Superconducting induction heating system for production line

A production line and induction heating technology, applied in induction heating, induction heating devices, electric/magnetic/electromagnetic heating, etc., can solve the problems of uneven heating, shallow heating depth, and low heating quality, and achieve convenient operation and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

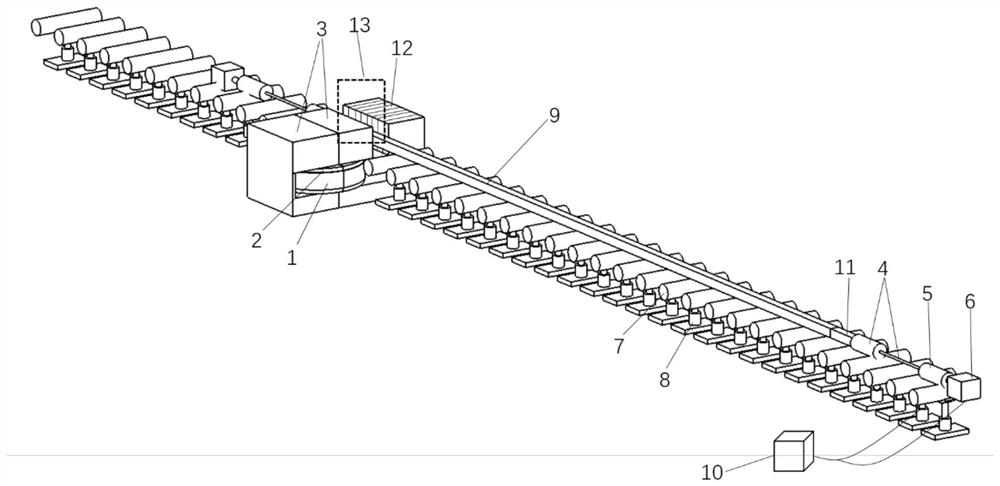

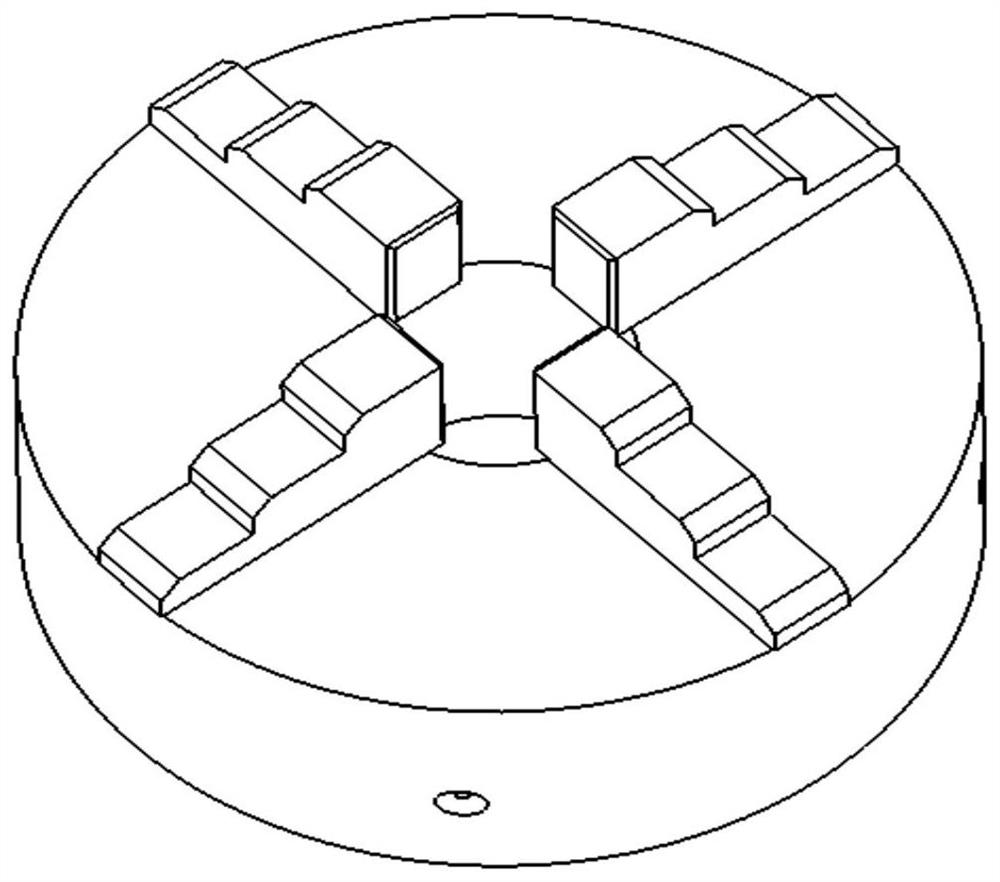

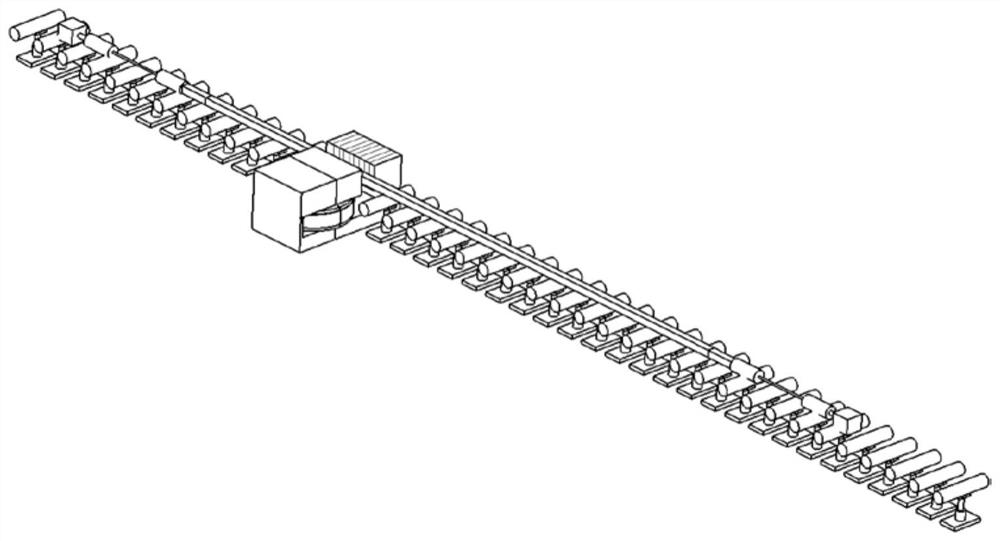

[0048] Such as figure 1 As shown, a superconducting induction heating system for a production line, the superconducting induction heating system includes a superconducting magnet system 1, an iron core 2, an iron yoke 3, a gradient adjustable iron yoke 12, a rotating motor 5, a mechanical Transmission system 4, control system 6, transmission system 7, support system 8, PLC control system 10, four-jaw chuck 11, metal workpiece to be heated 9 and heating air gap space 13;

[0049] The superconducting magnet system 1 comprises a superconducting magnet coil, a cryogenic vessel, a vacuum vessel, an infusion neck tube and a superconducting switch; the superconducting magnet coil adopts a single solenoid coil; the superconducting magnet coil is placed on In the cryogenic container, the cryogenic container is supported in the vacuum container by a tie...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap