Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14 results about "Coal gangue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gangue, also called coal gangue, is the solid waste discharged in coal mining process and coal washing process, black rock harder than coal. Its carbon content is low and exists along with coal seam. Gangue could be found in roof, bottom board, inter-layer, and it could be selected in washing process.

Method for extracting valuable metal elements from coal gangue

ActiveCN113061728ALow chemical stabilityAchieve primary separationSilicaCarbon compoundsFerric hydroxideCalcium silicate

The invention provides a method for extracting valuable metal elements from coal gangue. The method comprises the following steps of: crushing and grinding coal gangue ore, performing supercritical / subcritical water activation, classifying the coal gangue ore into an organic liquid phase and a slag phase by a hydrocyclone, and synthesizing carbon dioxide and water from the organic liquid phase through a supercritical reaction, wherein the carbon dioxide is used for a subsequent sodium aluminate reaction to obtain aluminum hydroxide, the water is used for supplementing water to a shaking table, and the slag phase passes through the shaking table to obtain enriched ore of carbon and silicon dioxide, aluminum oxide, silicate and ore containing a small amount of titanium and iron elements. Carbon and silicon dioxide are separated and collected through electric separation, aluminum oxide, silicate and ore containing a small amount of titanium and iron elements are added into sodium carbonate and calcium carbonate to be roasted and dissolved after roasting, slag of calcium silicate and calcium titanate is obtained and can be used as a coating, a dissolving solution contains sodium aluminate, sodium ferrite and other substances, sodium hydroxide is added into the dissolving solution to generate ferric hydroxide and sodium aluminate, the ferric hydroxide can be used as a coating, and carbon dioxide is introduced into the sodium aluminate to generate aluminum hydroxide which is used as an inorganic flame-retardant additive.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Tannery sludge and coal gangue treatment technology

Owner:CHANGZHOU UNIV

Decorative and thermal-insulation integrated novel lightweight walling material made from polishing brick waste

Owner:ZIBO YONGXU REFRACTORY MATERIALS

Coal gangue conveying vibration device

Owner:PINGDINGSHAN TIANAN COAL MINING +2

Preparation method for zeolite-activated carbon composite adsorbent

InactiveCN107876009AIncrease the areaLarge adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesSorbentCarbonization

Owner:SHAANXI SHENGMAI PETROLEUM

Organic fertilizer

Owner:徐州沐阳生物科技发展有限公司

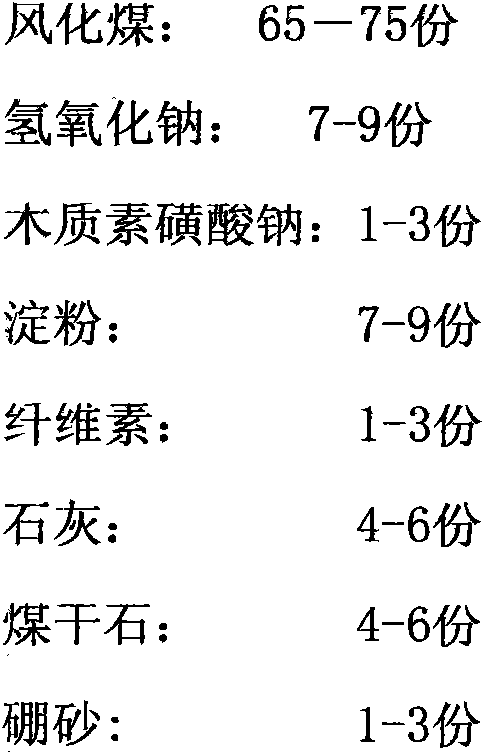

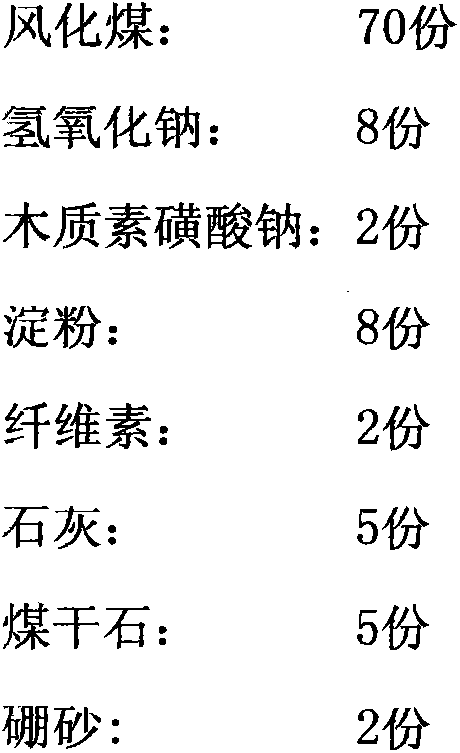

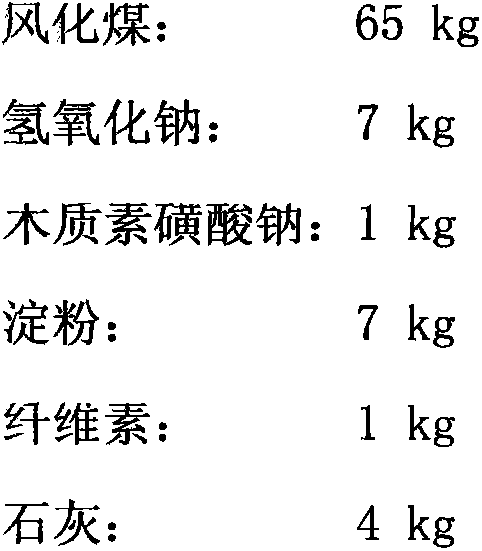

Efficient environment-friendly cheap adhesion agent of pellet and preparation method thereof

Owner:刘惠民 +1

Foamed concrete material and preparation method thereof

Owner:惠安县灿鑫新材料科技有限公司

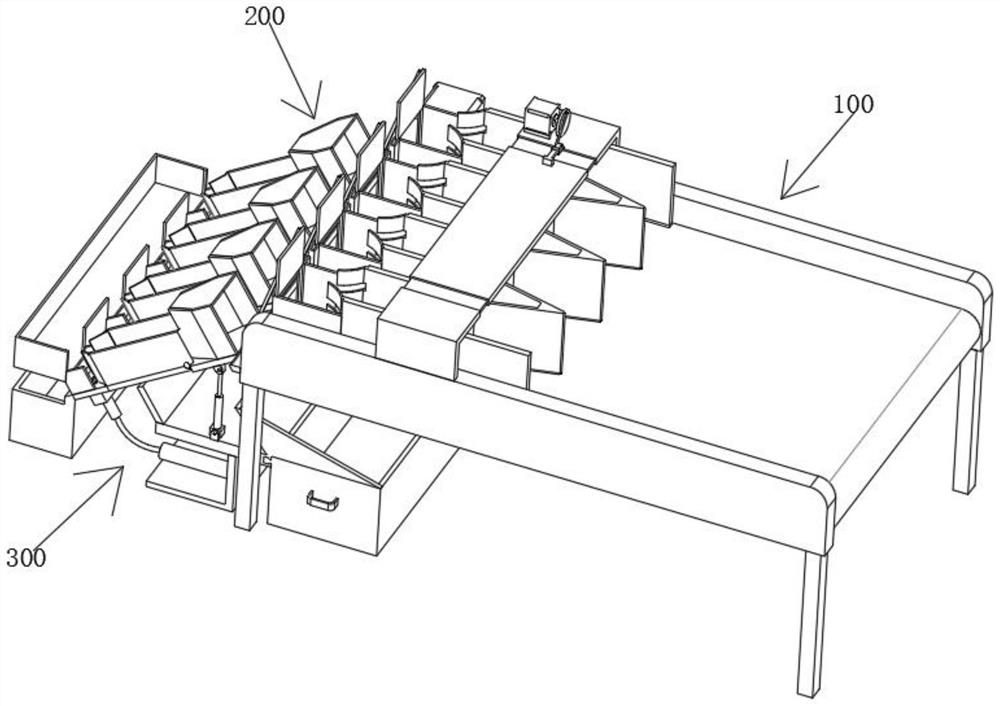

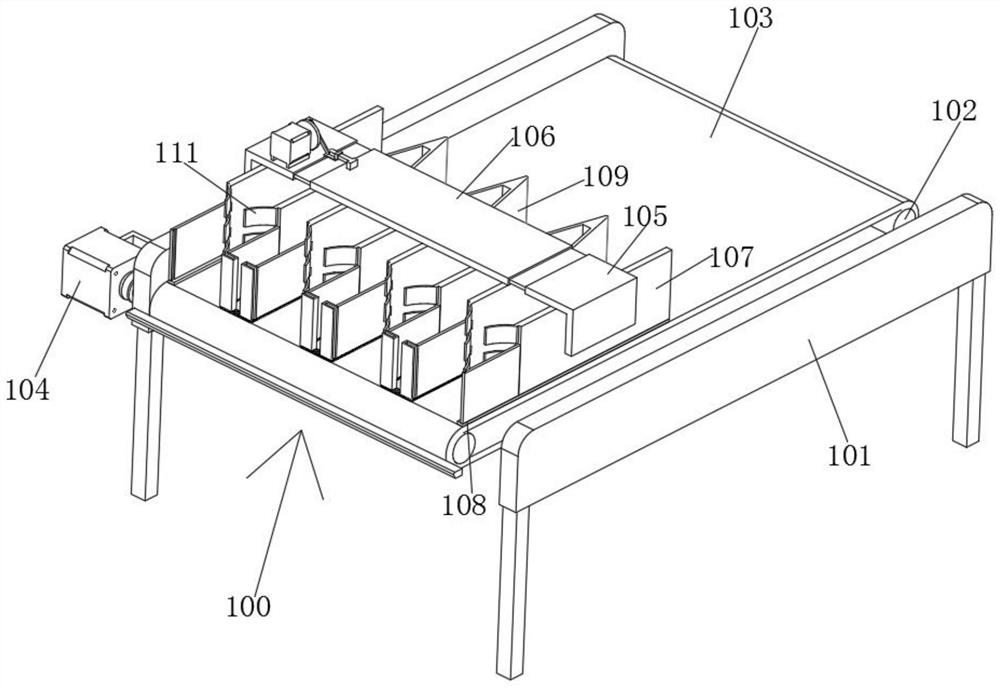

Quick sorting machine for coal gangues with different sizes

PendingCN114505236APrevent fallingAvoid damageGas current separationCleaningMining engineeringProcess engineering

Owner:原瑜

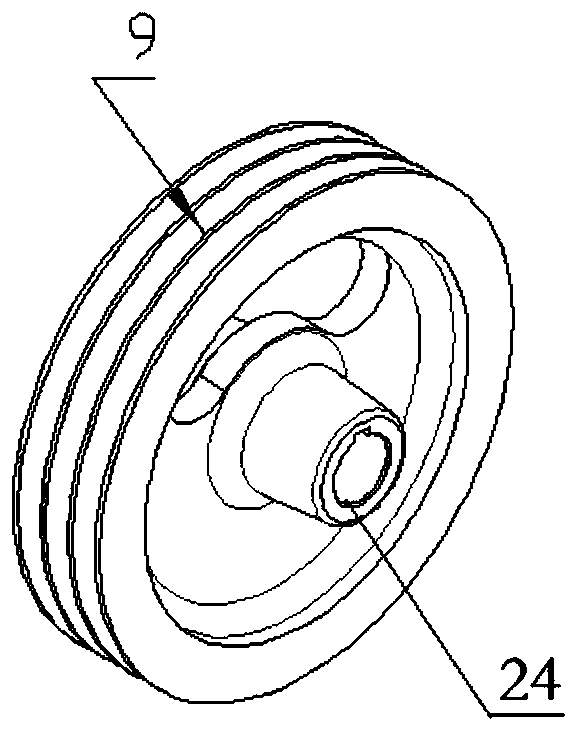

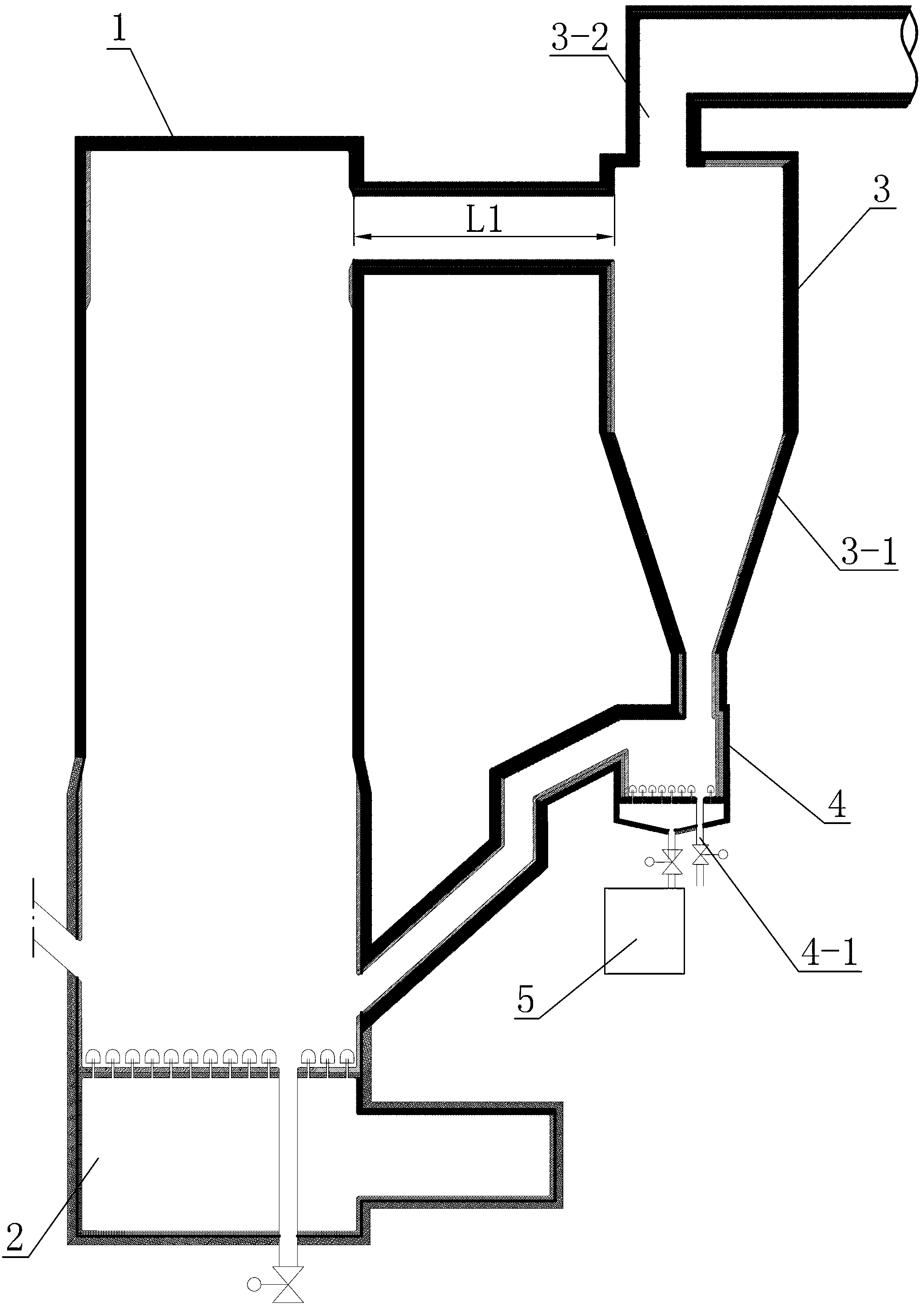

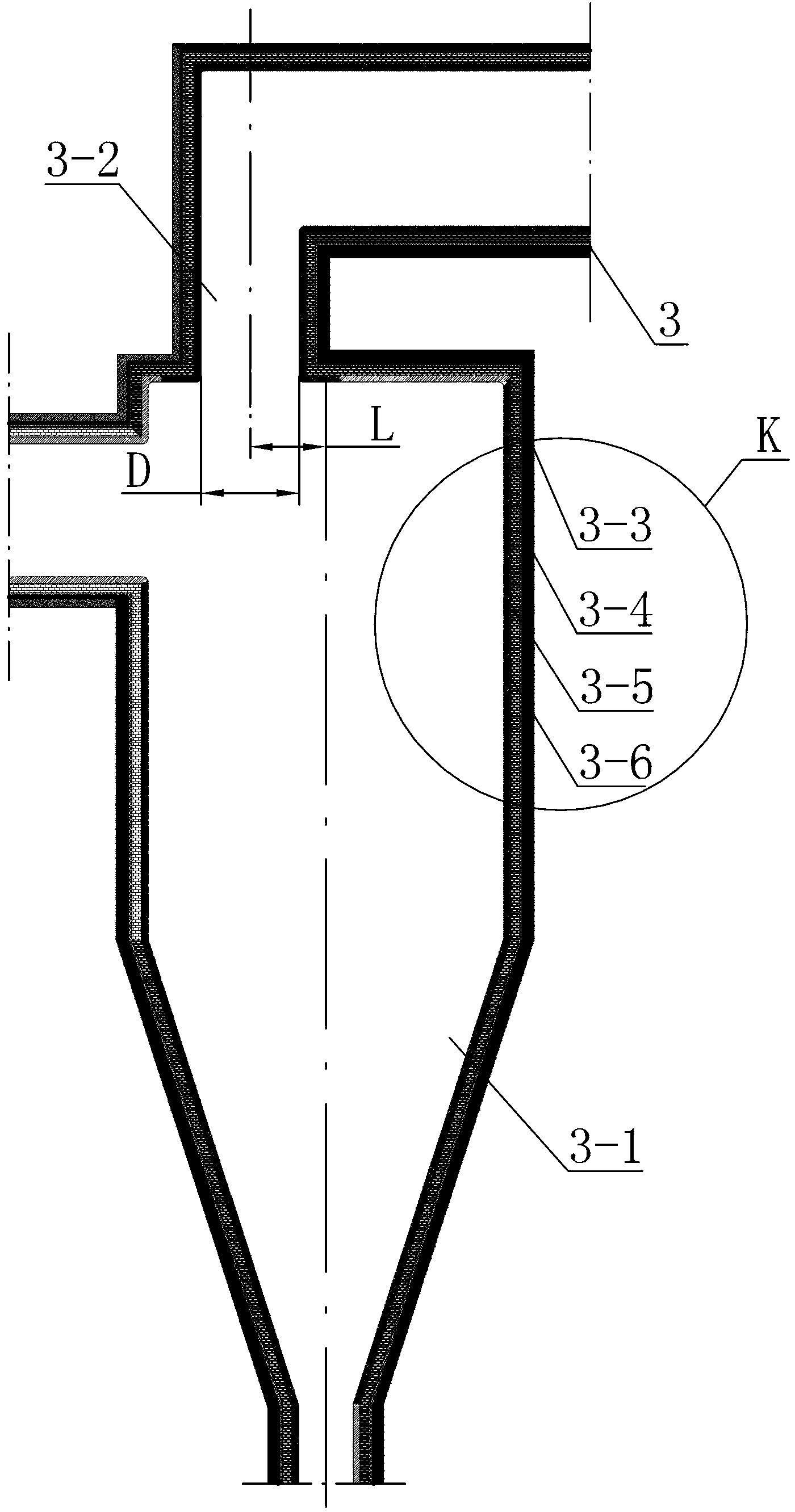

Coal gangue circulating fluidized bed boiler

InactiveCN103322557AReduce heat lossGood separation effectFluidized bed combustionApparatus for fluidised bed combustionCoal gangueCirculating fluidized bed boiler

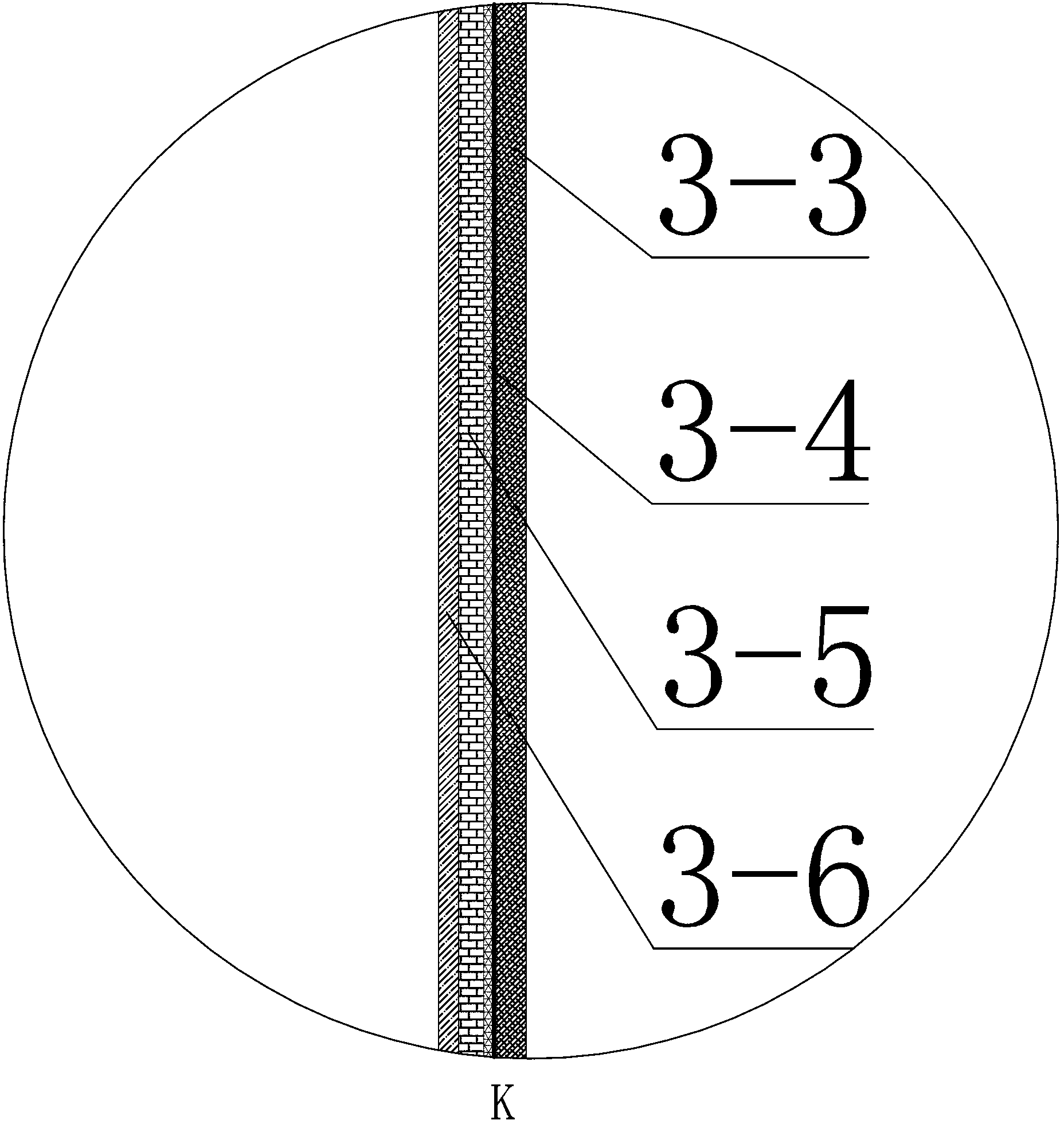

The invention discloses a coal gangue circulating fluidized bed boiler, and relates to a circulating fluidized bed boiler which can be used for solving the problems that existing coal gangue circulating fluidized bed boiler is higher in ash fusion point of fuel, unstable in fuel and inadequate in fuel combustion, the bed layer temperature cannot be ensured due to water cooling and gas cooling cyclone separators adopted, and the return device uses natural circulation by primary air which affects stable operation of the boiler. The boiler comprises a hearth, a water cooling air chamber, a cyclone separator, a return device and a return Roots blower, wherein the cyclone separator is communicated to the upper side wall of the hearth, insulating rock wool is arranged on the outer wall of a separator main body, an aluminum silicate insulating cotton plate, an insulating pouring material layer and a wear-resisting pouring material layer are sequentially arranged on the inner wall of the separator main body, an exhaust gas outlet cylinder of the cyclone separator is fixedly connected to an upper outlet of the separator main body in a deviating manner, and the lower end of the cyclone separator is communicated with the lower side wall of the hearth through the return device. The boiler provided by the invention is used for combusting coal gangue fuel.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM

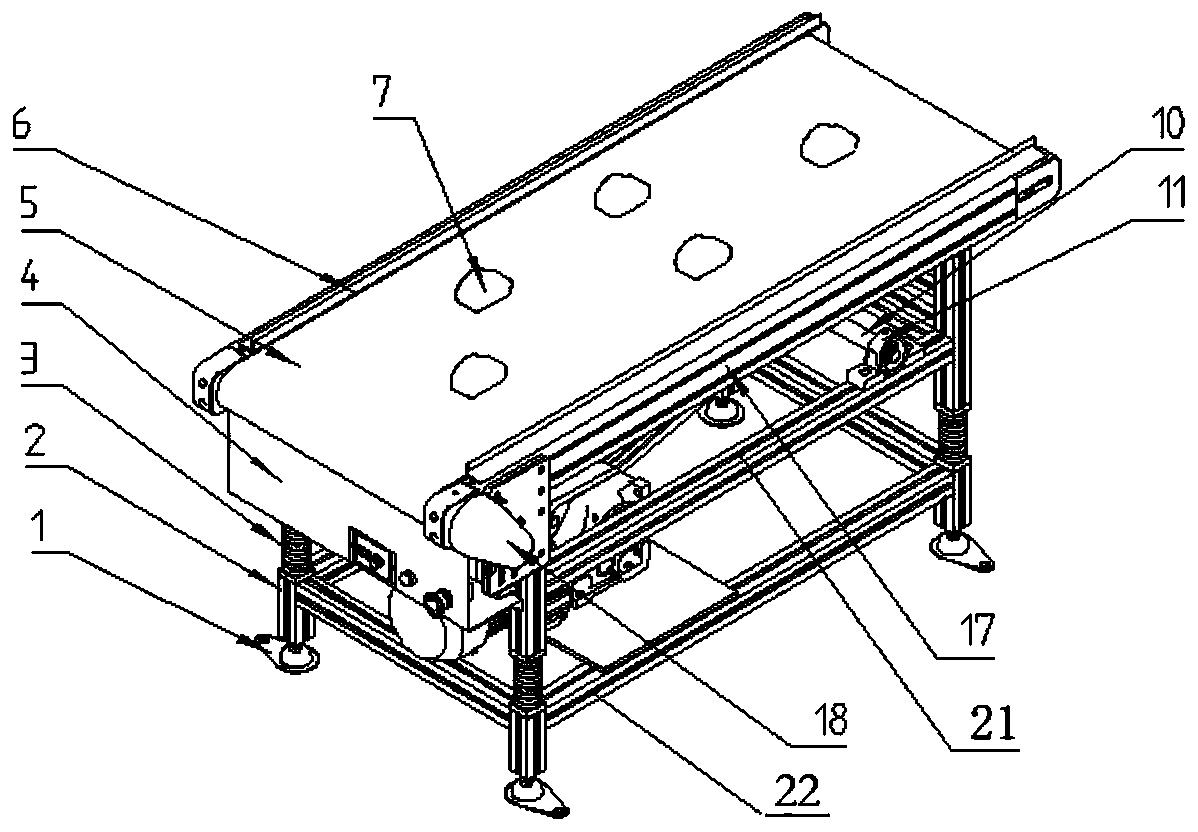

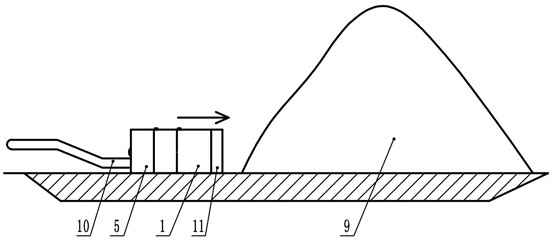

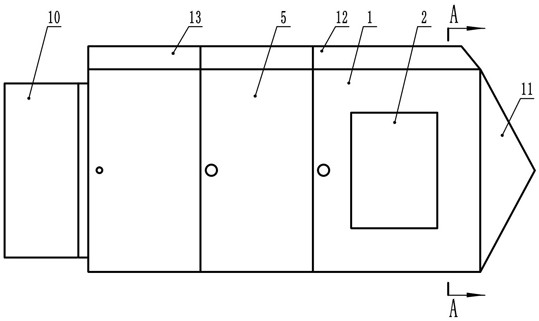

Conveyor for coal gangue feeding

ActiveCN114104757AIncrease the lengthLow production costLoading/unloadingConveyor partsThermodynamicsMining engineering

Owner:山西古县西山登福康煤业有限公司

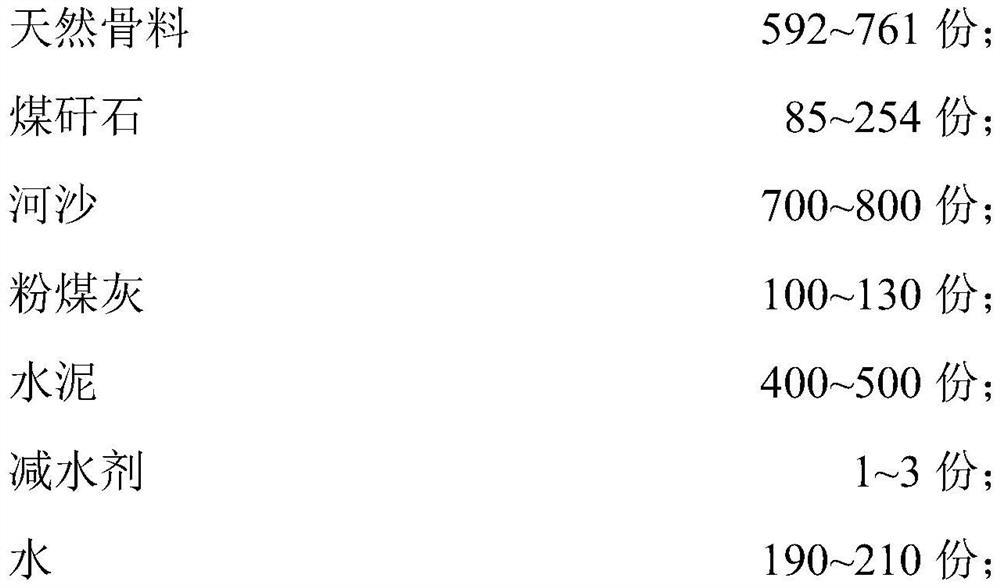

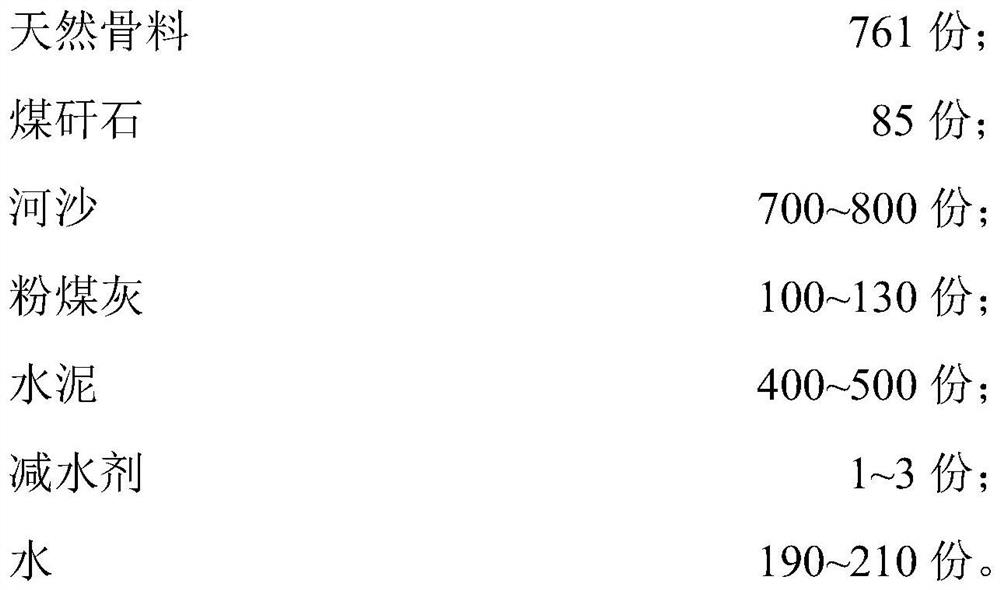

Single-size-fraction coal gangue self-compacting concrete

PendingCN112707700APromote post-hydrationHigh strengthSolid waste managementMining engineeringSorptivity

Owner:张家港市华诚混凝土构件有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap