Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

18 results about "Steel columns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

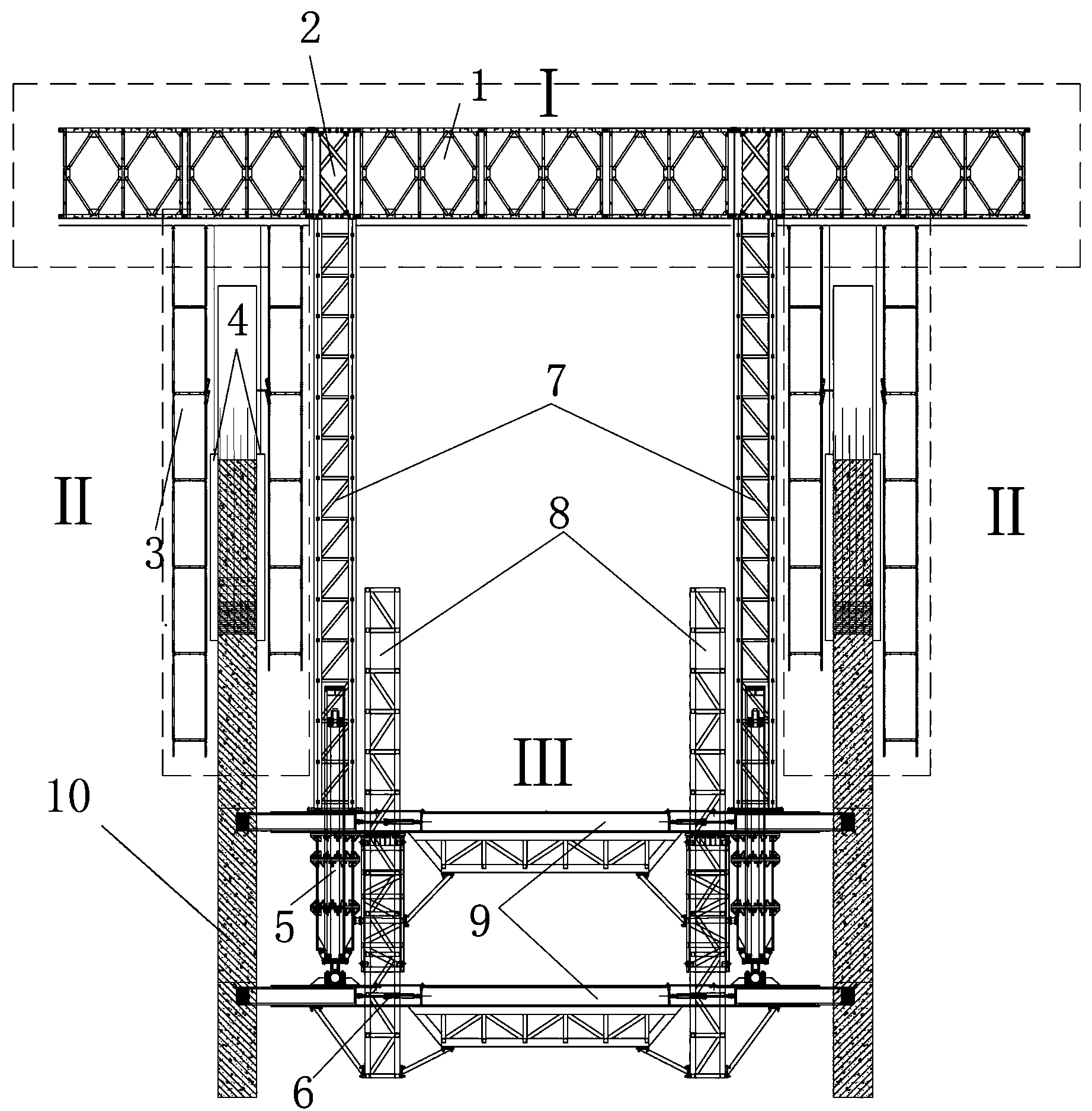

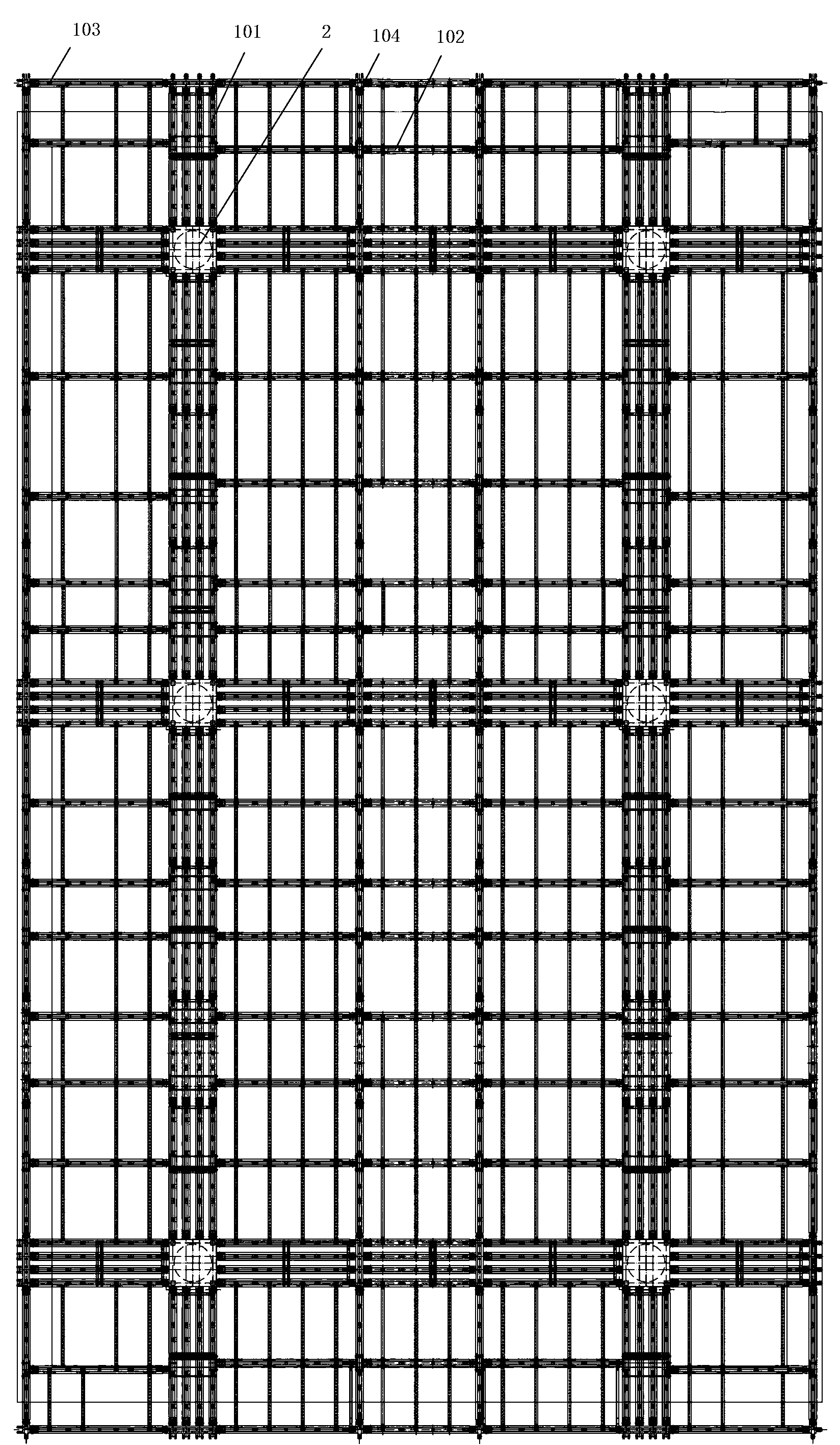

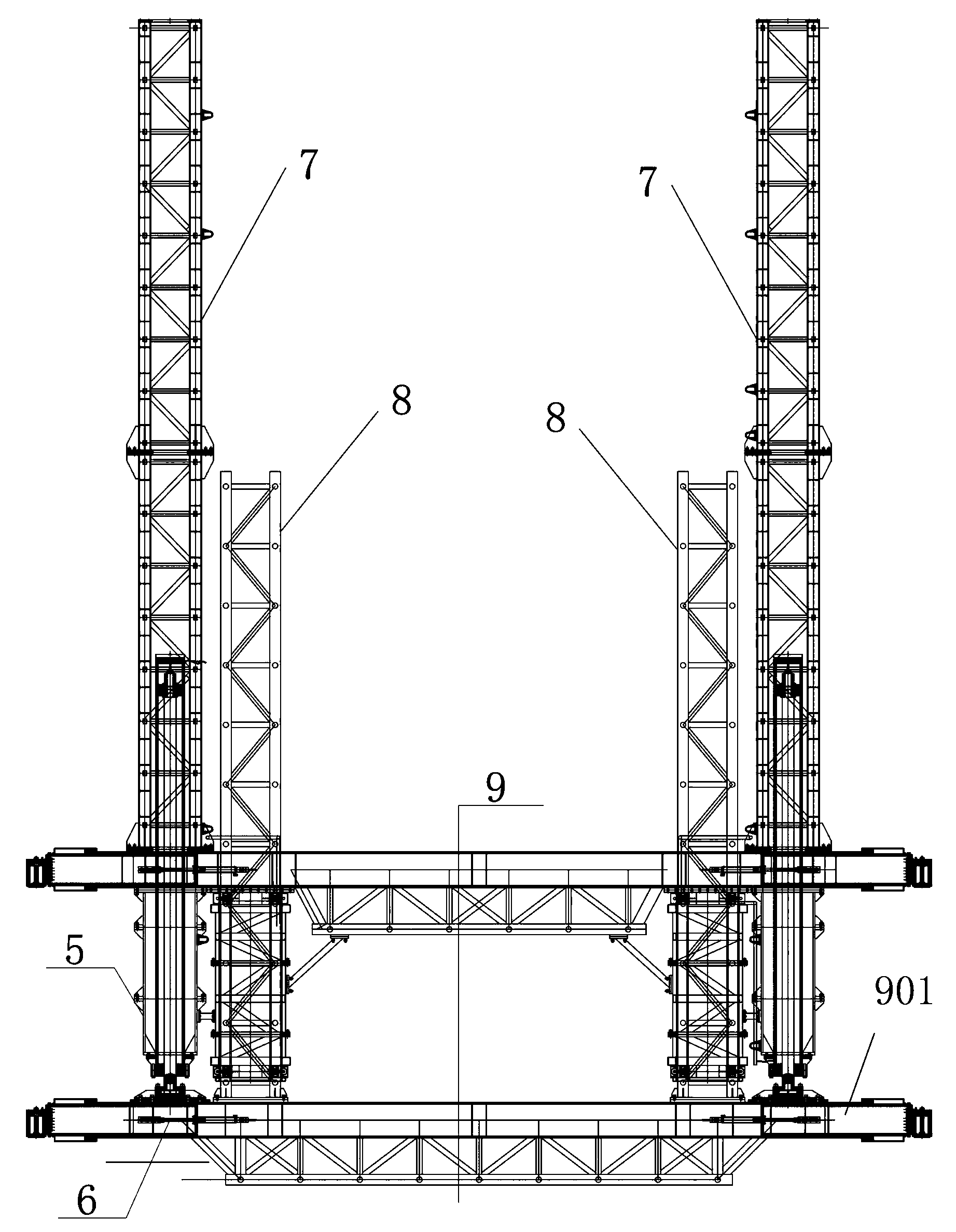

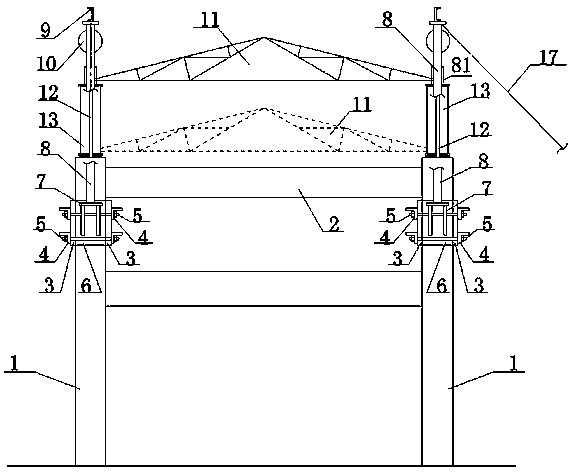

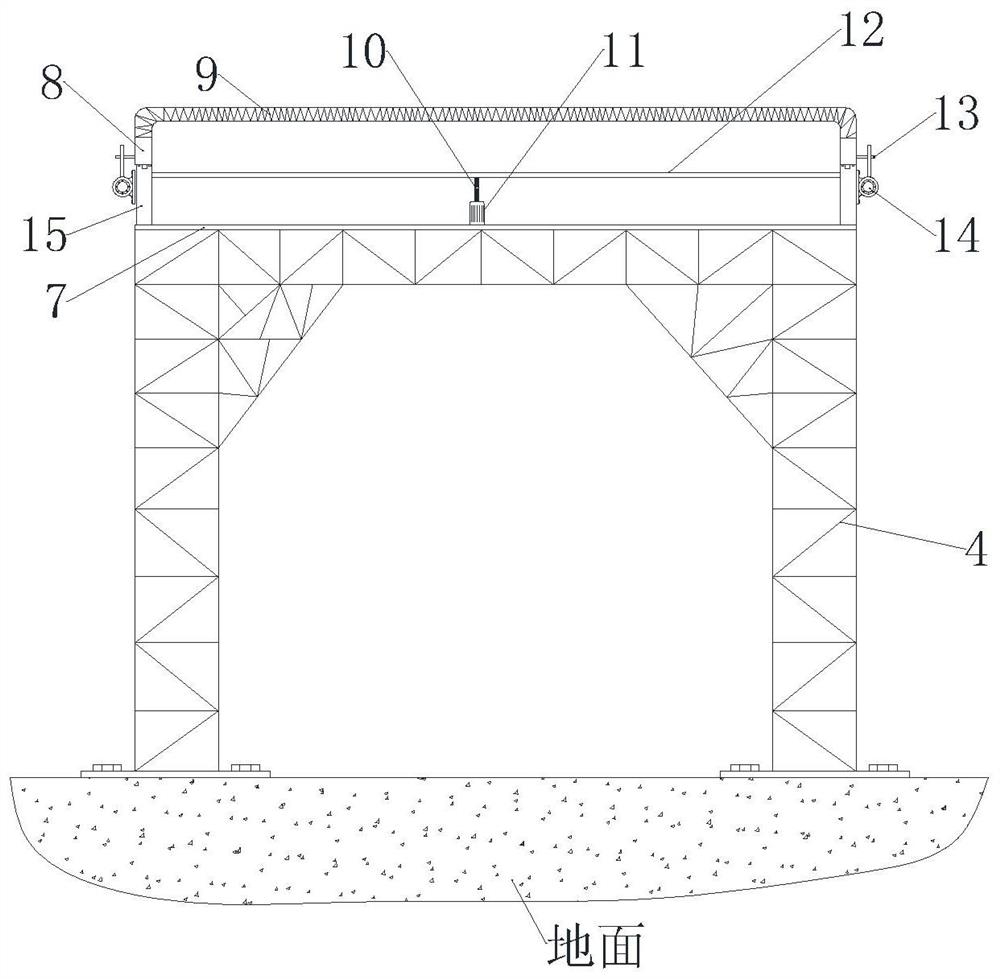

Standard Bailey truss assembling type jacking formwork system

ActiveCN103669832AForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSteel columnsStructural engineering

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

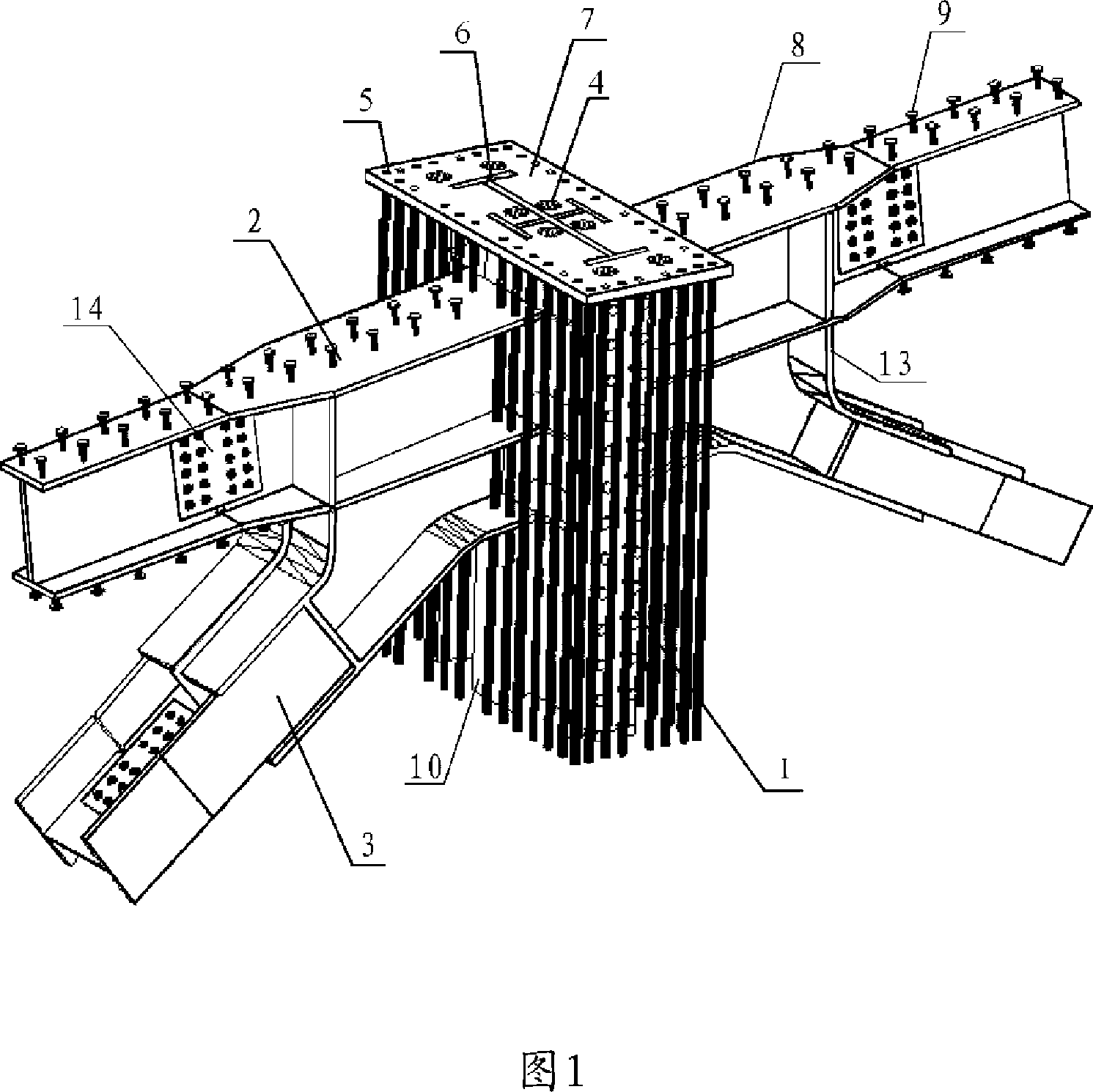

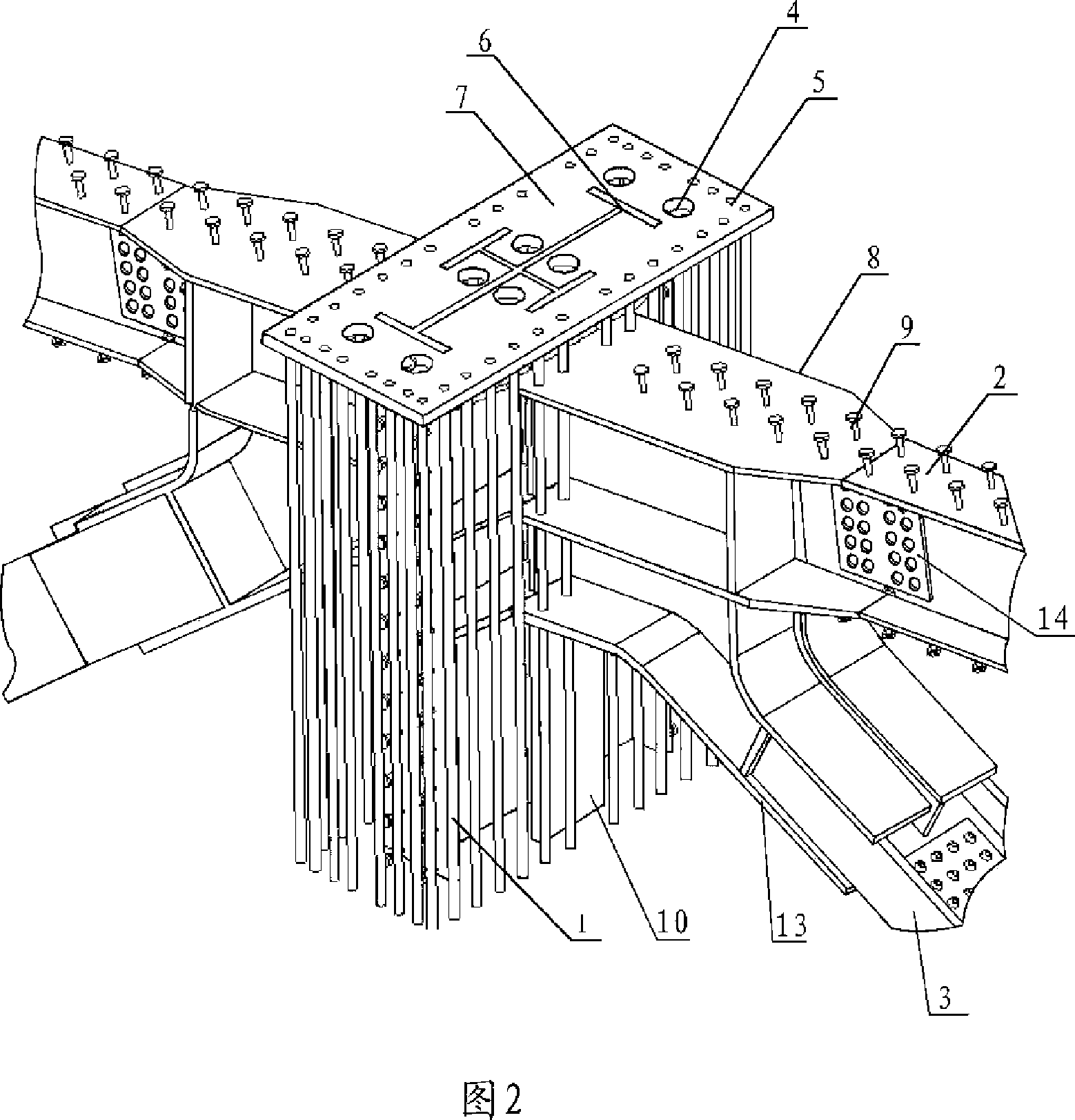

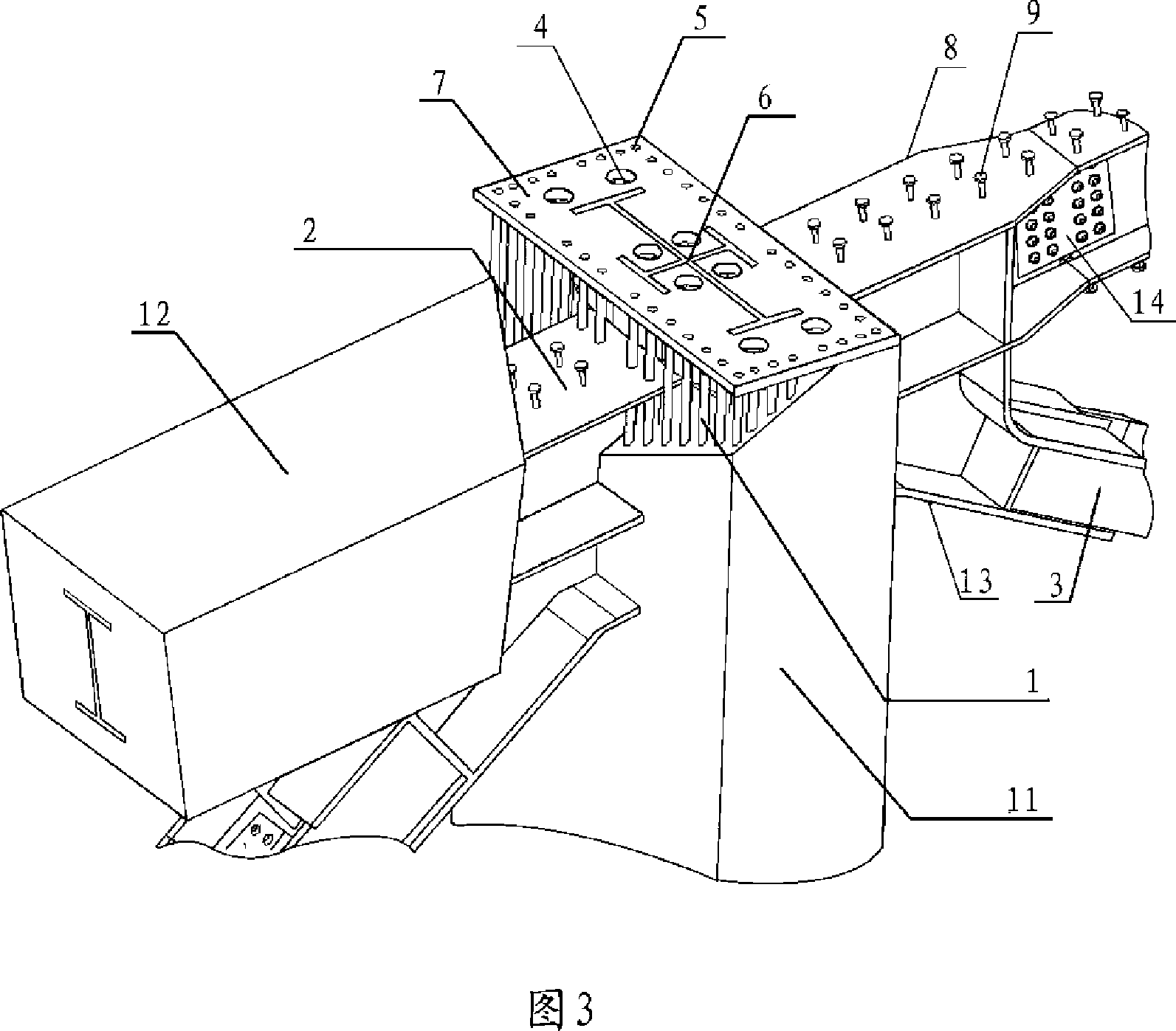

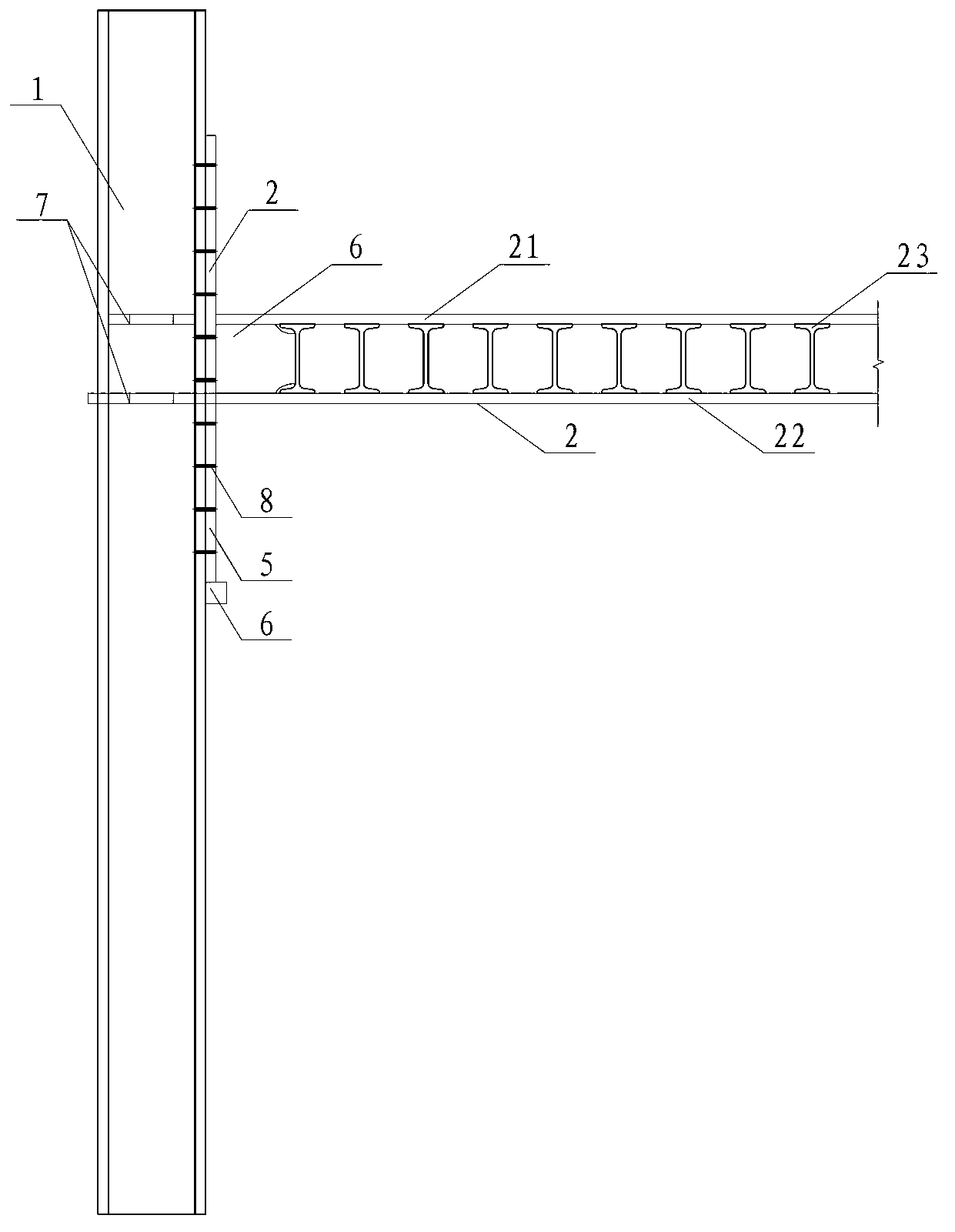

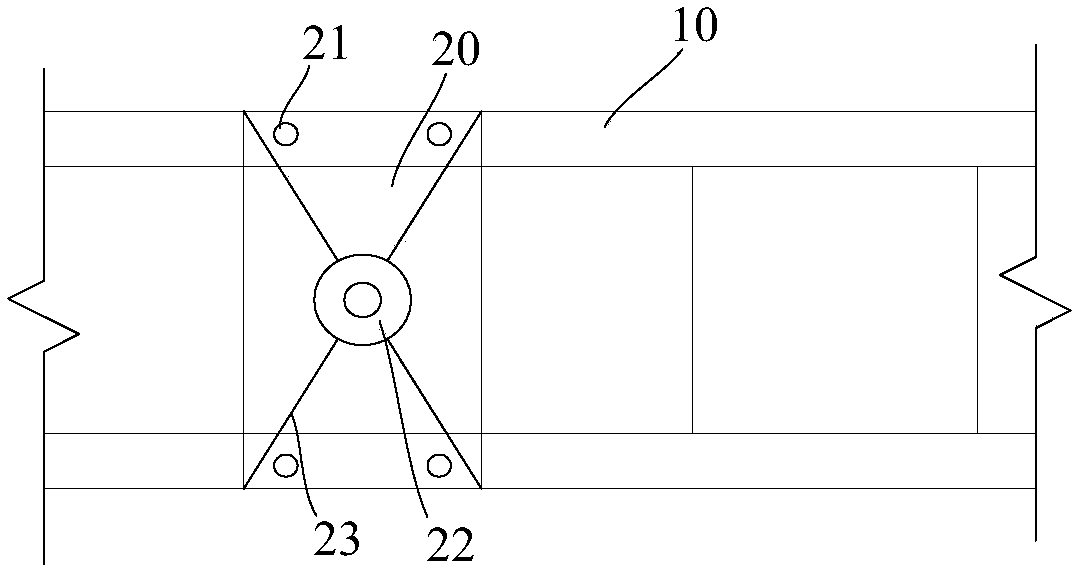

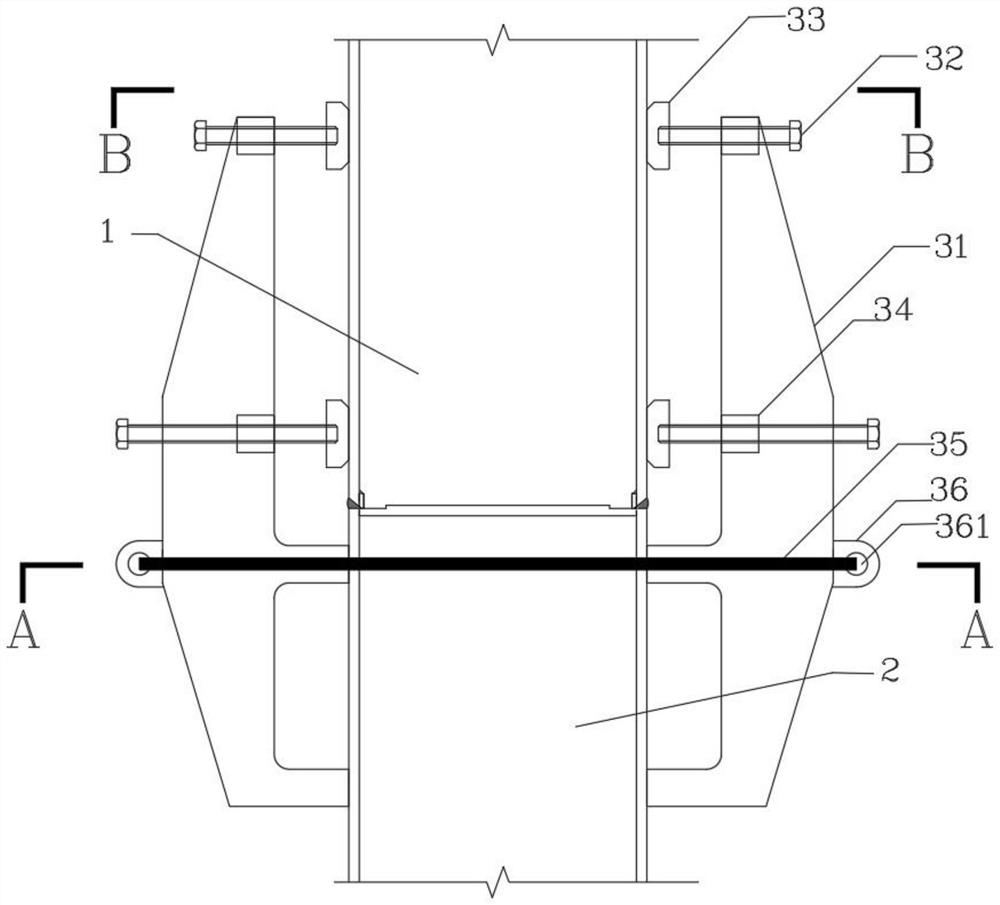

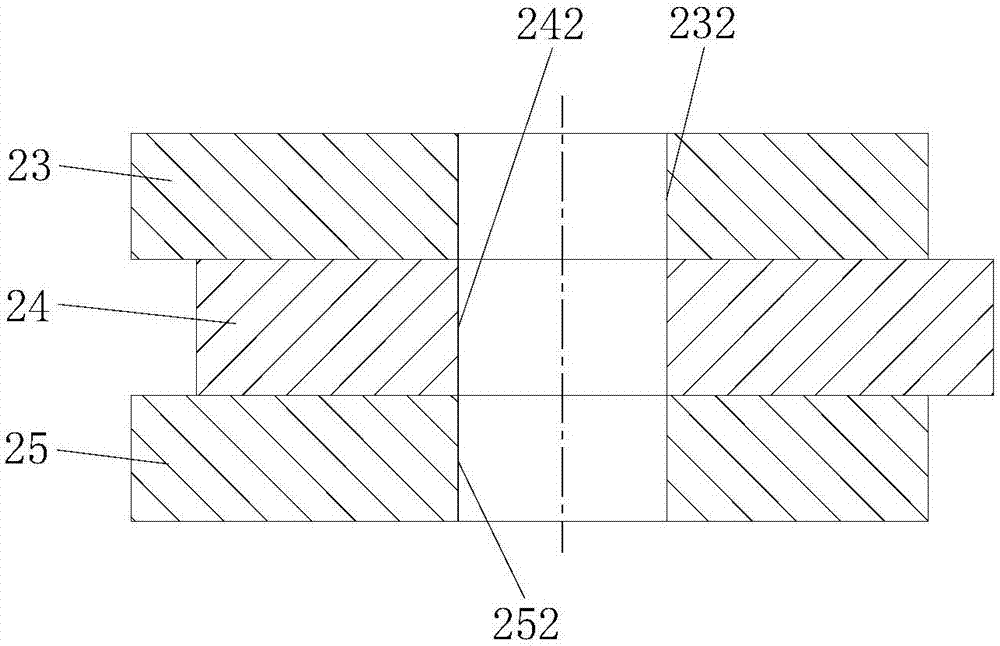

Shaped-steel concrete frame-steel supporting structure type steel column preconstraint node

ActiveCN101024974AImprove integritySafe and reliable connectionBuilding constructionsSheet steelSteel bar

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +1

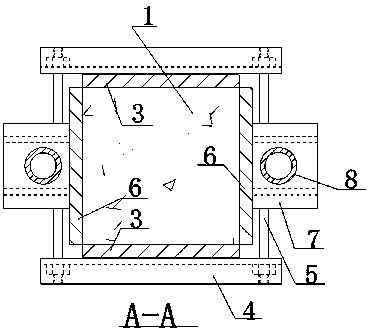

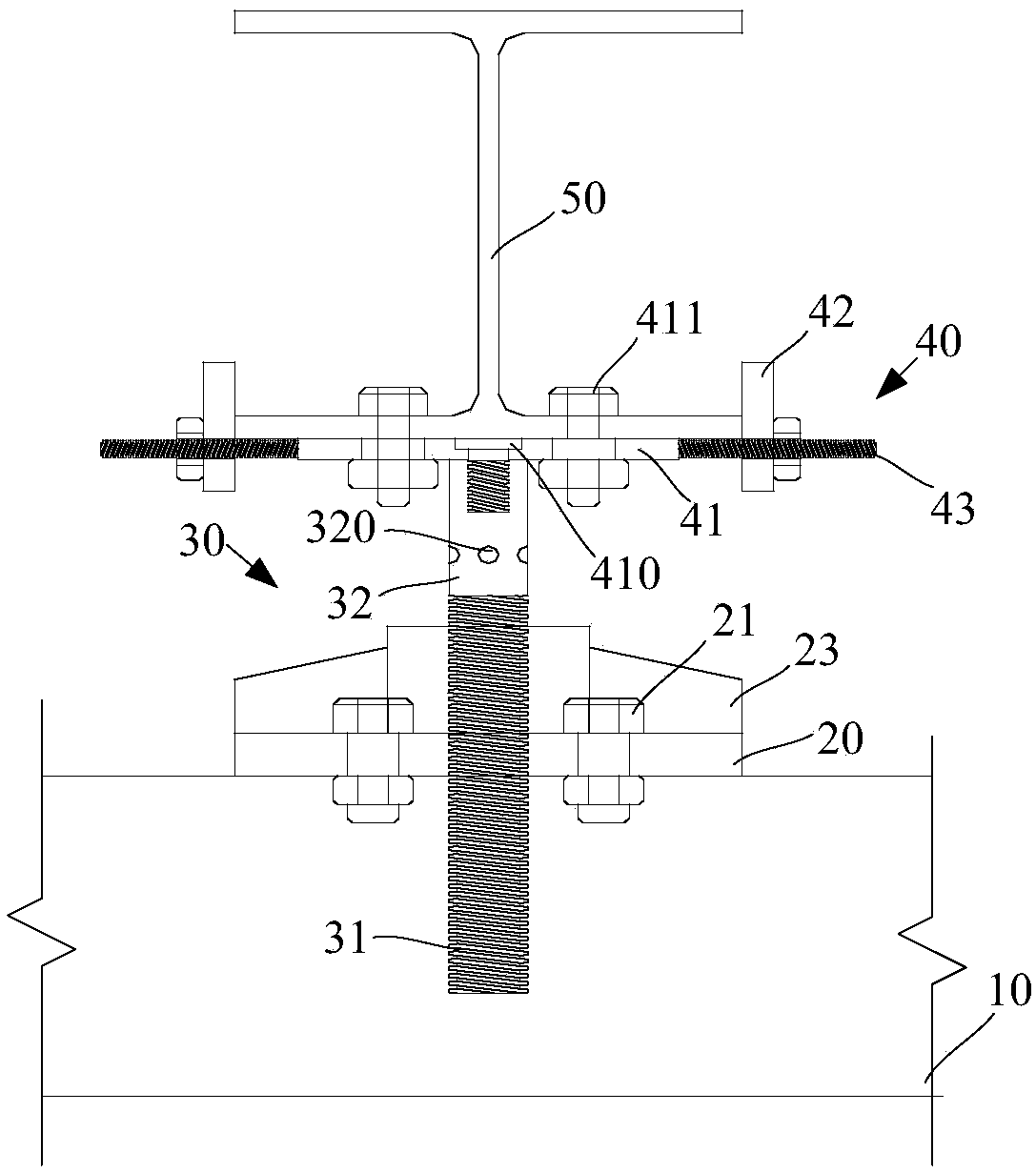

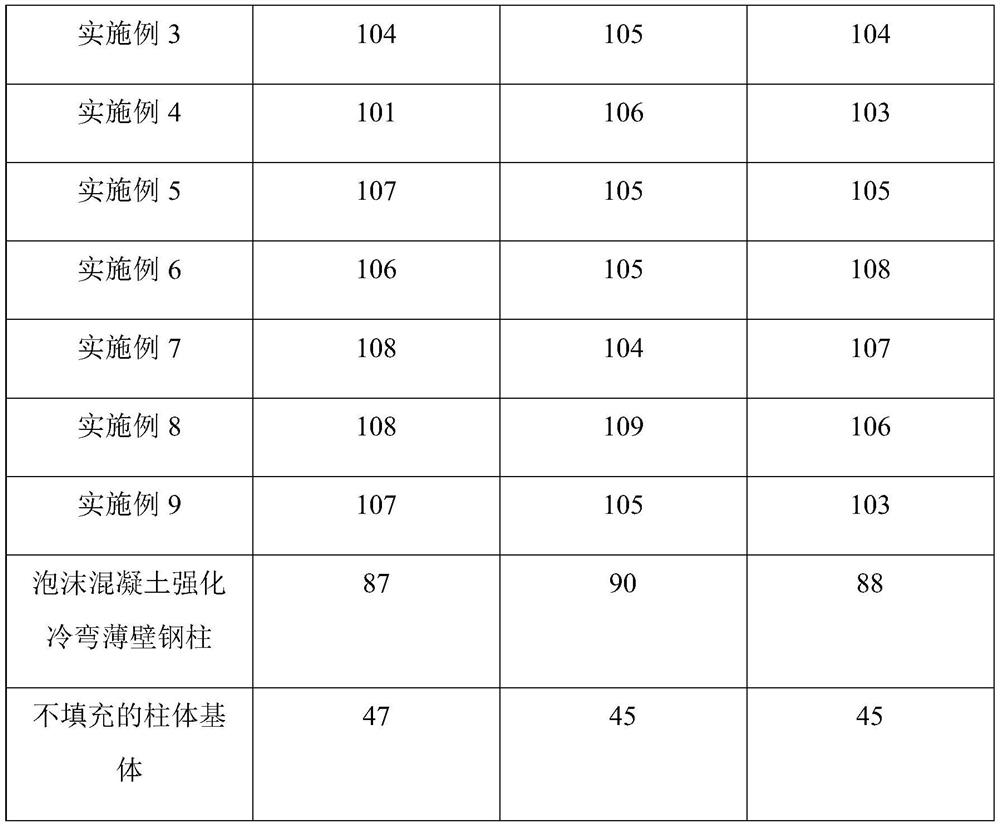

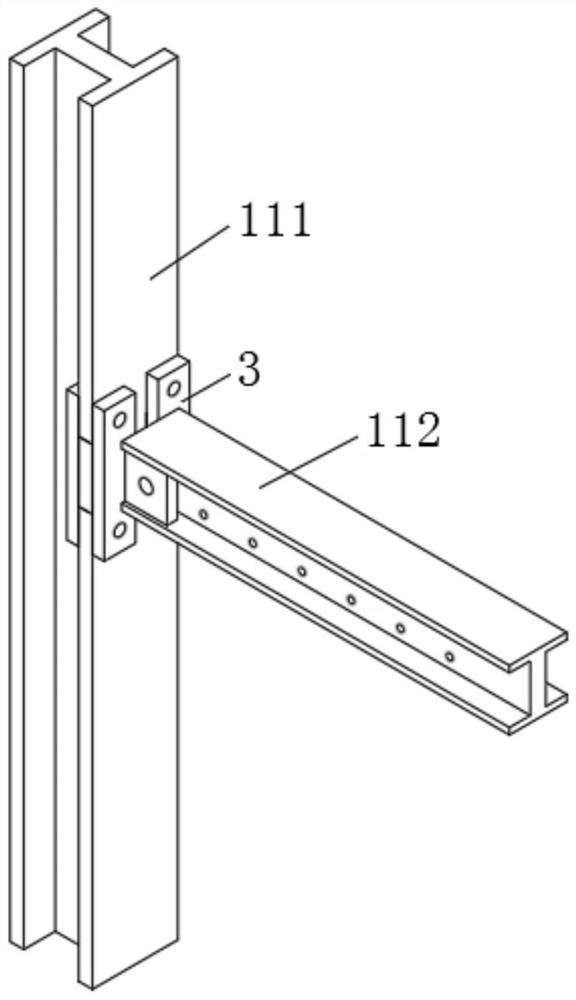

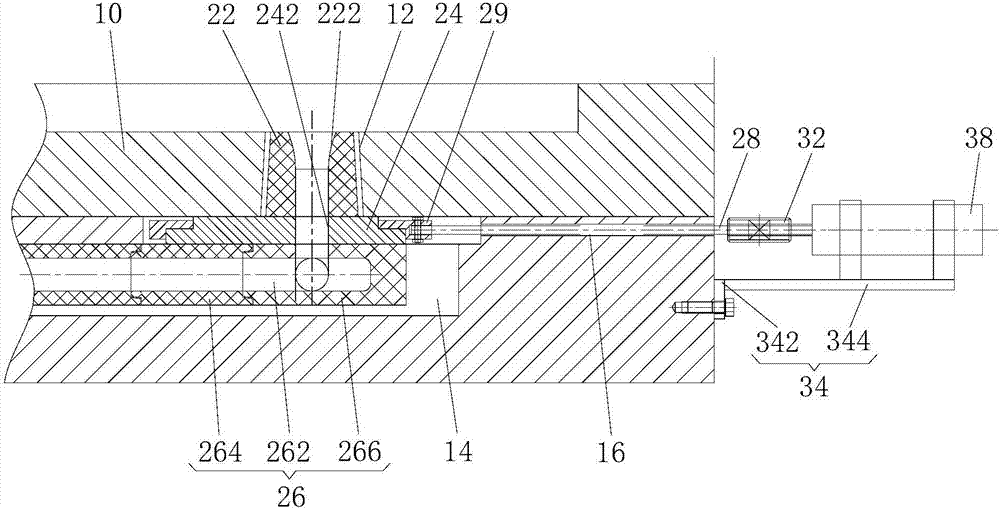

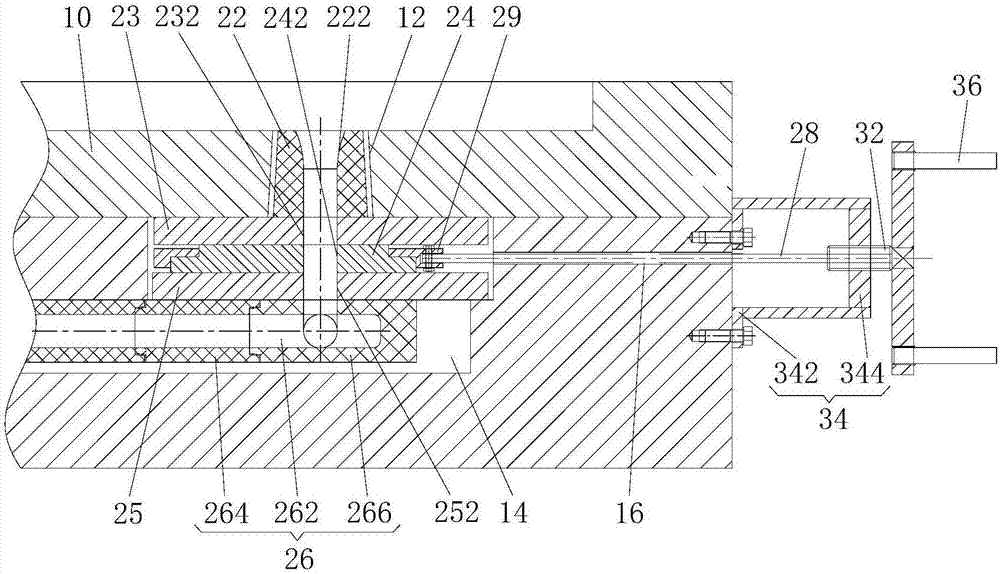

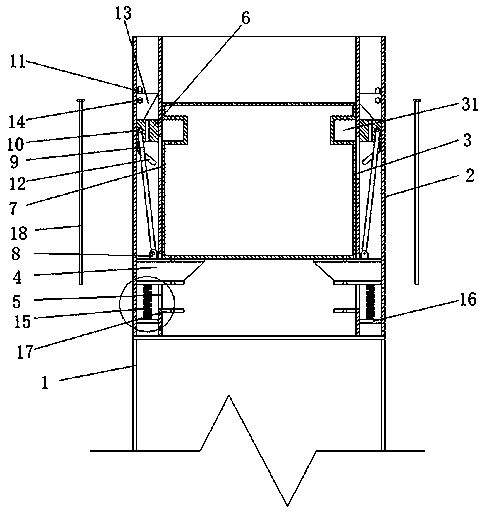

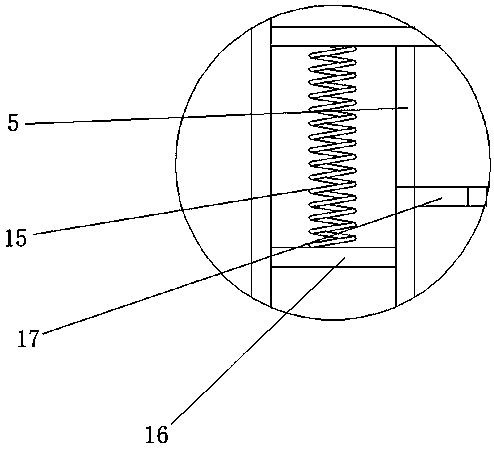

Auto-recovering reinforced column base and construction installation method thereof

PendingCN111075112AStrong self-resetting effectSolve the elastic resistance problemStrutsFoundation engineeringArchitectural engineeringSteel columns

The invention discloses an auto-recovering reinforced column base and a construction installation method thereof. The auto-recovering reinforced column base is constructed on a foundation, and comprises a steel column, a high-strength pull rod, a cantilever plate, limiting devices, anchor rods and limiting base plates, wherein the steel column is inserted and connected to a limiting groove of thefoundation; the high-strength pull rod penetrates through transverse stiffening ribs of the steel column, and a first disc spring set is installed on the top end of the transverse stiffening ribs andthe high-strength pull rod for fixing; the cantilever plate is horizontally fixed on the outer side of the steel column; the limiting devices are fixed on the top surface of the cantilever plate; thebottom ends of the anchor rods are connected with the foundation, rod bodies penetrate through the cantilever plate and through holes of the limiting devices, and is provided with a second disc springset in a sleeved mode, and the limiting base plates and high-strength nuts are symmetrically installed at the two ends of the rod bodies in a sleeving mode. According to the auto-recovering reinforced column base, pre-pressure is applied to disc springs, so that the steel column has auto-recovering capability; and during a strong earthquake, the steel column swings to reduce the earthquake damage, after the earthquake, the auto-recovering function is achieved through the disc springs, and the device is clear in concept, convenient to construct and has a wide engineering application prospect.

Owner:HAINAN UNIV

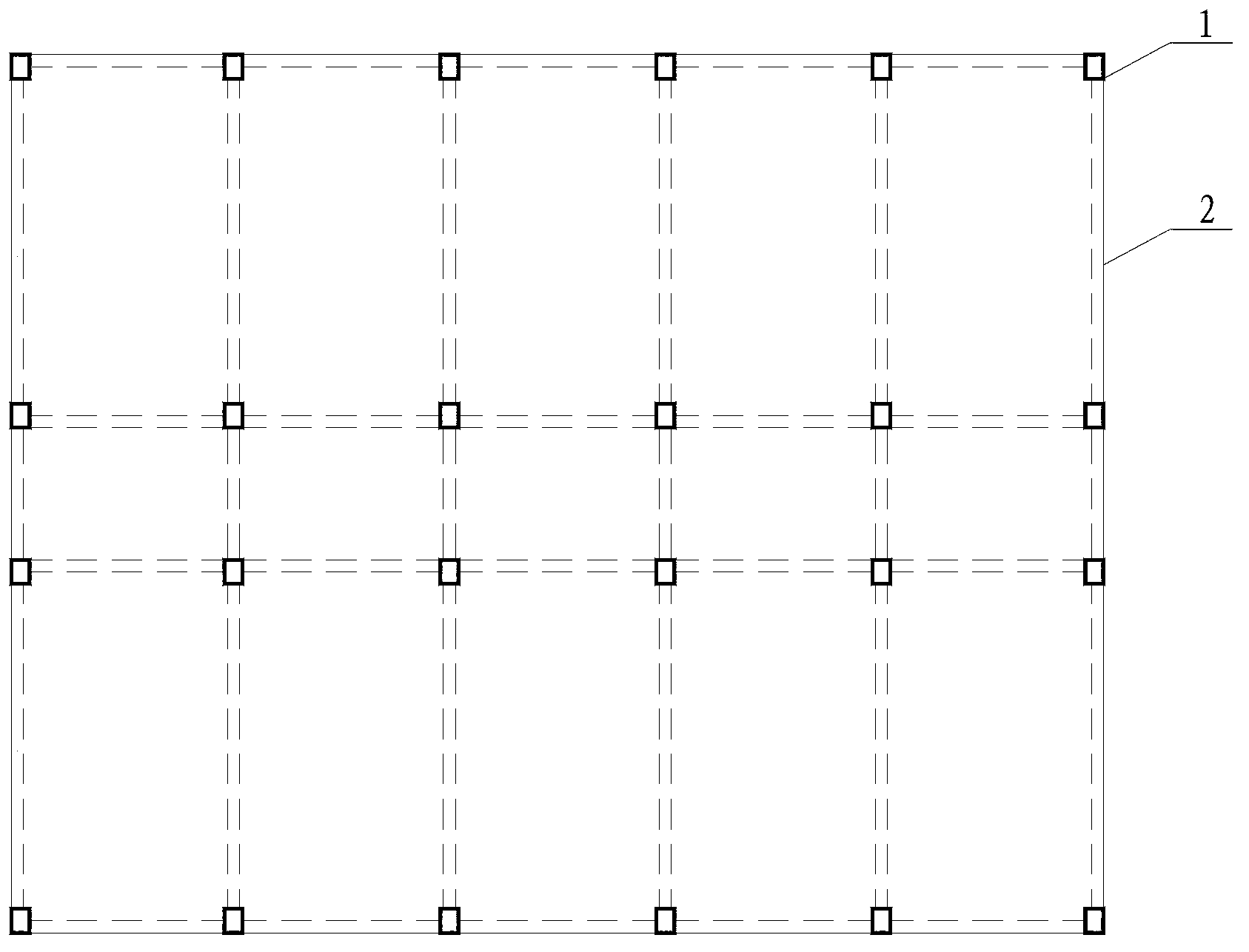

Steel-concrete slab-column structure system

ActiveCN103276795AReasonable structureConvenient on-site operationFloorsSteel columnsPrecast concrete

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

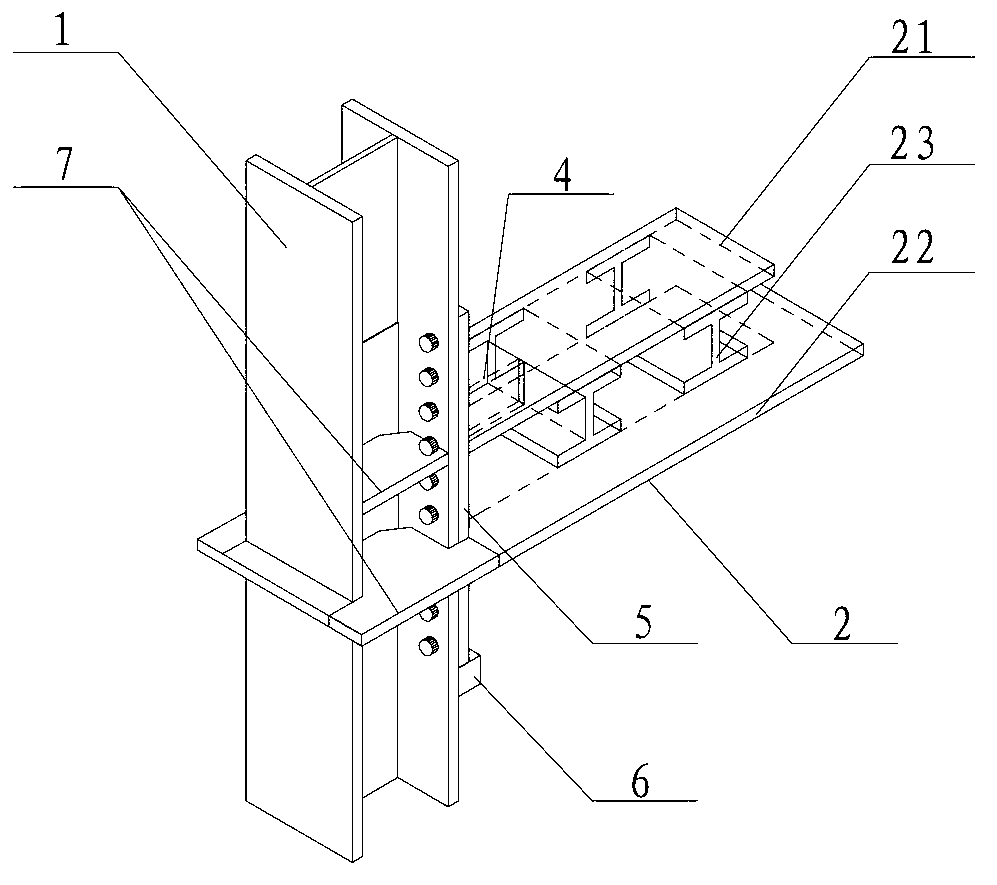

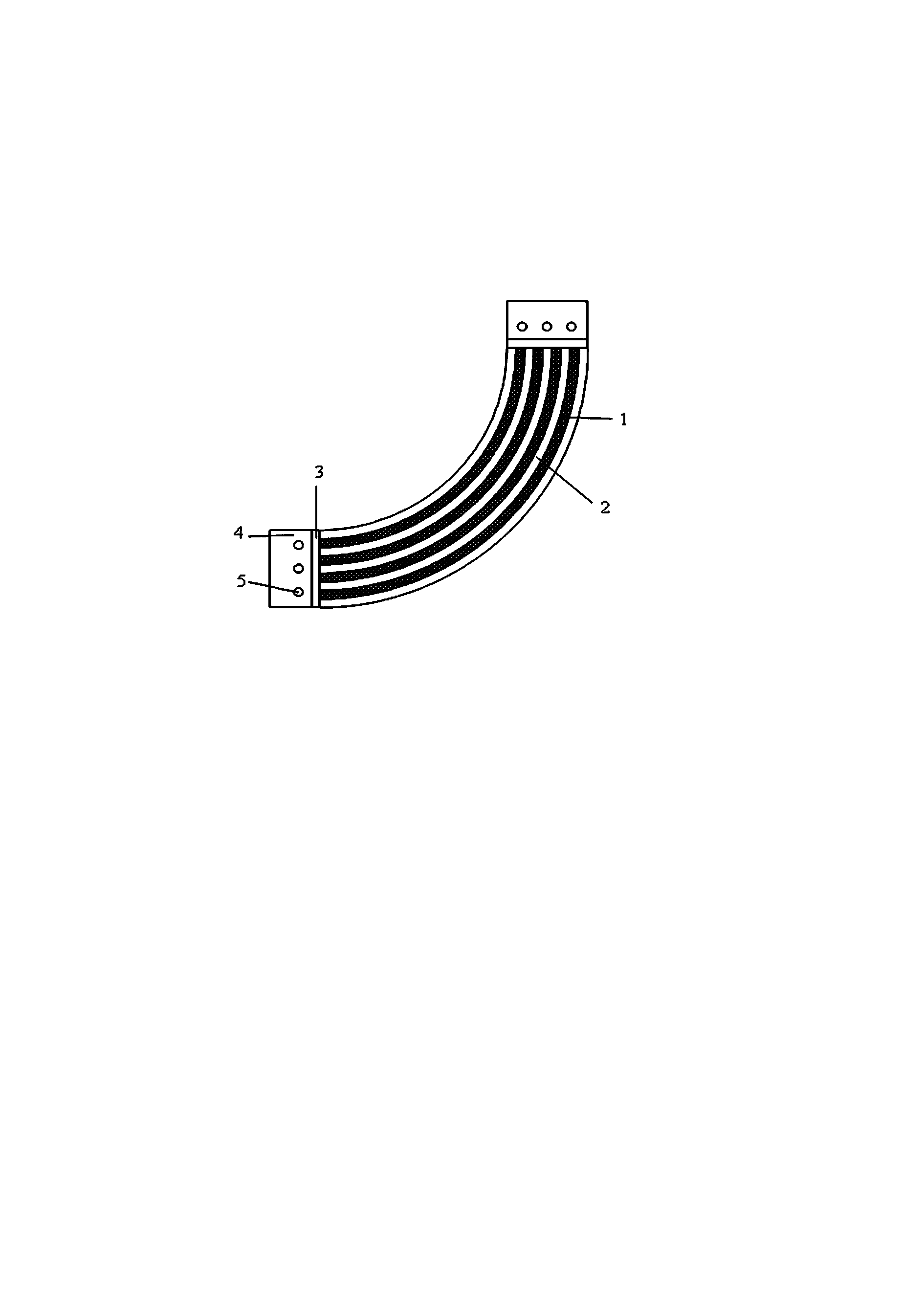

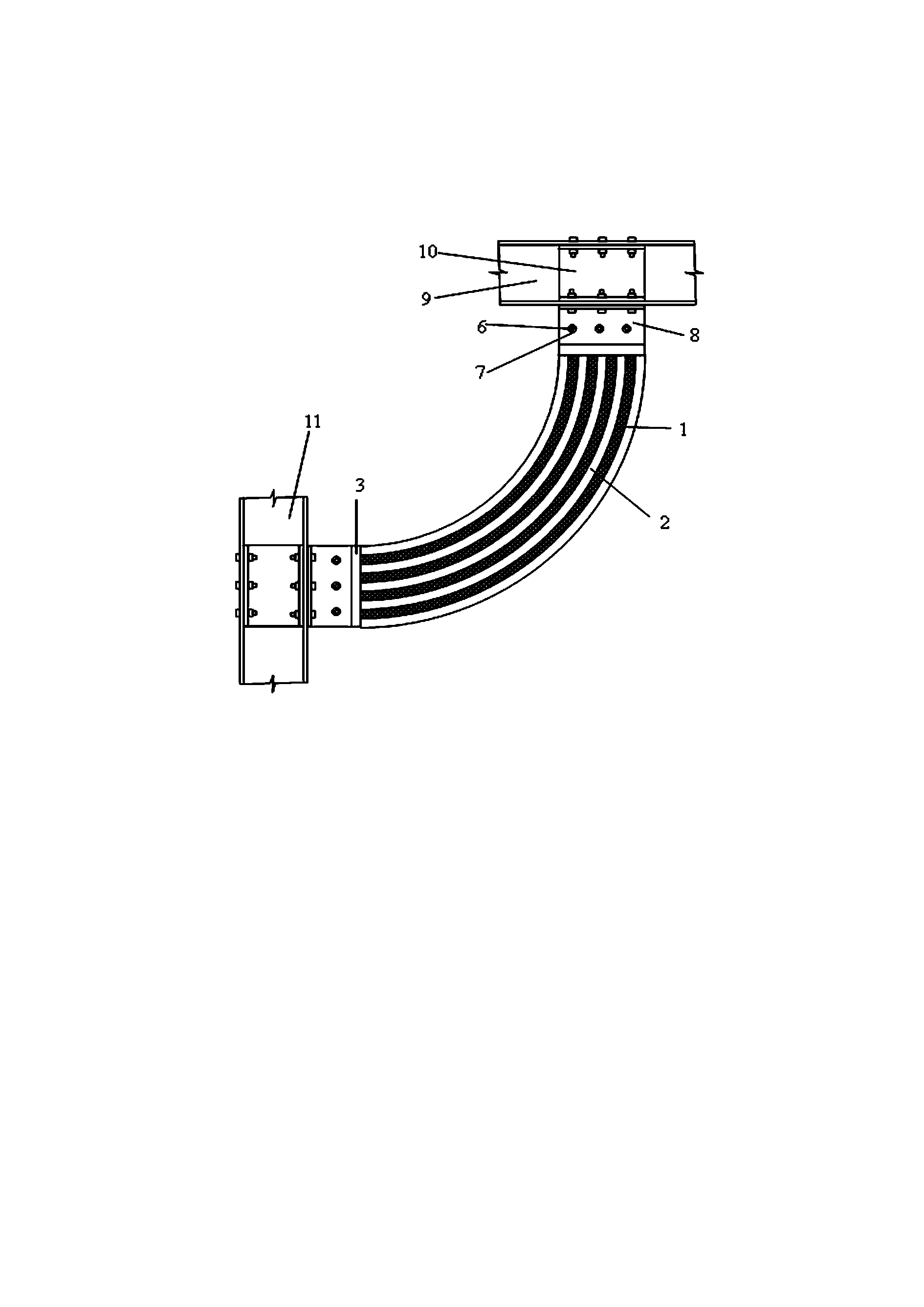

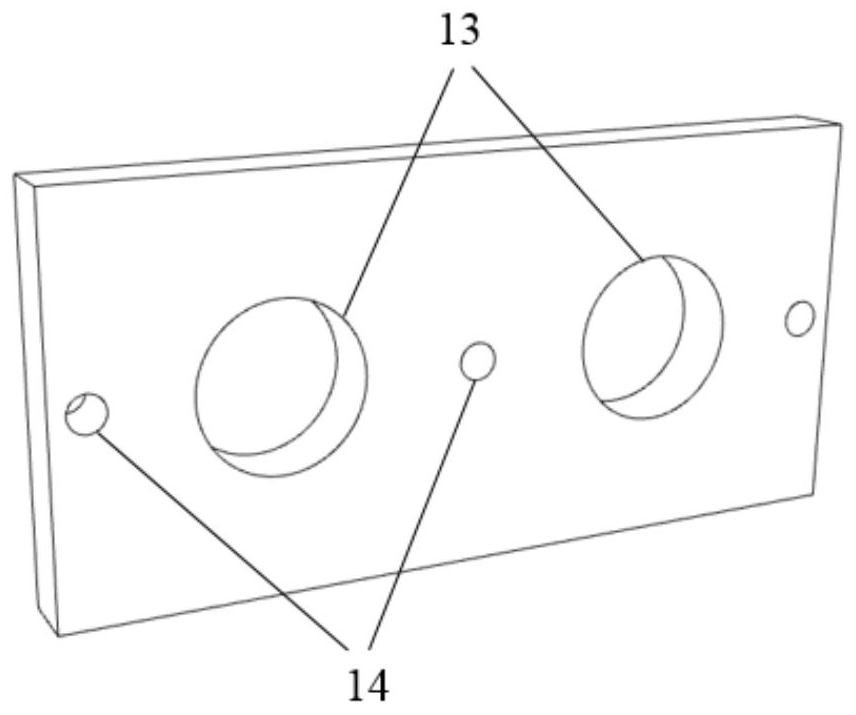

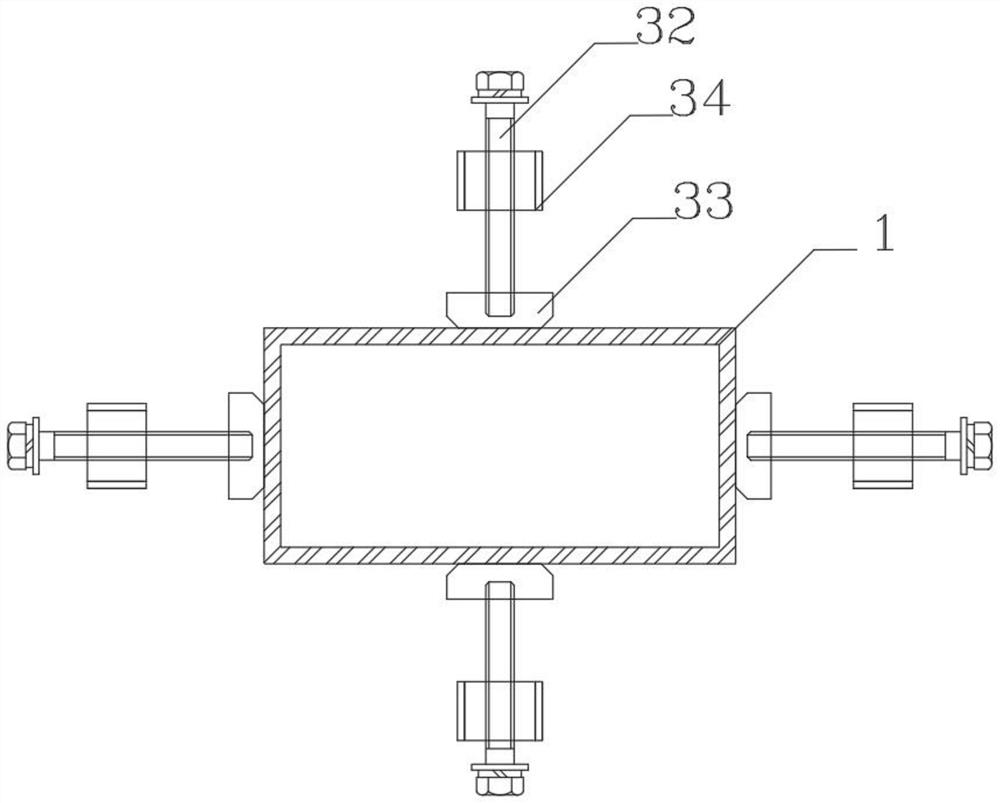

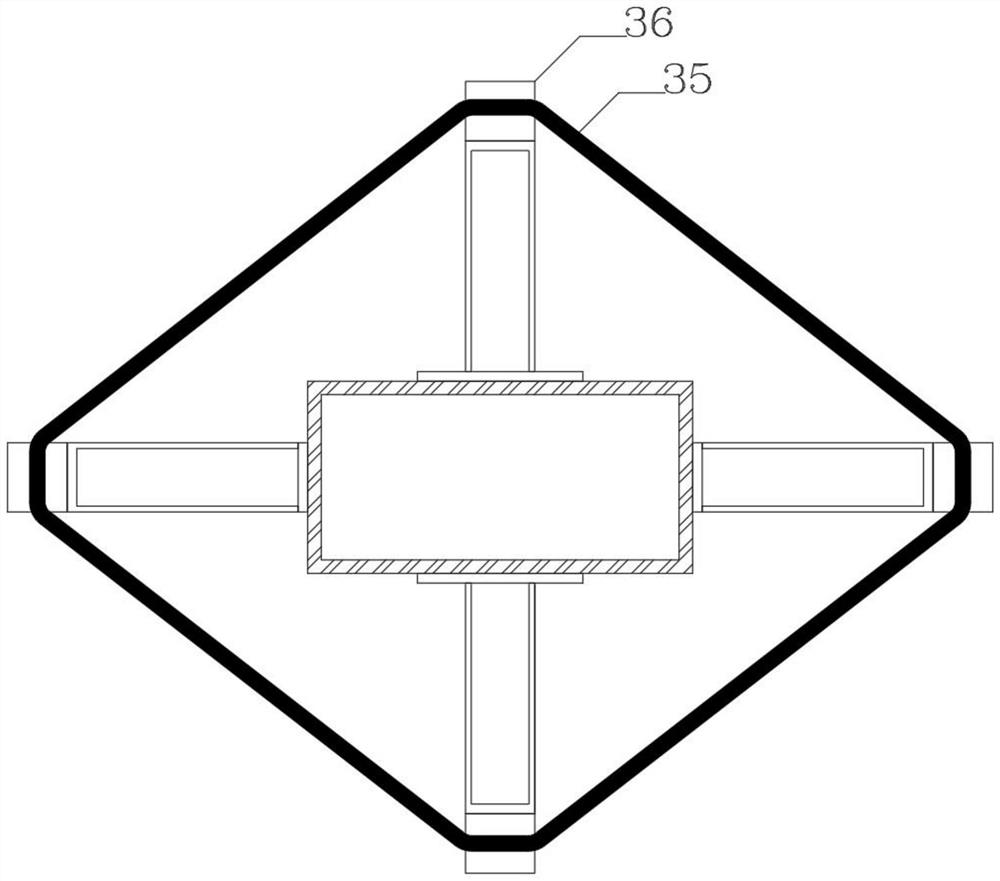

Steel lead lamination node damper

InactiveCN103790253AIncrease stiffnessImprove energy consumptionShock proofingStress concentrationSnubber

Owner:SHENYANG JIANZHU UNIVERSITY

Storey-adding structure and method of steel structure building

Owner:CHINA NAT CHEM ENG THIRD CONSTR

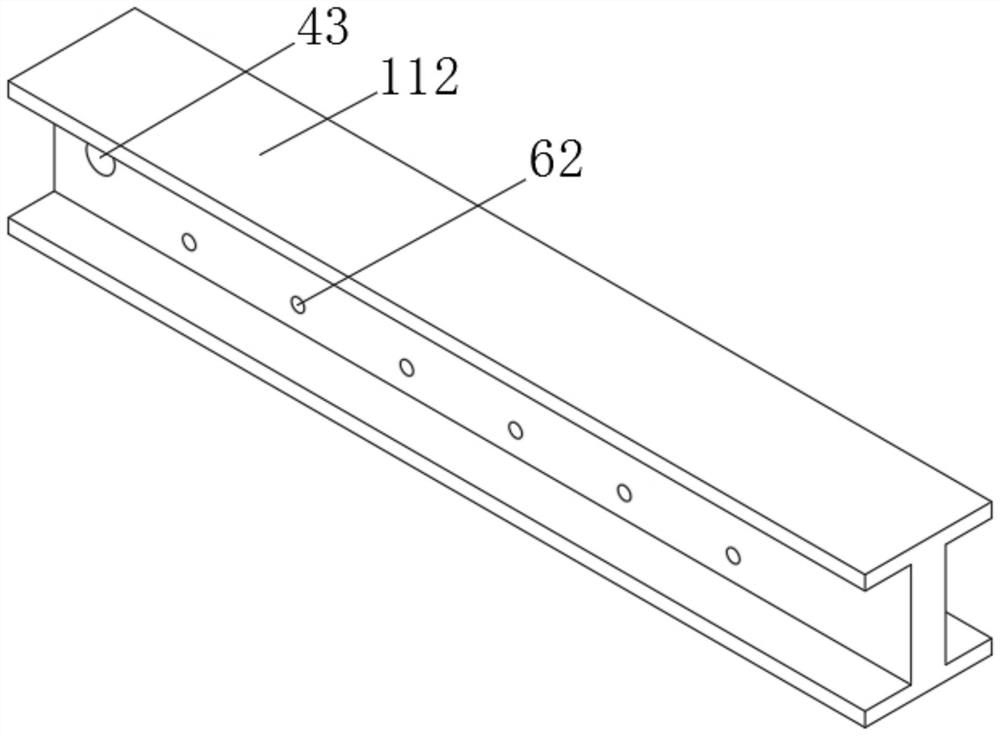

Displacement adjusting device for H-shaped steel support and construction method thereof

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

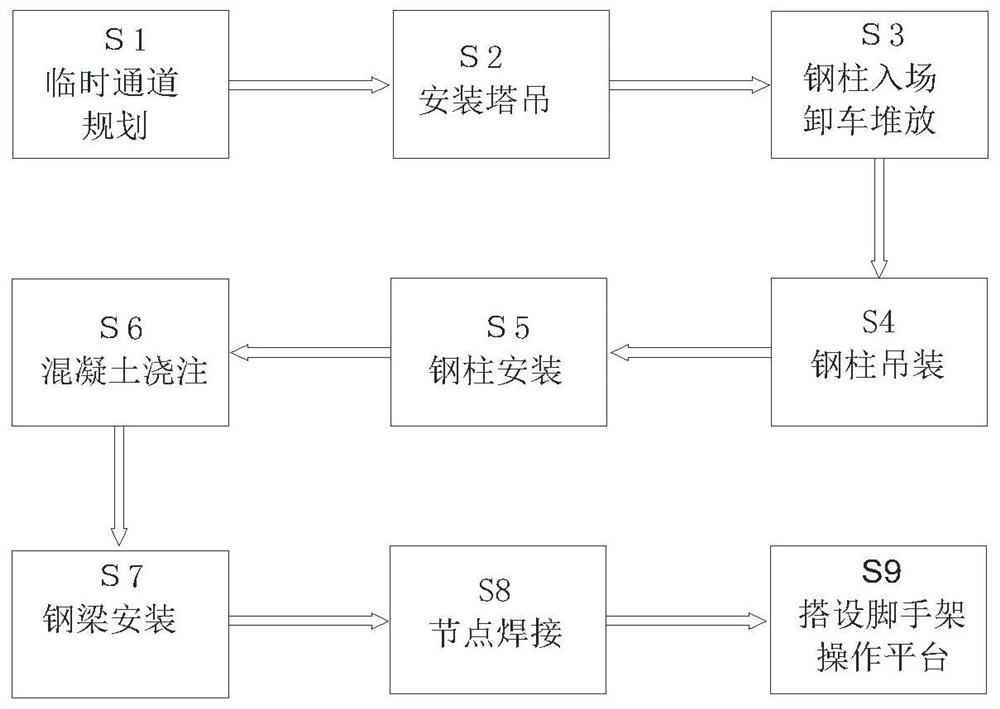

Sliding assembly type building steel structure mounting construction method

InactiveCN112144889ALift the installation firmnessEasy to transportBuilding material handlingShoresArchitectural engineeringSteel columns

Owner:陈淳

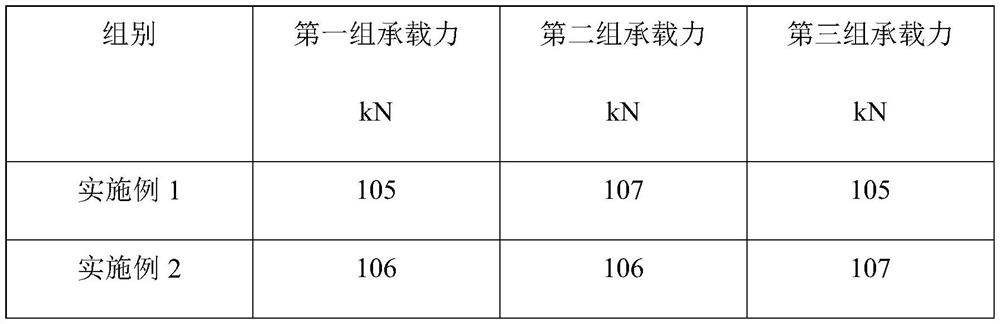

Method for strengthening cold-formed thin-walled steel column based on geopolymer foam concrete

PendingCN113896462AExcellent sound insulation and noise reductionEliminate hollow soundStrutsCement productionFoam concreteFiber

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Frame beam steel bar connecting system of profile steel column and concrete and pouring construction method

InactiveCN113062448AAccurate and quick installationReduce labor intensityBuilding reinforcementsBuilding material handlingReinforced concreteClassical mechanics

Owner:潮峰钢构集团有限公司

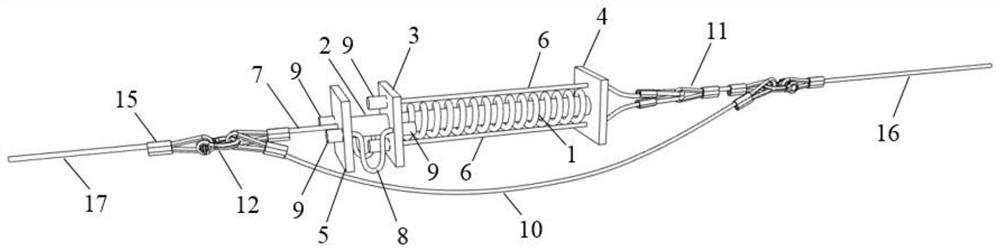

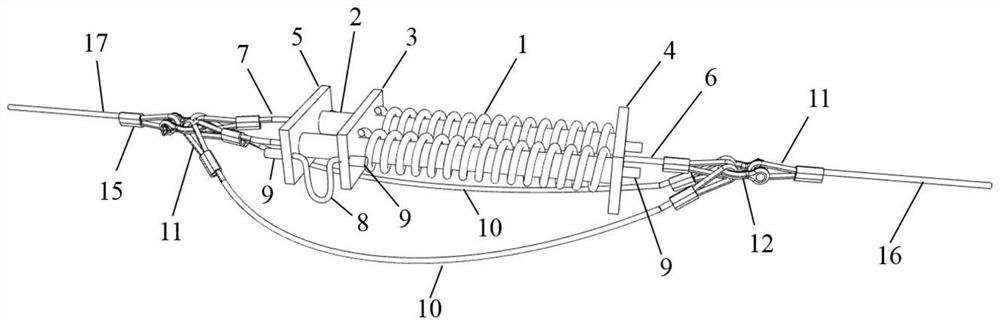

Toughness composite buffer for slope flexible protection system and design method of toughness composite buffer

Owner:SOUTHWEST JIAOTONG UNIV

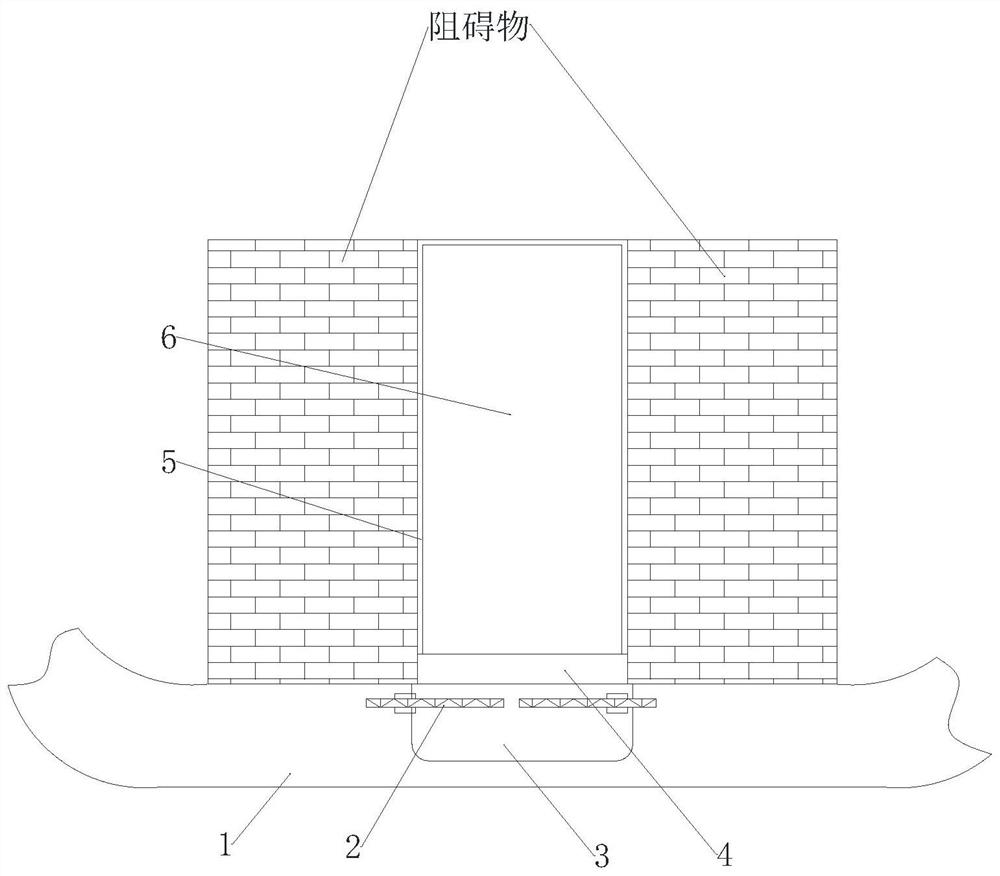

Moving system of large-diameter thickener

InactiveCN112933670AFast transferRealize recycling nearbySedimentation separationSteel columnsControl theory

The invention provides a moving system of a large-diameter thickener. The moving system comprises a first truck channel, a second truck channel, a third truck channel and a fourth truck channel which are arranged below a pool body of the thickener with an overhead steel structure. The first truck channel and the second truck channel are located on a same straight line and are symmetrical about the center below the pool body, and the third truck channel and the fourth truck channel are symmetrically arranged on the two sides of the center line of the first truck channel and the second truck channel. Each truck channel comprises paired steel columns arranged at equal intervals, a supporting cross beam is connected between each pair of steel columns, the heights of the supporting cross beams are the same, a truck is arranged in each truck channel, and a truck plate of the truck is connected with the supporting cross beam on the upper portion of the truck plate. The truck channels are connected above the truck plates of the heavy trucks, and the thickener is moved through the movement of the trucks.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Assembly type concrete component mounting method

InactiveCN111456453ASimplify the production and construction processEasy to installWallsFloorsReinforced concreteShaped beam

Owner:豫通工程管理有限公司

Potassium nitrate reaction kettle

InactiveCN108057411AWon't leakMultiple contact areasChemical/physical/physico-chemical stationary reactorsFeed devicesPotassium nitrateCoupling

The invention discloses a potassium nitrate reaction kettle, comprising a cabinet body, a servo motor, a heat insulating layer, a cylinder, a cylinder frame, thin electric heating wires, thick electric heating wires, a drive motor, a sleeve, a first steel column, main stirring blades, a feed pipe, a discharge pipe, a torsion spring, a steel wire, a steel wire ring, a handle, a control panel, a clamp plate, a second steel column and auxiliary stirring blades, wherein the cabinet body is internally provided with the cylinder frame, and the cylinder is fixed in the cylinder frame; the servo motoris fixed at the bottom of the cabinet body; one end of an output shaft of the servo motor is fixedly connected with the second steel column by means of a coupling, and the second steel column passesthrough the bottom of the cylinder; the auxiliary stirring blades are fixed at the outer side of the second steel column. According to the reaction kettle, two stirring rods are driven to mutually rotate by means of rotation of the output shafts of the servo motor and the drive motor, so that the contact area between the stirring rods and potassium nitrate is increased, and a better heating effectis achieved.

Owner:JIANGXI JINLIDA POTASSIUM IND LTD LIABILITY CO

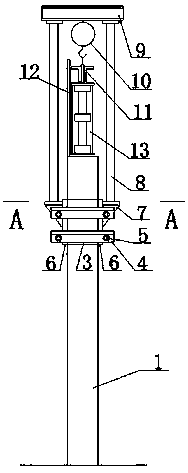

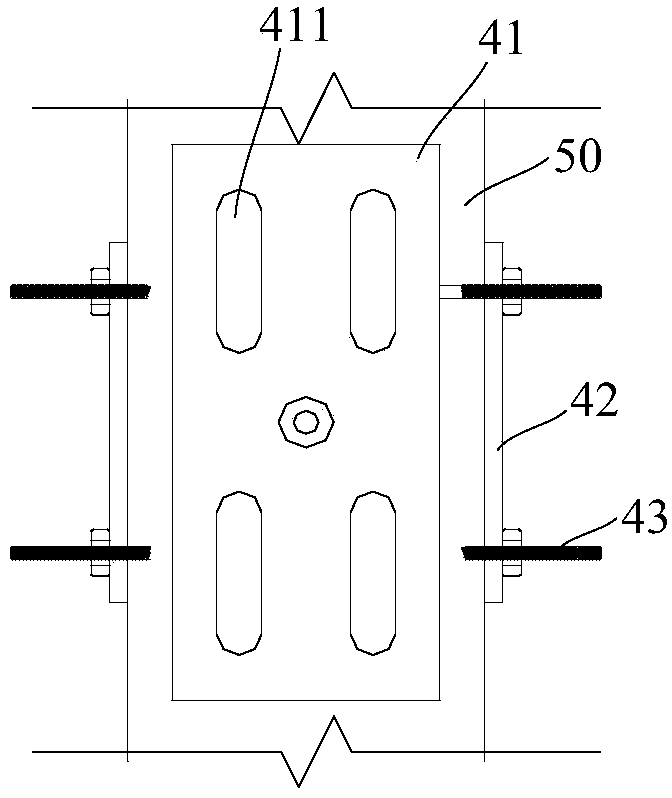

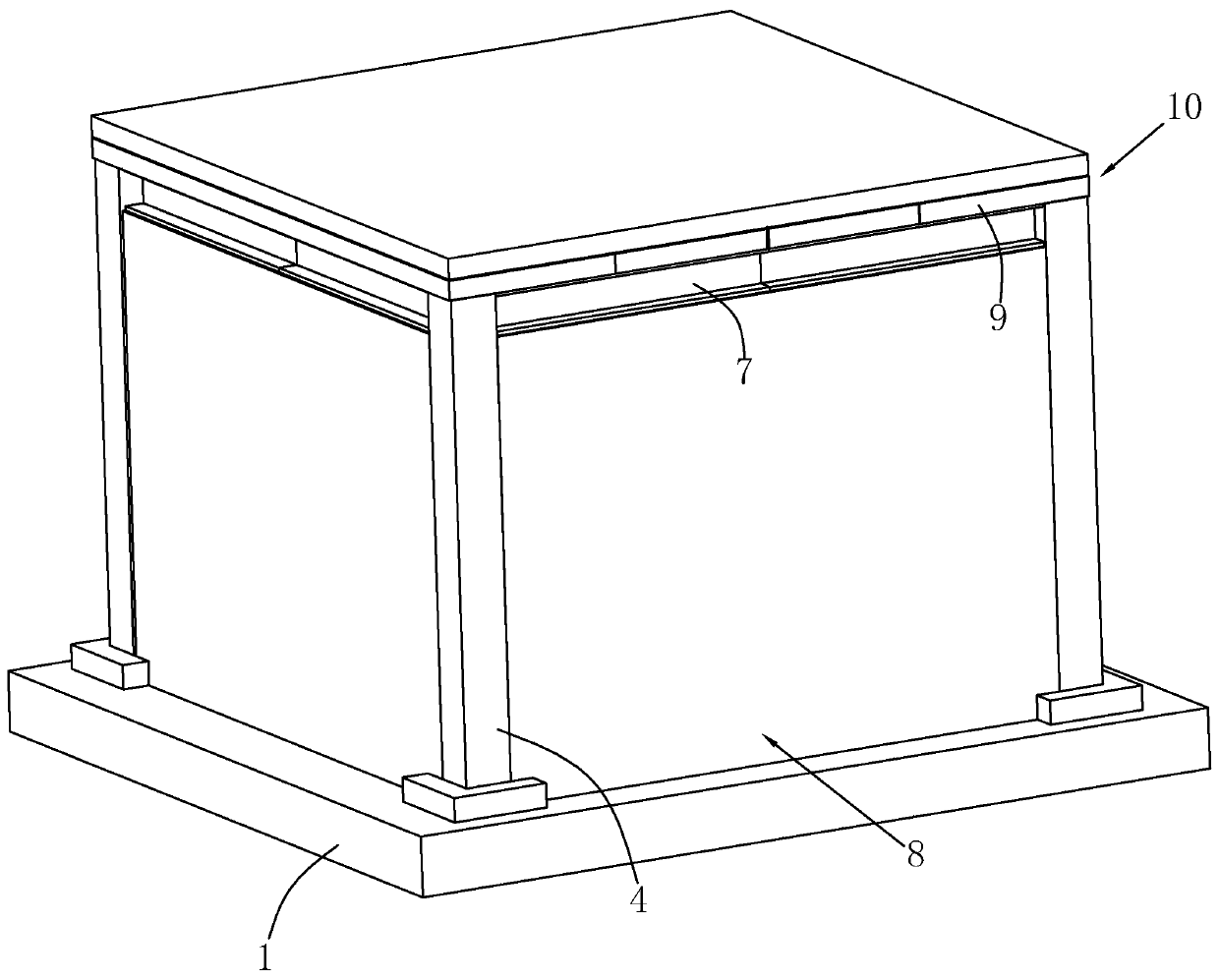

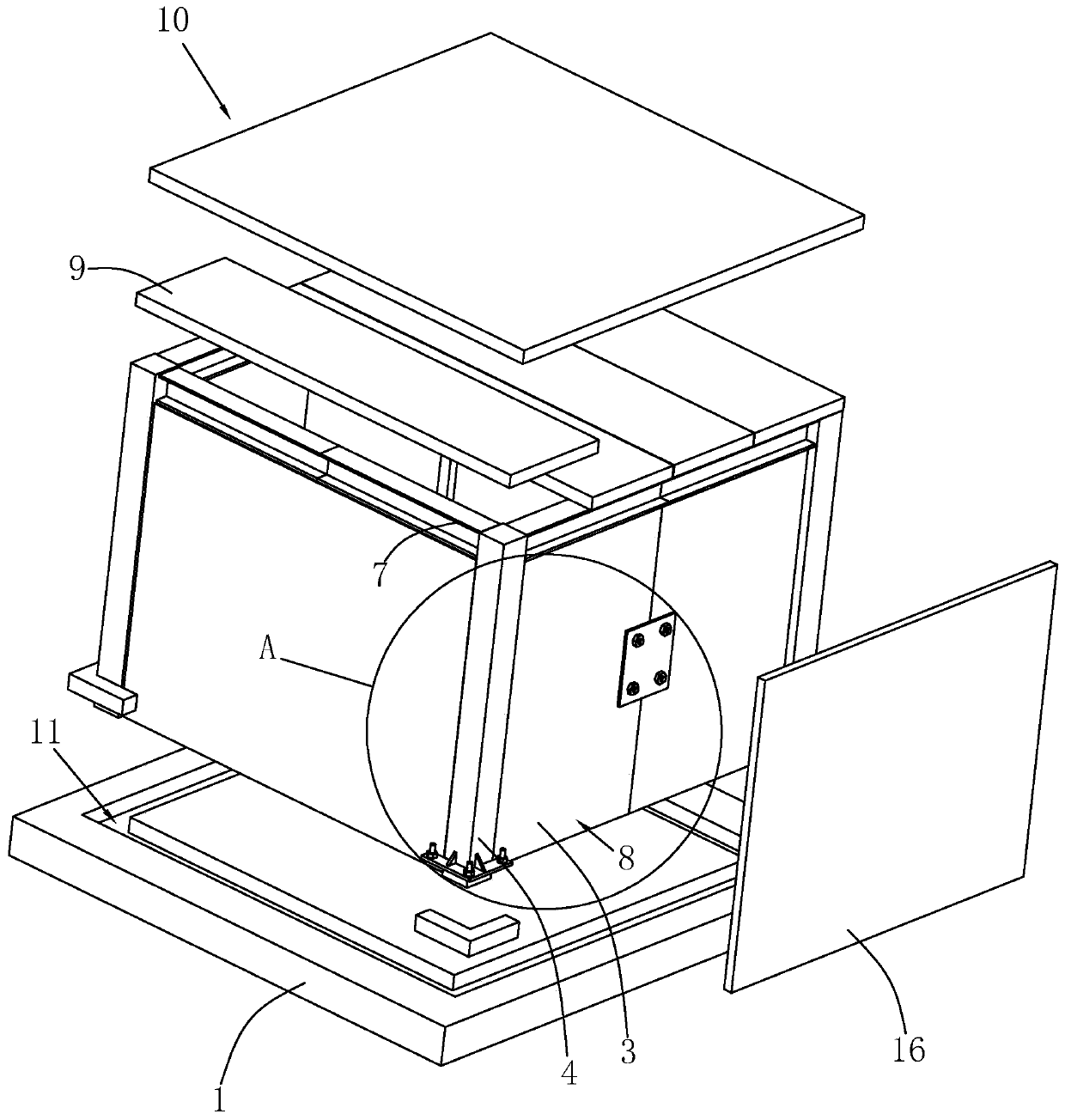

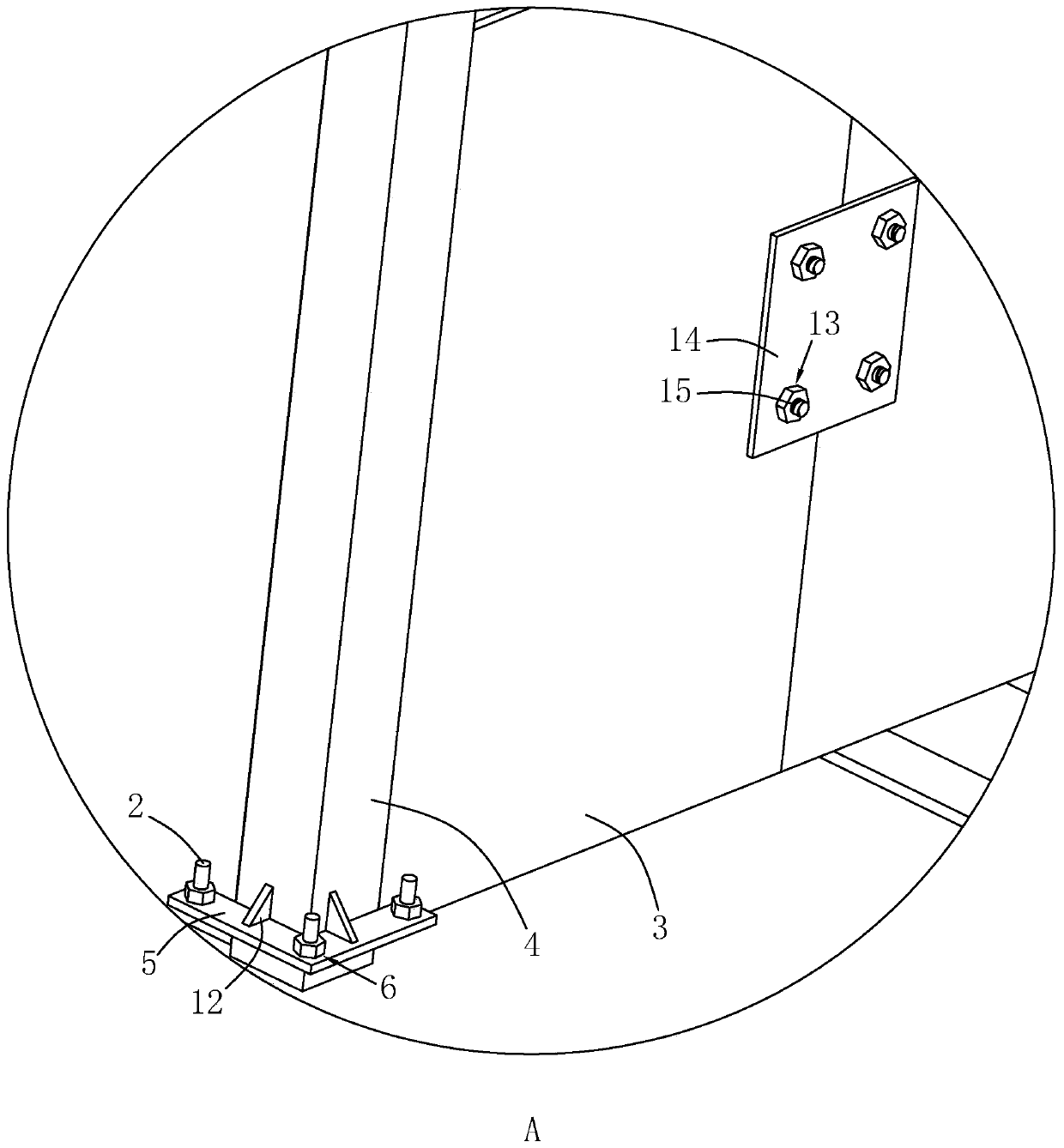

Steel column construction site splicing installation positioner

PendingCN114753511AEasy to processSave materialBuilding constructionsArchitectural engineeringStructural engineering

Owner:上海泰大建筑科技有限公司

Pouring base plate

ActiveCN106903297AMolten metal pouring equipmentsHorizontal projectionSteel columns

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Connecting structure between steel column and high-rise truss beam

Owner:SHANGHAI GREENLAND CONSTR GRP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap