Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Plasma processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma processing is a plasma-based material processing technology that aims at modifying the chemical and physical properties of a surface.

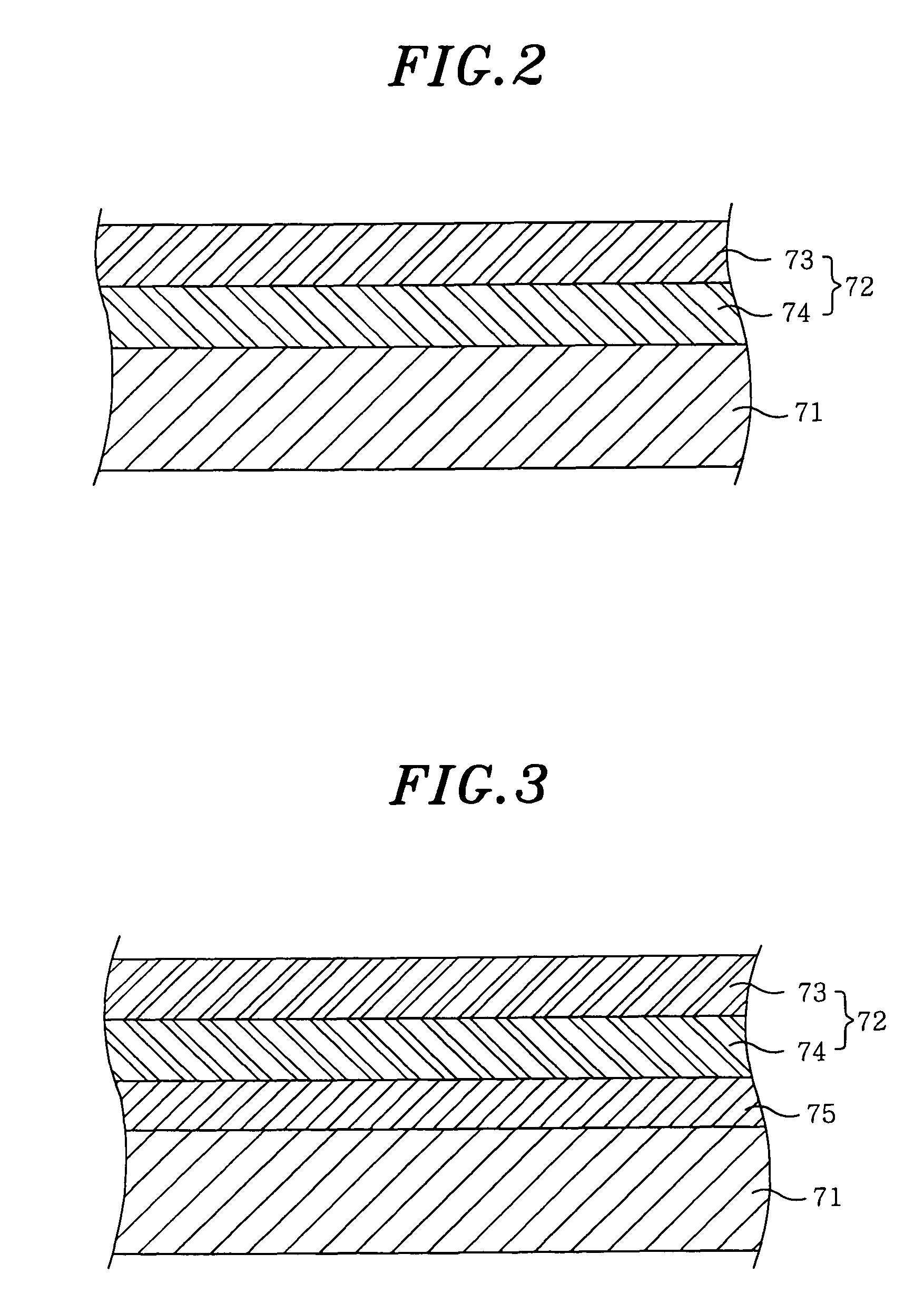

Internal member of a plasma processing vessel

ActiveUS7780786B2Prevent peelingLiquid surface applicatorsMolten spray coatingThermal sprayingMetallurgy

Owner:TOKYO ELECTRON LTD

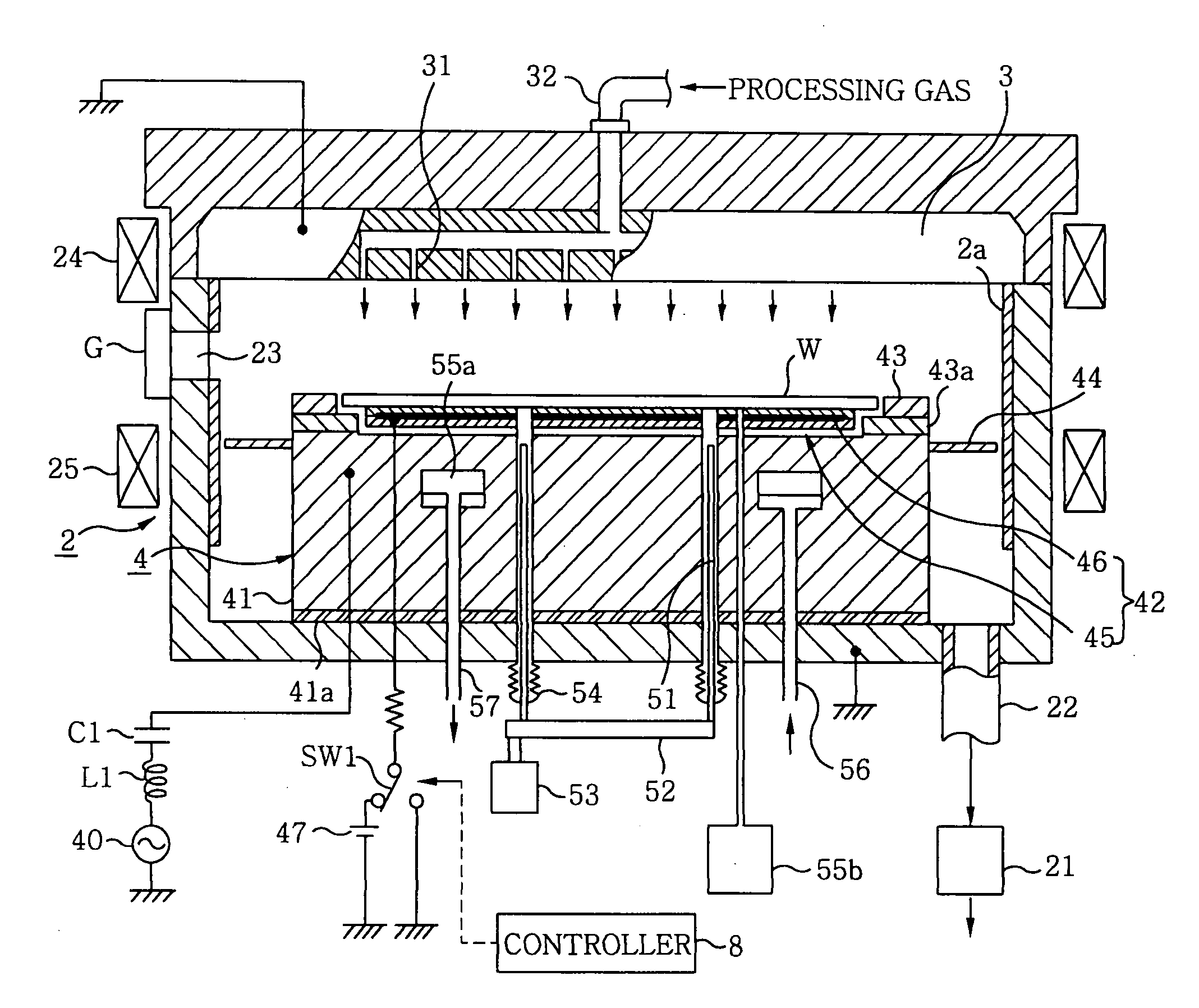

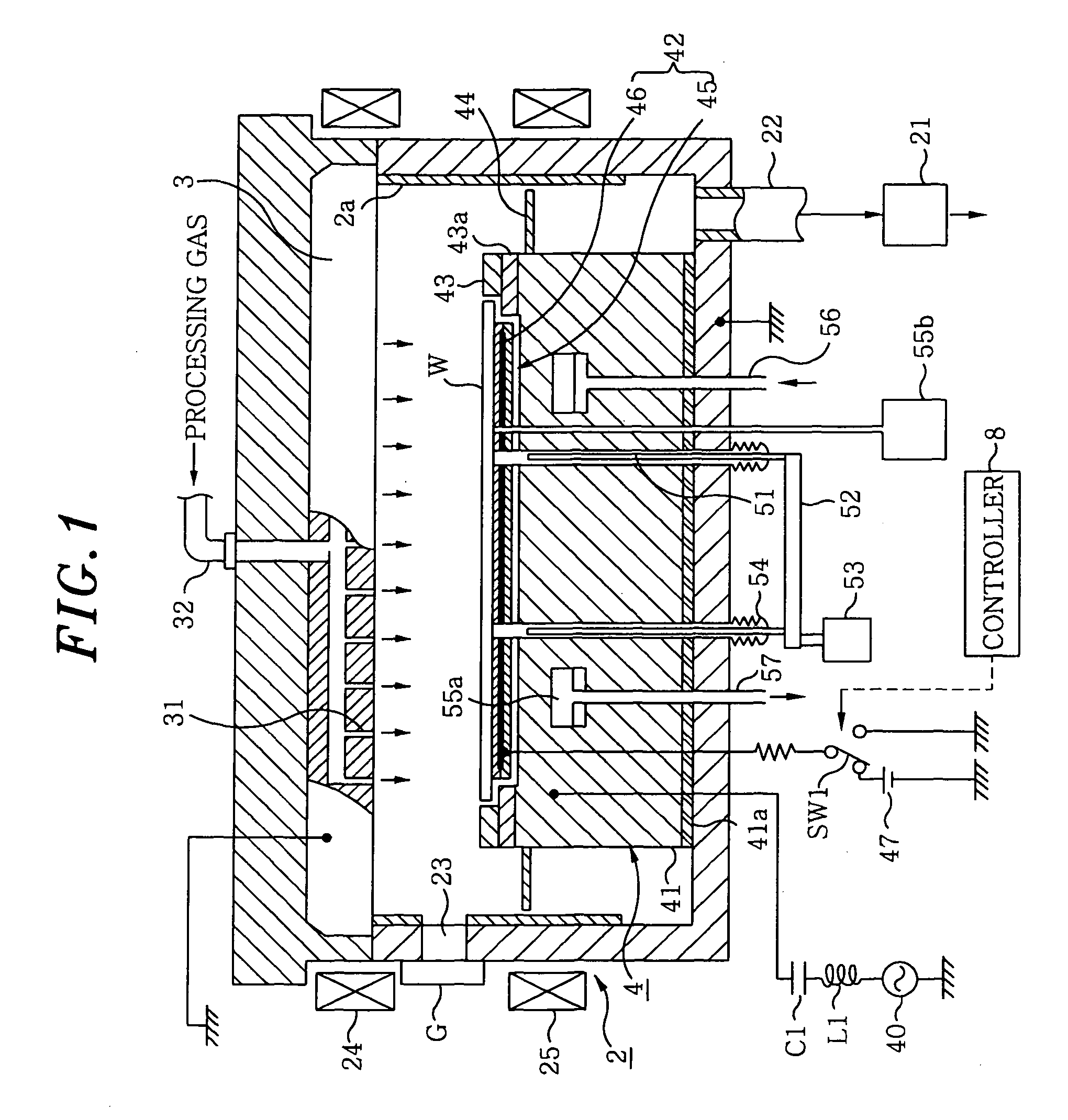

Plasma processing apparatus

InactiveUS20050217798A1Plasma discharge can be stabilizedLow running costElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringMaterials science

Owner:SHARP KK

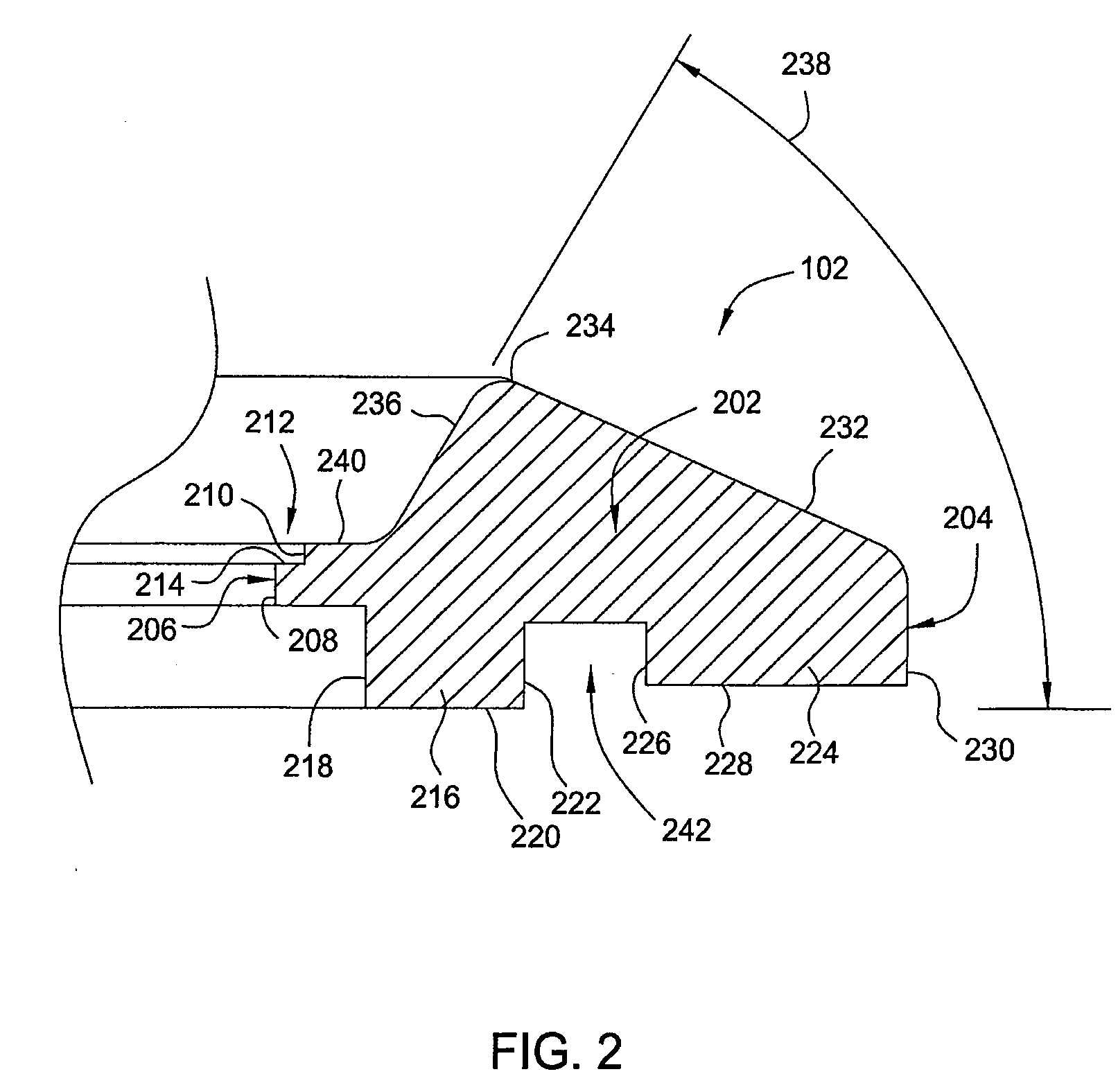

Low sloped edge ring for plasma processing chamber

ActiveUS20100059181A1Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringYttrium

Owner:APPLIED MATERIALS INC

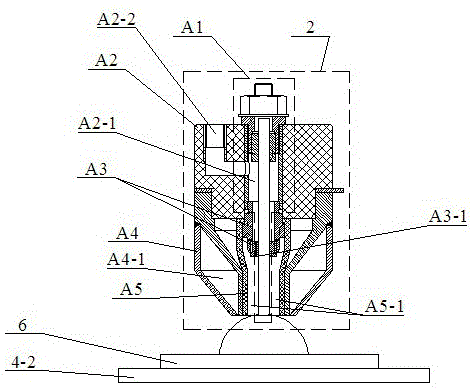

Apparatus and method for plasma treating and dispensing an adhesive/sealant onto a part

InactiveUS20060172081A1Minimal timeLow costMovable spraying apparatusPretreated surfacesAdhesiveSealant

Owner:NORDSON CORP

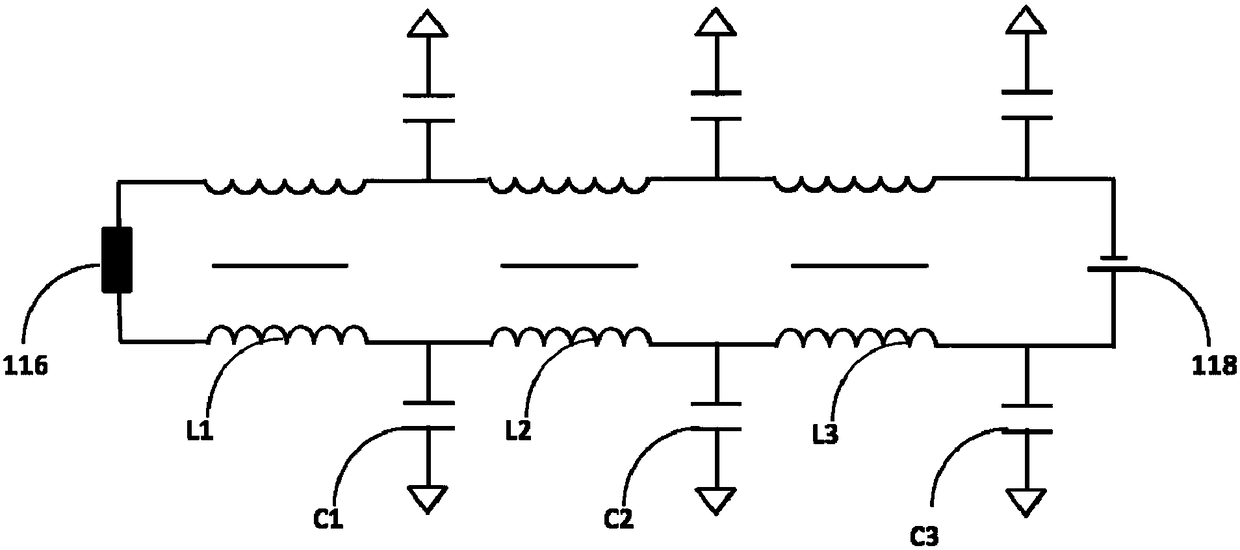

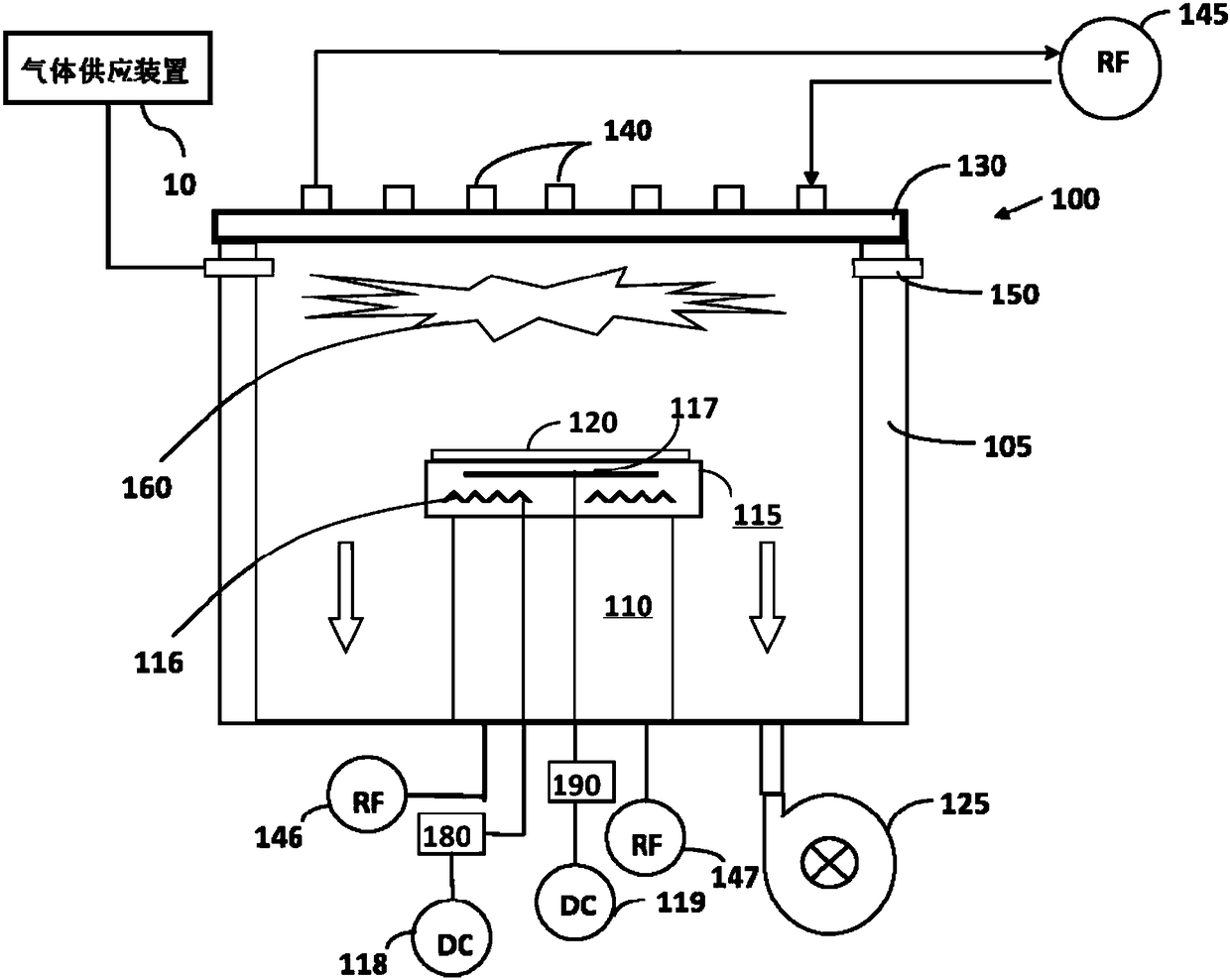

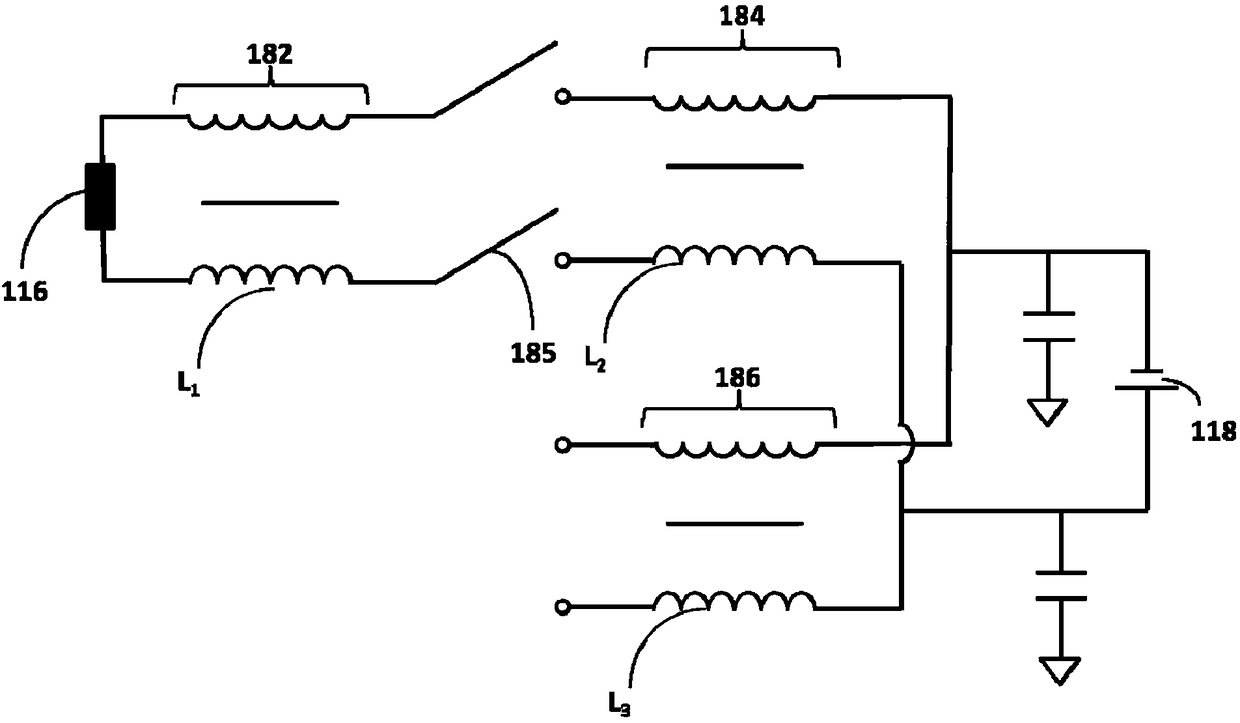

Plasma processing apparatus and radio frequency filtering circuit therefor

PendingCN108270412AImpedence networksElectric discharge tubesPlasma processingRadio frequency signal

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

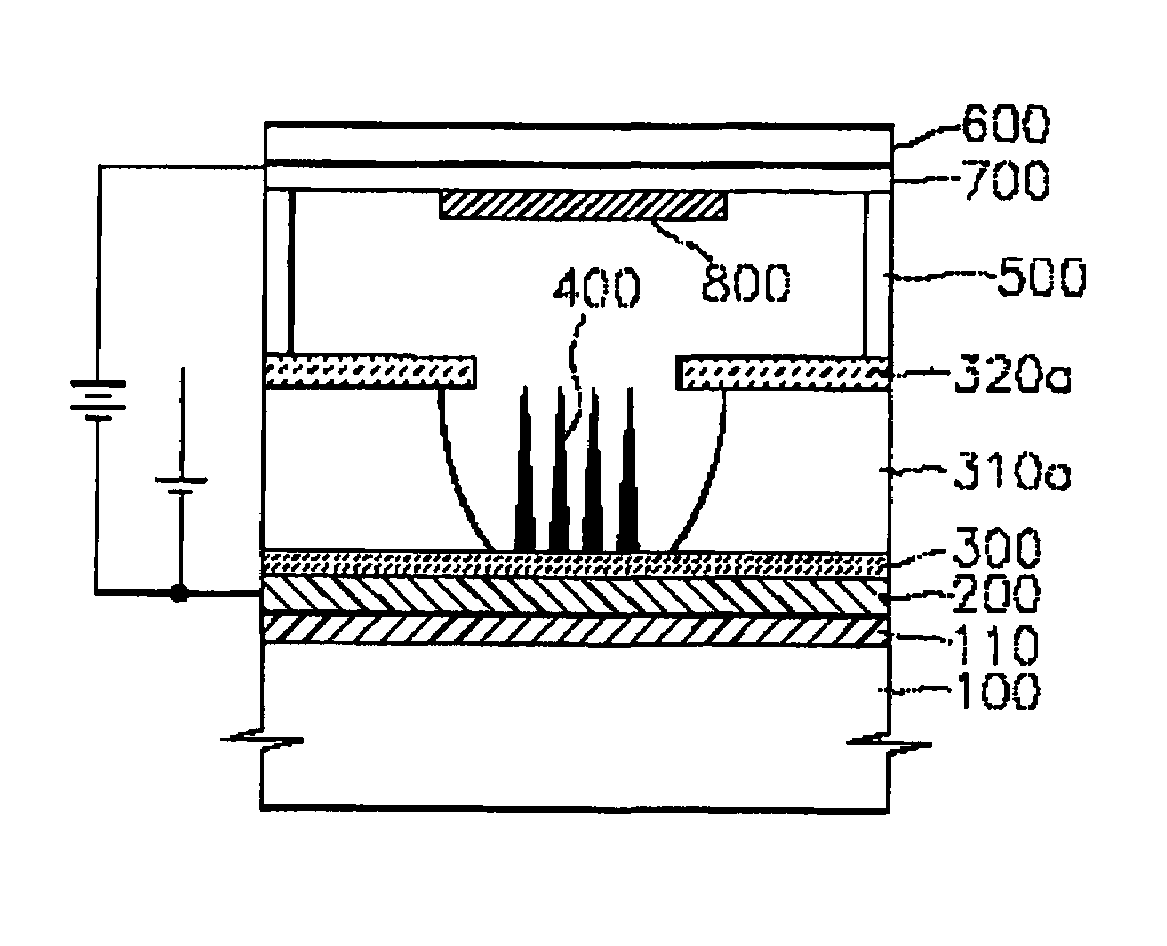

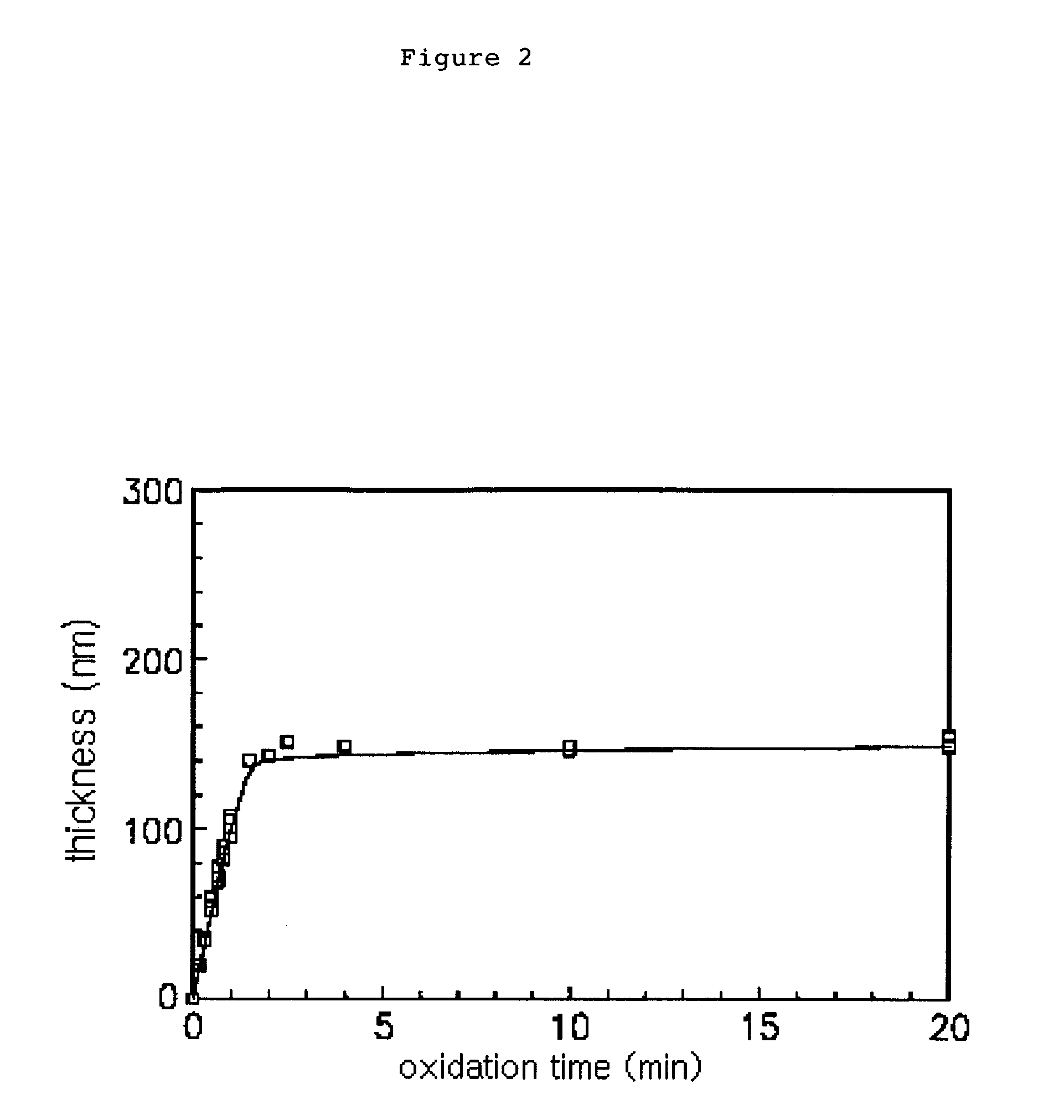

Low-temperature formation method for emitter tip including copper oxide nanowire or copper nanowire and display device or light source having emitter tip manufactured using the same

InactiveUS7041518B2Material nanotechnologyNanostructure manufactureCopper nanowiresPlasma processing

Owner:SEOUL NAT UNIV R&DB FOUND

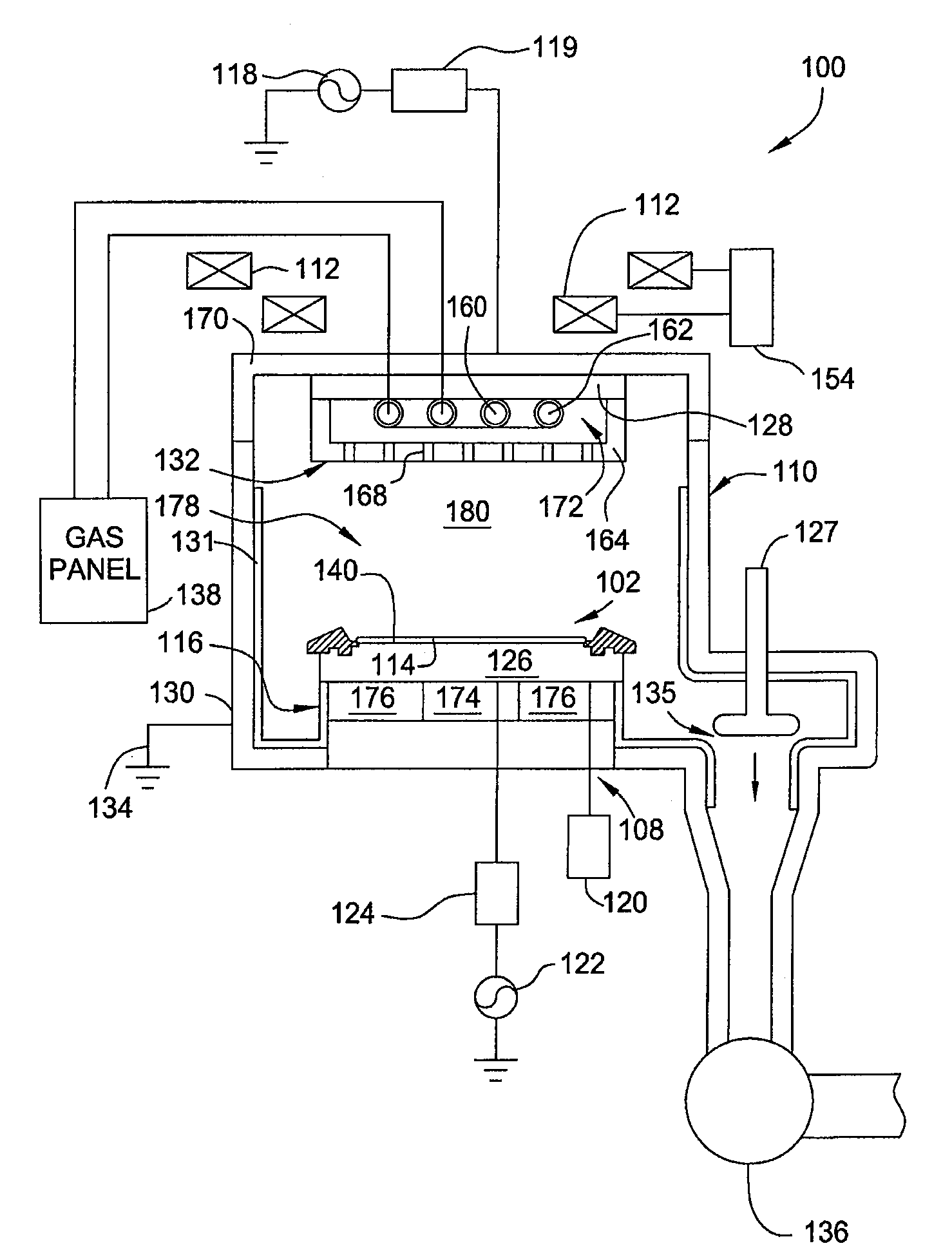

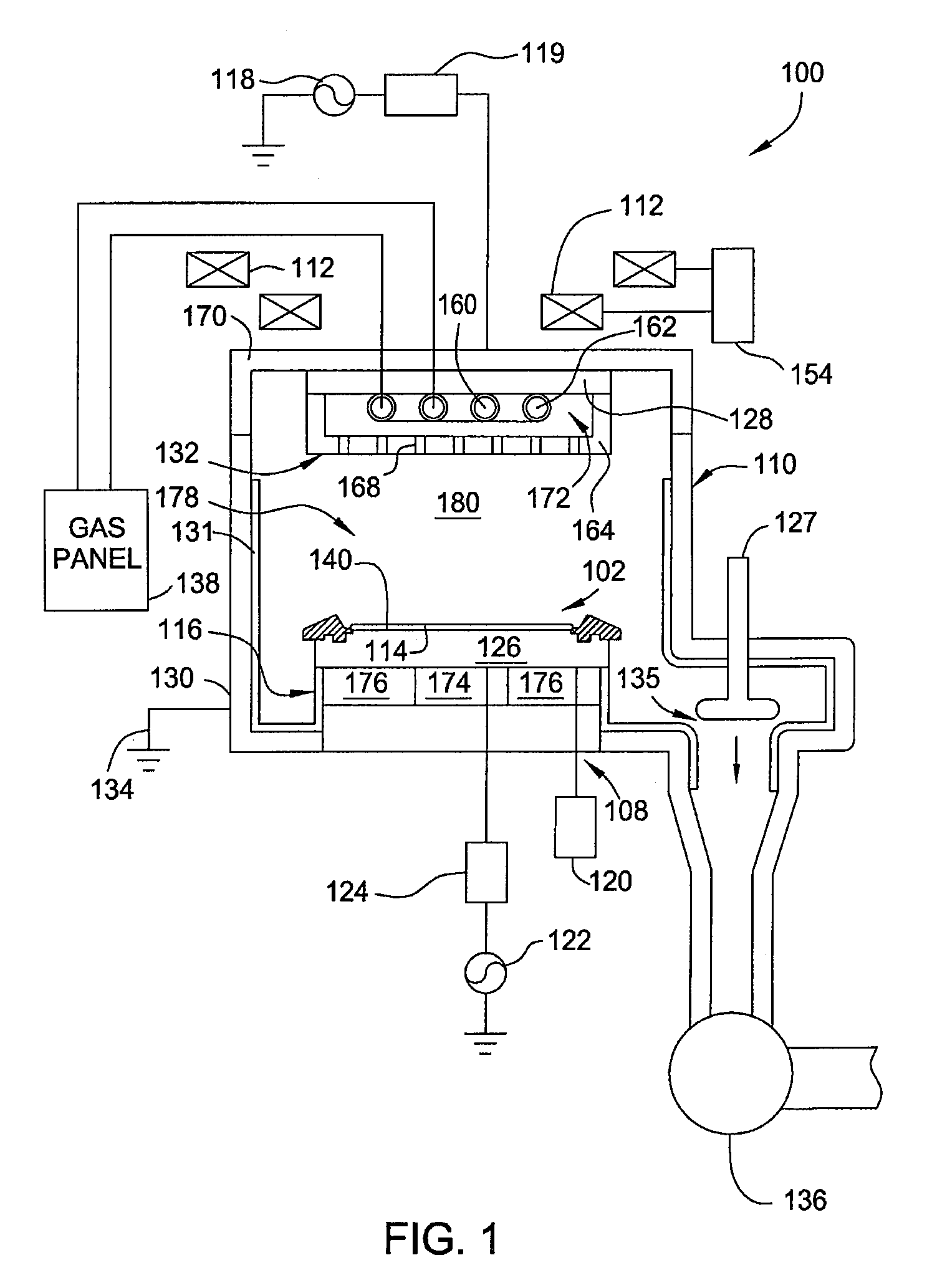

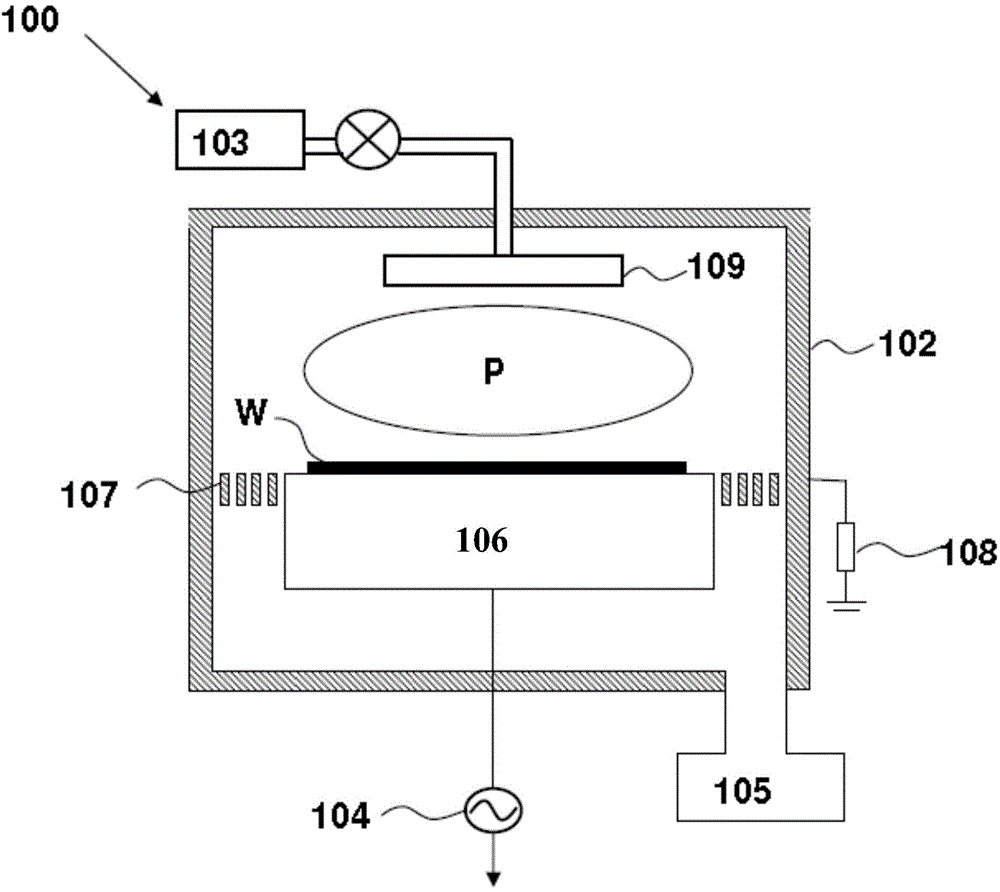

Computed Tomography using Intersecting Views of Plasma using Optical Emission Spectroscopy during Plasma Processing

ActiveUS20180252650A1Reconstruction from projectionEmission spectroscopyOptical emission spectrometryPlasma chamber

Described herein are technologies to facilitate computed tomographic techniques to help identifying chemical species during plasma processing of a substrate (e.g., semiconductor wafer) using optical emission spectroscopy (OES). More particularly, the technology described herein uses topographic techniques to spatially resolves emissions and absorptions in at least two-dimension space above the substrate during the plasma processing (e.g., etching) of the substrate. With some implementations utilize optical detectors positioned along multiple axes (e.g., two or more) to receive incident incoming optical spectra from the plasma chamber during the plasma processing (e.g., etching) of the substrate. Because of the multi-axes arrangement, the incident incoming optical spectra form an intersecting grid.

Owner:TOKYO ELECTRON LTD

Methods and apparatus for the optimization of photo resist etching in a plasma processing system

InactiveUS6949469B1Minimize the differenceSemiconductor/solid-state device manufacturingResistFluorine containing

In a plasma processing system, a method of minimizing the differences in an etch rate of a photo resist material in different regions of a substrate is disclosed. The method includes introducing the substrate having in sequential order thereon, an underlying layer and the photo-resist layer. The method also includes flowing the etchant gas mixture into a plasma reactor of the plasma processing system, the etchant gas mixture comprising a flow of a fluorine containing gas between about 0.1% and about 10% of the etchant gas mixture. The method further includes striking a plasma from the gas mixture; etching the photo-resist layer with the plasma; and, removing the substrate from the plasma reactor.

Owner:LAM RES CORP

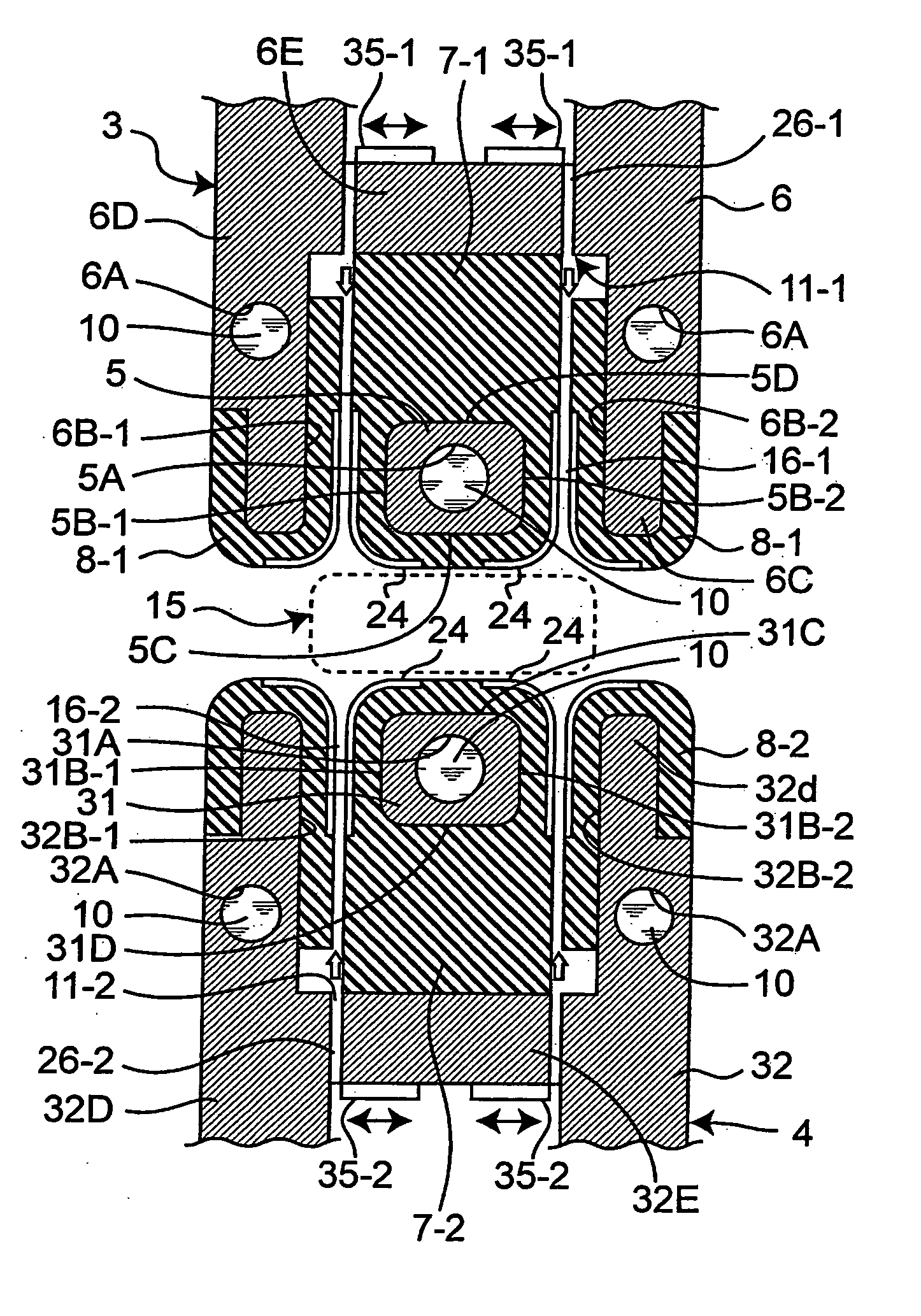

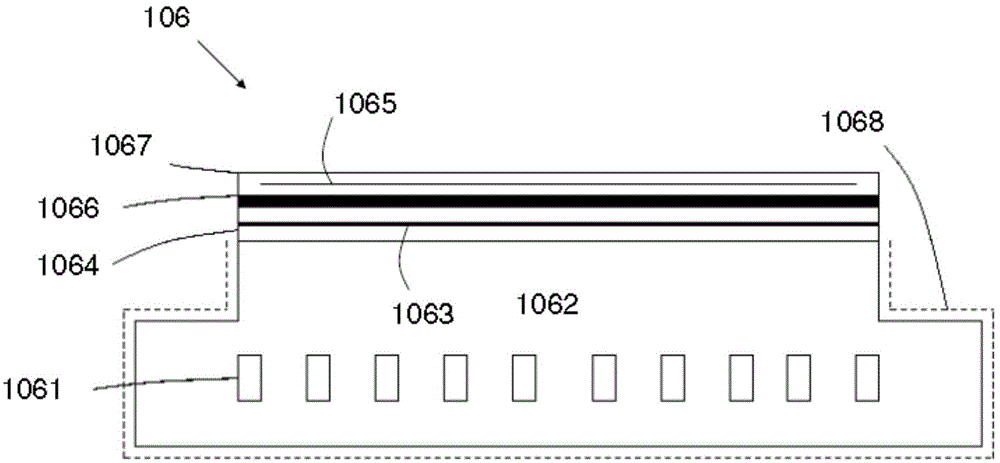

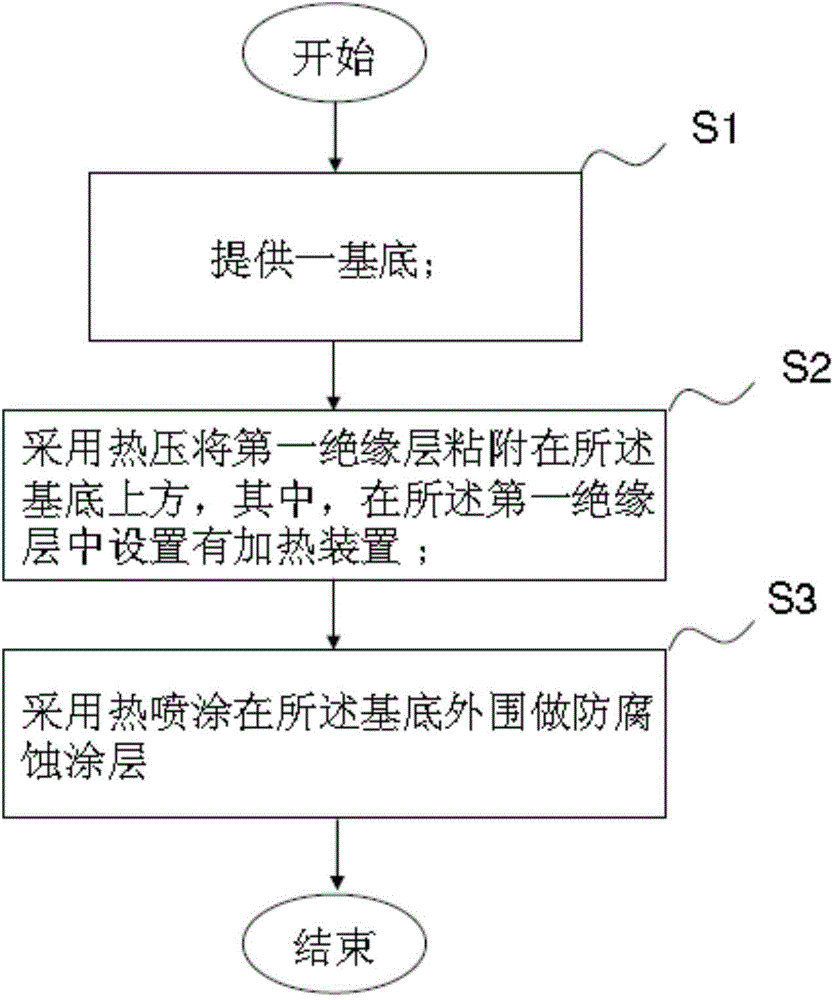

Plasma processing chamber and base manufacturing method therefor

ActiveCN104934279AAvoid pollutionVessels or leading-in conductors manufactureThermal sprayingTemperature difference

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

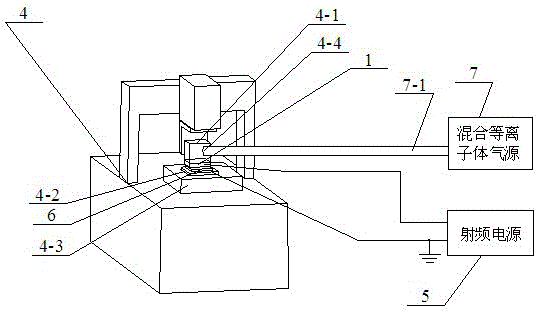

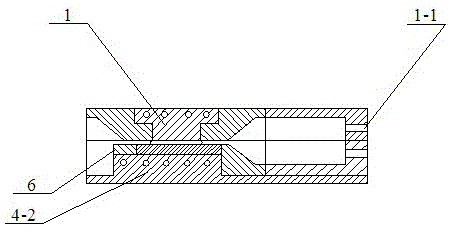

Atmospheric Plasma NC Machining Method of Freeform Surface Optical Parts

ActiveCN103273180BEfficient and precise shapingAvoid damagePlasma welding apparatusNumerical controlFree form

Owner:HARBIN INST OF TECH

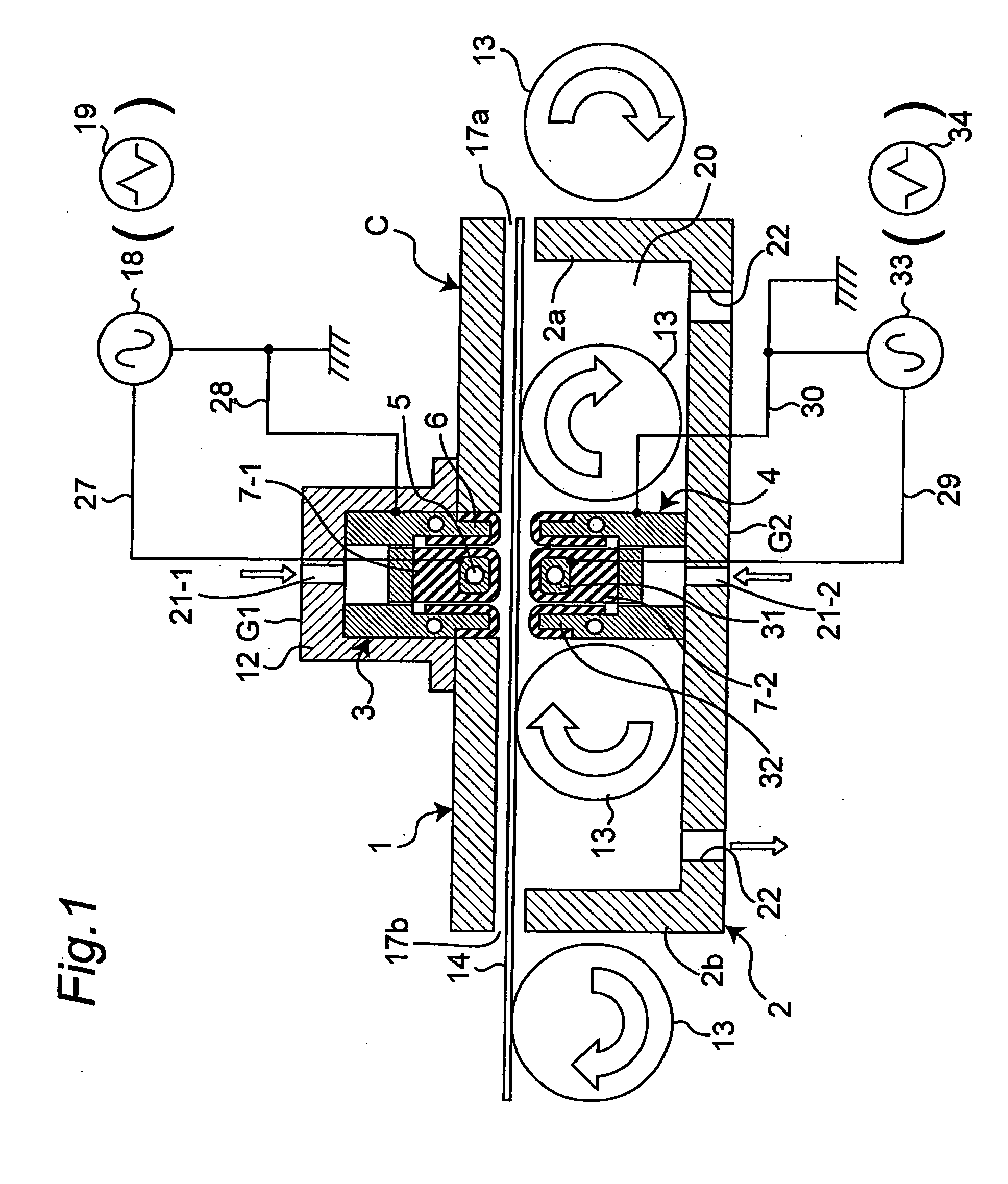

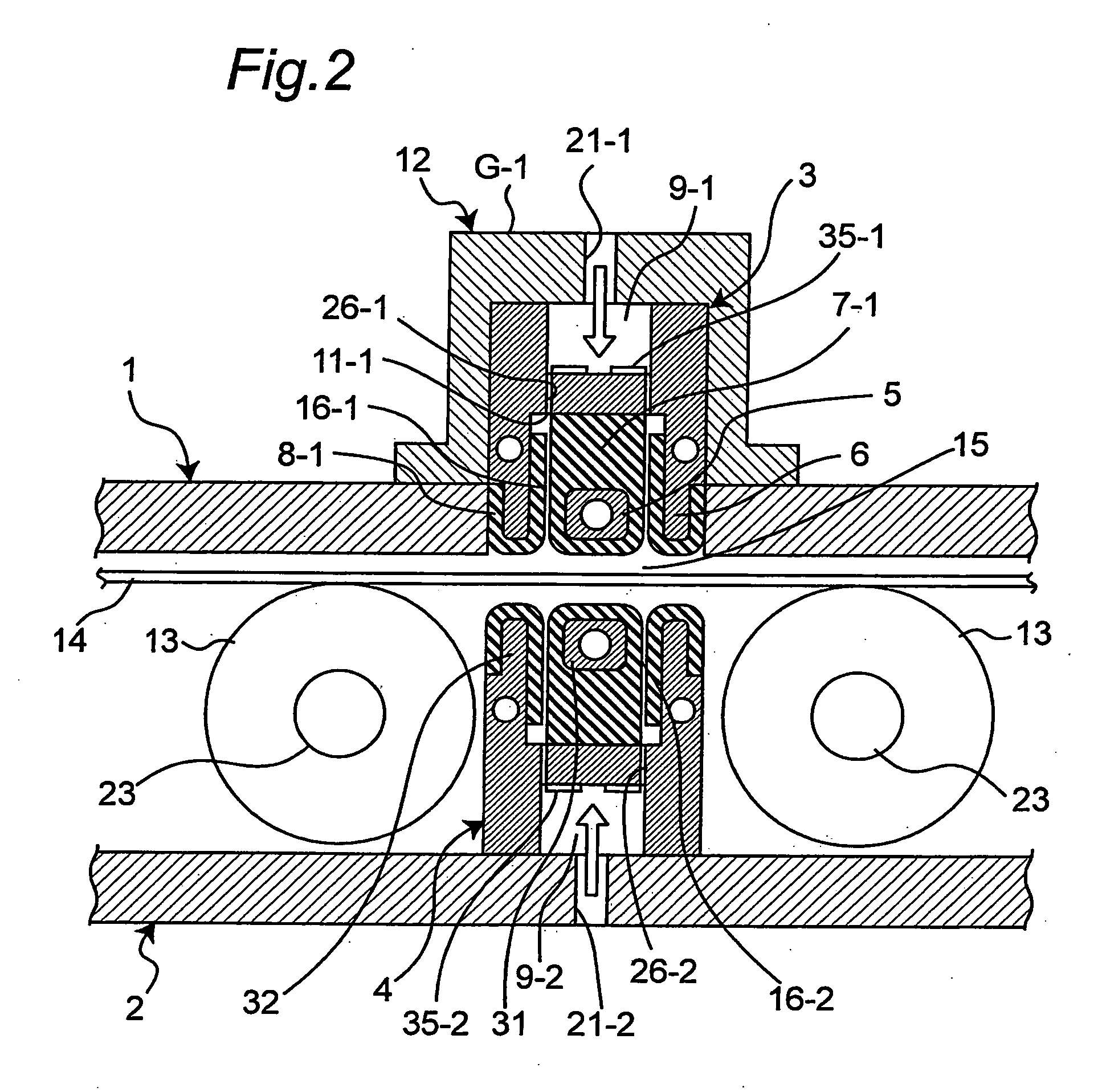

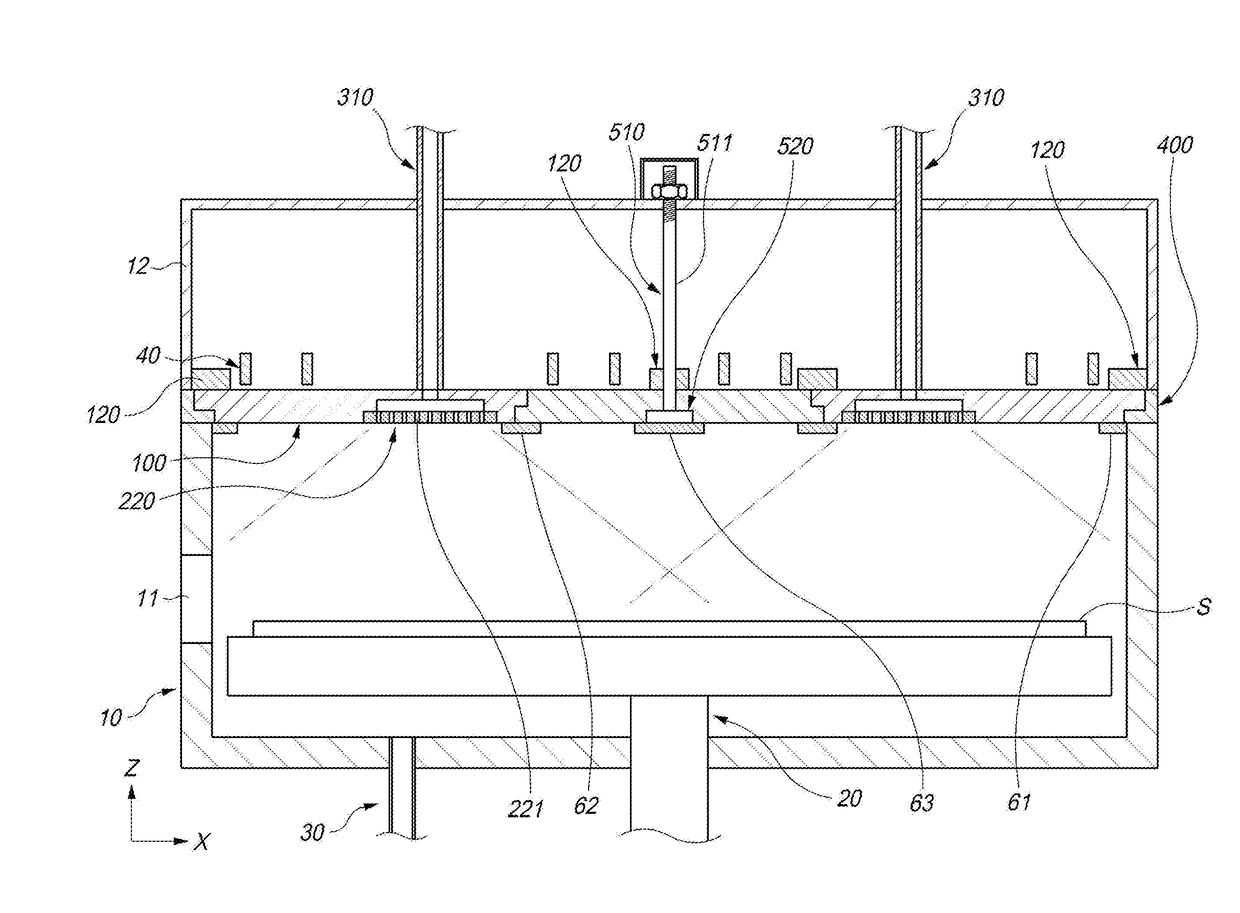

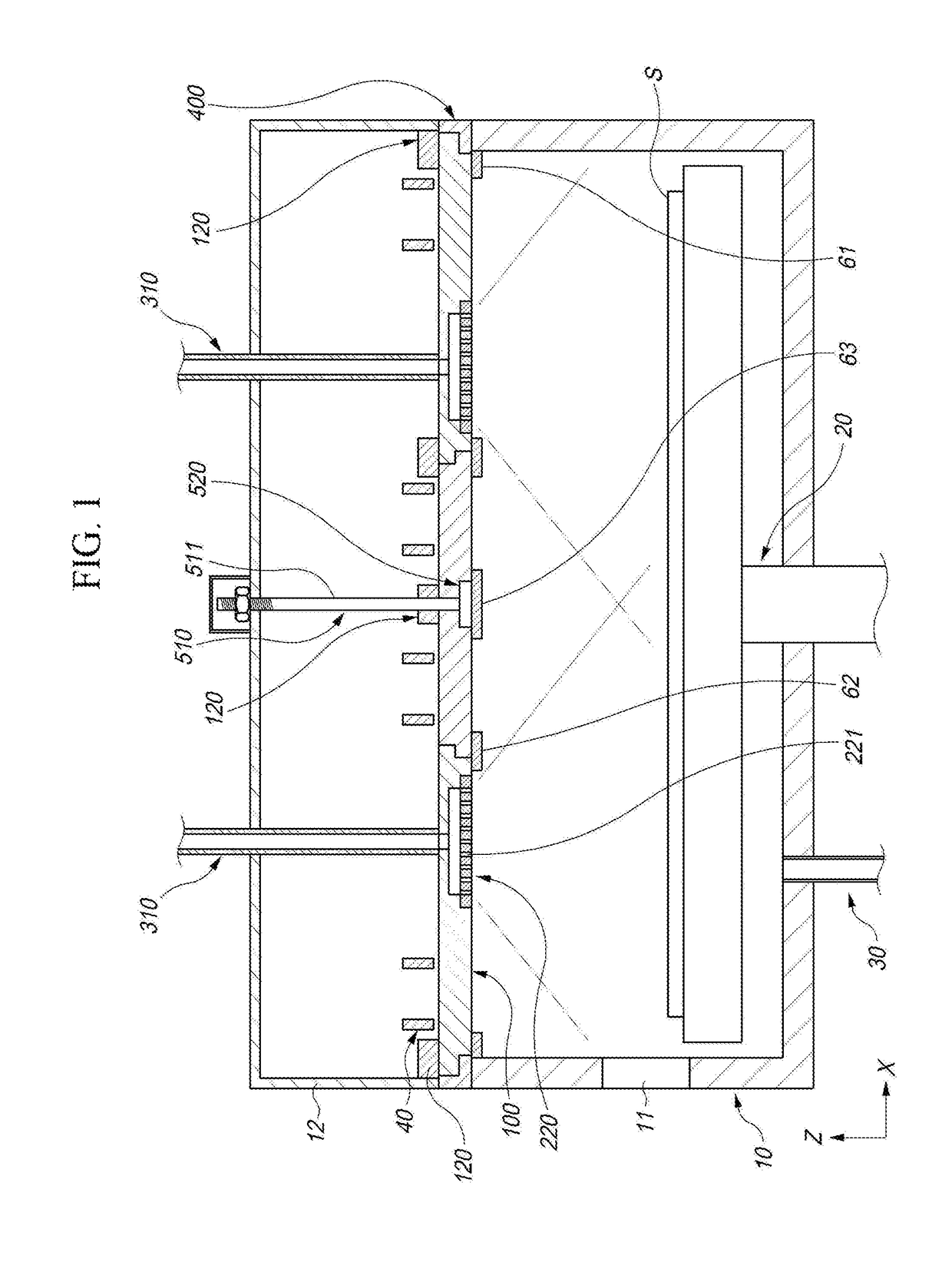

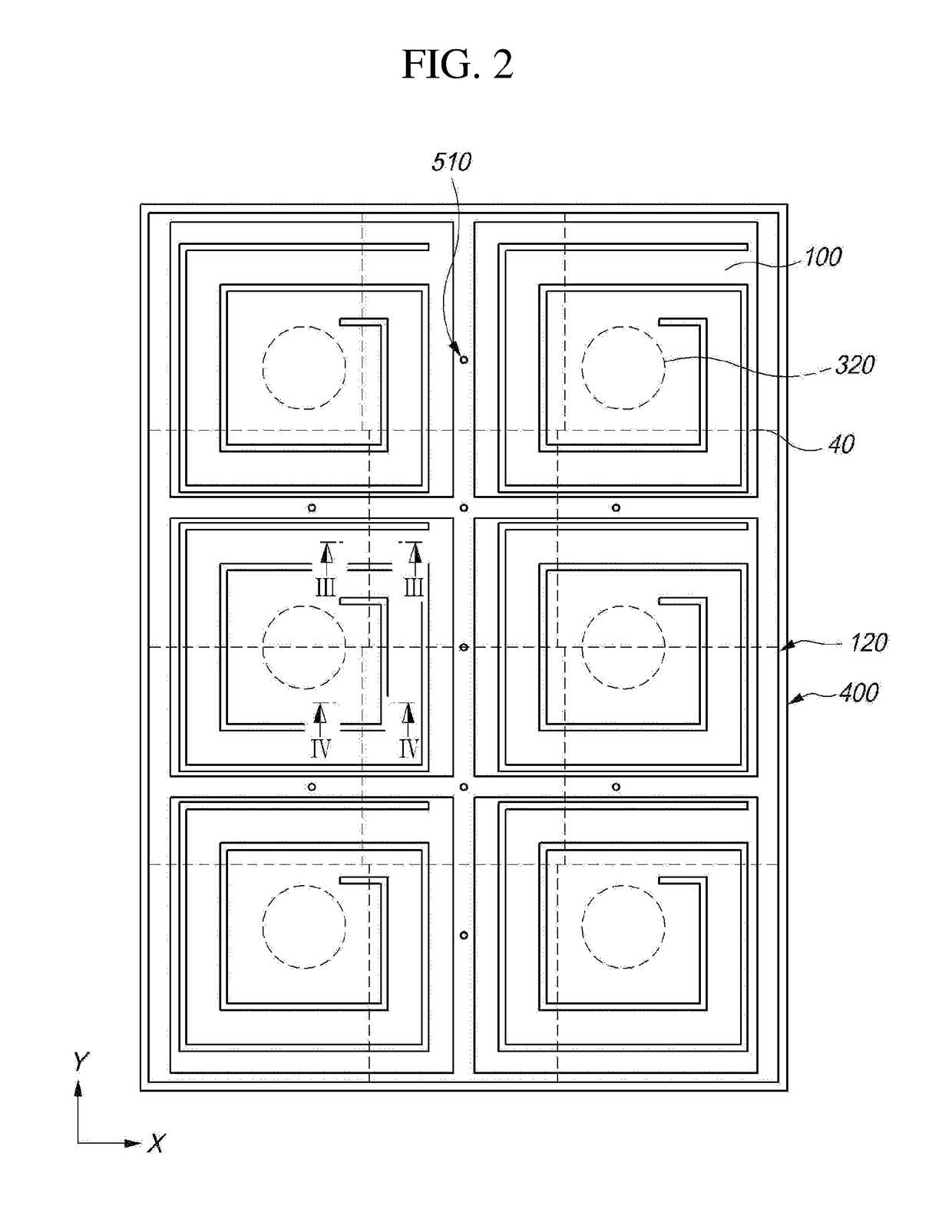

Dielectric window supporting structure for inductively coupled plasma processing apparatus

InactiveUS20170323770A1Use minimizedPower Loss MinimizationElectric discharge tubesElectric fieldPlasma processing

Owner:APPLIED MATERIALS INC

Lower electrode assembly and plasma processing device thereof

ActiveCN113035682ASmooth up and down movementHigh concentricityElectric discharge tubesFinal product manufactureEngineeringMechanical engineering

The invention relates to a lower electrode assembly and a plasma processing device thereof. The lower electrode assembly comprises: an electrostatic chuck comprising a bearing surface for bearing a to-be-processed substrate; a plurality of lifting pin holes penetrating through the electrostatic chuck, lifting pins respectively positioned in the lifting pin holes; porous sleeves located in the lifting pin holes and arranged around the lifting pins in a surrounding mode, wherein gaps are formed between the porous sleeves and the lifting pins, a plurality of pores are formed in the porous sleeves, and the pores are communicated with the gaps; an air floatation channel positioned in the electrostatic chuck and communicated with pores in the porous sleeves; and a gas conveying device used for conveying gas into the air floatation channel, so that a gas film is formed between the porous sleeve and the lifting pin. According to the invention, gas is conveyed into the air floatation channel through the gas conveying device, so that the gas film is formed between the porous sleeve and the lifting pin, friction between the lifting pin and the lifting pin hole can be avoided, the gap between the lifting pin and the lifting pin hole can be shrunk to be very small, and very high potential and energy can be resisted without generating electric arcs.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap