Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Dodecyl sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium dodecyl sulfate, synonymously sodium lauryl sulfate (or laurilsulfate; SDS or SLS, respectively), is a synthetic organic compound with the formula CH3(CH2)11SO4Na. It is an anionic surfactant used in many cleaning and hygiene products. The sodium salt is of an organosulfate class of organics.

Efficient nitrogen and phosphorus removal granular preparation and production process thereof

InactiveCN107055649AEasy to makeReduce energy consumptionWater treatment parameter controlWater contaminantsDodecyl sulfatePotassium ferrate

The invention relates to an efficient nitrogen and phosphorus removal granular preparation. The granular preparation is prepared from raw materials in parts by weight as follows: 20-100 parts of potassium ferrate, 20-100 parts of bentonite, 1-5 parts of disodium EDTA, 10-50 parts of cement and 1-5 parts of a sodium lauryl sulfate aqueous solution. The concentration of the sodium lauryl sulfate aqueous solution is 2-3 g / L. The production technology of the efficient nitrogen and phosphorus removal granular preparation comprises the steps as follows: (1) potassium ferrate, bentonite, disodium EDTA and cement are mixed and stirred uniformly in proportion, a mixture is obtained; (2) the sodium lauryl sulfate aqueous solution is added to the mixture in step (1) and mixed and stirred uniformly, granulation and drying are performed, and the granular preparation is obtained. The efficient nitrogen and phosphorus removal granular preparation and the production process thereof have the benefits that energy consumption is low in the preparation process of nitrogen and phosphorus removal granular preparation, preparation is simple, no secondary pollution is caused to the environment, and the heavy metal adsorption effect is good.

Owner:YIKANG TECH CO LTD

Preparation method of domperidone tablets

ActiveCN109481410AIncrease productivityHigh tablet hardnessOrganic active ingredientsDigestive systemCelluloseMagnesium stearate

The invention provides a preparation method of domperidone tablets, comprising the following steps: (1) material preparation: performing site-clearing inspection, getting a raw material domperidone, and ingredients lactose G200, pregelatinized starch, low-substituted hydroxypropyl cellulose, povidone K30, lauryl sodium sulfate, silica and magnesium stearate; (2) pelleting: sieving and uniformly mixing raw material and ingredients except povidone K30, silica and magnesium stearate, then slowly adding a povidone K30 solution, uniformly stirring, and sieving to prepare wet particles, drying, sieving and collecting to obtain dry particles; (3) generally blending: respectively adding silica and magnesium stearate into the dry particles obtained in the step (2), to obtain generally mixed particles; and (4) tabletting, and the like. The method is high in production efficiency, and can enable the prepared domperidone tablets to be high in dissolving-out speed and relatively long in expirationdate while ensuring relatively high streptomycin hardness.

Owner:WEIAO PHARM (SICHUAN) CO LTD

Production process of tpo stay wire body

Owner:天津市精志诚拉线厂

Multipurpose enhanced cleaning agent

InactiveCN111154551ALow costProduce secondary pollutionInorganic/elemental detergent compounding agentsSurface-active detergent compositionsSodium acetateActive agent

The invention relates to a multipurpose enhanced cleaning agent. The cleaning agent is characterized by comprising, by weight, 5-35 parts of turpentine, 10-40 parts of Chinese honeylocust fruits, 10-28 parts of sodium lauryl sulfate, 16-36 parts of a gemini surfactant, 3-10 parts of sodium acetate, 10-25 parts of citric acid, 4-20 parts of essence and 35-70 parts of water. The cleaning agent is energy-saving and environment-friendly, is low in cost, does not cause secondary pollution to the environment during cleaning, and protects the environment.

Owner:仪征市伟尔机械服务部

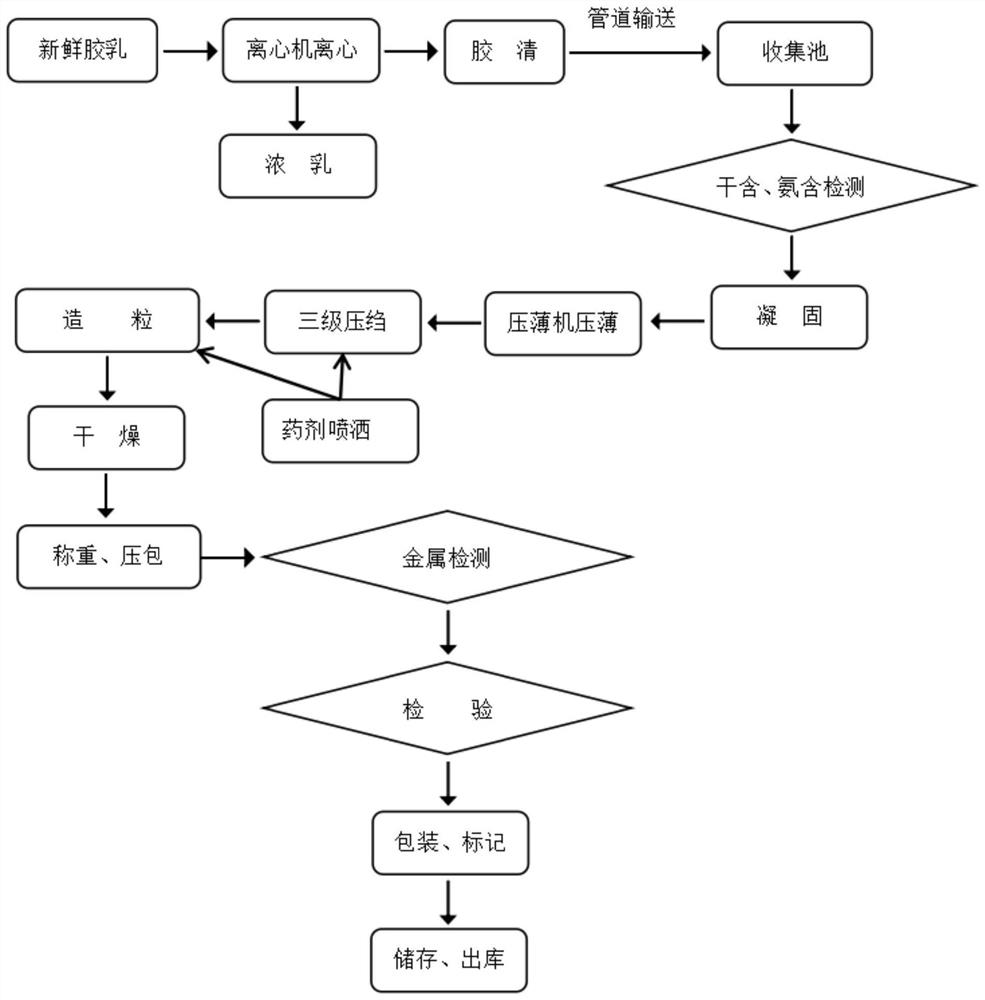

Composition for improving plasticity retention rate of standard gel as well as preparation method and application of composition

PendingCN114752111AImprove plasticity retentionImproved plasticity retentionCresolButylated hydroxytoluene

Owner:海南天然橡胶产业集团金橡有限公司

Metal pipe fitting processing lubricating oil

InactiveCN103602458AReduce roughnessReduce cutting temperatureLubricant compositionDioxyethylene EtherSodium sulfate

Disclosed metal pipe fitting processing lubricating oil is prepared from the following raw materials in parts by weight: 12-20 parts of nonylphenolpolyethoxylate, 10-15 parts of corn oil, 2-6 parts of sodium dodecyl sulfate, 2-5 parts of triethanolamine, 3-7 parts of sodium metaborate and 3-7 parts of urea. Compared with conventional lubricating oil, the metal pipe fitting processing lubricating oil has thixotropy, can be transformed from a paste into a liquid when conveyed to a to-be processed pipe fitting by an air powered pump or being stirred, is easy to convey and use, and helps to save the usage amount; the metal pipe fitting processing lubricating oil has extremely strong permeability and is easy to clean; the metal pipe fitting processing lubricating oil has extremely good lubricity, heat-transfer cooling performance, stability, rheological property and extreme pressure resistance; and the metal pipe fitting processing lubricating oil helps to furthest reduce cutting temperature and cutting force for processing metal pipe fittings, improve processing efficiency and precision, reduce workpiece roughness and improve surface quality.

Owner:QINGDAO HAIBAN PLASTIC IND & TRADE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap