Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16 results about "Gallium nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gallium nitride (GaN) is a binary III/V direct bandgap semiconductor commonly used in light-emitting diodes since the 1990s. The compound is a very hard material that has a Wurtzite crystal structure. Its wide band gap of 3.4 eV affords it special properties for applications in optoelectronic, high-power and high-frequency devices. For example, GaN is the substrate which makes violet (405 nm) laser diodes possible, without use of nonlinear optical frequency-doubling.

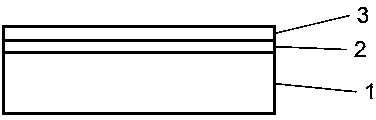

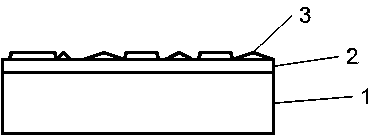

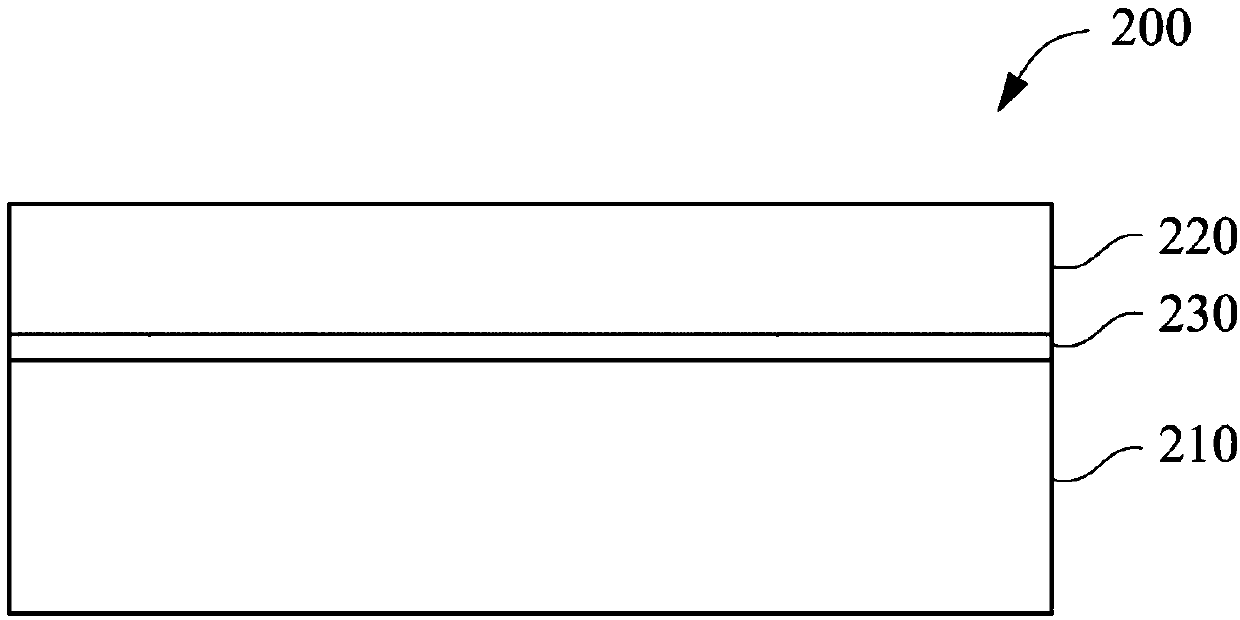

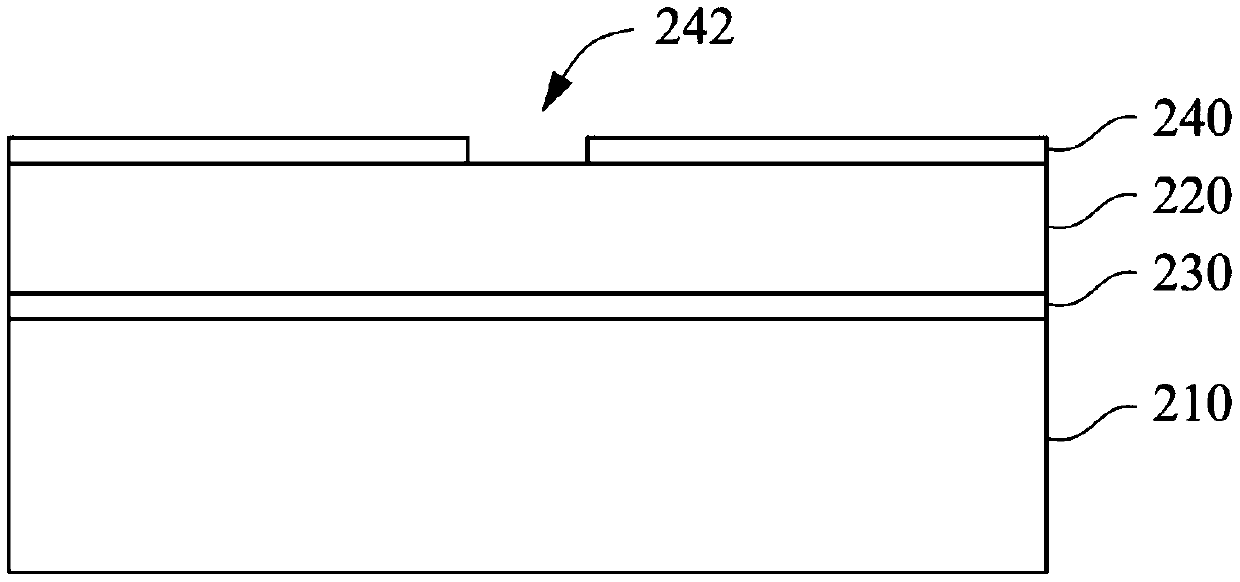

Method for preparing self-supporting mono-crystal gallium nitride substrate

InactiveCN101685768AUniform stress reliefImprove yieldLaser detailsSemiconductor/solid-state device manufacturingLaser lightStress relief

Owner:PEKING UNIV

Method for preparing light emitting element

Owner:ANHUI SANAN OPTOELECTRONICS CO LTD

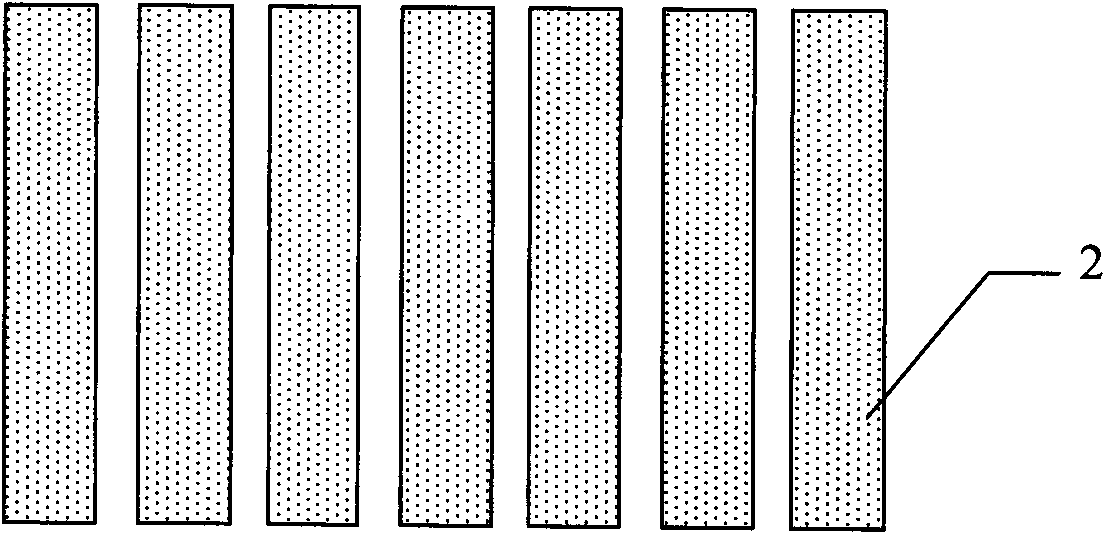

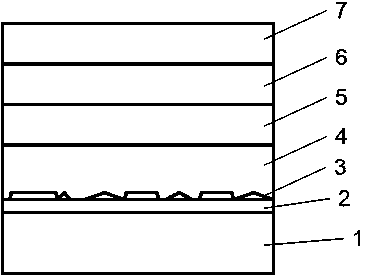

Gallium nitride semiconductor film, gallium nitride-based light emitting dioxide and preparation method therefor

ActiveCN106282917AUniform thicknessHigh precisionVacuum evaporation coatingSputtering coatingChemical reactionNitrogen

Owner:北京埃德万斯离子束技术研究所股份有限公司

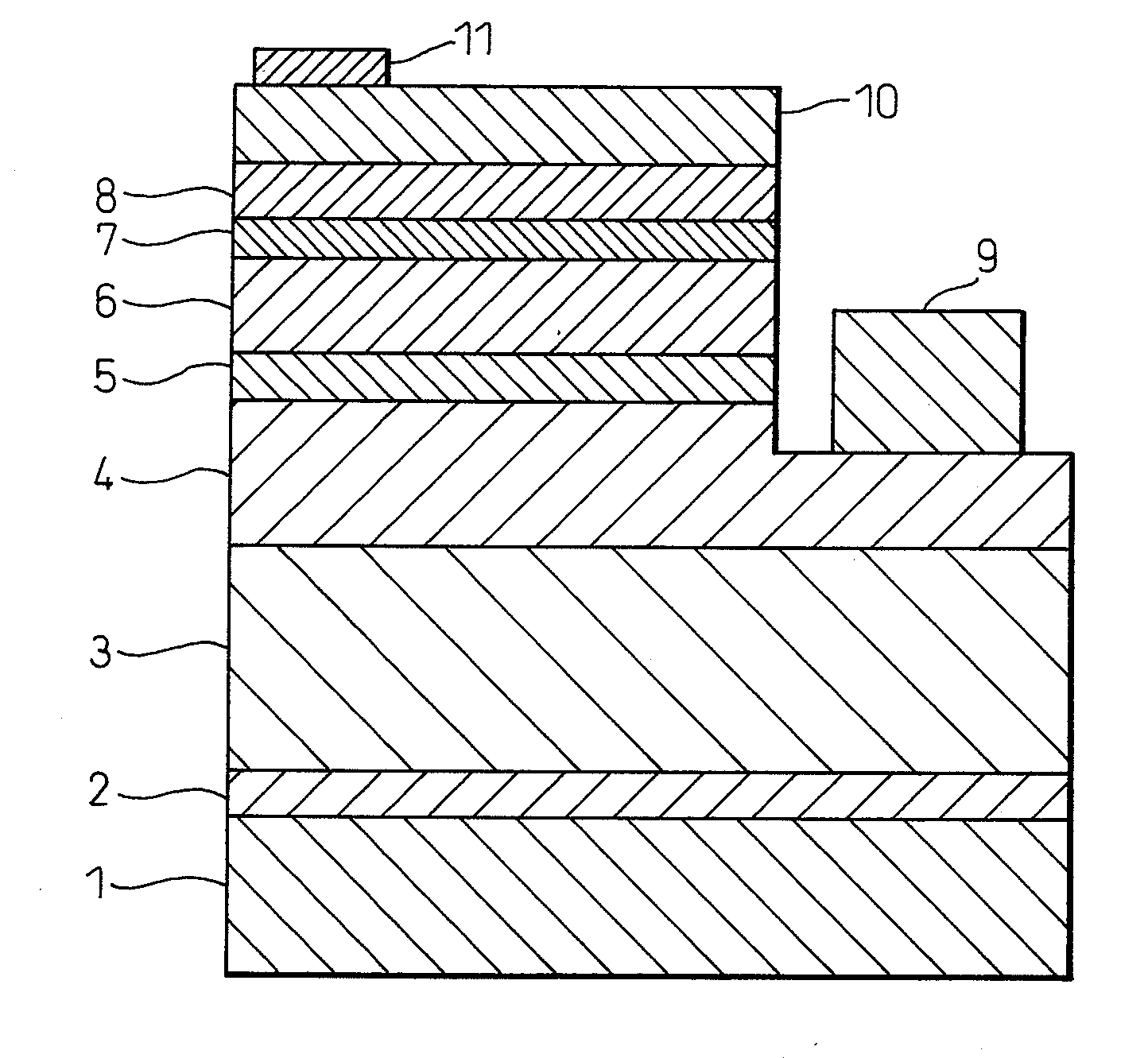

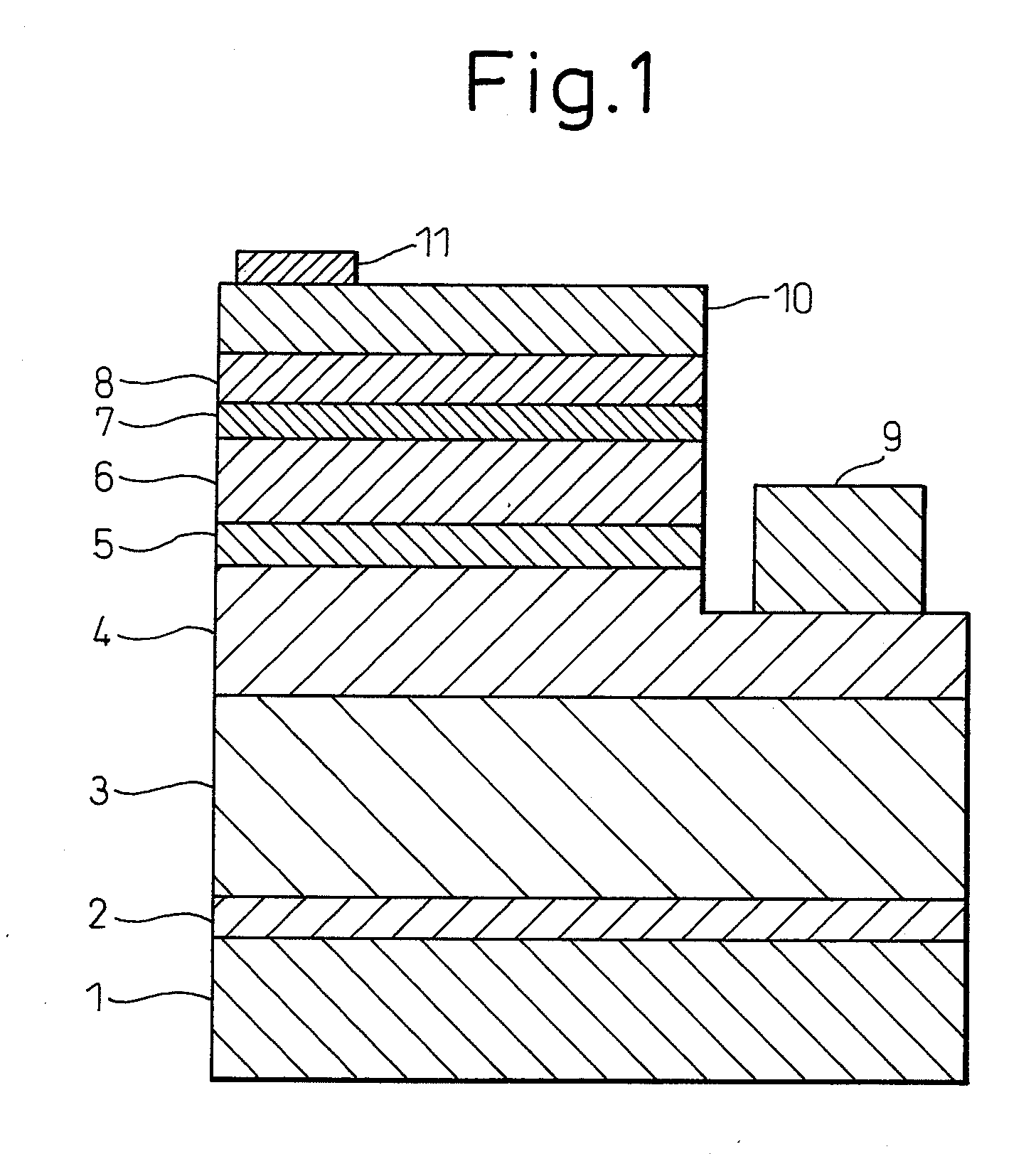

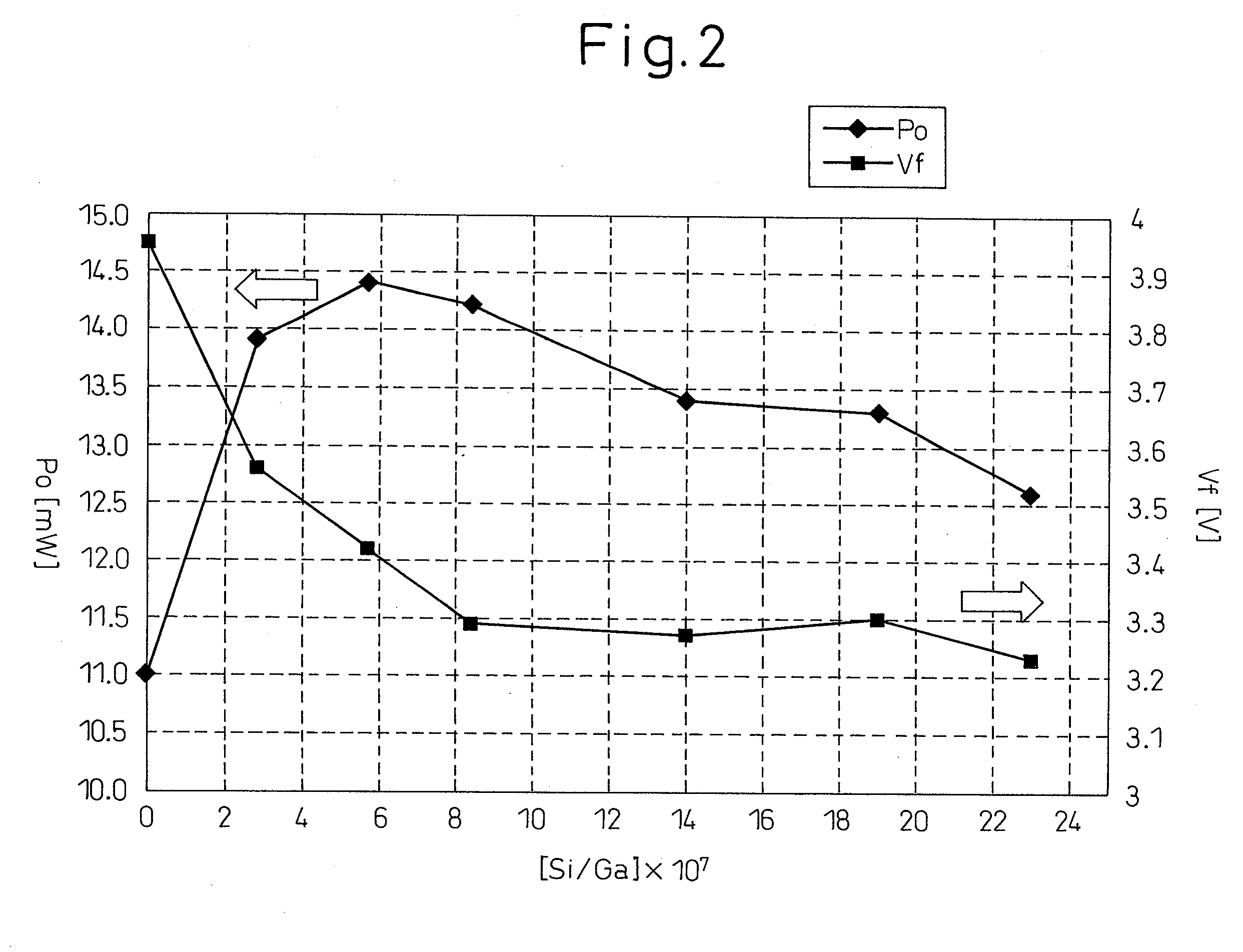

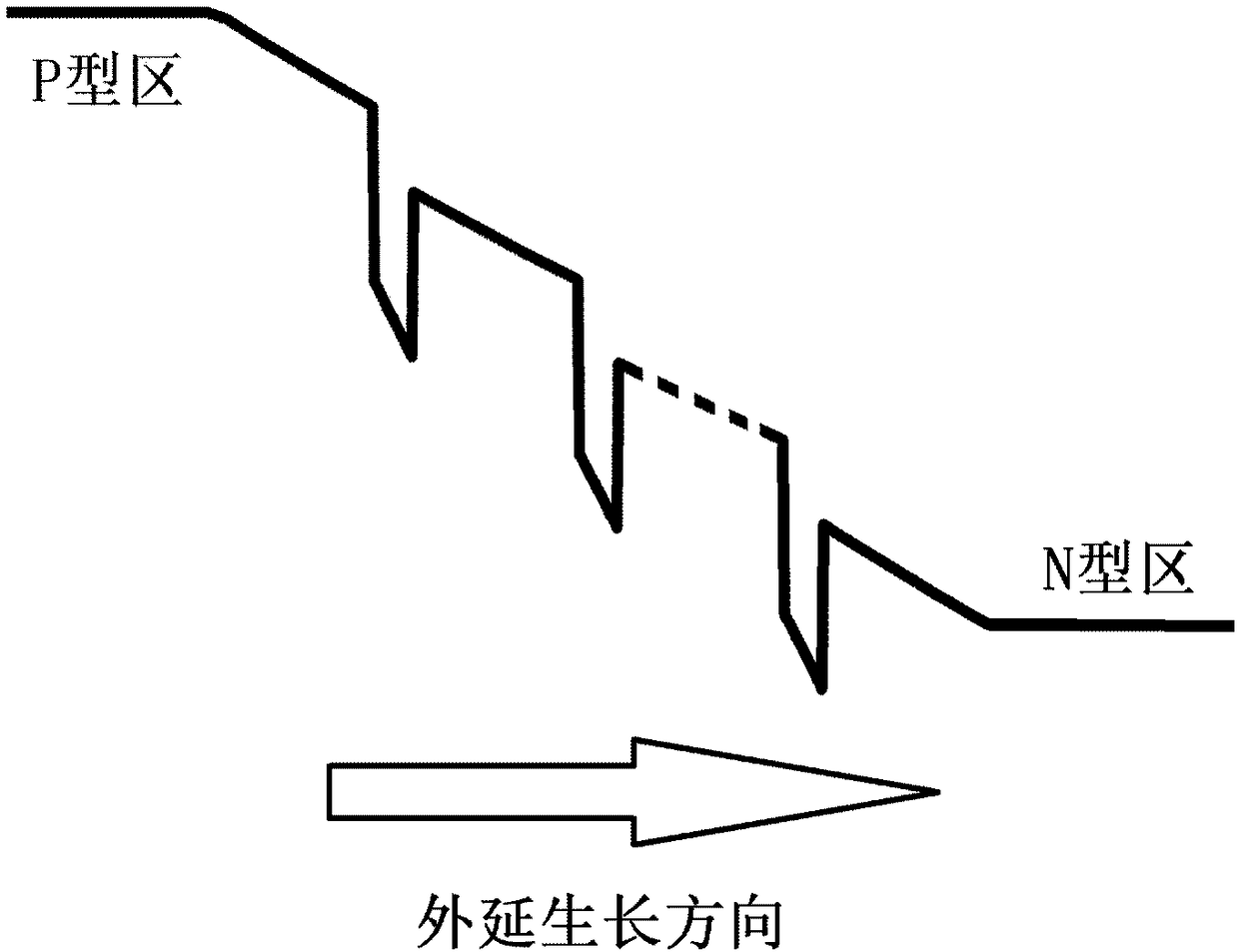

Process for production of gallium nitride-based compound semiconductor light emitting device

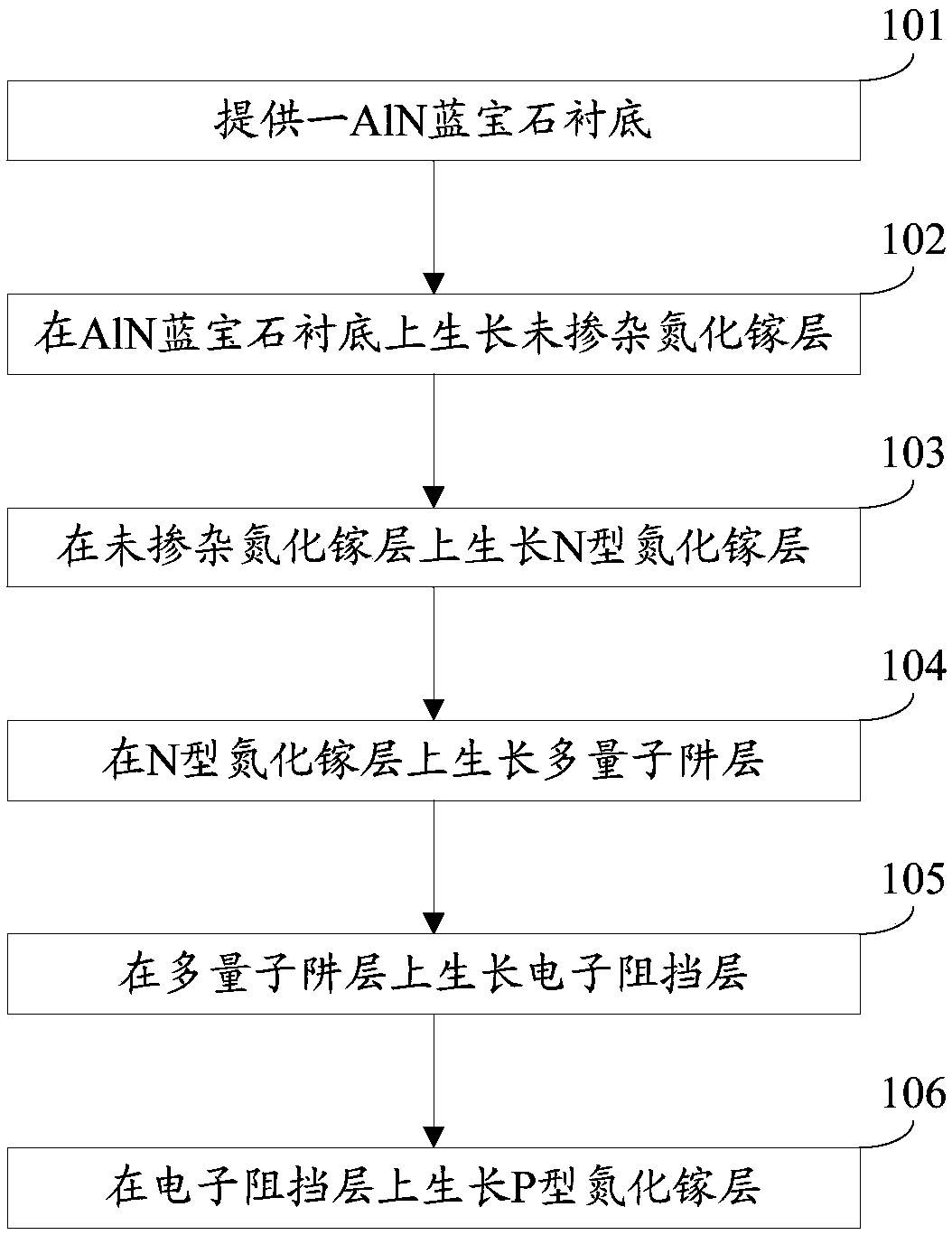

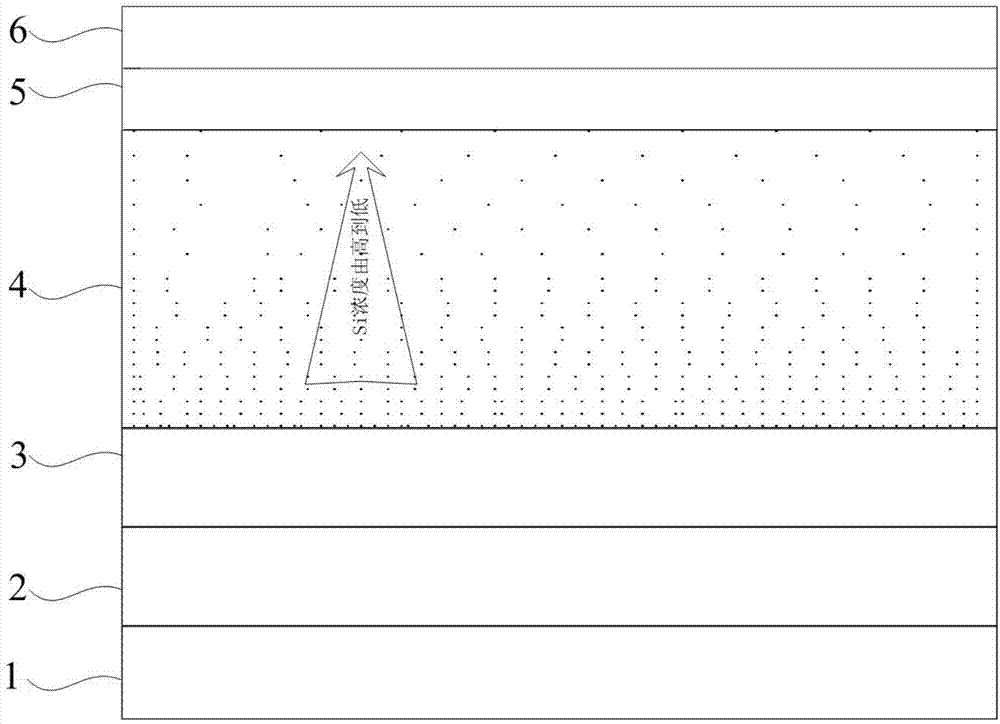

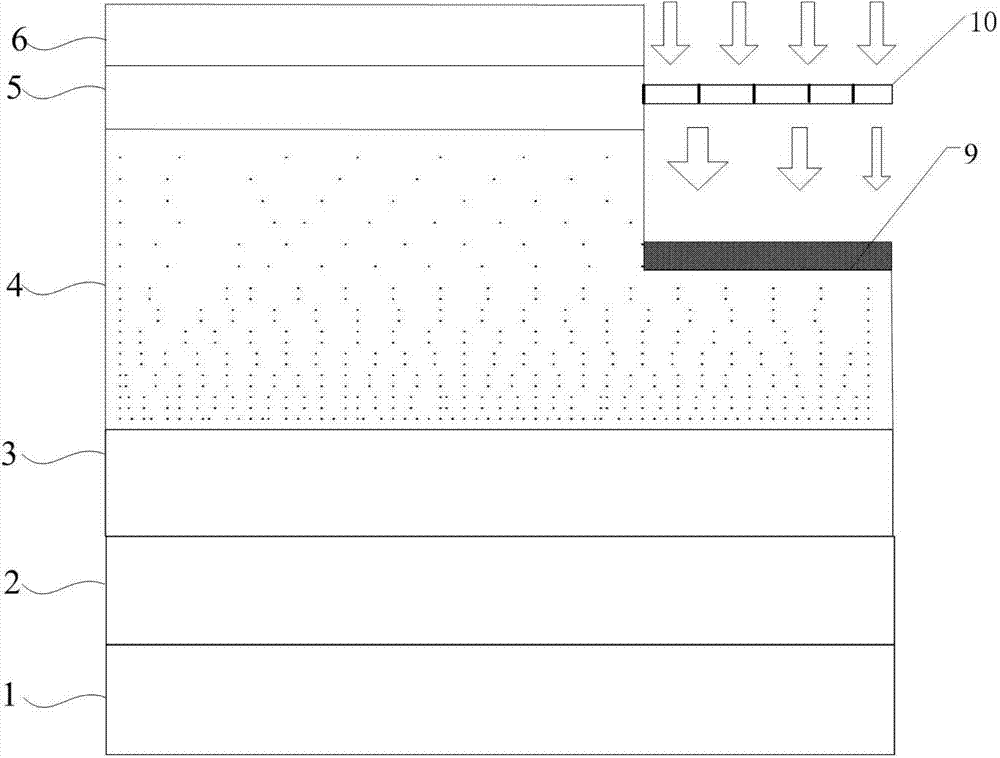

InactiveUS20100006874A1High luminous intensityReduce the driving voltageSemiconductor/solid-state device manufacturingSemiconductor devicesDopantGallium nitride

Owner:SHOWA DENKO KK

Preparation method of light emitting diode epitaxial wafer

Owner:HC SEMITEK SUZHOU

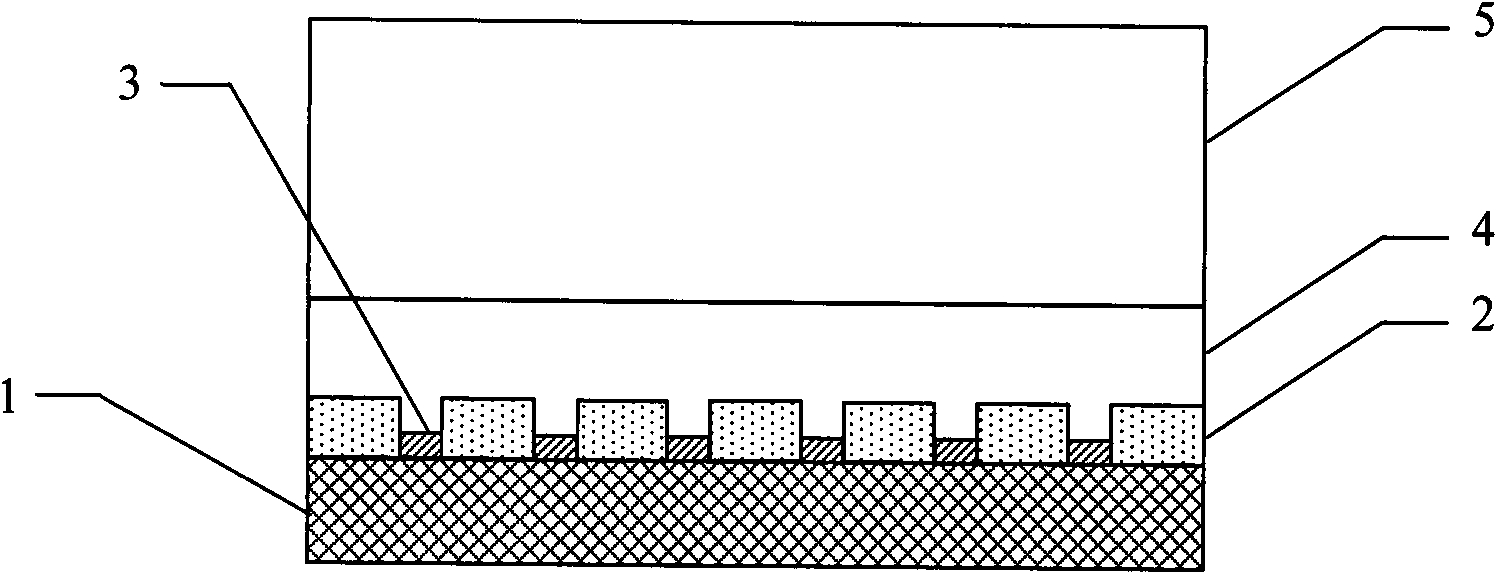

Extension structure of light emitting diode (LED)

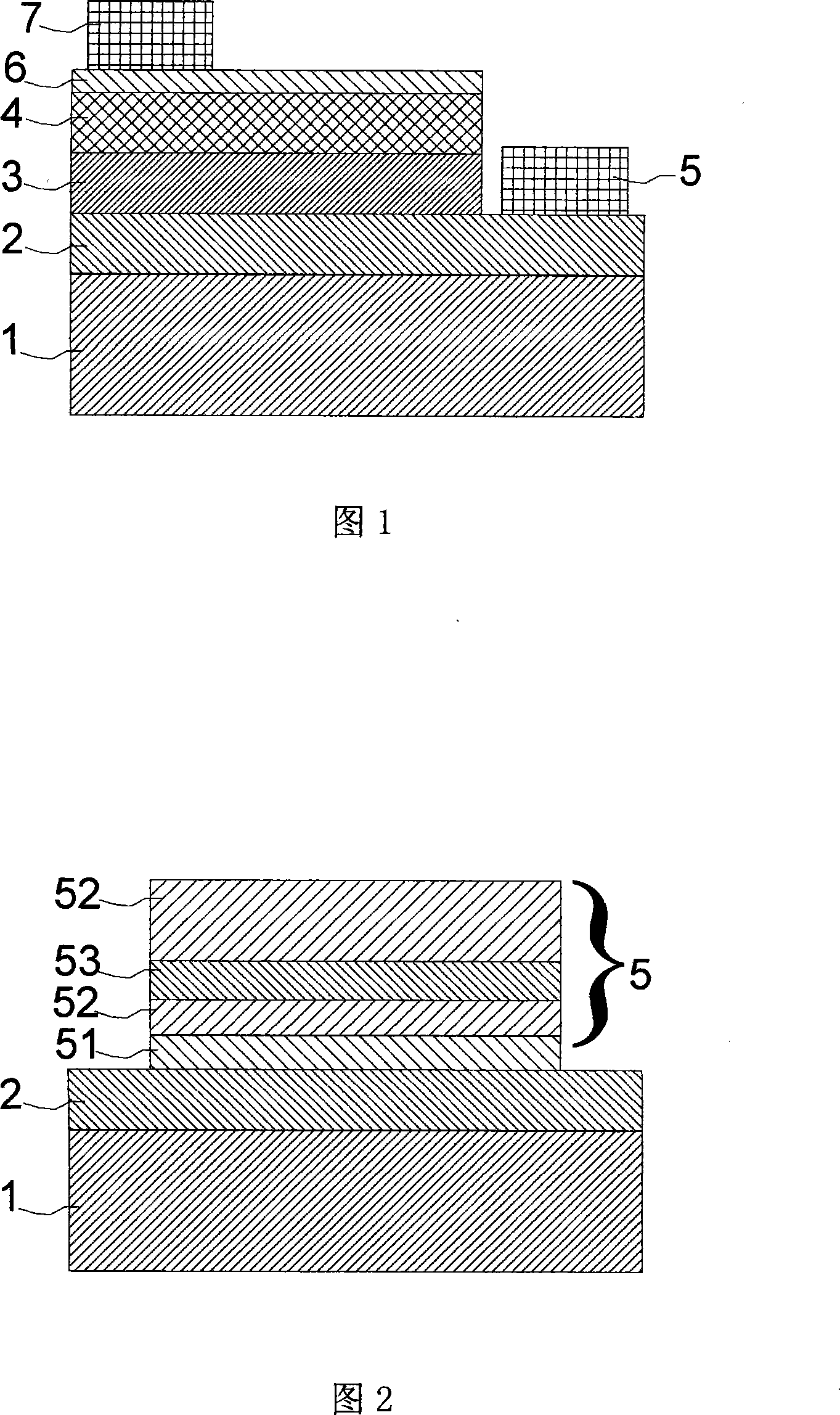

InactiveCN104332538ASimple structureImprove luminous efficiencySemiconductor devicesState of artQuantum well

Owner:AQUALITE CO LTD

Method for manufacturing gallium nitride base semiconductor photoelectric device

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

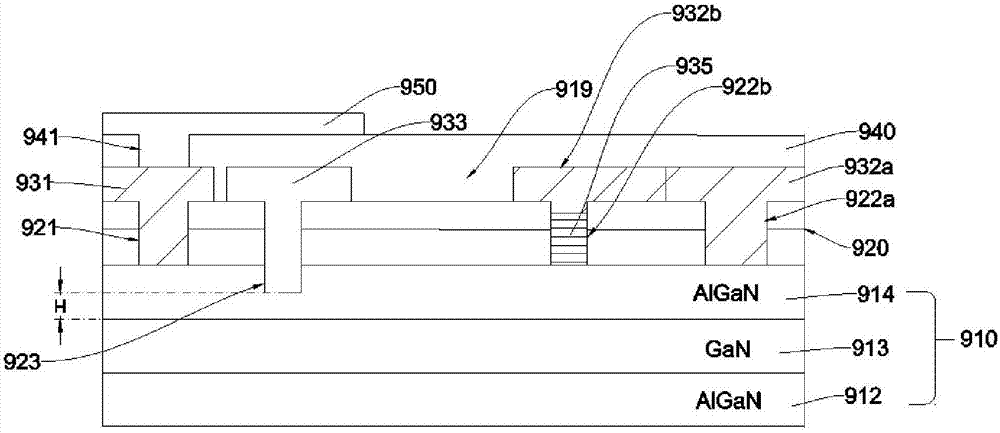

GaN semiconductor device and fabrication method thereof

InactiveCN107316891ASemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideAluminium

Owner:SHENZHEN JING XIANG TECH CO LTD

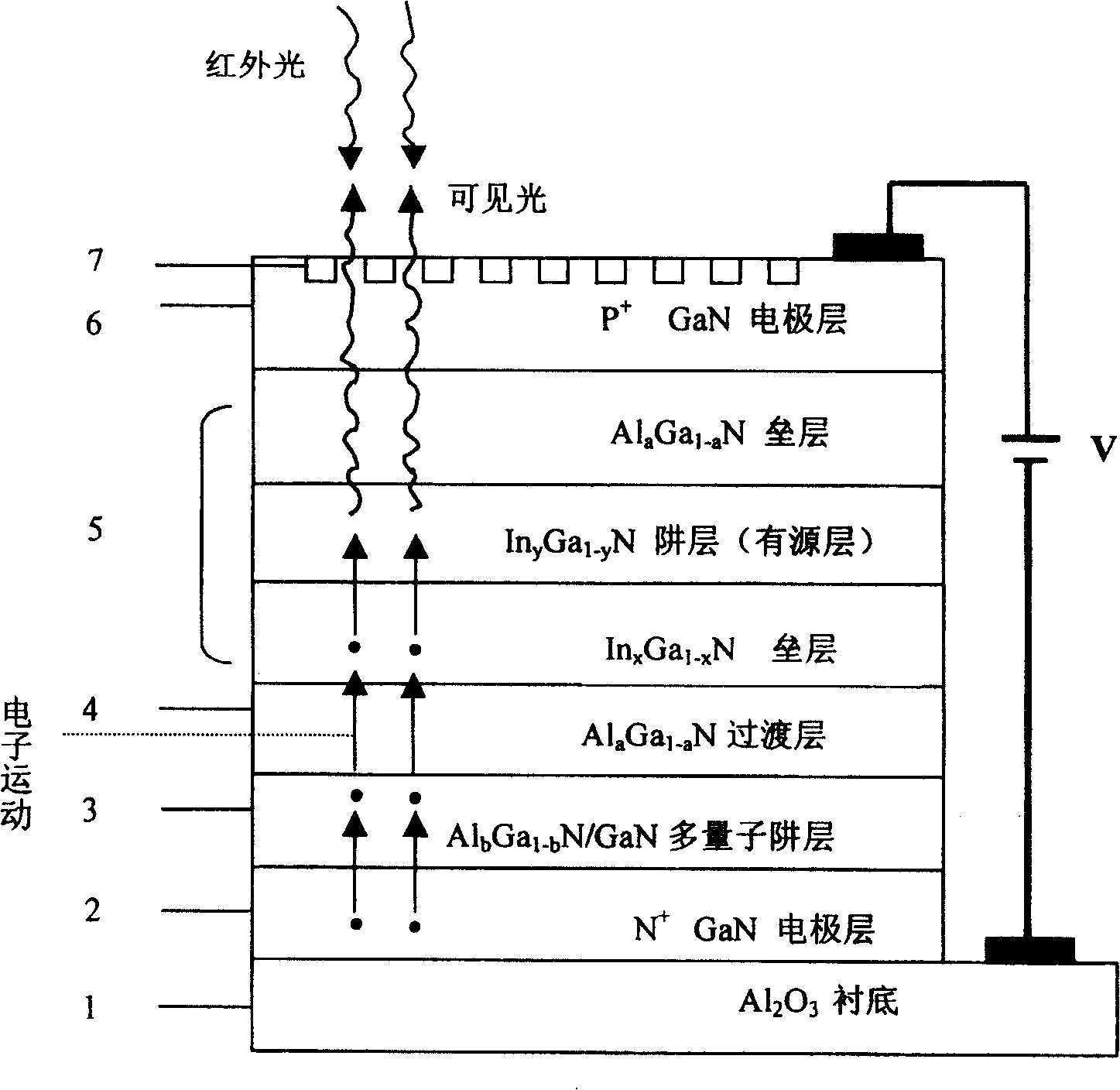

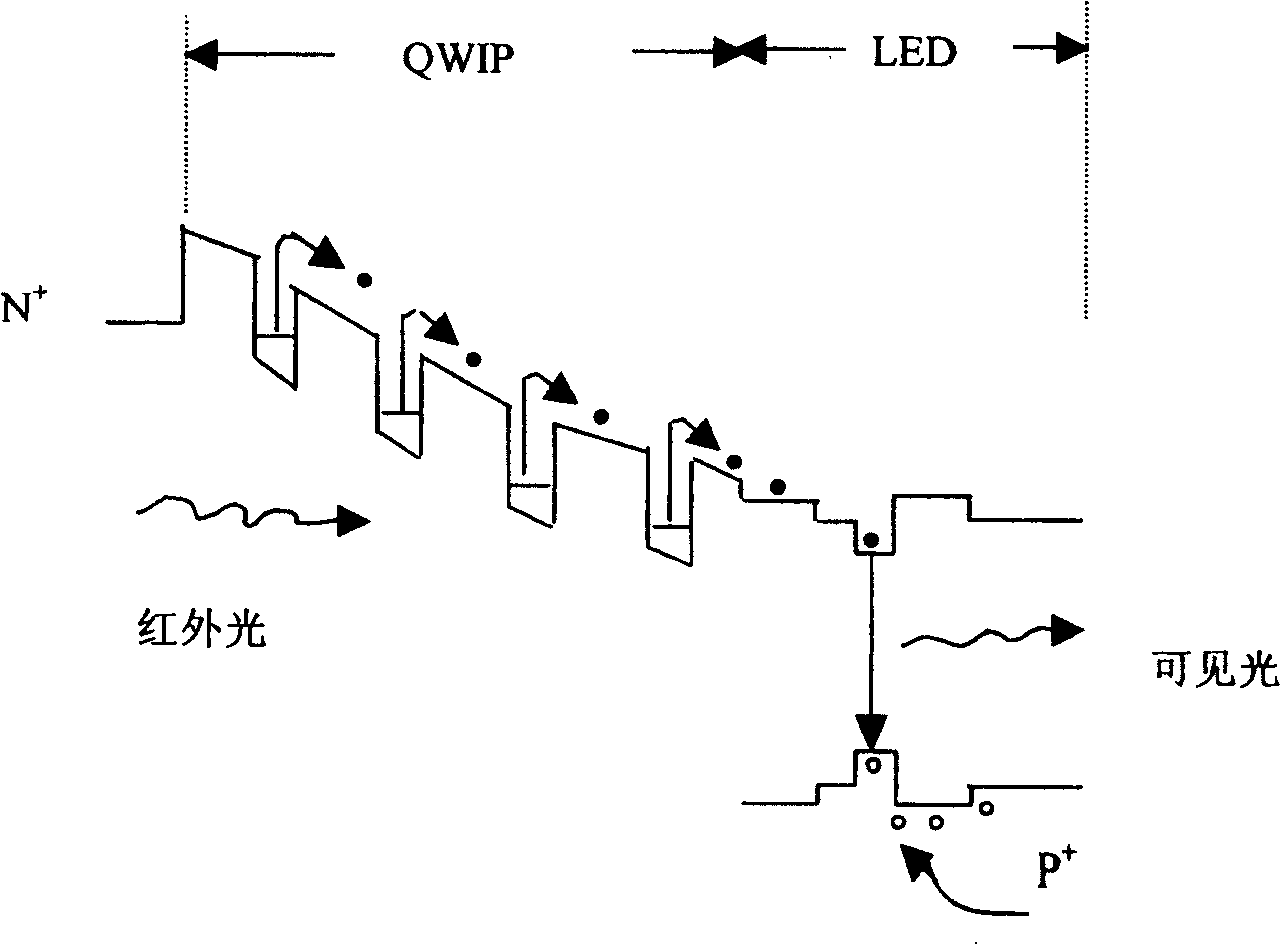

Gallium nitride-base infrared visable wavelength conversion detector

InactiveCN100424897CProperly adjust componentsAppropriate componentsSemiconductor devicesGallium nitrideLight signal

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI +1

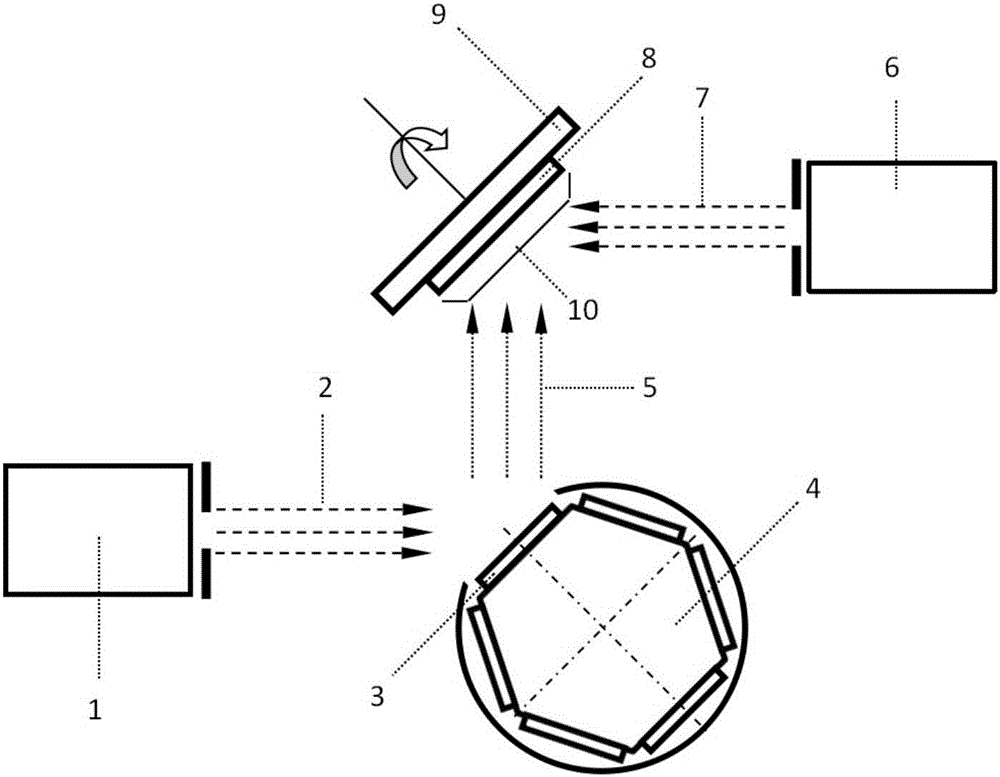

GaN single crystal manufacturing device

ActiveCN113026107AImprove intuitivenessImprove reaction efficiencyPolycrystalline material growthFrom chemically reactive gasesThermal dilatationSingle crystal

The invention relates to the technical field of GaN single crystal preparation, and discloses a GaN single crystal manufacturing device which comprises a quartz reaction pipe, a connecting flange and a separating flange. A high-temperature electric furnace matched with the quartz reaction pipe is annularly arranged on the outer side of the quartz reaction pipe. A quartz guide inlet pipe, a quartz guide gas pipe, a quartz inner container, a quartz outer container, a quartz Ga groove, a quartz spiral reaction pipe, a quartz flange connecting pipe, a quartz stepped outer frame, an inner spray pipe and a middle spray pipe are arranged in the quartz reaction pipe; and a flange plate of the quartz inner container is clamped between two flange plates of the connecting flange. According to the manufacturing device of the GaN single crystal, an HVPE method and an MOCVD method are used in the same device to control the growth of the GaN single crystal, so that the situation that a gallium nitride crystal is cracked when the gallium nitride crystal grows thick or is cooled due to stress caused by a lattice constant and a thermal expansion number can be effectively avoided, and the grown gallium nitride is easy to strip from sapphire when being cooled. The manufacturing and production cost of the product is effectively reduced.

Owner:WUXI WUYUE SEMICON CO LTD

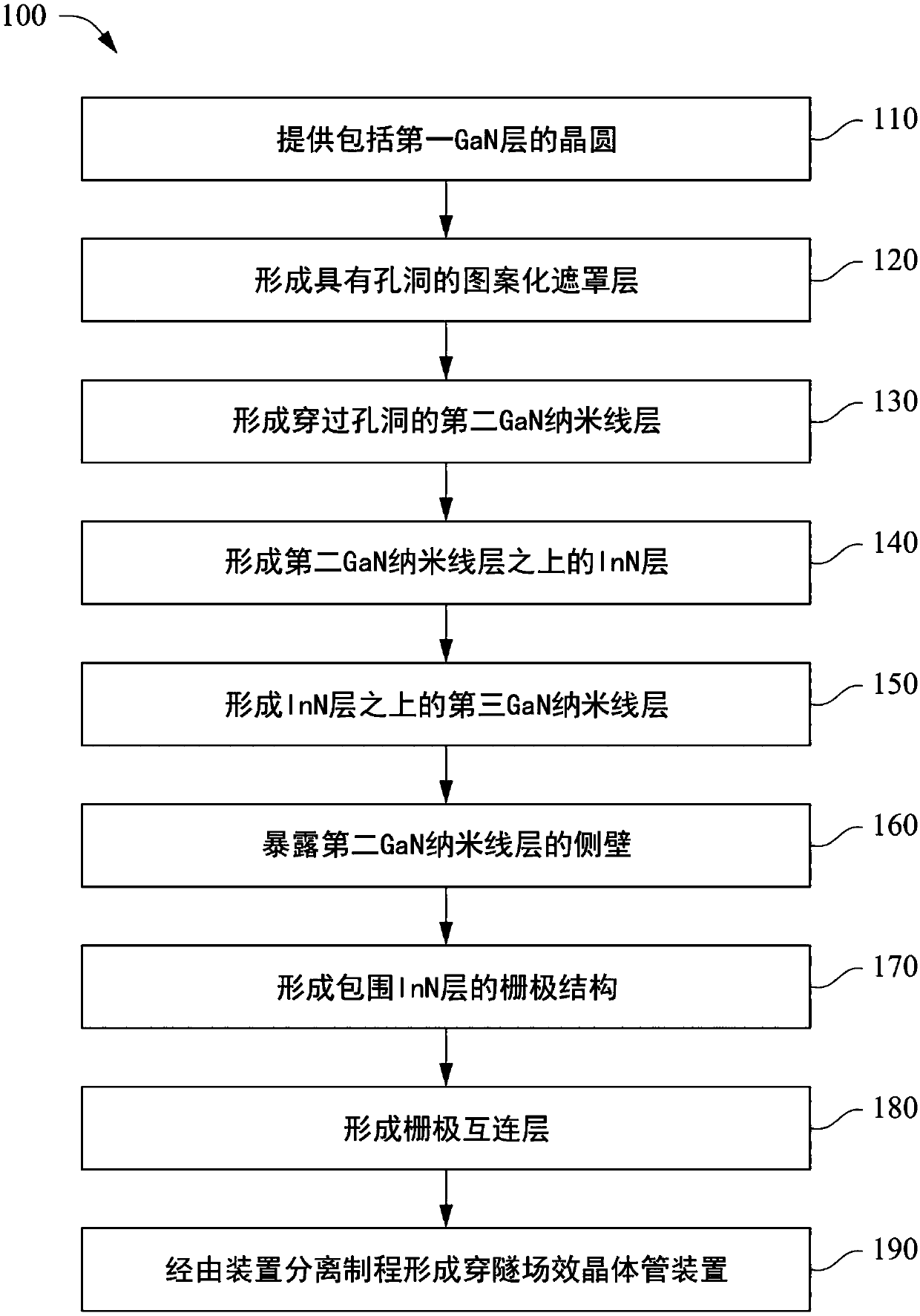

Steep sloped vertical tunnel field-effect transistor

InactiveCN110504303ANanoinformaticsSemiconductor/solid-state device manufacturingGallium nitrideNanometre

Owner:TAIWAN SEMICON MFG CO LTD

Surface passivation process of semiconductor material

PendingCN114005762AImprove insulation performanceImprove corrosion resistanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor materialsSemiconductor chip

Owner:徐州领测半导体科技有限公司

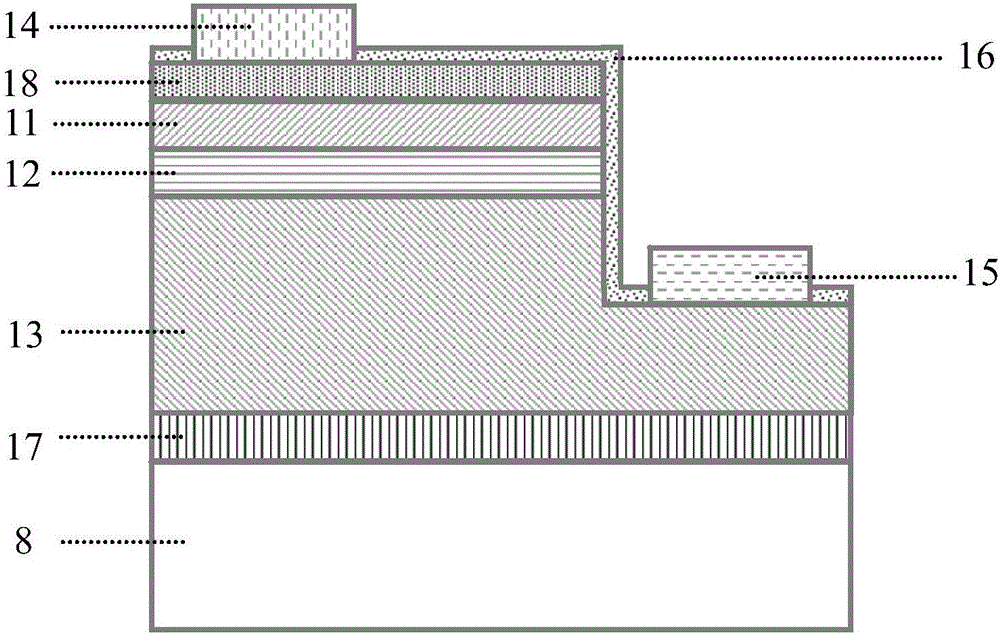

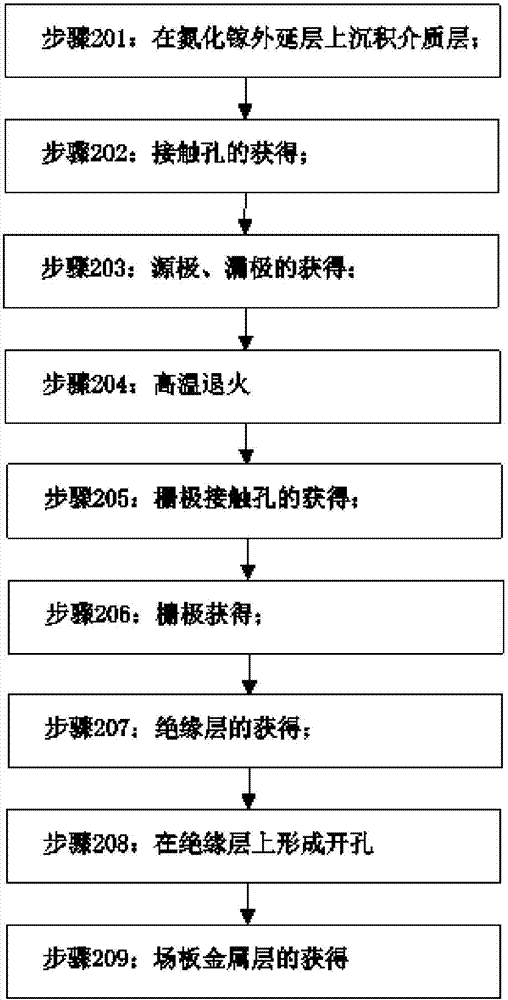

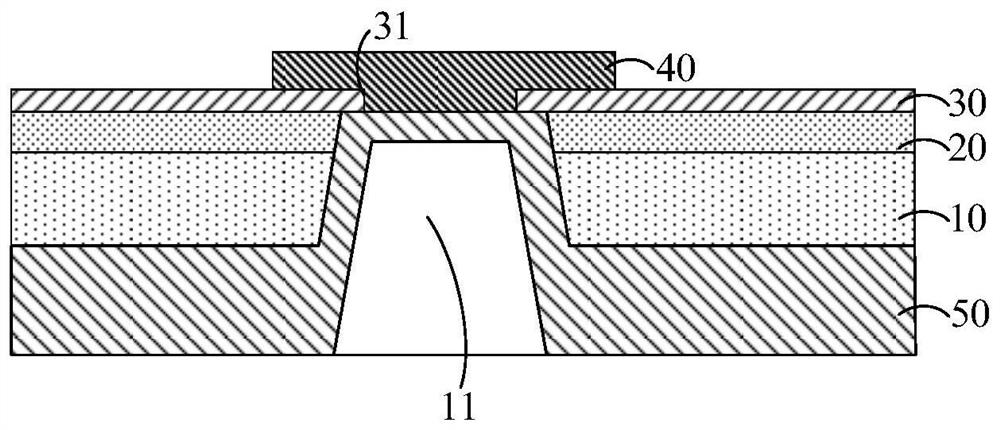

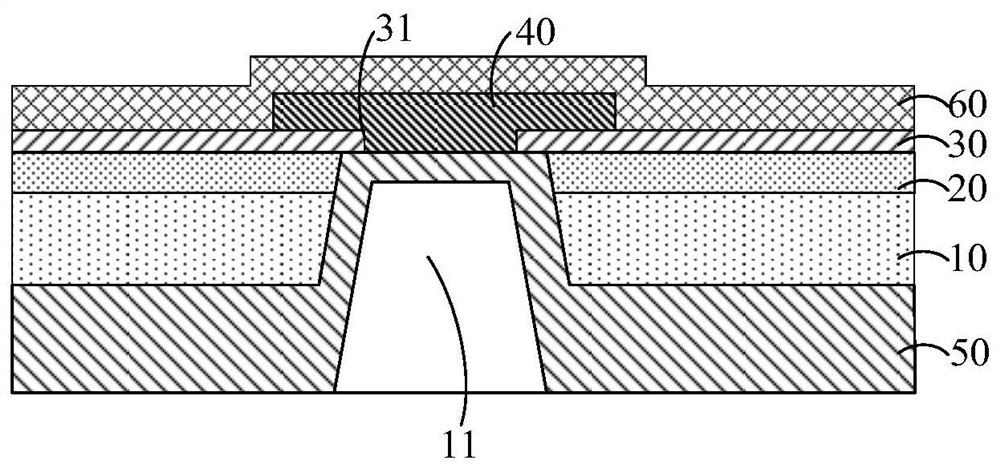

GaN-based semiconductor device and manufacturing method thereof

PendingCN111883590AGood groundingImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesDevice materialGallium nitride

Owner:XIAMEN SANAN INTEGRATED CIRCUIT

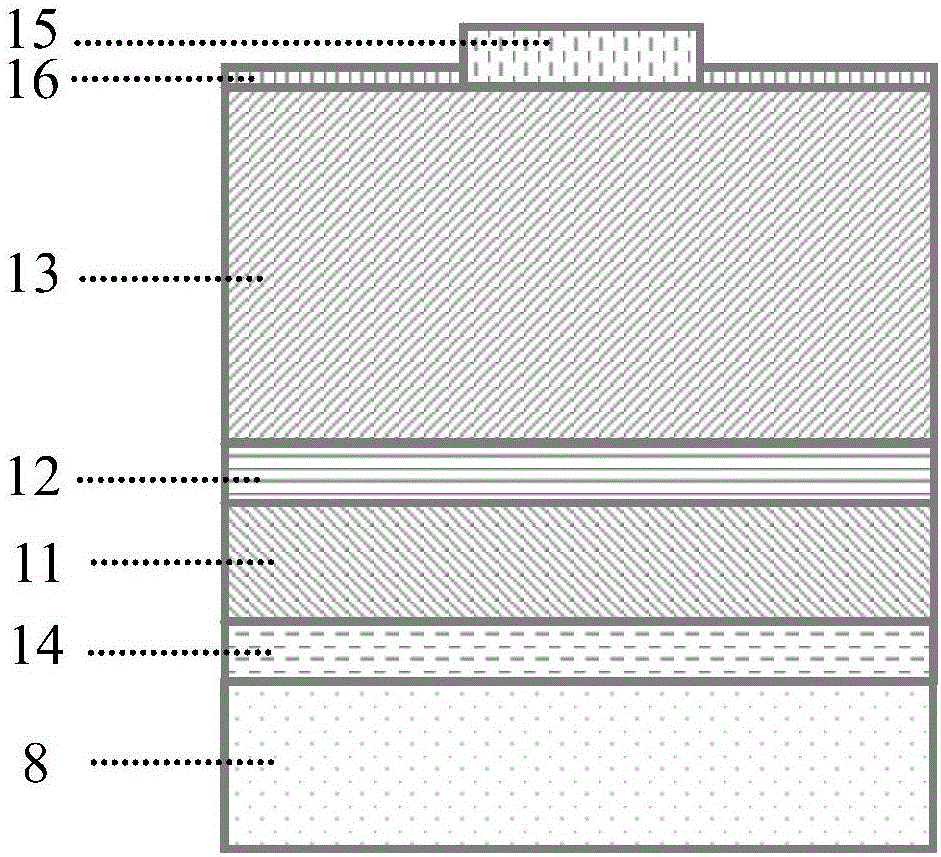

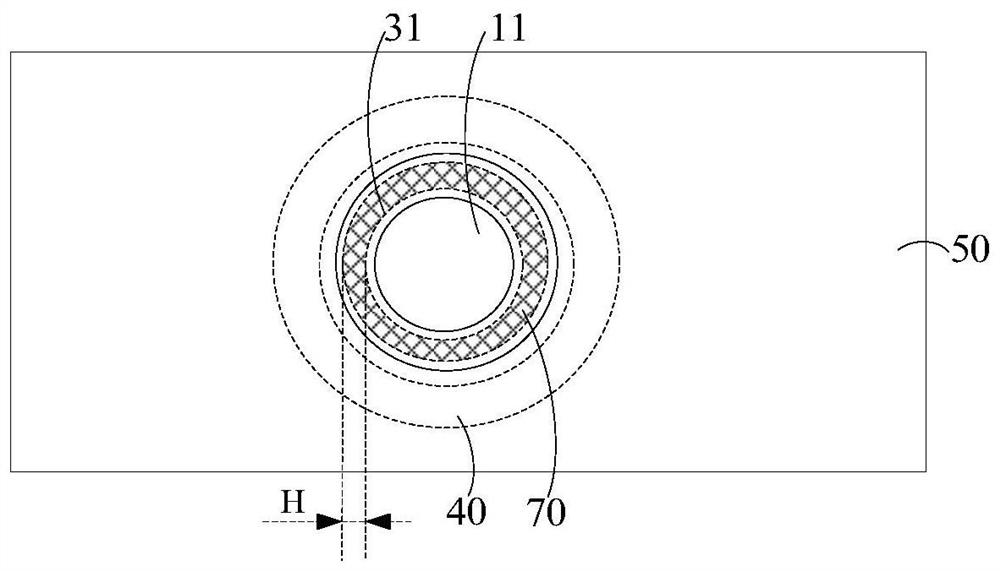

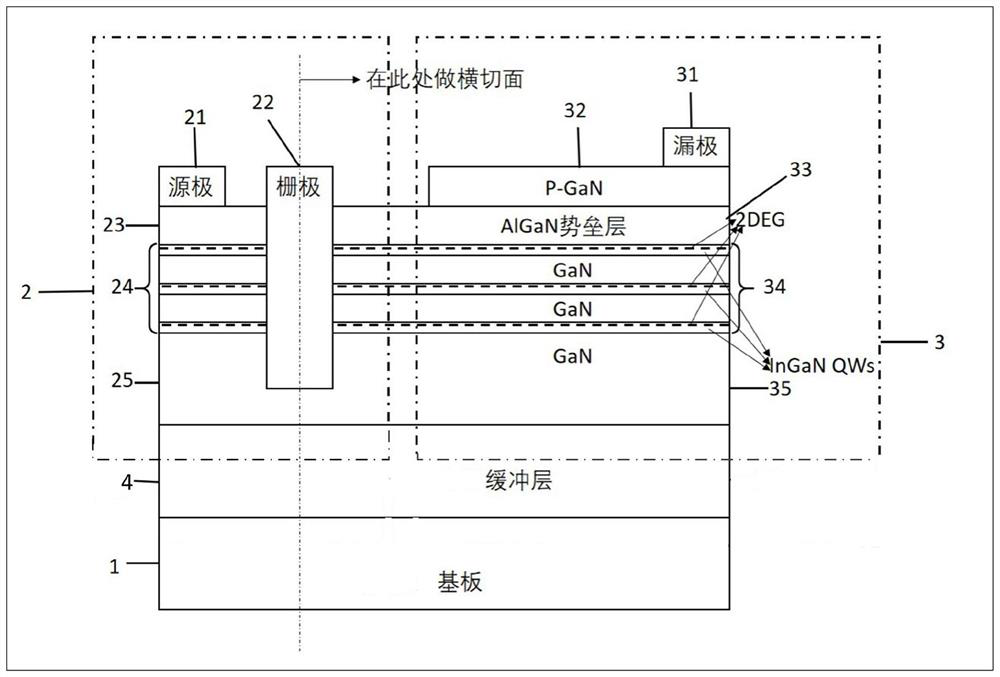

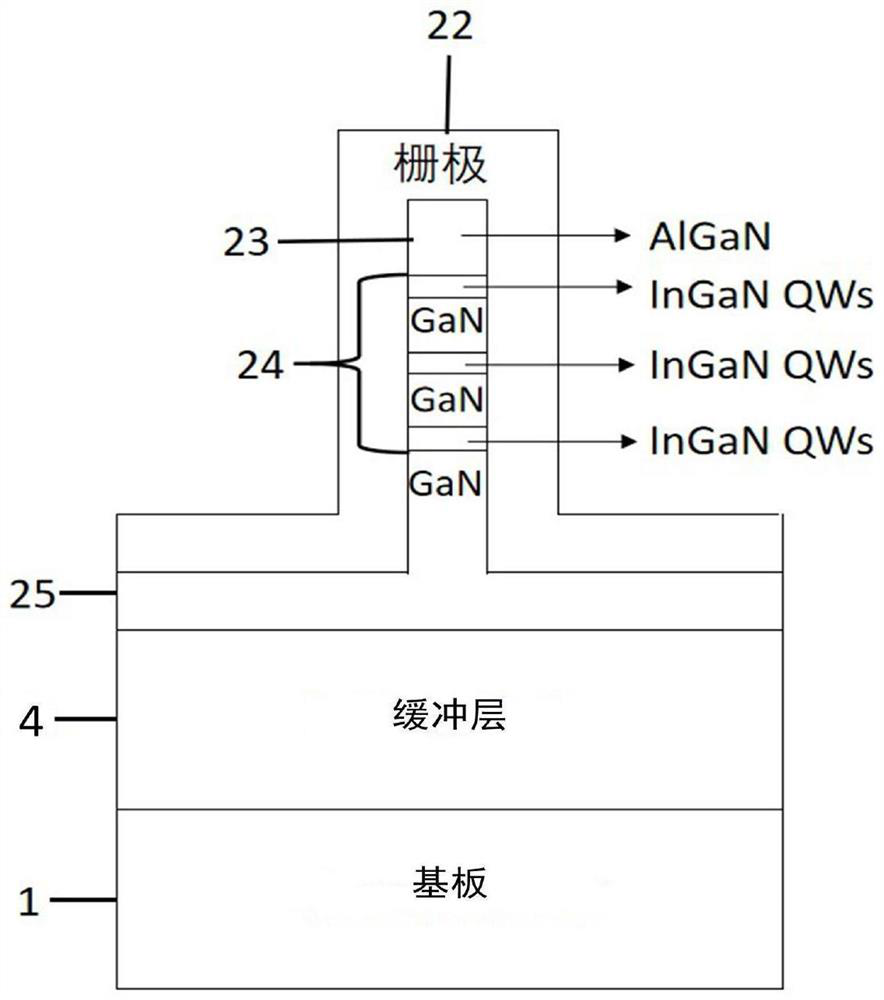

Improved high-electron-mobility light-emitting transistor

The invention relates to an improved high-electron-mobility light-emitting transistor, comprising: a substrate; a high-electron-mobility transistor (HEMT) region which is arranged on the substrate; and a gallium nitride LED area, arranged on the substrate. Each of the HEMT region and the LED region comprises at least one 2DEG layer, and the HEMT region and the LED region are connected through the 2DEG layers; the HEMT region further comprises a grid electrode; the grid electrode is of a three-dimensional fin type structure, wraps the 2DEG layer in the HEMT region from top to bottom and is used for controlling whether the LED region emits light or not and controlling the light emitting intensity. According to the invention, a three-dimensional fin-type gate structure is adopted, and the gate wraps the three sides of the conducting channel formed by the 2DEG layer, so that the conducting channel of the whole HEMT region is controlled to be switched on and switched off, and then whether the LED region emits light or not and the light emitting intensity are controlled.

Owner:SHANGHAI UNIV

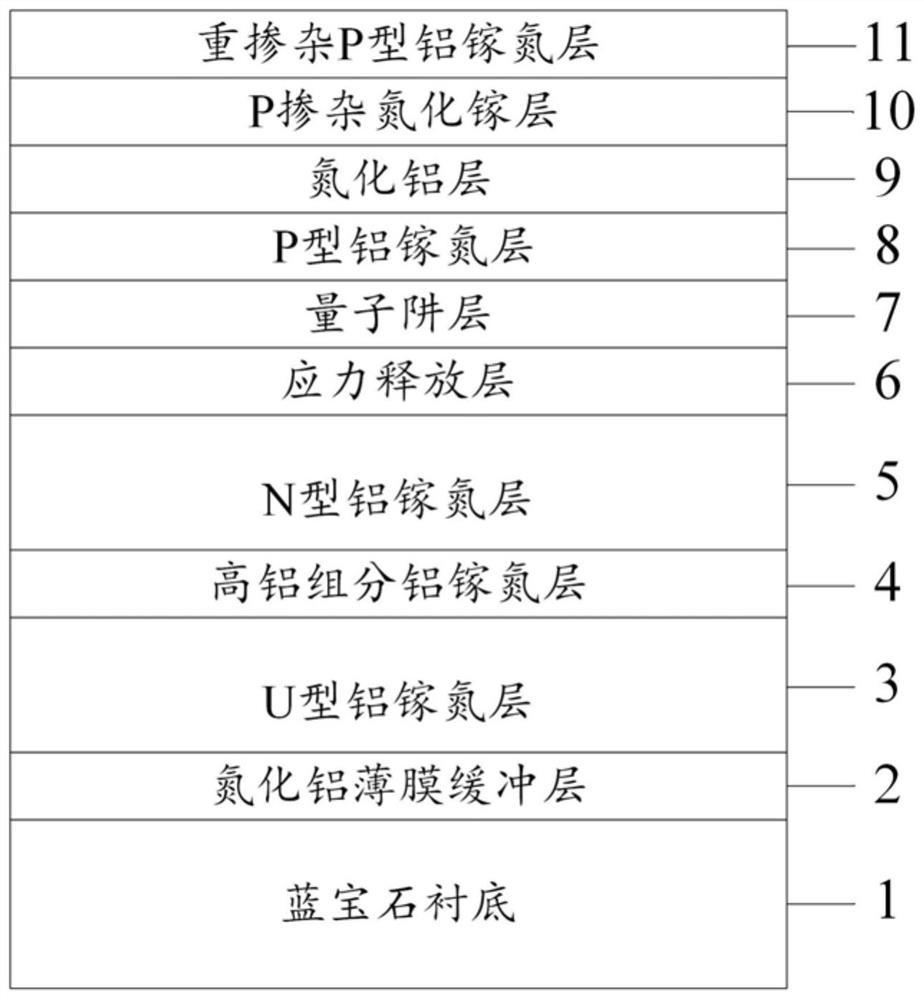

Deep ultraviolet epitaxial wafer and preparation method thereof

Owner:FUJIAN PRIMA OPTOELECTRONICS CO LTD

InGaN/GaN heterogeneous epitaxial structure and growing method thereof

InactiveCN108598192AEliminate hindranceImprove collection efficiencyPhotovoltaic energy generationSemiconductor devicesGallium nitrideSolar cell

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap