Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13 results about "Lacquer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term lacquer is used for a number of hard and potentially shiny finishes applied to materials such as wood. These fall into a number of very different groups. The term lacquer originates from the Sanskrit word lākshā (लाक्षा) representing the number 100,000, which was used for both the lac insect (because of their enormous number) and the scarlet resinous secretion, rich in shellac, that it produces that was used as wood finish in ancient India and neighbouring areas.

Aqueous texture wallpaper paint and method for making same

The invention relates to a watercraft texture wallpaper paint, characterized in that the invention comprises the following components: 31 percent to 35 percent of styrene-acrylic emulsion, 23.94 percent of superfine weight calcium, 1 percent to 2 percent of nano-titanium dioxide, 10 percent to 18 percent of titanium pigment, 8 percent to 9.8 percent of calcined kaolin, 1.2 percent to 1.8 percent of ethylene glycol, 0.2 percent to 0.5 percent of hydroxyethylcellulose, 0.8 percent to 1.5 percent of film forming additive, 0.15 percent to 0.25 percent of multi-functional additive, 0.3 percent to 0.5 percent of dispersant, 0.1 percent to 0.2 percent of wetting agent, 0.15 percent to 0.21 percent of defoamer, 0.08 percent of anticorrosion and insecticide, 0.8 percent to 2 percent of thickener and 20 percent to 22 percent of water. The invention is the watercraft texture wallpaper paint, is environment-friendly, has strong elastic tension, has good covering and anti-cracking effect on the fine cracking of wall, and has good scrape resistance performance, greatly enhancing the degree of wall surface protection; meanwhile, the invention still has strong waterproof performance, without color-changing and decortication and mildew and can fully solve the common problems existing in wall decoration.

Owner:FOSHAN SHUNDE QINGDA RUNCAI COATING CO LTD

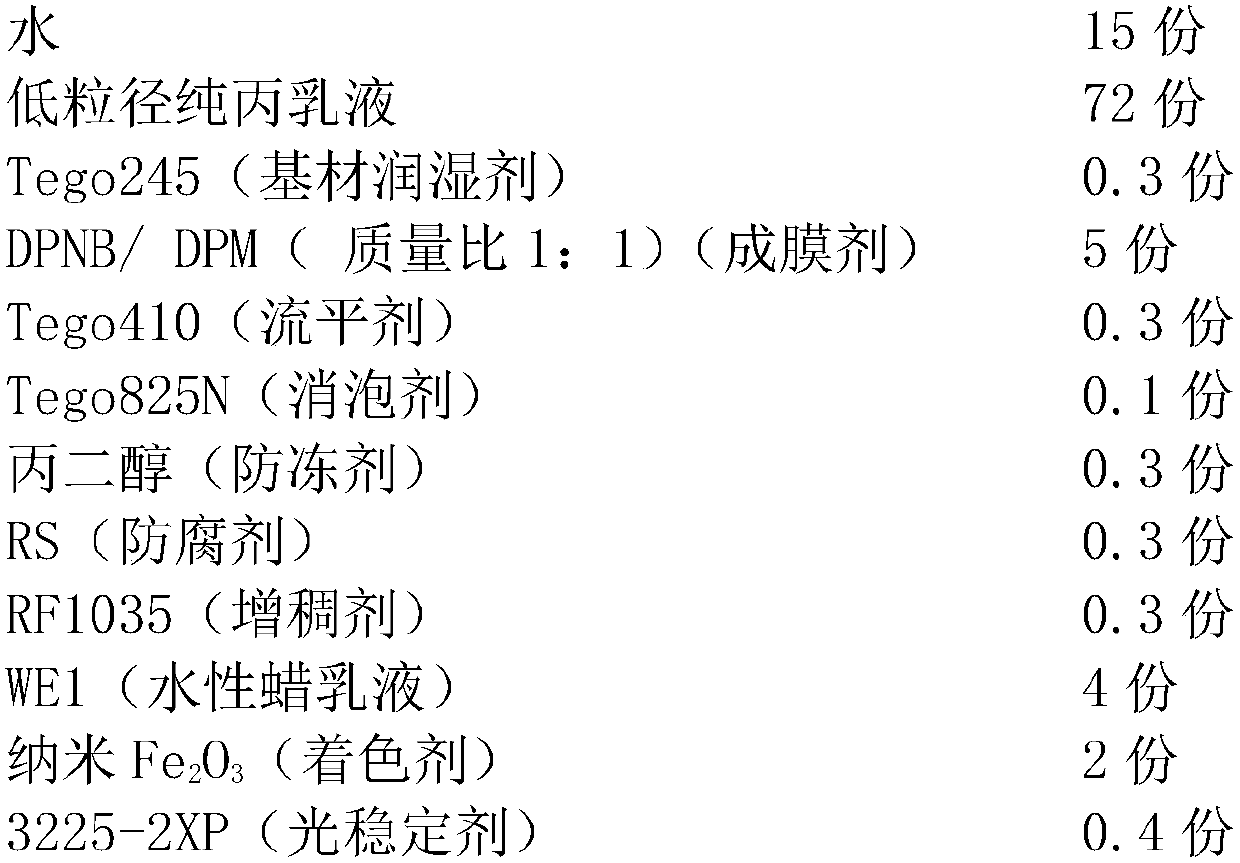

Outdoor waterborne woodenware penetration paint and preparation method thereof

InactiveCN107936742AReduced shear damageResist moisture intrusionPolyurea/polyurethane coatingsEmulsionLacquer

The invention belongs to the field of coatings for architectural ornament, and particularly relates to an outdoor waterborne woodenware penetration paint and a preparation method thereof. The penetration paint is prepared from the following components by weight: 10 to 15 parts of water, 65 to 80 parts of waterborne emulsion, 2 to 5 parts of coalescing agent, 2 to 25 parts of coloring agent and 4.5to 9 parts of other aids. The outdoor waterborne woodenware penetration paint prepared by the method has good base material closing property, excellent weather fastness and water resistance on the basis of a traditional woodenware paint; in addition, the cracking of a substrate can be reduced and the substrate can be protected from being corroded to a certain extent.

Owner:SHENYANG RES INST OF CHEM IND

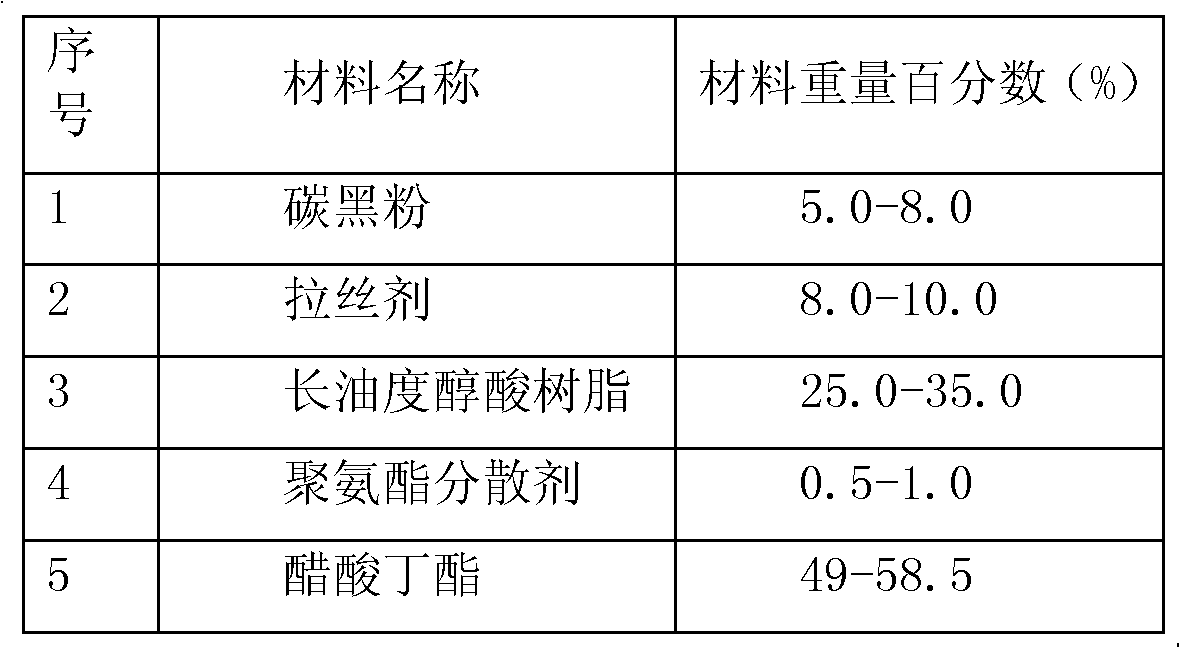

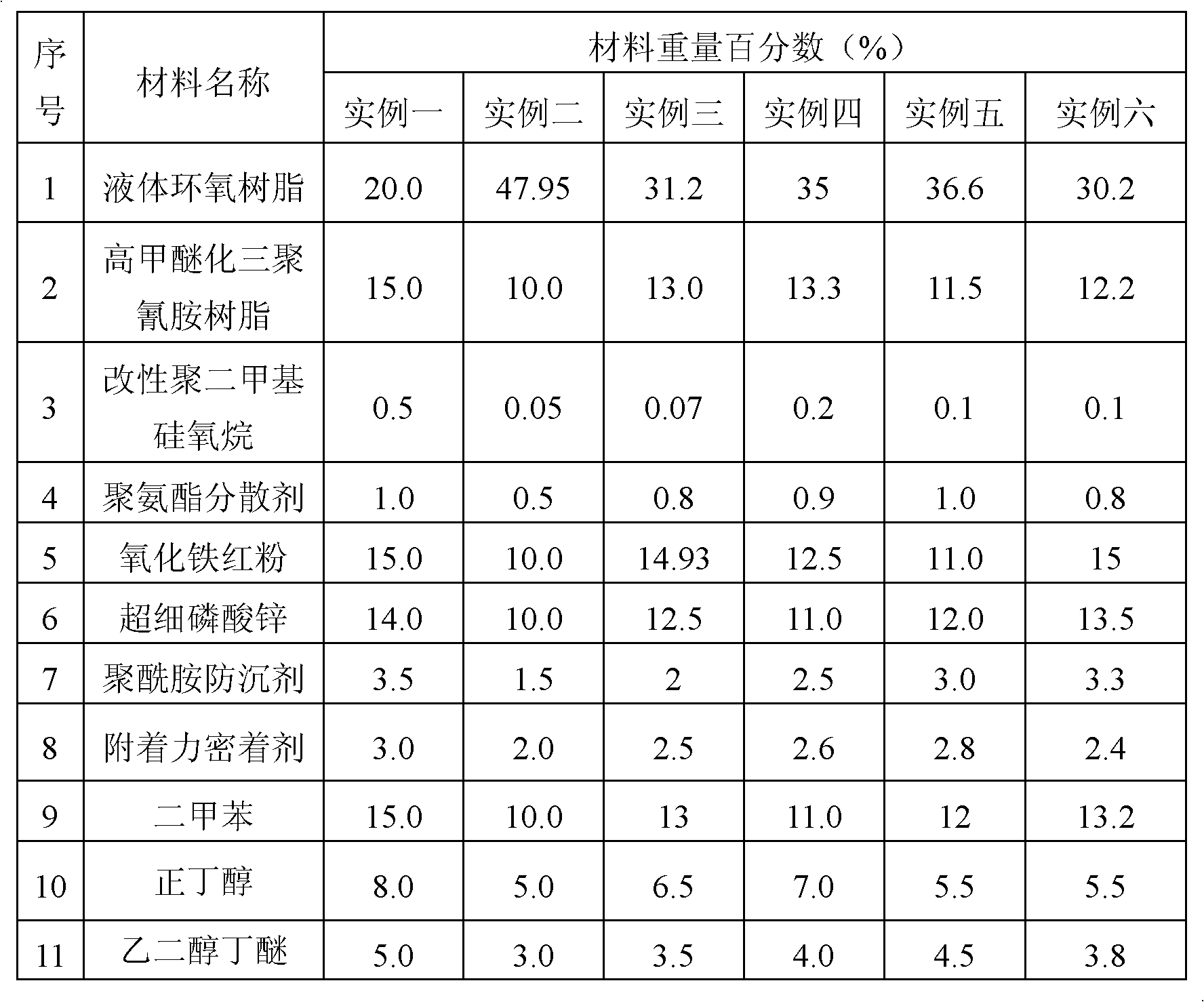

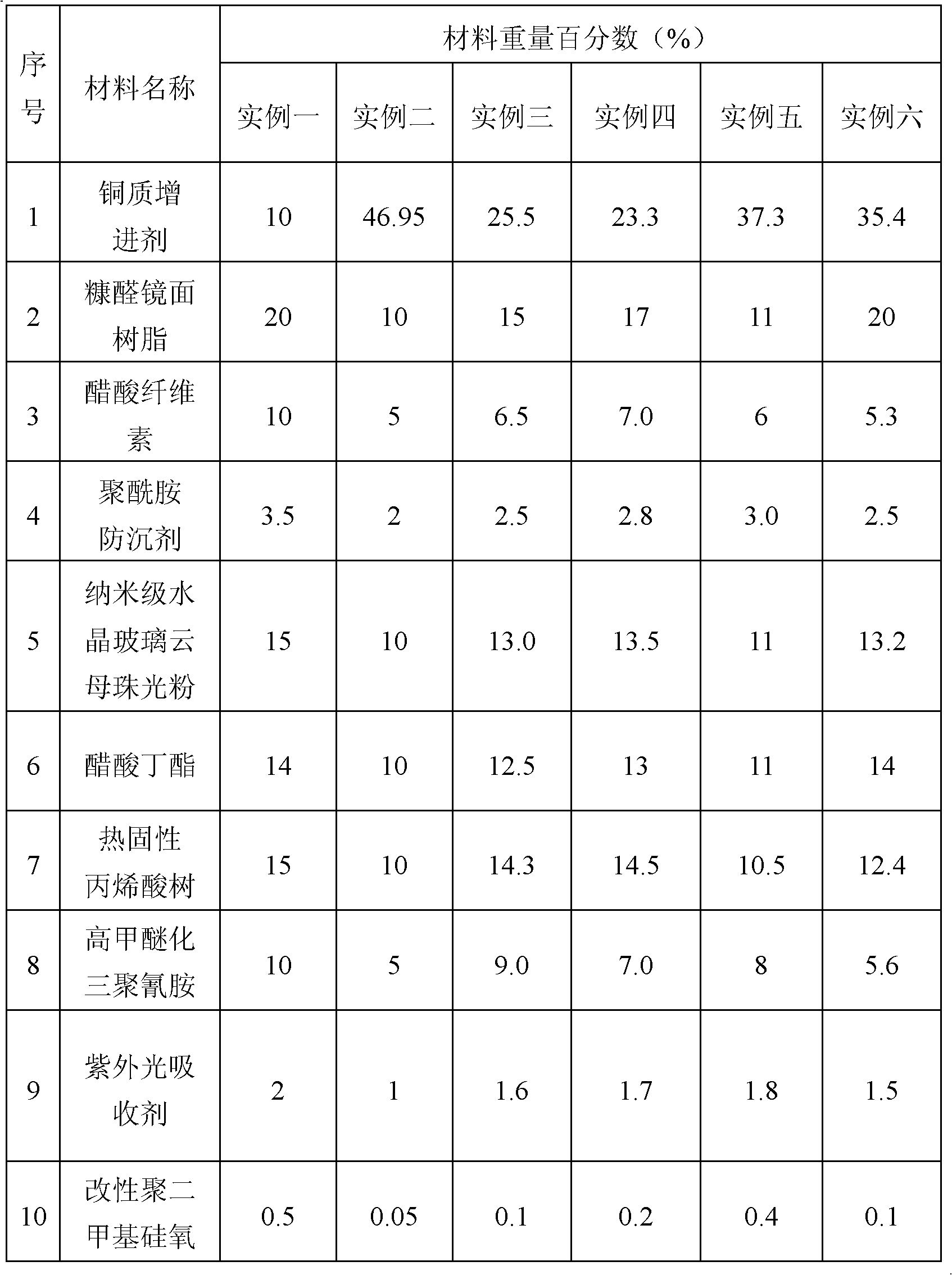

True copper metallic combination paint as well as preparation method and construction process thereof

InactiveCN102533056AImprove anti-corrosion performanceExcellent anti-rustPretreated surfacesAnti-corrosive paintsEpoxyProduction line

Owner:江苏佳尔利装饰材料有限公司 +1

Modified acrylic acid special type coating

Owner:上海海悦涂料有限公司

Paint spraying technology for water screen vortex roll spray room

InactiveCN104174519AImprove purification efficiencySimple structureSpray nozzlesLacquerVolumetric Mass Density

The invention discloses a paint spraying technology for a water screen vortex roll spray room. The technology comprises the following processes: a conveying fixture carrying a paint spraying product travels along a conveying track and the paint spraying product is then sprayed with paint by an automatic spray gun on one side of the conveying fixture; paint mist generated in the paint spraying process flows to a serration plate along with the air flow under the action of a suction groove; high-speed air flow and negative pressure are formed at notches of the serration plate due to the fact that the ventilation section area is suddenly decreased, so that water at the notches is atomized and the high-speed air flow passes through the serration plate and then enters a vortex roll plate; paint grains with greater density is in full contact with water under the action of centrifugal force and then collected and taken down by water; the rest of paint mist collides and in contact with atomized water repeatedly for many times in the vortex roll along with the air flow, condenses into water droplets containing paint mist and enters a circulating water pool. The paint spraying technology is good in paint mist capturing effect, and besides, the water screen vortex roll spray room is simple in structure, pipelines are less prone to blockage, and the purification efficiency is high.

Owner:CHANGXING HUARUI MACHINERY EQUIP

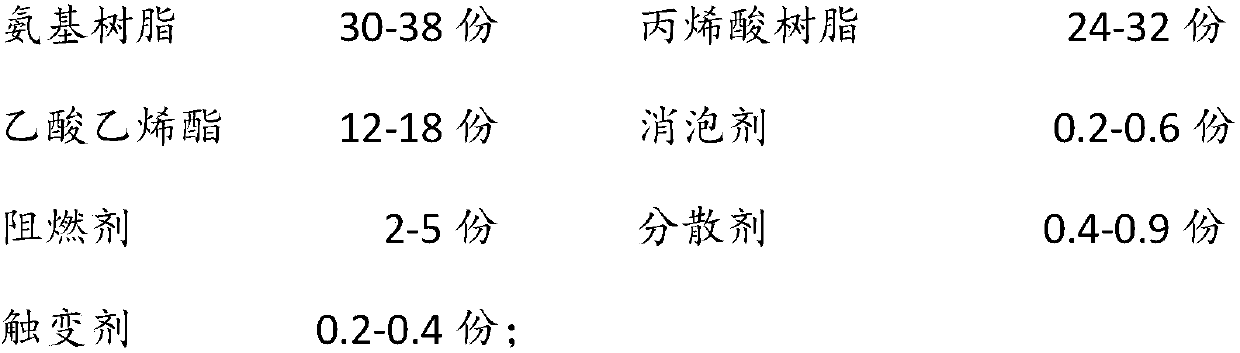

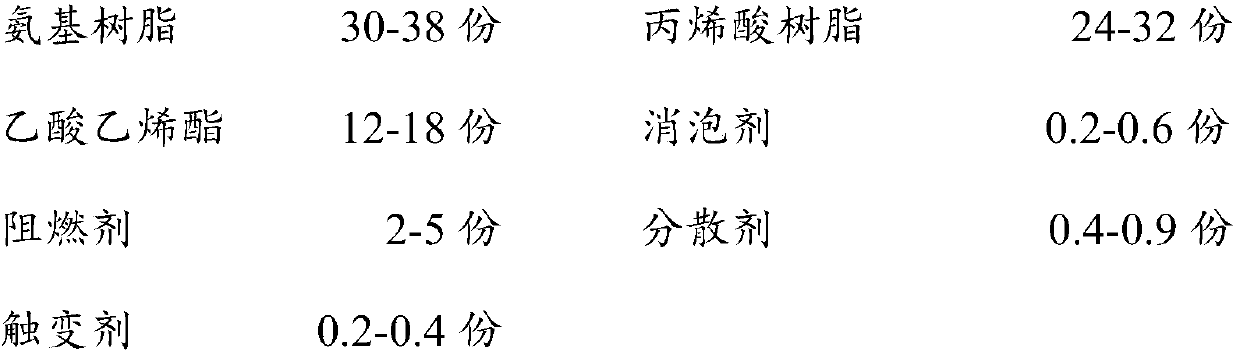

Flame-retardant finish paint for furniture

InactiveCN107629661AImprove flame retardant performanceStrong impact resistanceFireproof paintsPolyurea/polyurethane coatingsAcrylic resinLacquer

Owner:佛山市三水区白坭镇巨财红木厂

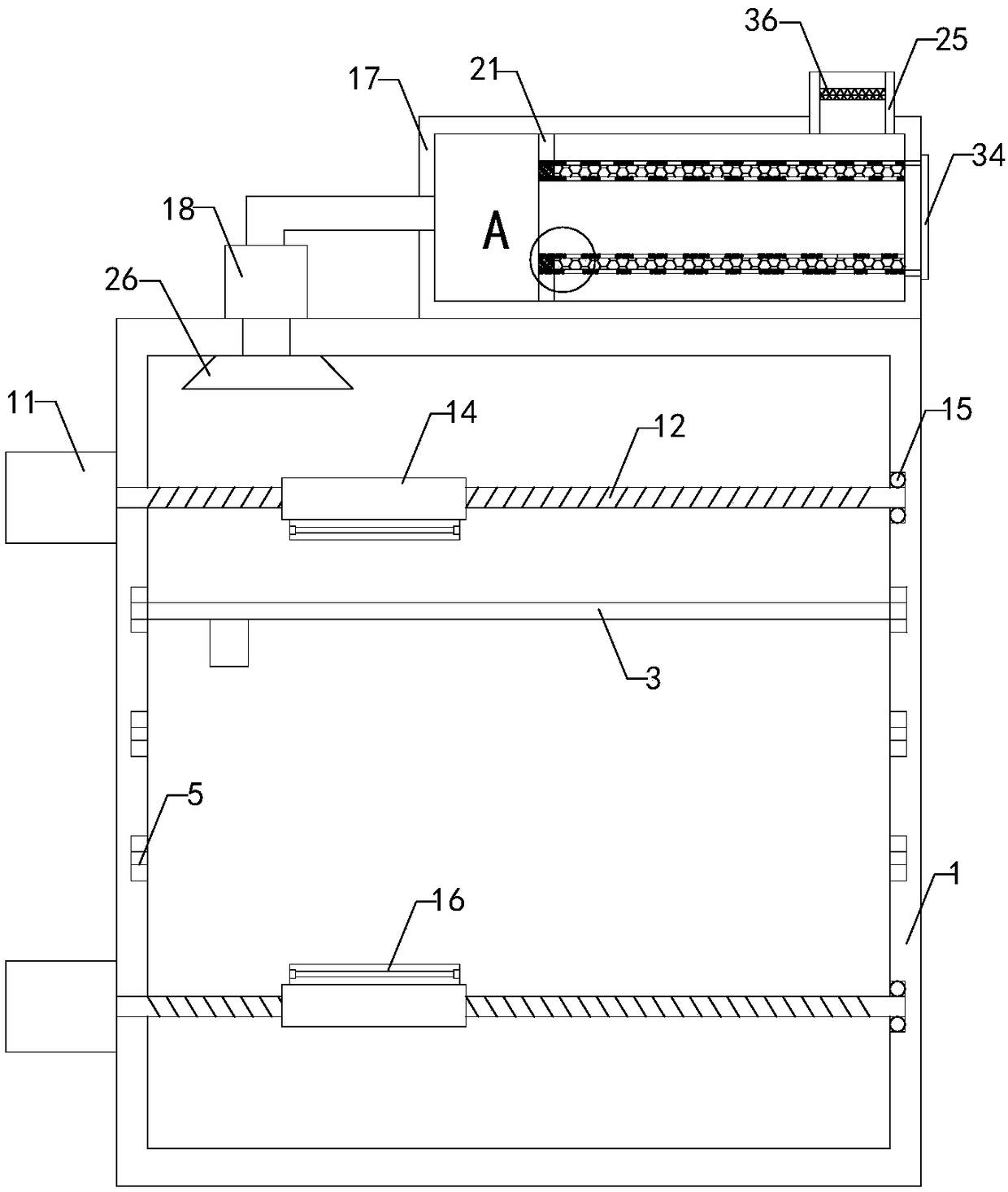

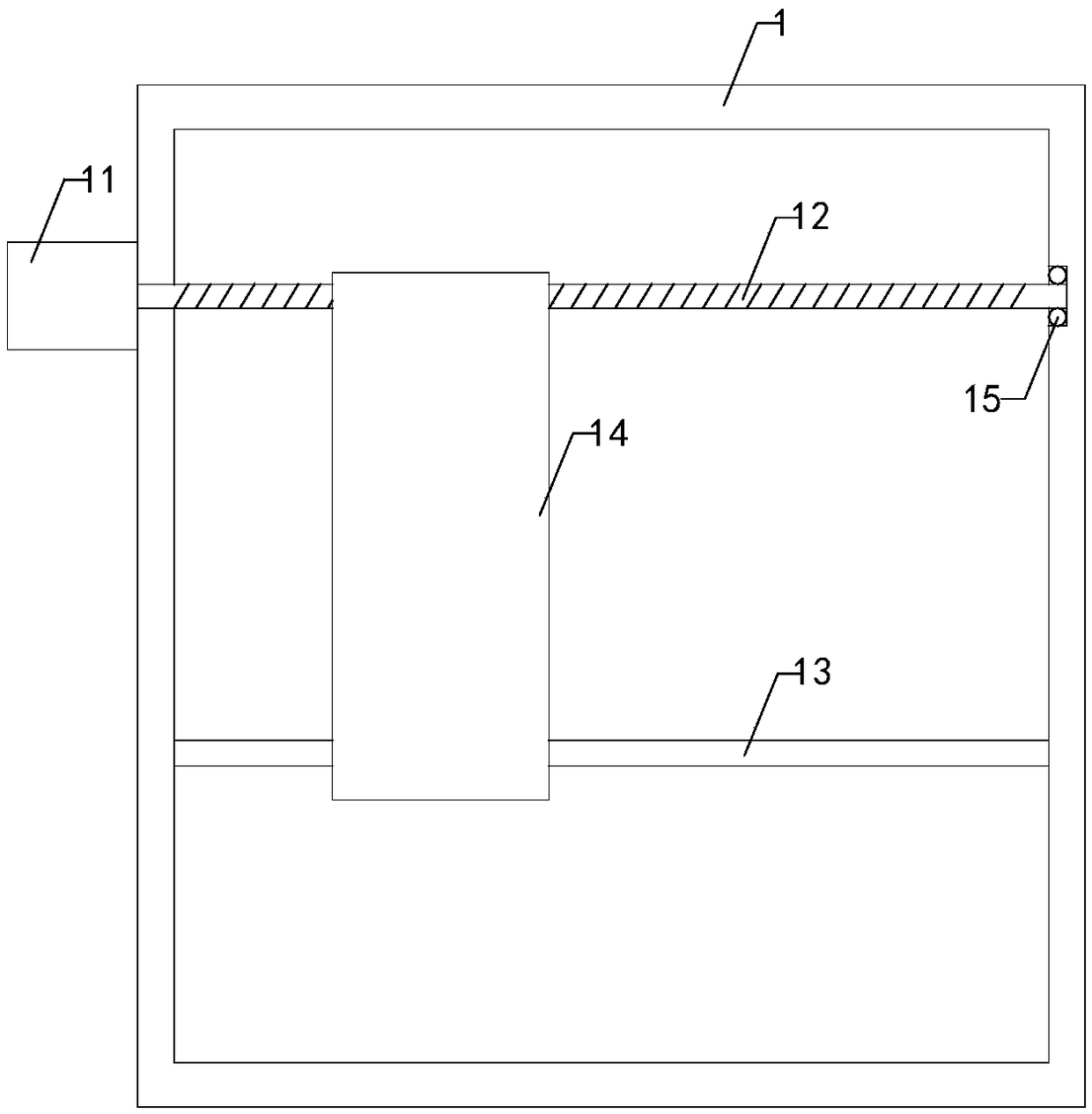

Paint drying device for agricultural machine part

Owner:JIANGSU ZIQIANG COATING MACHINERY

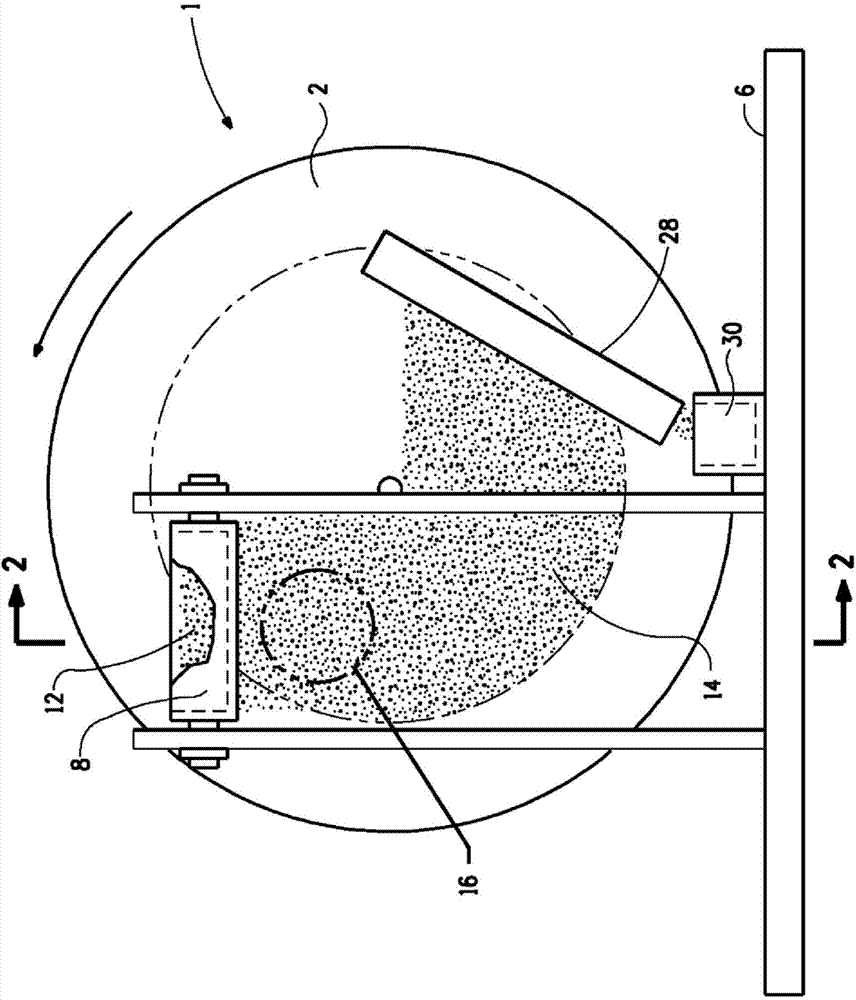

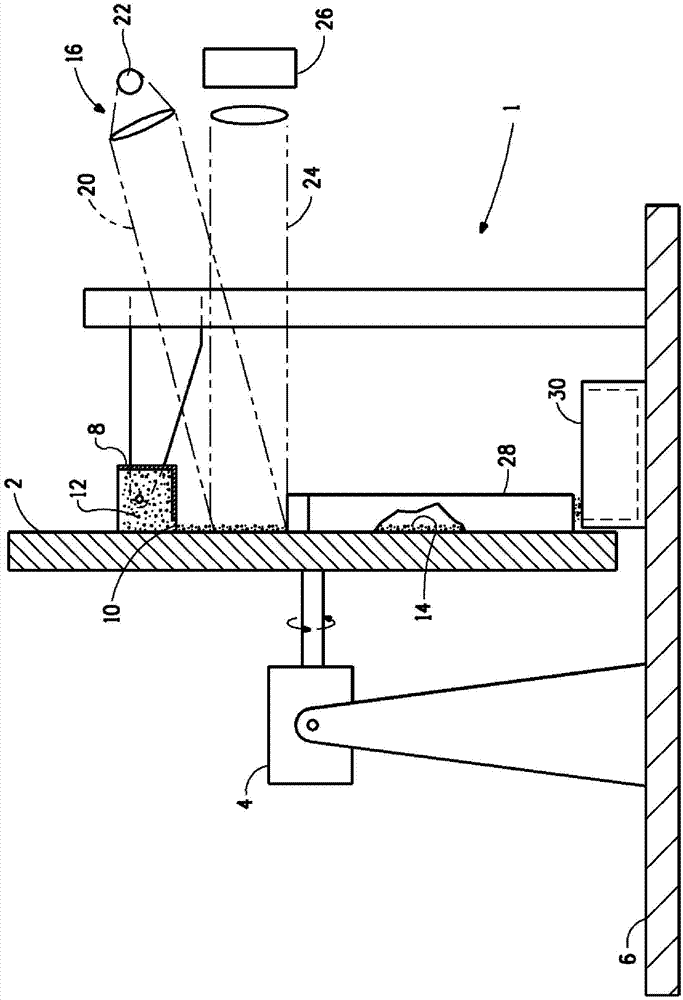

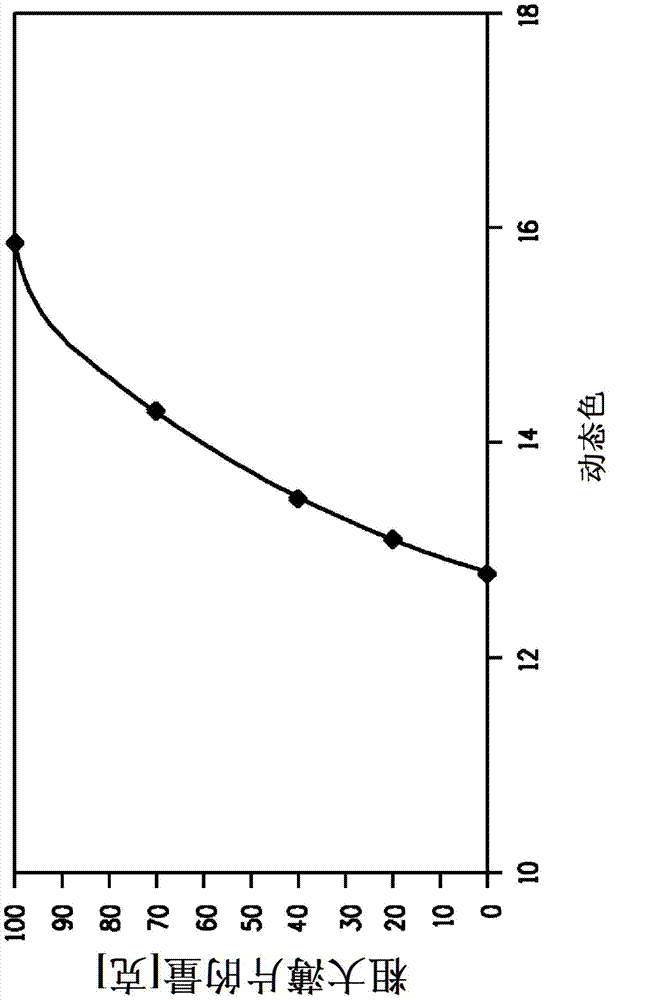

Device for predicting amount of coarse flakes in coating compositions by wet color measurement

ActiveCN104303041AScattering properties measurementsColor/spectral properties measurementsLacquerAutomotive oem

Owner:AXALTA COATING SYST GMBH

Acrylic resin for water-borne wood paint finishing coat and preparation method of acrylic resin

Owner:LINFEN TIE HUAN PAINT IND

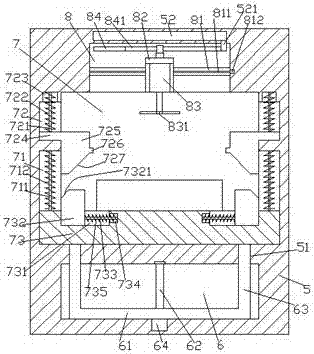

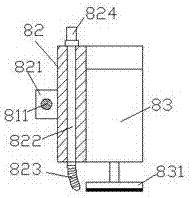

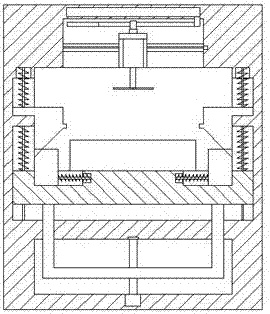

Proportioning apparatus for environment-friendly paint

InactiveCN107096445AShaking/oscillating/vibrating mixersTransportation and packagingLacquerAerospace engineering

Owner:深圳市汇呈实业有限公司

Manufacturing method of grain lacquer painting

PendingCN110733288ASimple methodLow costSpecial ornamental structuresSpecial artistic techniquesLacquerHusk

Owner:占剑华

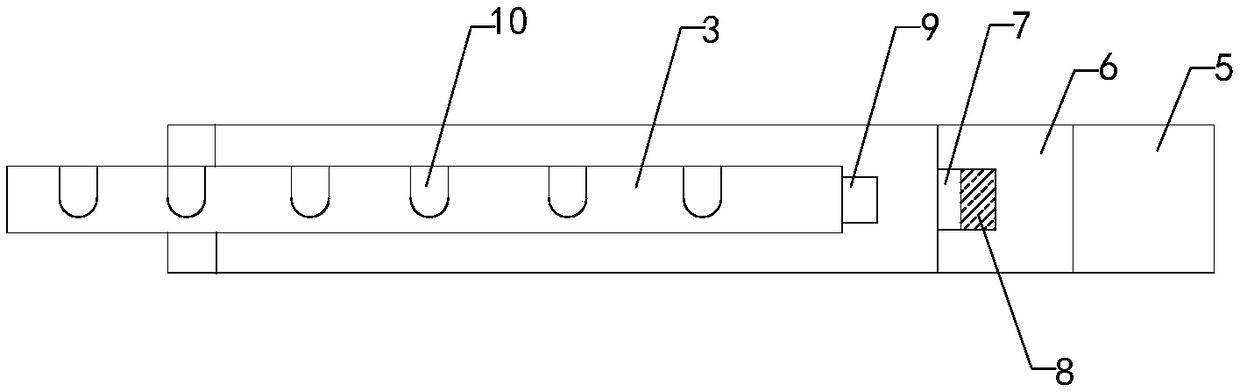

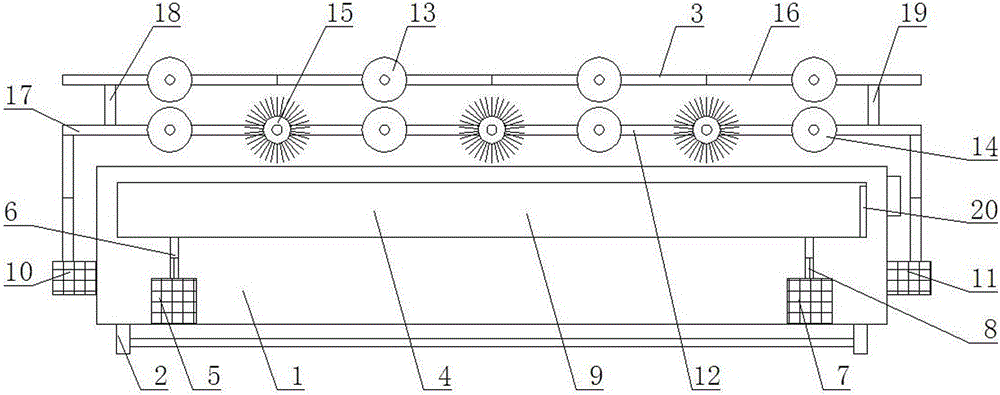

Bottom plate lacquering device for lacquer painting manufacturing

InactiveCN106216162AImprove work efficiencyShort working hoursLiquid surface applicatorsCoatingsLacquerIndustrial engineering

Owner:哈尔滨漆艺之星科技发展有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap