Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14 results about "Load cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A load cell is a type of transducer, specifically a force transducer. It converts a force such as tension, compression, pressure, or torque into an electrical signal that can be measured and standardized. As the force applied to the load cell increases, the electrical signal changes proportionally. The most common types of load cell used are hydraulic, pneumatic, and strain gauge.

I-beam type vehicle dynamic weighing sensor

InactiveCN104374459AUniform force distributionExtended service lifeWeighing apparatus using elastically-deformable membersOscillations damping for weighingElectricityVehicle dynamics

The invention relates to the technical field of sensors and provides an I-beam type vehicle dynamic weighing sensor. The I-beam type vehicle dynamic weighing sensor comprises an I-beam type elastic body, a measurement unit, power transmission blocks and an insulating protective sleeve, wherein a through cavity is formed in the I-beam type elastic body, the measurement unit and the power transmission blocks are arranged in the cavity, the measurement unit can be accommodated between the power transmission blocks in a pre-tightened mode, the measurement unit comprises an upper electrode, piezoelectric materials and a lower electrode from top to bottom in sequence, the horizontal surface of the insulating protective sleeve is arranged between the upper electrode and the lower electrode, through holes are formed in the horizontal surface of the insulating protective sleeve at equal intervals, the shape of each through hole is matched with that of each piezoelectric material, the insulating protective sleeve is made from an insulating material, and the piezoelectric materials are placed in the through holes. By the adoption of the I-beam type vehicle dynamic weighing sensor, insulation resistance is increased, a measurement result is more accurate, the pressure acting on the measurement unit is reduced, the piezoelectric materials are protected against damage caused by pressure, and service life is prolonged.

Owner:SICHUAN STONE EDGE POLYTRON TECH INC

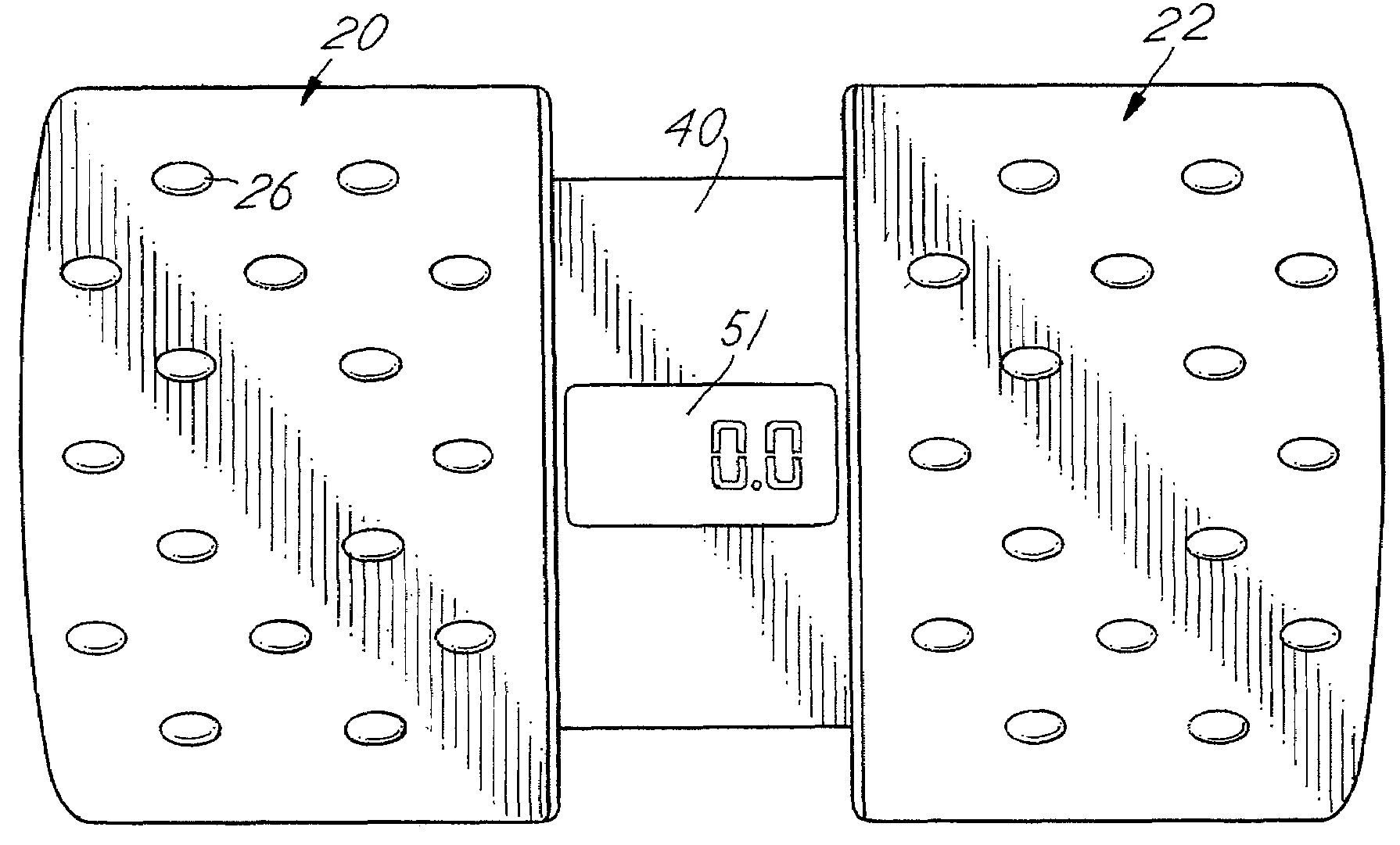

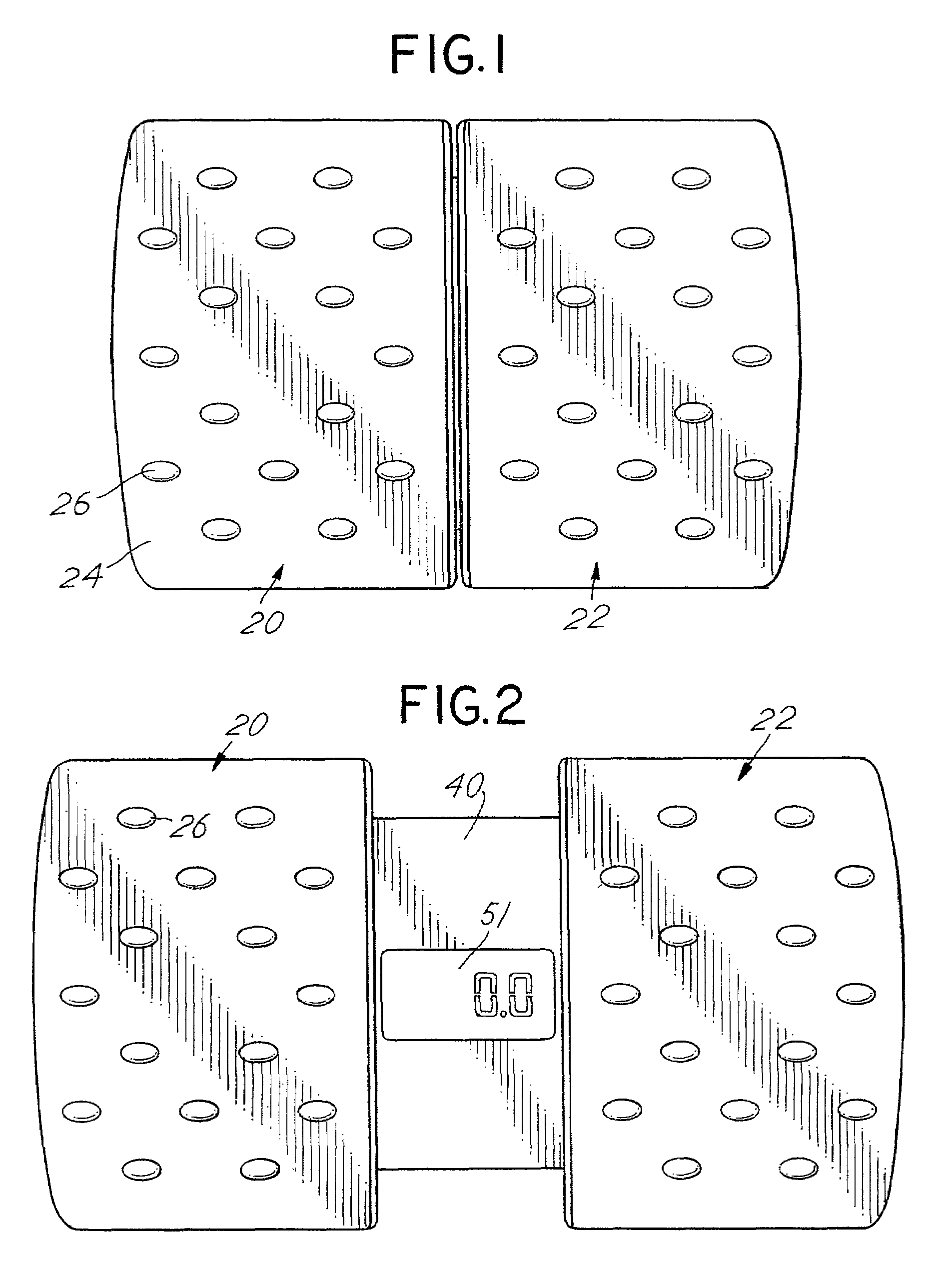

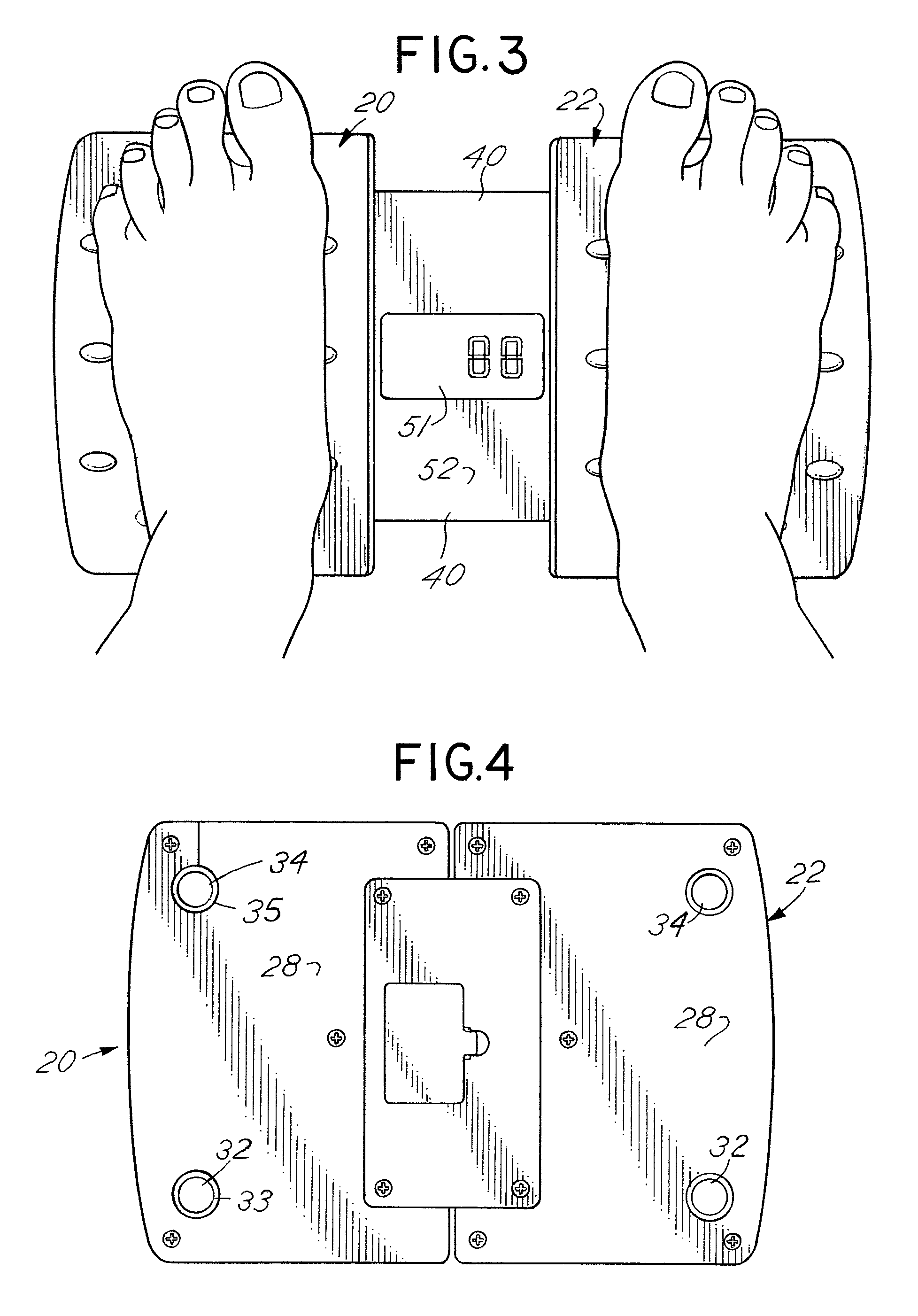

Portable scale

InactiveUS7521638B1Easy to prevent slippingPrevent movementWeighing apparatus detailsSpecial purpose weighing apparatusEngineeringLoad cell

Owner:TRAVEL CADDY

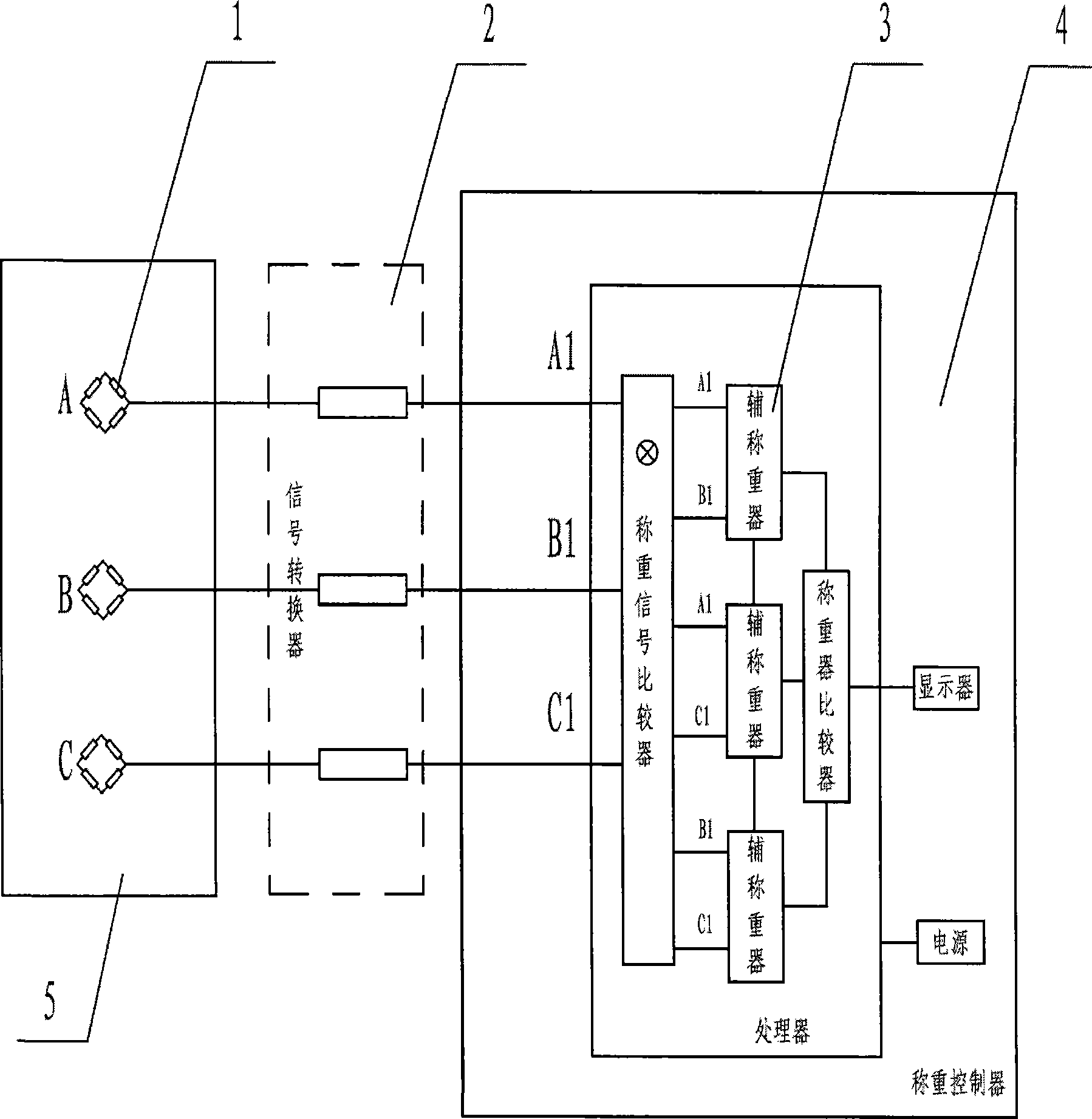

Weighing control device of hopper scale and method thereof

ActiveCN101532869AWeighing apparatus for materials with special property/formWeighing apparatus with automatic feed/dischargeEngineeringLoad cell

Owner:SAIMO ELECTRIC +1

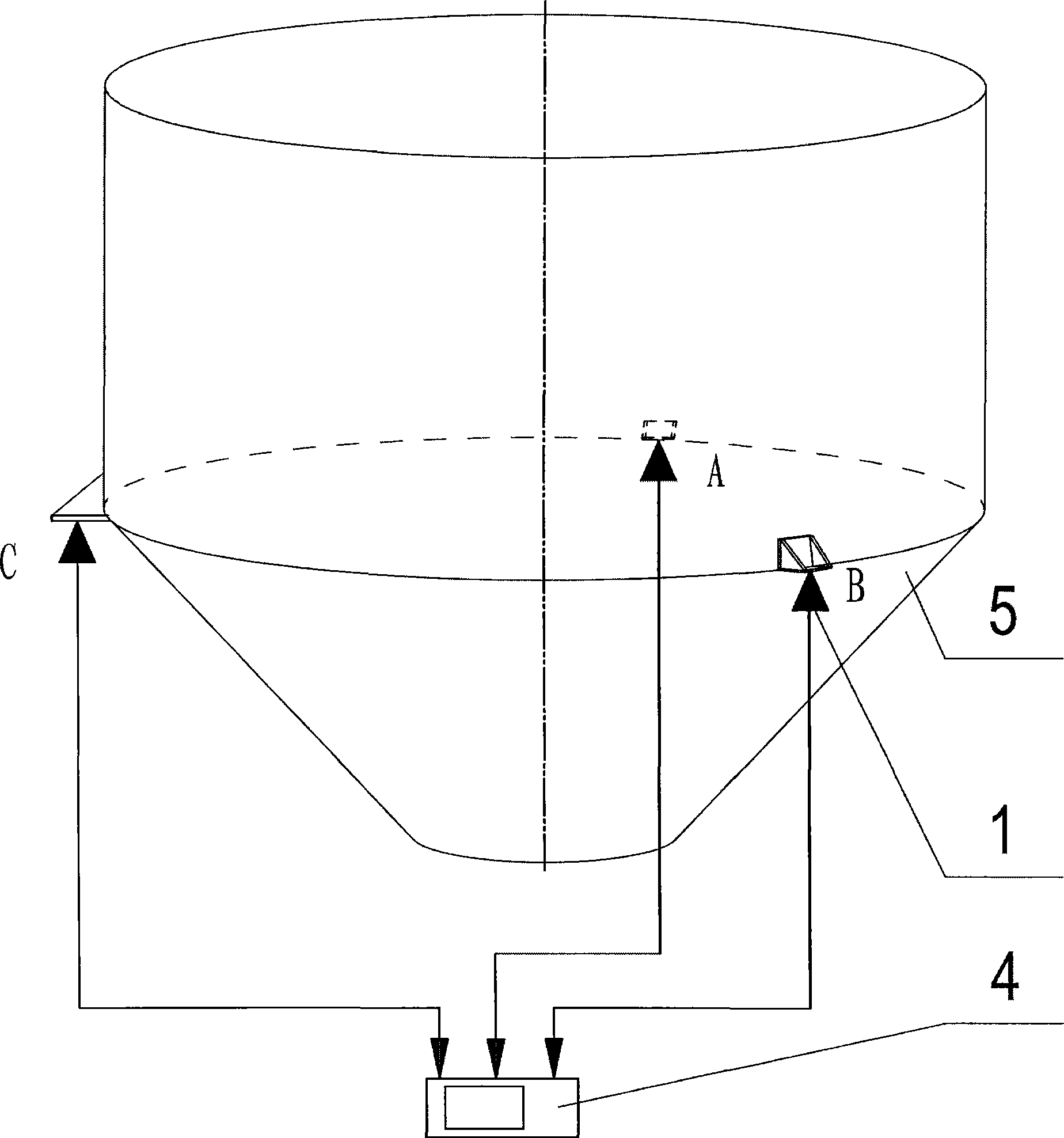

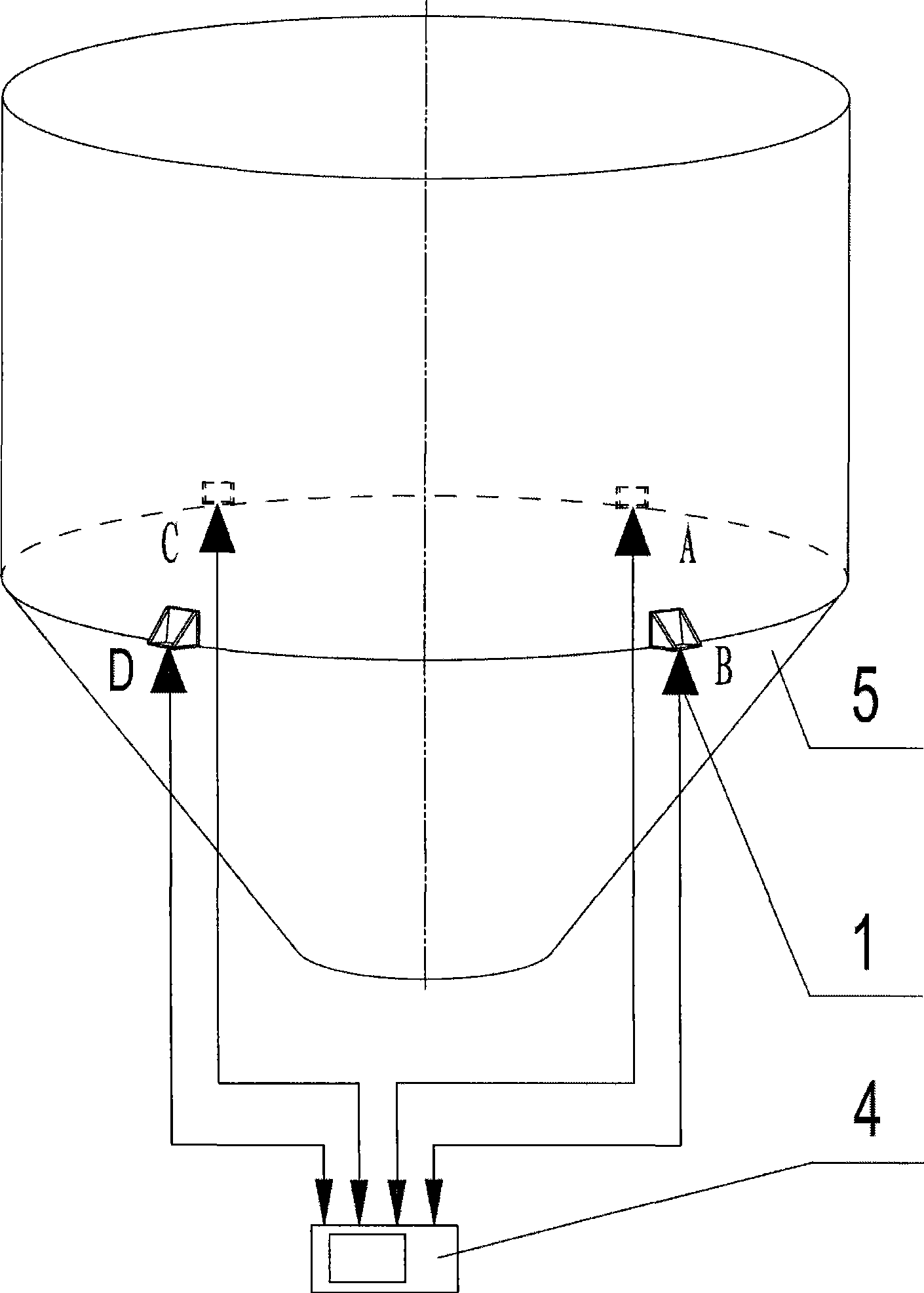

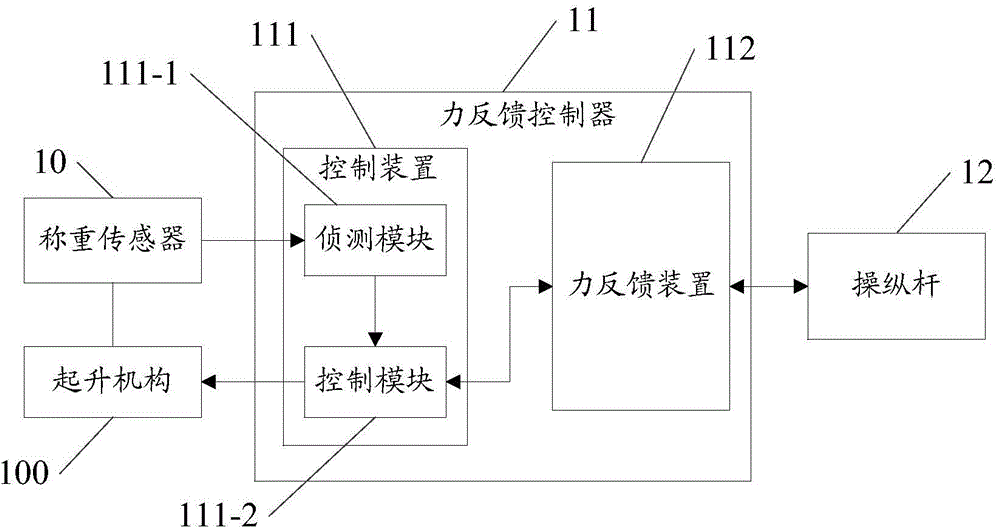

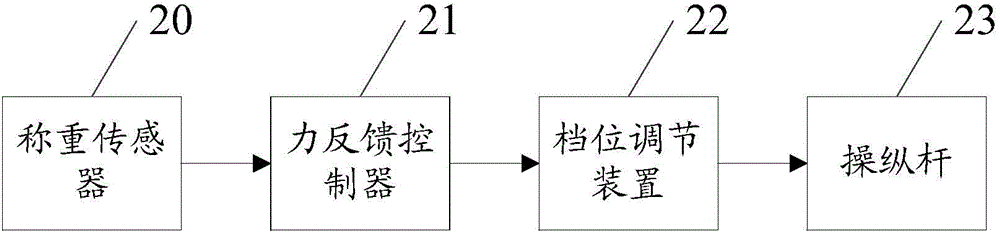

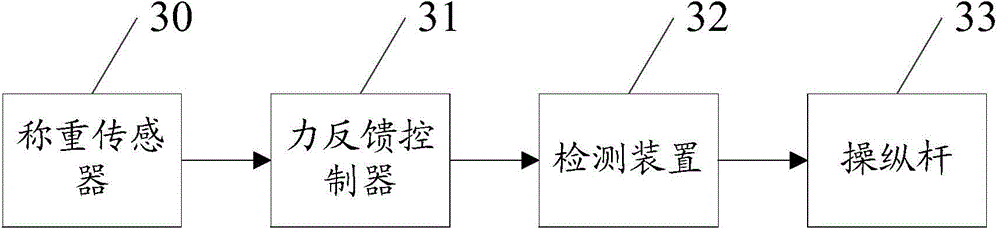

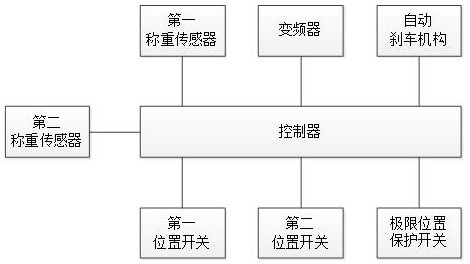

Crane force feedback system

InactiveCN104627840AImprove efficiencyImprove securityCranesSafety gearFeedback controllerOperability

Owner:SHENZHEN SINE ELECTRIC

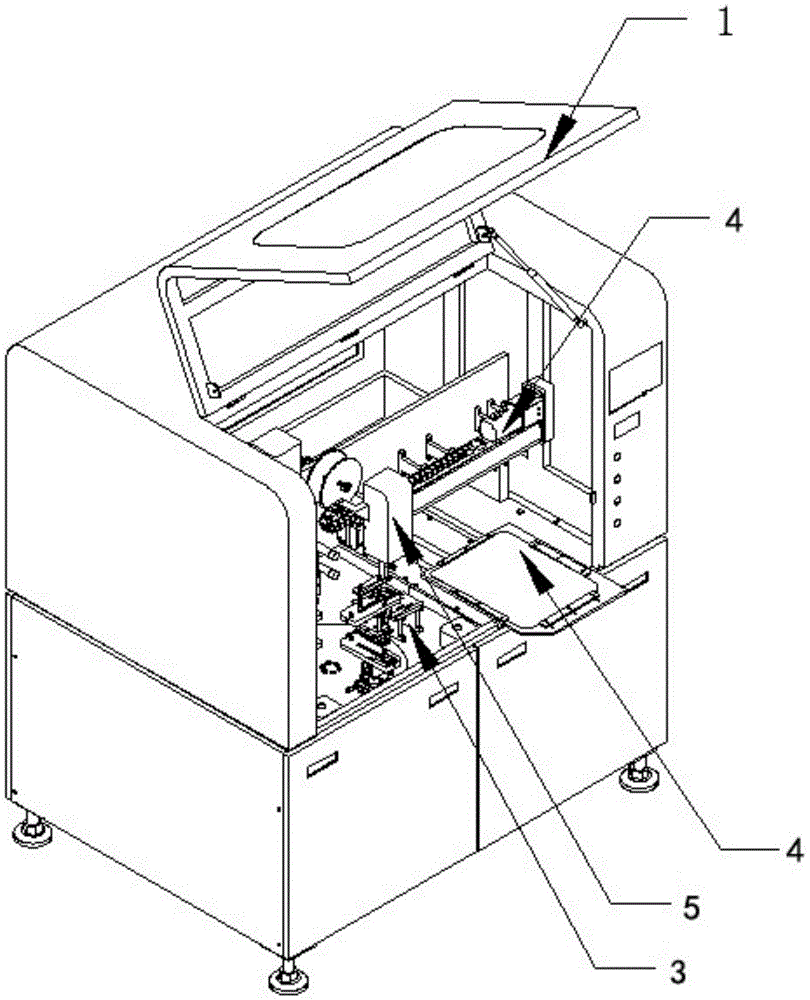

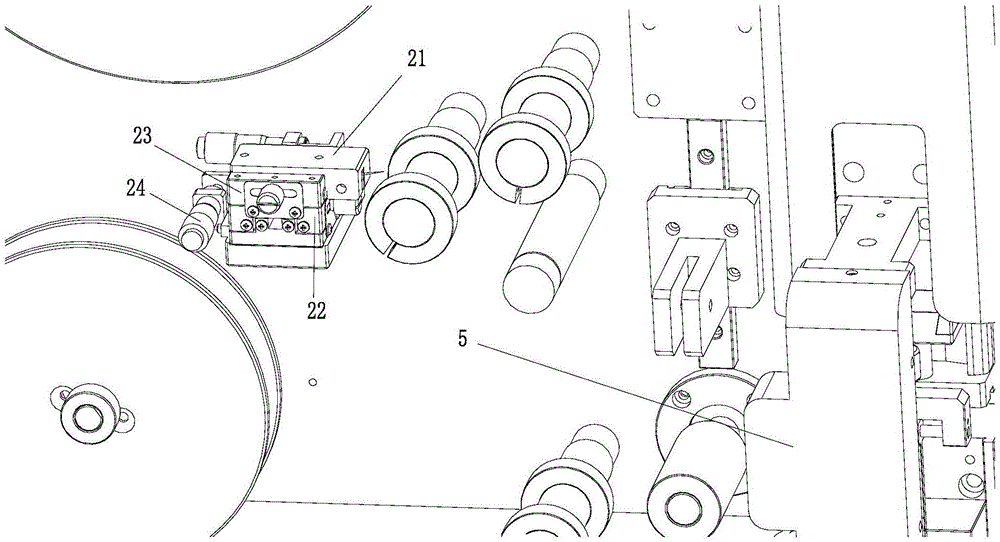

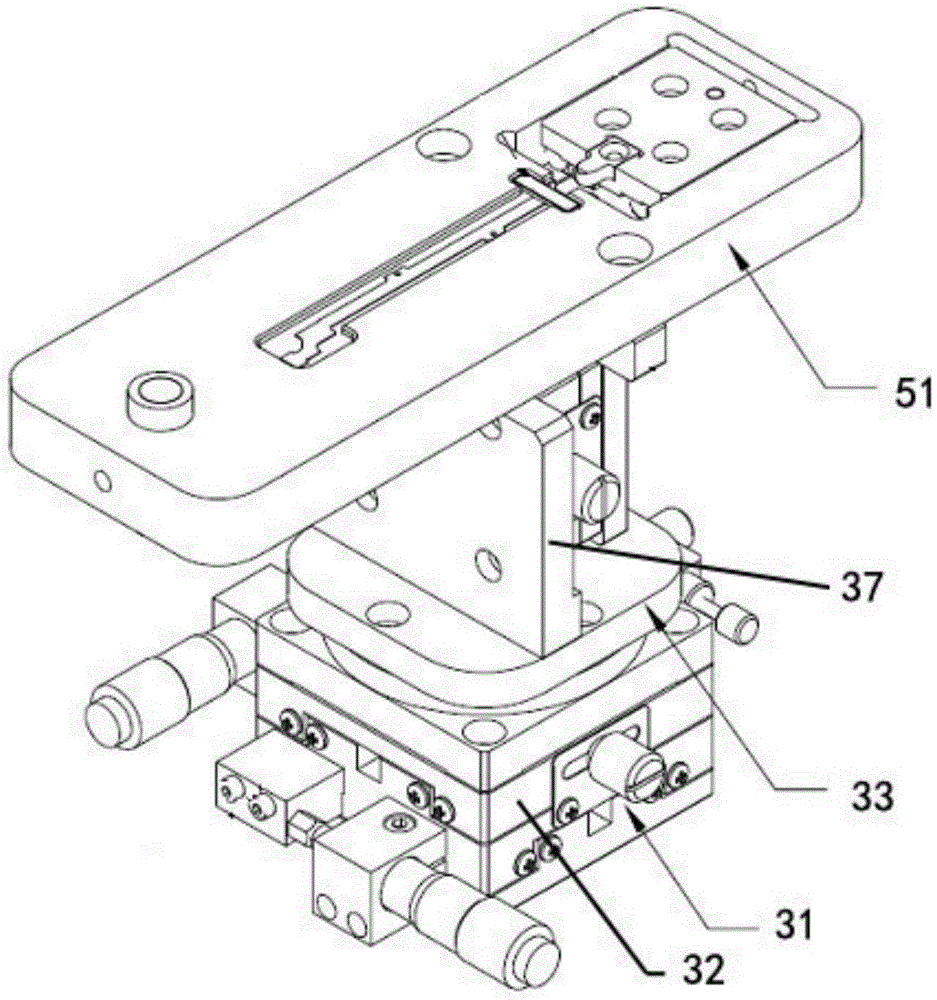

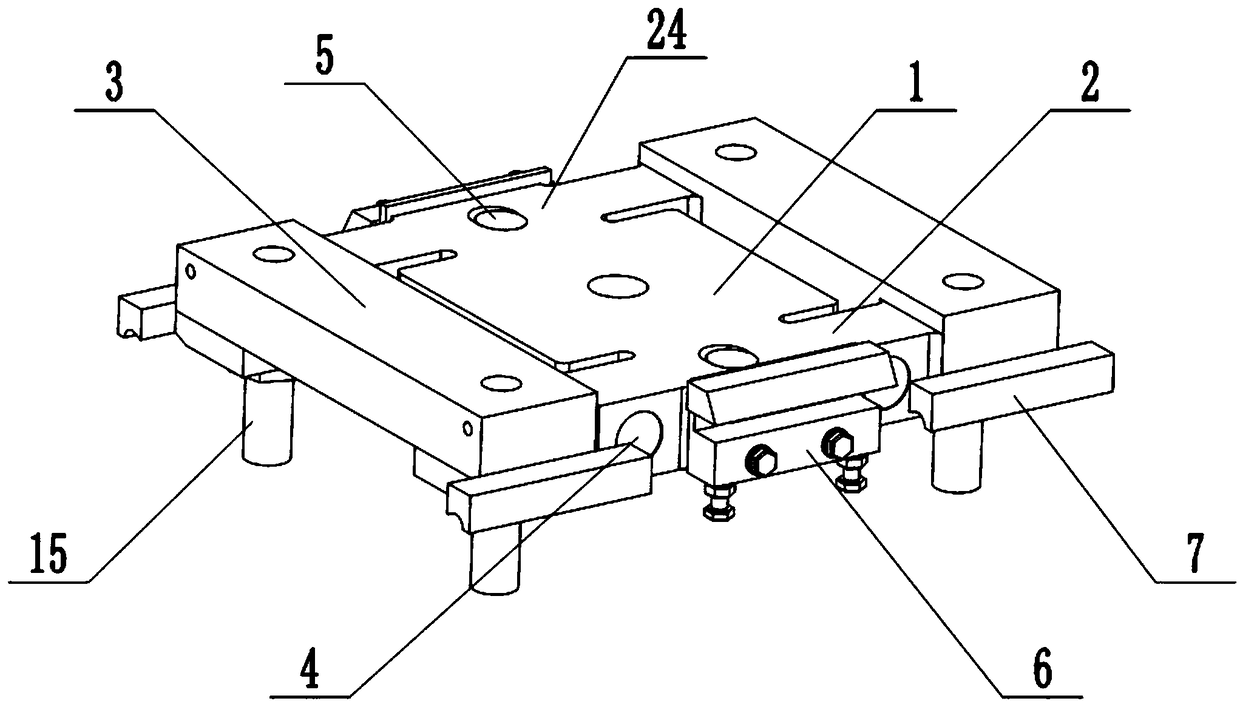

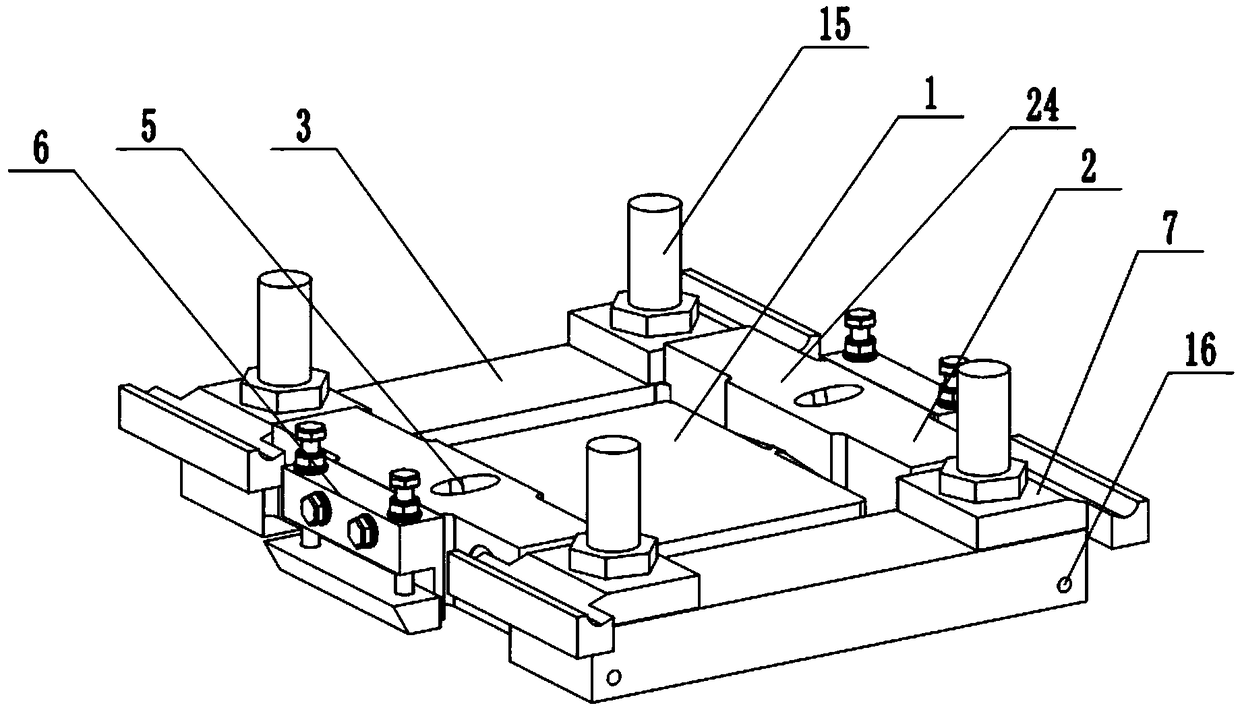

Automatic adhesive paper sticking integrated machine and working method thereof

InactiveCN105563555AGuaranteed dimensional accuracyRealize integrated operationMetal working apparatusAdhesiveEngineering

Owner:深圳市鼎晖伟业自动化设备有限公司

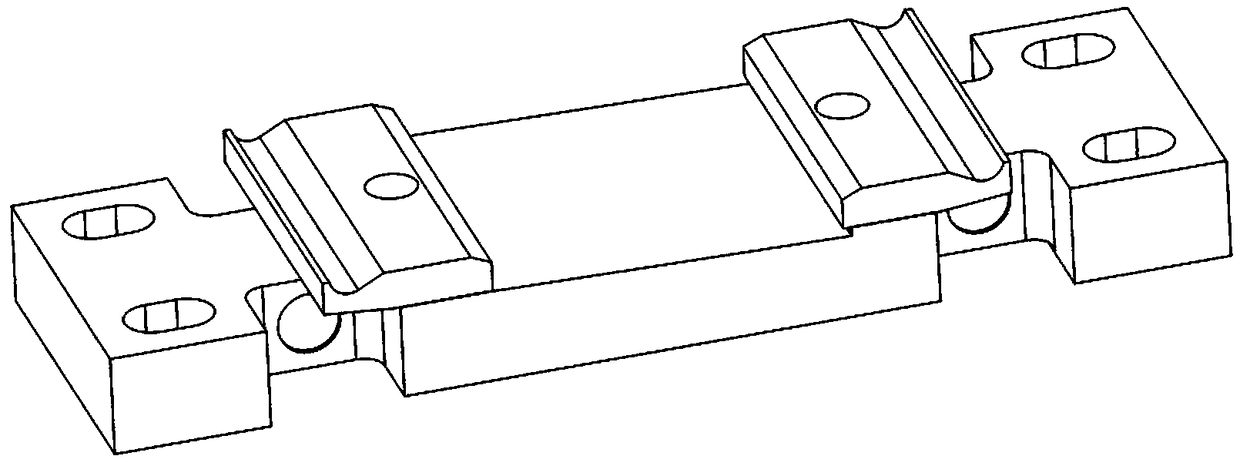

Frame type rail weighing sensor

PendingCN109211383AGuaranteed lengthShorten the lengthSpecial purpose weighing apparatusEngineeringLoad cell

Owner:BEIJING HUAHENG NEW TECH DEV +1

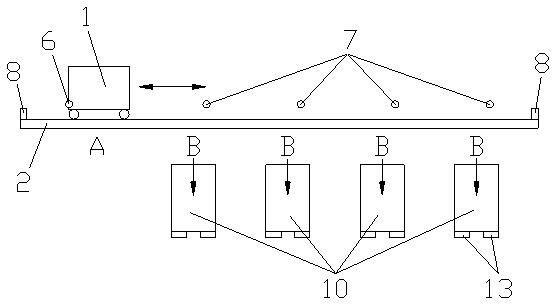

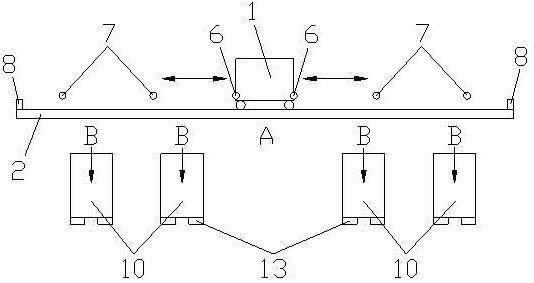

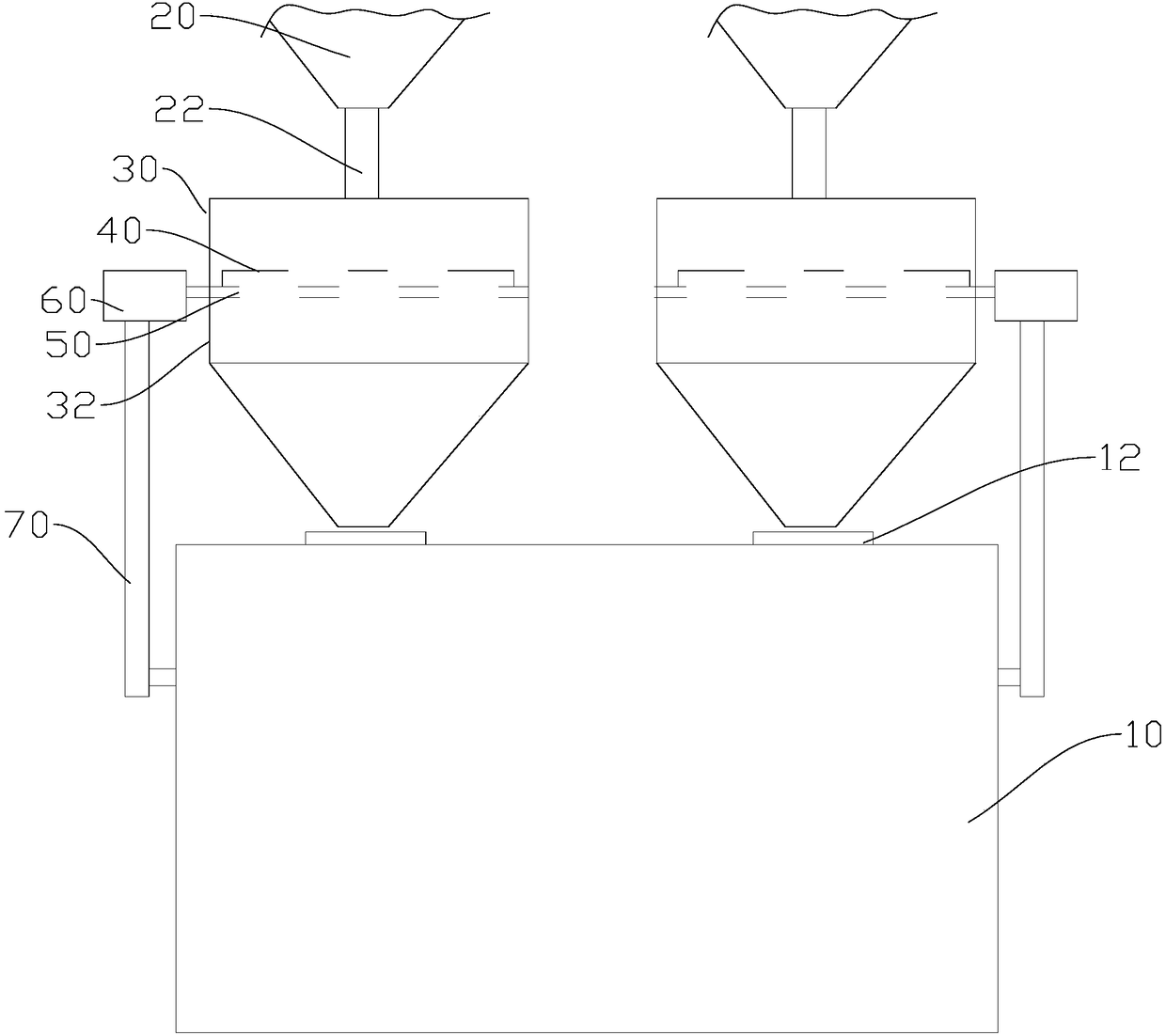

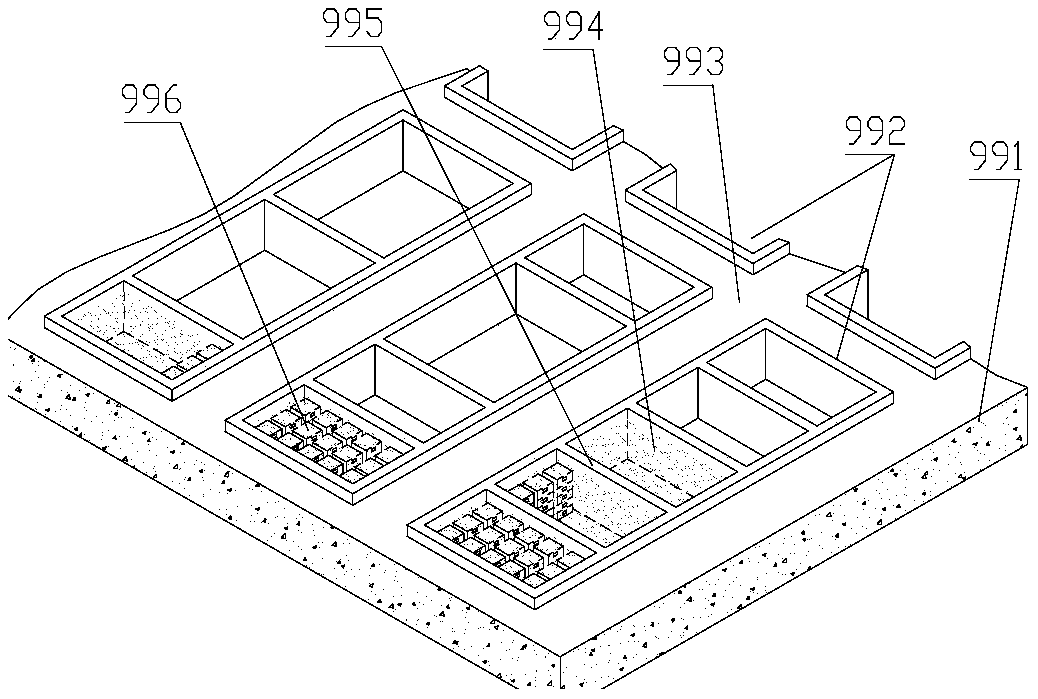

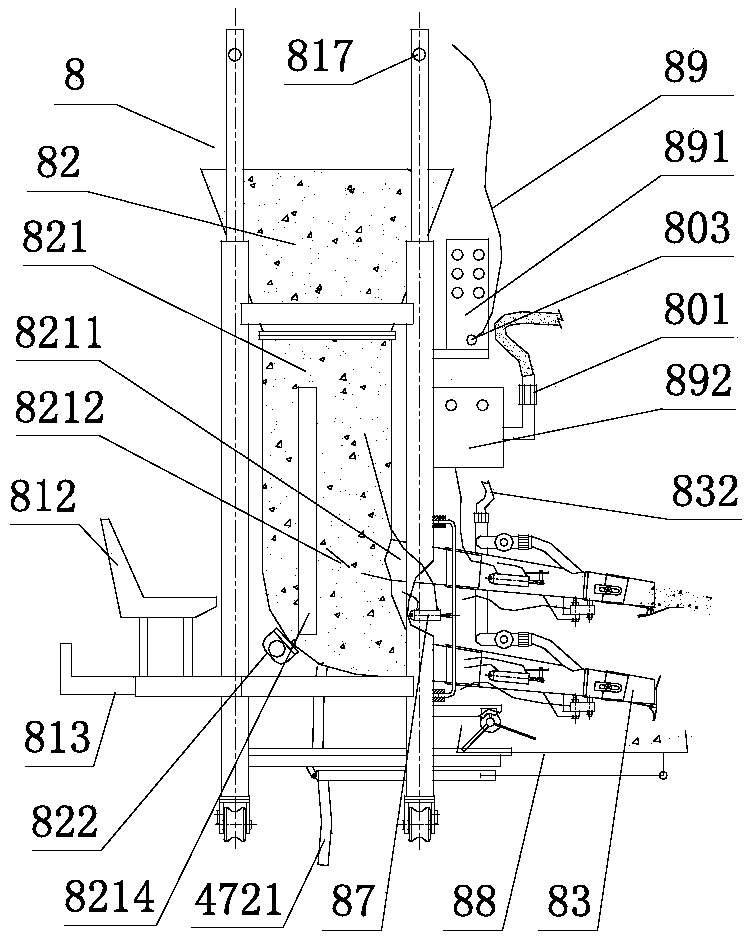

Efficient feeding system and method for asphalt mixture level batching bins

InactiveCN112061707ATimely replenishmentImprove efficiencyControl devices for conveyorsWeighing apparatus with automatic feed/dischargeFrequency changerAutomatic braking

Owner:FUJIAN QUANCHENG MACHINERY

Magnetic material mixing equipment

InactiveCN108421493AIncreased scale accuracyQuality improvementTransportation and packagingMixer accessoriesEngineeringControl valves

Owner:FOSHAN SUIYUAN HENGKE BUILDING MATERIAL CO LTD

Electronic balance with voice reading function

InactiveCN105509847ASimple structureLight in massWeighing apparatus using counterbalanceWeighing indication devicesEngineeringLoad cell

The invention discloses an electronic balance with a voice reading function. The electronic balance comprises an electronic balance body which is made of high-quality titanium magnesium alloy. The electronic balance body comprises a weighing loading table, a weighing control device and a weighing display screen. The weighing loading table is arranged at the upper end of the electronic balance body. The weighing display screen is arranged at the front end of the electronic balance body. The weighing control device is arranged in the electronic balance body. The weighing control device comprises a master control chip, and a control circuit, a weighing sensor, a storage module, an input module, a display module and a voice output module which are electrically connected with the master control chip. The input module is electrically connected with a braille keyboard. With application of the mode, the electronic balance has the voice output module and can be externally connected with the braille keyboard so that use is facilitated for the blind.

Owner:CHANGSHU JIAHENG BALANCE INSTR CO LTD

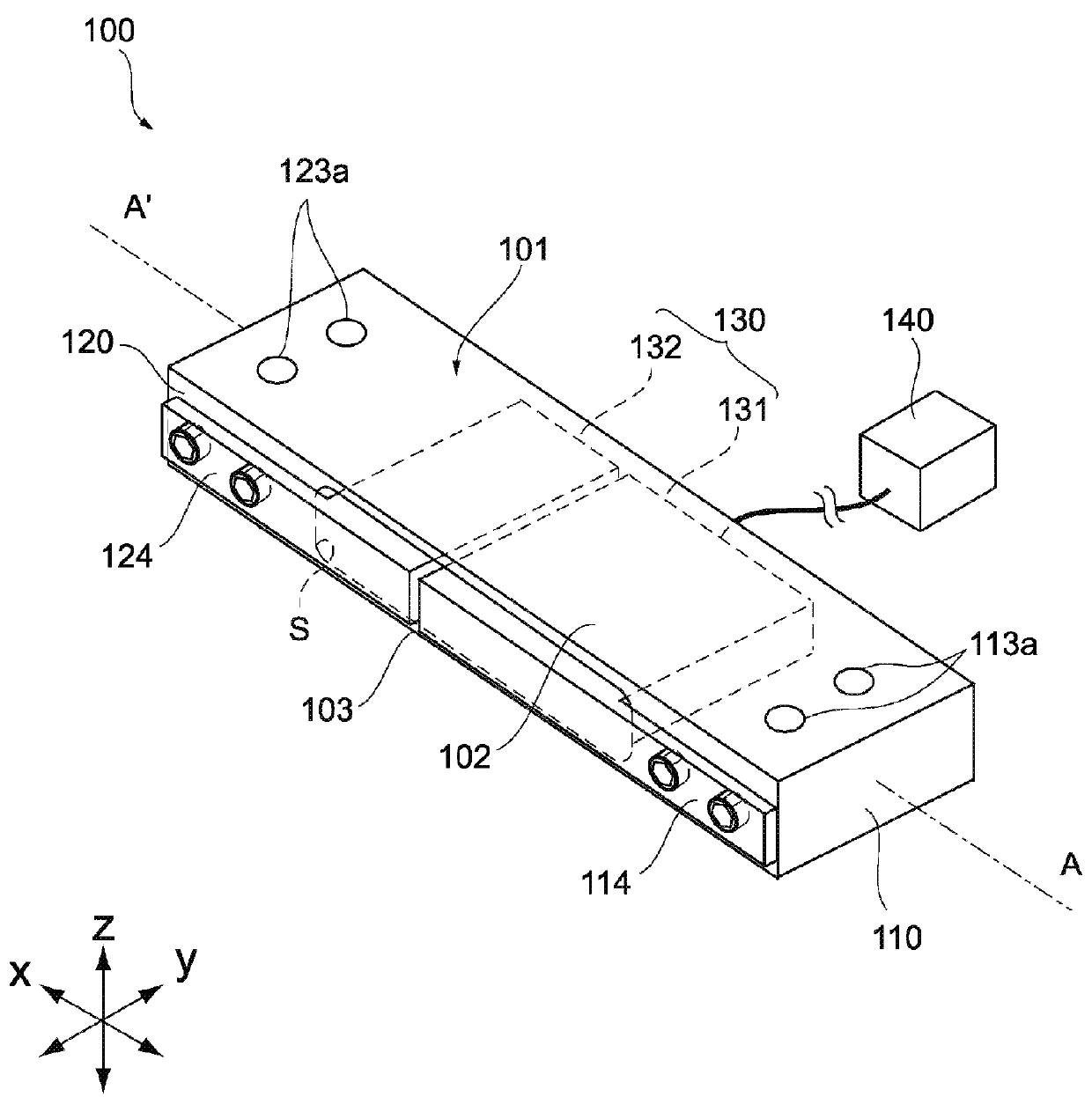

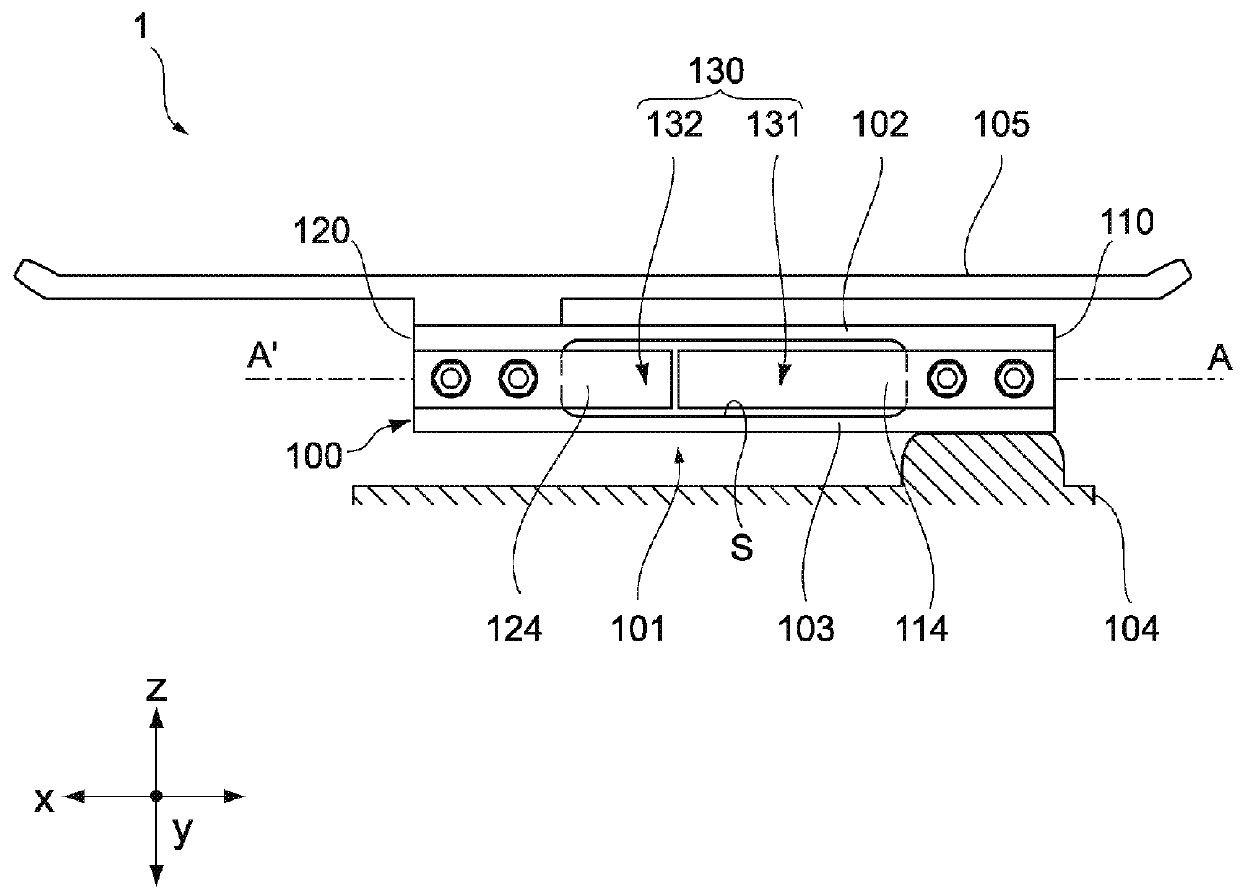

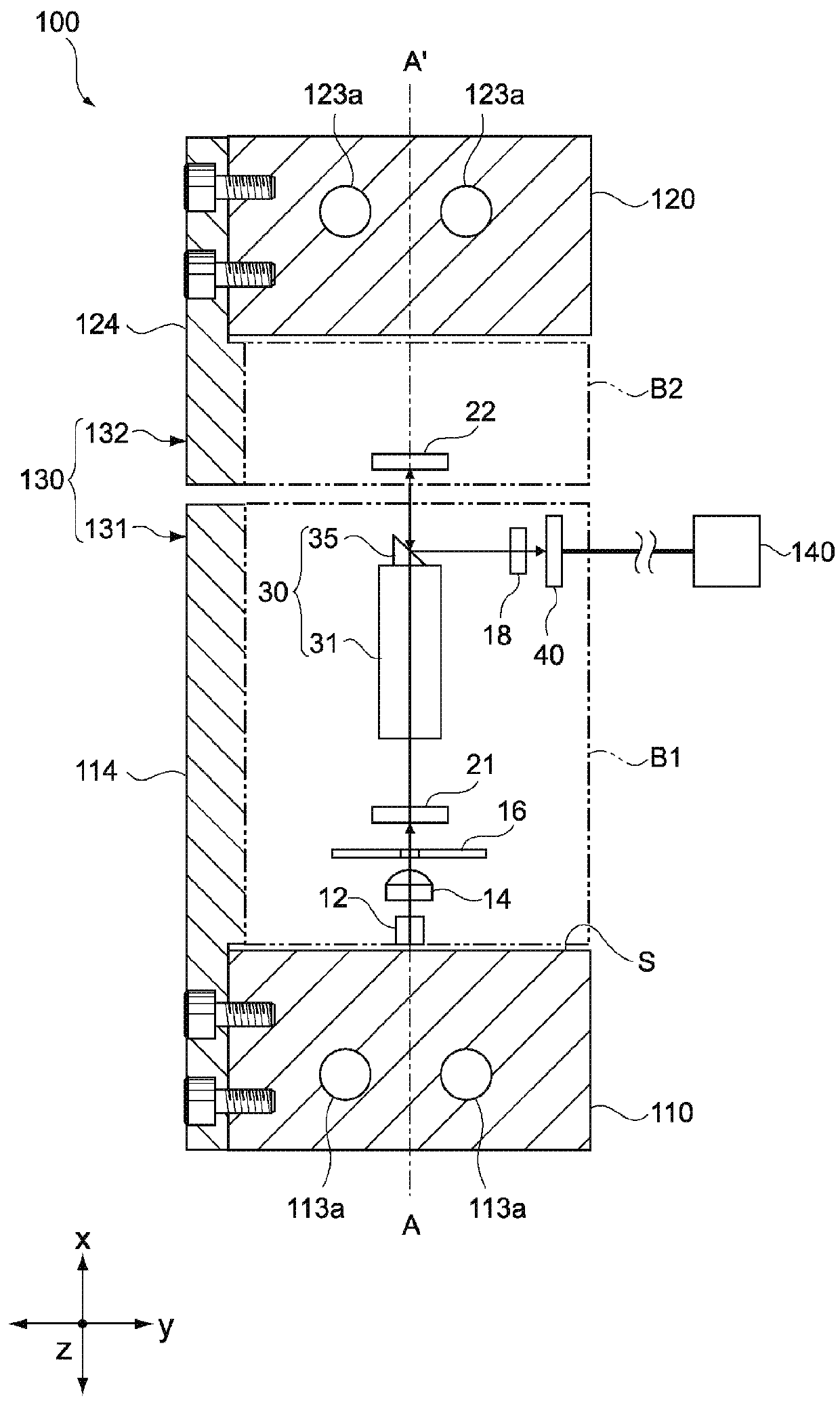

Load cell

ActiveUS20180106690A1High resolutionImprove signal-to-noise ratioForce measurement by permanent gauge deformationForce measurement by measuring optical property variationRelative displacementElastomer

Owner:TAIYO YUDEN KK

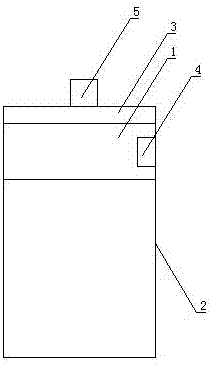

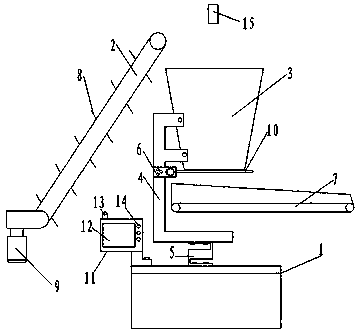

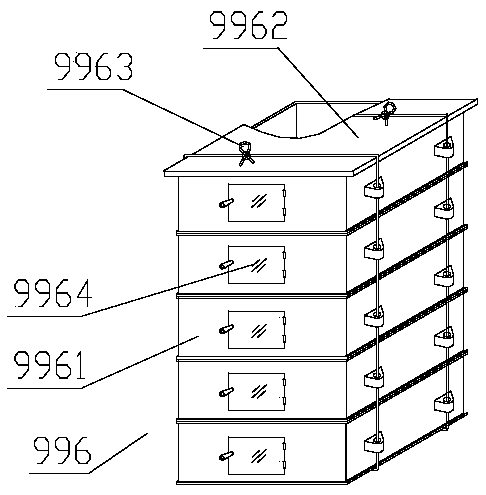

Feeding device

InactiveCN110668206ASmooth feedingImprove product qualityConveyorsWeighing apparatus with automatic feed/dischargeProduction lineControl system

Owner:TAICANG JINHAODA NEW MATERIAL CO LTD

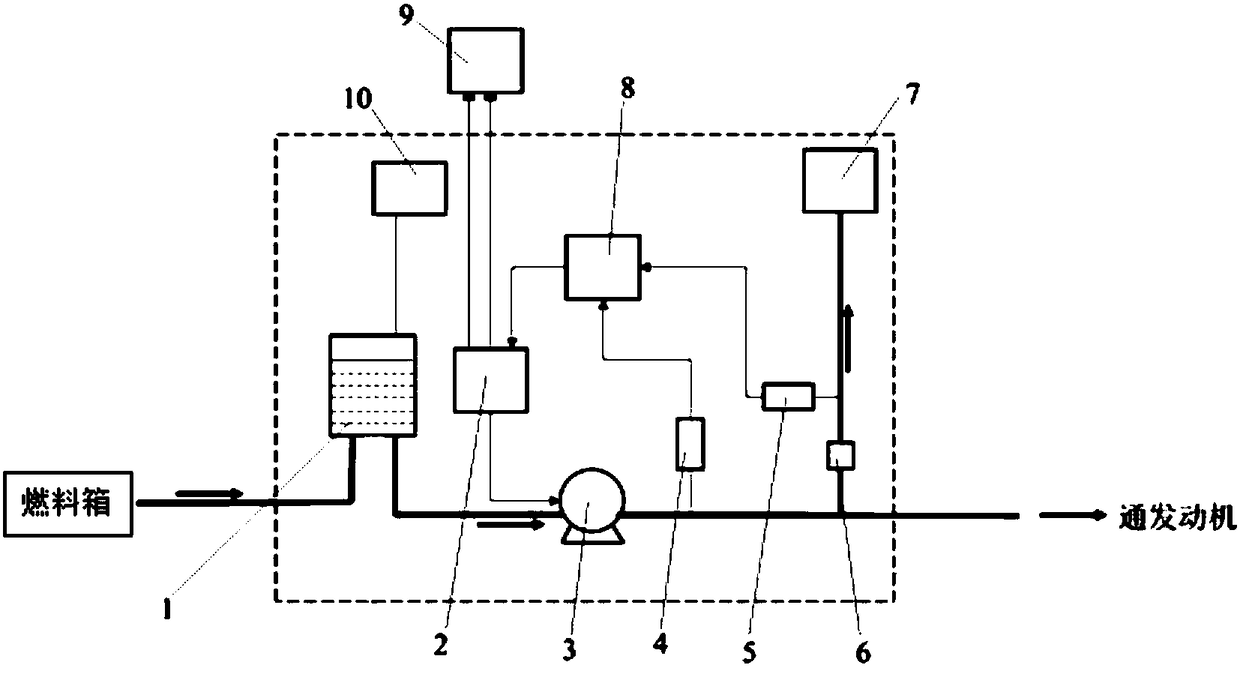

System for controlling fuel quantity of alcohol consumption instrument

ActiveCN108120601AThe engine test went wellSave energyEngine testingFluid pressure control using electric meansPower controllerMethanol fuel

Owner:HUAZHONG UNIV OF SCI & TECH

Feeding machine with weighing system

InactiveCN108967302AConvenient and precise feedingAccurate external feedingClimate change adaptationPisciculture and aquariaEngineeringHigh pressure water

Owner:张达英

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap