Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Ammonium bicarbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium bicarbonate is an inorganic compound with formula (NH₄)HCO₃, simplified to NH₅CO₃. The compound has many names, reflecting its long history. Chemically speaking, it is the bicarbonate salt of the ammonium ion. It is a colourless solid that degrades readily to carbon dioxide, water and ammonia.

Prepn of nano-cobaltosic oxide powder

InactiveCN1344682ASuitable for large-scale industrial productionEasy to operateCobalt oxides/hydroxidesCobalt carbonatesCobalt(II,III) oxideCobalt salt

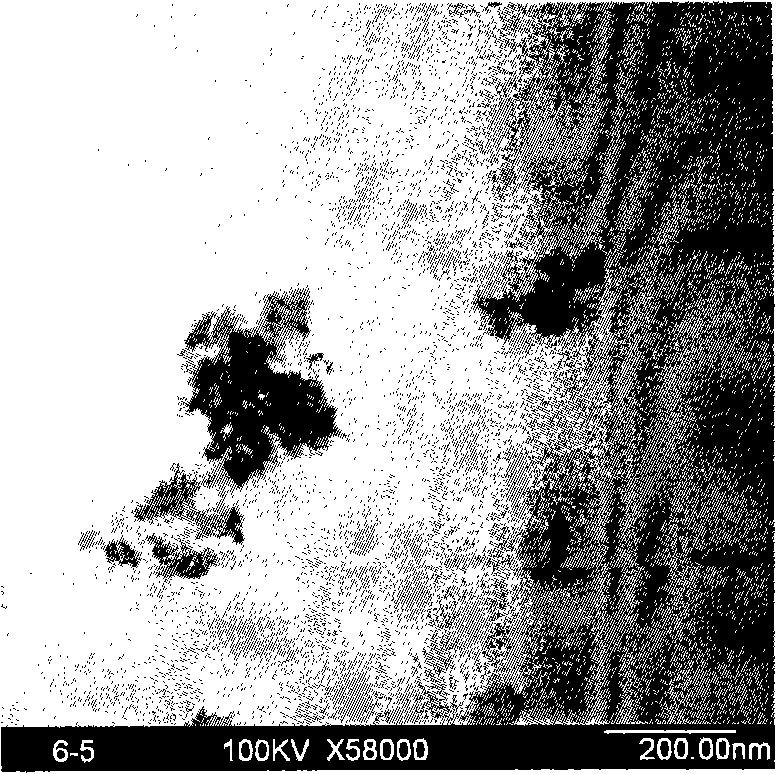

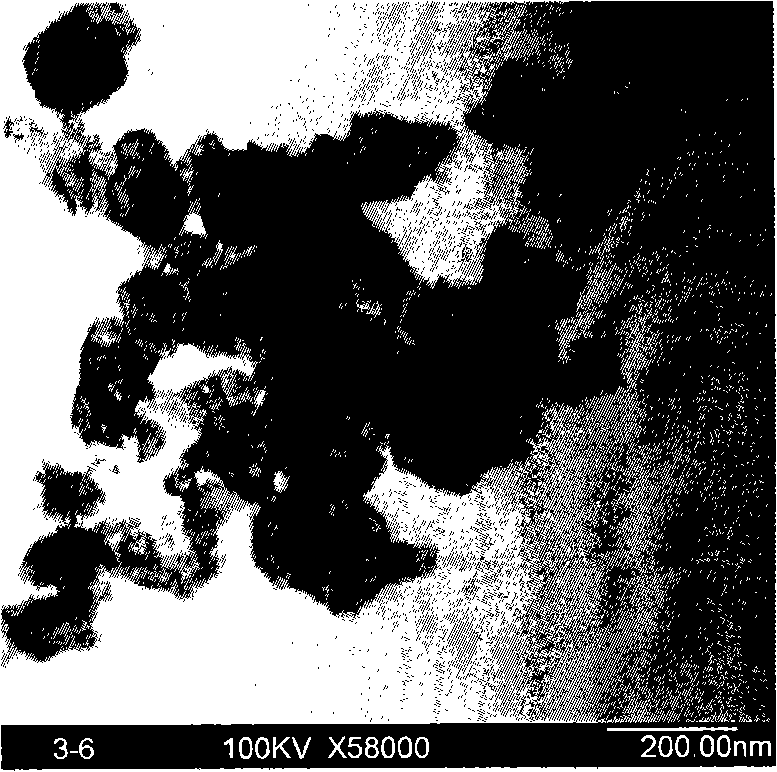

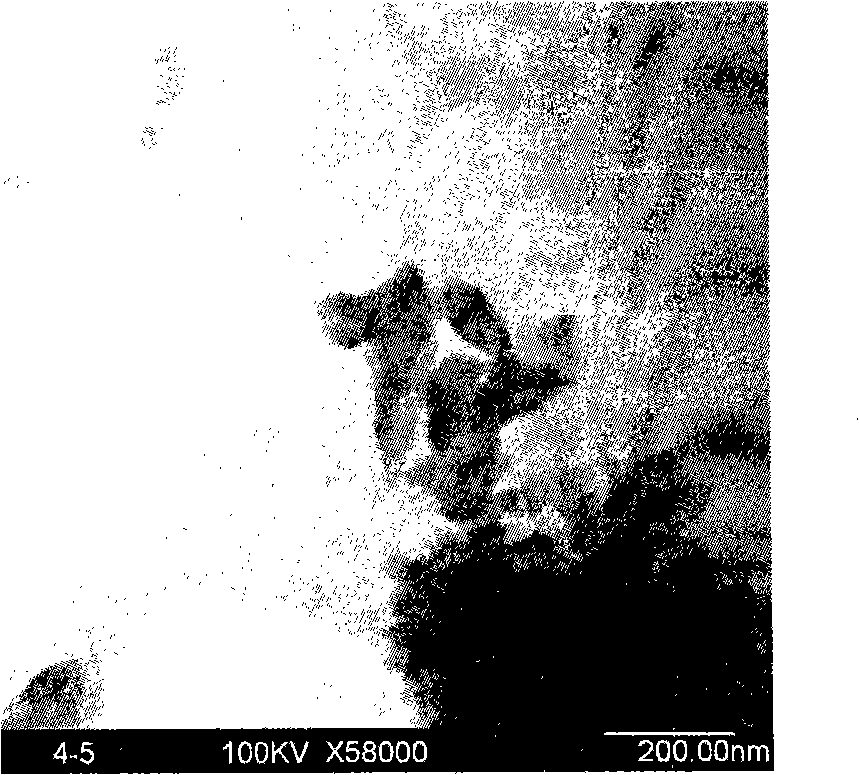

The present invention relates to chemical industry technology. The preparation of nanometer cobaltosic oxide powder includes purifying material, cobalt salt deposition, solid-liquid separation and solid calcination. Cobalt sheet is dissolved in nitric acid while being heated and high purity water is added to regulate solution density and pH value so as to obtain cobalt nitrate solution of 1.5-1.65 g / cu cm density and pH 4-5; ammonium bicarbonate suspension in 14-30 wt% is prepared with ammonium bicarbonate and water; cobalt nitrate solution is added into the suspension slowly to result in weight ratio of carbonate radical to cobalt ion being 2.4-2.6; and the wet cobalt carbonate material is heated to 300-450 deg.c for 3-6 hr to obtain black Co3O4 powder.

Owner:SHANDONG UNIV +1

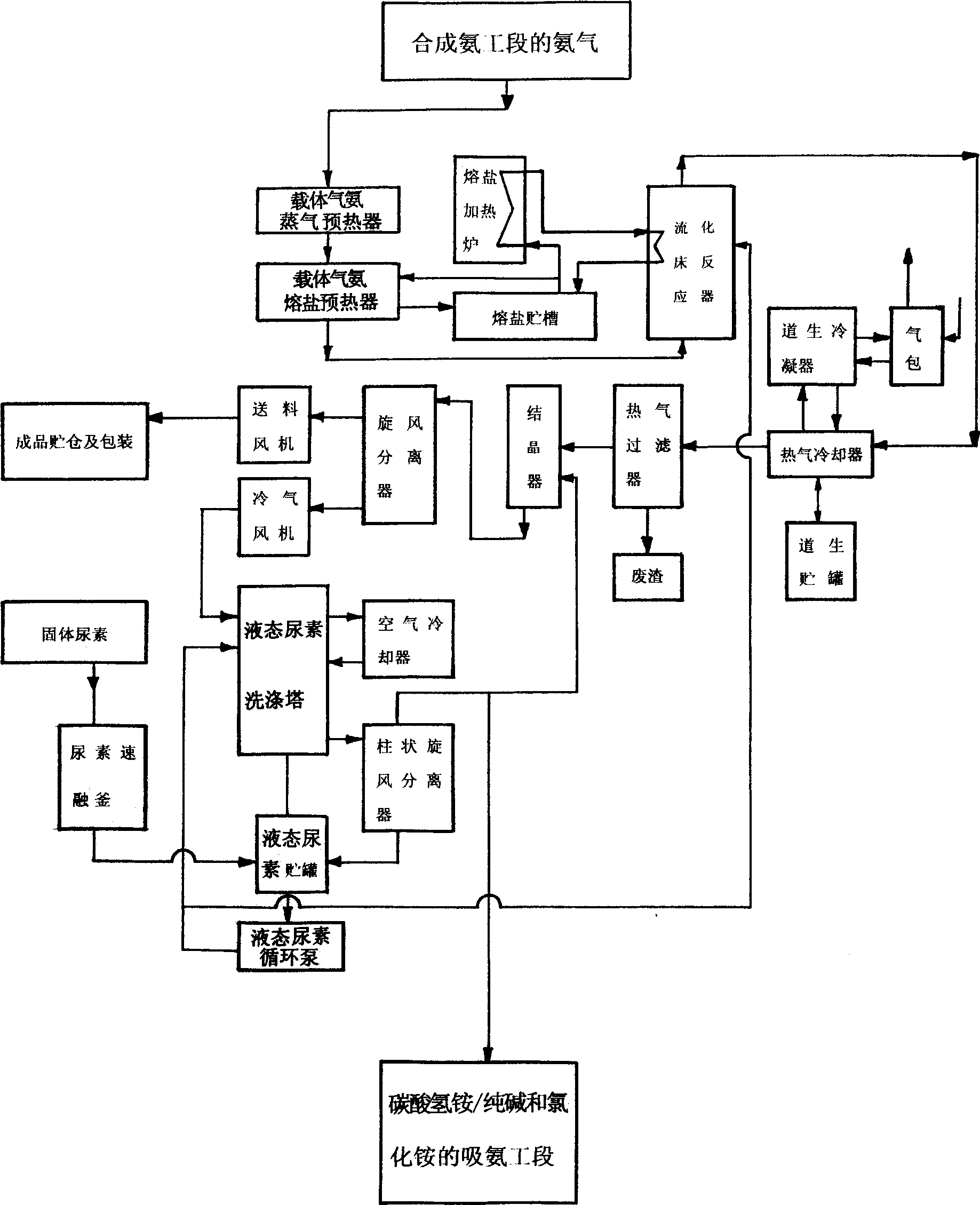

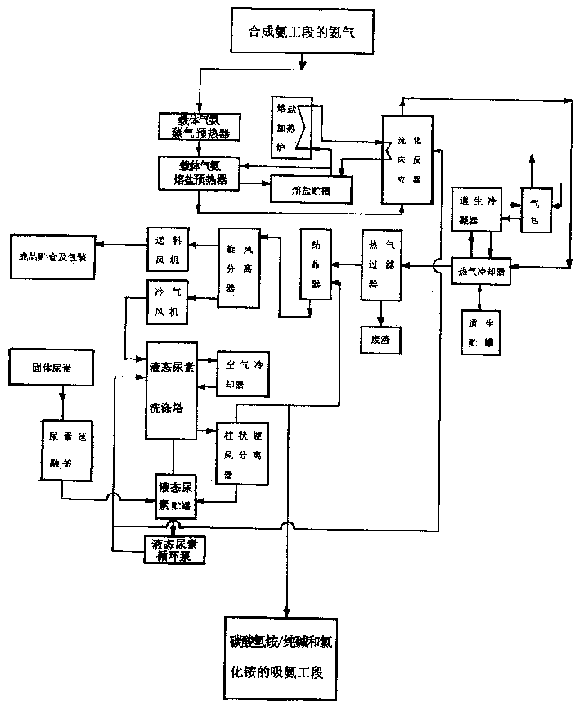

Trimeric cyanamide joint production method using one step method

InactiveCN1493565AImprove product qualityReduce labor intensityOrganic chemistryChemistryAmmonium chloride mixture

Owner:河南金山化工有限责任公司

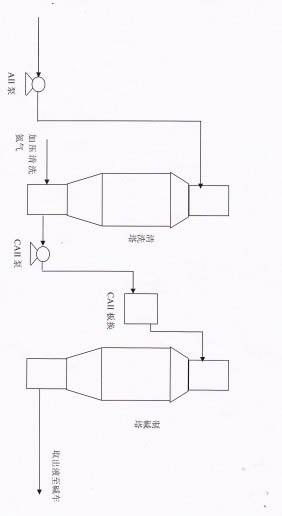

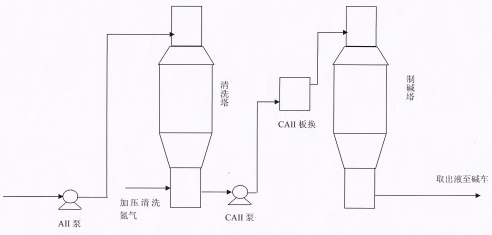

Carbonization cleaning process of carbonizer for producing heavy soda ash

InactiveCN102432041AImprove the degree of carbonization conversionRaise the temperature of IICarbonate preparationCooling towerCarbonization

Owner:SICHUAN HEBANG

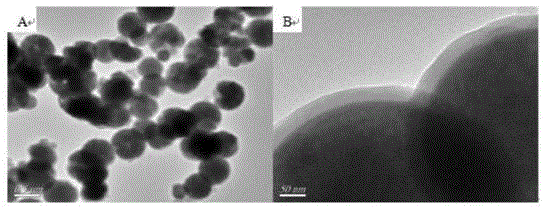

Stephanoporate zinc oxide nano-powder and preparation method thereof

InactiveCN101318690AReduce the probability of collisionAvoid formingZinc oxides/hydroxidesNanoparticleZinc nitrate

Owner:WUHAN UNIV

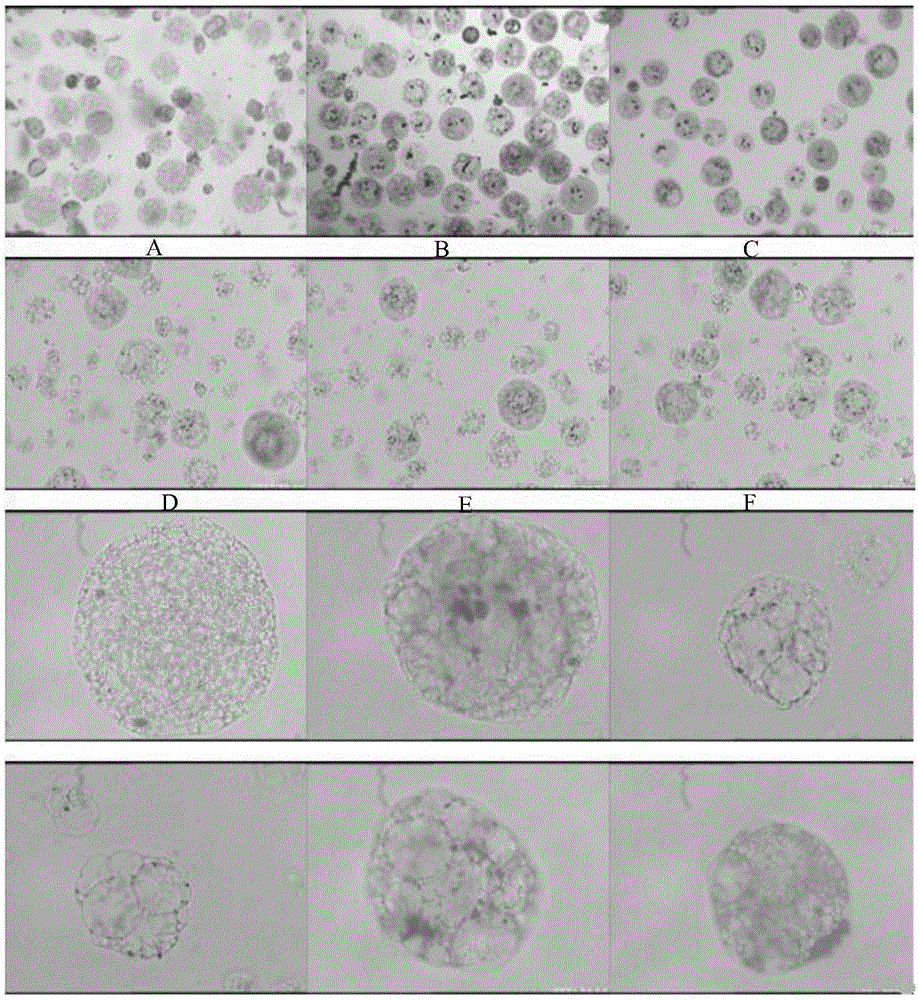

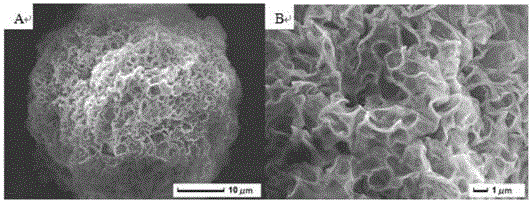

Three-dimensional wrinkle polylactic acid microballoons and preparation method and uses thereof

InactiveCN105273216AAchieve transformationLarge specific surface areaTissue cultureLiquid separationCell adhesionMicrosphere

Owner:JIANGSU UNIV

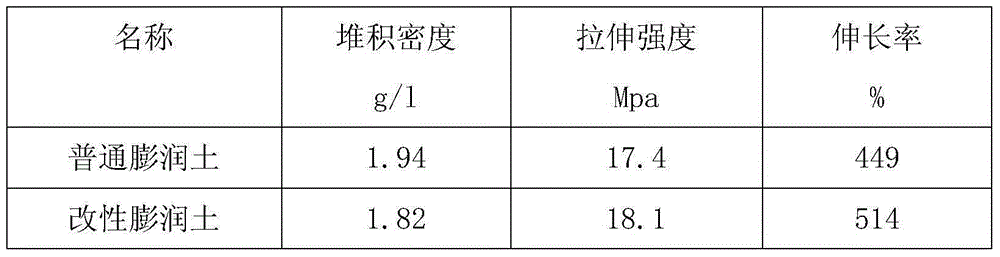

Porous modified bentonite with foaming effect and preparation method thereof

InactiveCN105126779APorousReasonable formulaOther chemical processesAlkali metal oxides/hydroxidesPorositySodium Bentonite

Owner:安徽雪城超细碳酸钙有限公司

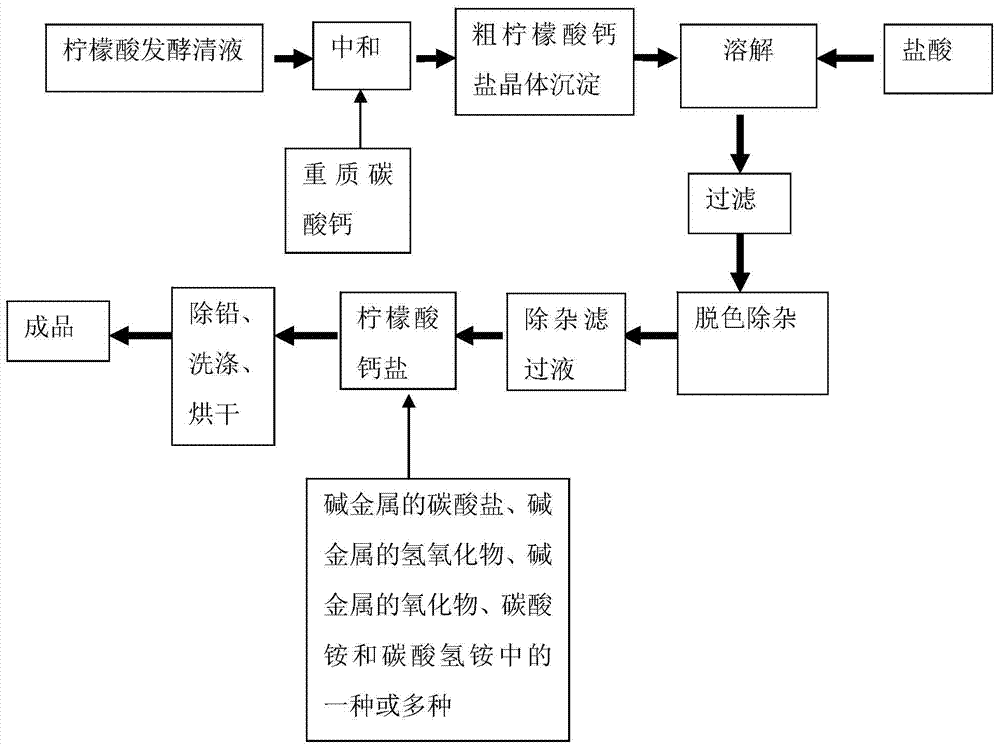

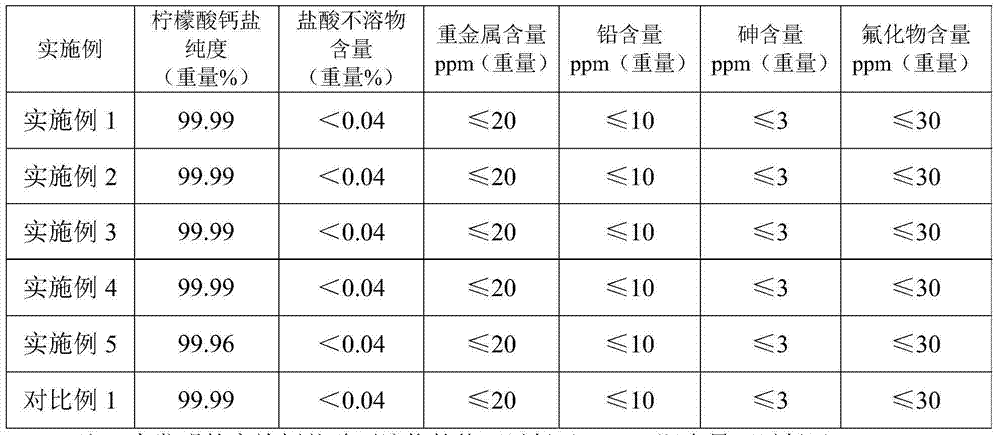

Calcium citrate producing method

ActiveCN104513154AHigh purityOrganic compound preparationCarboxylic acid salt preparationFood additiveImpurity

Owner:COFCO BIOTECHNOLOGY CO LTD

Method for preparing lithium manganate by wet-doping method

InactiveCN103337619AIncrease the average oxidation stateSuppress purityCell electrodesManganates/permanganatesOxidation stateManganate

Owner:HUNAN DAHUA NEW ENERGY

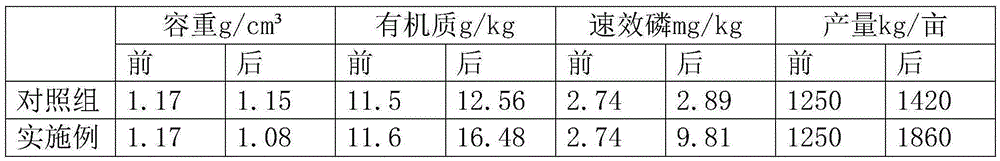

Soil ripening regulating agent for sweet orange garden

Owner:DANYANG HUADU GARDENING

Dedicated fruit tree set fertilizer

InactiveCN106748288AImprove fertilityAvoid the effects of organic pollutionBio-organic fraction processingAlkali orthophosphate fertiliserPotassium permanganateOrganic component

The invention discloses dedicated fruit tree set fertilizer which is prepared from the following raw materials in parts by weight: 34 to 36 parts of soybean meal, 15 to 18 parts of needle mushroom dreg, 20 to 24 parts of monosodium glutamate residue, 3 to 4 parts of potassium pyrophosphate, 4 to 6 parts of ammonium bicarbonate, 1 to 2 parts of sodium polyphosphate, 2 to 3 parts of sodium silicate, 10 to 14 parts of chitosan, 0.3 to 0.5 part of potassium permanganate, 1.5 to 1.8 parts of manganese sulfate, 1 to 2 parts of acrylamide, 0.3 to 0.4 part of N,N'-methylene bisacrylamide, 2 to 3 parts of ammonium persulfate, 1 to 2 parts of zinc acetate, 0.2 to 0.4 part of yttrium nitrate, a defined amount of absolute ethyl alcohol and a defined amount of water. According to the fertilizer disclosed by the invention, organic components and inorganic components are reasonably matched; thus, the fertilizer has comprehensive nutrient elements and is easy to decompose and absorb; meanwhile, a release characteristic of a coating material of the fertilizer aims at different growth stages of a fruit tree germination stage, a growth period and a fruit swelling period; counterpart supplying of the total nutrient amount is achieved, fertilizer consumption is reduced, nutrient utilization rate is improved at the same time, a fertilizing process is simplified, and economic benefit of planting fruit trees is improved.

Owner:SUZHOU TIANYU CULTURE GRP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap