Thin circuit board structure

A technology of circuit board and build-up structure, applied in the direction of circuit substrate materials, circuits, printed circuits, etc., can solve the problems of signal noise, electrical characteristics limitation, unfavorable signal transmission, etc., to reduce parasitic capacitance and inductance, and improve electrical characteristics. , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

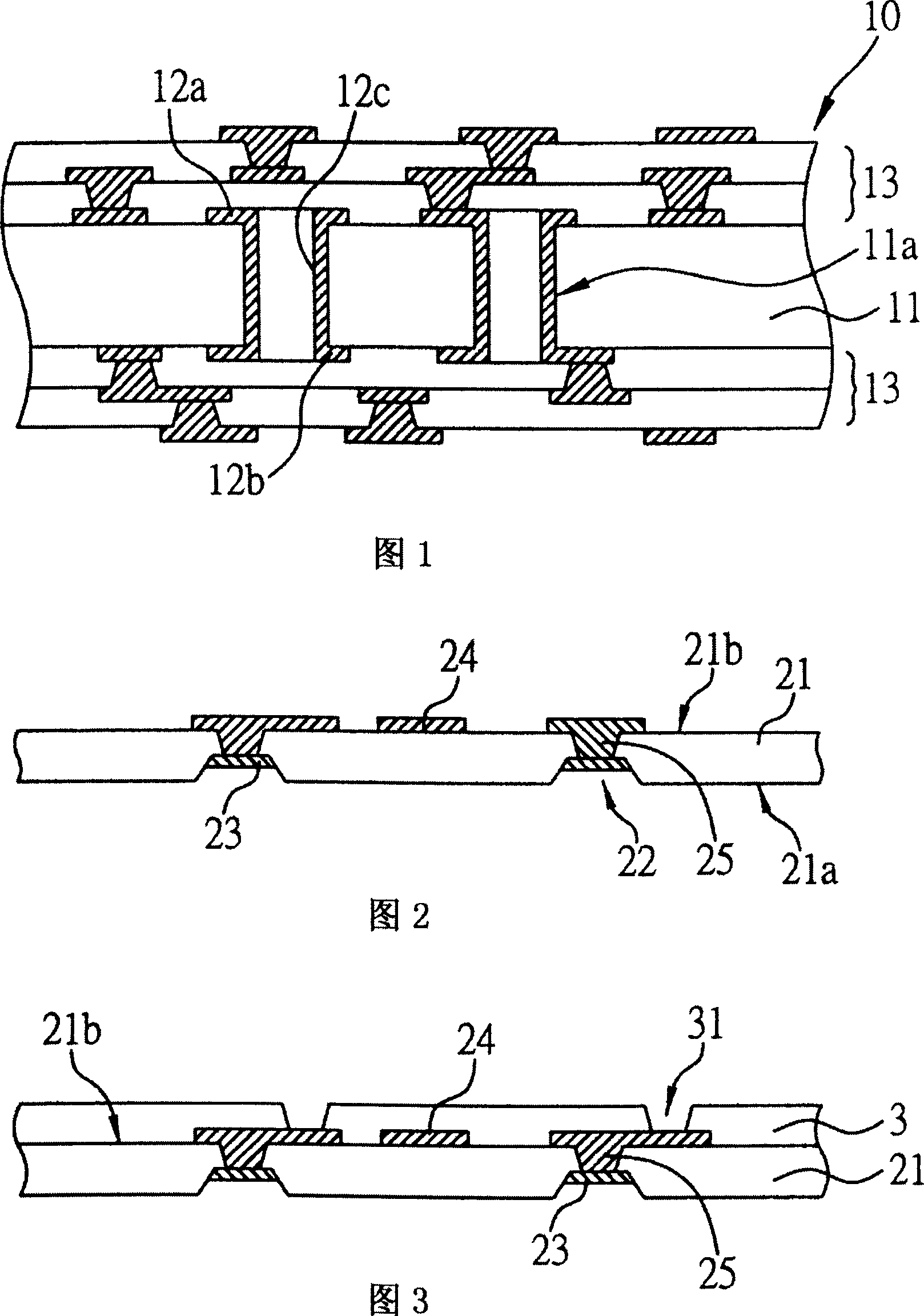

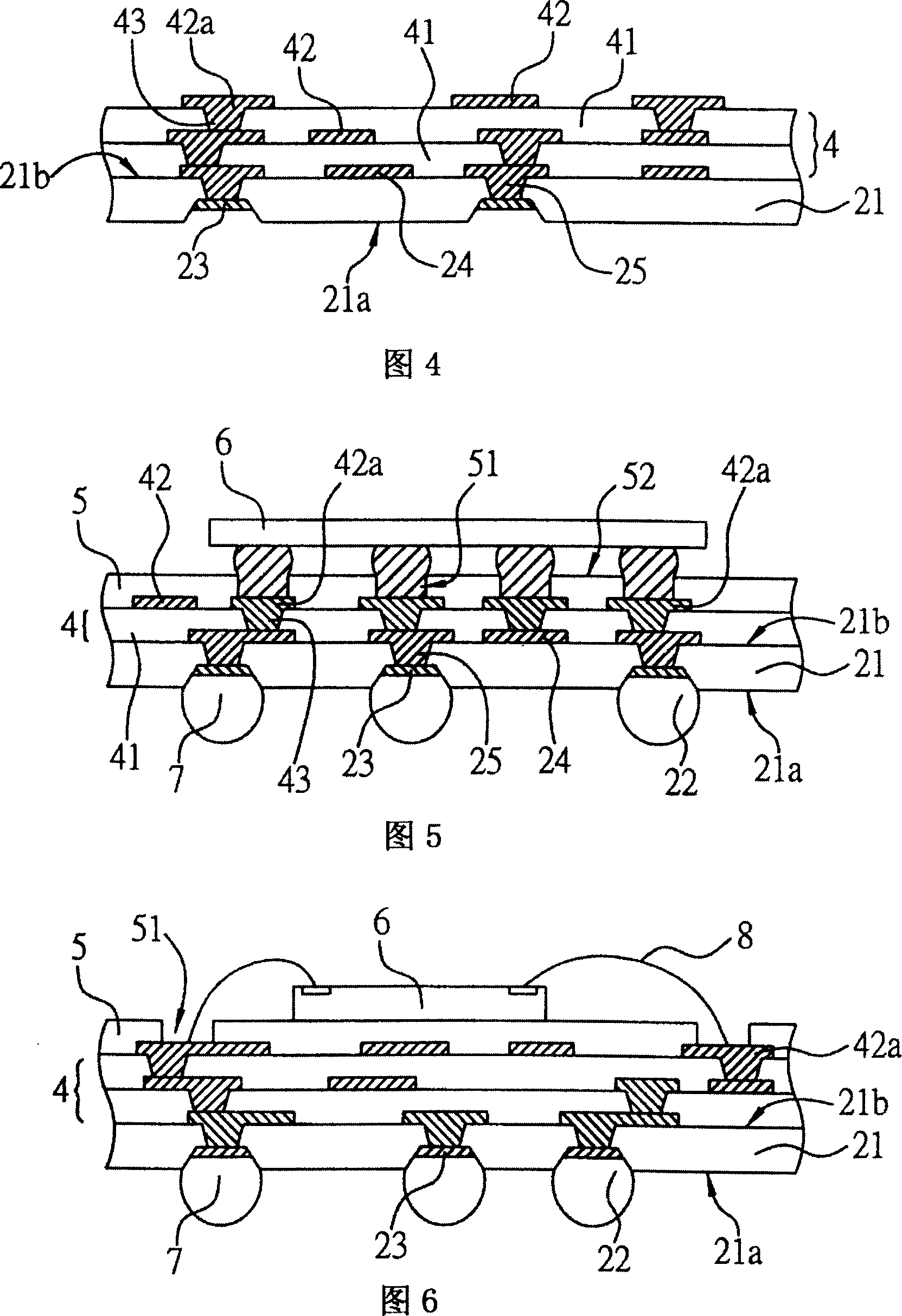

[0025] Please refer to FIG. 2 , which is a schematic cross-sectional view of a thinned circuit board structure according to the present invention. The thinned circuit board structure includes: a dielectric layer 21 forming at least one recessed area 22 on a surface 21a thereof. The dielectric layer 21 It is a dielectric material, and the dielectric layer 21 is, for example, a soft board or a hard board made of organic polymer materials, ceramic materials, polymer materials filled with ceramic powder, etc.; a metal pad 23 is formed in the recessed area In 22, the metal pad 23 is selected from gold, nickel, palladium, silver, tin, nickel / palladium, chromium / titanium, nickel / gold, copper / nickel / gold, palladium / gold, nickel / palladium / gold, copper, tin, Nickel, chromium, titanium, copper / chromium alloy or tin / lead alloy; at least one circuit layer 24, formed on the other surface 21b of the dielectric layer 21; and a plurality of conductive blind holes 25, formed in the dielectric la...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap