Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

23 results about "Large size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

1. of more than average size, quantity, degree, etc.; big; great: a large house. 2. on a great scale: a large producer of kitchen equipment. 3. of great scope or range; extensive; broad: a large variety of interests. 4. grand or pompous: large talk.

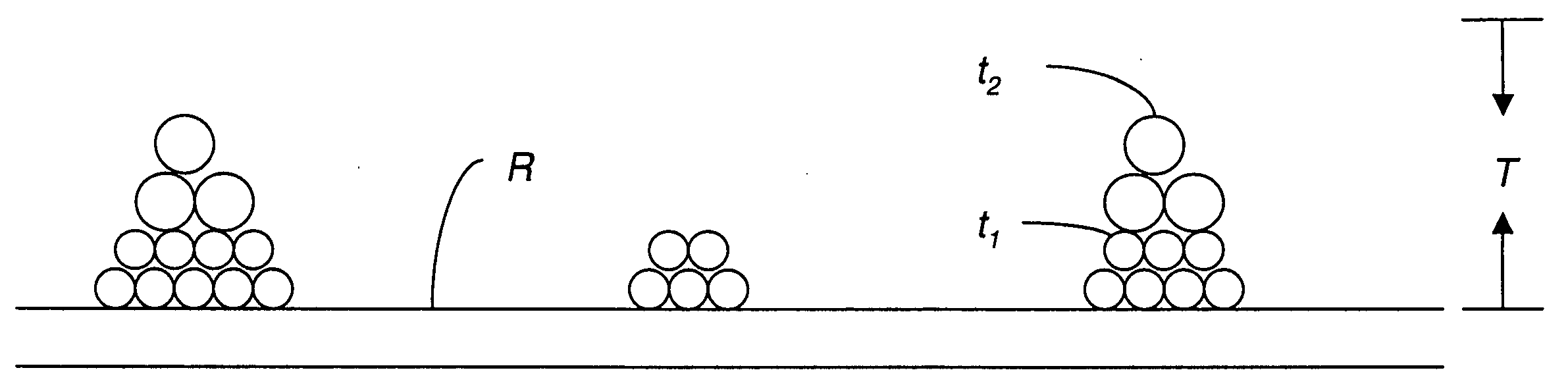

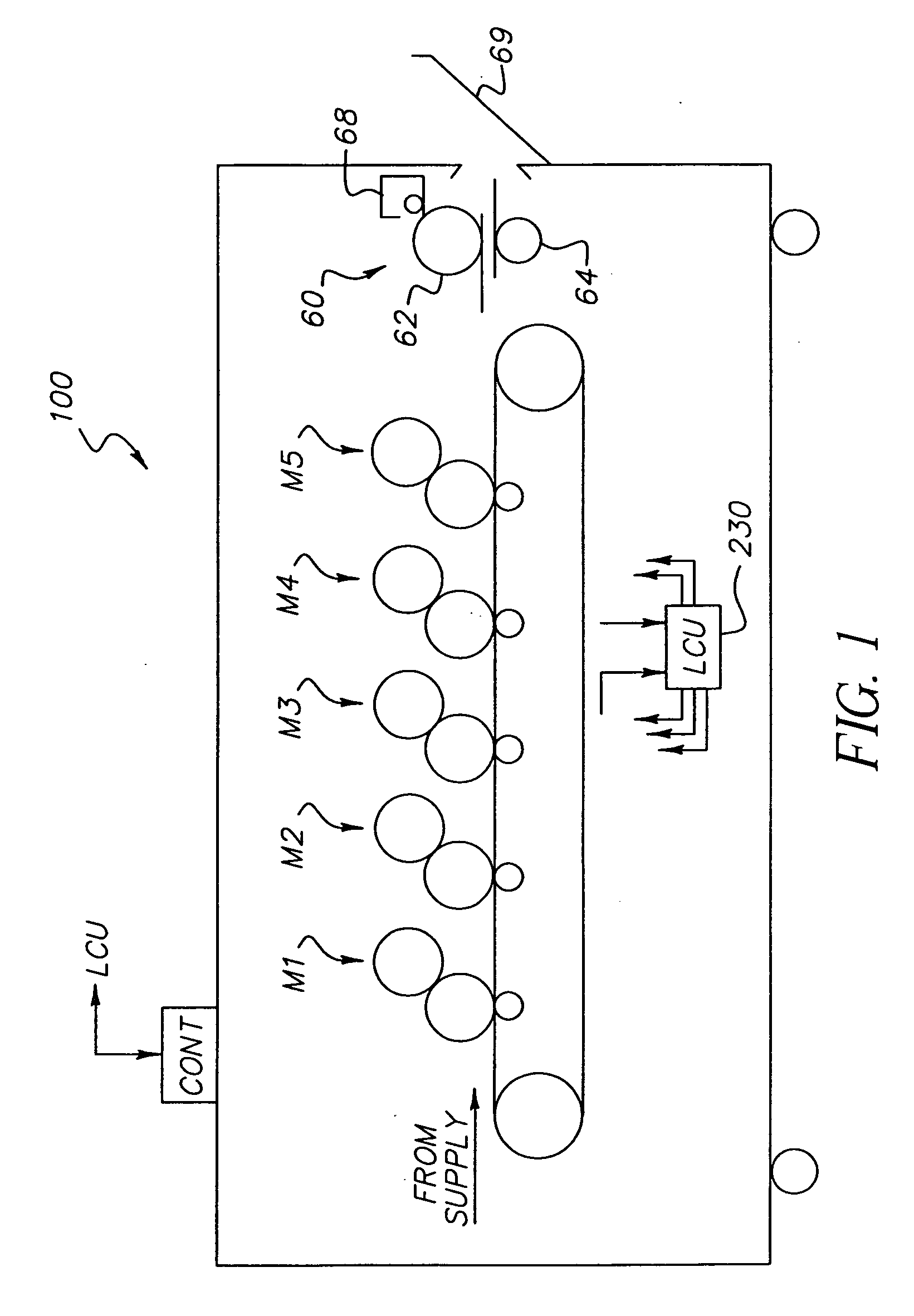

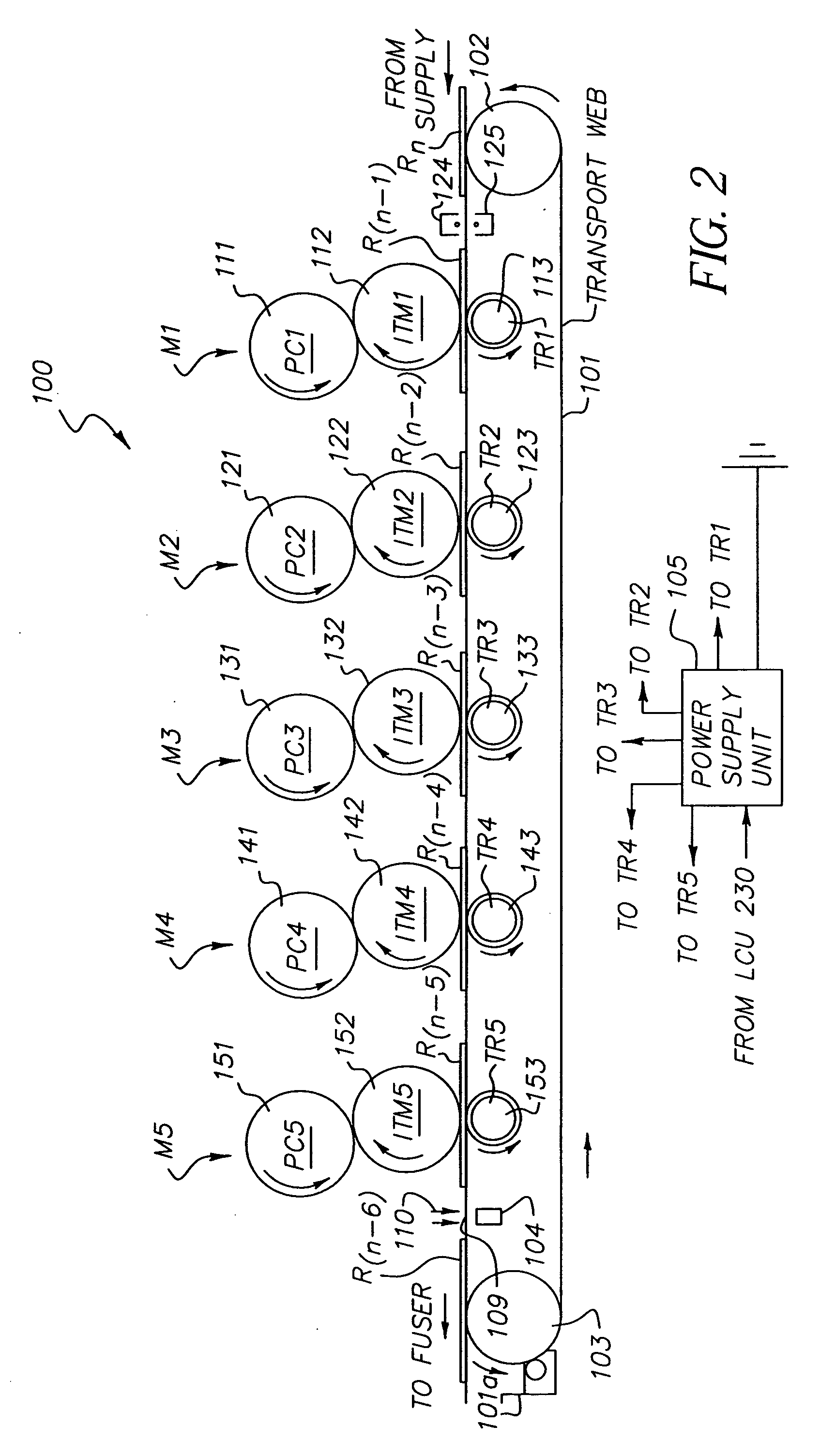

Selective printing of raised information by electrography

ActiveUS20080159786A1Small sizeElectrographic process apparatusTeaching apparatusEngineeringLarge size

Owner:EASTMAN KODAK CO

Multi-axis imaging system with single-axis relay

InactiveUS20060291048A1Provided simply and efficiently to the array microscopeSolve the lack of spaceMicroscopesTelescopesBeam splitterWavefront

A single-axis optical system is introduced in the imaging channel of an array microscope in order to relay the image of the sample object onto a detector placed apart from the array. Because of the relatively large size of the single-axis system, sufficient space is available to provide simultaneous epi-illumination to all objectives in the array with a single lateral source directed toward the sample object by a beam splitter positioned along the imaging train. As a result of this configuration, conjugate aperture-stop positions are provided that can be used to place optical elements in the system to affect the properties of the illumination and / or the imaging wavefronts.

Owner:DMETRIX INC

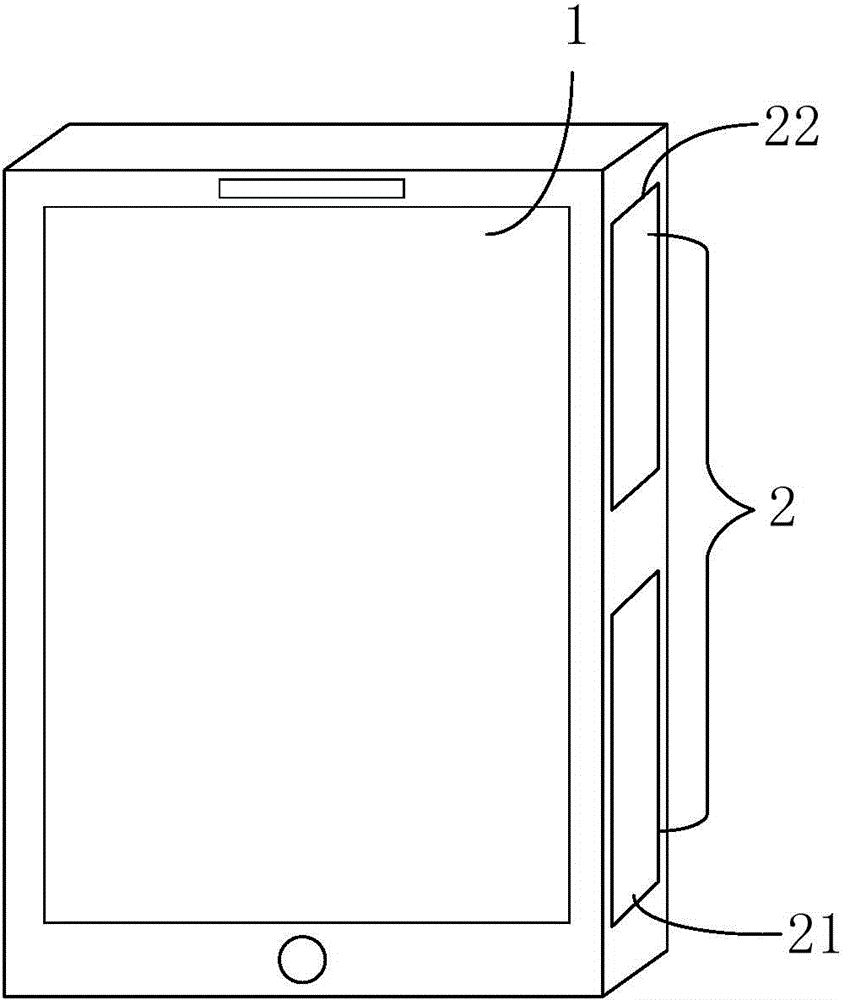

Handheld touch control device

ActiveCN104915073AIncreased flexibility of useConvenient one-handed operationInput/output processes for data processingTouch SensesHand held

Owner:FOCALTECH ELECTRONICS SHENZHEN CO LTD

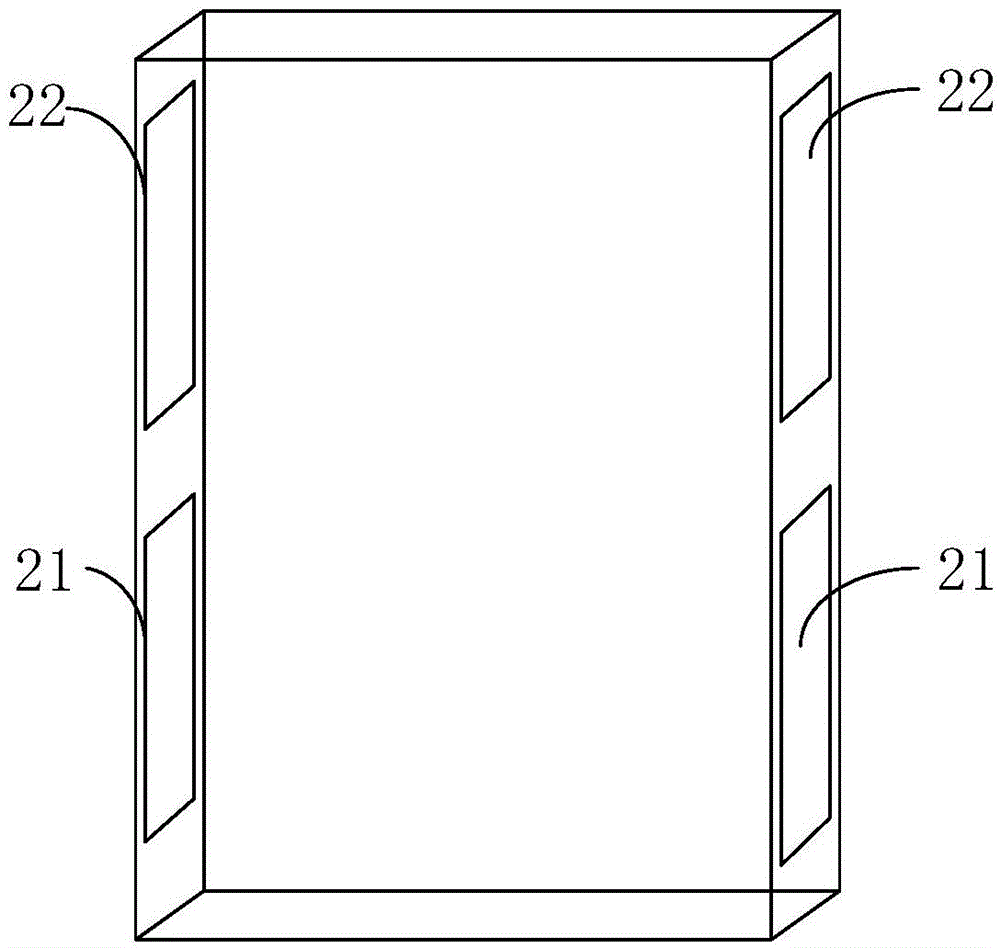

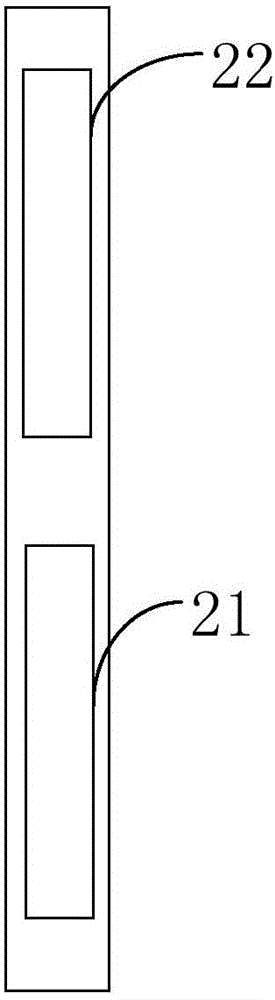

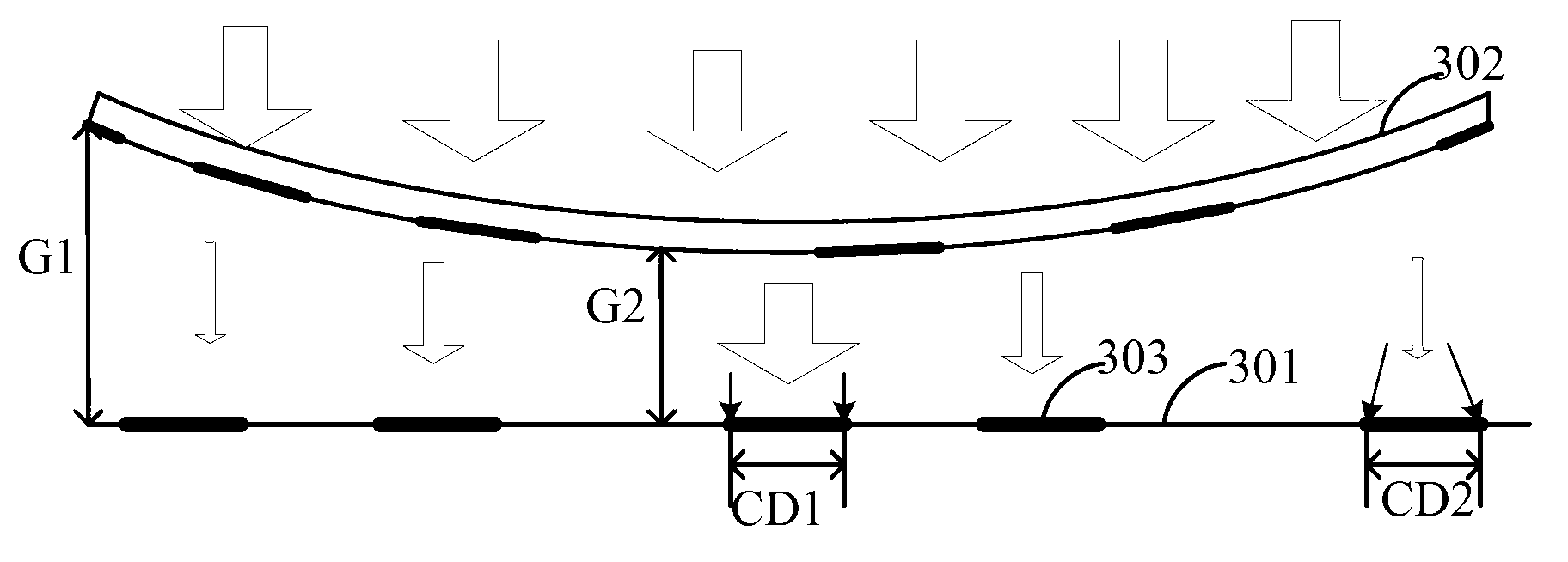

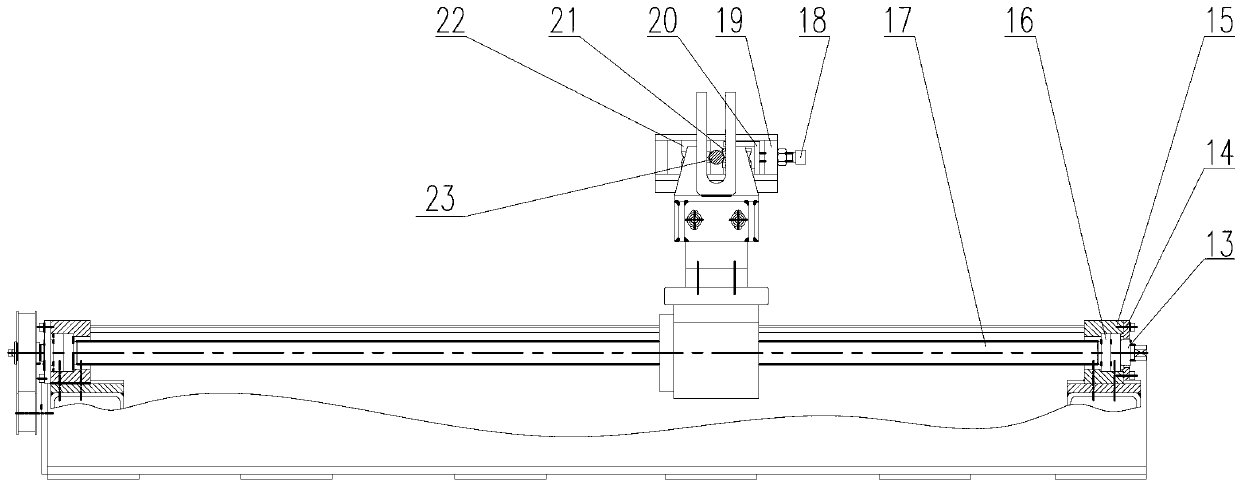

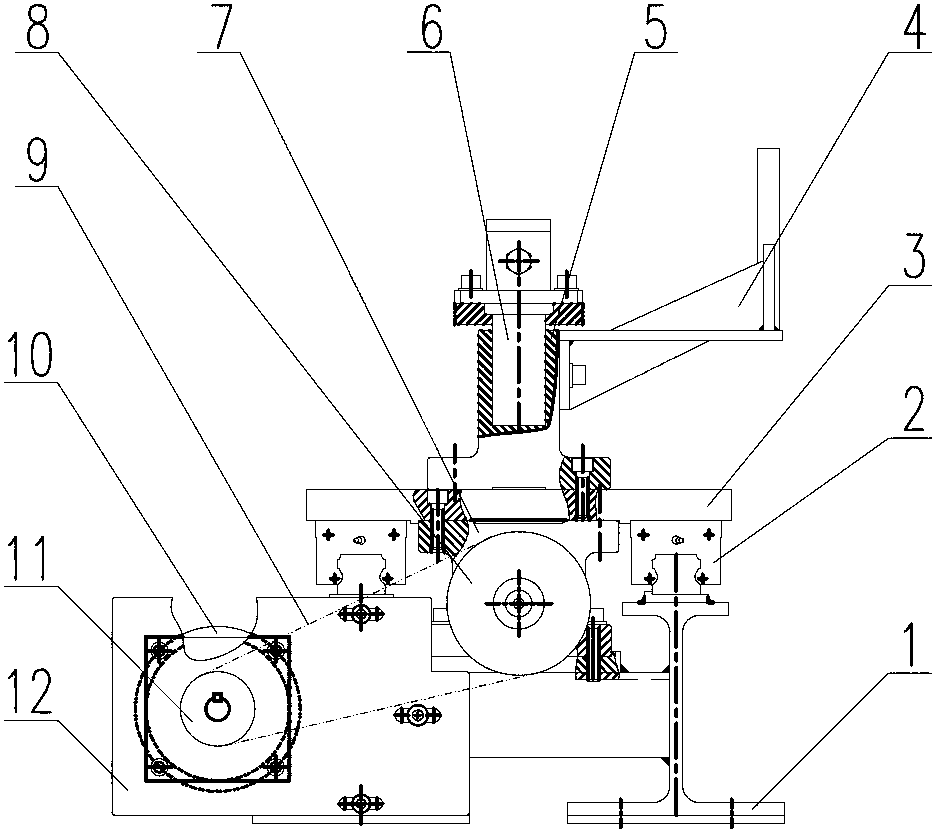

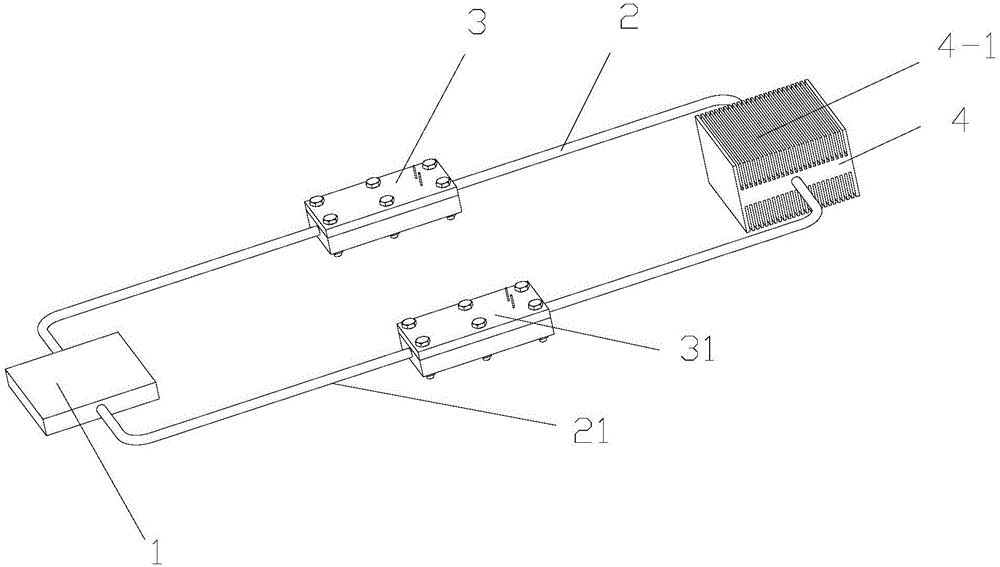

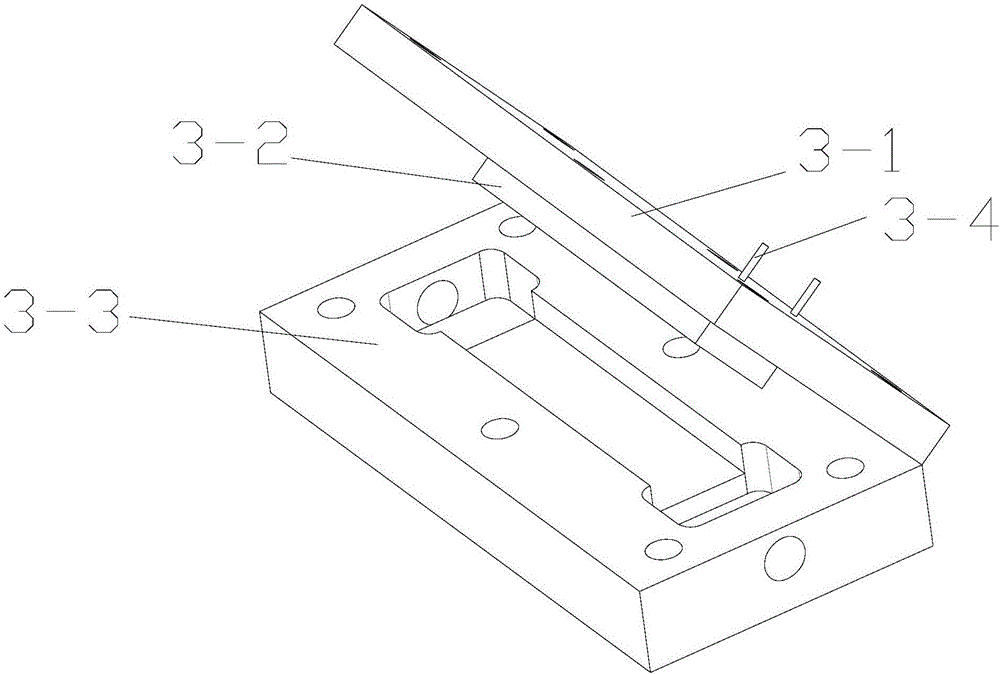

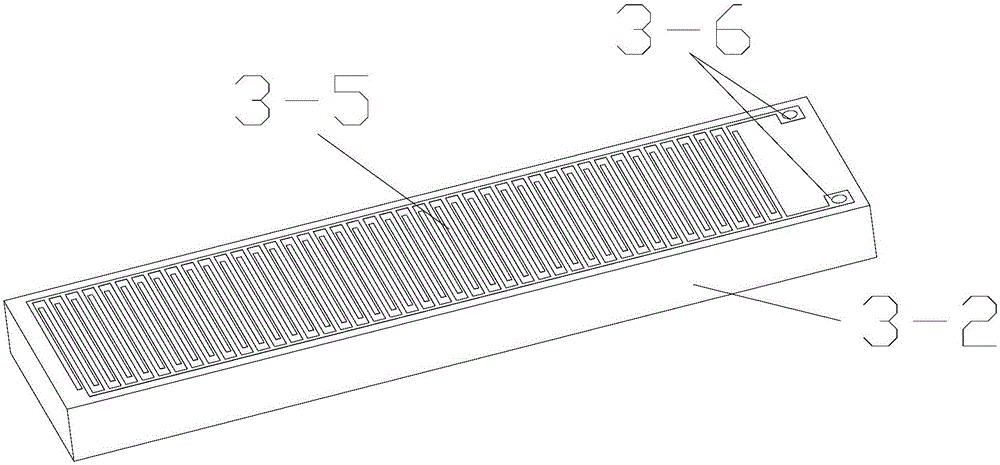

Large-size liquid crystal panel detection device

Owner:SUZHOU JINGLAI OPTO CO LTD

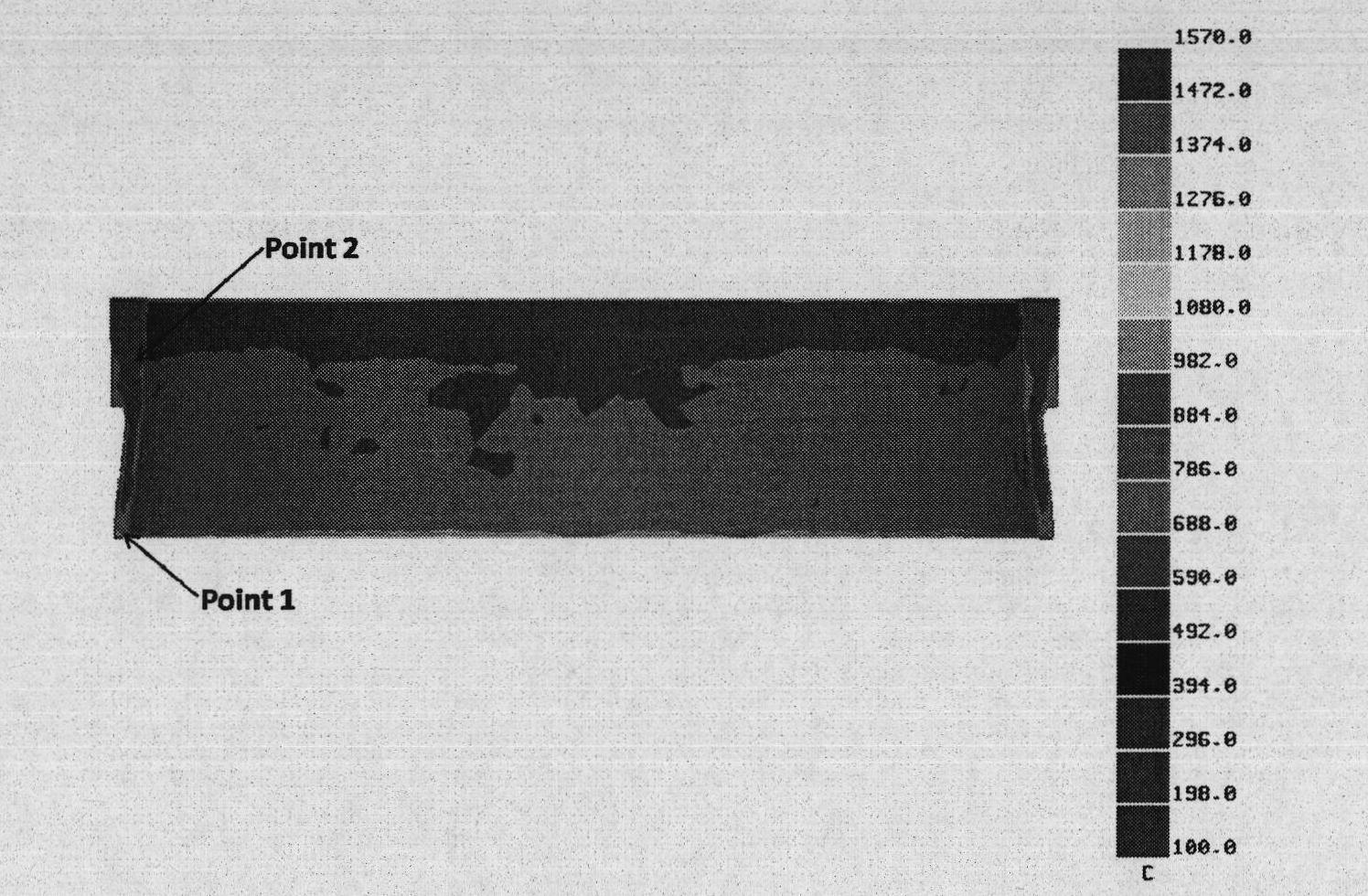

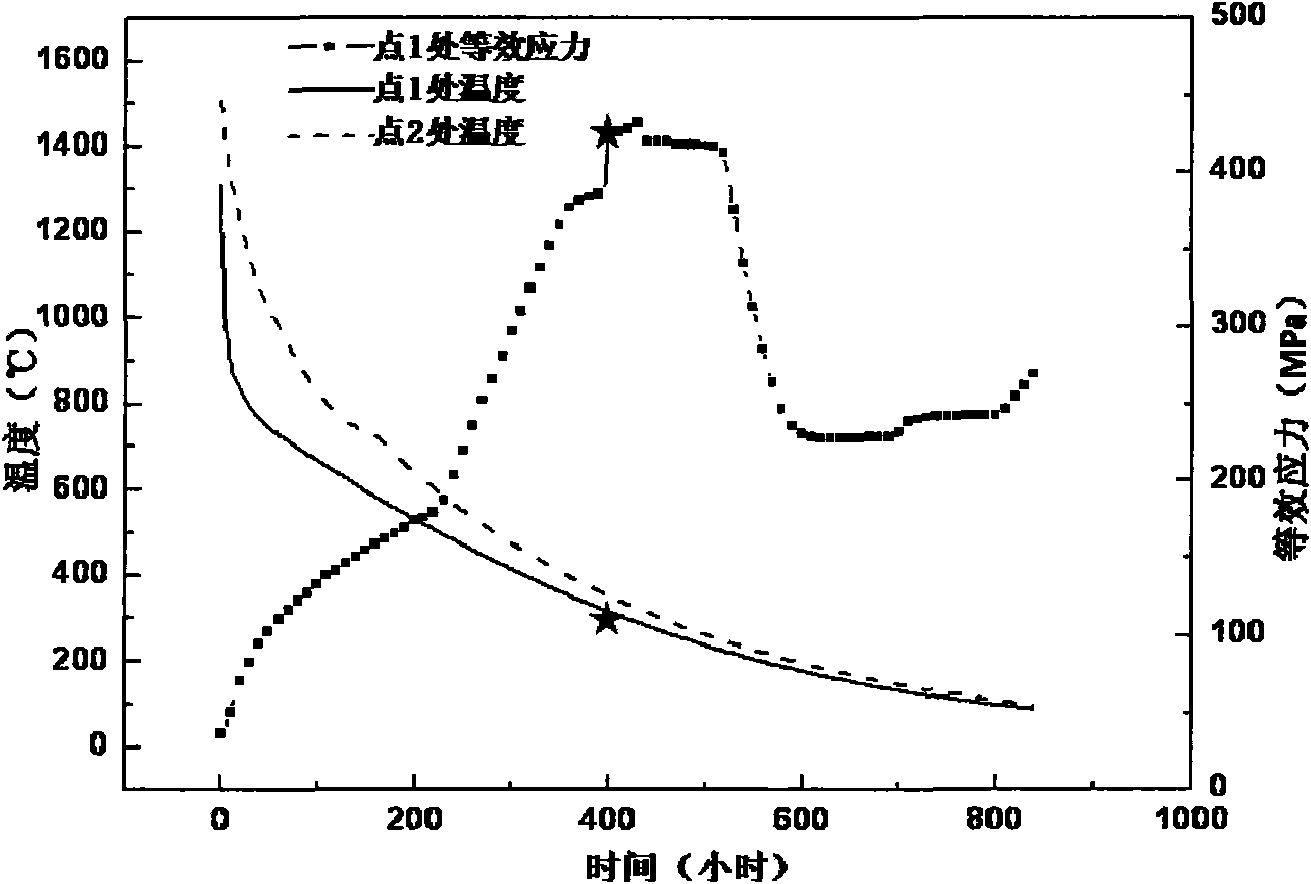

High-temperature shakeout process applied to large-size martensitic stainless steel cast

ActiveCN102211179AReduce the use of sand boxesShorten the timeTemperature controlMartensitic stainless steel

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

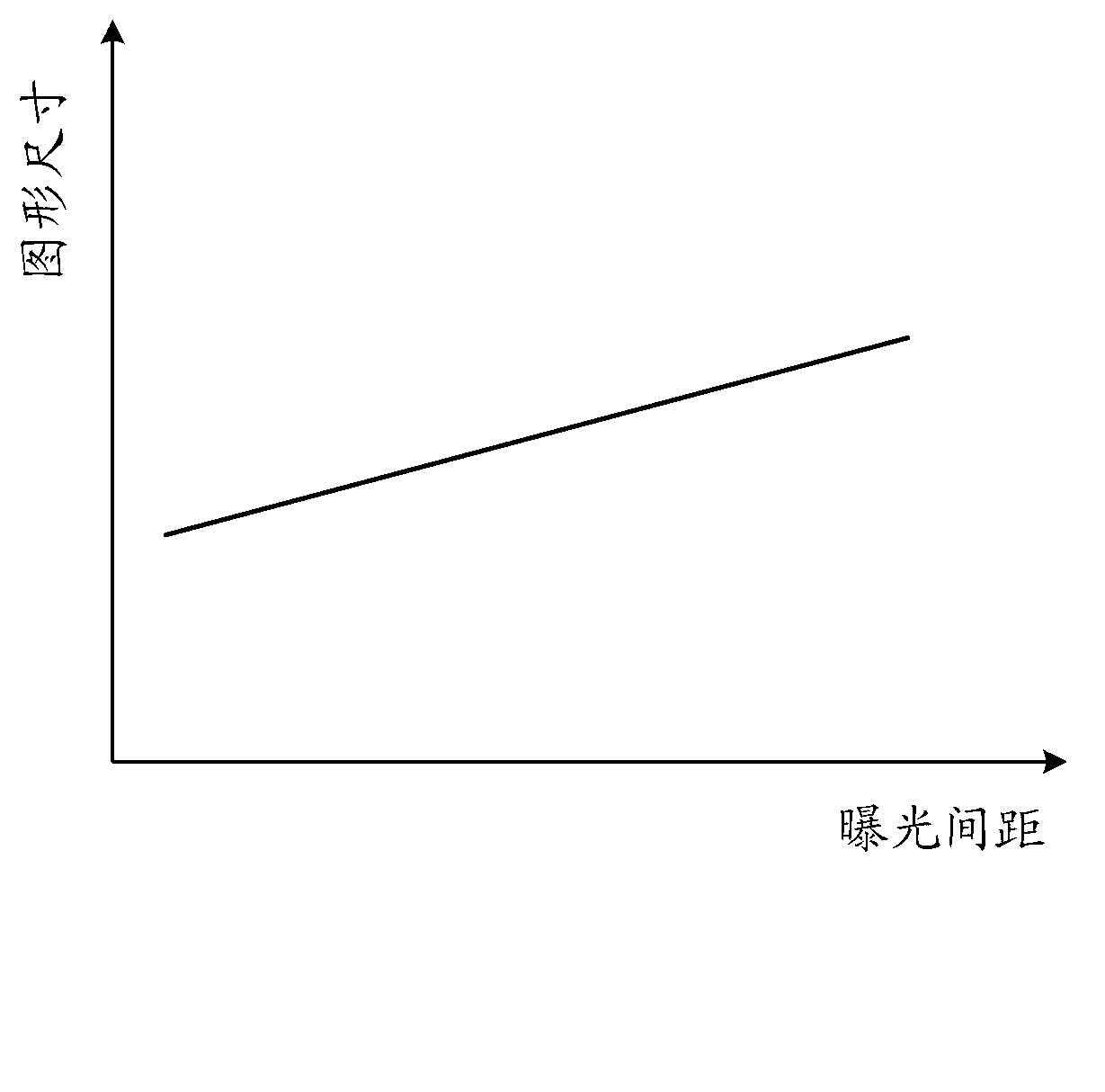

Mask plate and manufacturing method thereof

ActiveCN103019028AImprove transmittanceReduce exposureOriginals for photomechanical treatmentEngineeringLarge size

Owner:BOE TECH GRP CO LTD +1

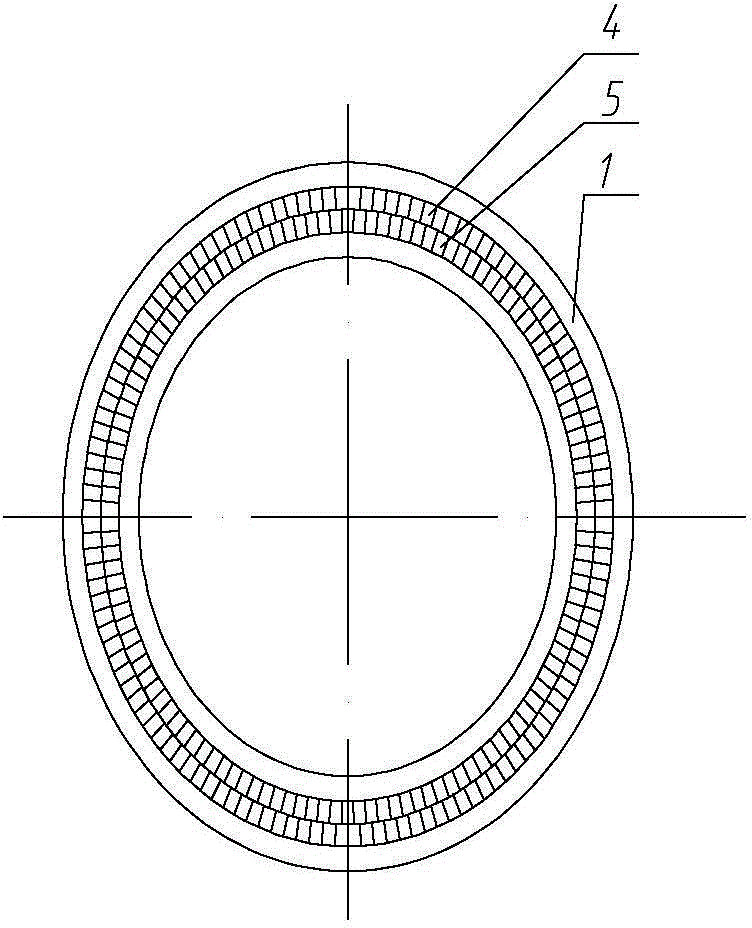

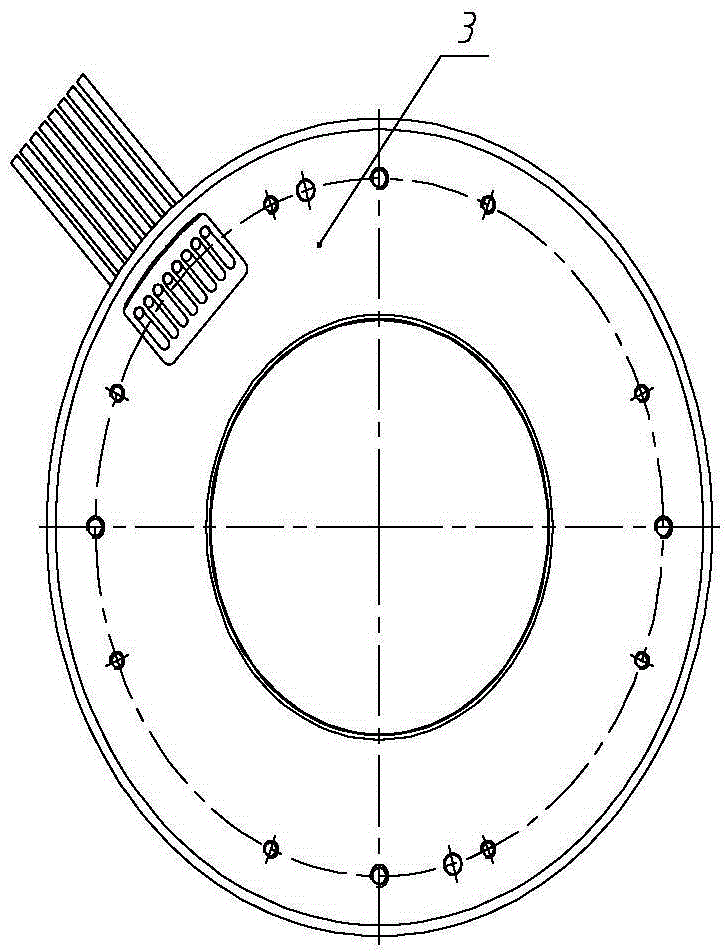

Magnetoelectric type absolute position sensor with large central hole structure and method for measuring absolute position

ActiveCN104634367ALight in massConvenient ArrangementConverting sensor output electrically/magneticallySignal processing circuitsMagnetic poles

Owner:HARBIN INST OF TECH

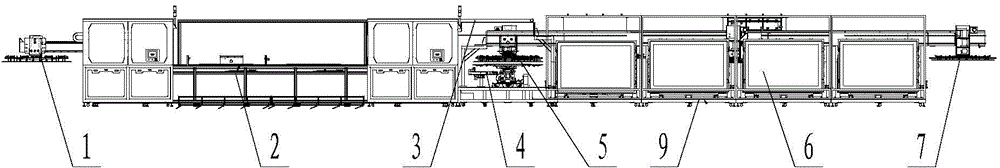

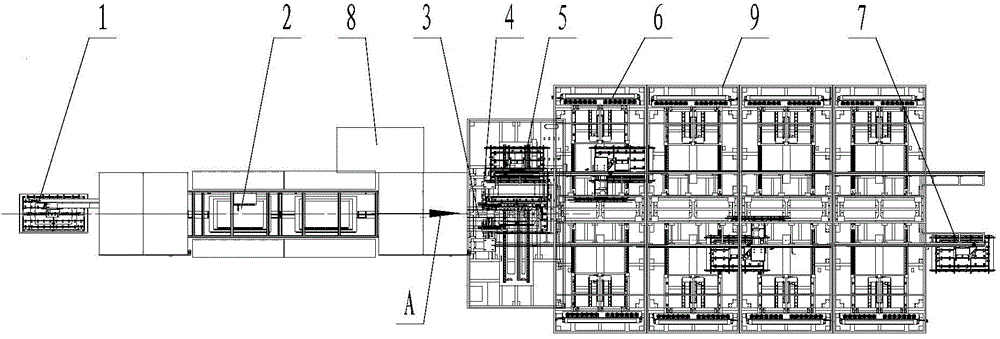

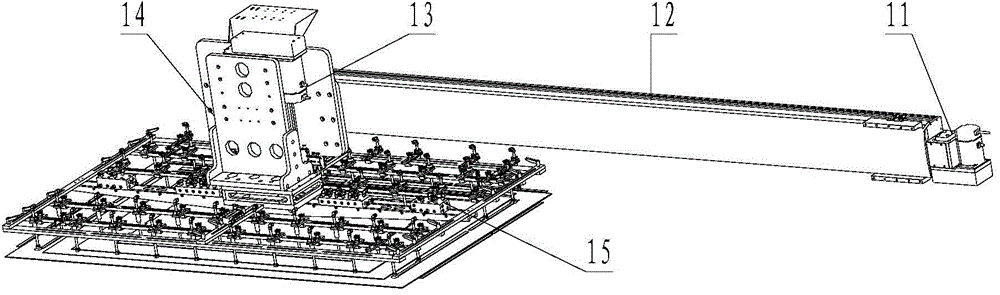

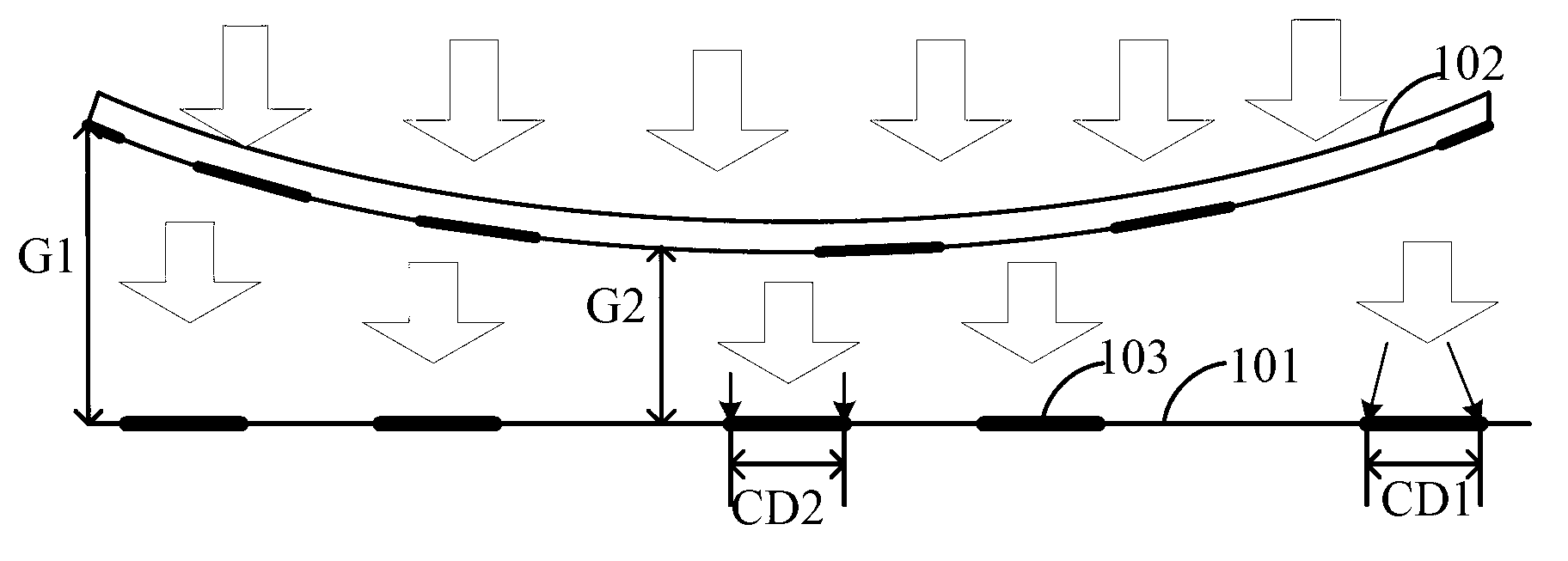

Laminating device and method applied to large-size battery assembly

PendingCN110370778ADistribute stressReduce shockLaminationLamination apparatusElectrical batteryThermal expansion

The invention relates to a laminating device and method applied to a large-size battery assembly. The laminating device comprises a laminating cavity, a curing cavity, pre-cooling cavities and a cooling cavity which are connected sequentially, and the temperature in the pre-cooling cavities is higher than the temperature in the cooling cavity; and in the laminating process, the assembly is sequentially subjected to the four steps of laminating, curing, pre-cooling and cooling, wherein in the pre-cooling process, the assembly is cooled from 130-160 DEG C to 50-80 DEG C firstly and then placed into the cooling cavity to be cooled to 20-50 DEG C. The laminating device and method have the beneficial effects that the laminating device including the one or more pre-cooling cavities is adopted, through a stepped cooling method, the influences of quick cooling on large-size battery pieces are reduced, stress, caused by thermal expansion and cold contraction phenomena in the cooling process, ofthe surface of a silicon wafer is dispersed, impact borne by the surfaces of the battery pieces is buffered, the phenomena of laminating fragments and subfissure of the battery pieces are obviously reduced, the efficiency of assembly preparation is improved, and the qualified rate of assembly preparation is increased.

Owner:DONGFANG HUANSHENG PHOTOVOLTAIC (JIANGSU) CO LTD

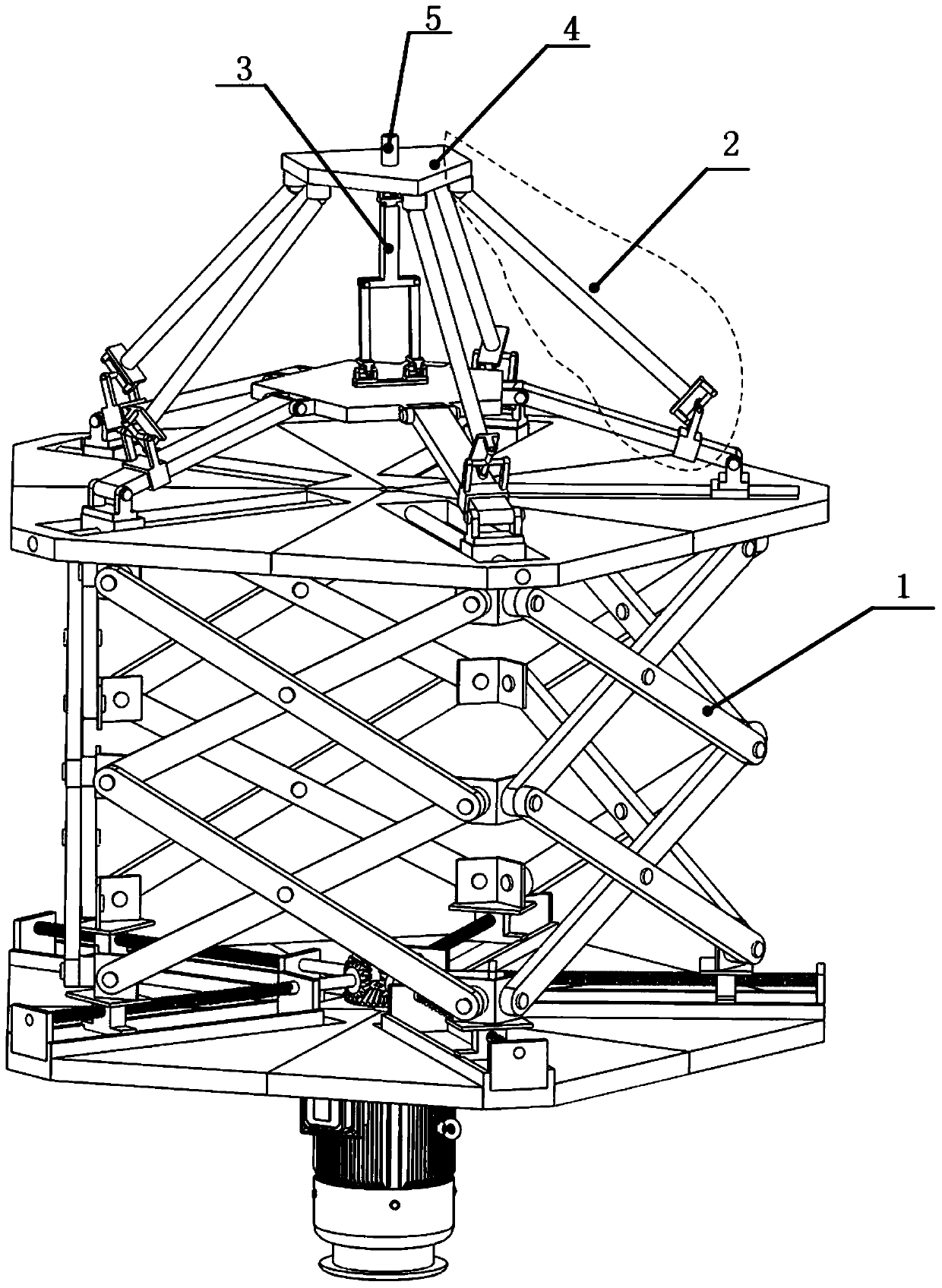

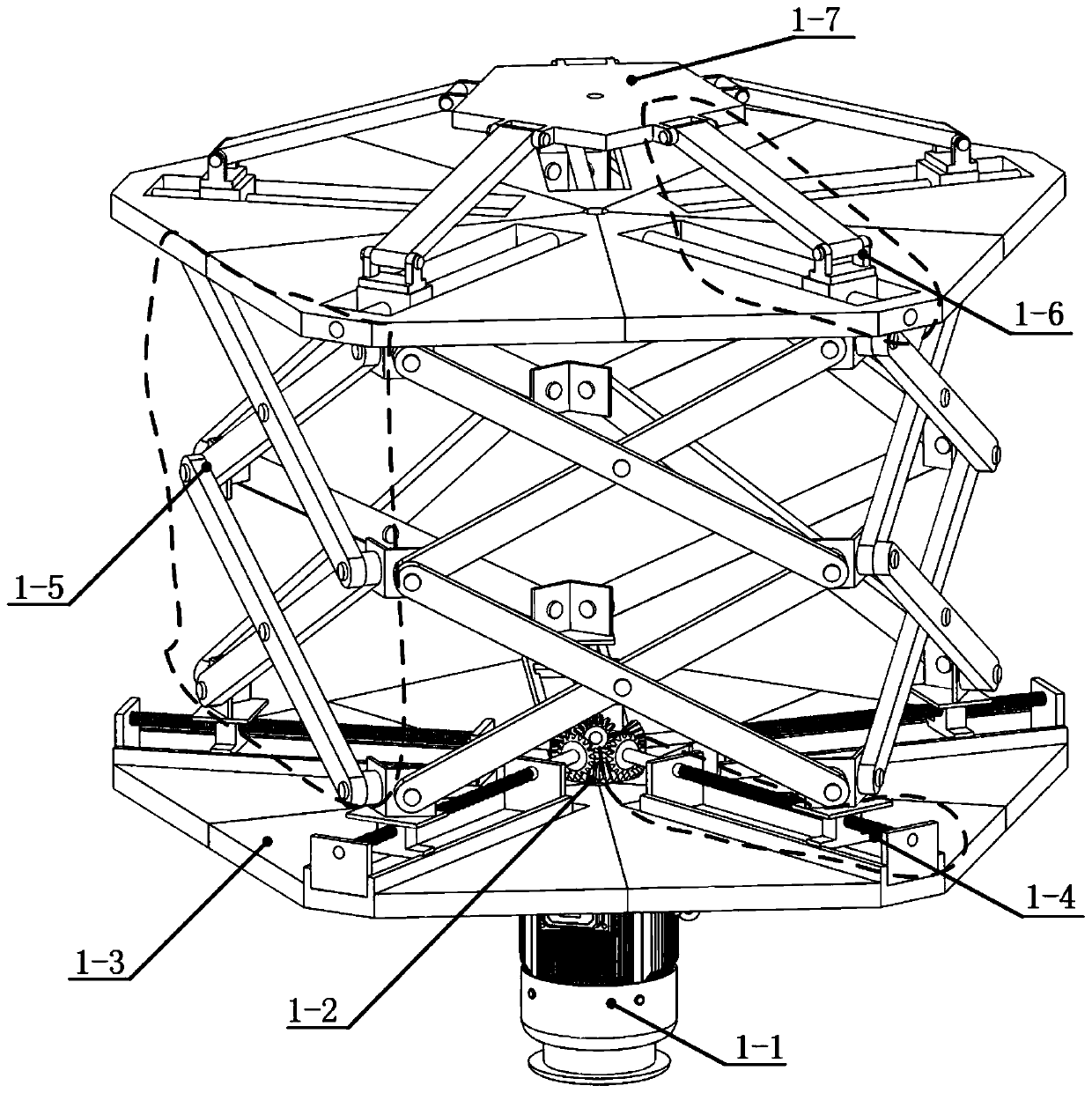

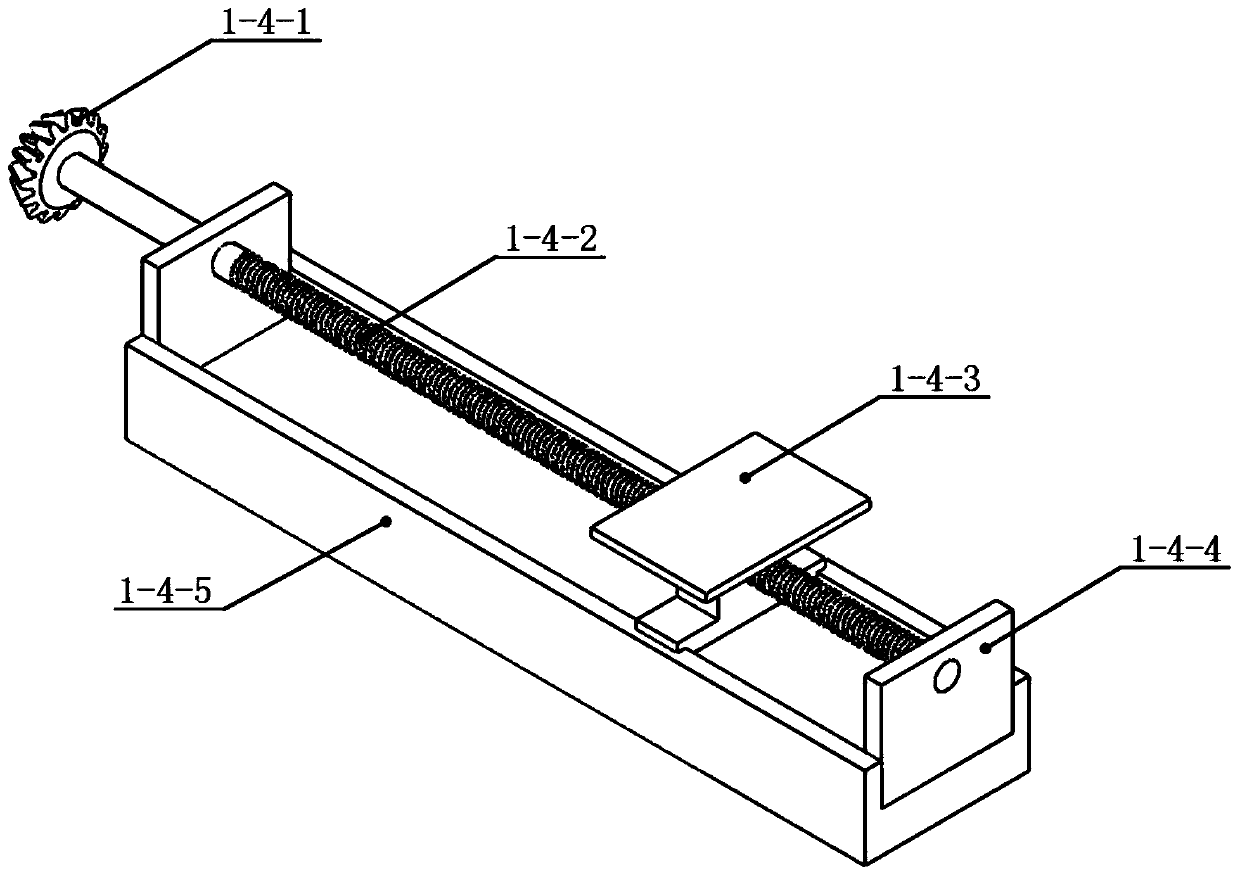

Large-stroke five-degree-of-freedom hybrid machine tool with reconfigurable characteristics

InactiveCN110026786AMeet processing needsReconfigurableProgramme-controlled manipulatorLarge fixed membersEngineeringDegrees of freedom

Owner:BEIJING JIAOTONG UNIV

Rubber composition used for treads of middle-large-size automobile tires

ActiveCN107759860AIncrease elasticityImprove wear resistanceSpecial tyresVulcanizationPolymer science

Owner:ZHAOQING JUNHONG CO LTD

Detection system for display screen of liquid crystal panel

InactiveCN102122094AImprove compatibilityImprove performanceNon-linear opticsDisplay deviceHigh voltage

Owner:陈宇晓

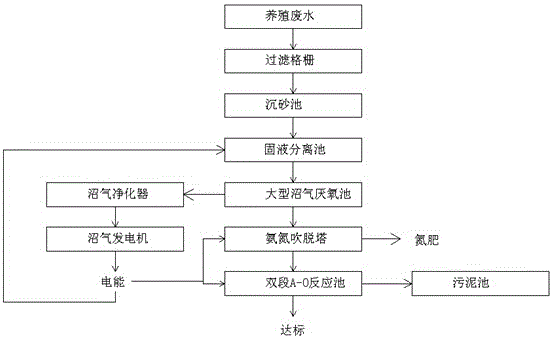

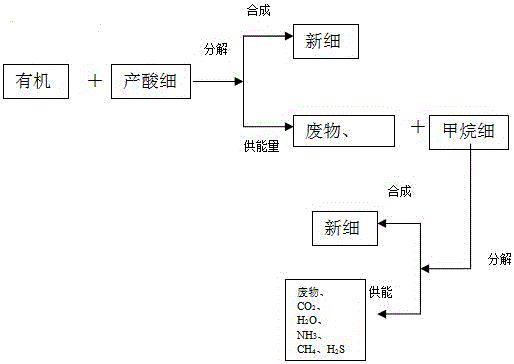

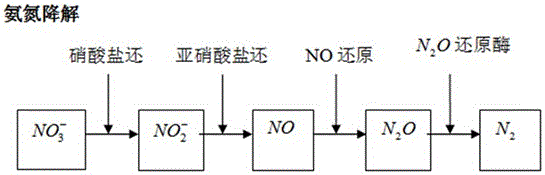

Culture waste water energy self circulation disposal system and method thereof

InactiveCN105152473AIncrease productionImprove electricity consumptionGaseous fuelsWaste based fuelSludgePollution

Owner:GUANGXI YINENG ENVIRONMENTAL PROTECTION ENG CO LTD

Control method of surface waviness of large-size optical element processed through single point diamond milling method

ActiveCN102837367AEasy to controlSimple control principleStone-like material working toolsDiamond turningLarge size

The invention discloses a control method of surface waviness of a large-size optical element processed through a single point diamond milling method and belongs to the field of ultraprecision machining of a large-size brittle optical element. The invention aims to solve the problem that the existing SPDT (single point diamond turning) method cannot guarantee waviness errors and frequency domain evaluation index PSD1 when a large-size optical element is processed. The control method disclosed by the invention comprises the following steps: 1. carrying out rough machining; 2. acquiring a space cycle T of longitudinal strips; 3. judging rigidity of the processing lathe, executing the step 4 if the rigidity is too low and executing the step 5 if the rigidity is too high; 4. increasing average pressure between a beam and a leveling pad body and then executing step 6; 5. reducing average pressure between the beam and the leveling pad body or contact rigidity, and then executing step 6; 6. carrying out secondary ultraprecision machining; 7. detecting the PSD1 value again; 8. judging whether the fact that PSD1 is less than or equal to 15nm<2>.mm is right or false; returning to the step 2 if the fact is false; and if the fact is right, completing the control of the waviness errors and the frequency domain index PSD1 of the large-size optical element U processed through the single point diamond milling method.

Owner:HARBIN INST OF TECH

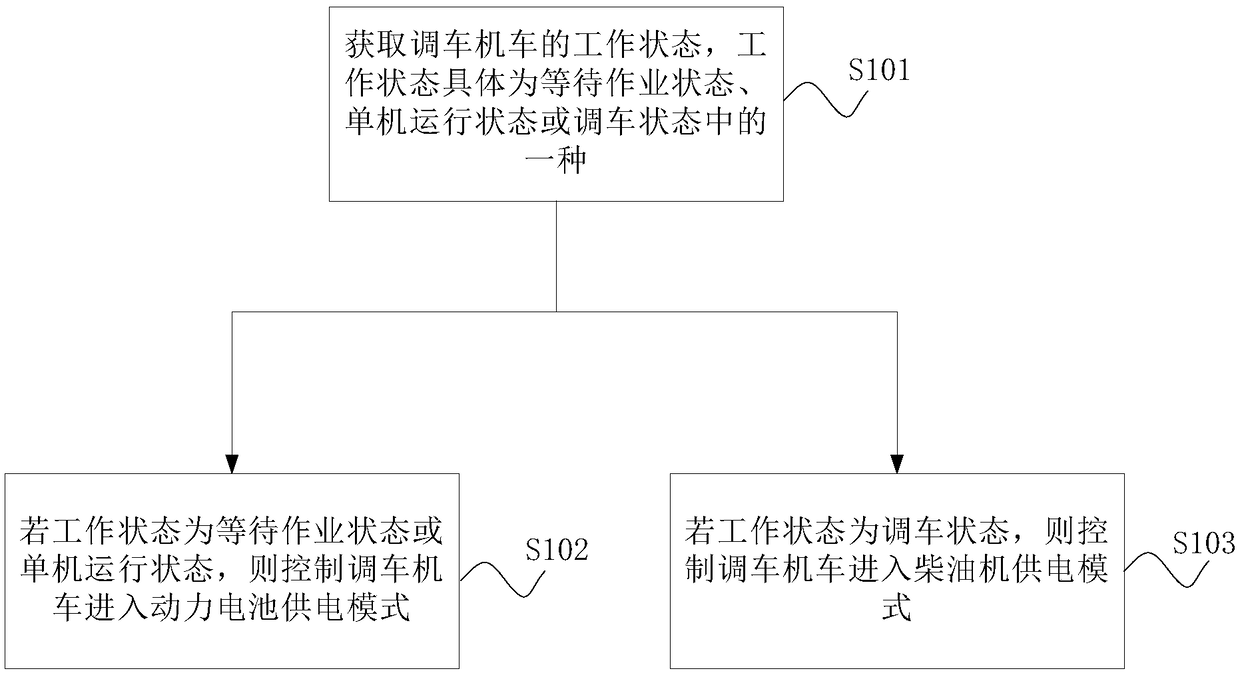

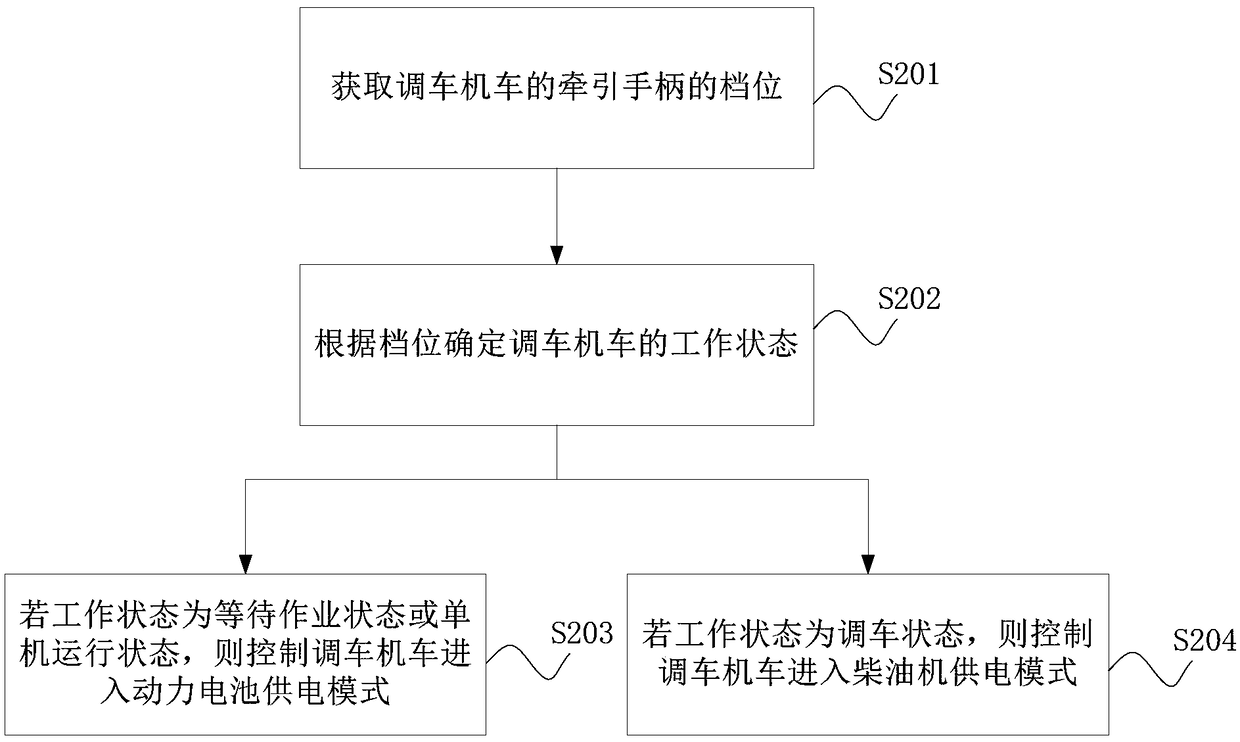

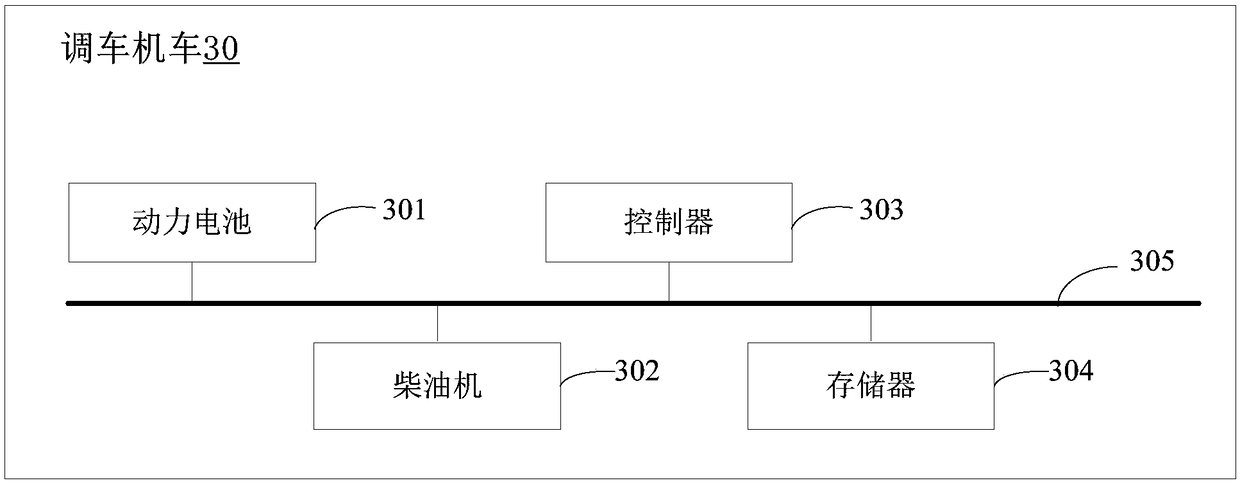

Shunting locomotive control method and shunting locomotive

ActiveCN109278764AAvoid the problem of large power lossAvoid the problem of large capacity and large volumeHybrid vehiclesRailway transportPower batteryLarge size

Owner:CRRC DALIAN CO LTD +1

Secondary battery anode material

InactiveCN106299370ASolving intractable dendrite problemsCell electrodesElectrochemical responseElectron

The invention discloses a secondary battery anode material. The material comprises a framework, chelating / adsorption groups and active substances. The framework does not participate in electrochemical reaction and just provides carriers for the chelating / adsorption groups; the chelating / adsorption groups outer layer electrons of contained atoms such as N, S, P and O which have lone pair electrons and can form chelating or chemisoptive bonds (represented by iminodiacetic acid chelating groups in the drawing) along with divalent or multivalent metals; the active substances are divalent or multivalent metal ions which can be reduced into a lower-valence state. During charging, the metal ions used as the active substances are reduced into a lower-valence state or metal elementary substance state, and during discharging, metal ions can be reversibly produced and can form ionic bonds or coordination bonds along with the chelating / adsorption groups. The anode material can be matched with many cathode materials to form a battery. The battery anode disclosed by the invention is novel in principle and structure, and is very expected to be applied to electric automobiles and large-size energy storage projects due to low cost and high reliability.

Owner:颜竞

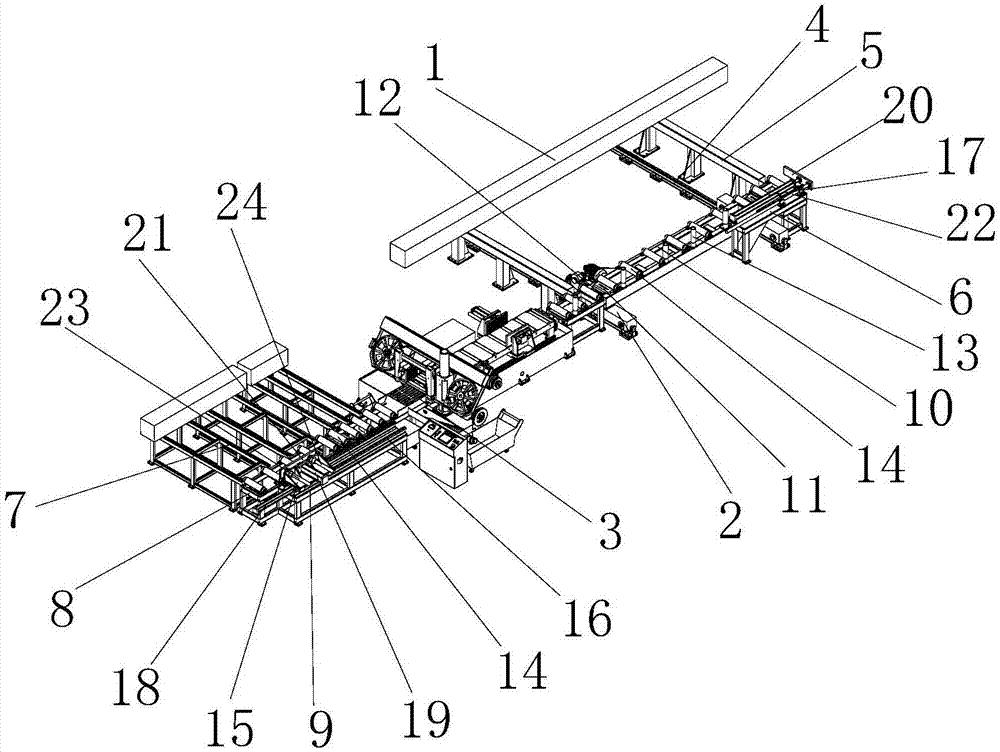

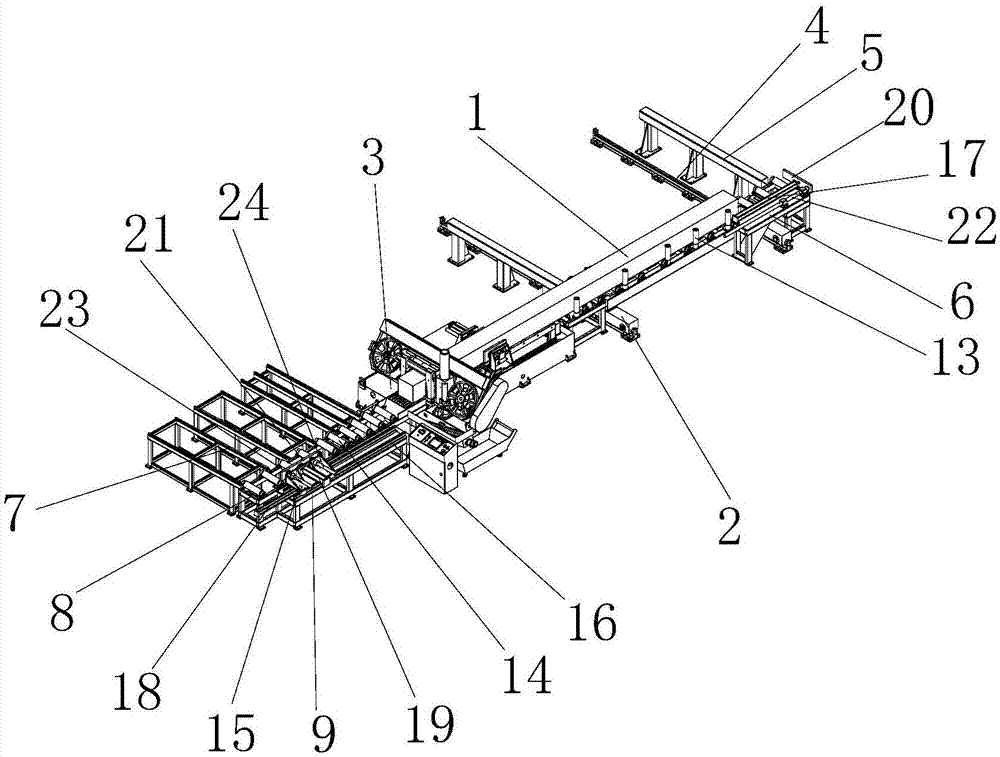

Numerical-control rope moving mechanism

InactiveCN103341749AReduce labor intensityIt takes two people to solveMetal working apparatusNumerical controlBall screw

Owner:WUXI HONGYUAN DEVFLEX

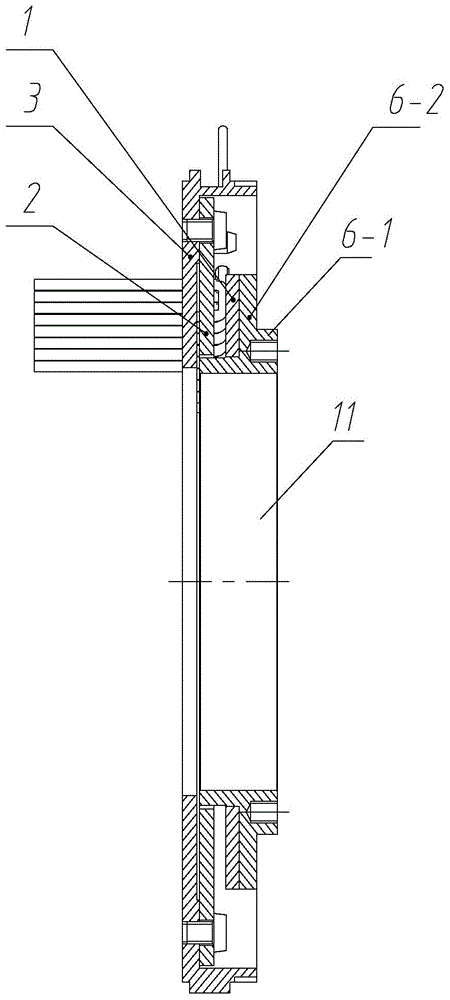

Small liquid cooling system driven by electro-hydraulic micropumps and method

InactiveCN106098657ASolution volumeReduce power consumptionSemiconductor/solid-state device detailsSolid-state devicesWorking fluidHydraulic pump

Owner:SOUTH CHINA UNIV OF TECH

Position change device for polarizing sheet

ActiveCN101604095AReduce the bottom areaStable deliveryNon-linear opticsLiquid-crystal displayPolarizer

The invention relates to a polarizing sheet sticking device. A first polarizing sheet sticking device (600) and a second polarizing sheet sticking device (700) are provided with frame components (601 and 701) which are rotationally arranged by using rotating shafts (P11 and P12) as centers and are provided with four lateral surfaces. Therefore, when polarizing sheets (2 and 3) are stuck to a liquid crystal unit substrate (1) at a polarizing sheet sticking station (S14), covered films can be peeled from the polarizing sheets (2 and 3) at a covered film peeling station (S13), and the polarizing sheet (3) is accepted at a polarizing sheet accepting station (S11). As a result, the polarizing sheet sticking device which can inhibit the increment of the bottom area thereof due to large size of a color liquid crystal display can be provided.

Owner:YODOGAWA MEDEC

Method for producing 23MnB steel based on converter flow path

ActiveCN102409134AReduce acid soluble aluminum contentLight weightManufacturing convertersTitaniumOxygen

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Preparation method of polyacrylamide reverse-phase emulsion

Owner:SHANDONG UNIV

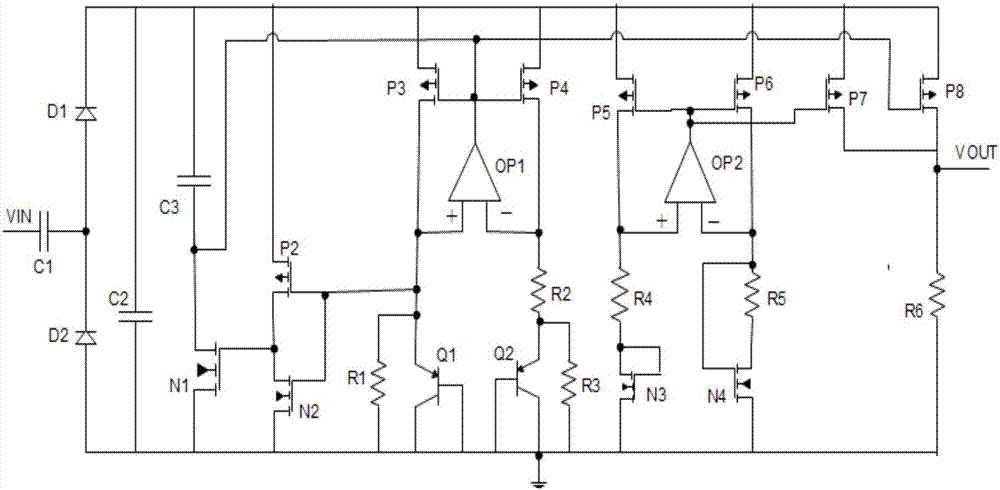

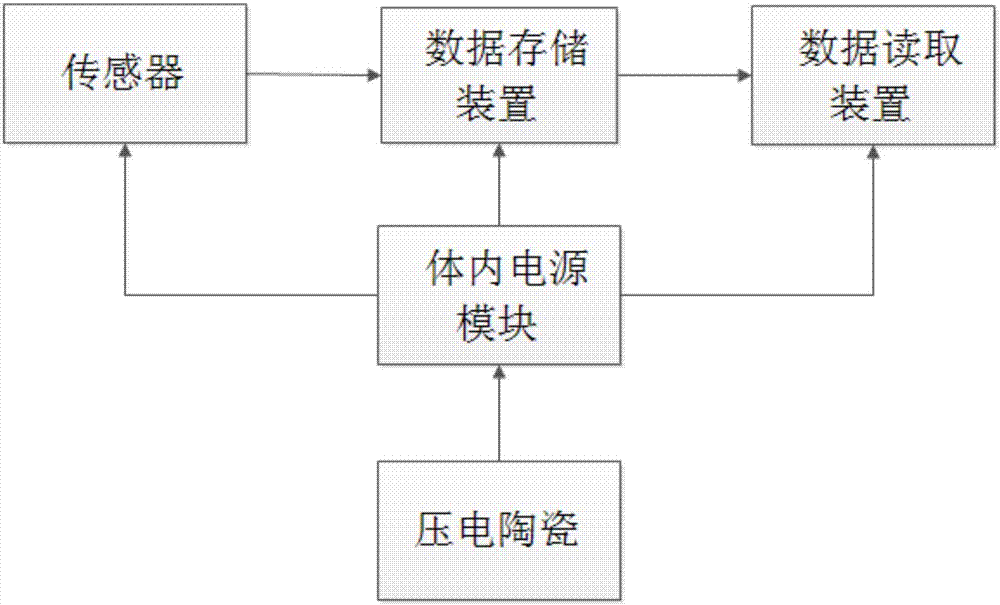

Built-in power supply module of medical treatment chip and chip system

InactiveCN106911256ASolve the weight problemSolve the accuracy problemPiezoelectric/electrostriction/magnetostriction machinesAc-dc conversionComputer moduleLarge size

Owner:刘博文

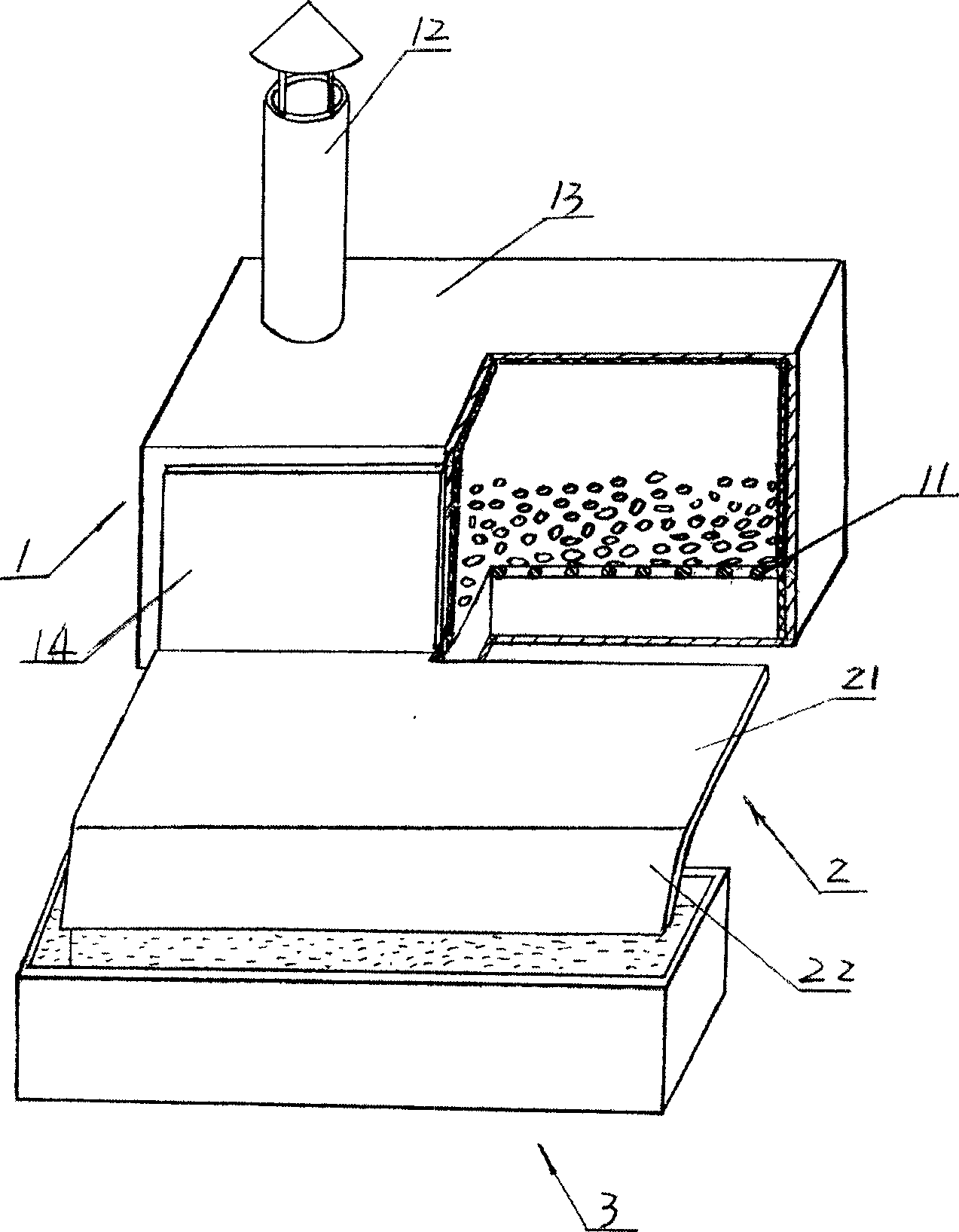

Method and equipment for crashing steel piece in large size

InactiveCN1695815AEasy to operateReduce crushing costsGrain treatmentsThermal expansionHeating furnace

Owner:范培友

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap