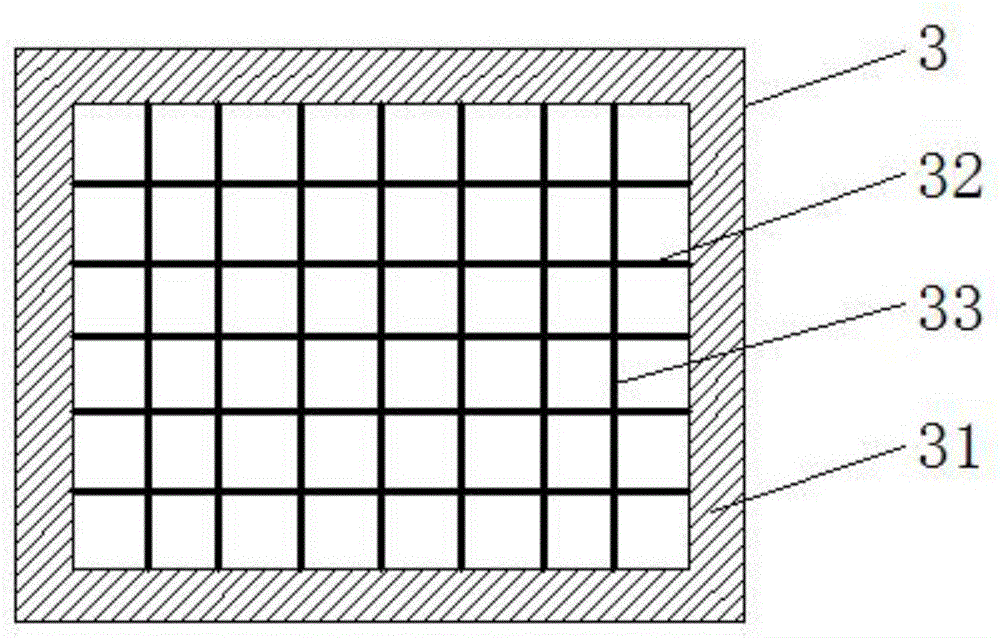

Polymer modified cement mortar steel fabric surface layer reinforcing structure

InactiveCN106639350AEnsure stabilityImprove practicalityBuilding repairsSurface layerPolymer modified

Owner:天津大盛基业新材料科技股份有限公司

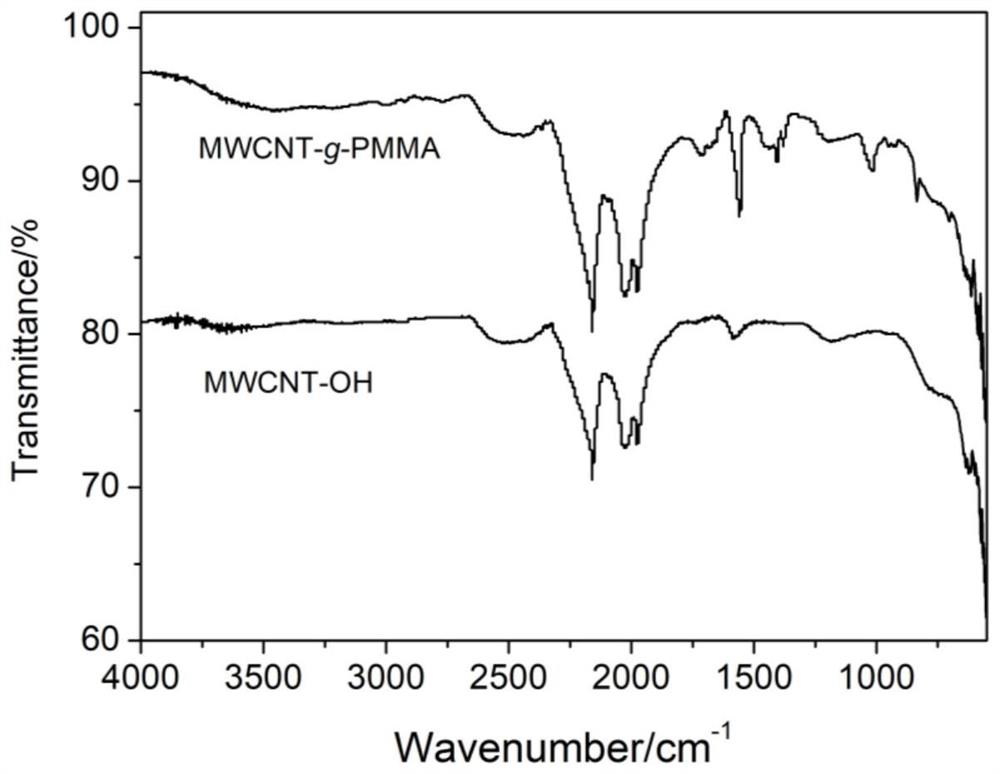

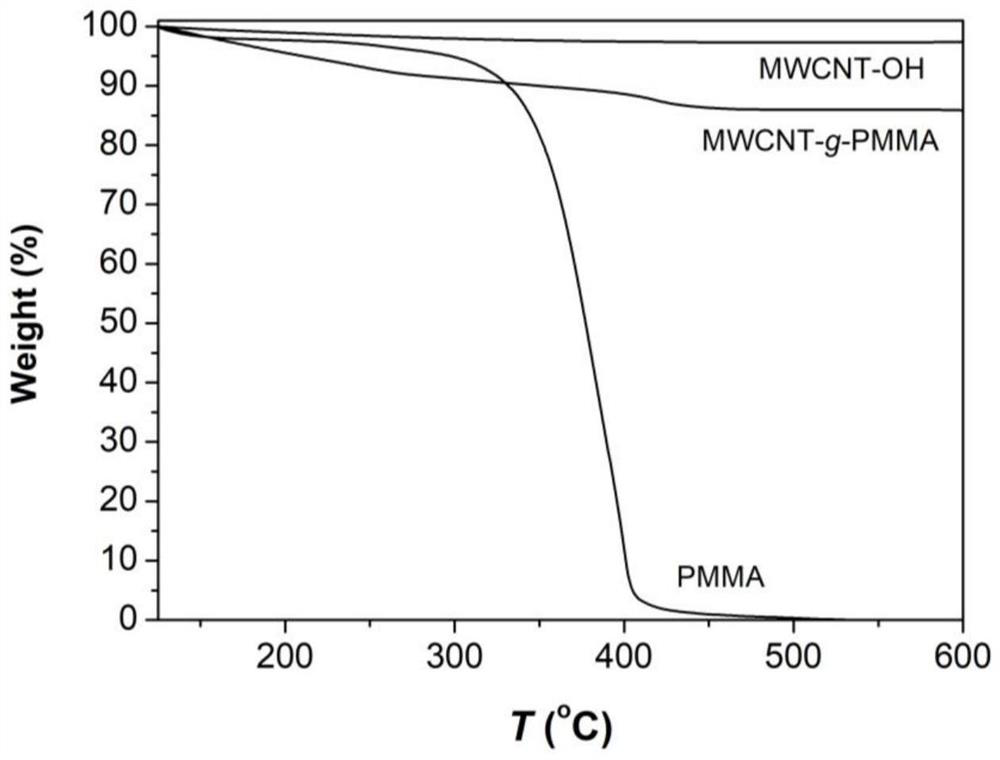

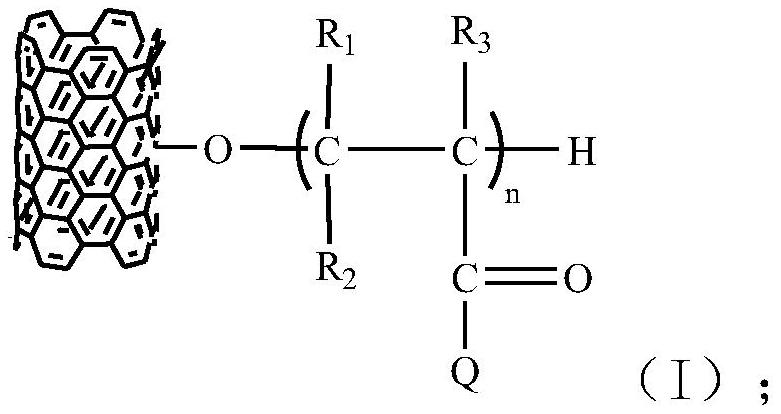

Polymer-modified carbon nanotube and preparation method thereof

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +1

Polymer modified bentonite and preparation process thereof

The invention discloses polymer modified bentonite and a preparation process thereof, and belongs to the field of bentonite preparation. The polymer modified bentonite provided by the invention is prepared from the following components in parts by mass: 40 to 60 parts of bentonite; 4 to 6 parts of magnesium oxide; 20 to 30 parts of a waterborne polyurethane emulsion; 5 to 10 parts of isocyanate; 5 to 10 parts of polyol; 1 to 3 parts of acrylic acid; 10 to 16 parts of N, N-dimethyl bisacrylamide; 1 to 2 parts of alkali liquor; and 5 to 9 parts of a lubricant. After the prepared polyurethane material and the high-water-absorption material are mixed, the viscosity of bentonite can be improved, a linear flocculation mixture is formed by the polymer and the bentonite, the interlayer spacing of the bentonite is increased, and thereby the water absorption performance and the lubricating performance of the prepared modified bentonite are both qualitatively improved.

Owner:JURONG KANGTAI BENTONITE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap