Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15 results about "Surface modified" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

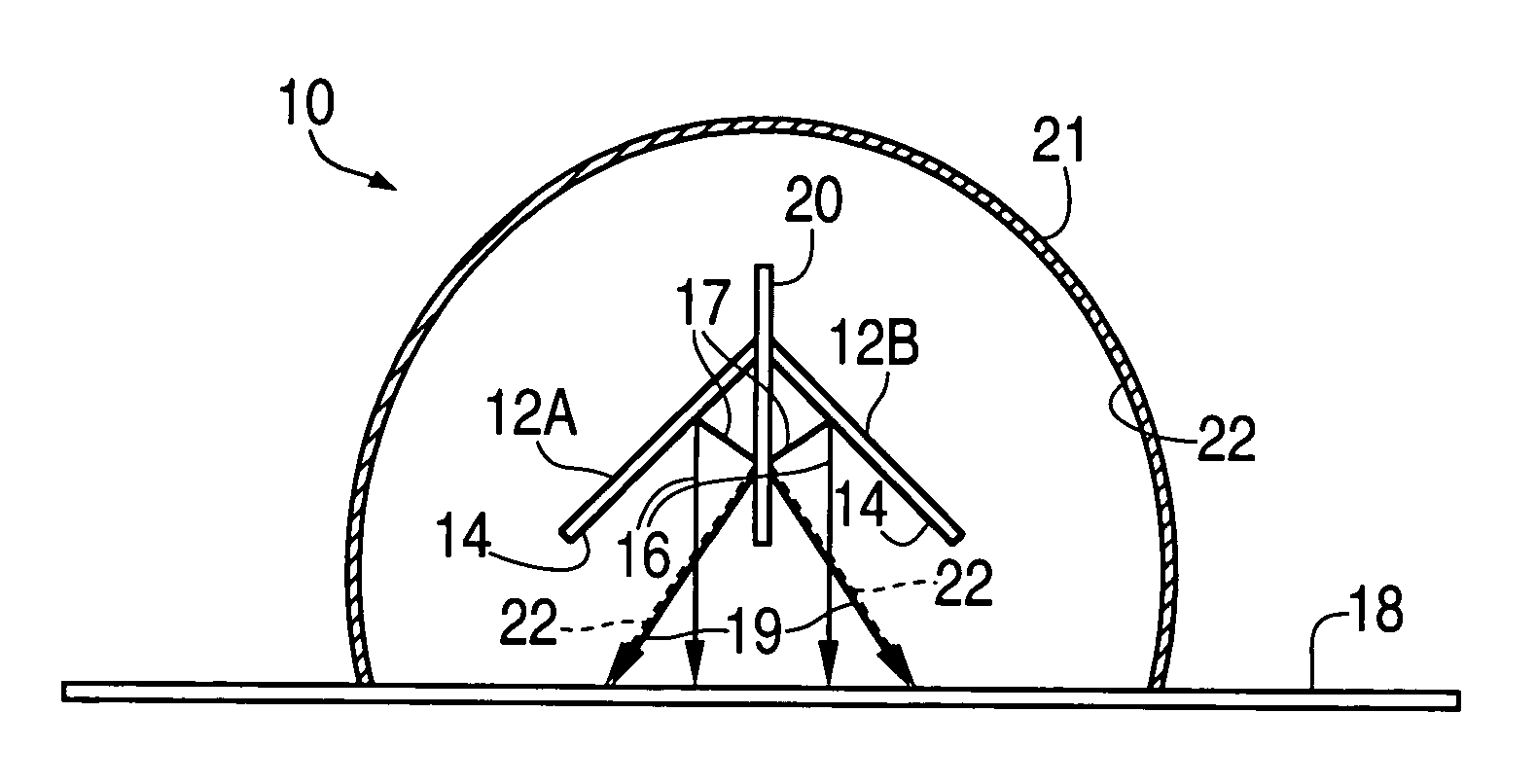

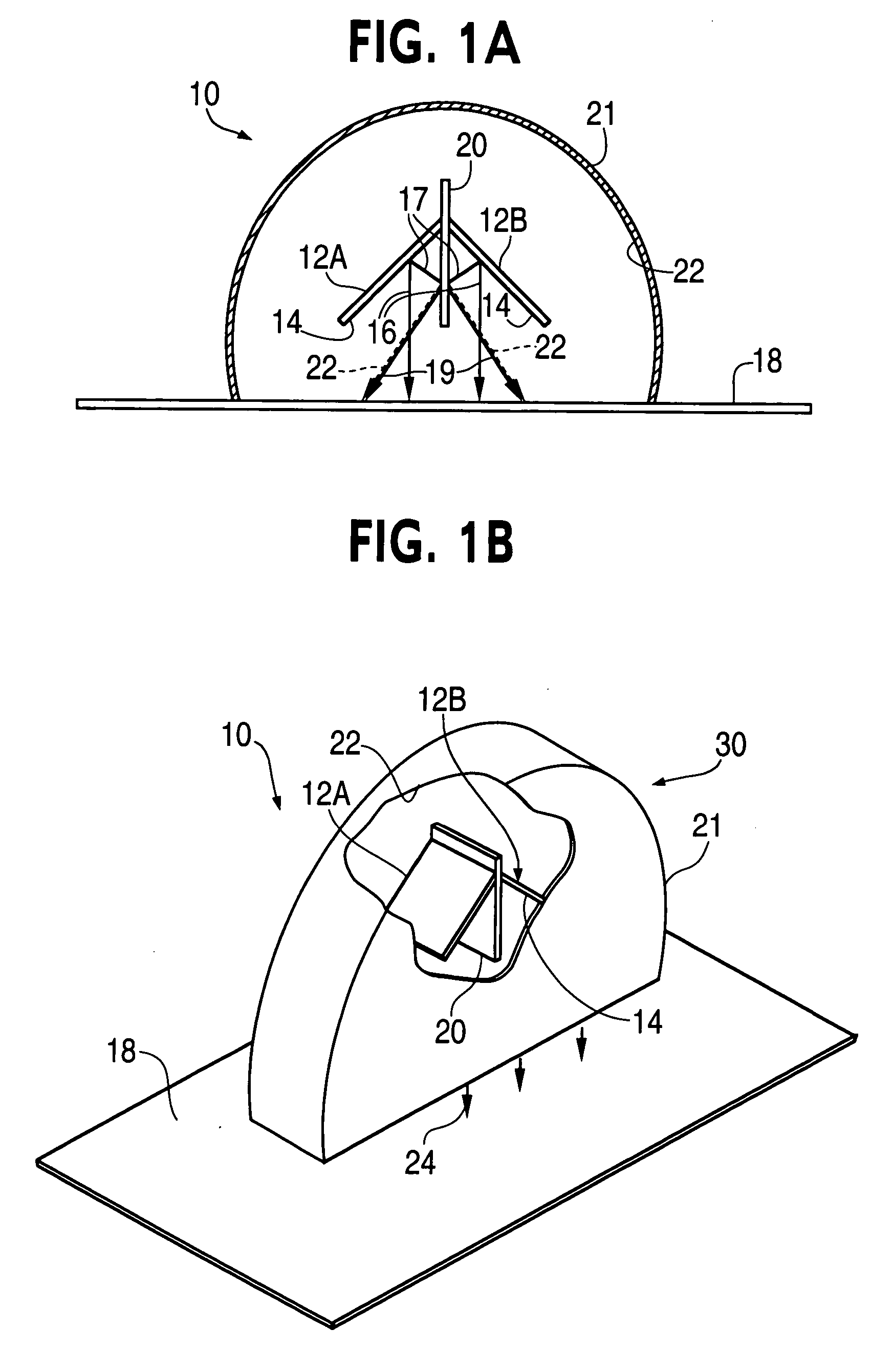

Solid-state light sources for curing and surface modification

InactiveUS20060274421A1Improve stabilityExtended service lifePoint-like light sourcePretreated surfacesMultiwavelength spectroscopyLight beam

Owner:HERAEUS NOBLELIGHT AMERICA

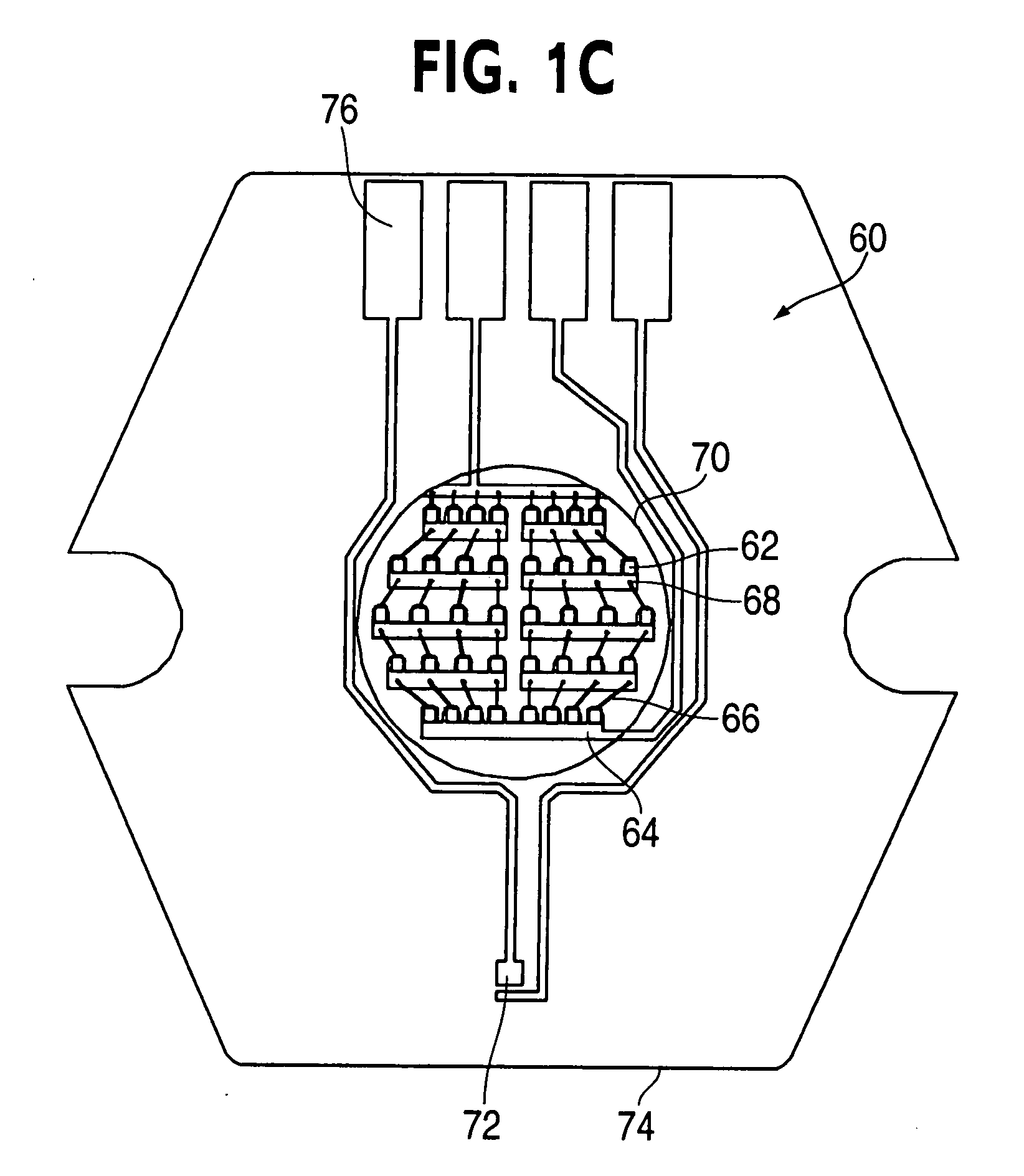

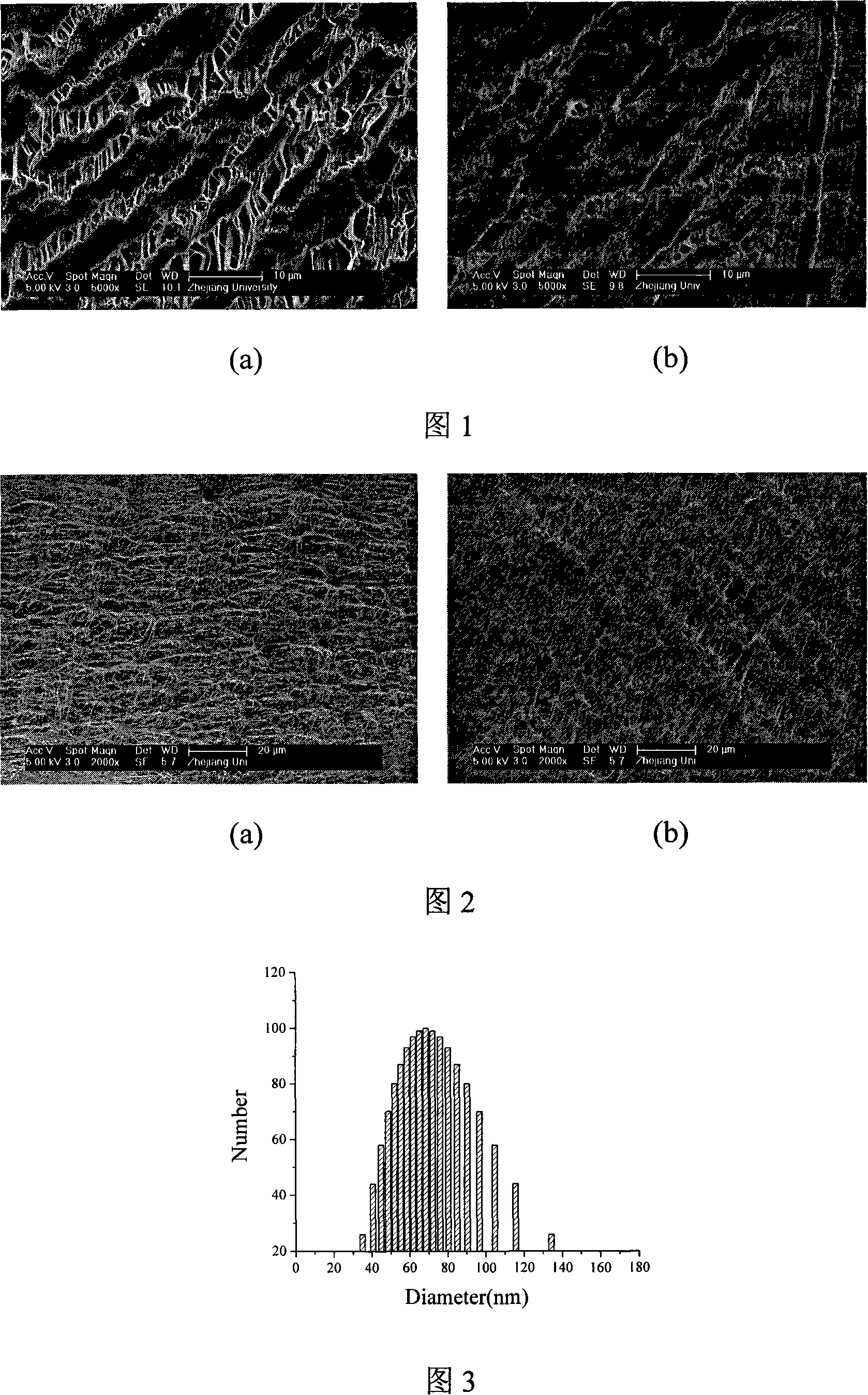

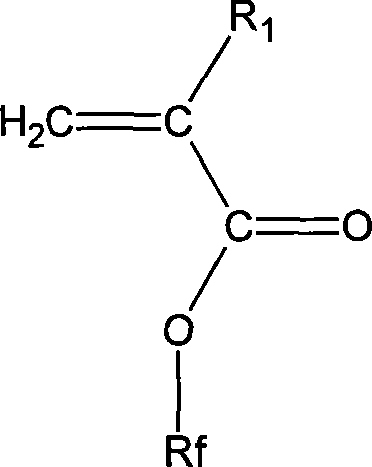

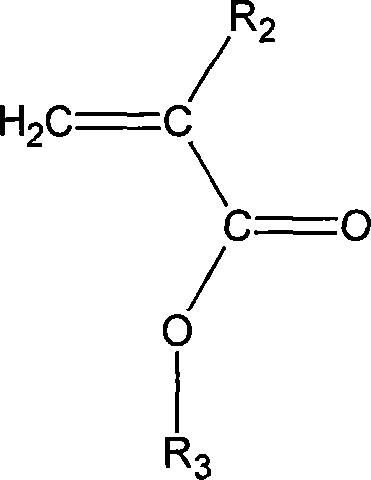

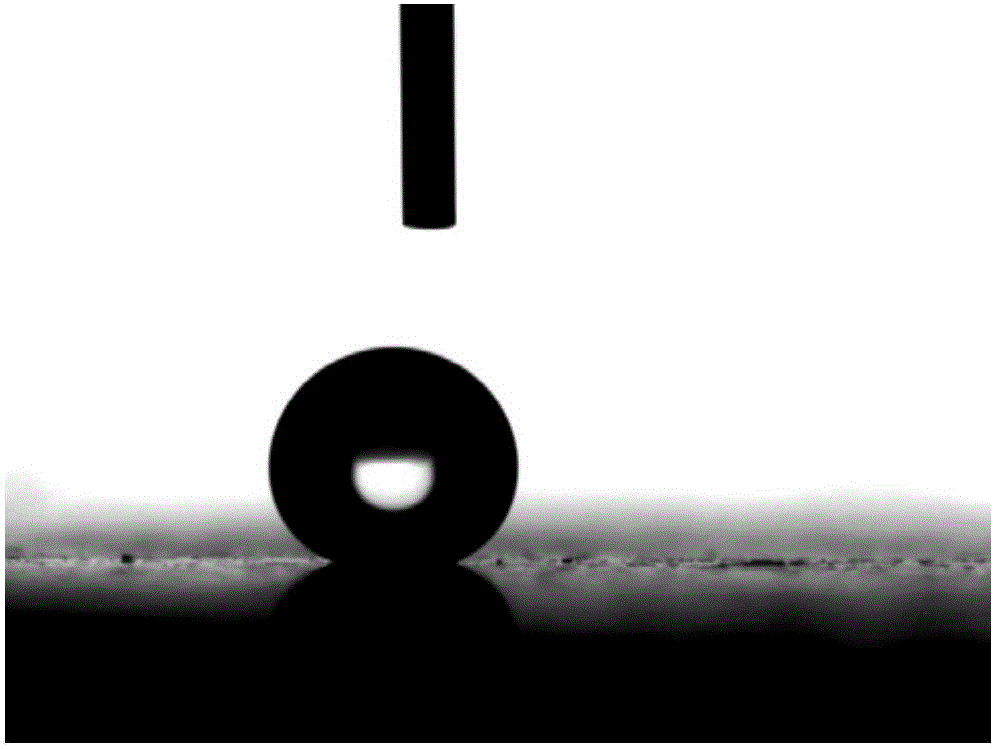

Method of amphipathic nature fluorine-contained copolymer modifying surface of polytetrafluoroethylene porous membrane

InactiveCN101108313AImprove anti-pollution performanceImprove hydrophilic abilitySemi-permeable membranesFiberTetrafluoroethylene

Owner:ZHEJIANG UNIV

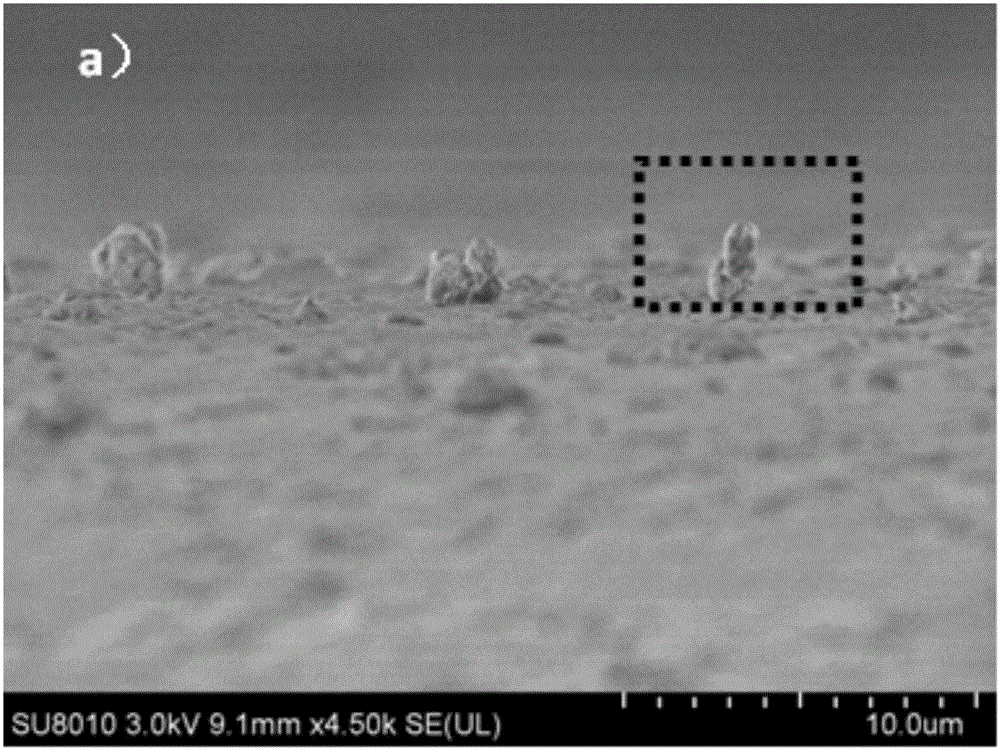

Super-hydrophobic polypropylene film and preparation method thereof

Owner:ZHEJIANG UNIV

Functionalized support for analytical sample preparation

Owner:AGILENT TECH INC

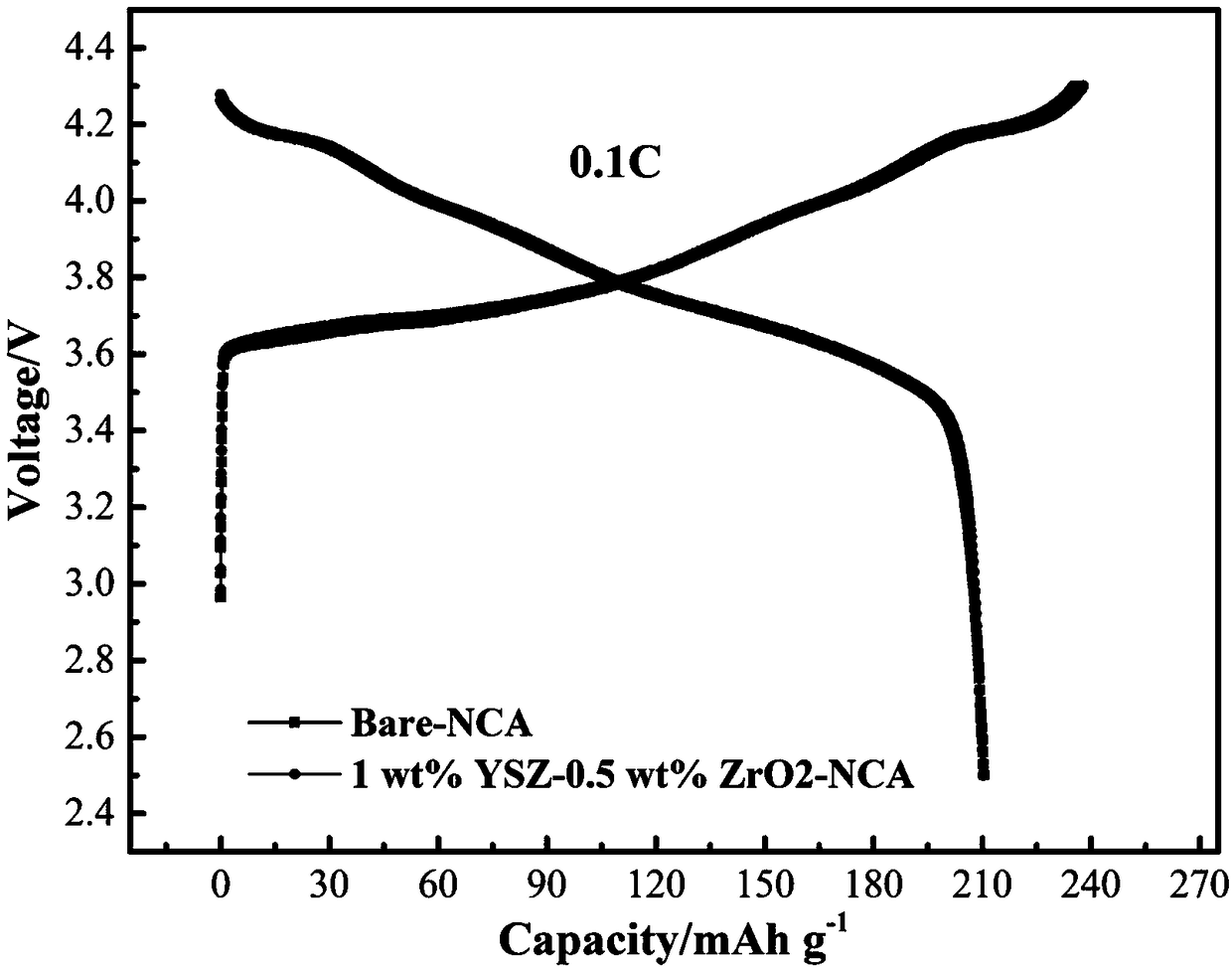

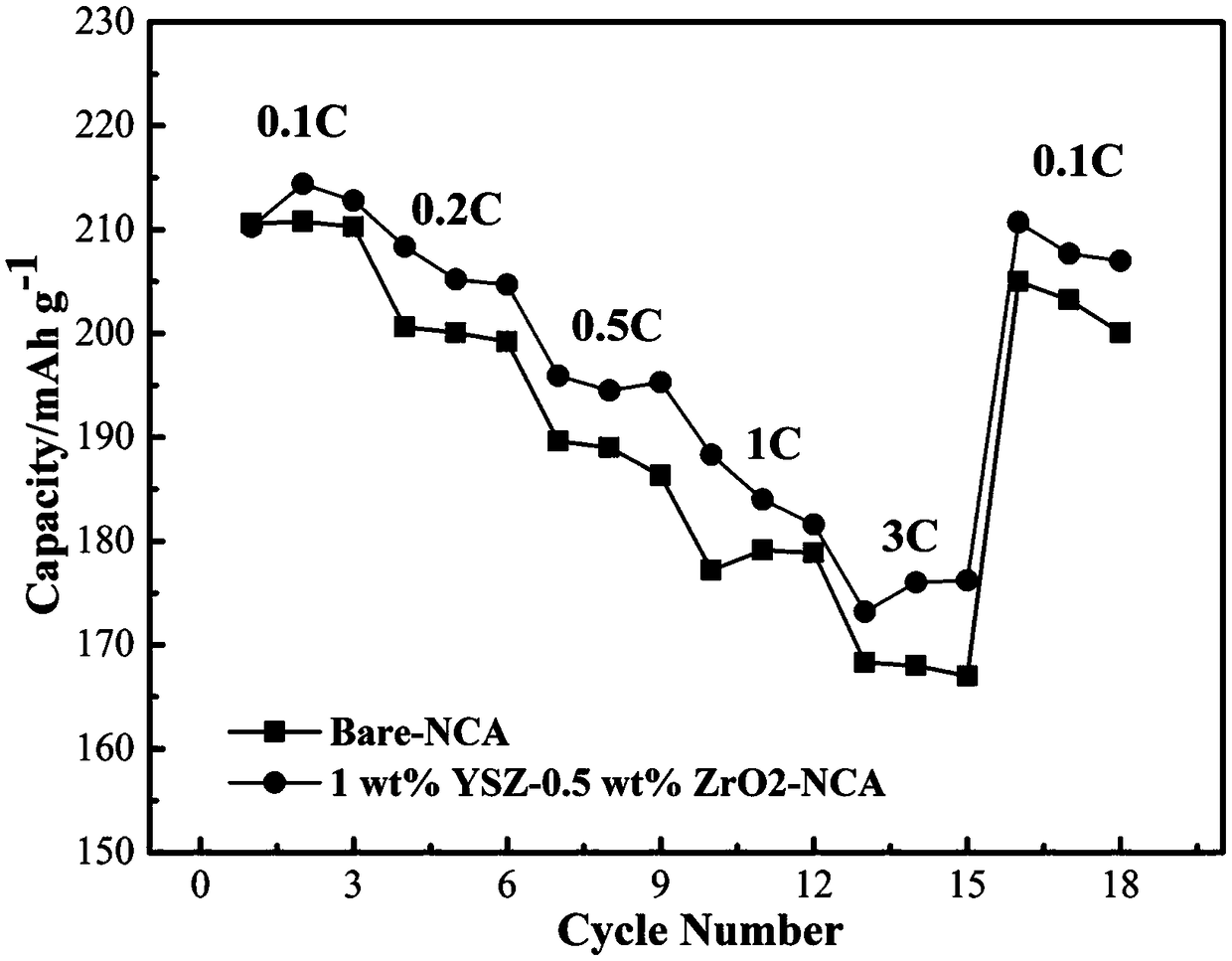

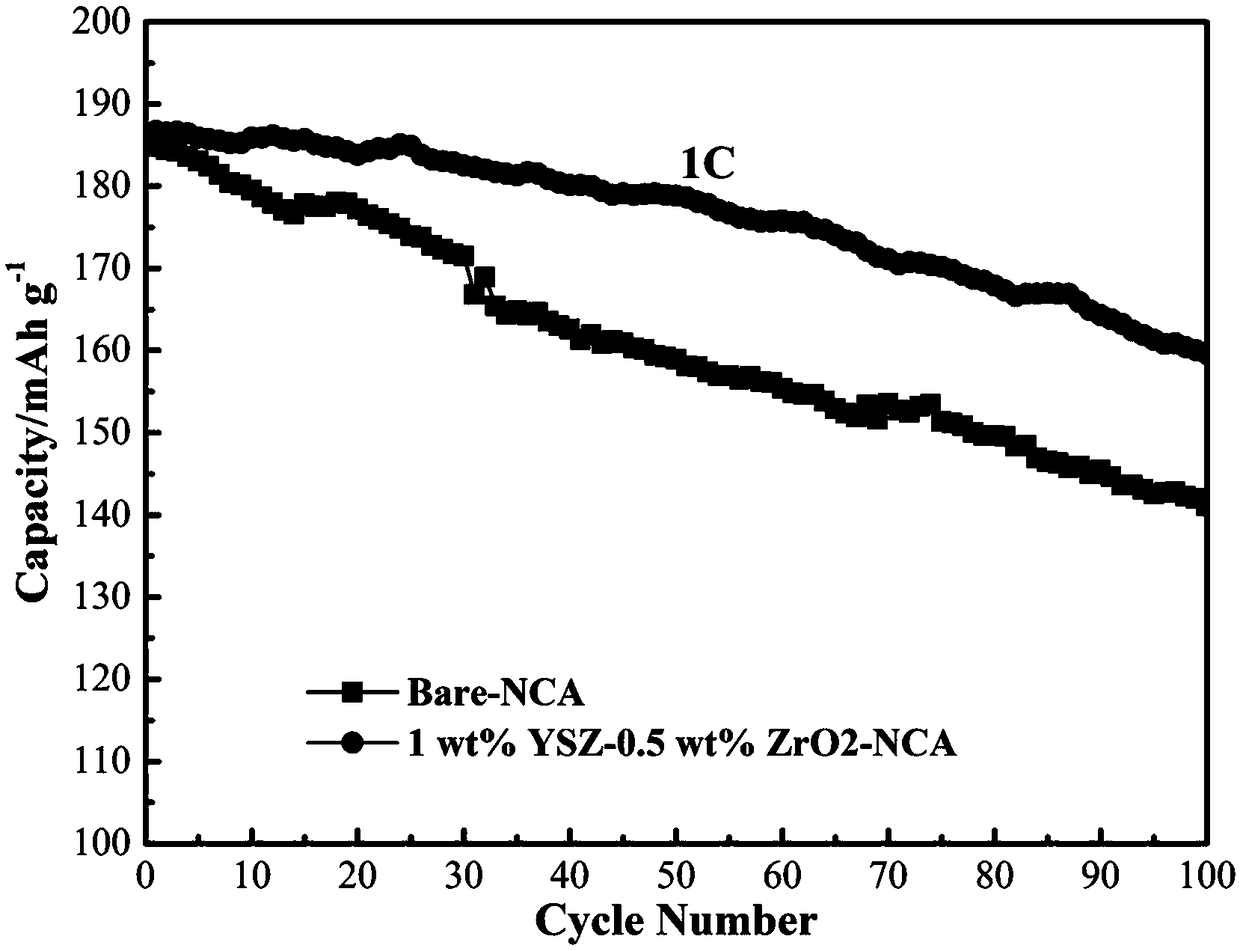

A surface modify ternary cathode material, a preparation method thereof, and a battery made of that surface modified ternary cathode material

ActiveCN109065858APromote migrationFast migration rateCell electrodesSecondary cellsOxygen vacancyMagnification

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Negative-working imageable elements with improved abrasion resistance

ActiveUS20090233227A1Influence overall viscosityHigh viscosityPhotosensitive materialsDuplicating/marking methodsSilica particleFumed silica

Owner:EASTMAN KODAK CO

Preparation of aramid fiber modifying solution

Owner:烟台泰和工程材料有限公司 +1

Metal reflector and manufacturing method thereof

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Preparation method of biodegradable fallout radioactive material for treating cancer

InactiveCN101417135AConcentration control of radioactive substancesLow priceRadioactive preparation carriersAntineoplastic agentsBiocompatibility TestingAminolysis

Owner:TONGJI UNIV

Liquid acidic hard surface cleaning compositions having improved viscosity

ActiveUS20190352579A1Organic detergent compounding agentsSurface-active detergent compositionsHydrotropeSurface cleaning

The need for an acidic hard surface cleaning composition which provides further improvements in the maintenance of surface shine, especially on inclined hard surfaces, while also using less thickener is met by formulating the acidic hard surface cleaning composition using a combination of a surface modification polymer and sulfonate hydrotrope.

Owner:PROCTER & GAMBLE CO

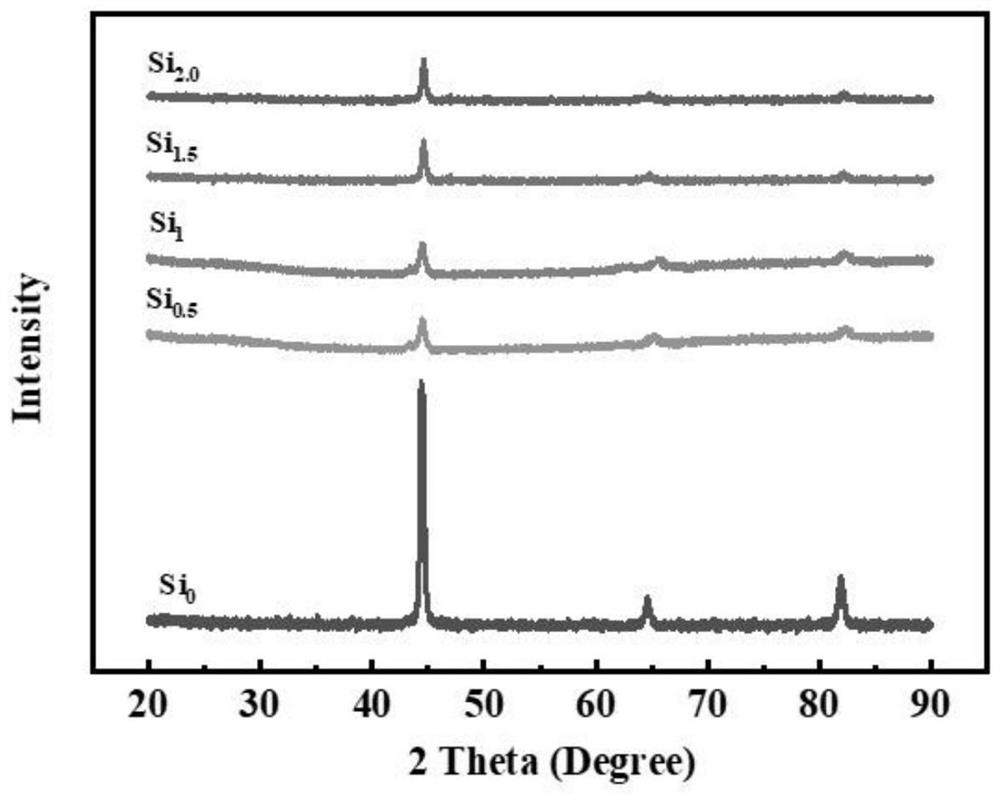

Novel FeCrMnVSix high-entropy alloy coating and preparation method thereof

ActiveCN114774754AImprove wettabilityPromote lattice distortionIncreasing energy efficiencyMetallic material coating processesHigh entropy alloysAlloy coating

Owner:HARBIN INST OF TECH

Method of surface-modifying polyether ether ketone material

ActiveCN104975267AGood biocompatibilityHas antibacterial propertiesVacuum evaporation coatingSputtering coatingPhysical chemistryPlasma-immersion ion implantation

The invention relates to a method of surface-modifying a polyether ether ketone material, which includes a step of performing zinc ion implantation or zinc / oxygen binary ion implantation through the surface of the polyether ether ketone material through a plasma immersed ion implantation technology to obtain the modified polyether ether ketone material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

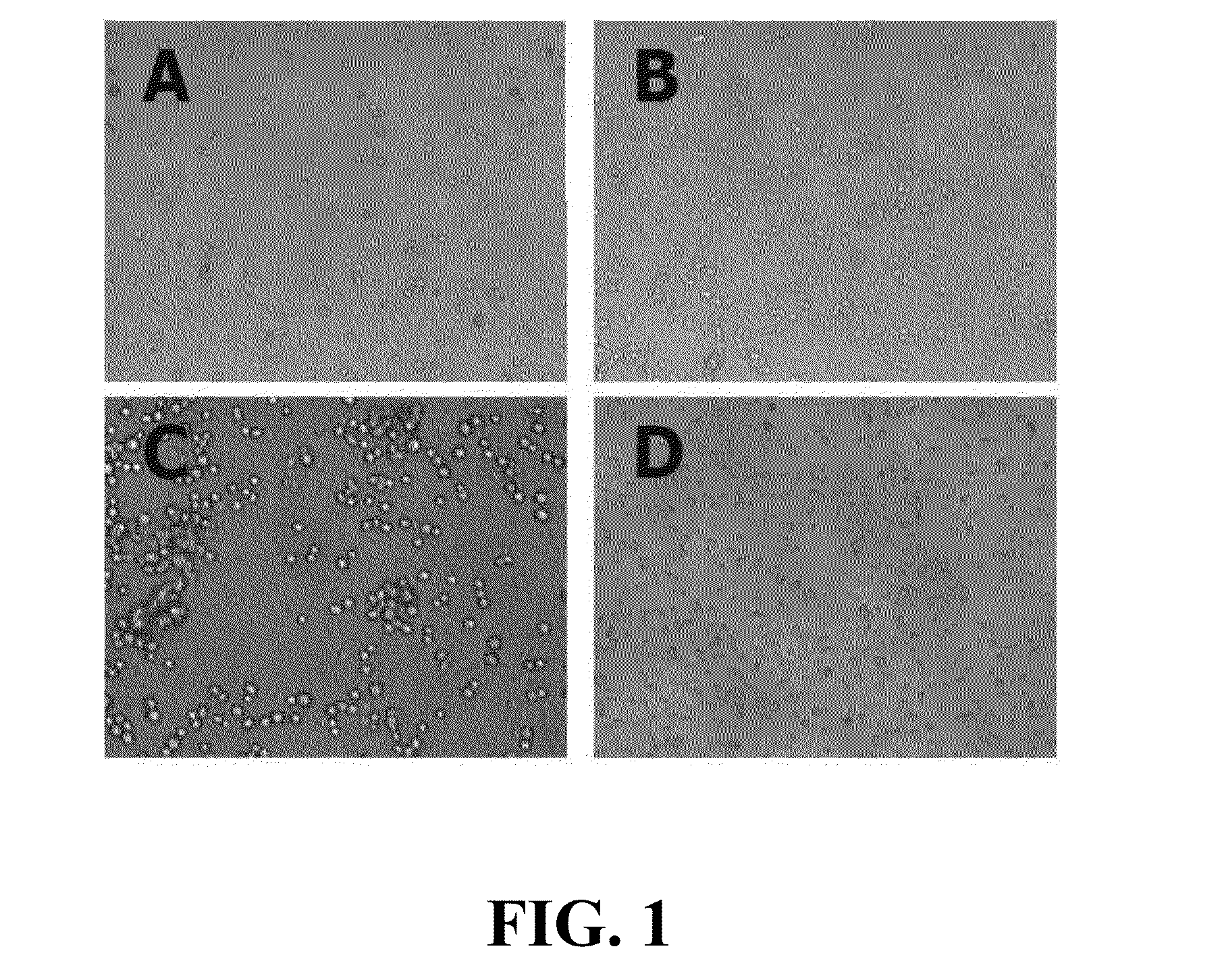

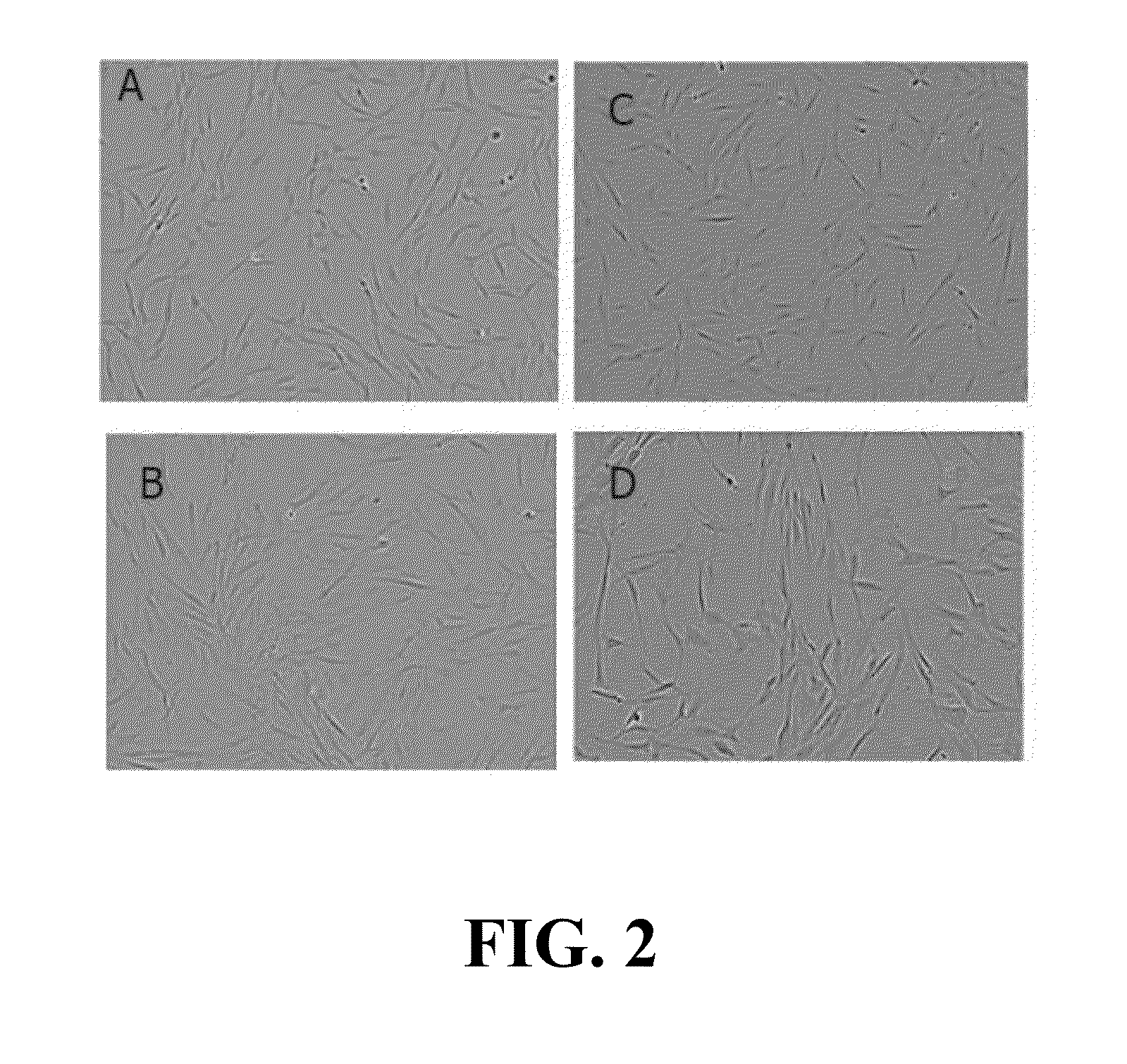

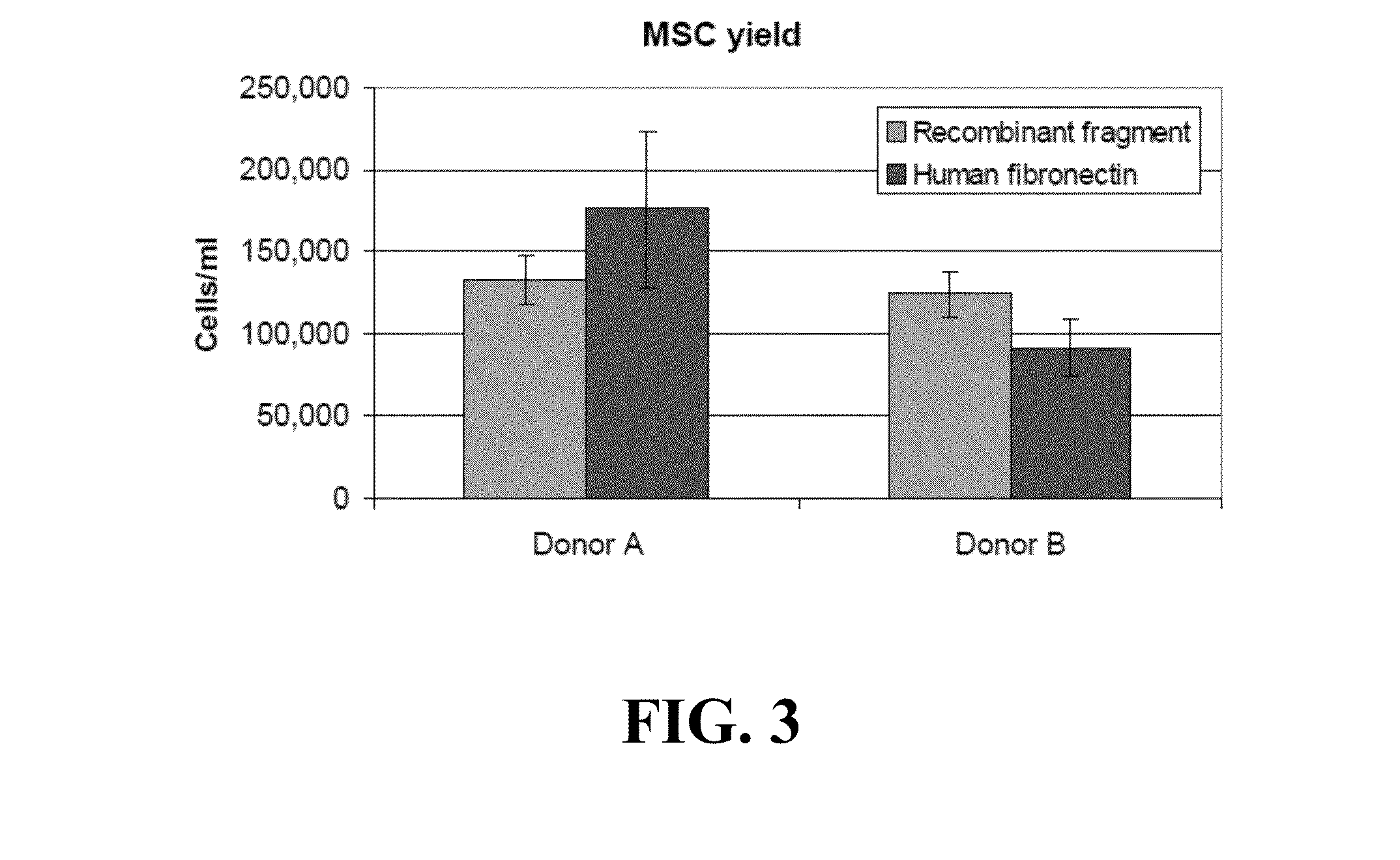

Recombinant human fibronectin fragment for cell culture

ActiveUS20140120616A1Avoid issuingBone marrow stroma cellsBioreactor/fermenter combinationsCell bindingCell adhesion

Owner:CORNING INC

Low-temperature gas-phase multi-element strengthening method preset with three-stage process

ActiveCN106048516ATroubleshoot narrow temperature rangesRealize multiple compound co-infiltrationSolid state diffusion coatingGas phaseThree stage

The invention discloses a low-temperature gas-phase multi-element strengthening method preset with a three-stage process. The low-temperature gas-phase multi-element strengthening method preset with the three-stage process comprises the following steps: (1) performing sand blasting or pickling on a to-be-treated workpiece, and putting the to-be-treated workpiece subjected to sand blasting or pickling into a clamp; (2) putting the clamp into a heating furnace for heat treatment: (21) increasing a temperature in the heating furnace to 350 DEG C, preserving the heat for 20-30 minutes, warming, and introducing ammonia gas into the heating furnace; (22) when the temperature is increased to 500-560 DEG C, introducing ammonia gas and a permeating agent A into the heating furnace, preserving the heat for 1-3 hours and continuously warming; (23) when the temperature is increased to 570-670 DEG C, introducing the ammonia gas and the permeating agent A into the heating furnace again, preserving the heat for 0.5-1.5 hours, and cooling; and (24) when the temperature is reduced to 500-520 DEG C, introducing ammonia gas and a permeating agent B into the heating furnace, preserving the heat for 1-3 hours, and then, cooling and discharging. The low-temperature gas-phase multi-element strengthening method preset with the three-stage process solves the problem that temperature range is relatively narrow, and can carry out alpha-Fe high-temperature-section surface modifying and strengthening treatment at a temperature being 500-670 DEG C.

Owner:赵海军

Anti-scratch paint protecting film and preparation method thereof

ActiveCN104694036AImprove scratch resistanceImprove water and oil repellency, acid and alkali resistanceFilm/foil adhesivesTectorial membraneSilicon

The invention relates to an anti-scratch paint protecting film and a preparation method thereof. The anti-scratch paint protecting film comprises an anti-scratch polyurethane film, acrylic glue and release paper, wherein the anti-scratch polyurethane film is prepared by performing surface modifying on one surface of a polyurethane film through a surface modifier of the polyurethane film; the modified surface contains a fluorine-silicon-containing chain section; when in use, the modified surface faces the outer side and is directly in contact with air, so that the anti-scratch performance of the polyurethane film can be greatly improved, and meanwhile, the resistance to water, oil, acid and alkaline can be improved, the hydrating and ageing in use can be greatly reduced, the protecting performance can be improved, and as a result, the service life is prolonged.

Owner:CHUZHOU YUNLIN DIGITAL IMAGING SUPPLIES CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap