Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

18 results about "Turbine blade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A turbine blade is the individual component which makes up the turbine section of a gas turbine or steam turbine. The blades are responsible for extracting energy from the high temperature, high pressure gas produced by the combustor. The turbine blades are often the limiting component of gas turbines. To survive in this difficult environment, turbine blades often use exotic materials like superalloys and many different methods of cooling that can be categorized as internal and external cooling , and thermal barrier coatings. Blade fatigue is a major source of failure in steam turbines and gas turbines. Fatigue is caused by the stress induced by vibration and resonance within the operating range of machinery. To protect blades from these high dynamic stresses, friction dampers are used.

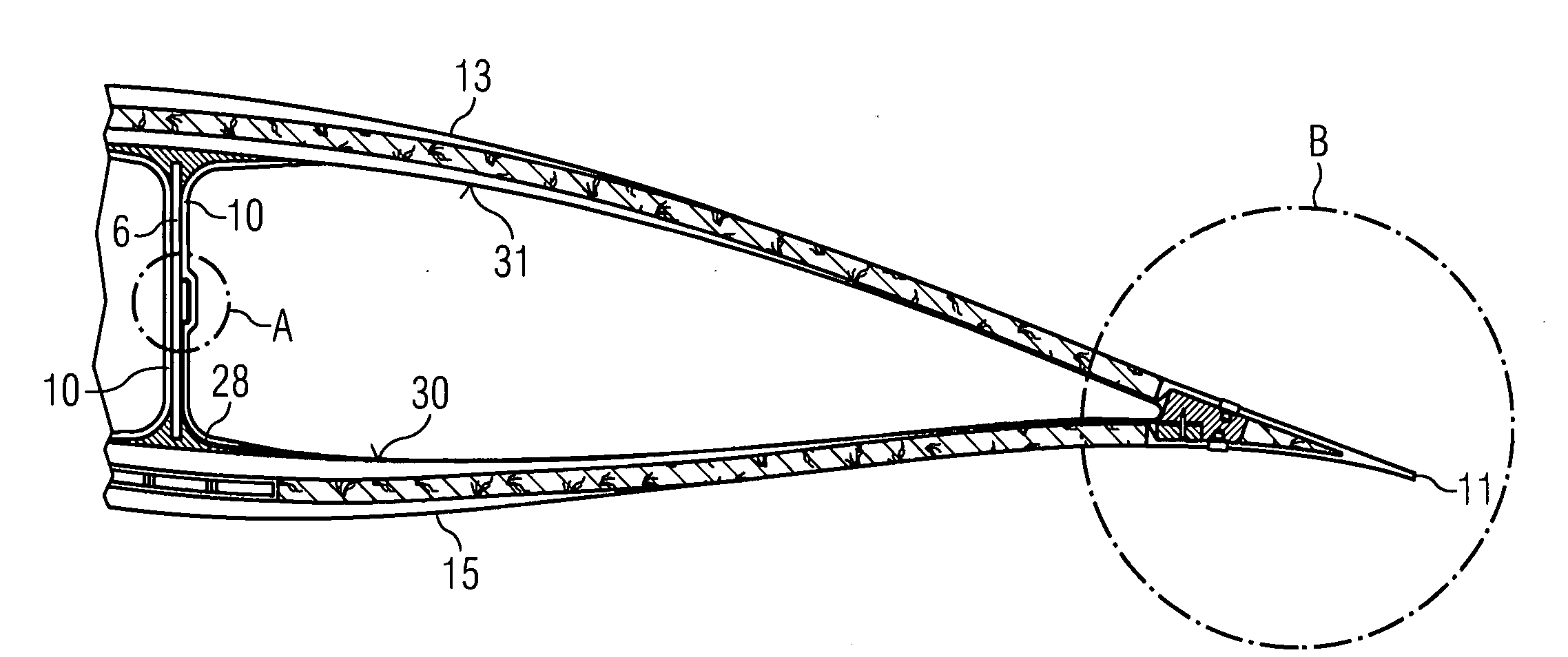

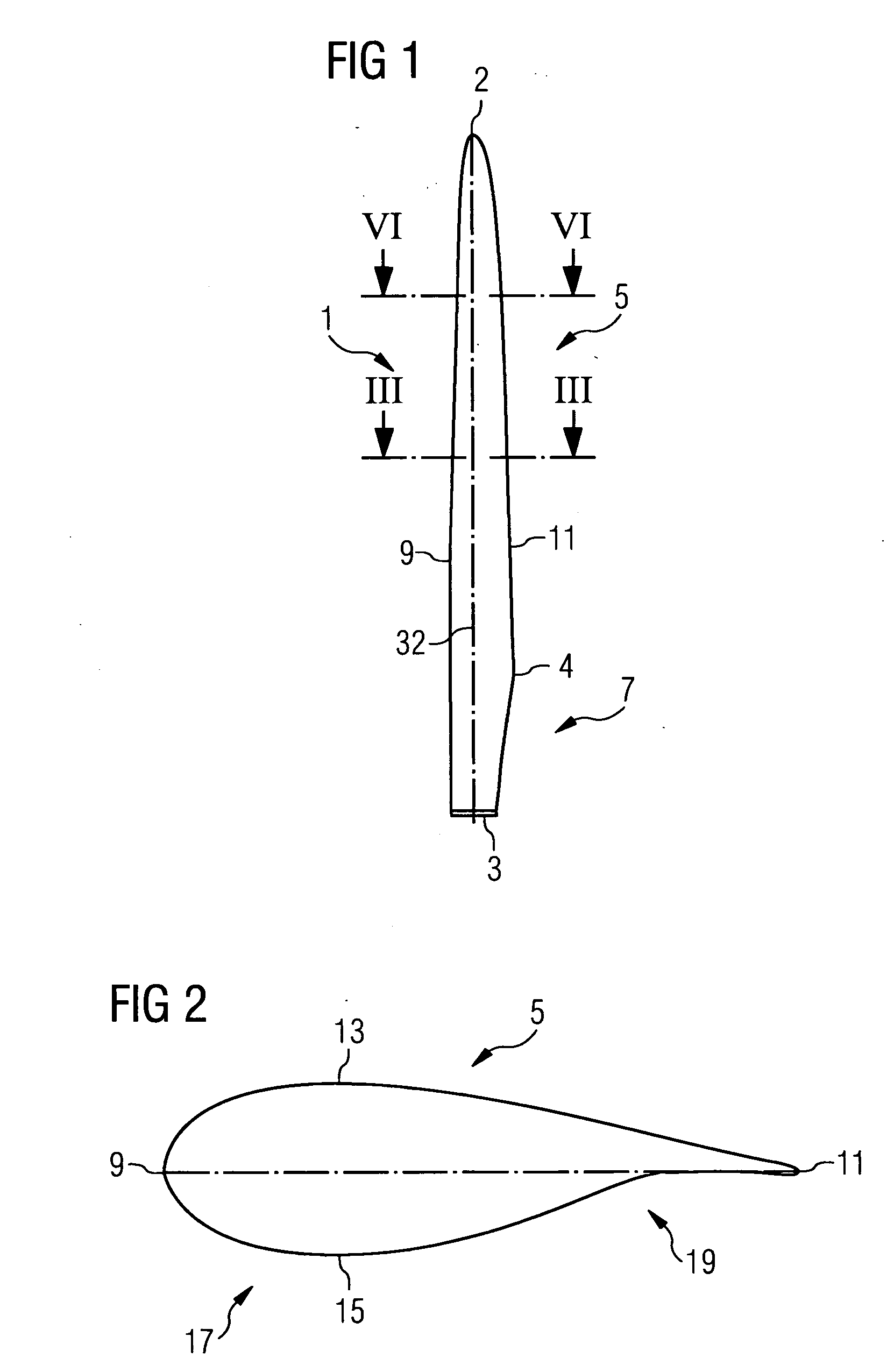

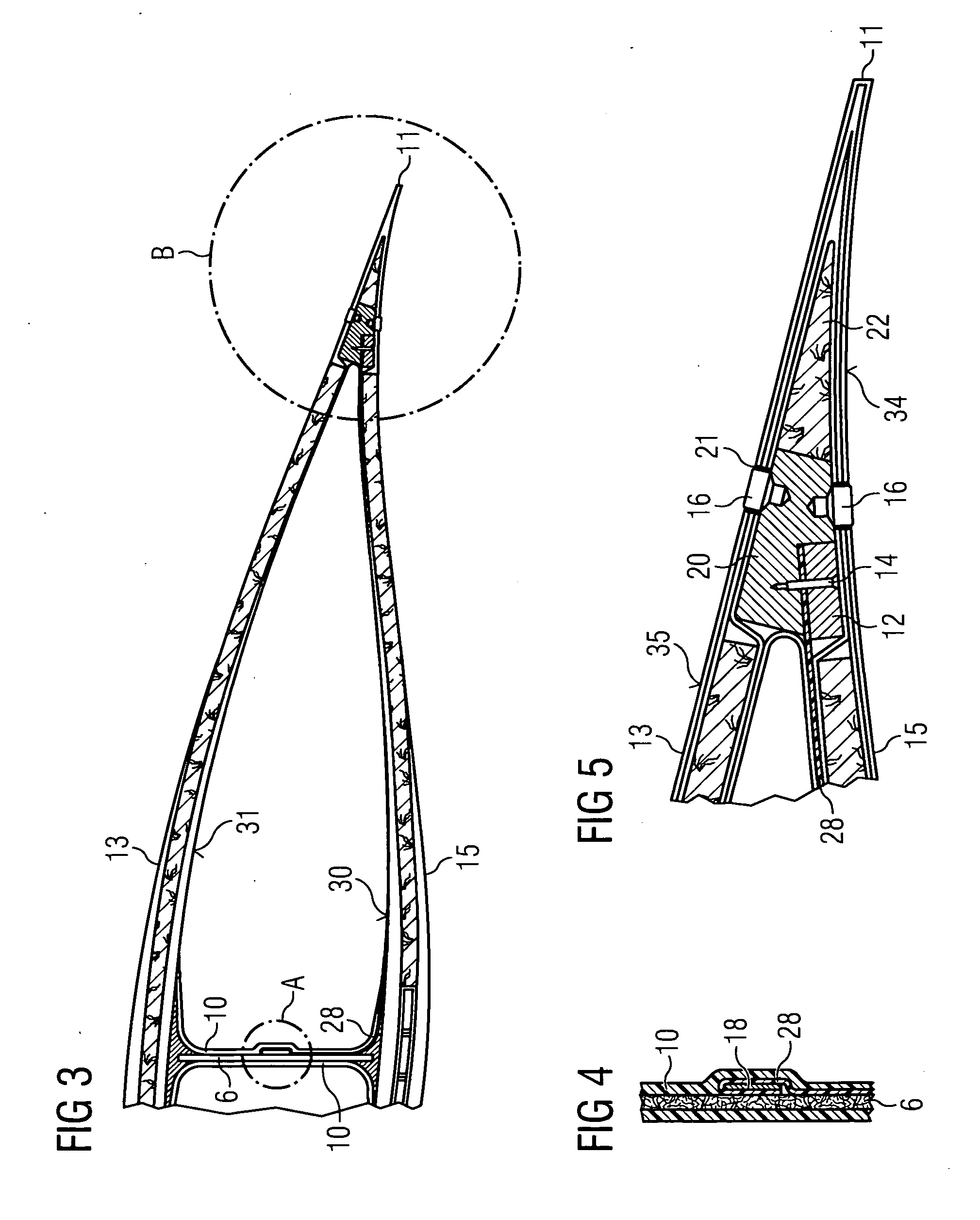

Wind Turbine Blade with an Integrated Lightning Conductor and Method for Manufacturing the Same

ActiveUS20090257881A1Reduce mechanical stressEasy to mergeFinal product manufactureLaminationElectrical conductorTurbine blade

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

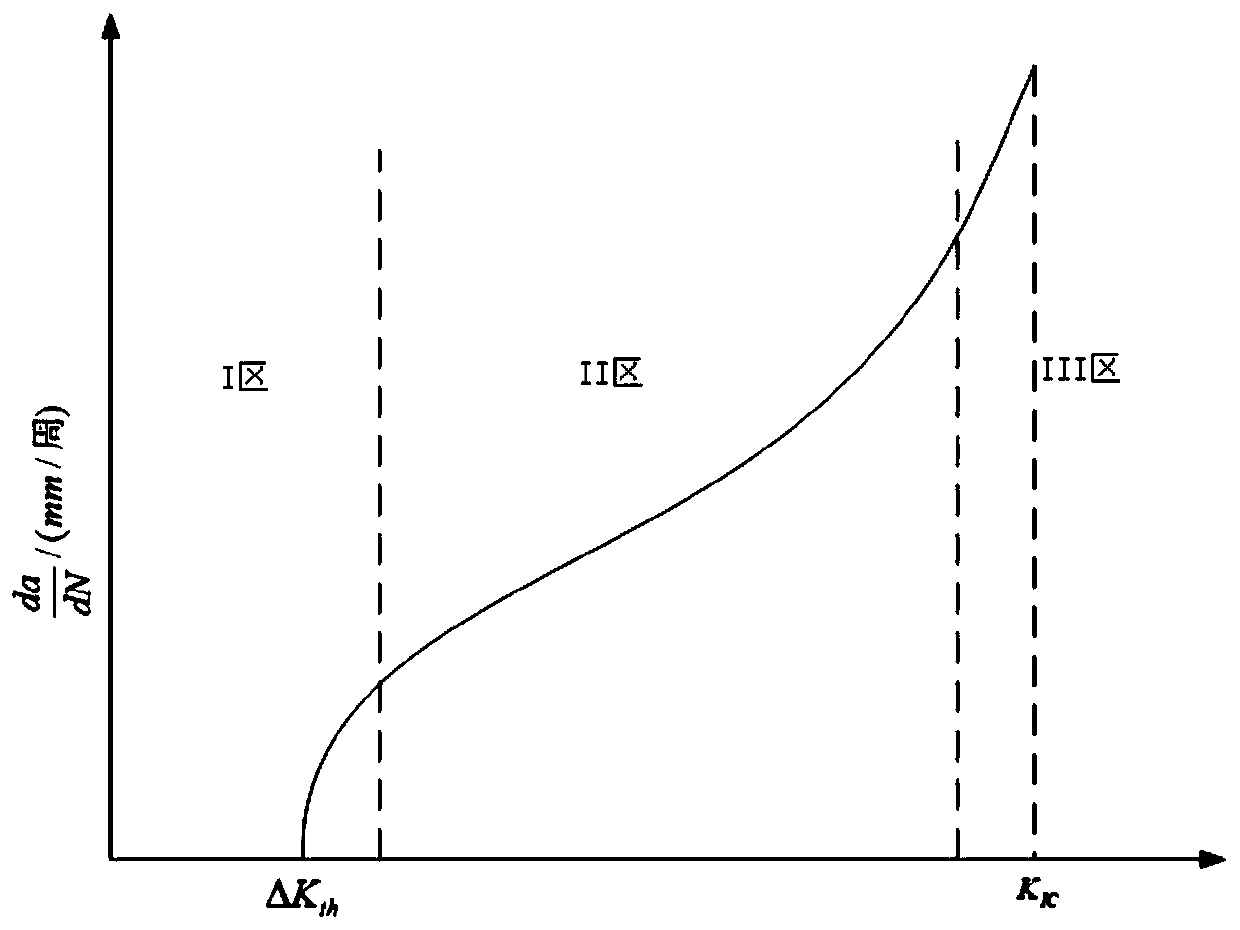

Aero-engine turbine blade reliability evaluation method based on fracture mechanics

InactiveCN110147618AAccurate lifeAccurate and reliableGeometric CADDesign optimisation/simulationReduced modelAviation

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Wind turbine blades with reinforcing, supporting and stabilizing components and enlarged swept area

ActiveUS8629570B1Low costEasy constructionWind motor controlWind energy with garvitational potential energyTurbine bladeHorizontal axis

A rotor assembly for a horizontal-axis wind turbine with blades support attachments. Each end of the supporting elements is fixedly or rotatably attached to one blade. In a new and improved embodiment, the blades start from the support element, skipping the swept area inside these elements but at the same time increasing many times the total swept area with substantially reduced cost. The support elements might be additionally attached to already existing wind turbine rotors. The reinforcing elements support and protect the blades from bending, breaking or falling apart in strong and gusty winds. The rotor of a wind turbine occasionally will rotate with speeds higher then normal and if the blades are not reinforced and properly balanced the whole assembly may start wobbling and then break apart from the tower or the blades may be damaged or may bend or break.

Owner:KAMENOV KAMEN GEORGE

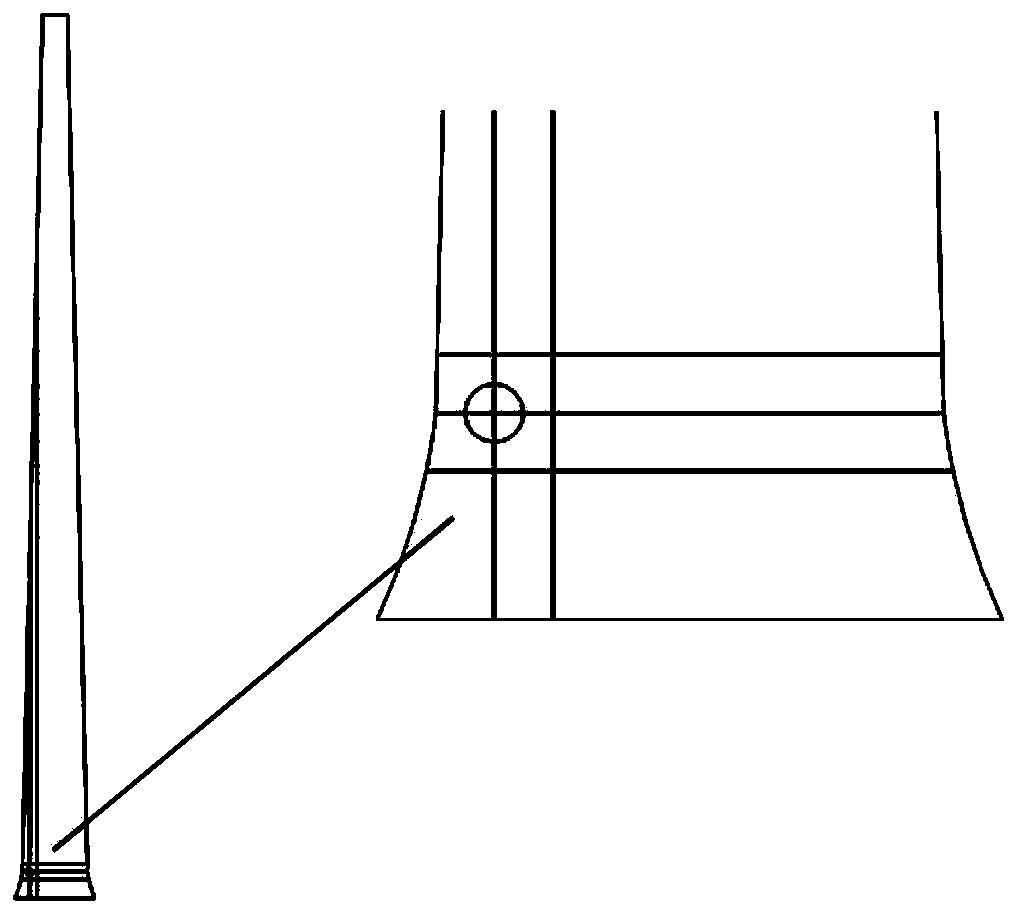

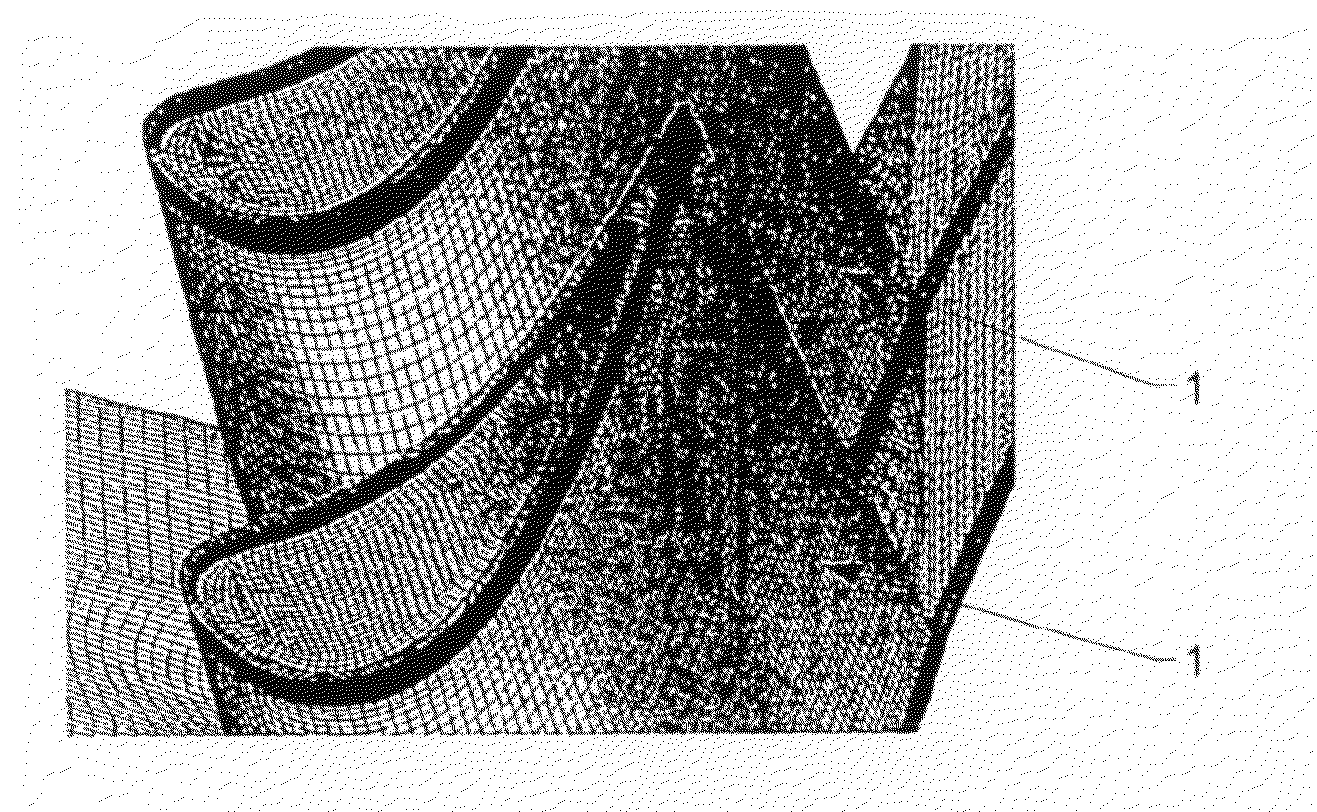

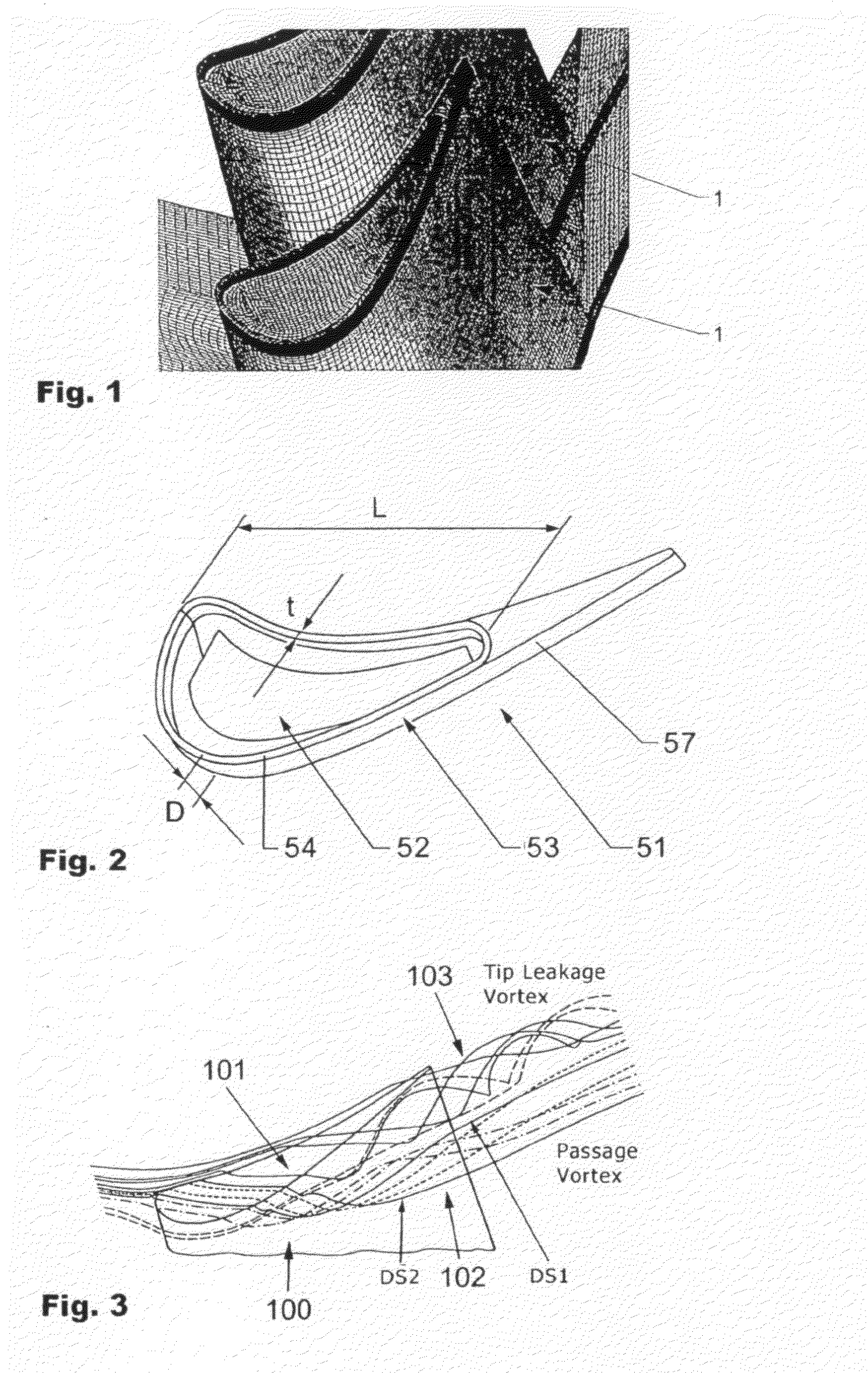

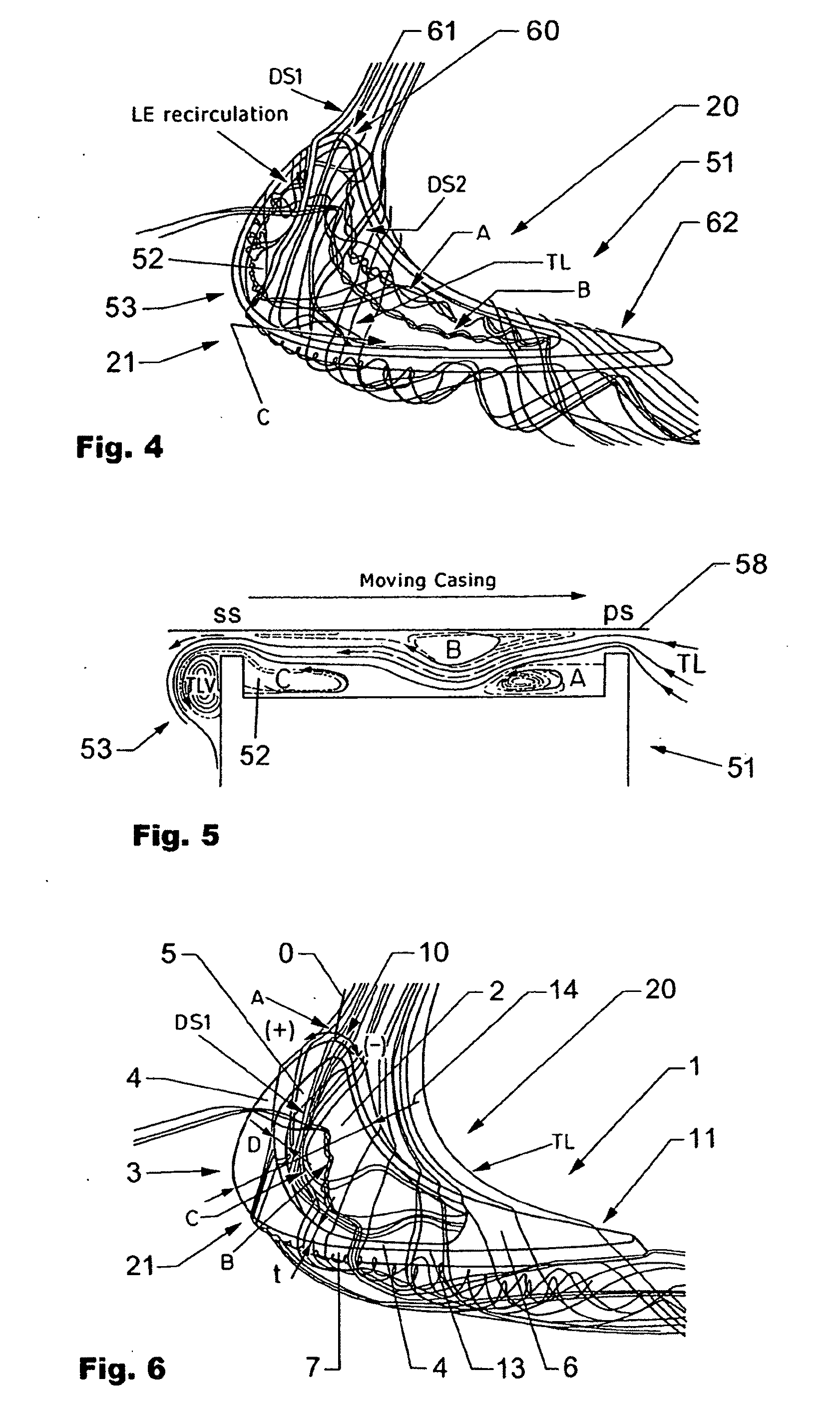

Turbine Blade With Recessed Tip

InactiveUS20090180887A1Improve performanceReduce heat loadBlade accessoriesLeakage preventionTurbine bladeAerodynamics

Owner:ZURICH ETH

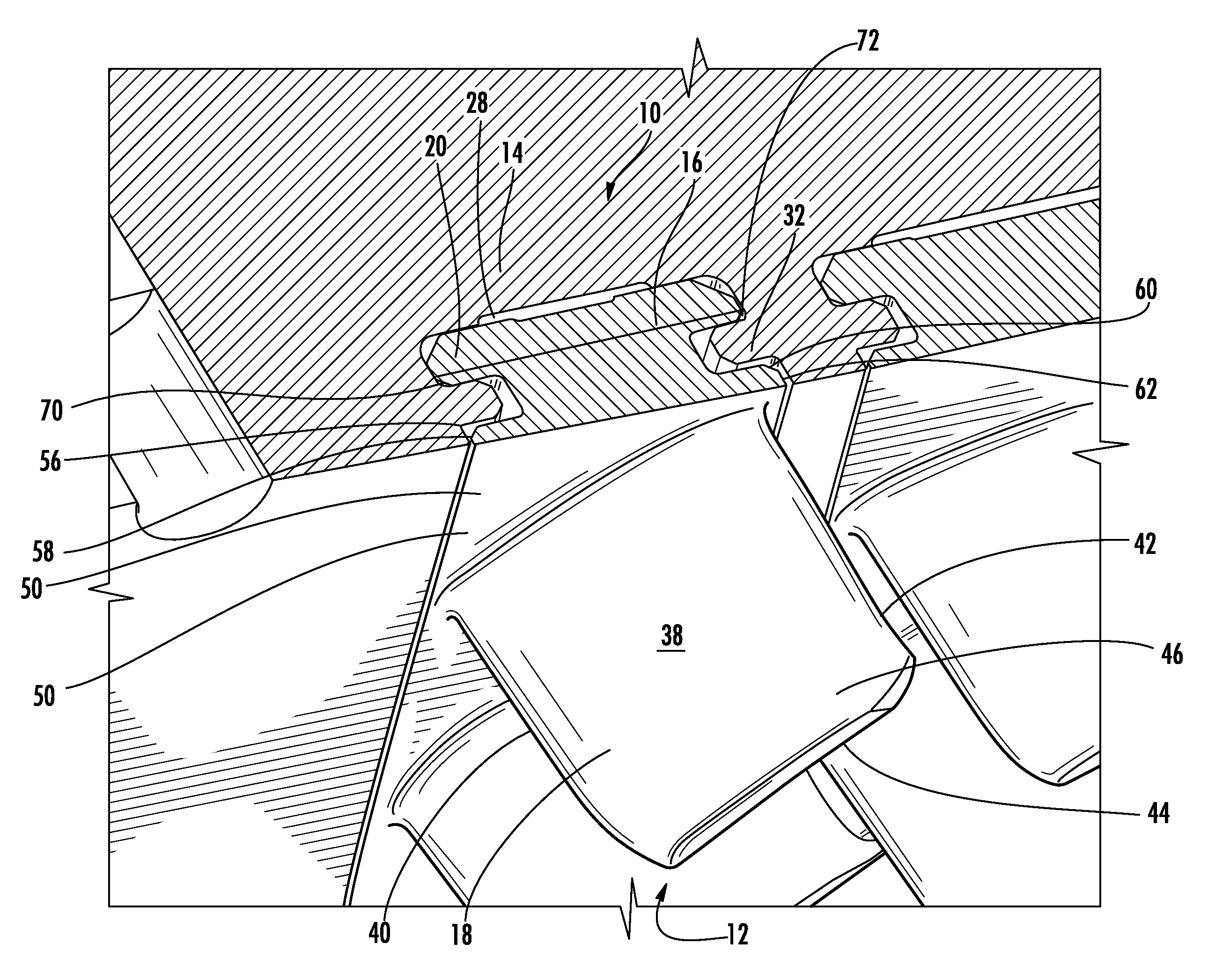

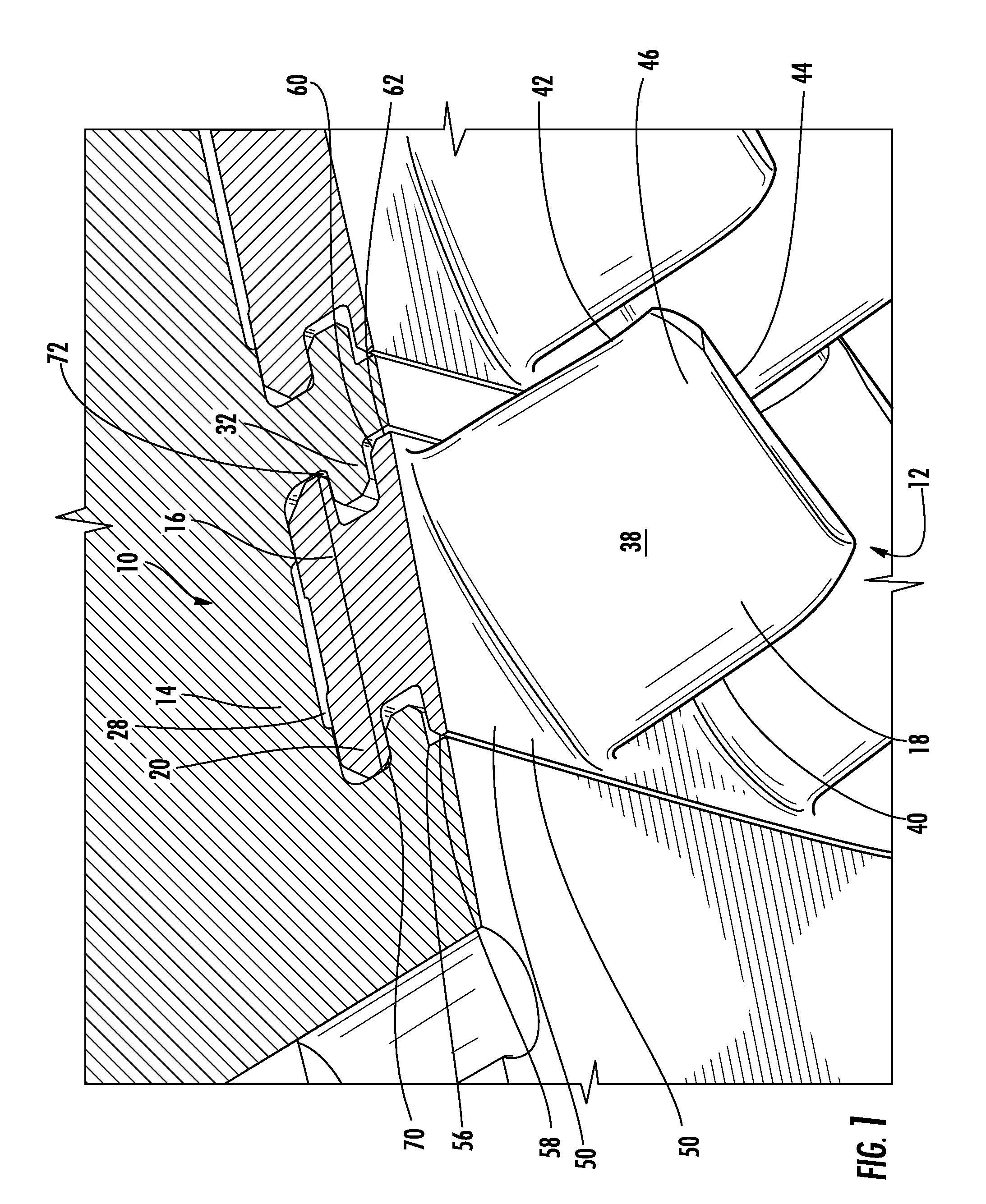

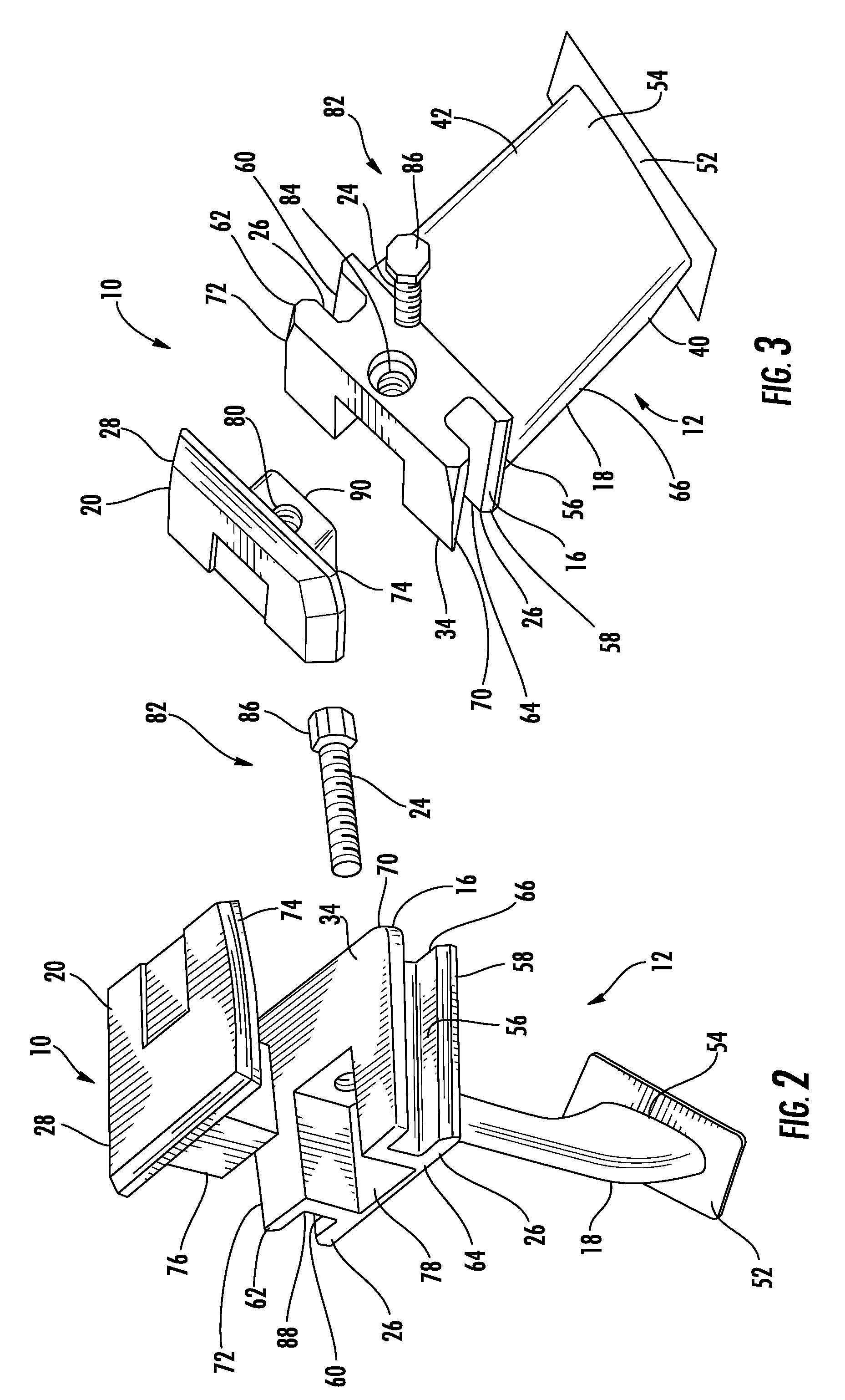

Turbine Vane Securing Mechanism

InactiveUS20090053056A1Eliminate relative motionPrevent movementEngine manufacturePump componentsTurbine bladeBearing surface

Owner:SIEMENS ENERGY INC

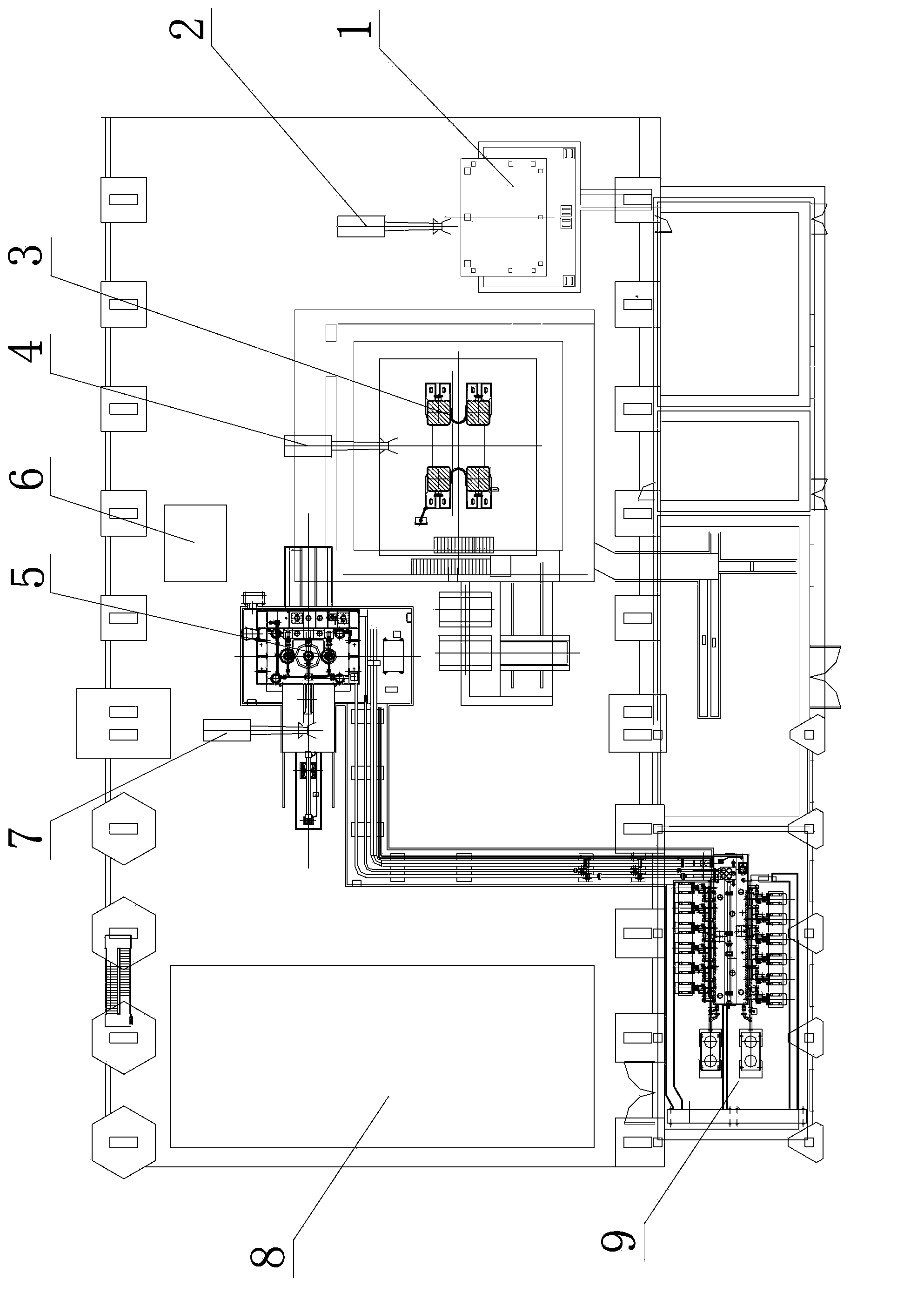

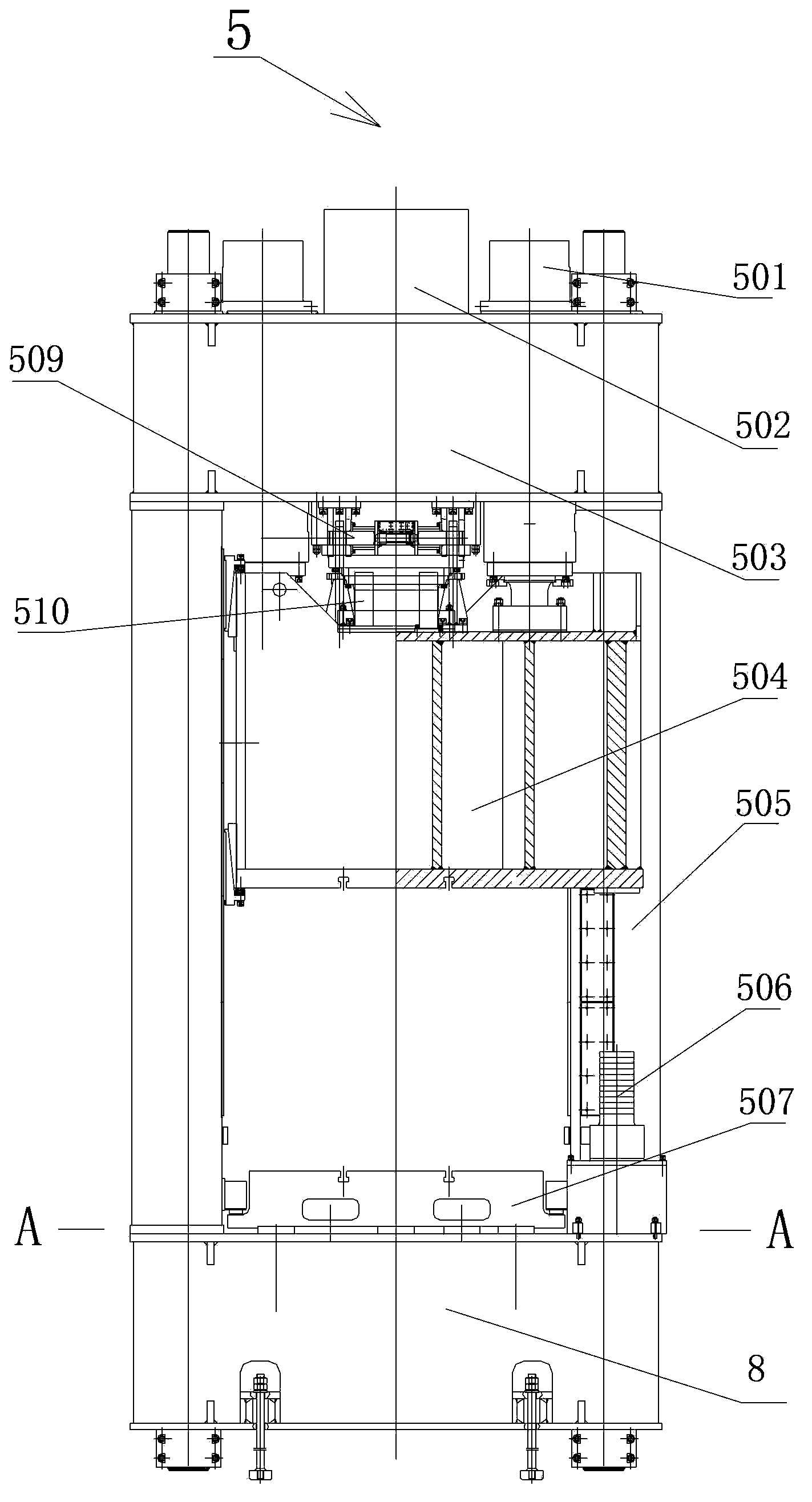

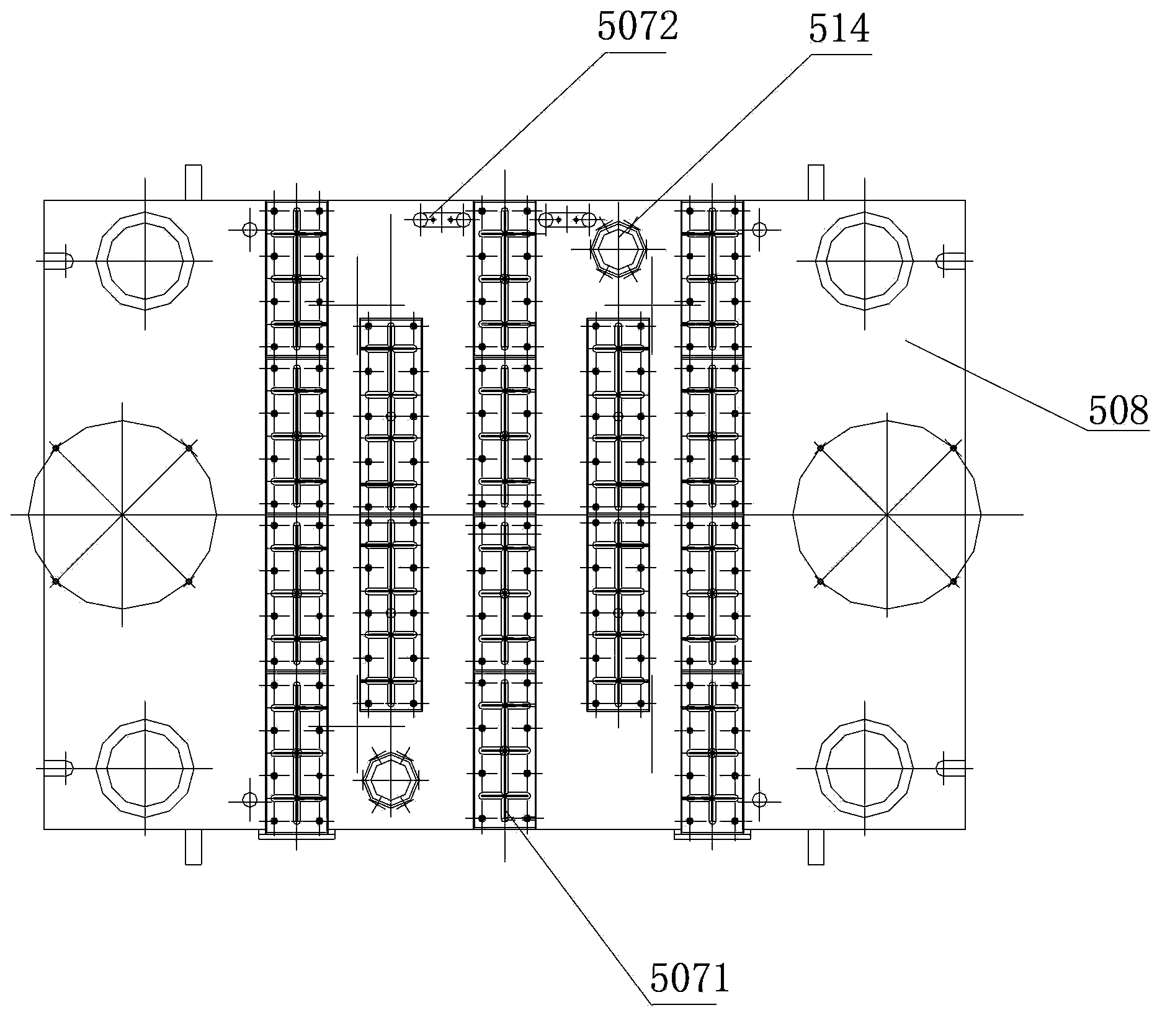

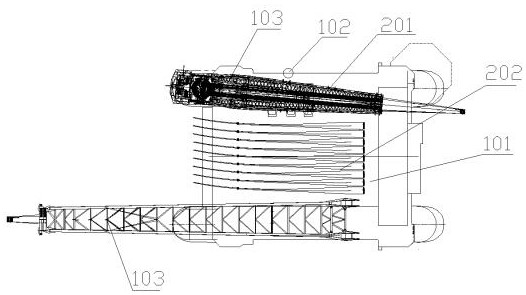

Full-automatic pressing production line for large turbine blade

Owner:TIANJIN TIANDUAN PRESS CO LTD

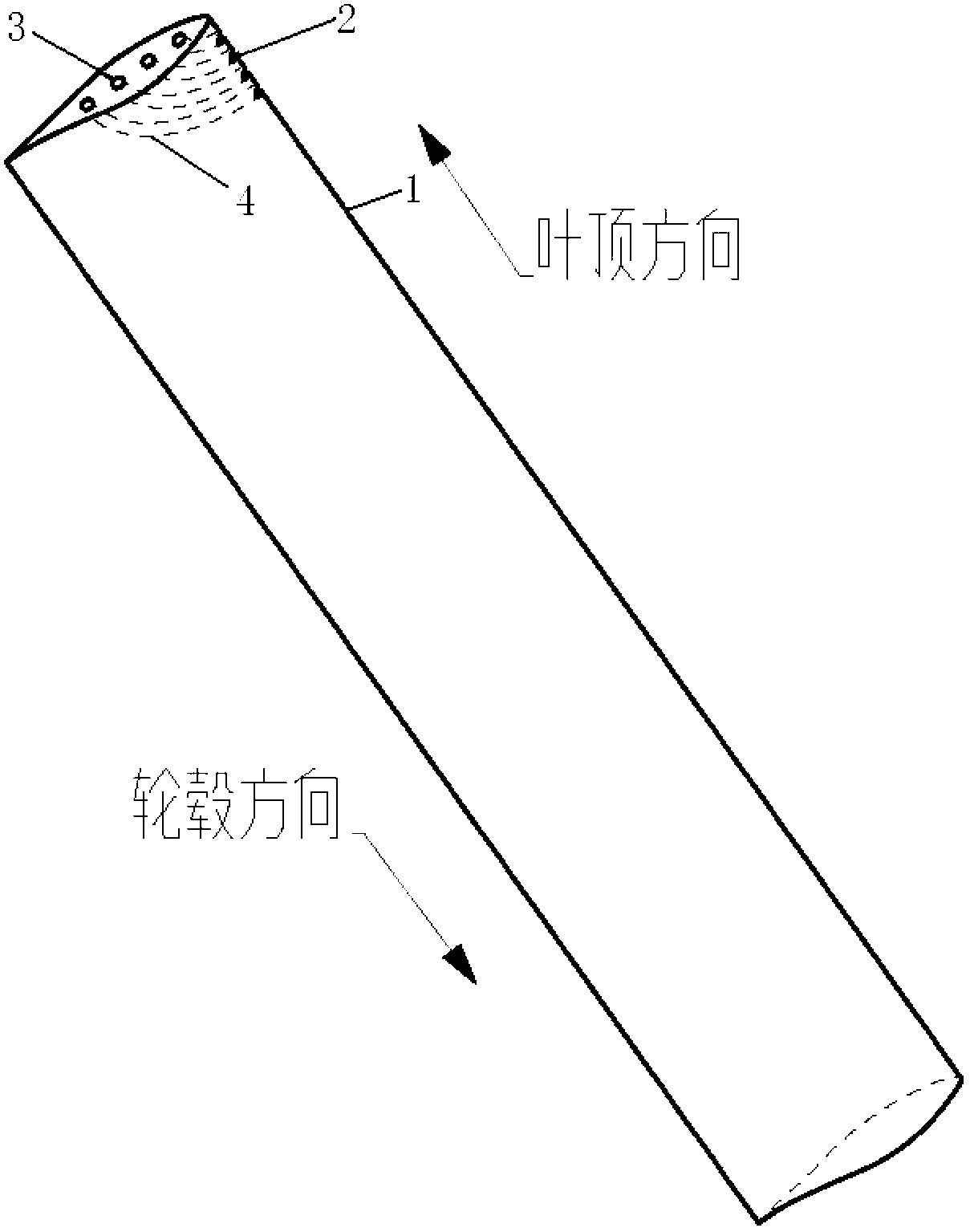

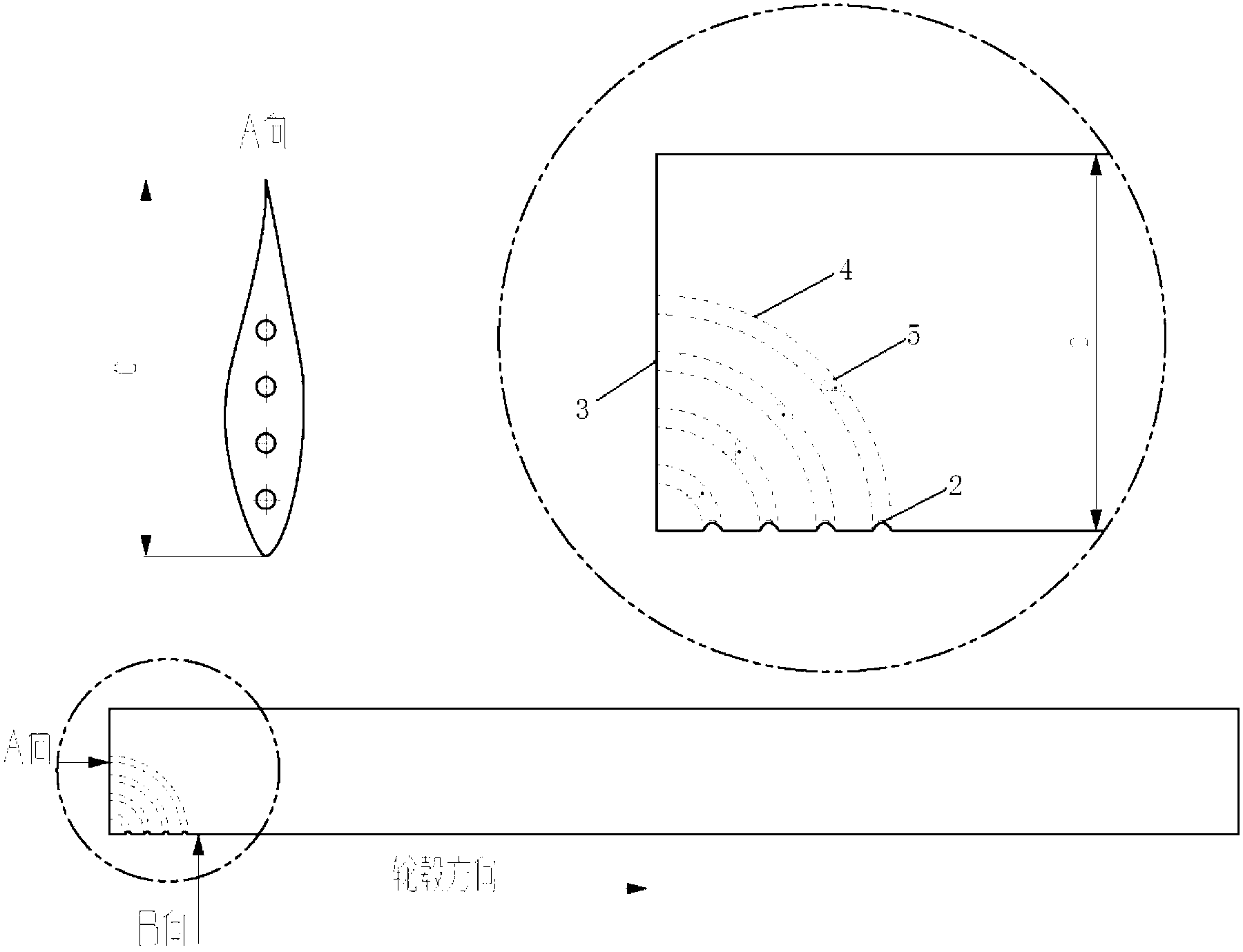

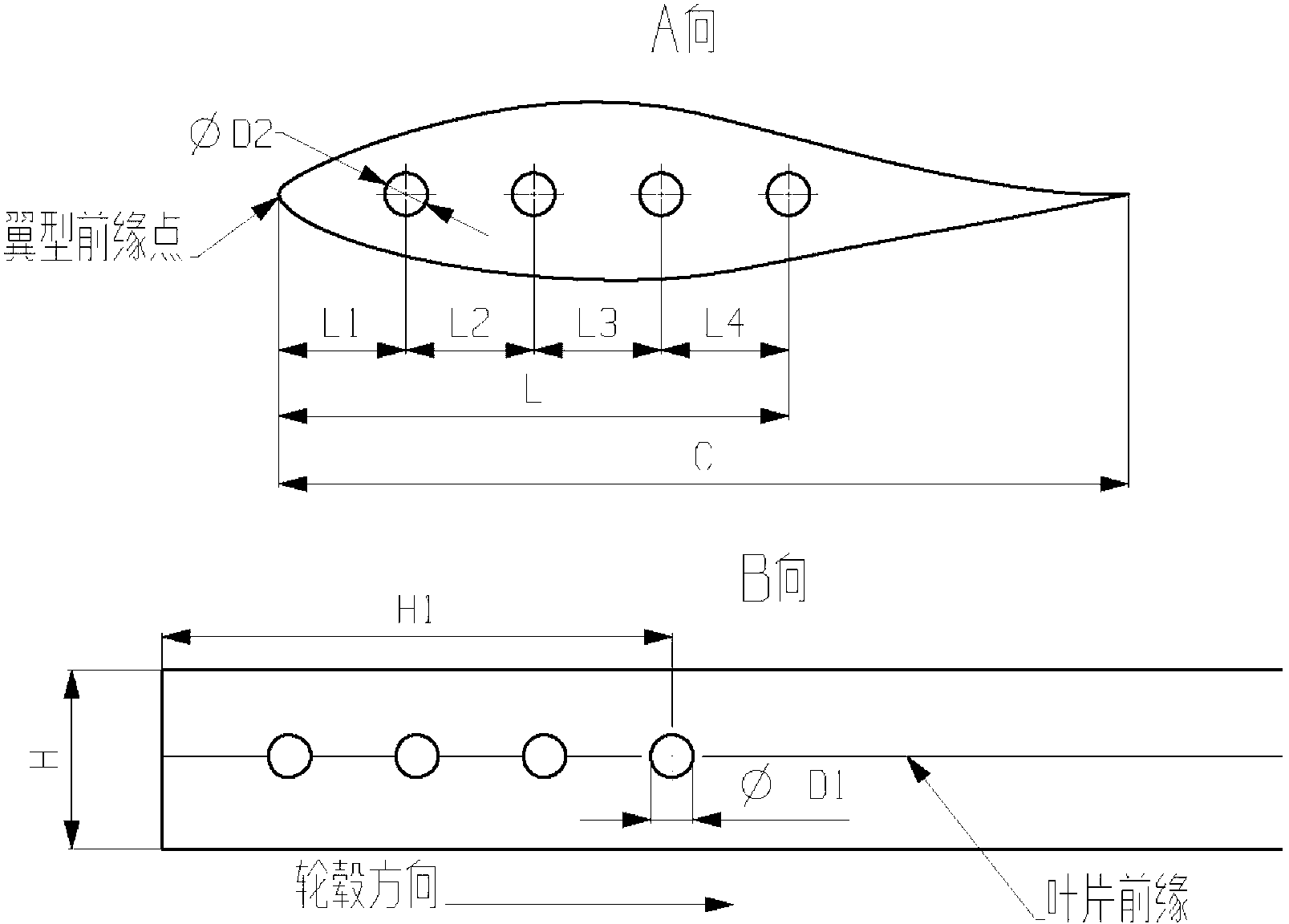

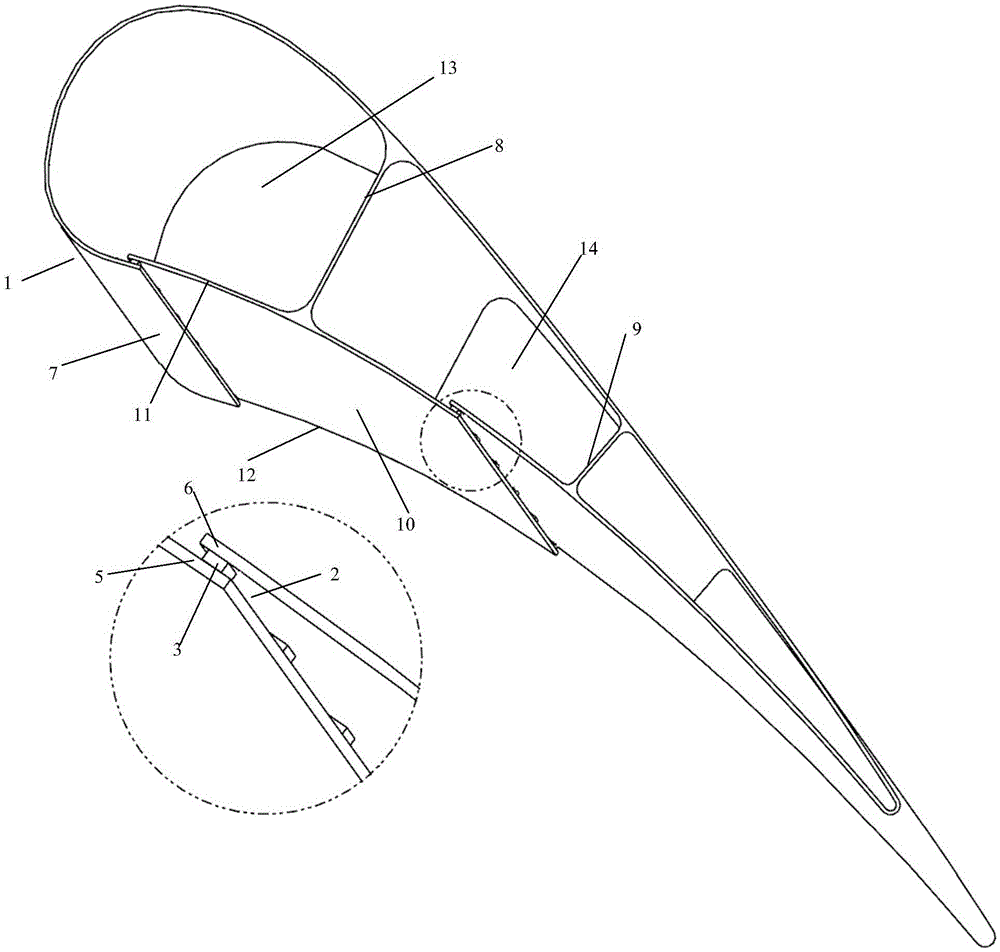

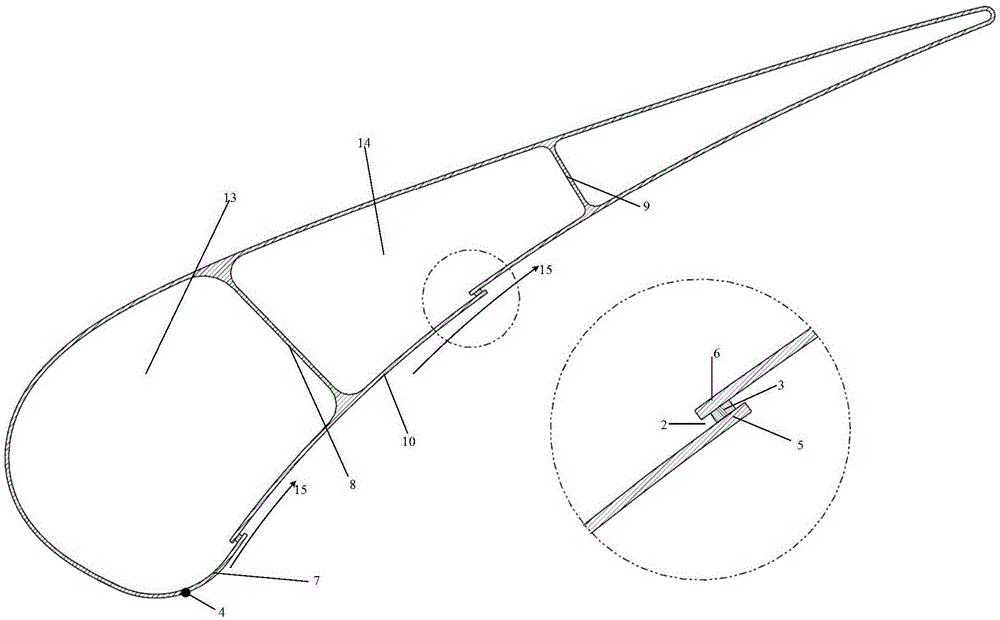

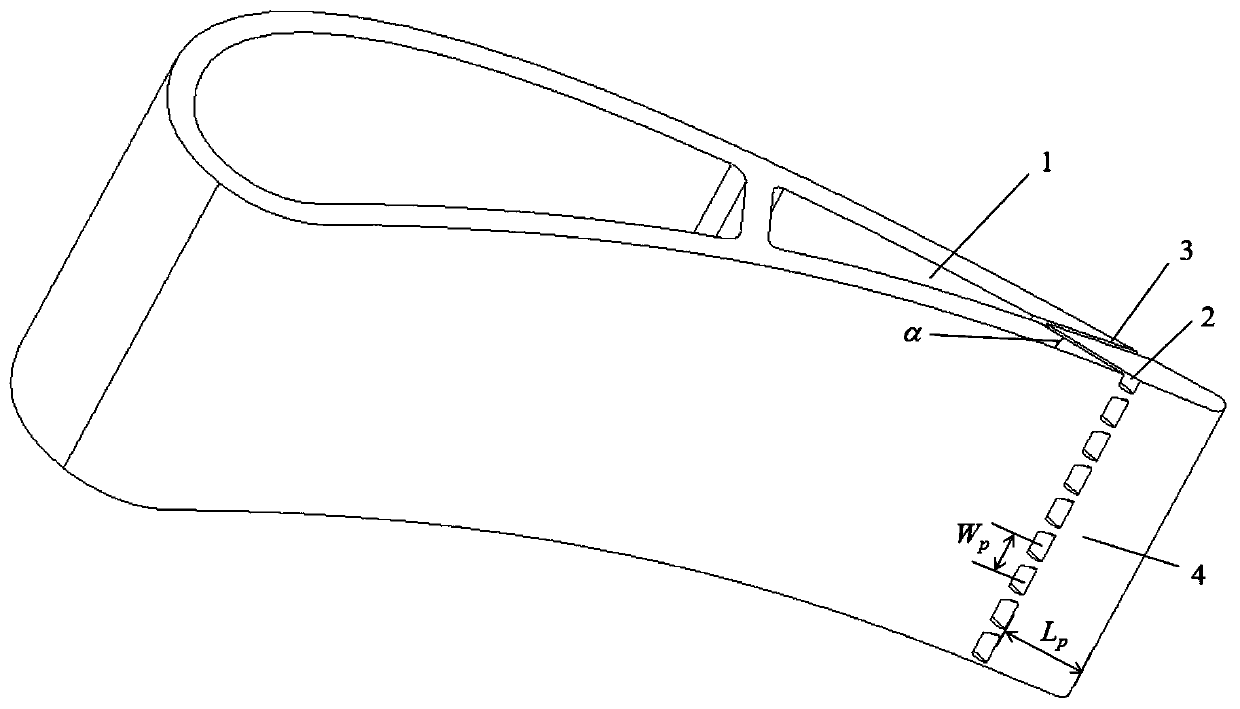

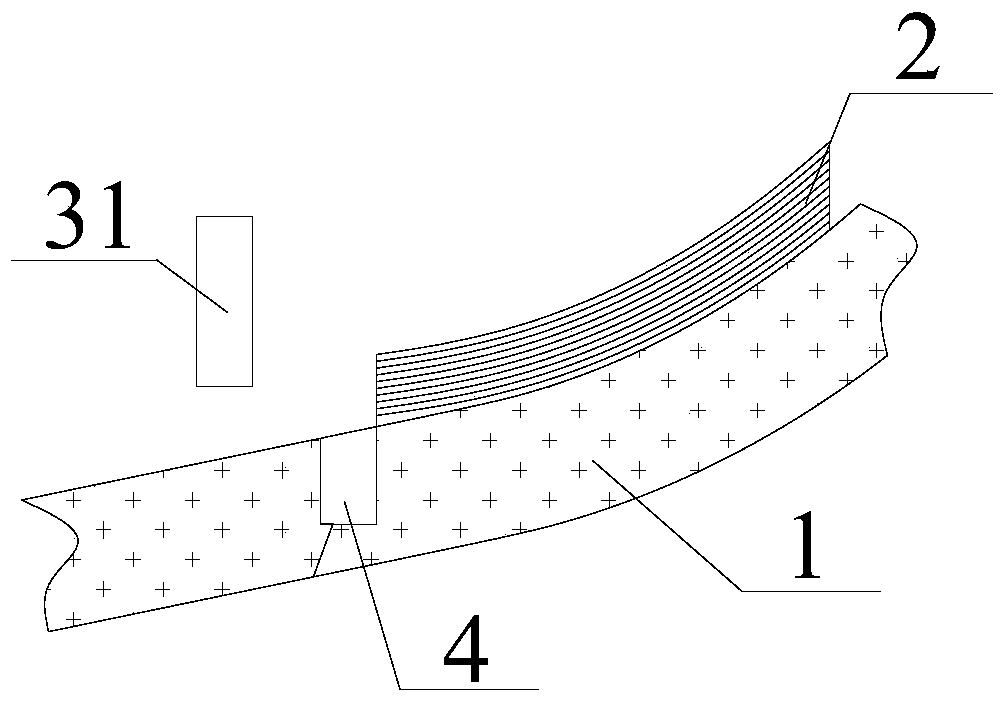

Wind turbine blade with embedded diversion pipe capable of controlling tip vortex

Owner:SHANGHAI JIAO TONG UNIV

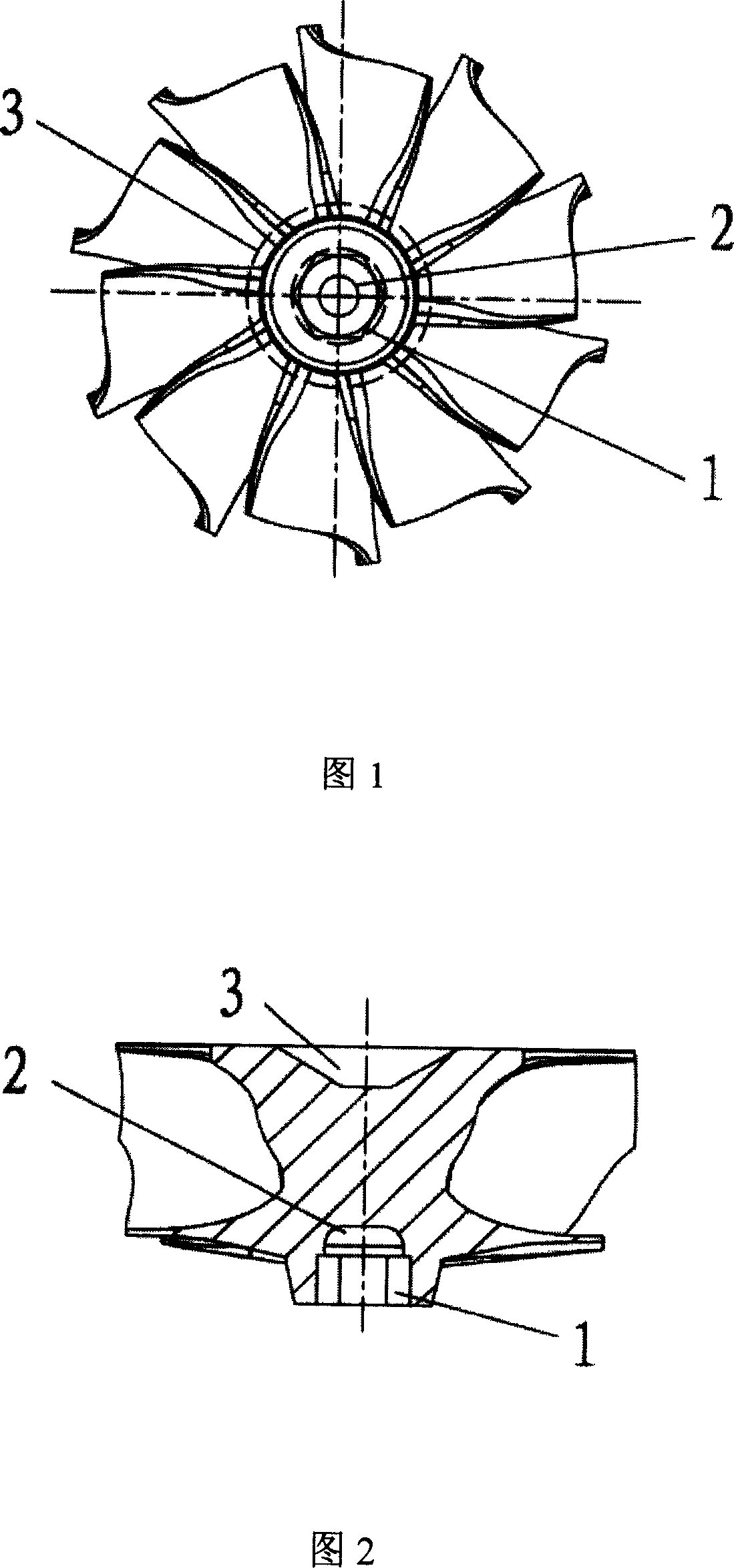

Structure of turbine blade wheel weight reducing for pressurizer

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Heat treatment method for recovering performance of K465 alloy turbine blade

ActiveCN103643188ARecovery performance (creep) effect is obviousSquare shapeFurnace typesHeat treatment furnacesTurbine bladeAlloy

The invention discloses a heat treatment method for recovering the performance of a K465 alloy turbine blade and belongs to the technical field of metallurgy. The heat treatment method comprises the following steps of 1, blade feeding, 2, furnace heating and then heat preservation: in vacuum or inert gas protective atmosphere, carrying out heat preservation at a temperature of 950-960 DEG C for 40-45min, carrying out heat preservation at a temperature of 1190-1200 DEG C for 2-2.5h and carrying out heat preservation at a temperature of 1230 DEG C for 4-4.5h, and 3, furnace cooling: (1), carrying out cooling from a temperature of 1230 DEG C to a temperature of 1000 DEG C at a cooling rate of 40+ / -25 DEG C / min by inert gas-based differential pressure cooling, and (2), feeding inert gas at a temperature of 1000 DEG C, carrying out cooling to a temperature of 300 DEG C, and opening a furnace door at a temperature below 300 DEG C and carrying out cooling. The heat treatment method can obviously recover the performance (such as creep deformation) of the K465 alloy turbine blade after a service cycle. Through the heat treatment method, transgranular gamma' polygonal or flower basket-shaped morphology is transformed into the cubical morphology so that morphology squaring is promoted.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

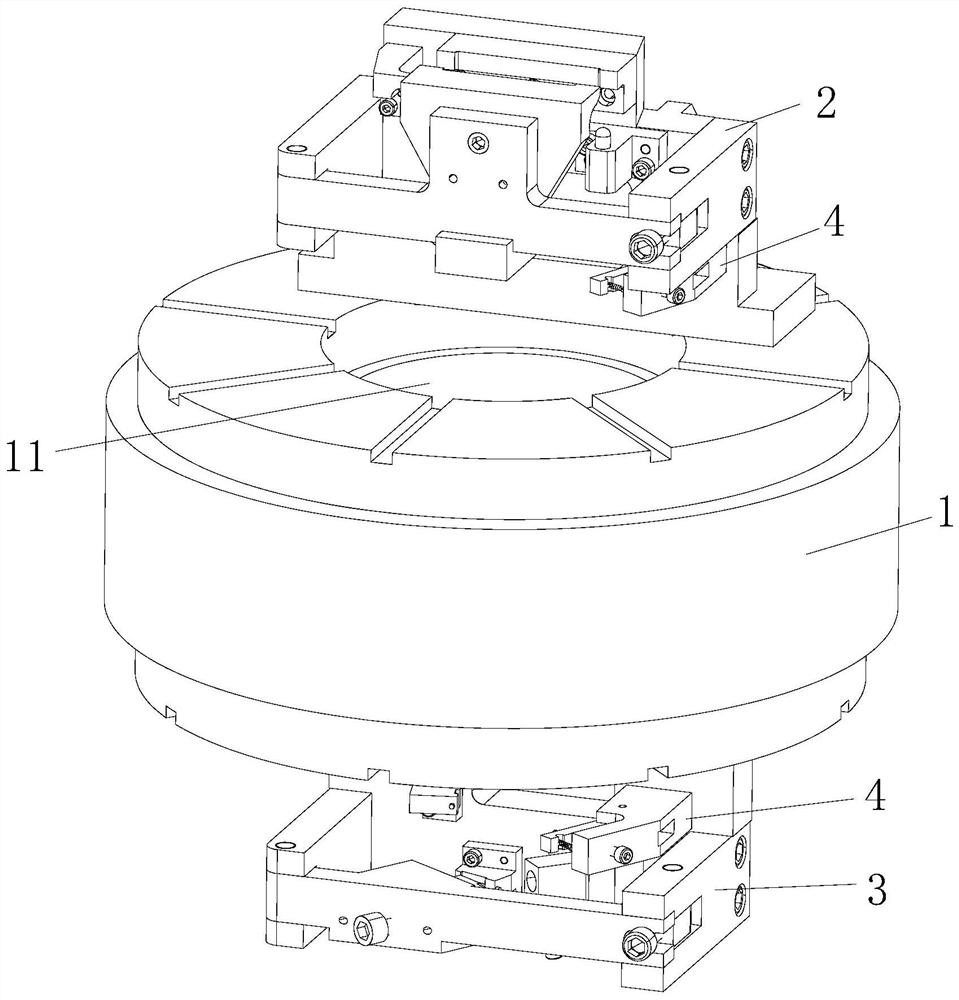

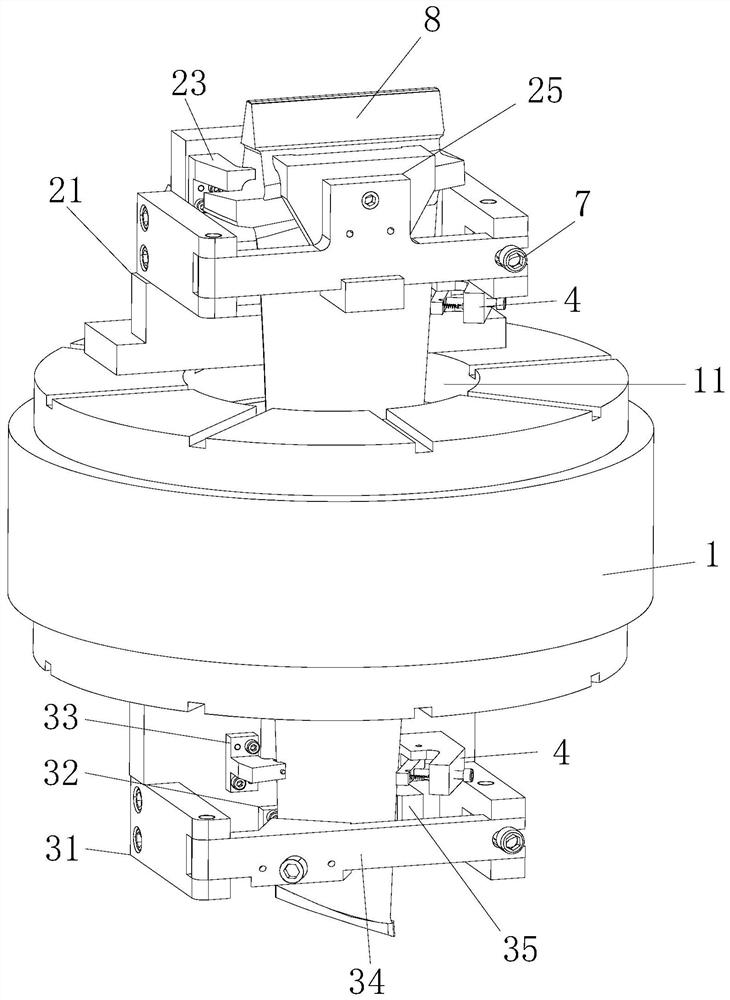

Machining tooling and machining method for ultra-large gas turbine blade

Owner:成都和鸿科技股份有限公司

Turbine blade with step gap cooling structure on pressure surface

Owner:BEIHANG UNIV +1

Novel building supermarket ventilation fireproof floor tile

InactiveCN113027068AReduce labor intensityImprove air qualityBatteries circuit arrangementsLighting and heating apparatusElectrical batteryTurbine blade

The invention discloses a novel building supermarket ventilation fireproof floor tile. The novel building supermarket ventilation fireproof floor tile comprises a box body, a metal plate is fixedly connected to one side of the box body, a sliding block is welded and fixed to the lower part of the metal plate, the sliding block penetrates through the box body, a permanent magnet is welded and fixed to the end, located in the box body, of the sliding block, and an electromagnetic coil is arranged outside the permanent magnet. The electromagnetic coil is connected with a battery through a wire, the battery is fixedly connected into the box body, a connecting box is fixedly connected into the box body, an air inlet is formed in the top of the box body, the air inlet communicates with the connecting box, and a heat conduction plate is arranged at the top of the box body. The novel building supermarket ventilation fireproof floor tile has the advantages that a pedestrian walks on the floor tile to drive a felt to move left and right, so that a rack moves up and down and is meshed to drive a straight gear to rotate and drive a turbine blade to rotate, air in a supermarket is sucked in through the air inlet and exhausted through an exhaust pipeline, air exchange is carried out, and the air quality in the supermarket is improved.

Owner:蒋岱青

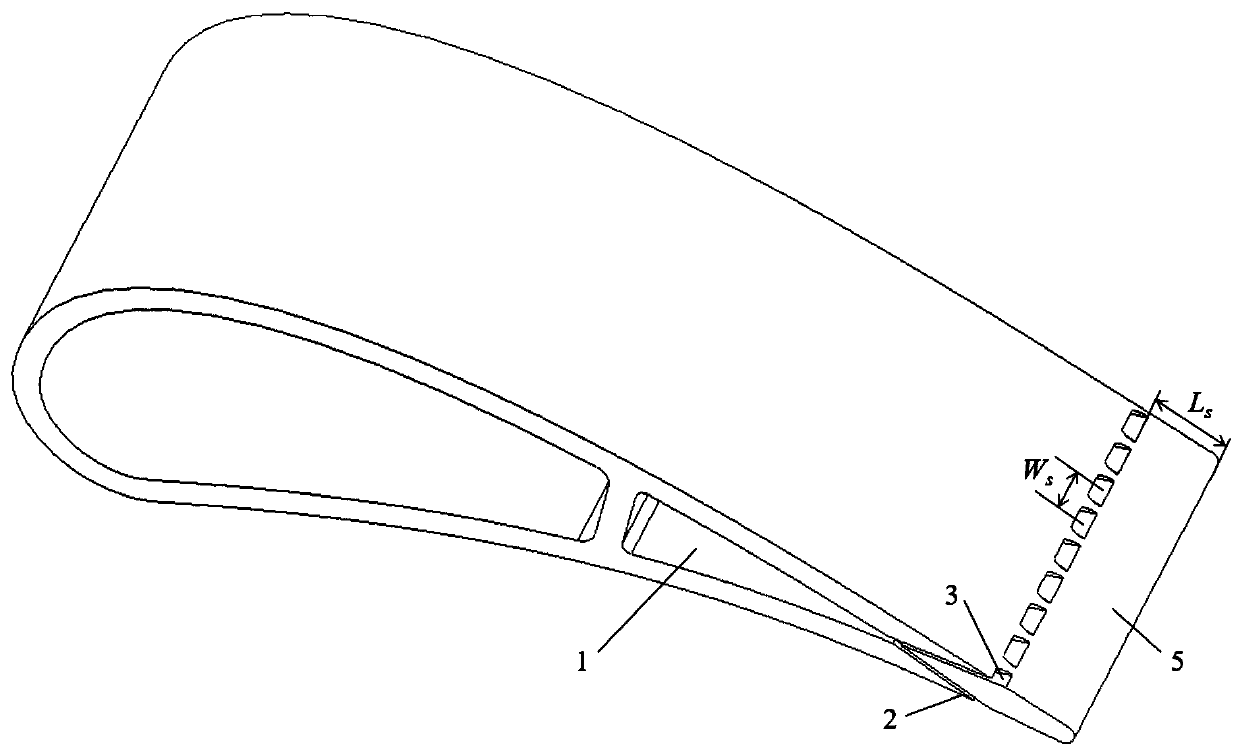

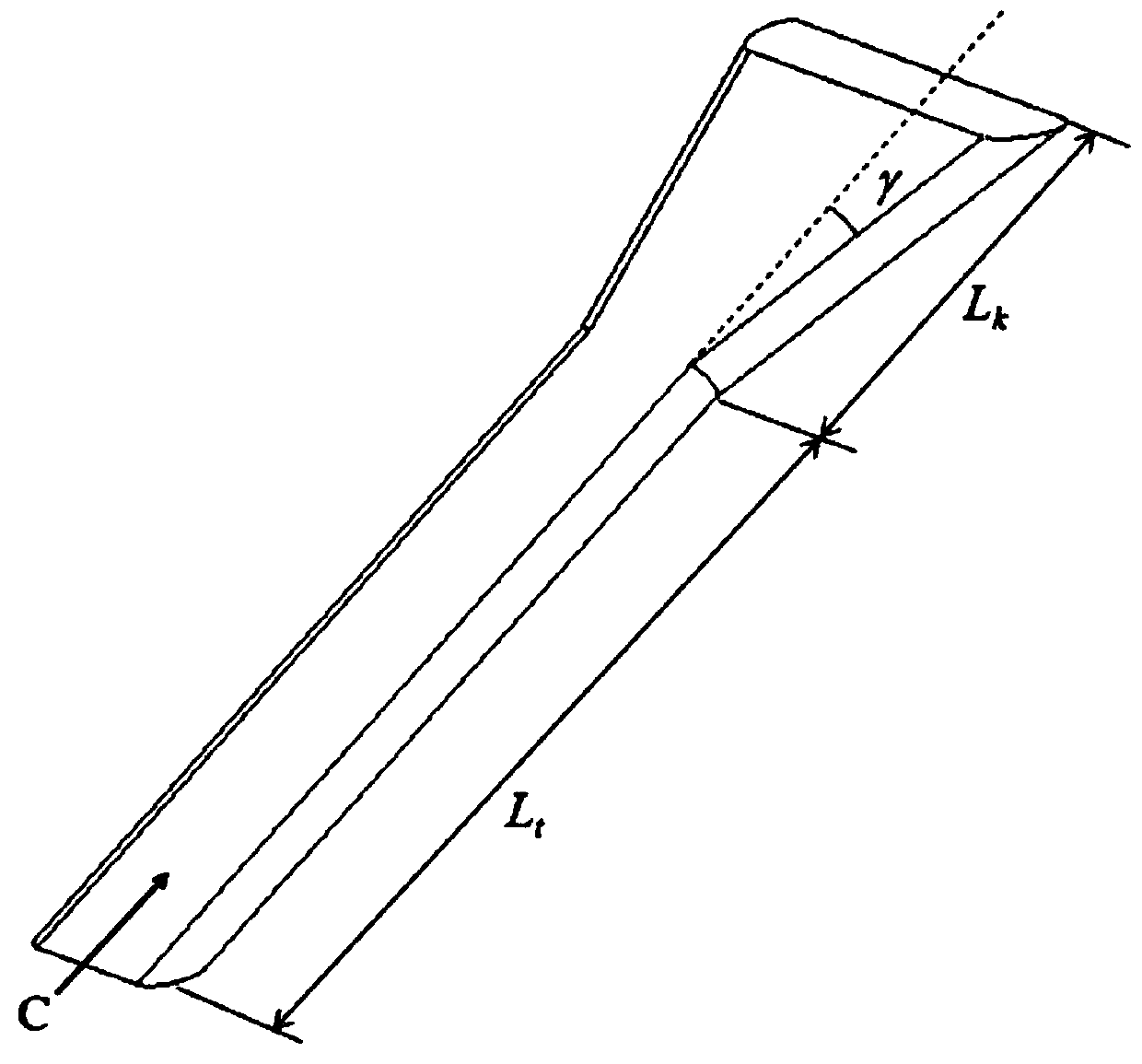

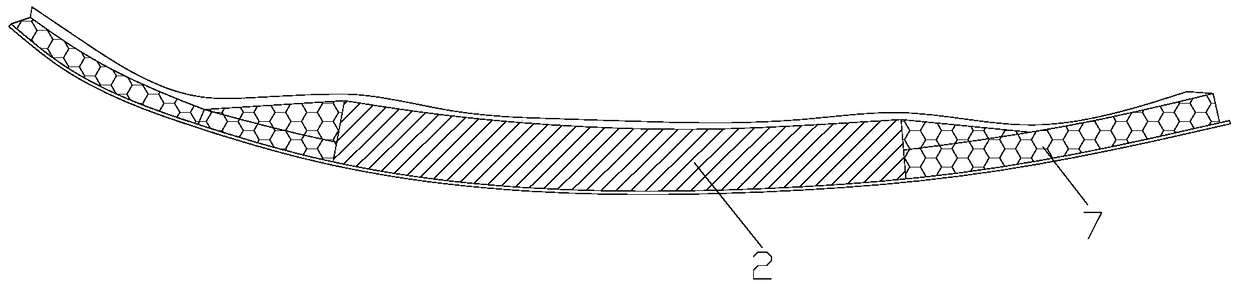

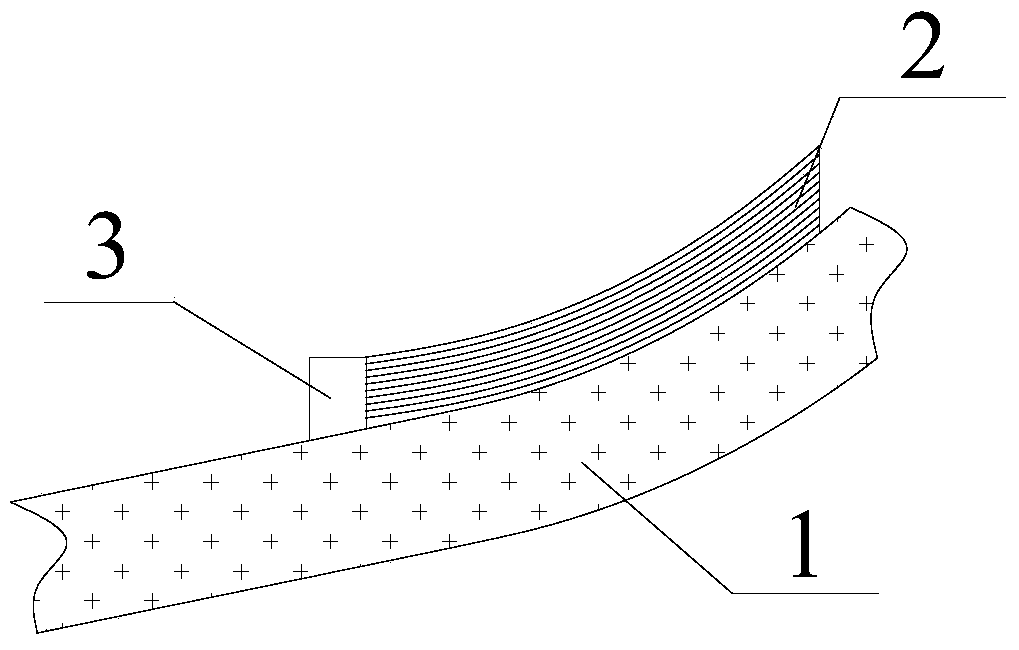

Turbine blade trailing edge cooling structure

InactiveCN111412020AImprove structural strengthEnhanced film cooling effectBlade accessoriesMachines/enginesCold airTurbine blade

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Mold and method for making wind turbine blades

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

System and method for reducing grain boundaries in shrouded airfoils

A turbine bucket includes an airfoil and a shroud. The shroud includes first and second bearing surfaces, and the first and second bearing surfaces each comprise a single grain structure. A method for forming a turbine bucket includes orienting a mold vertically, wherein the mold includes a first portion that defines a shank, a second portion connected to the first portion that defines an airfoil, and a third portion connected to the second portion that defines a shroud, wherein the third portion includes first and second sides, and wherein the first portion is higher than the second portion and the second portion is higher than the third portion. The method further includes flowing a molten metal into the mold and selectively growing large single grains in at least one of the first or second sides.

Owner:GE INFRASTRUCTURE TECH INT LLC

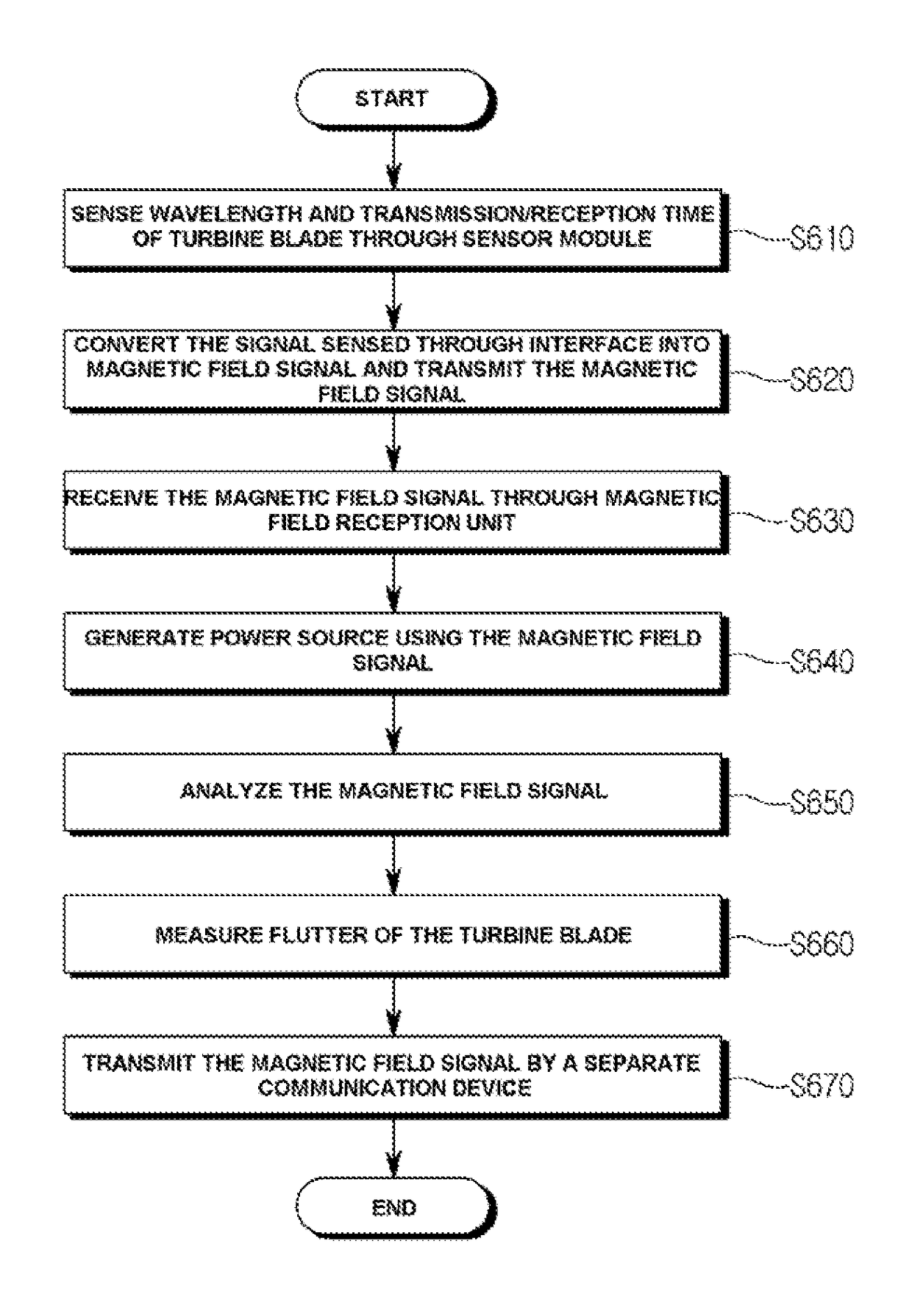

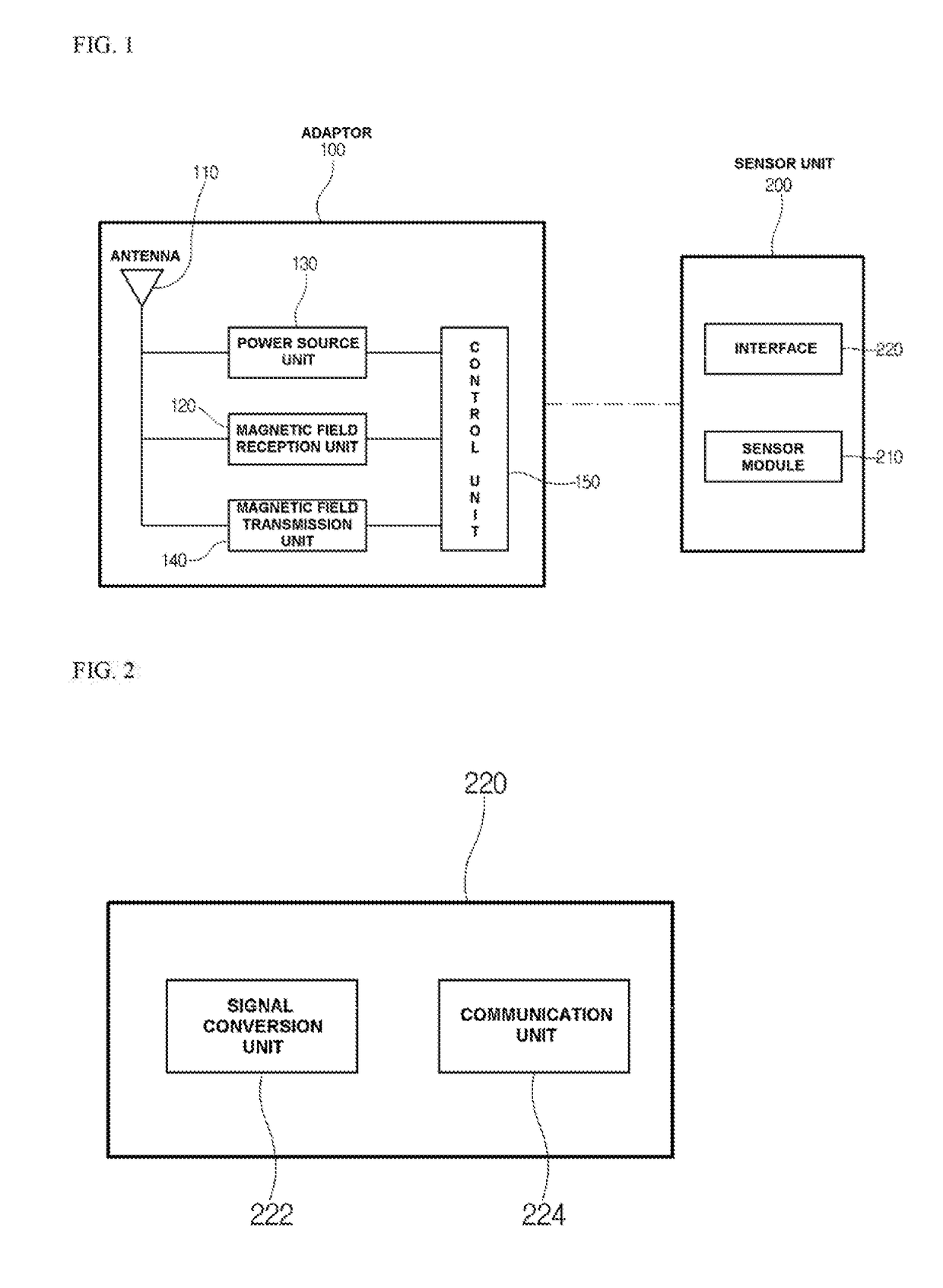

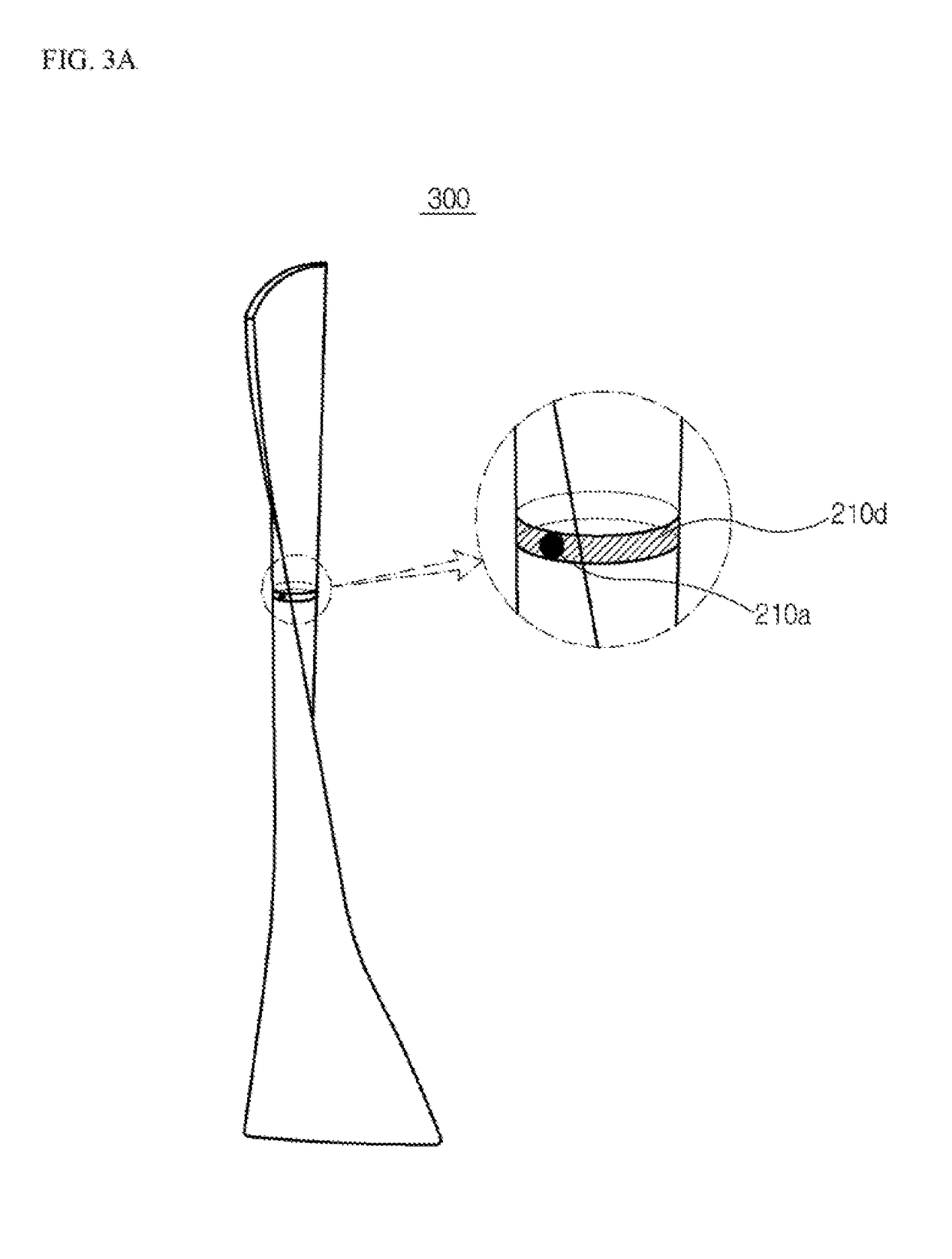

Magnetic field communication system and method for measuring flutter of turbine blade

ActiveUS20180283936A1Reduce harmSimple configurationVibration measurement in solidsNear-field transmissionCommunications systemSignal on

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

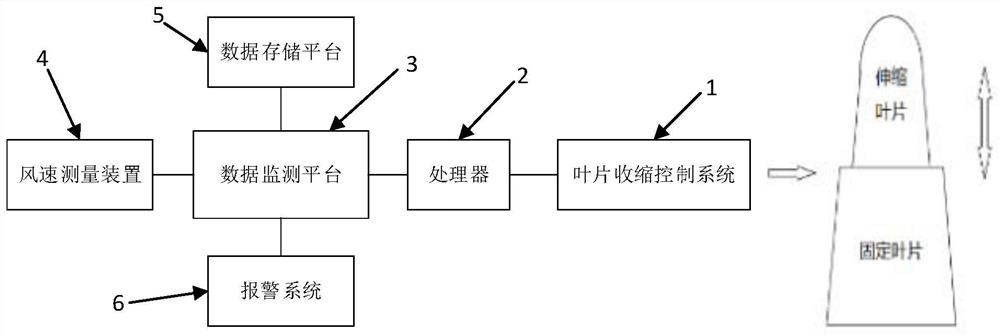

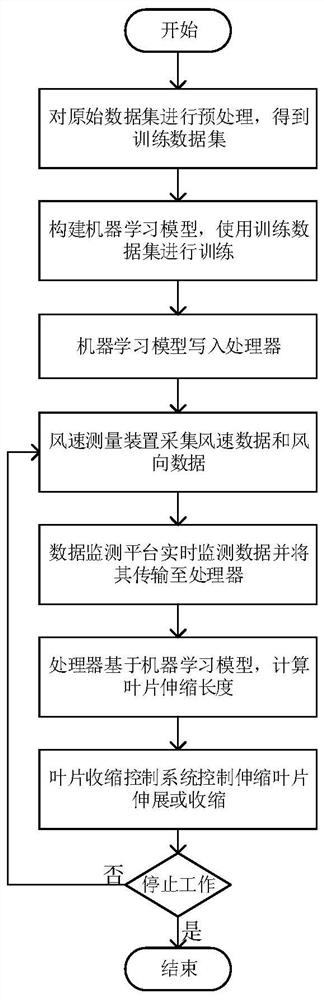

Automatic retracting wind turbine blade and control method thereof

PendingCN112594125AWon't hurtEfficient captureWind motor controlMachines/enginesData setControl system

Owner:SHANGHAI DIANJI UNIV

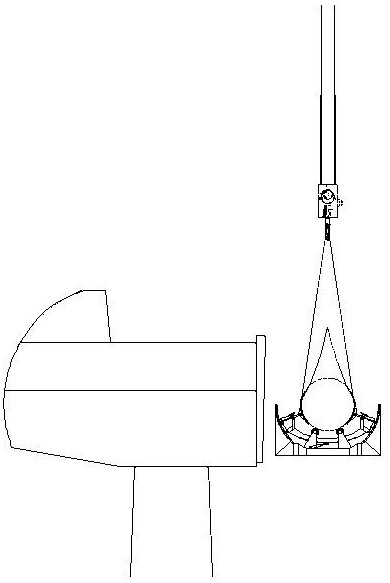

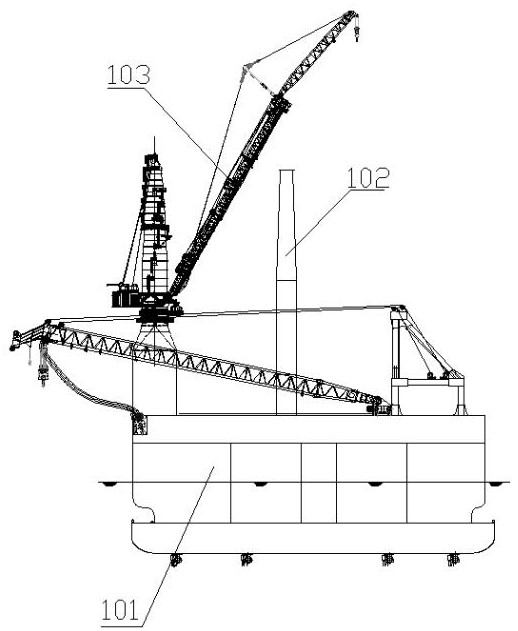

Offshore wind turbine pre-assembly process

PendingCN114228946AWaterborne vesselsNacelleTurbine blade

Owner:山东宏洲海洋工程有限公司 +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap