Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14 results about "Coating materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial coatings provide a covering that can be applied to the surface of an object, usually referred to as the substrate. They are specifically engineered for their protective and functional properties. The focus of an industrial coating is wear protection and refurbishment.Typical coating materials are:Pure metals, such as Aluminum (Al), Copper (Cu), Molybdenum (Mo), etc.Alloys, such as Nickel Chrome (NiCr), Nickel Aluminum (NiAl), Aluminum Bronze (CuAl), etc.Ceramic (Oxide), such as Aluminum Oxide (Al2O3), Chrome Oxide (Cr2O3), Zirconium Oxide (ZrO2), Titanium Oxide (TiO2), etc.Cermets, such as Wolfram Carbide Cobalt (WCCo), Chrome Carbide Nickel Chrome (Cr3C2/NiCr), various metal-ceramic compounds.

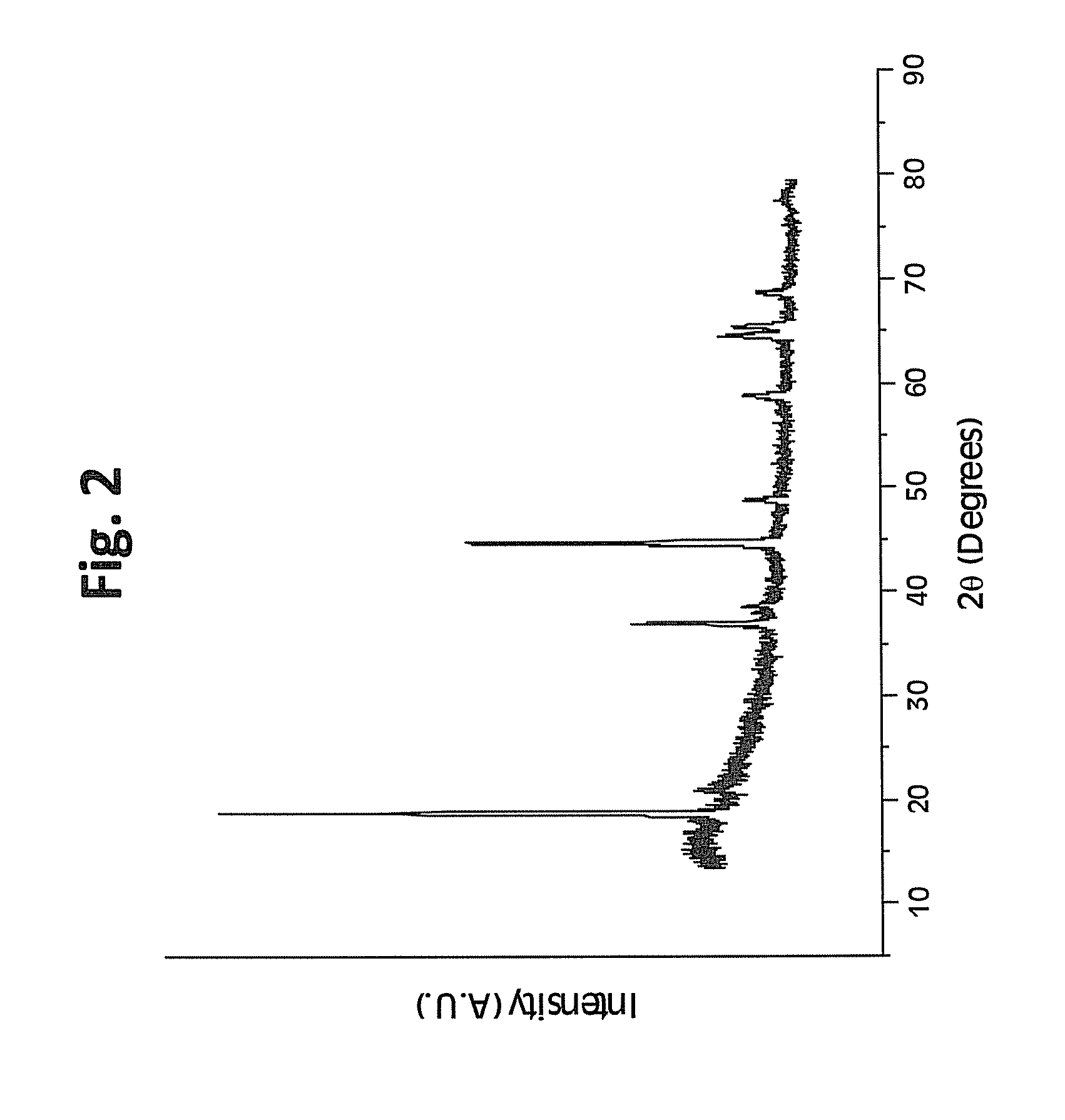

Positive electrode materials for lithium ion batteries having a high specific discharge capacity and processes for the synthesis of these materials

ActiveUS20100086853A1Electrode manufacturing processesAlkali metal oxidesDischarge rateLithium-ion battery

Owner:IONBLOX INC

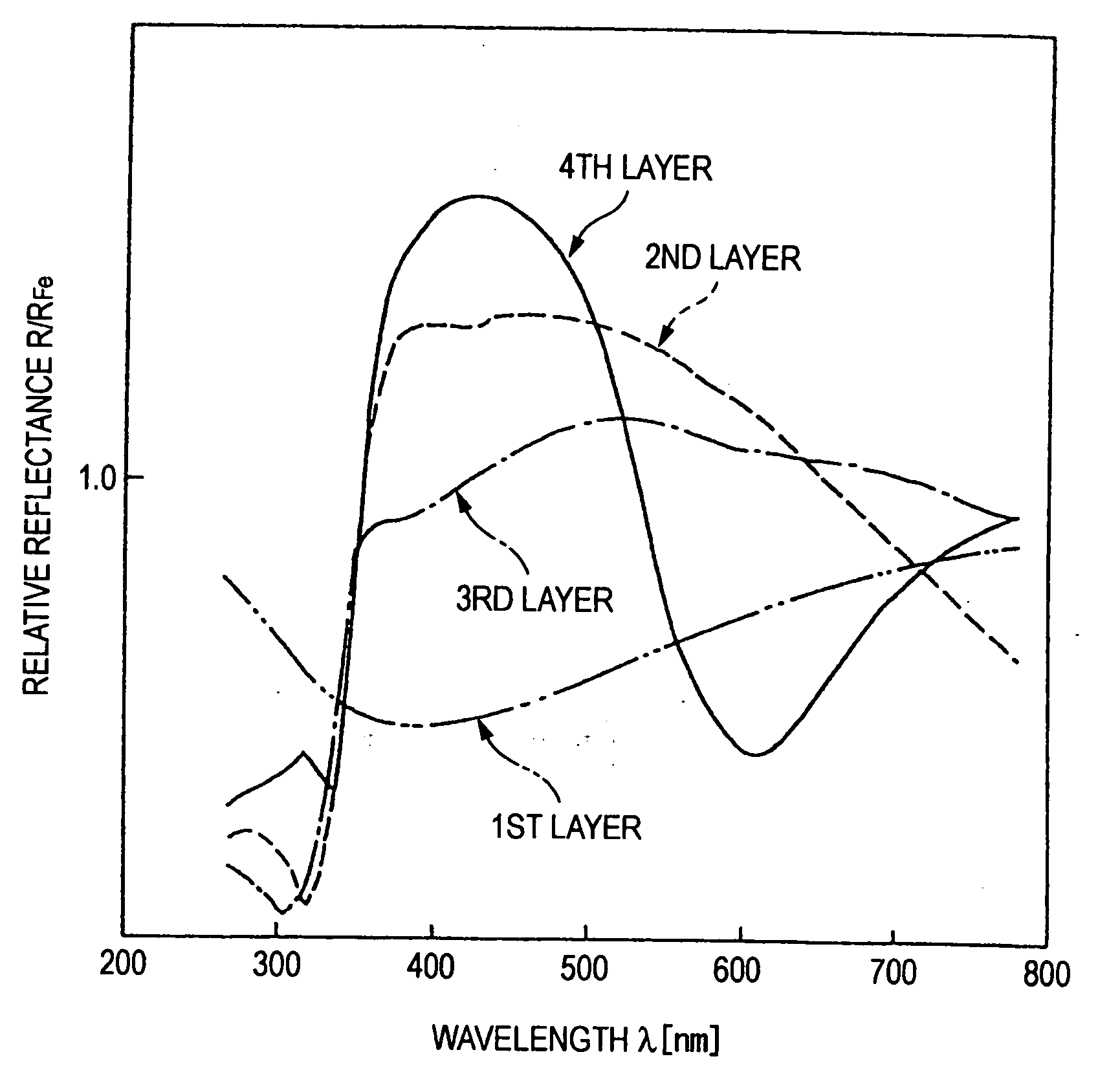

Coated powder, coating composition, and coated article

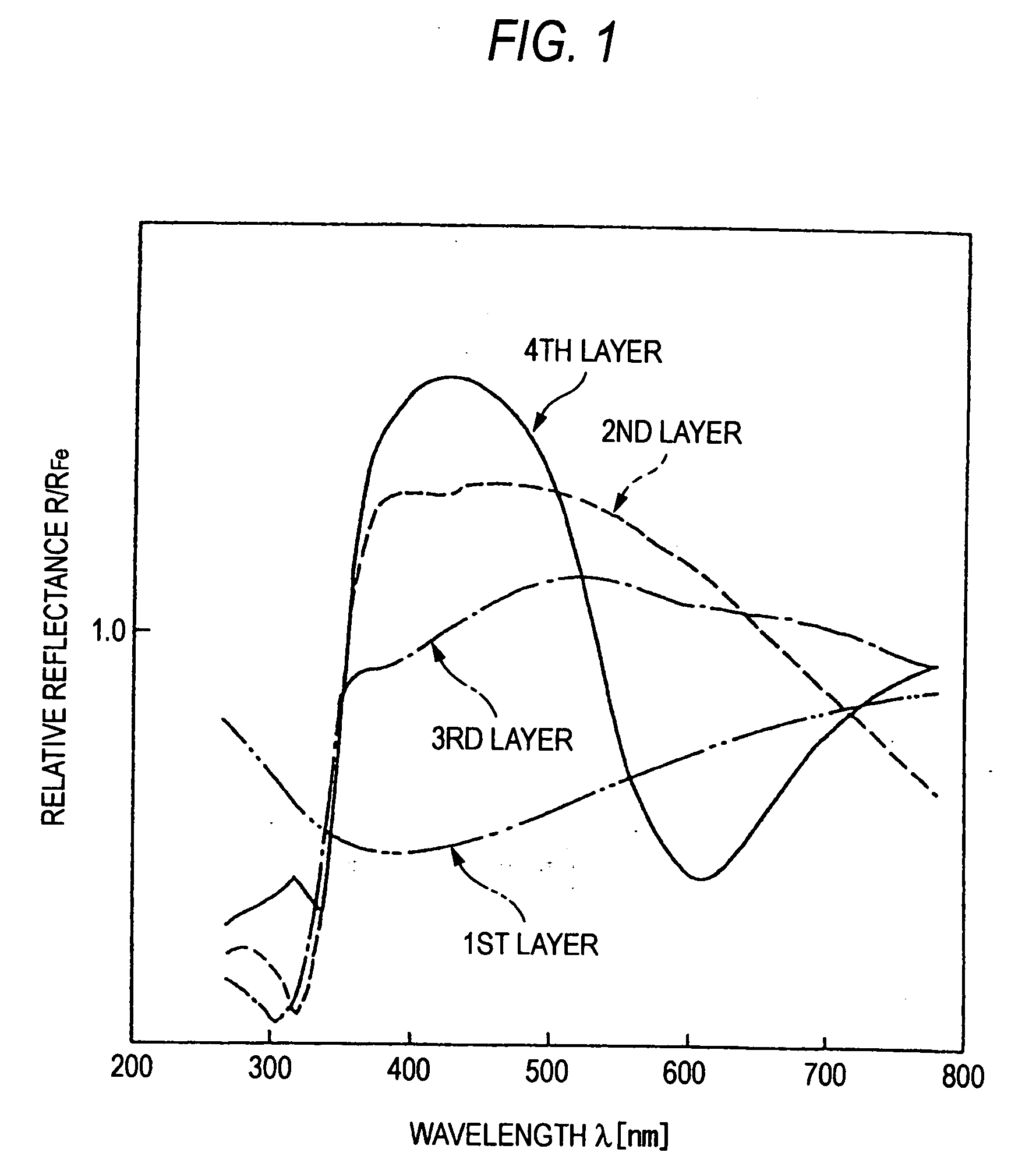

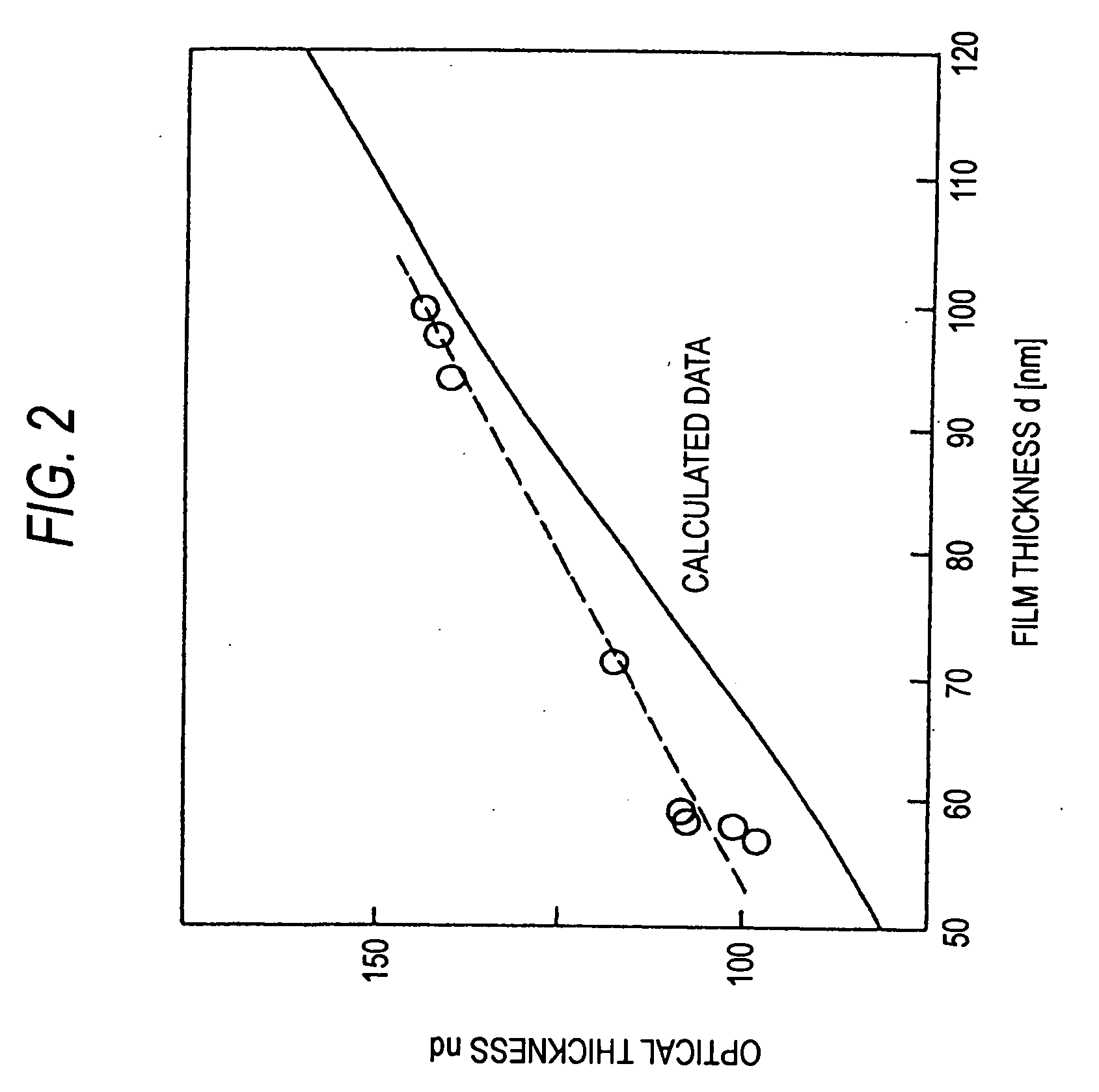

InactiveUS20050208303A1Accurate particle sizeInorganic pigment treatmentSynthetic resin layered productsMetallurgyLength wave

Owner:NITTETABU MINING CORP +1

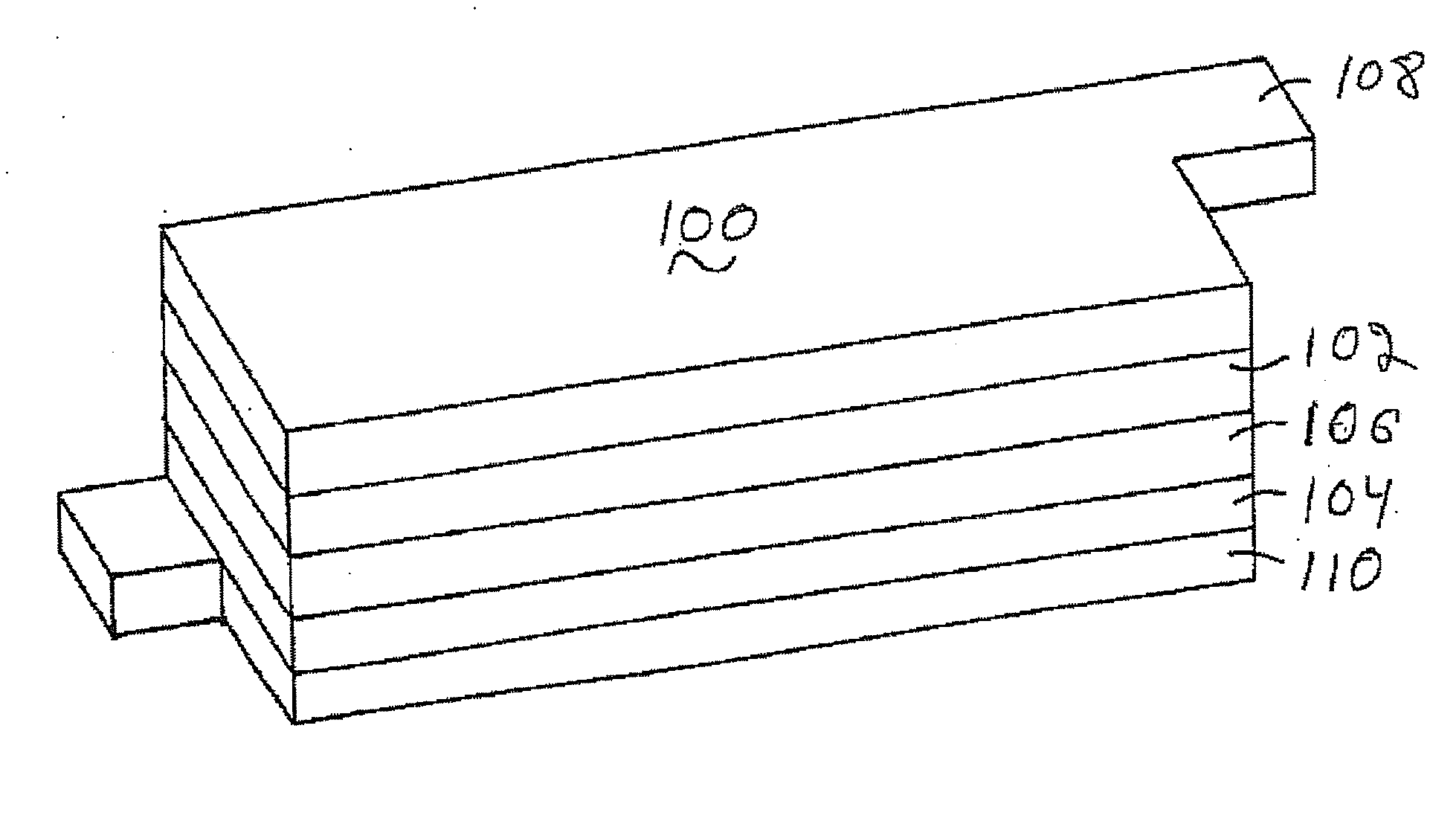

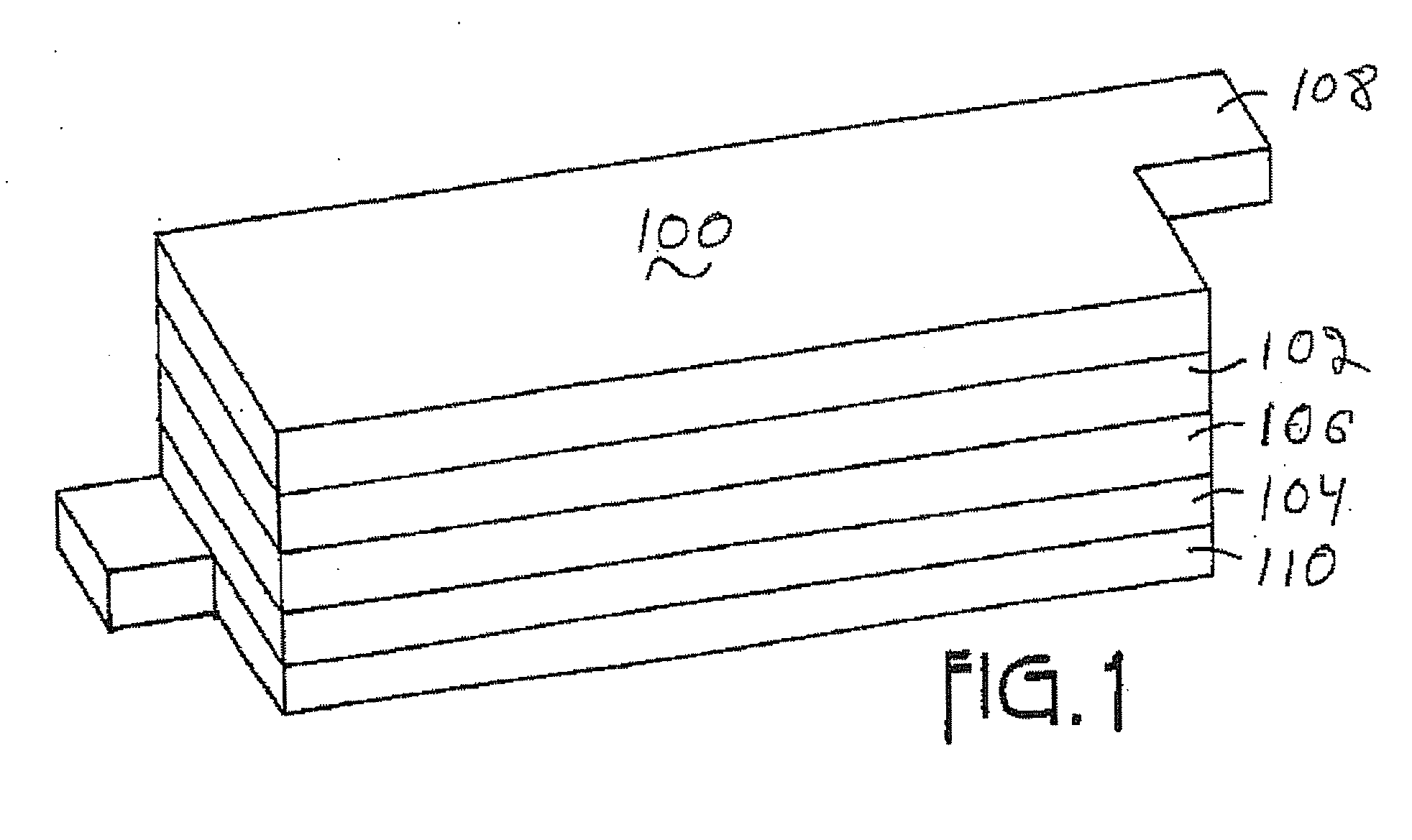

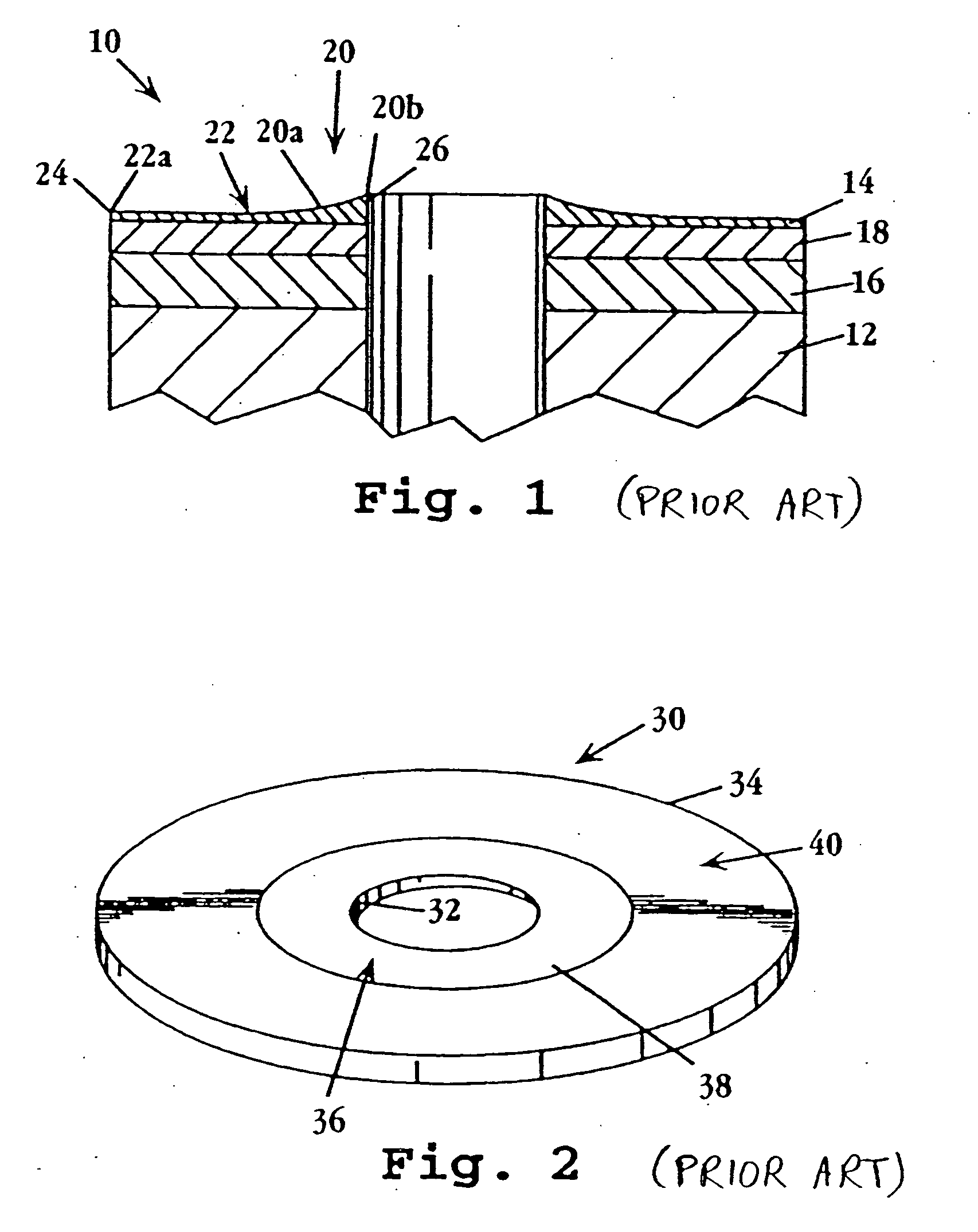

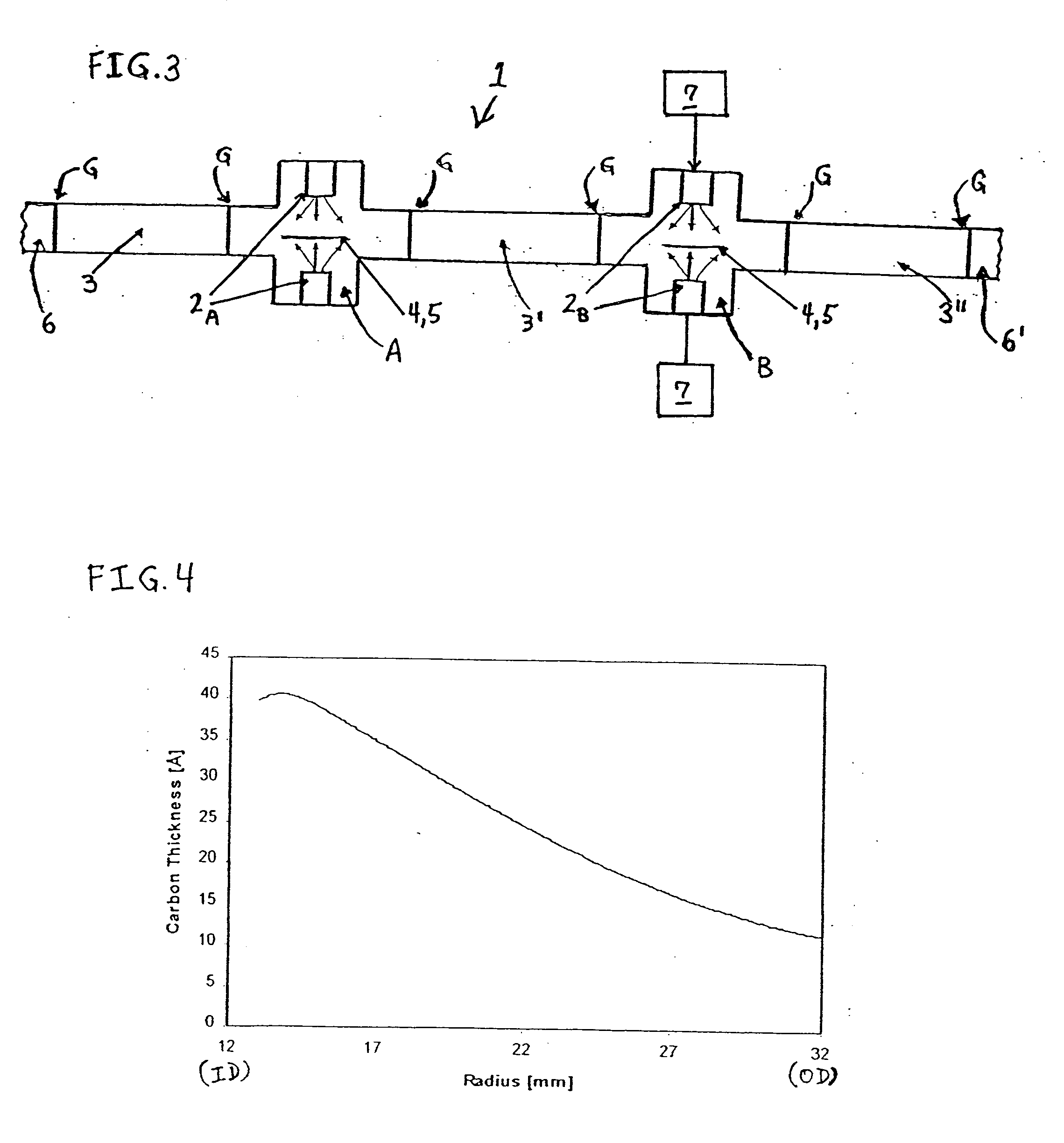

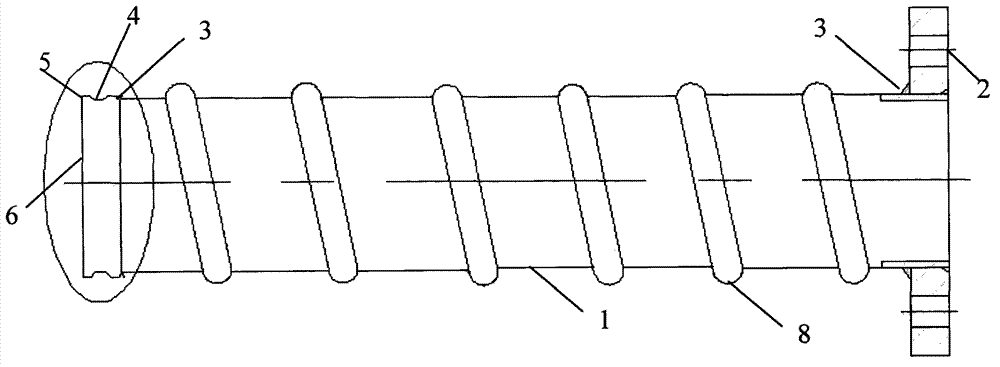

Thickness gradient protective overcoat layers by filtered cathodic arc deposition

InactiveUS20050249983A1Simple methodApparatus is enlargedCellsProtective coatings for layersCathodic arc depositionMaterials science

Owner:SEAGATE TECH LLC

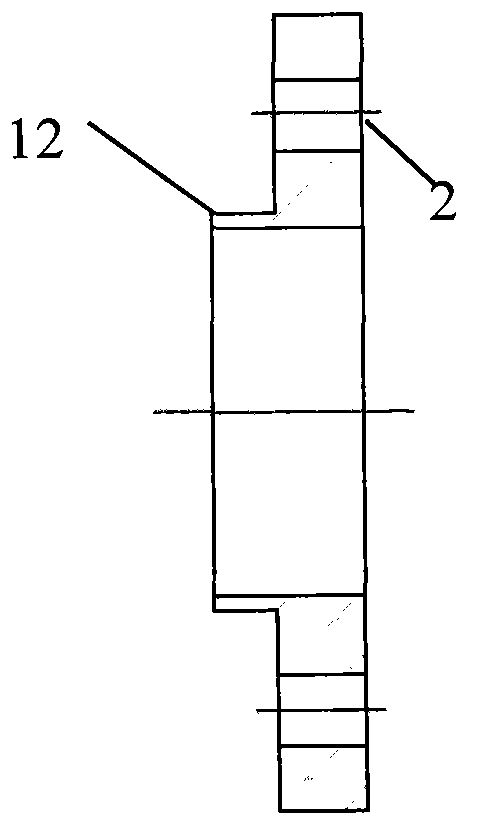

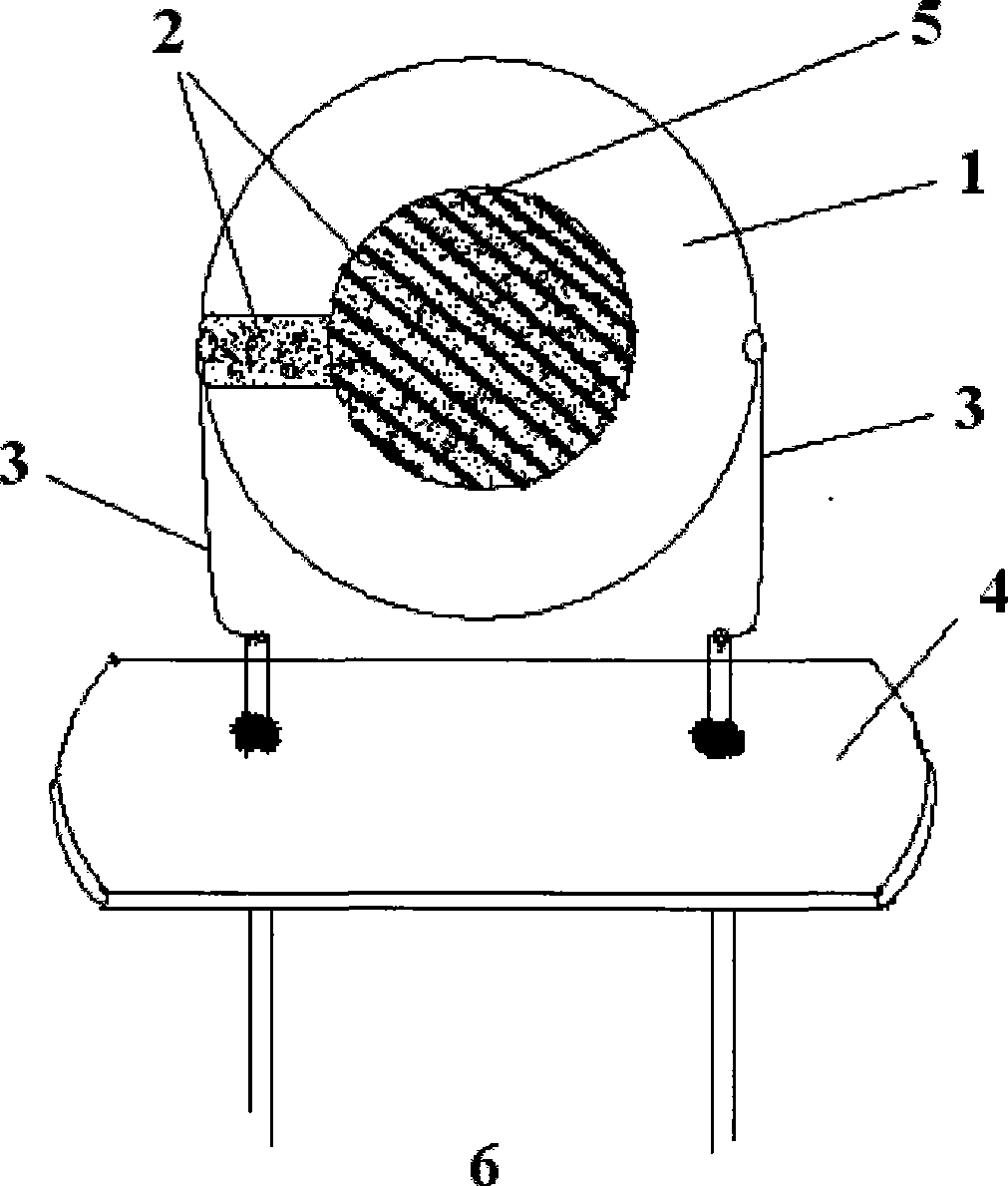

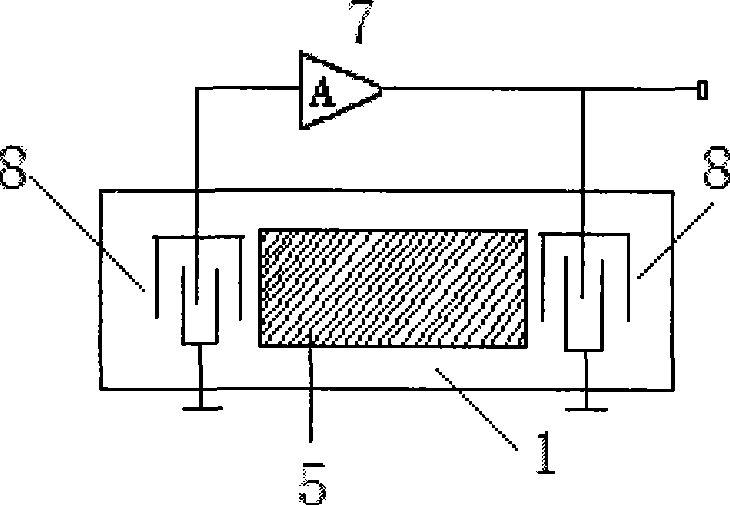

Mineral methane gas drainage pipe and production method thereof

ActiveCN103195988AReduce weightImprove corrosion resistanceCorrosion preventionPipe protection against corrosion/incrustationHigh pressureMethane gas

Owner:河北拓安管业有限公司

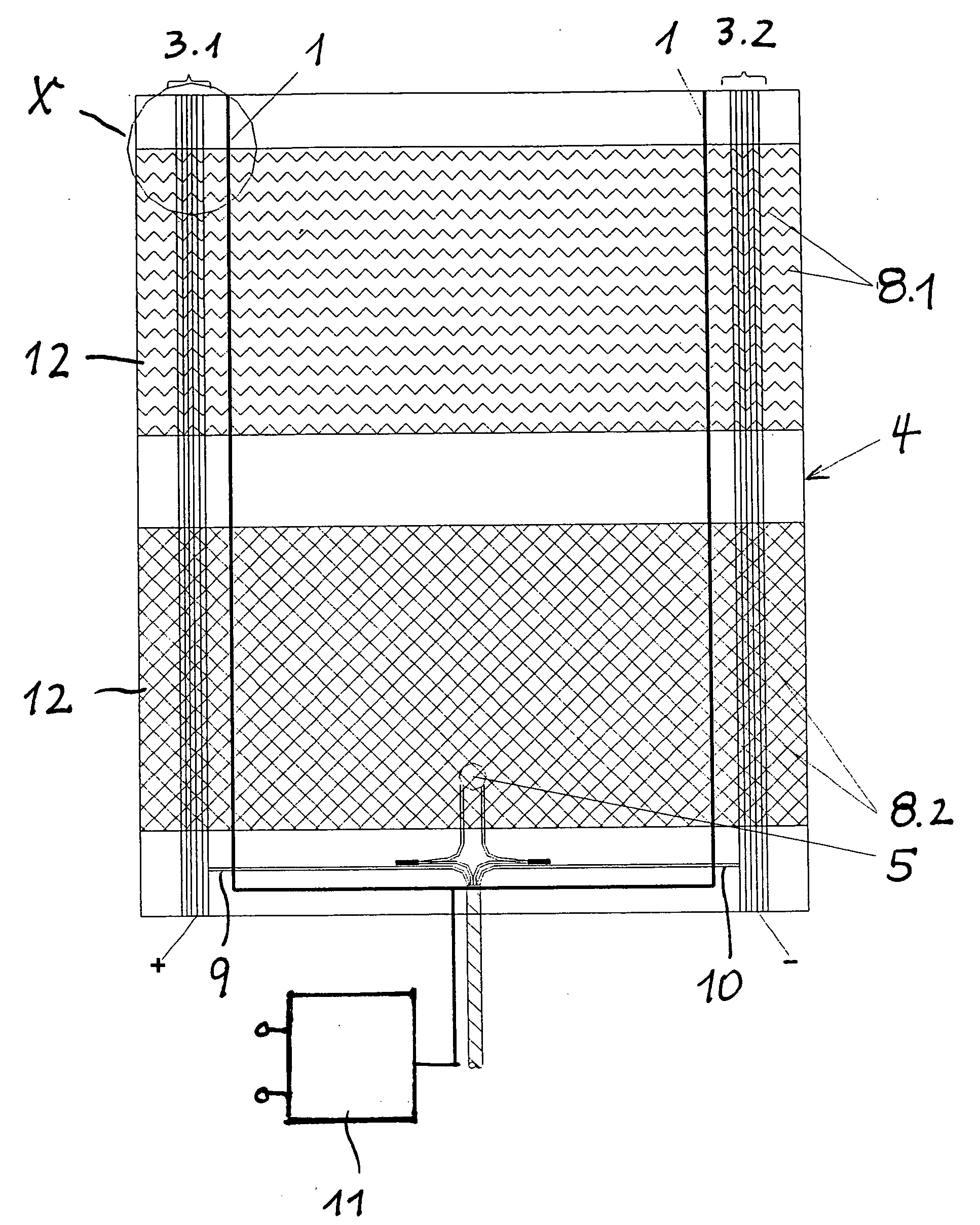

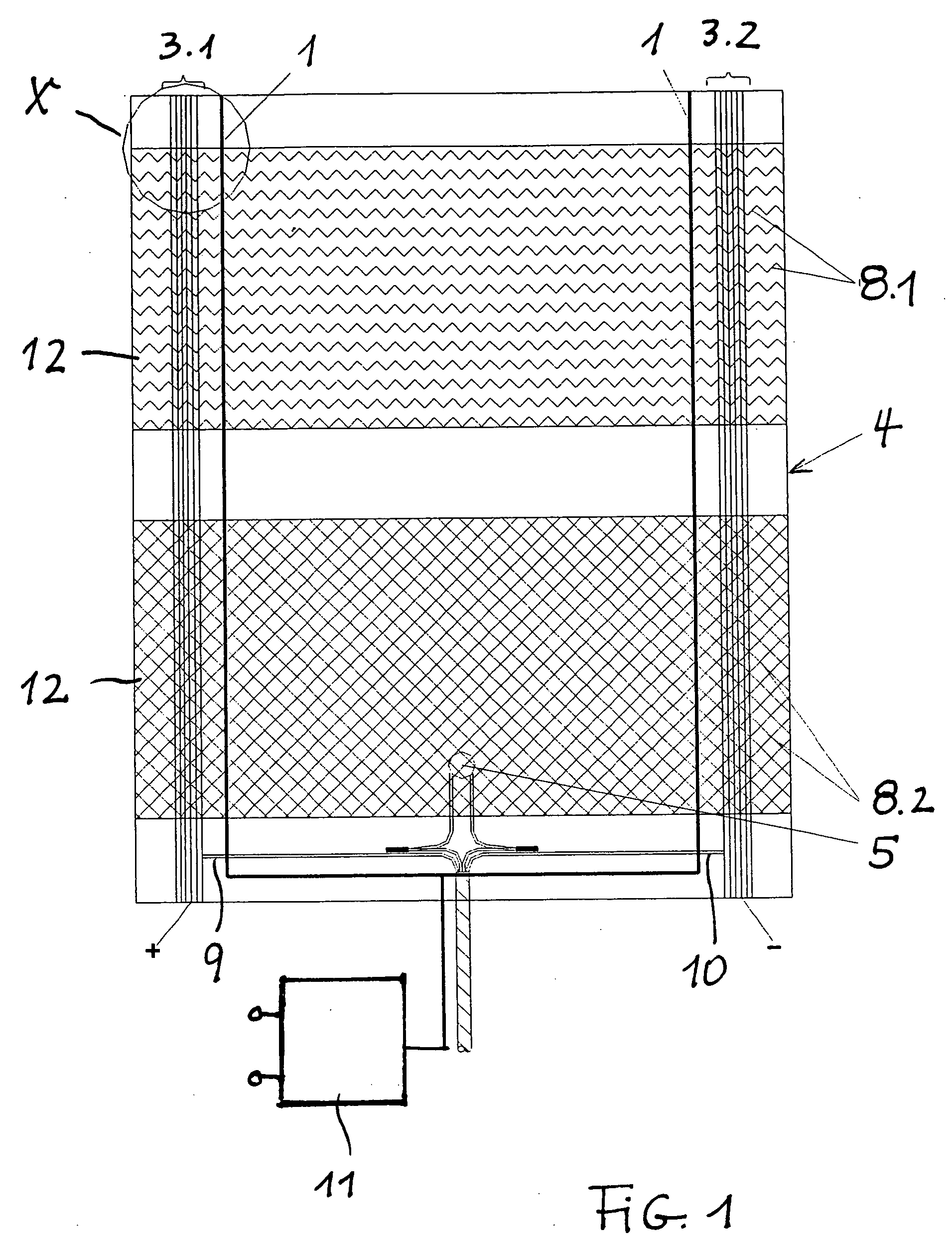

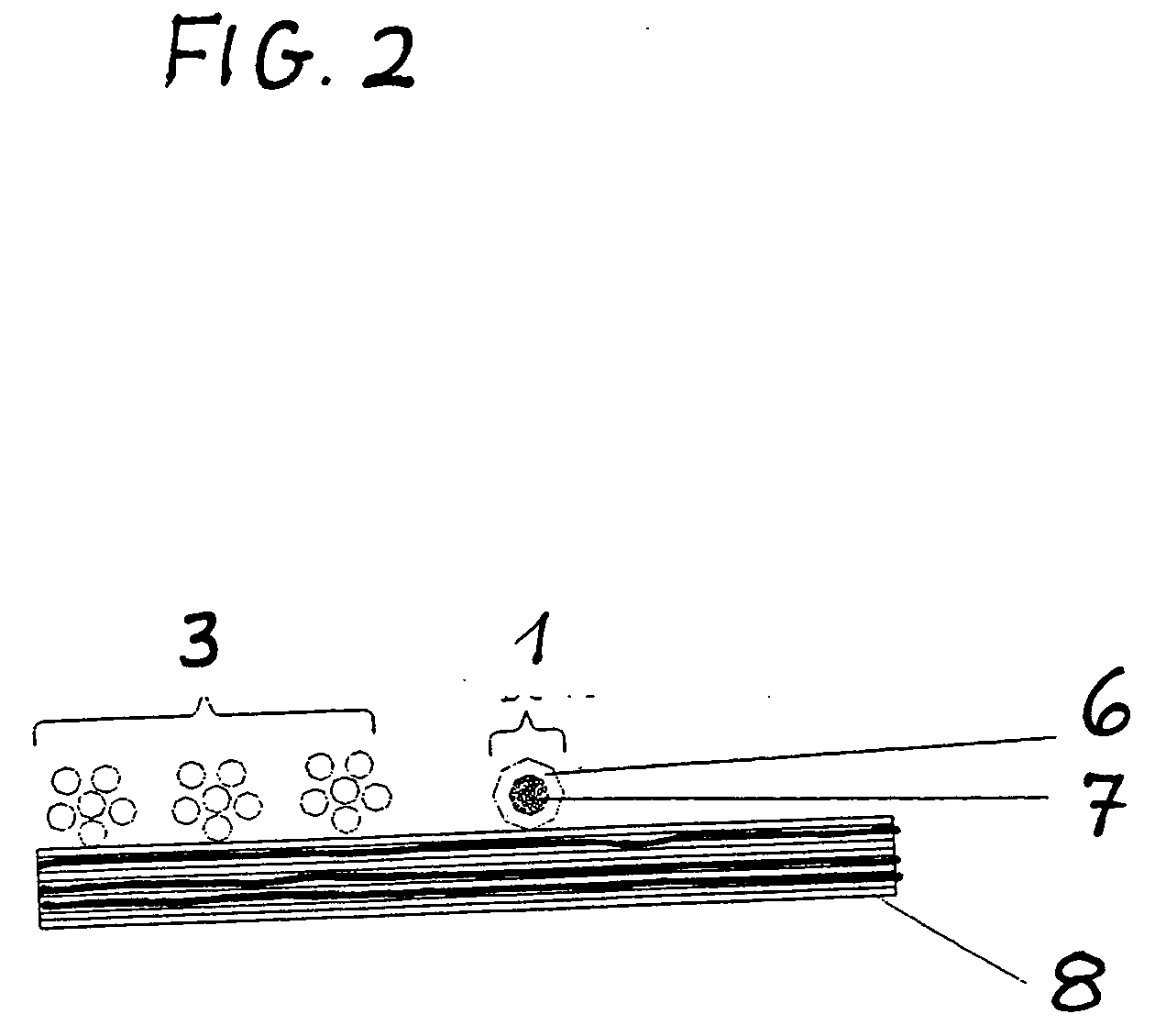

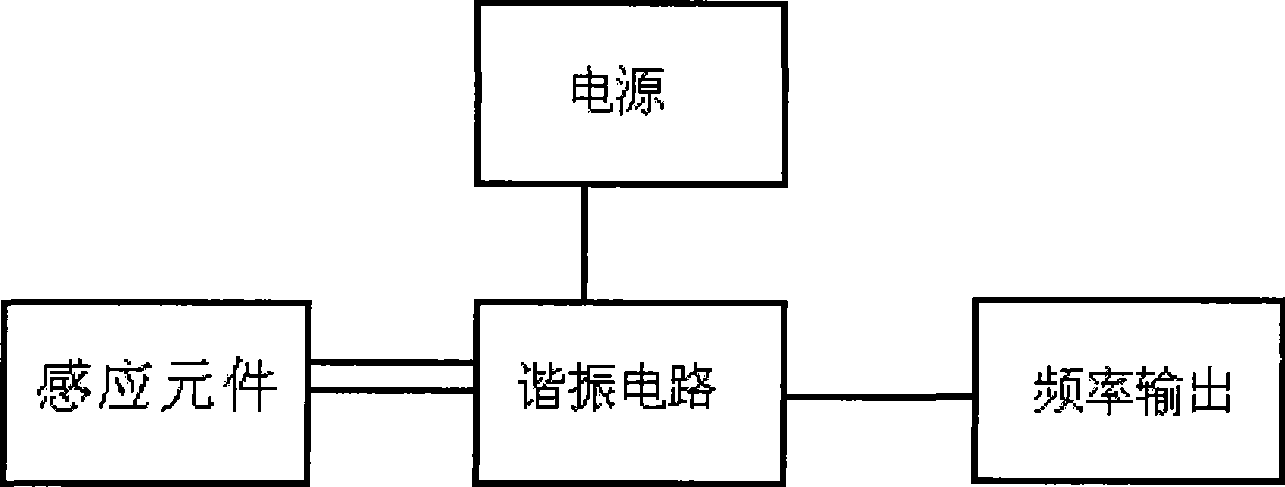

Monitoring device for flexible heating elements

Owner:I G BAUERHIN GMBH

Characterization method for ionic liquid dissolvability

InactiveCN101470063AImprove solubilityReliable dataWeighing by absorbing componentSolubilityDissolution

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Environment-friendly ceramic coating material for water faucet

InactiveCN106189561ACorrosion resistantWear-resistantAnti-corrosive paintsCarbon fibersPolybutylene terephthalate

Owner:朱燕华

Anticorrosive coating material for reinforced concrete, preparation method and applications thereof

ActiveCN108300166AAvoid corrosionReduce film thicknessAnti-corrosive paintsEpoxy resin coatingsRebarPhenol

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

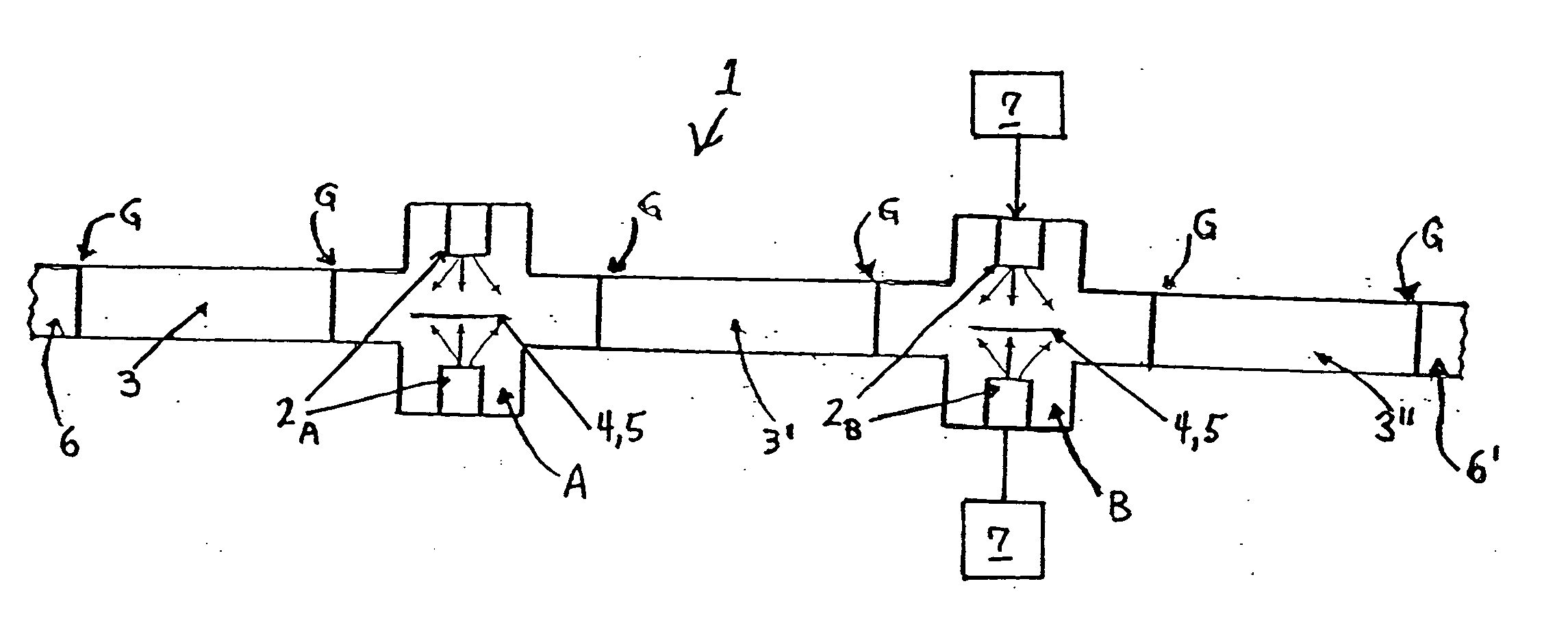

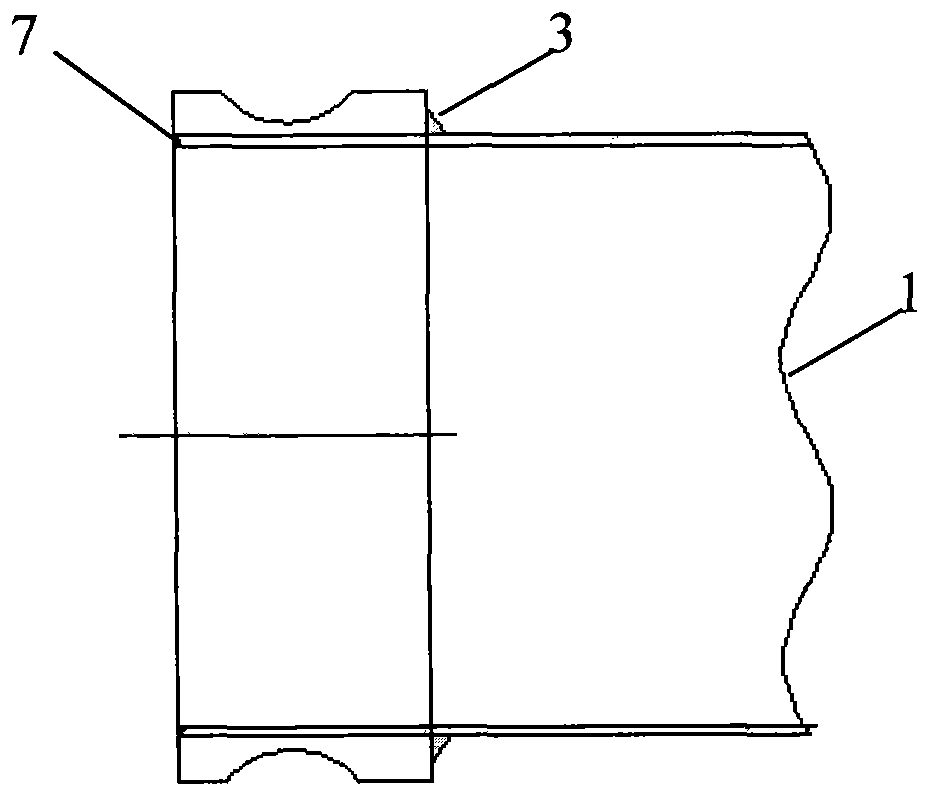

Hot dip coating device and method

ActiveCN110809633AReduced risk of damaging sheet metalHot-dipping/immersion processesMetal coatingMetal sheet

The invention relates to a hot dip coating device to provide a metal coating on a moving metal sheet, containing a liquid bath of metal coating material in use, wherein the metal coating material is to be provided on the moving metal sheet in use, comprising a container for the liquid bath, at least a guide or sink roll that is provided in the container below surface level of the liquid bath in use to guide the moving metal sheet through the bath, and a gas knife that is provided above the liquid bath in use, said gas knife having an outlet to project wiping gas on the metal coating provided on the metal sheet that in use passes along the gas knife, and wherein at least one supporting roll is provided which together with the guide or sink roll in use influence a shape of the metal sheet inits width direction at least at the location of the gas knife. According to the invention, in use the at least one supporting roll is placed above surface level of the liquid bath on a position enabling it to operate on the metal sheet before the metal sheet enters the liquid bath. The invention also relates to a method for use of the hot dip coating device.

Owner:TATA STEEL NEDERLAND TECH BV

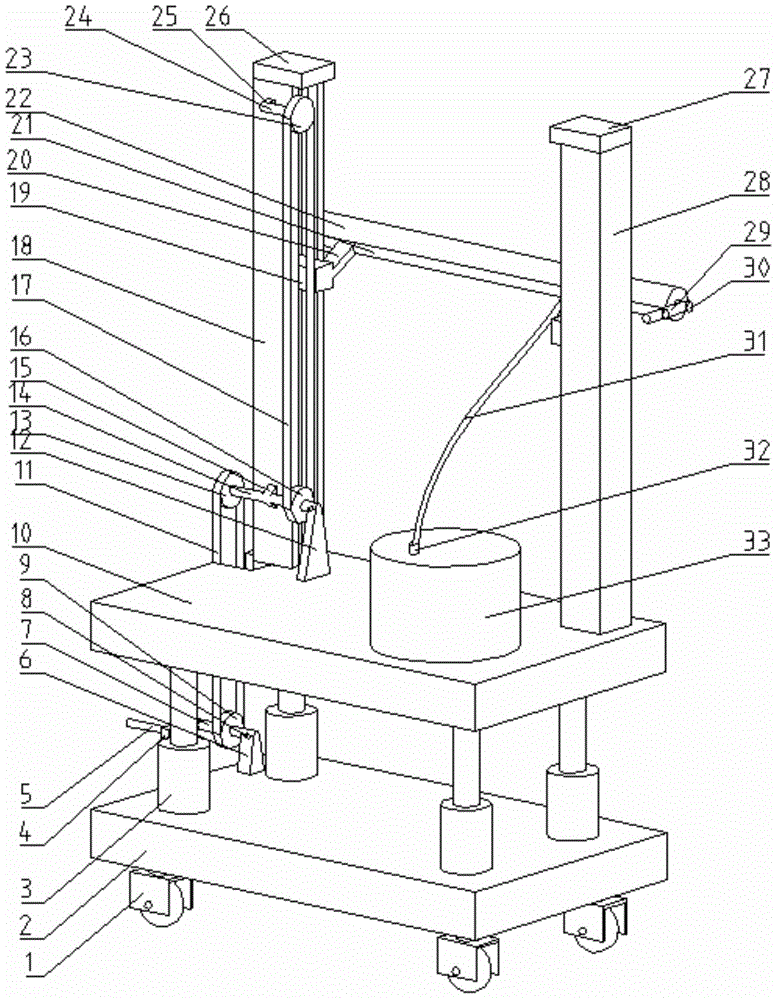

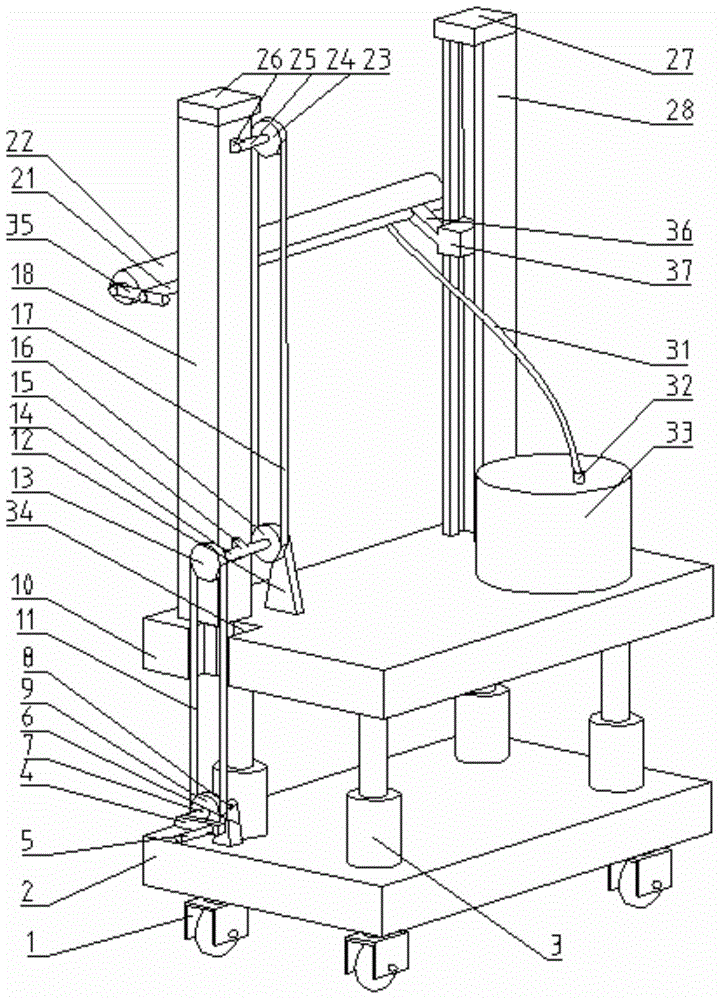

Hydraulic lifting wall brushing machine manually controlled by sprockets and chains

Owner:GUANGXI UNIV

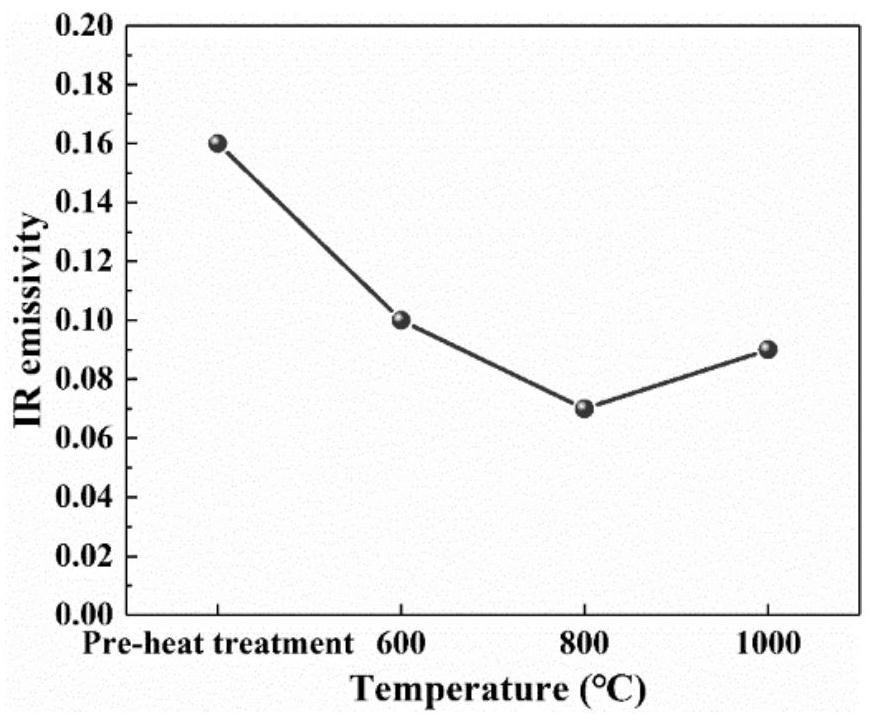

High-temperature-resistant, water-oxygen-resistant and low-infrared-emissivity composite film for ceramic-based composite material and preparation method

ActiveCN113403594AReduce IR emissivityEasy to useVacuum evaporation coatingSputtering coatingComposite filmLow emissivity

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Inorganic-organic coating composite material for nodular cast iron pipe and preparation method of inorganic-organic coating composite material

ActiveCN114231171AImprove high temperature resistanceImprove corrosion resistanceFireproof paintsAnti-corrosive paintsCoated surfaceMontmorillonite

Owner:SHANDONG GUOMING DUCTILE IRON PIPES TECH CO LTD

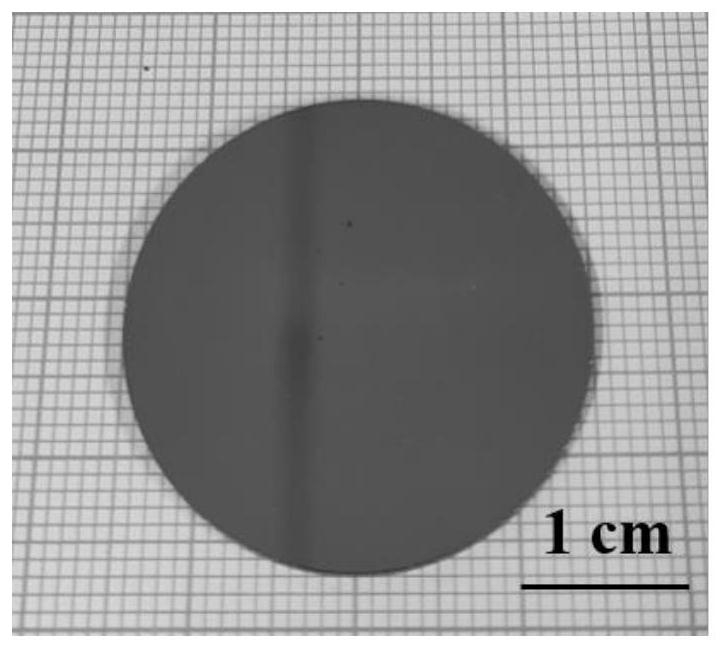

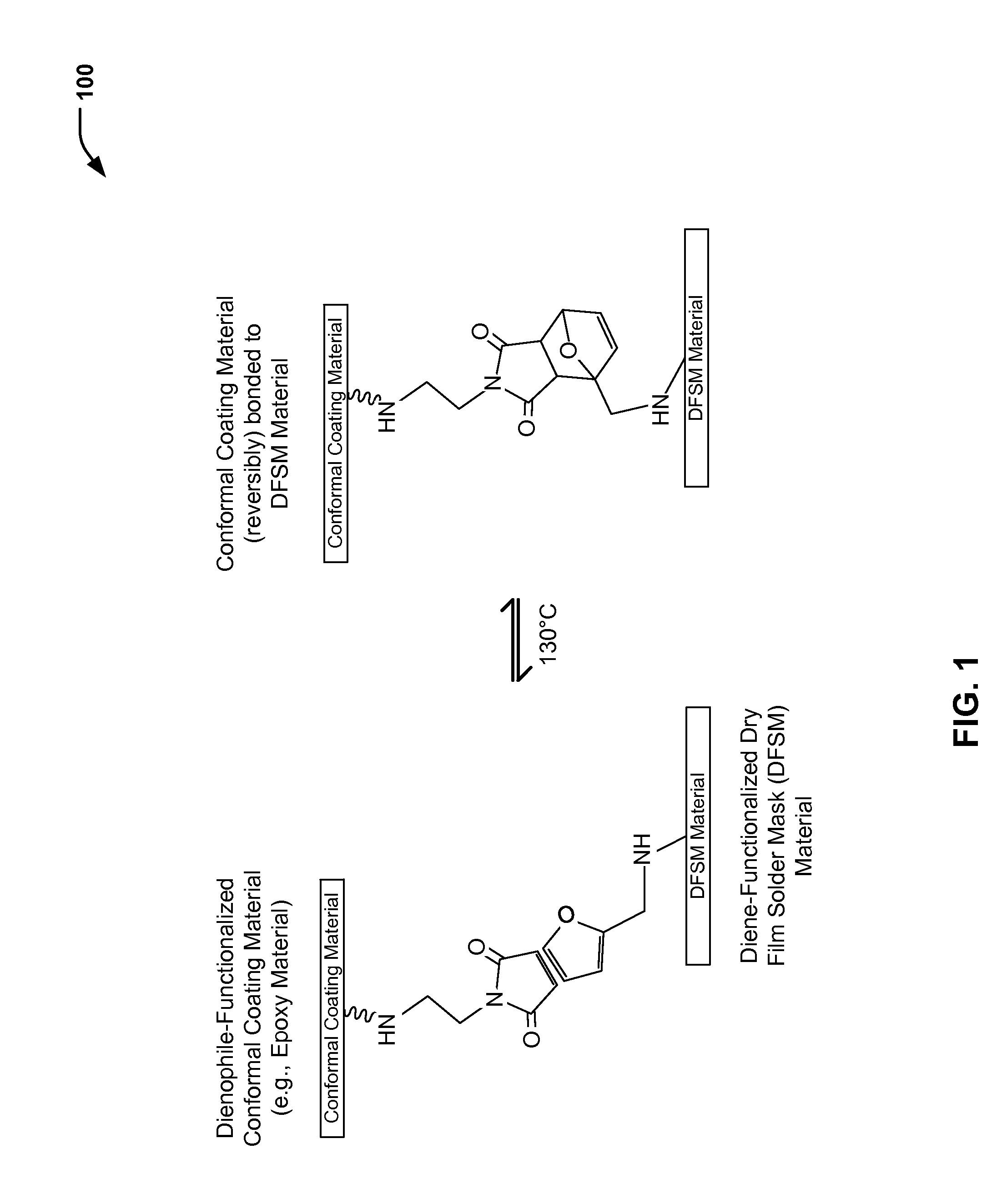

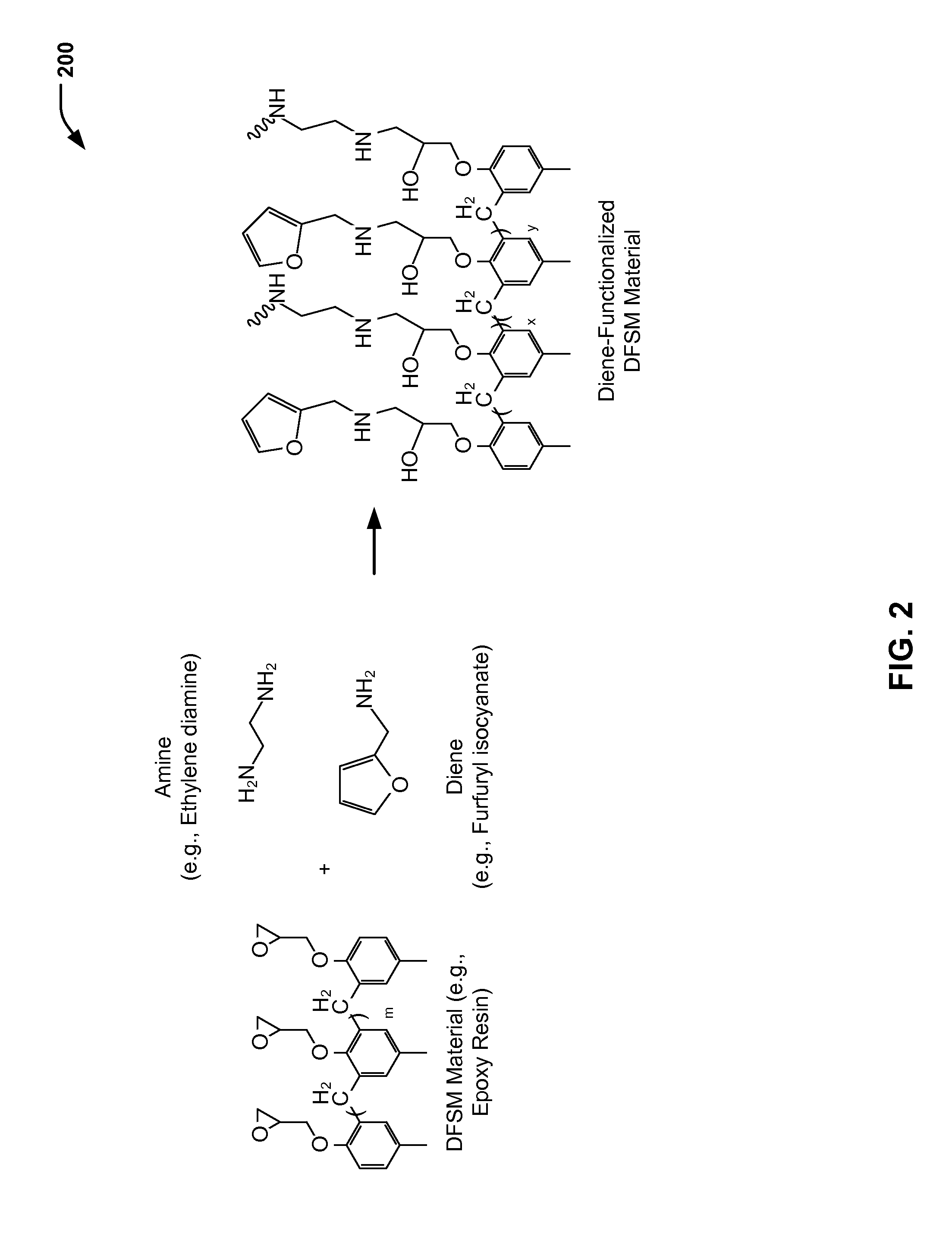

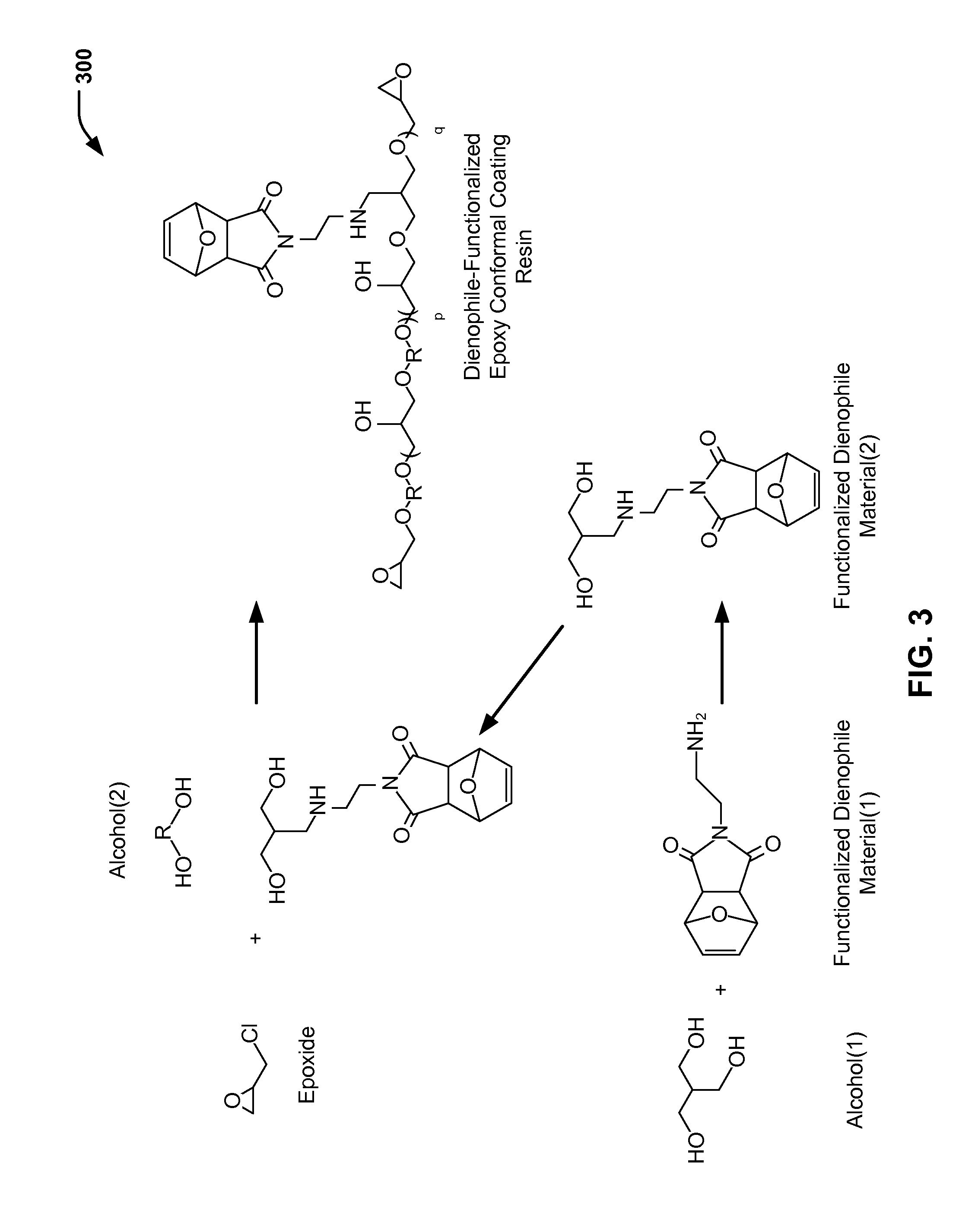

Conformal coating materials

InactiveUS20170027064A1Improve protectionLaminating printed circuit boardsPrinted circuit aspectsSolder maskChemical reaction

Owner:IBM CORP

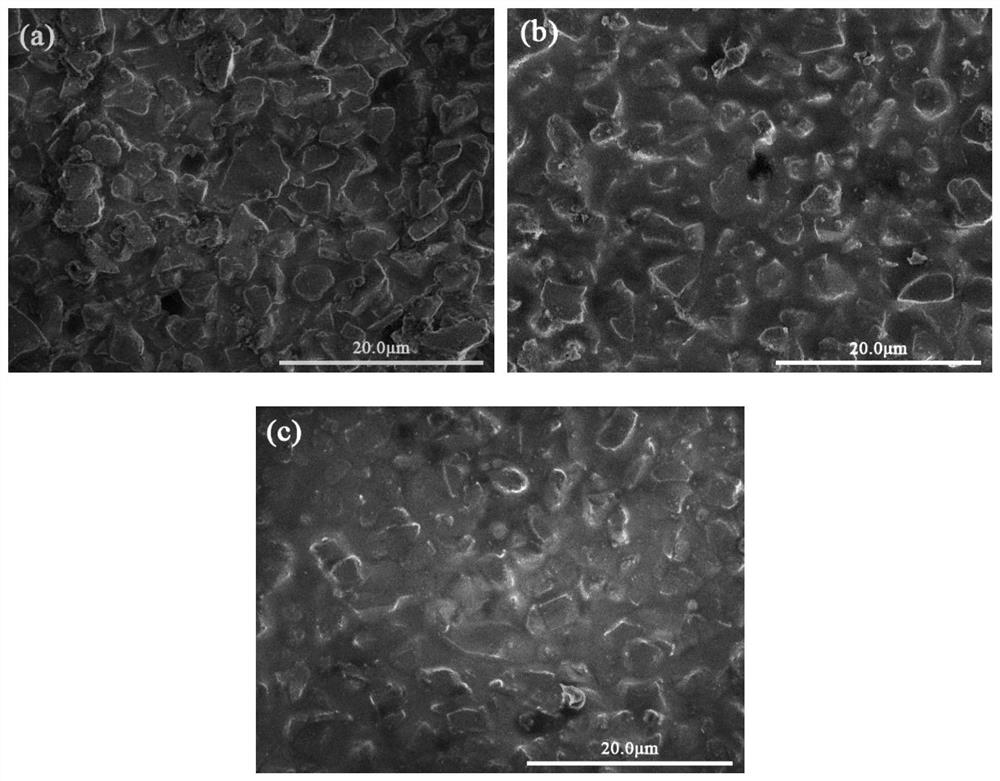

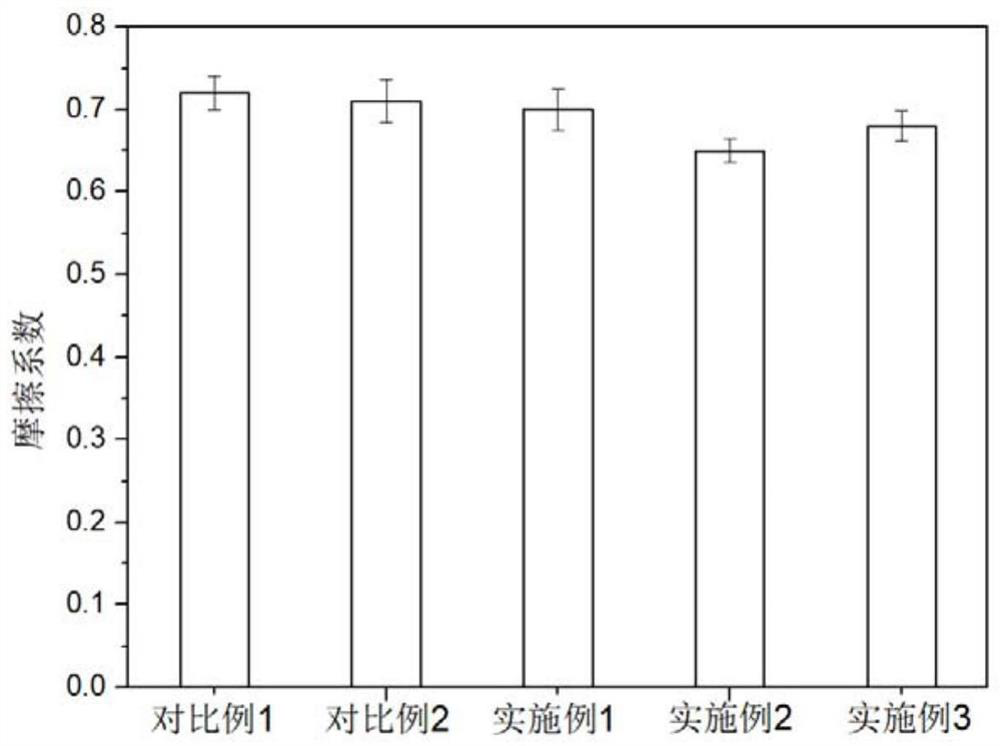

Nickel-coated graphite reinforced wear-resistant antifriction corrosion-resistant ceramic coating material, coating, and preparation method and application thereof

ActiveCN113564574AImprove wear resistance, friction reduction and corrosion resistanceImprove the lubrication effectHeat inorganic powder coatingSodium molybdateMetal coating

Owner:CHANGZHOU UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap