Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9 results about "High velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

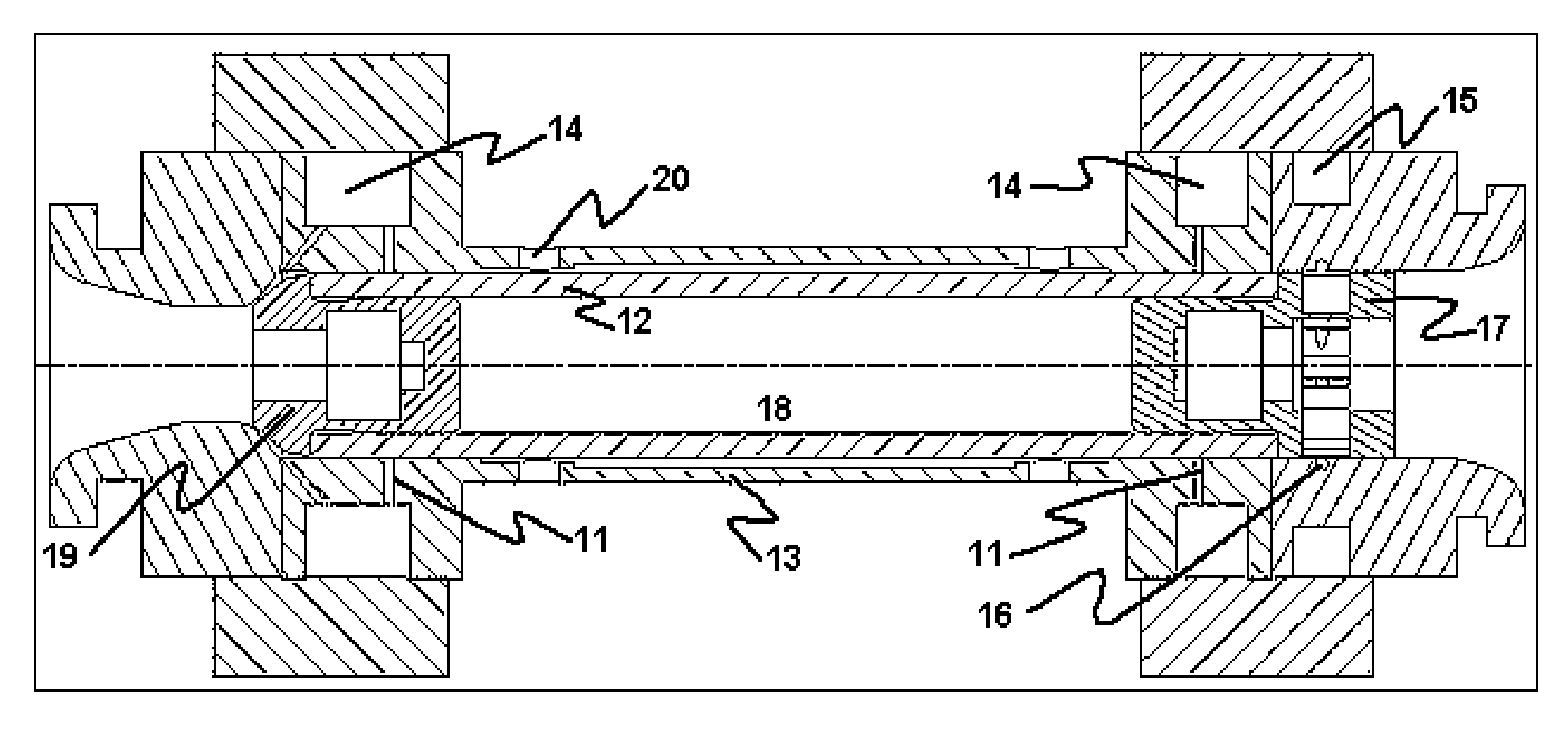

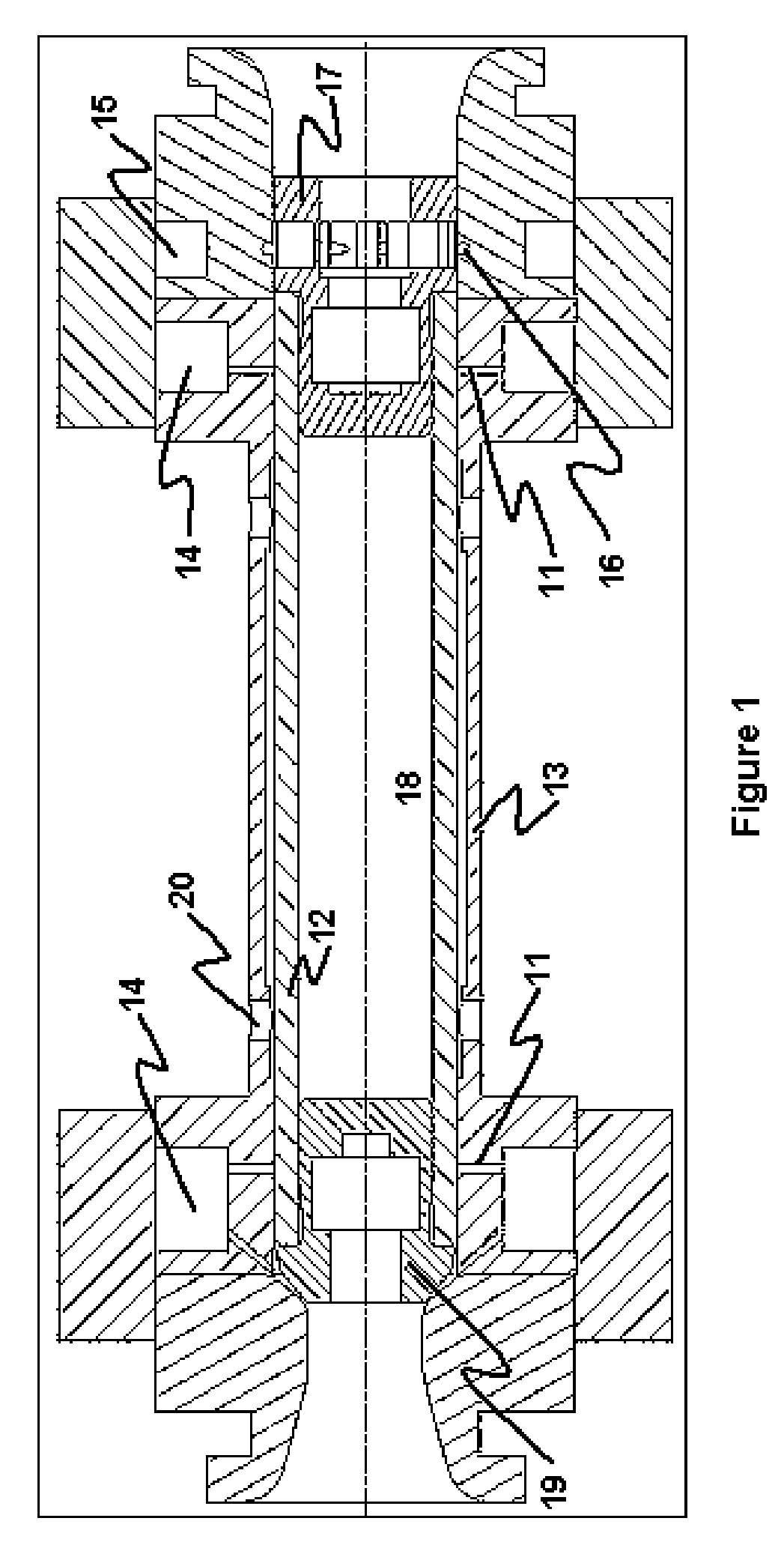

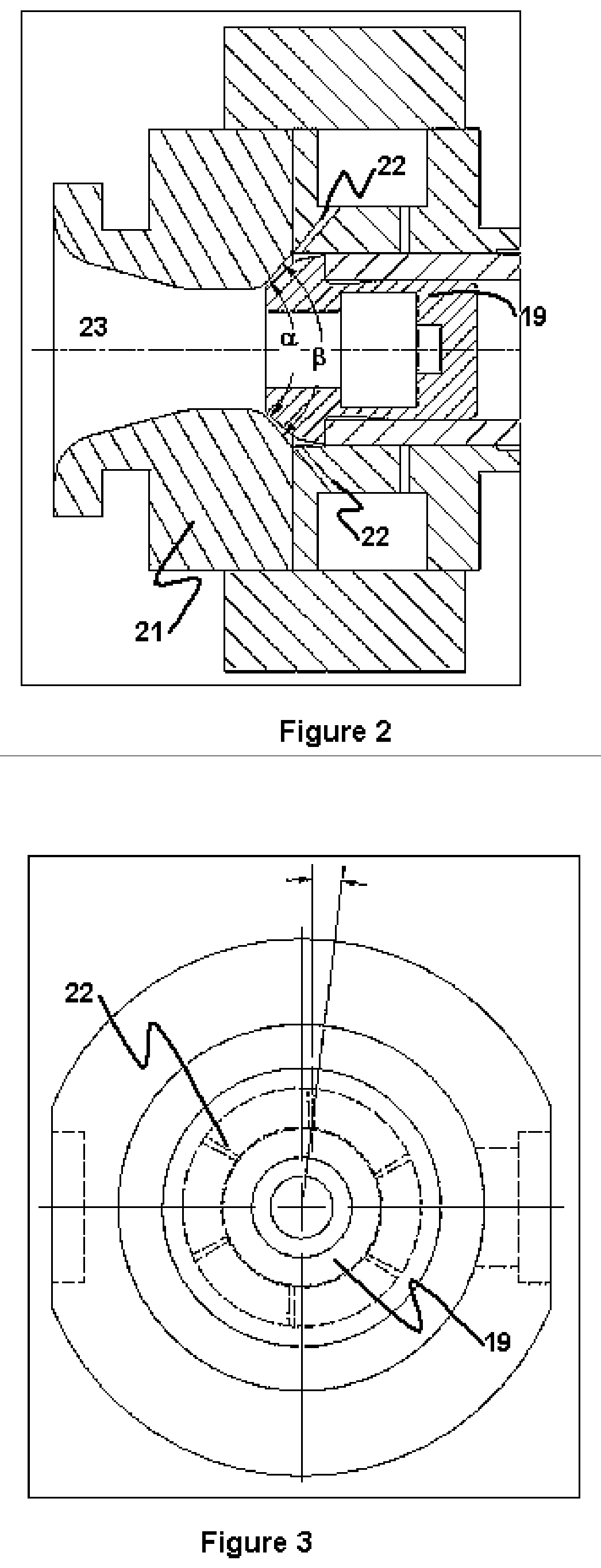

NMR MAS inflow bernoulli bearing

ActiveUS20060082371A1Improve stabilityIncrease stiffnessMagnetic circuit rotating partsMagnetic measurementsAxial pressureSurface velocity

Owner:DOTY SCI

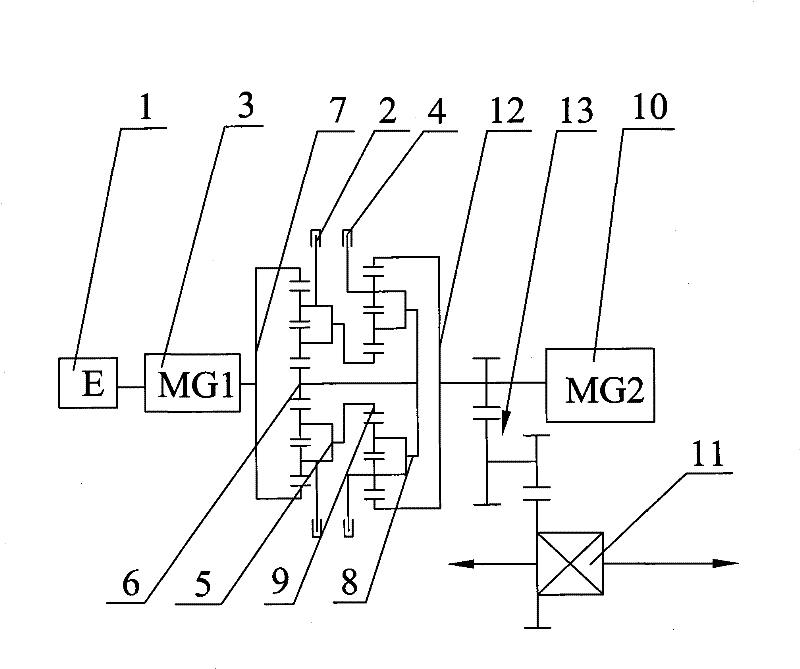

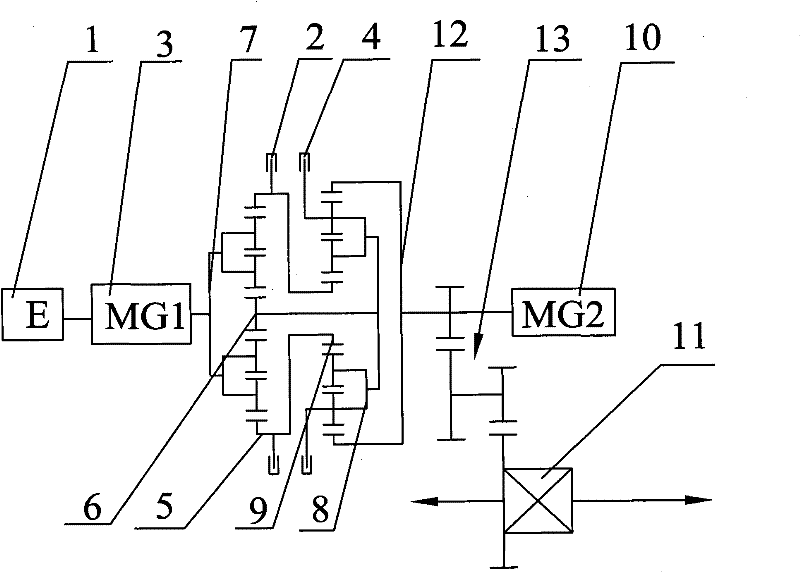

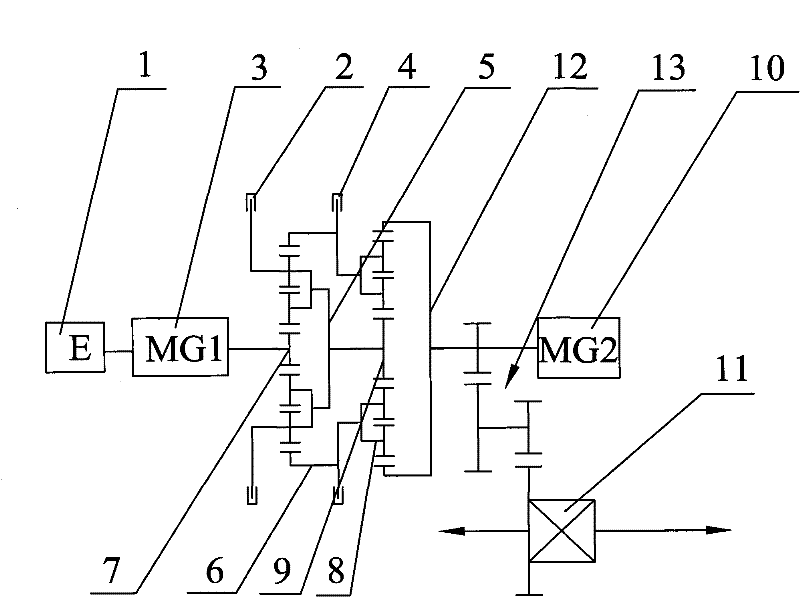

Hybrid driving system and vehicle including same

ActiveCN102343796AMeet the driving needs under different working conditionsEasy dischargeGas pressure propulsion mountingToothed gearingsLow speedInternal combustion engine

Owner:BYD CO LTD

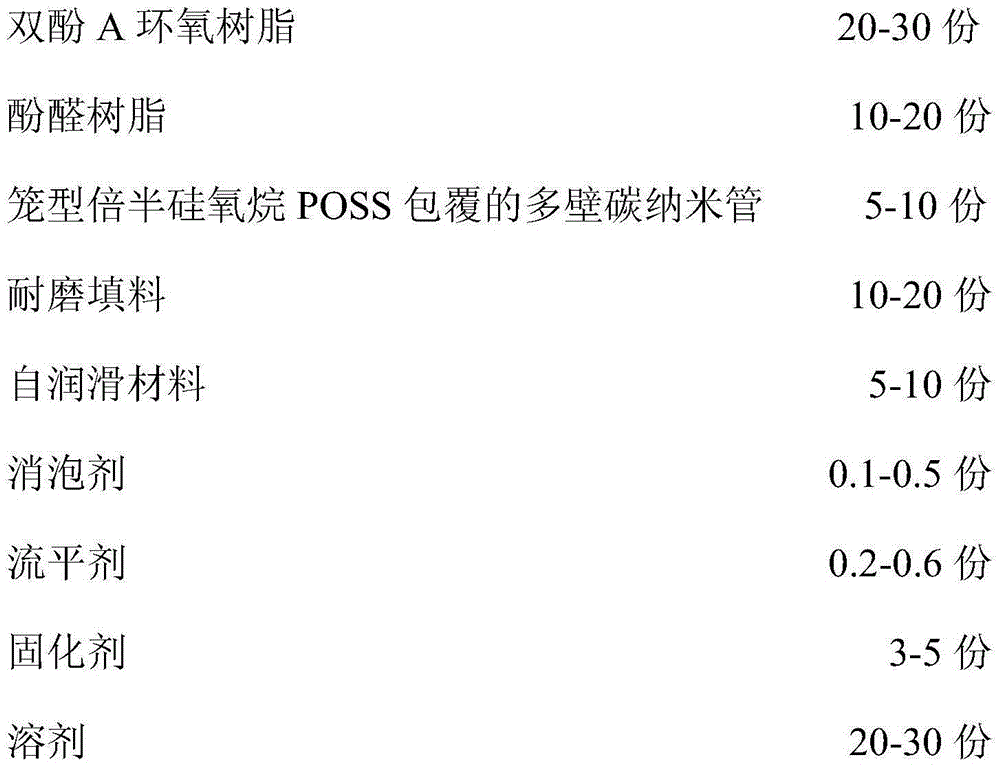

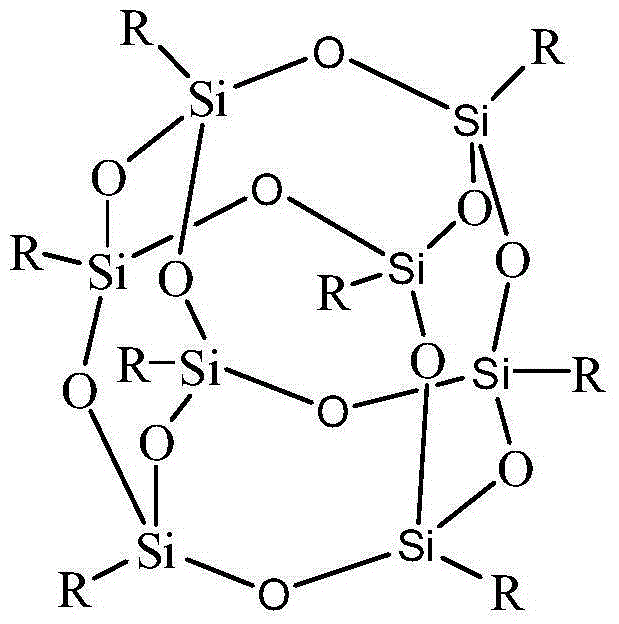

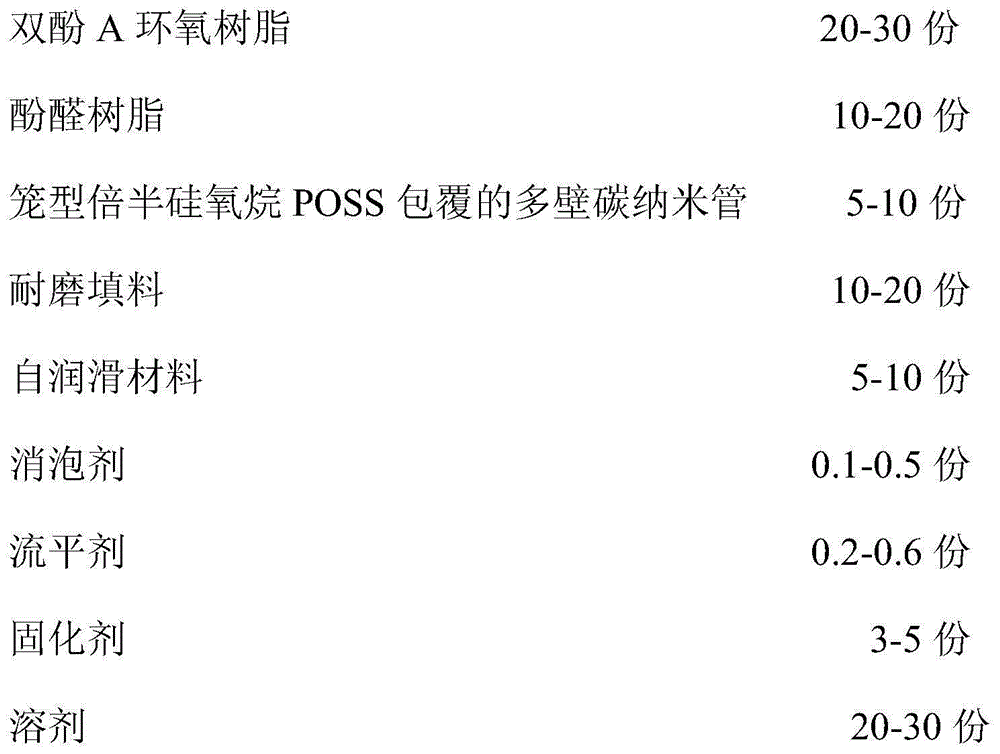

Anti-corrosion and wear-resisting coating for throwing disc of pneumatic type feeder and preparation method of coating

InactiveCN105062300AImprove corrosion resistanceImprove high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsMultiwalled carbonRoom temperature

Owner:JINHU JIEDA MACHINERY MFR

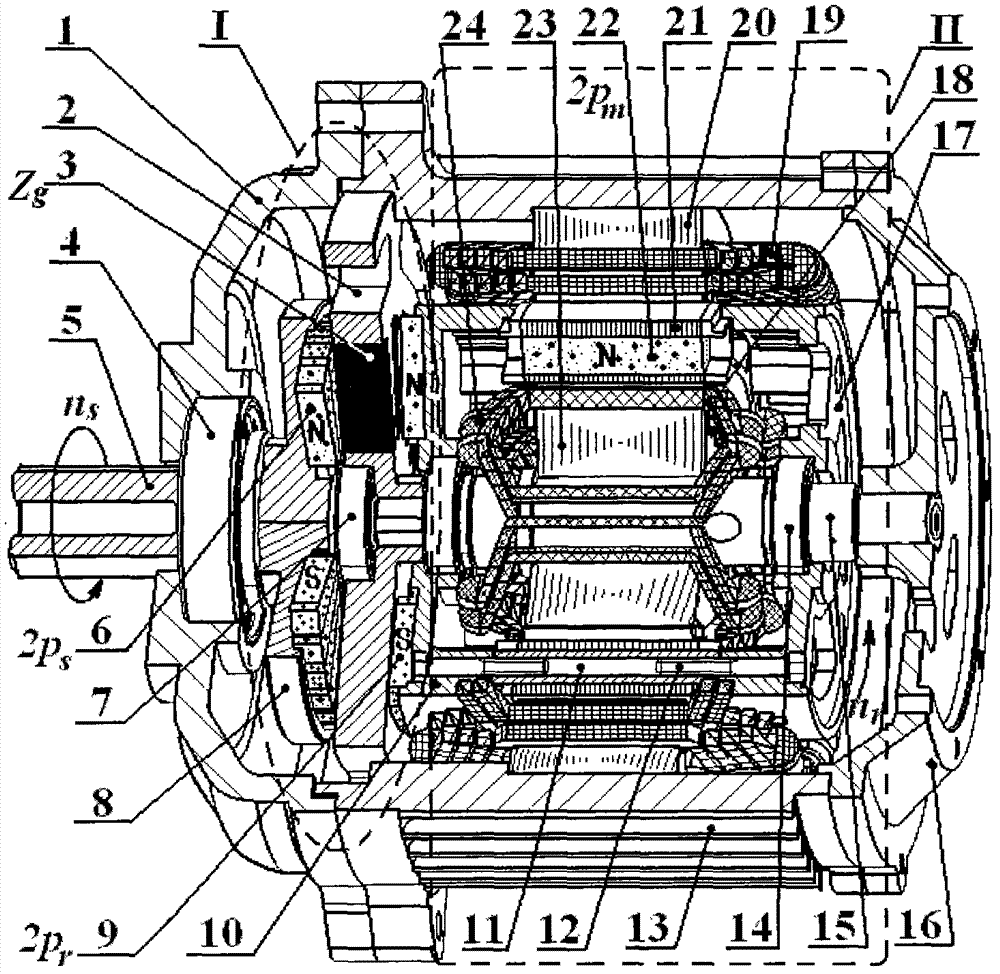

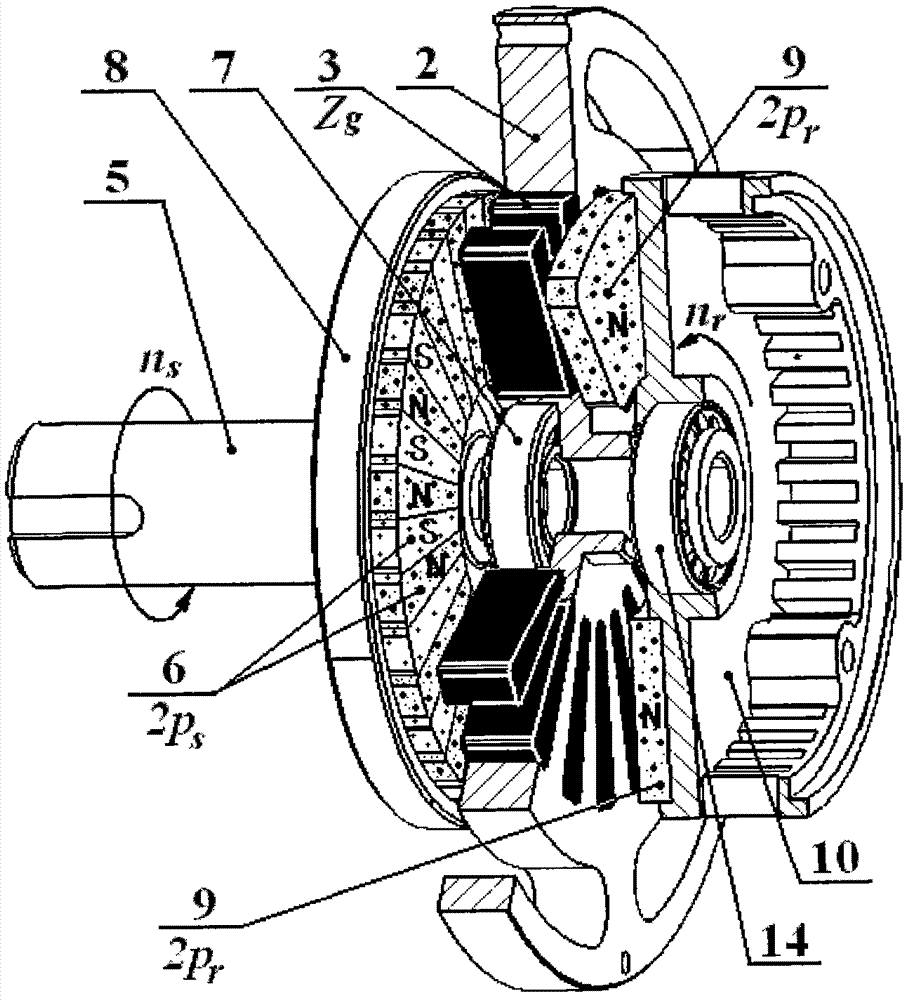

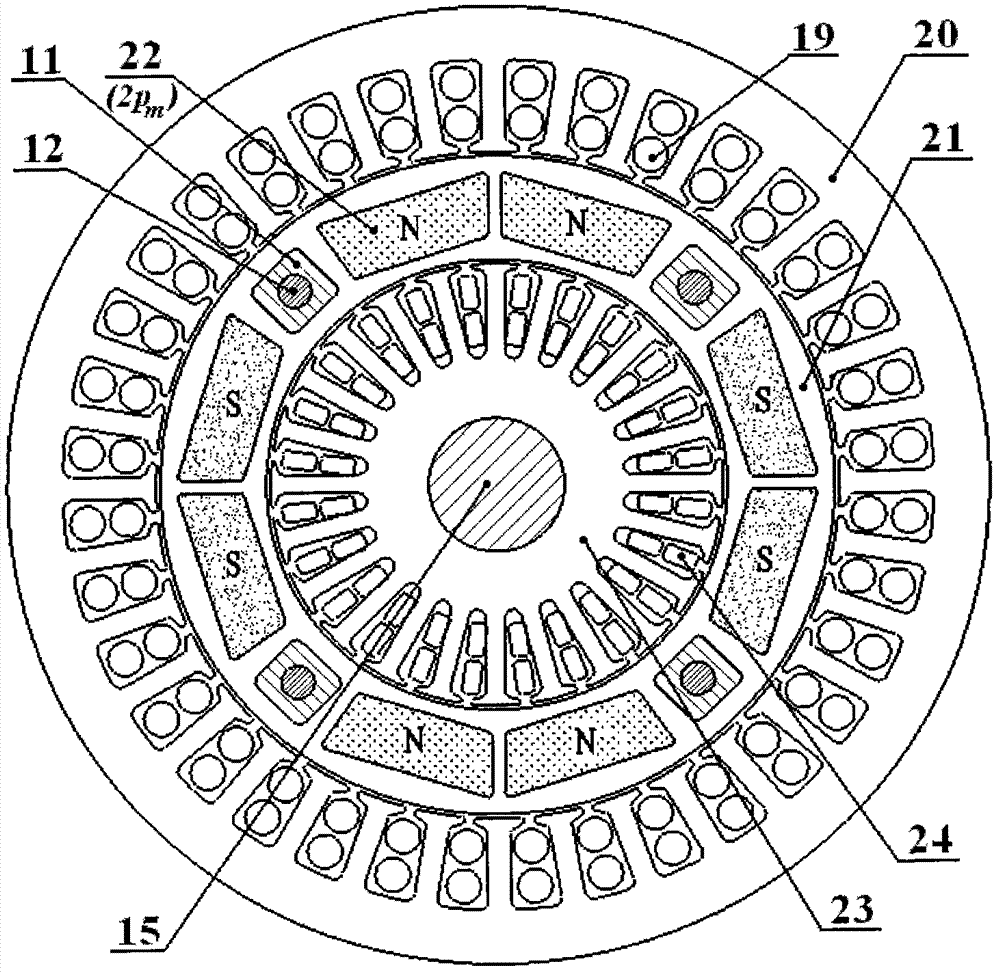

Direct-drive composite permanent magnet motor with magnetic transmission and dual-stator structure

InactiveCN102957260ATo achieve technical and economic effectSimple structureElectric machinesDynamo-electric gearsLow speedTransmission technology

Owner:余虹锦

Manufacturing method for high-speed permanent magnetic rotor

Owner:HARBIN DONGAN ENGINE GRP

Nanoscale activated calcium carbonate and processing method thereof

InactiveCN110358328AReduce surface polarityOleophilic and hydrophobicMaterial nanotechnologyPigment physical treatmentCalciteHigh velocity

The invention discloses nanoscale activated calcium carbonate. The nanoscale activated calcium carbonate comprises calcite, a dispersant and a coupling agent; a mass part ratio of the calcium carbonate to the dispersant in a grinding process is 100:(0.2-5); and a mass part ratio of the dried nanometer calcium carbonate to the coupling agent in a high-speed mixing and stirring process is 100:(0.5-8). The method reduces the surface polarity of the nanometer calcium carbonate, so the surface of the nanometer calcium carbonate has strong oleophilic and hydrophobic properties, the dispersion property is improved, the dispersibility of the nanometer calcium carbonate in the composite material and the compatibility of the nanometer calcium carbonate with an organic high polymer are improved, andthe nanoscale activated calcium carbonate is obtained. The invention also discloses a processing method of the nanoscale activated calcium carbonate. The processing method comprises the following steps: 1, raw material washing; 2, choosing; 3, coarse crushing; 4, intermediate crushing; 5, addition of the dispersant, and grinding; 6, ATP grading (fine powder + coarse powder); 7, addition of the coupling agent, and high-speed mixing and stirring; and 8, cooling and packaging. The processing method adopting dry process modification has the advantages of low production cost, and suitableness for large-scale industrial production.

Owner:LIANG DE NANO POWDER LNNOVATION & TECH (ANHUI) CO LTD

High-strength and low-percolation UHMWPE (ultrahigh molecular weight polyethylene)/superconductive carbon black composite material and preparation method thereof

The invention discloses a high-strength and low-percolation UHMWPE / superconductive carbon black composite material and a preparation method thereof. The high-strength and low-percolation UHMWPE / superconductive carbon black composite material is composed of, by weight parts of 85-98.9 parts of UHMWPE powder, 1-14.8 parts of superconductive carbon black, 0.1-0.6 part of antioxidant and 0.1-0.6 partof coupling agent. The preparation method of the high-strength and low-percolation UHMWPE / superconductive carbon black composite material comprises raw material drying, high-speed mixing and preparation of UHMWPE / superconductive carbon black hybrid particles, and high-temperature press forming. When the added amount of the superconductive carbon black is 1 wt%, the high-strength and low-percolation UHMWPE / superconductive carbon black composite material achieves a conductivity up to 10<-5> s / cm and is low in percolation value and high in tensile strength and tenacity. A conductive sheet press-formed by the high-strength and low-percolation UHMWPE / superconductive carbon black composite material is not only endowed with excellent mechanical performance comparable with that of the ultrahigh molecular weight polyethylene, but also endows ultrahigh molecular weight polyethylene engineering plastics with new special functions such as anti-static property and electromagnetic shielding.

Owner:FUJIAN NORMAL UNIV

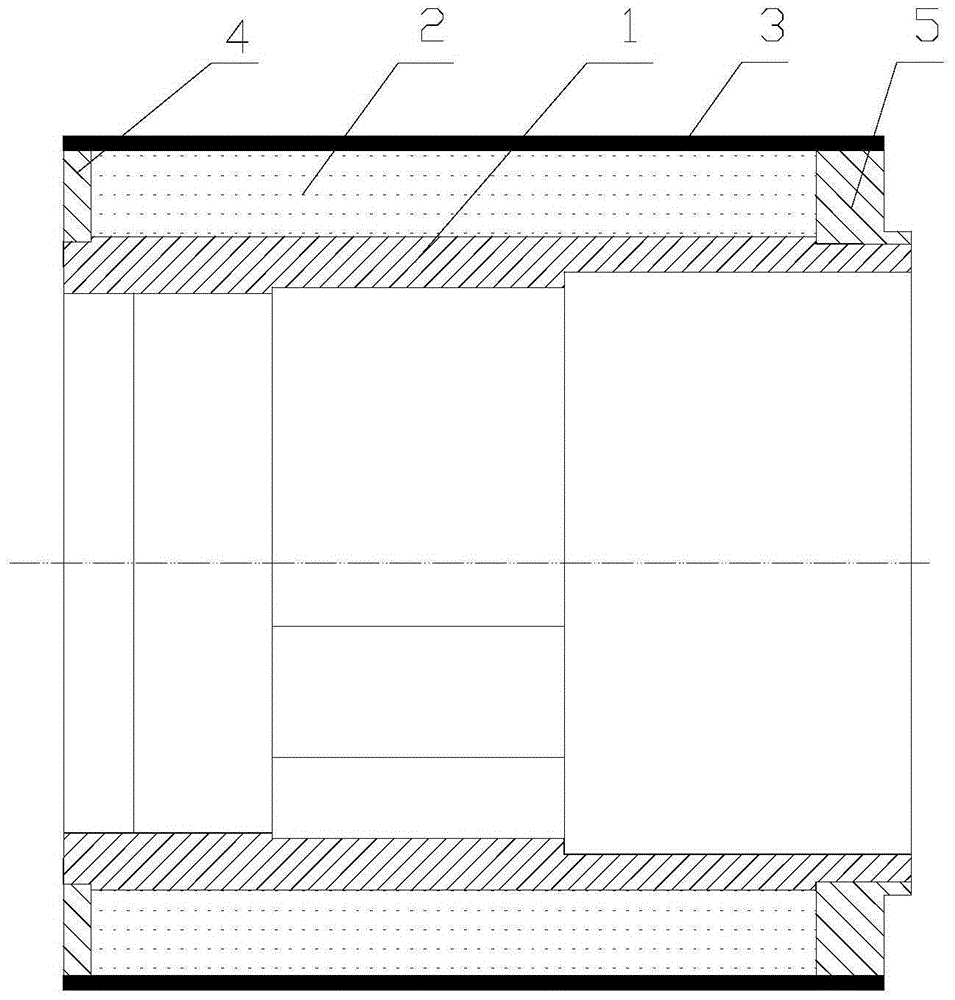

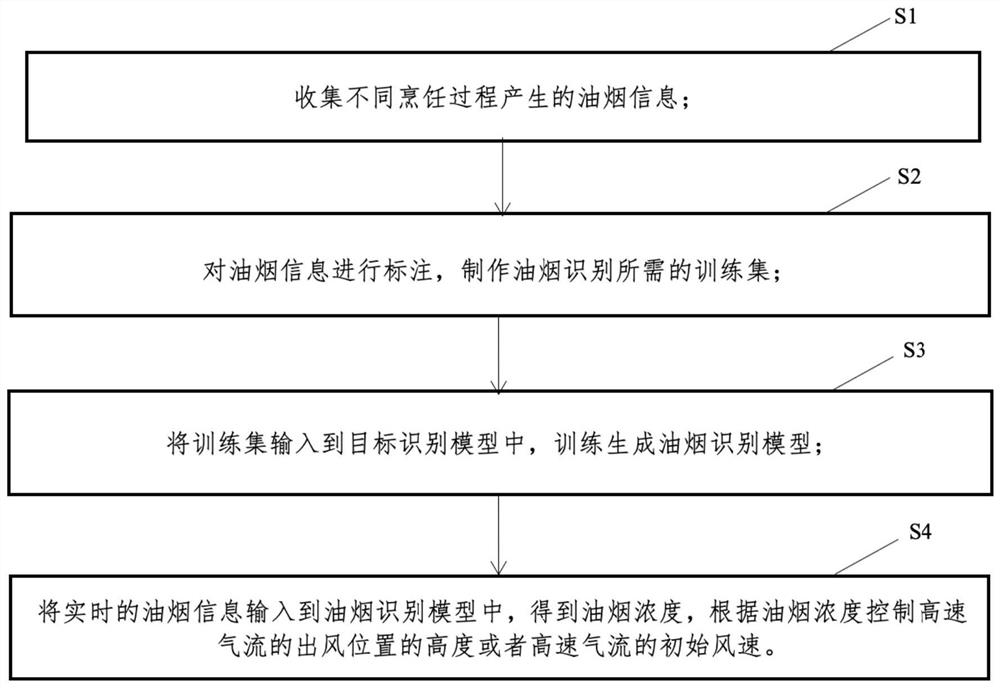

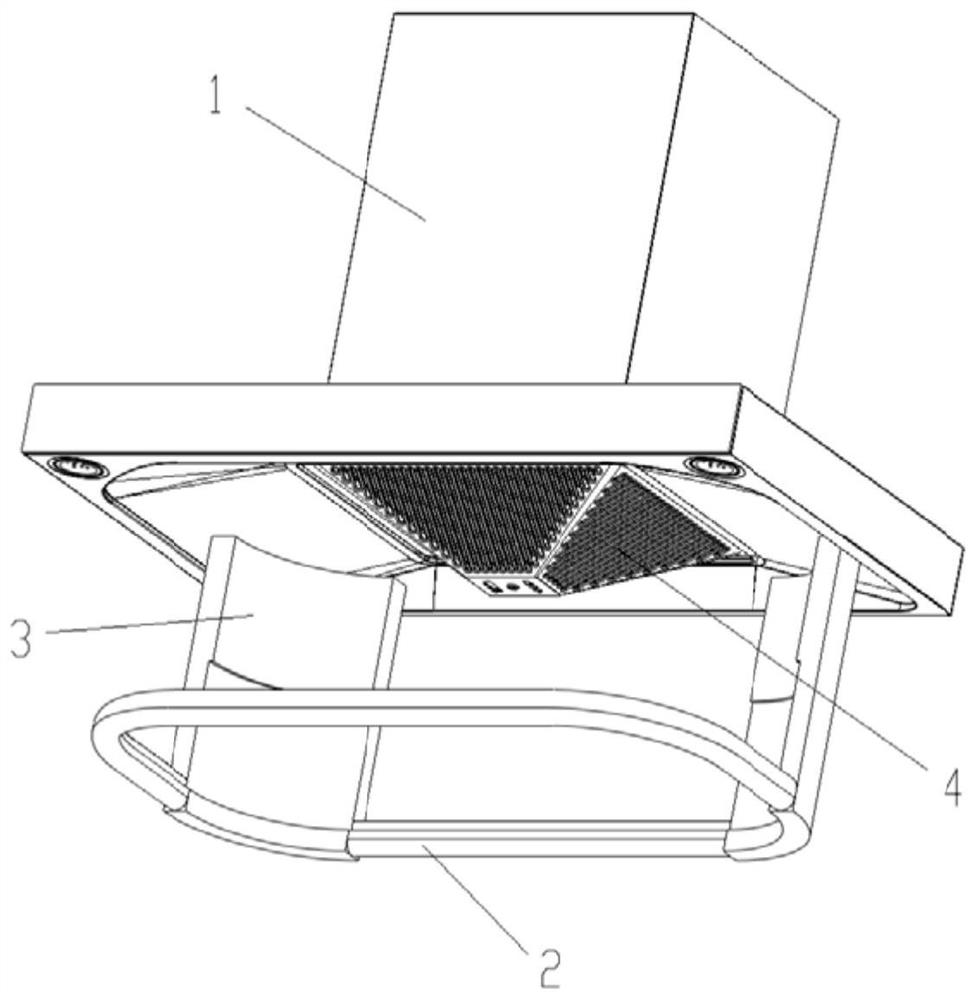

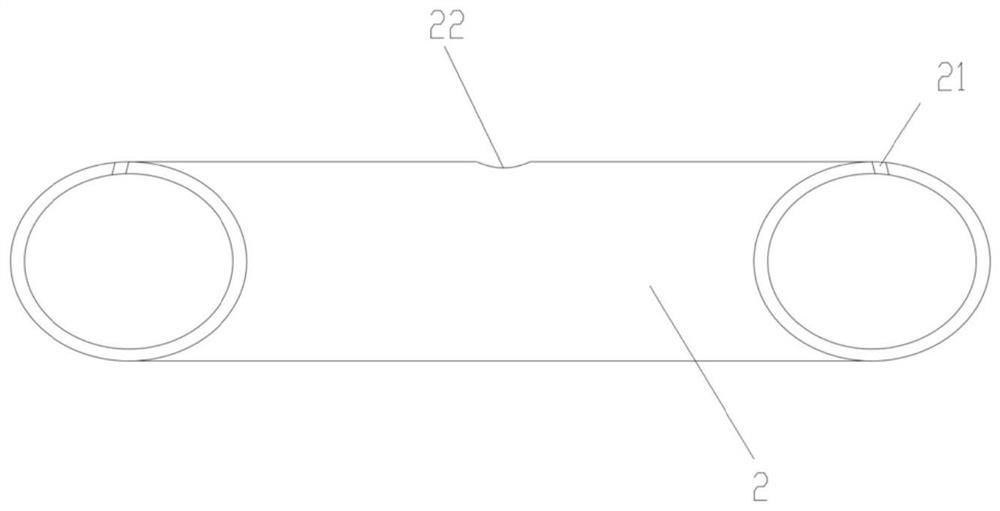

Oil fume controlling method and system based on object identifying model, and computer equipment

PendingCN111780185APrevent proliferationPromote absorptionDomestic stoves or rangesLighting and heating apparatusAir velocityMining engineering

Owner:合肥瑞纳通软件技术开发有限公司

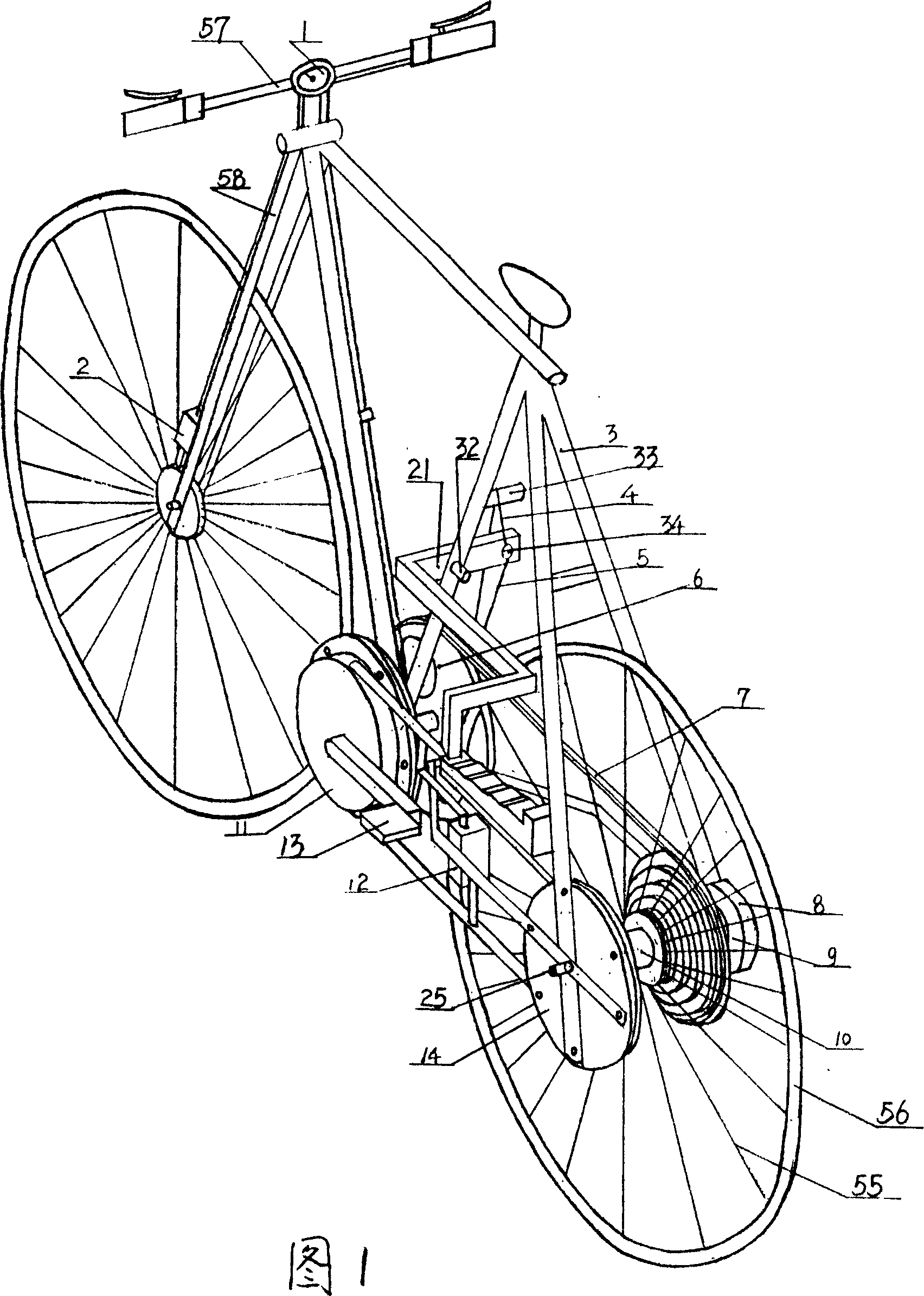

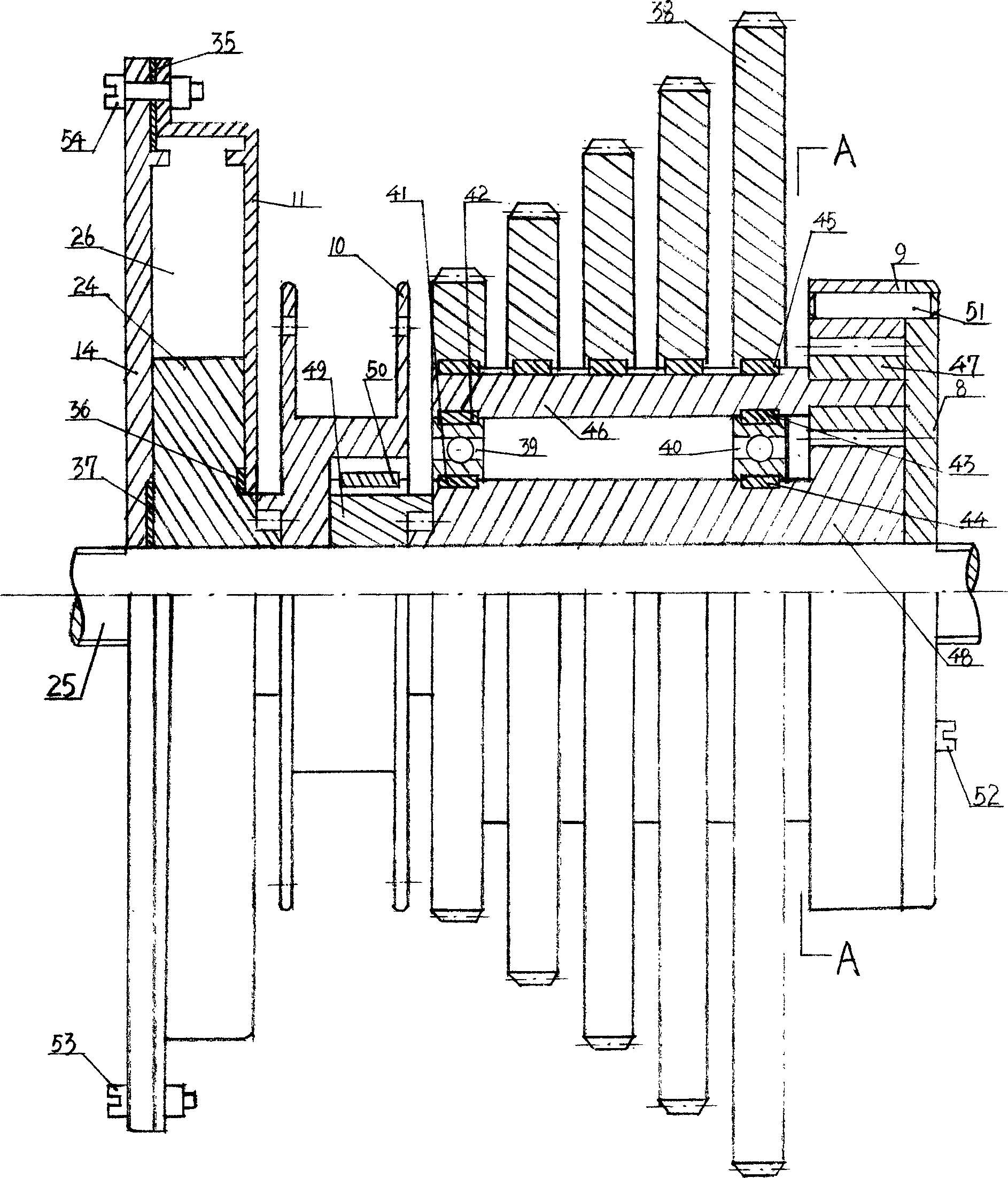

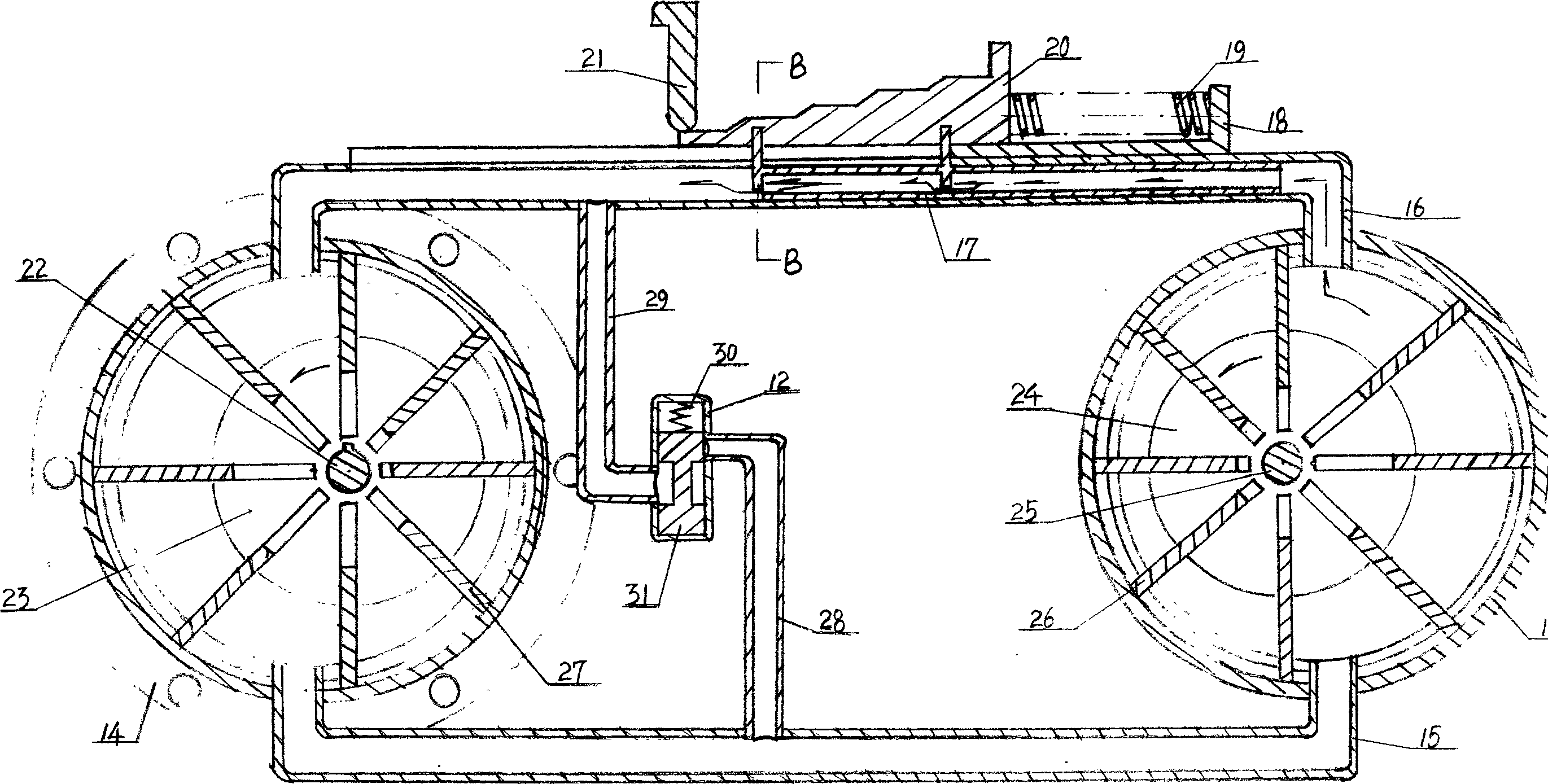

High-speed power-saving bicycle

InactiveCN1730347AIncrease speedEffort-saving pedalingWheel based transmissionNon-mechanical gearing transmissionImpellerVehicle frame

Owner:莫昌清

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap