Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Plasma treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma treatment uses a controlled vacuum plasma to alter the surface of a material in order to improve bonding, printing, painting, coating, or wettability. The process is performed in a plasma chamber under vacuum pressure. It is commonly used in the manufacturing of electronic devices, medical devices, textiles, plastics, rubbers, and more.

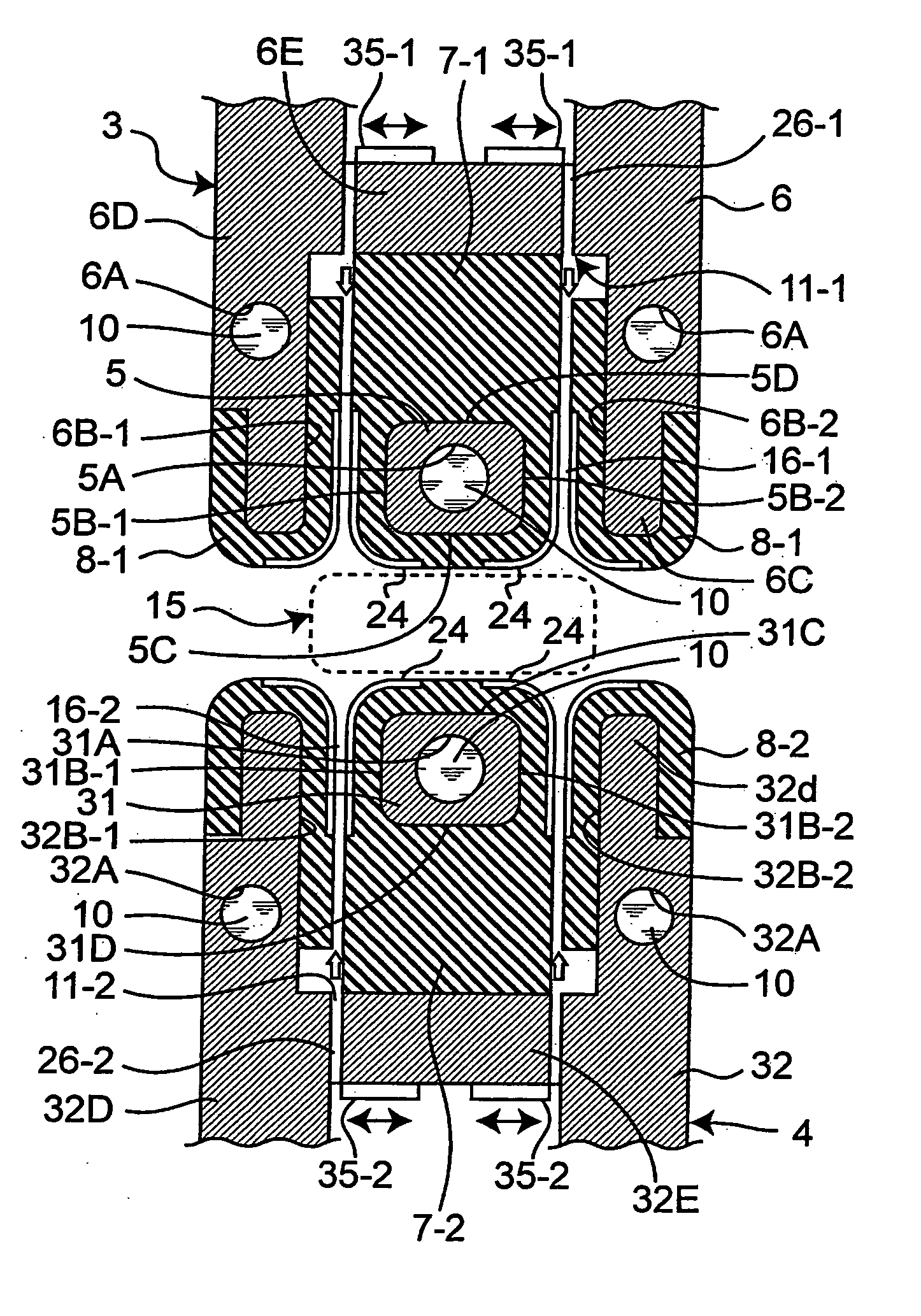

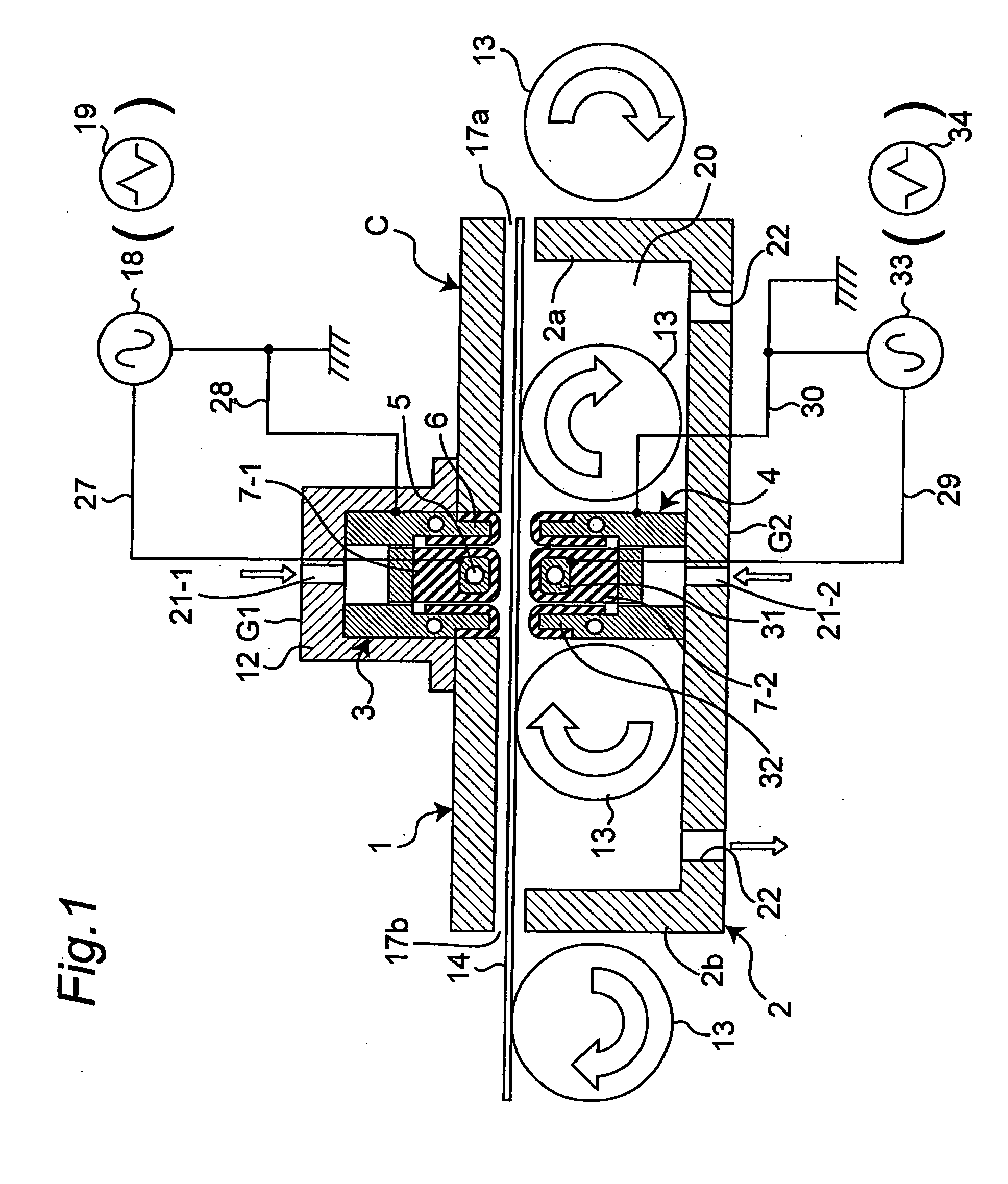

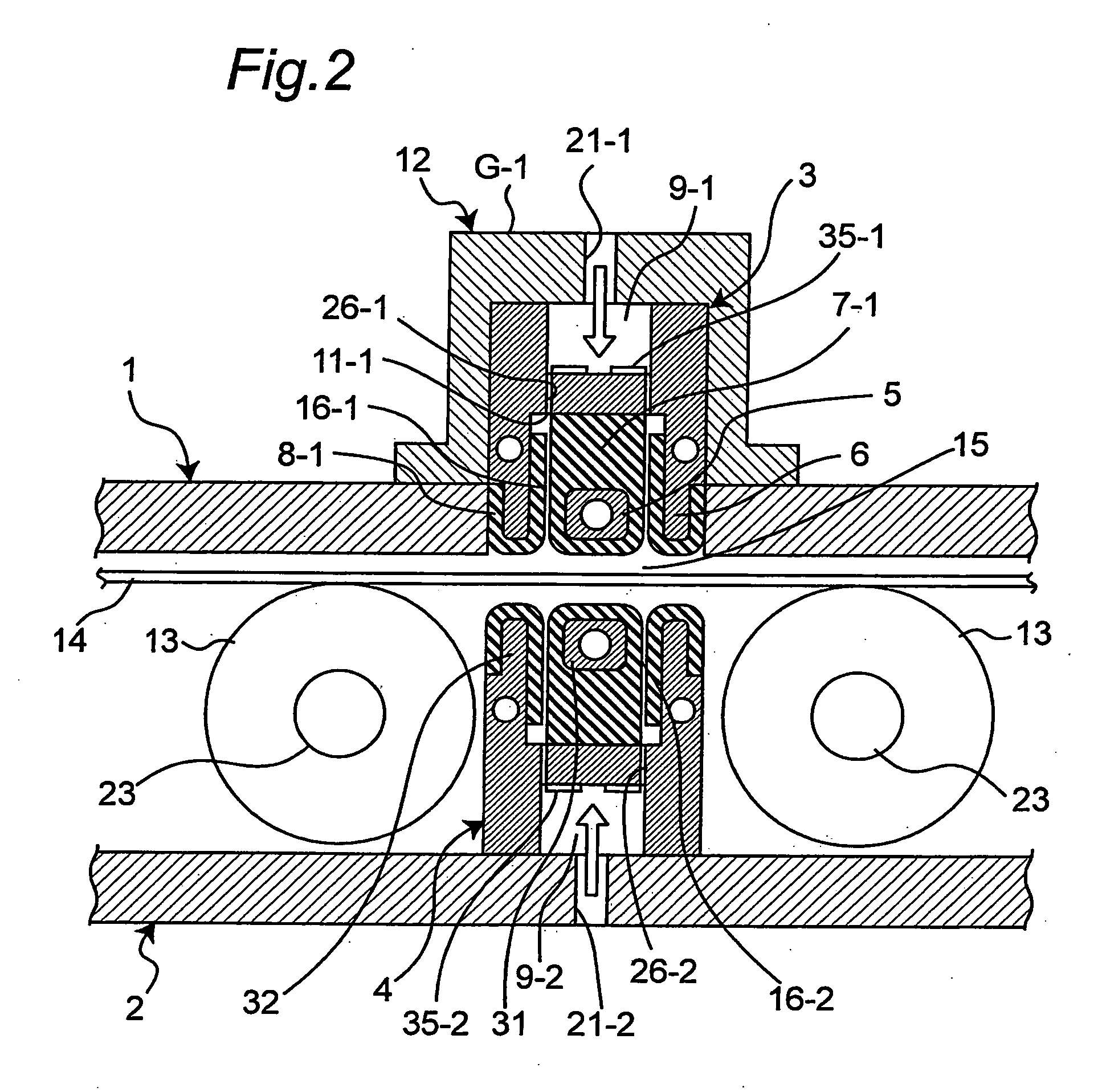

Plasma processing apparatus

InactiveUS20050217798A1Plasma discharge can be stabilizedLow running costElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringMaterials science

Owner:SHARP KK

Apparatus and method for plasma treating and dispensing an adhesive/sealant onto a part

InactiveUS20060172081A1Minimal timeLow costMovable spraying apparatusPretreated surfacesAdhesiveSealant

Owner:NORDSON CORP

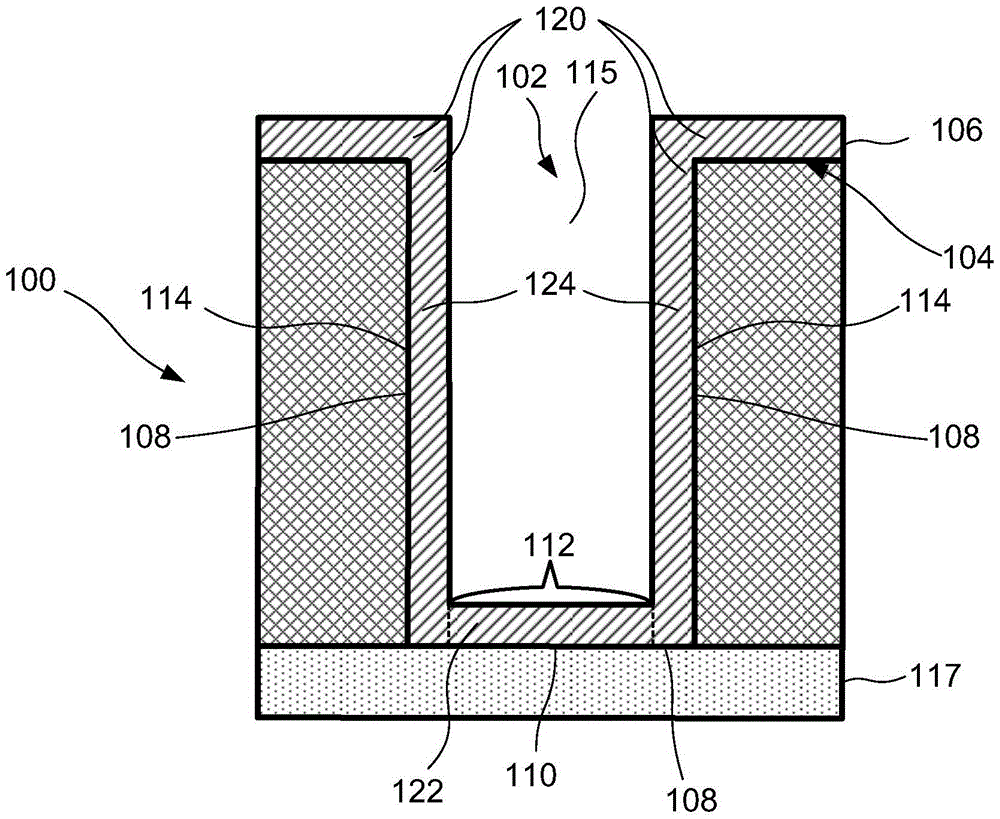

Plasma treatment method

ActiveCN105720006ASolid-state devicesSemiconductor/solid-state device manufacturingEtchingSemiconductor structure

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

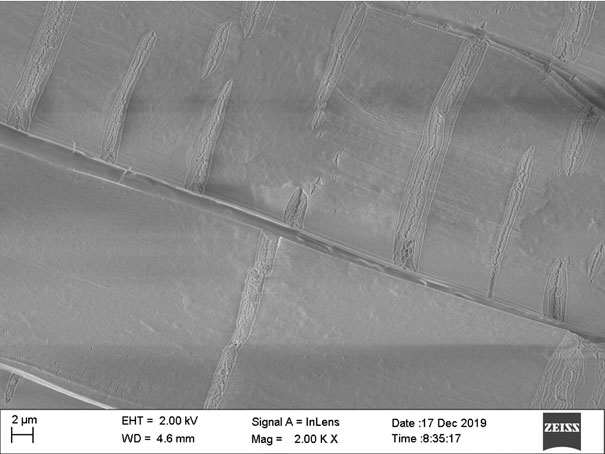

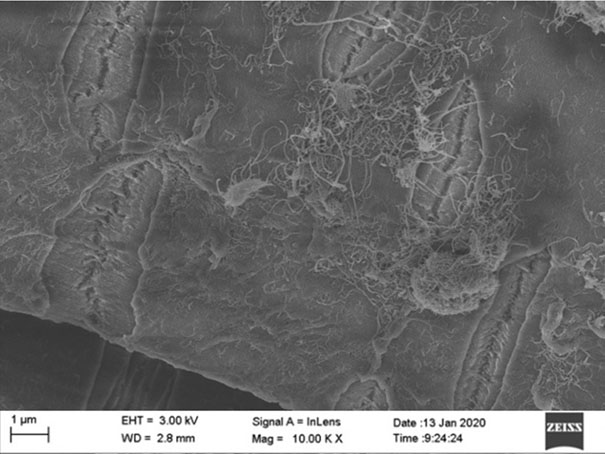

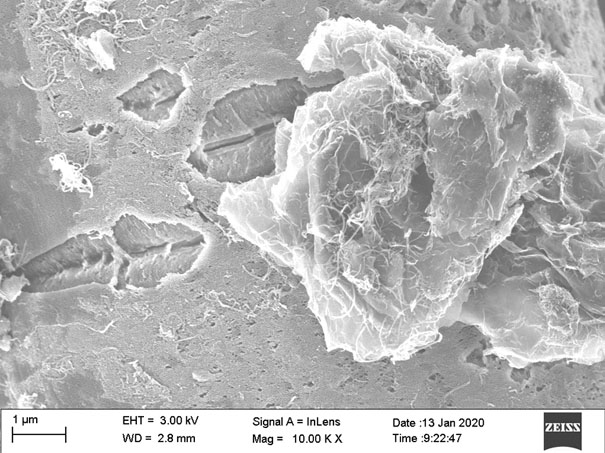

Carbon nanomaterial modified ultra-high molecular weight polyethylene fiber and preparation method thereof

InactiveCN111705501APhysical treatmentFibre typesPlasma treatmentUltrasonic technology

Owner:SHANDONG NON METALLIC MATERIAL RES INST

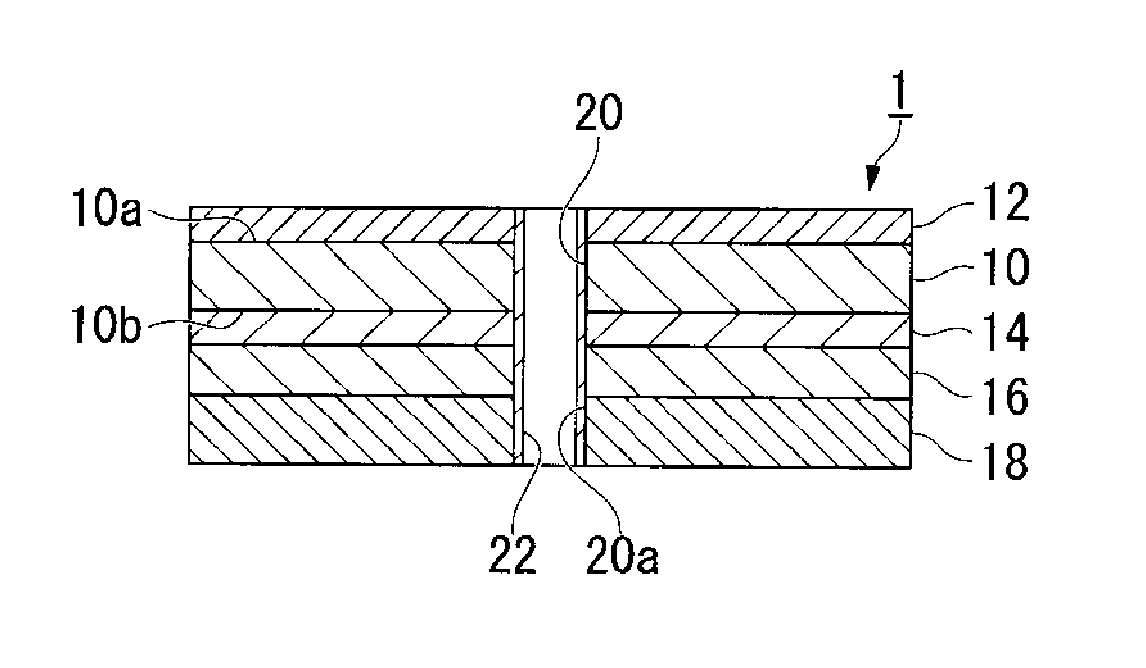

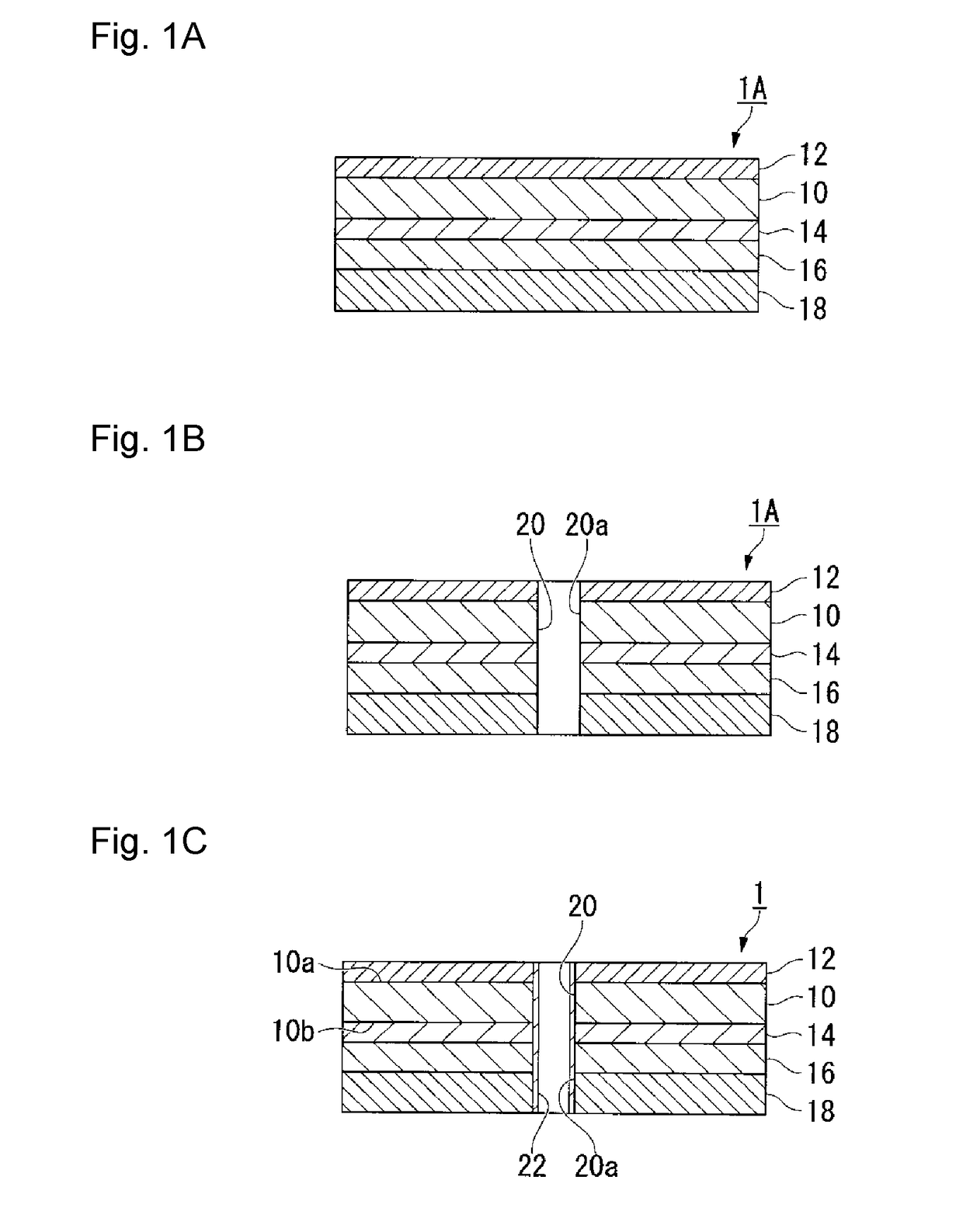

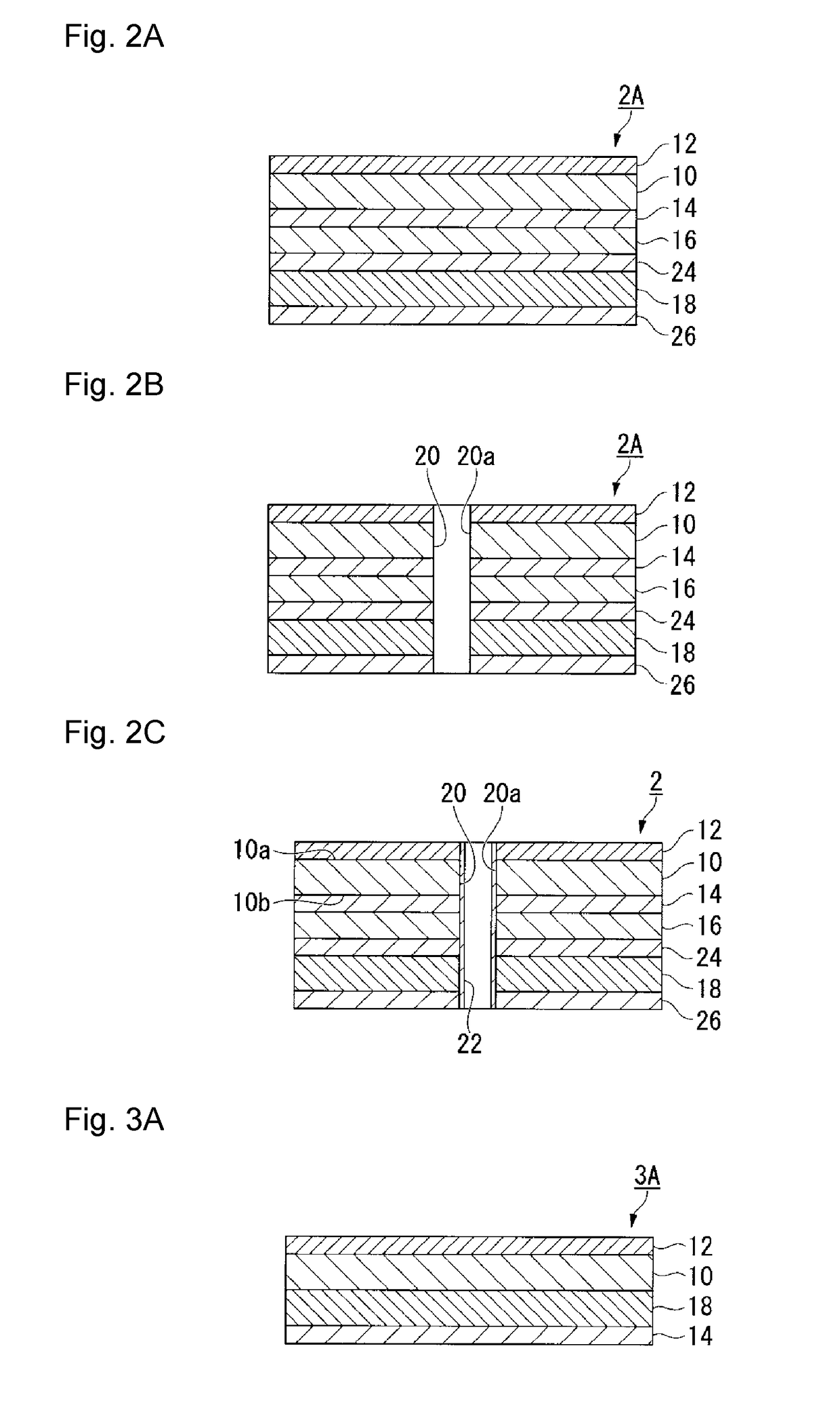

Manufacturing method for gas barrier film, and electronic member or optical member provided with gas barrier film

InactiveCN104114287AEfficient preparationThere will be no problem of poor sealingVacuum evaporation coatingSynthetic resin layered productsOrganic solventHigh humidity

The present invention pertains to: a method for producing a gas barrier film that includes at least a base that is formed of a synthetic resin, and a gas barrier layer that is formed on the base, the method comprising a step 1 and 2 below; and an electronic member or an optical member that includes a gas barrier film obtained by the method. In the gas barrier film obtained by means of the present invention, a problem of adhesion failure between the gas barrier layer and the base dose not occur even when the gas barrier film is subjected to high-temperature / high-humidity conditions. [Step 1] that applies a silicon-based polymer compound solution that includes a silicon-based polymer compound and an organic solvent to the base to obtain a film of the silicon-based polymer compound solution, and dries the film by heating to form a layer that includes the silicon-based polymer compound, the base having a gel fraction of 70% or more and less than 98% when immersed in the organic solvent at 23°C for 72 hours; [Step 2] that subjects the layer that includes the silicon-based polymer compound to a plasma treatment to form the gas barrier layer.

Owner:LINTEC CORP

Process for producing wiring substrate

ActiveUS20180213641A1Excellent electrical propertiesConduction failureDielectric materialsRadiating elements structural formsFiberElectrical conductor

Owner:ASAHI GLASS CO LTD

Glass cover plate preparation process

InactiveCN108909223AReduce consumptionIncrease productivityDuplicating/marking methodsOther printing apparatusGlass coverMegasonic cleaning

Owner:DONGGUAN JINGBO PHOTOELECTRIC BIT CO

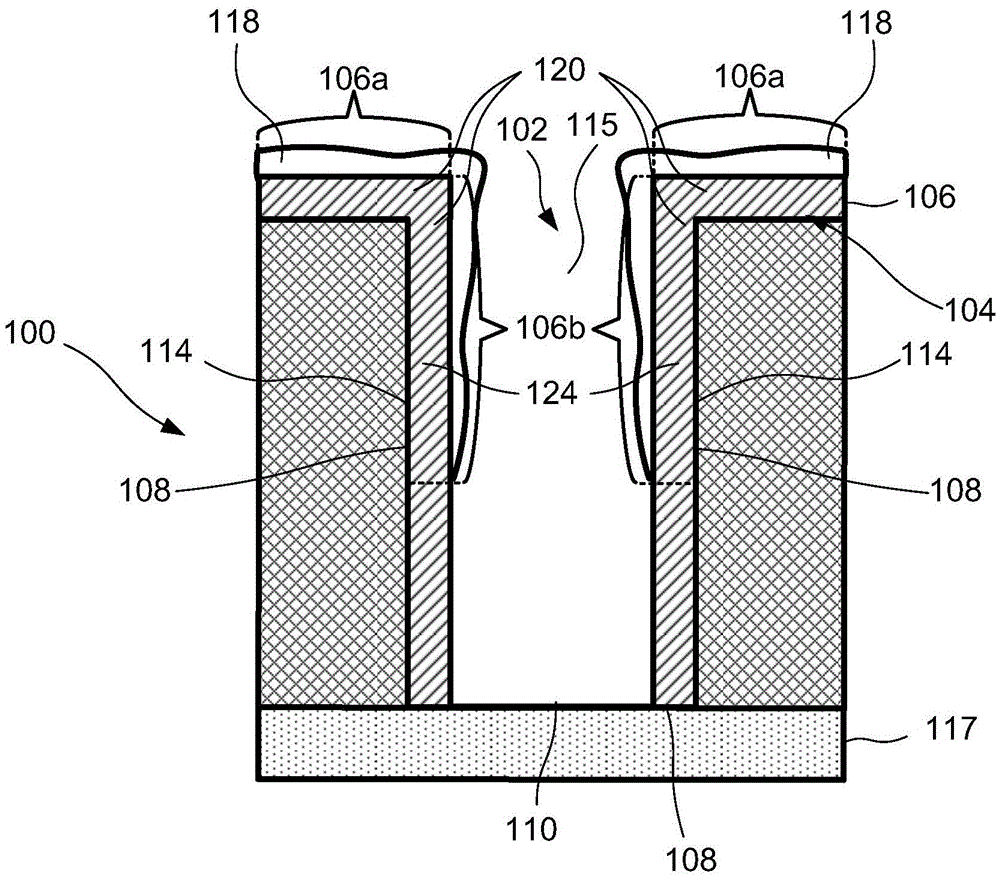

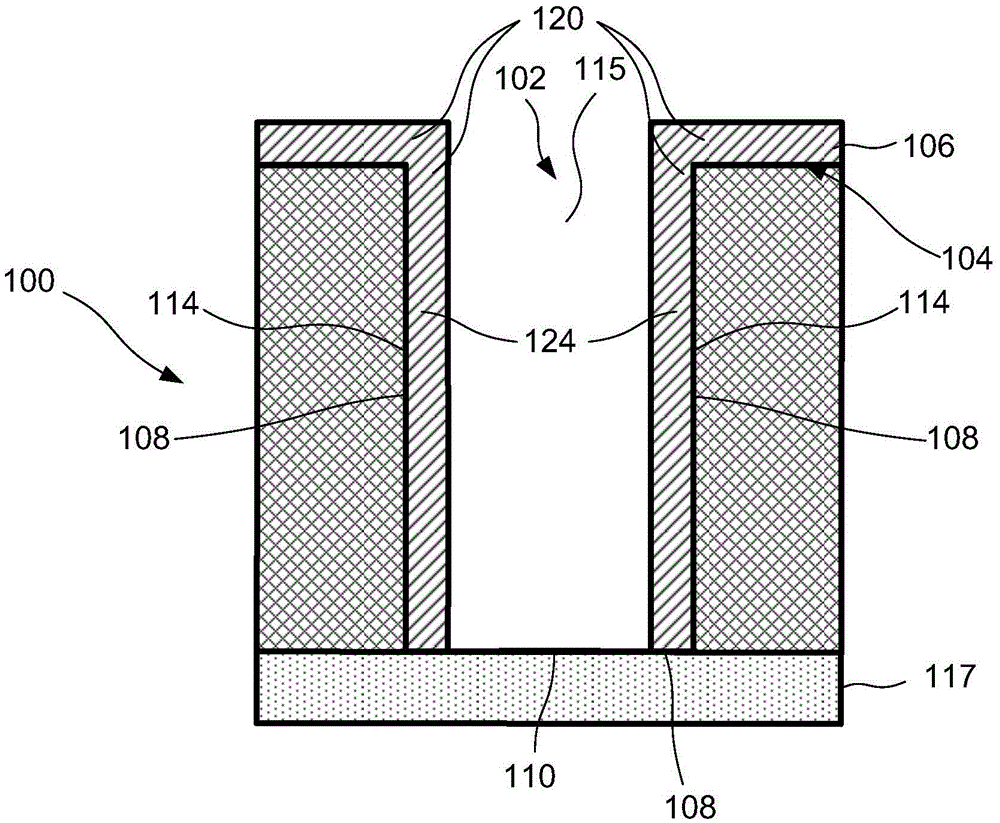

Grid side wall imaging method

ActiveCN103824765ASolve voidSimple processSemiconductor/solid-state device manufacturingSemiconductor devicesPlasma treatmentEngineering

The invention discloses a grid side wall imaging method. The method comprises the steps that a semiconductor structure which has a grid and a first side wall which covers the side wall of the grid is provided; a polycrystalline carbon layer is prepared to cover the surface of the semiconductor structure; the polycrystalline carbon layer is partially removed, so that a second side wall of the grid is formed on the surface of the first side wall; after a source drain implantation process is carried out on the semiconductor structure, the second side wall is removed; and a source drain annealing technology is continued. According to the grid side wall imaging method provided by the invention, through oxygenated plasma treatment, a polycrystalline carbon side wall which is used as a main side wall can be neatly removed; without using an SPT process which needs to be carried out in a specific etching cavity, the problem of void in a high stress through hole etching stop layer process can be solved; a process flow is simplified; and the production cost is reduced.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

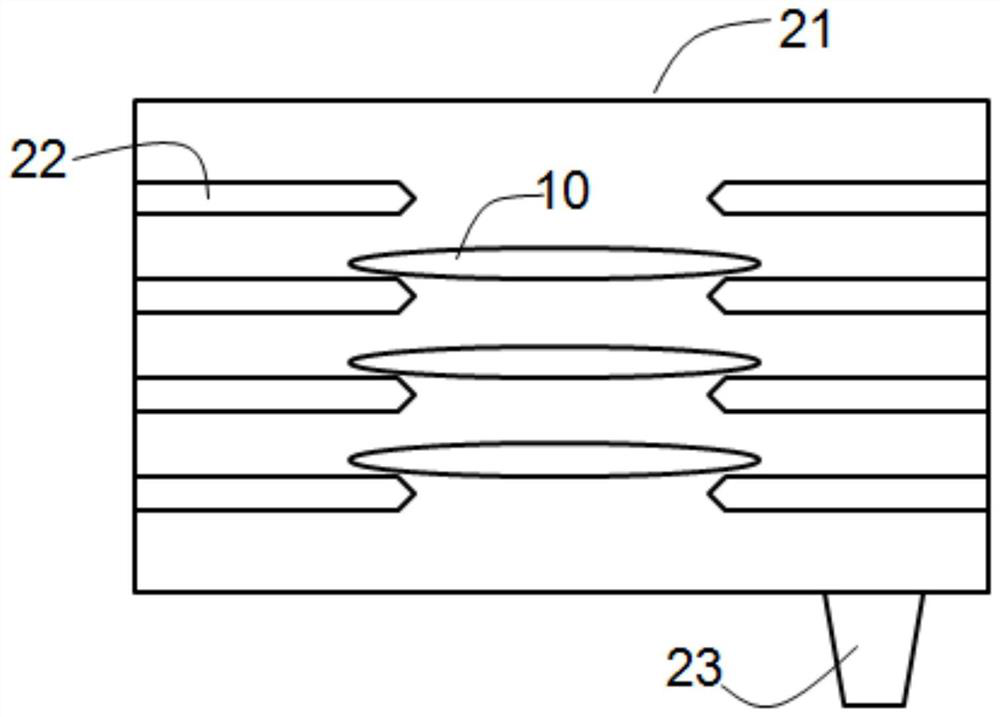

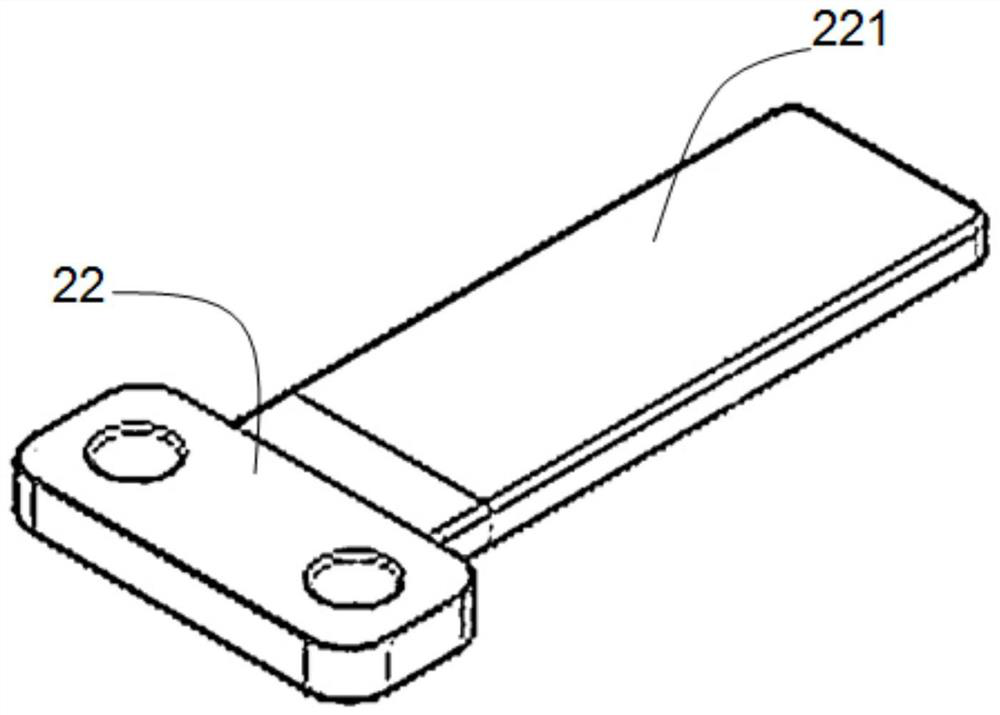

Supporting claw, airlock chamber and plasma processing device host platform

PendingCN112071799AElectric discharge tubesSemiconductor/solid-state device manufacturingPhysicsPlasma treatment

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Lower electrode assembly and plasma processing device thereof

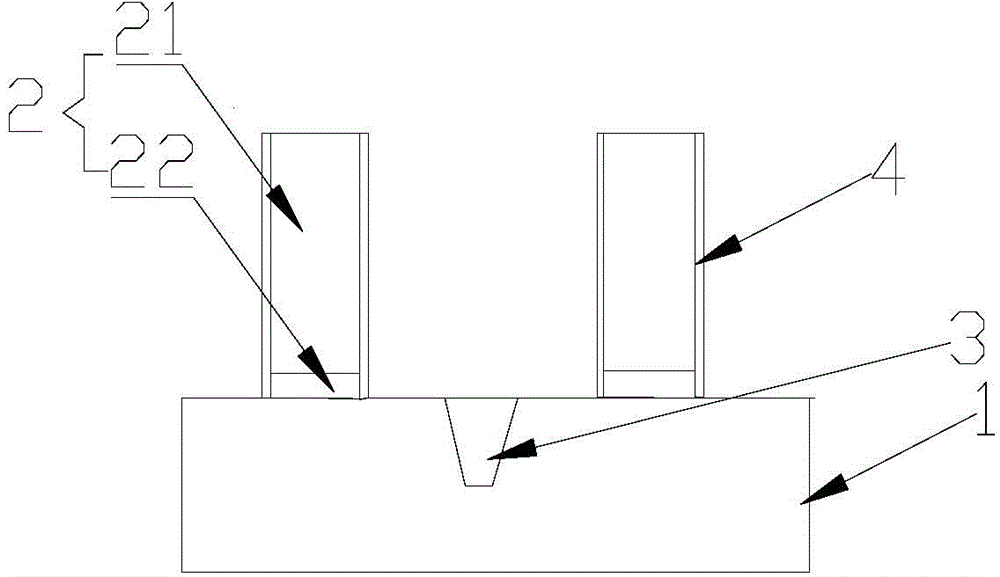

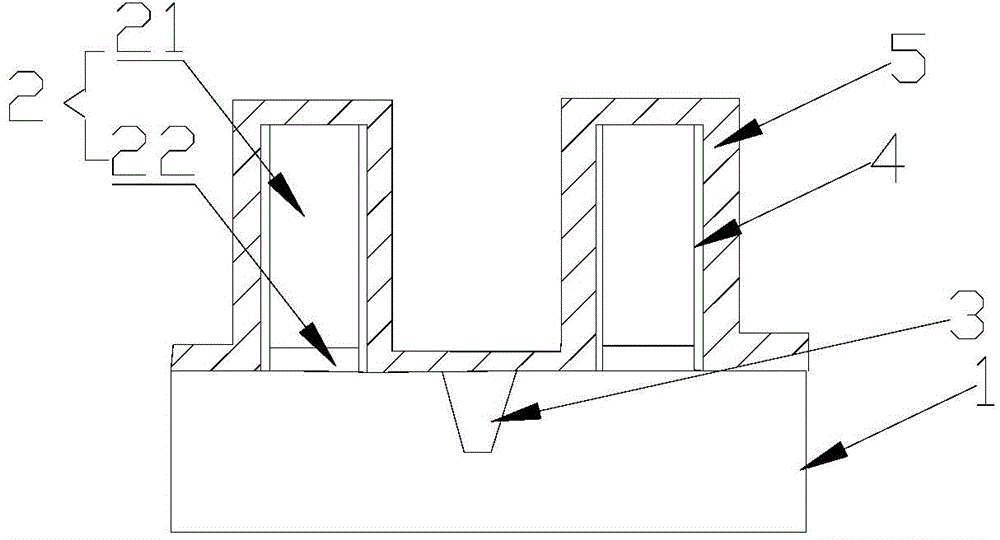

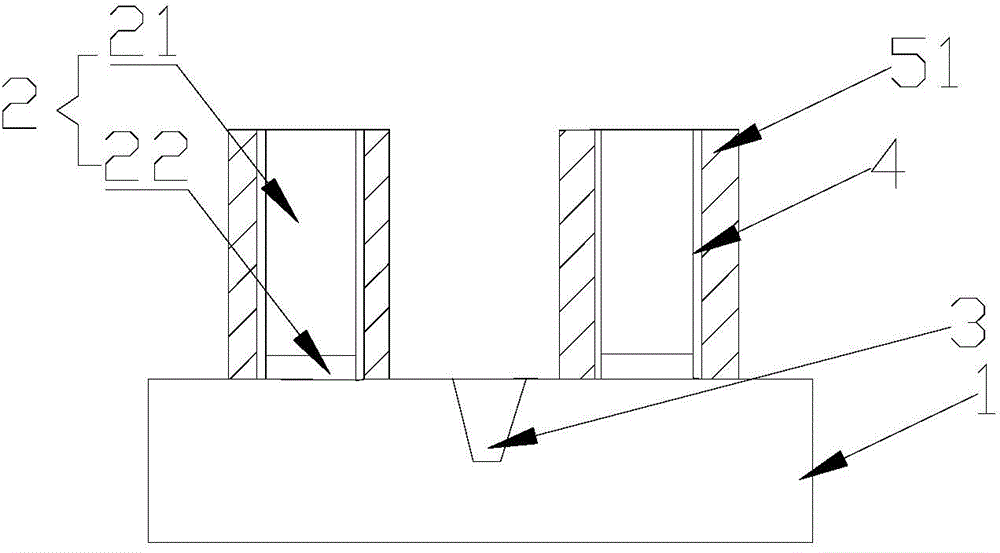

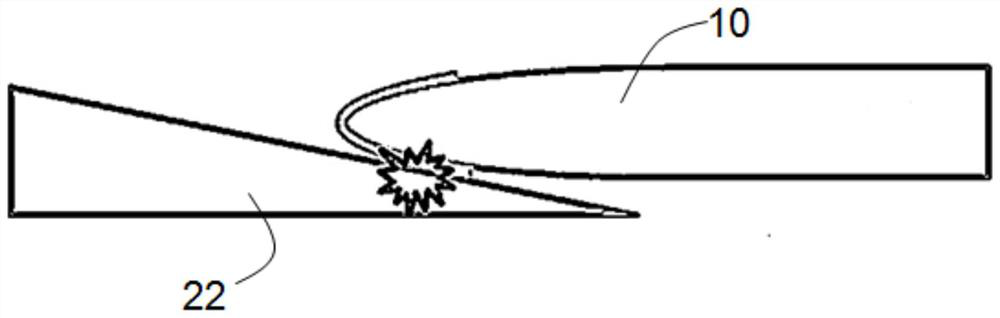

ActiveCN113035682ASmooth up and down movementHigh concentricityElectric discharge tubesFinal product manufactureEngineeringMechanical engineering

The invention relates to a lower electrode assembly and a plasma processing device thereof. The lower electrode assembly comprises: an electrostatic chuck comprising a bearing surface for bearing a to-be-processed substrate; a plurality of lifting pin holes penetrating through the electrostatic chuck, lifting pins respectively positioned in the lifting pin holes; porous sleeves located in the lifting pin holes and arranged around the lifting pins in a surrounding mode, wherein gaps are formed between the porous sleeves and the lifting pins, a plurality of pores are formed in the porous sleeves, and the pores are communicated with the gaps; an air floatation channel positioned in the electrostatic chuck and communicated with pores in the porous sleeves; and a gas conveying device used for conveying gas into the air floatation channel, so that a gas film is formed between the porous sleeve and the lifting pin. According to the invention, gas is conveyed into the air floatation channel through the gas conveying device, so that the gas film is formed between the porous sleeve and the lifting pin, friction between the lifting pin and the lifting pin hole can be avoided, the gap between the lifting pin and the lifting pin hole can be shrunk to be very small, and very high potential and energy can be resisted without generating electric arcs.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

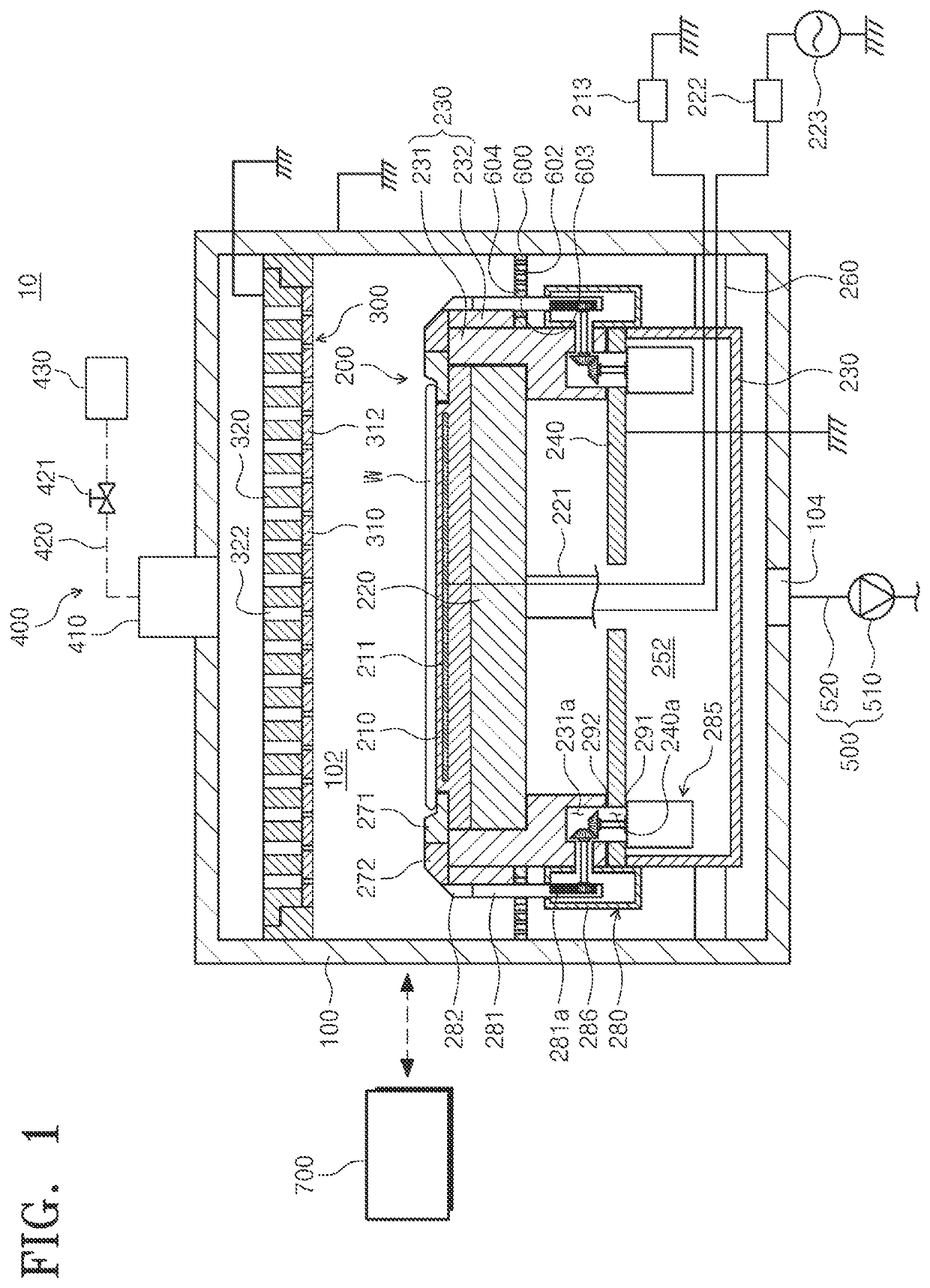

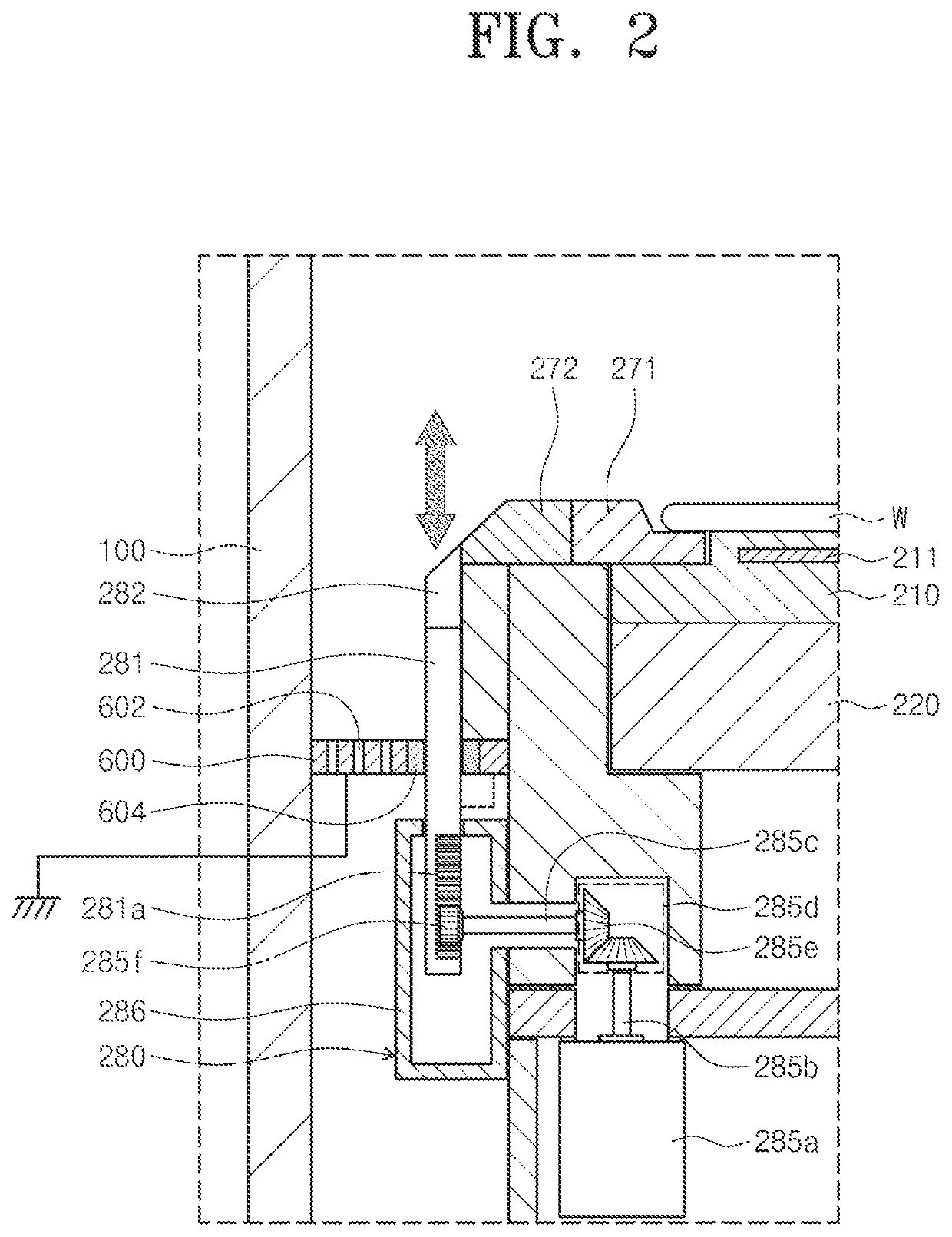

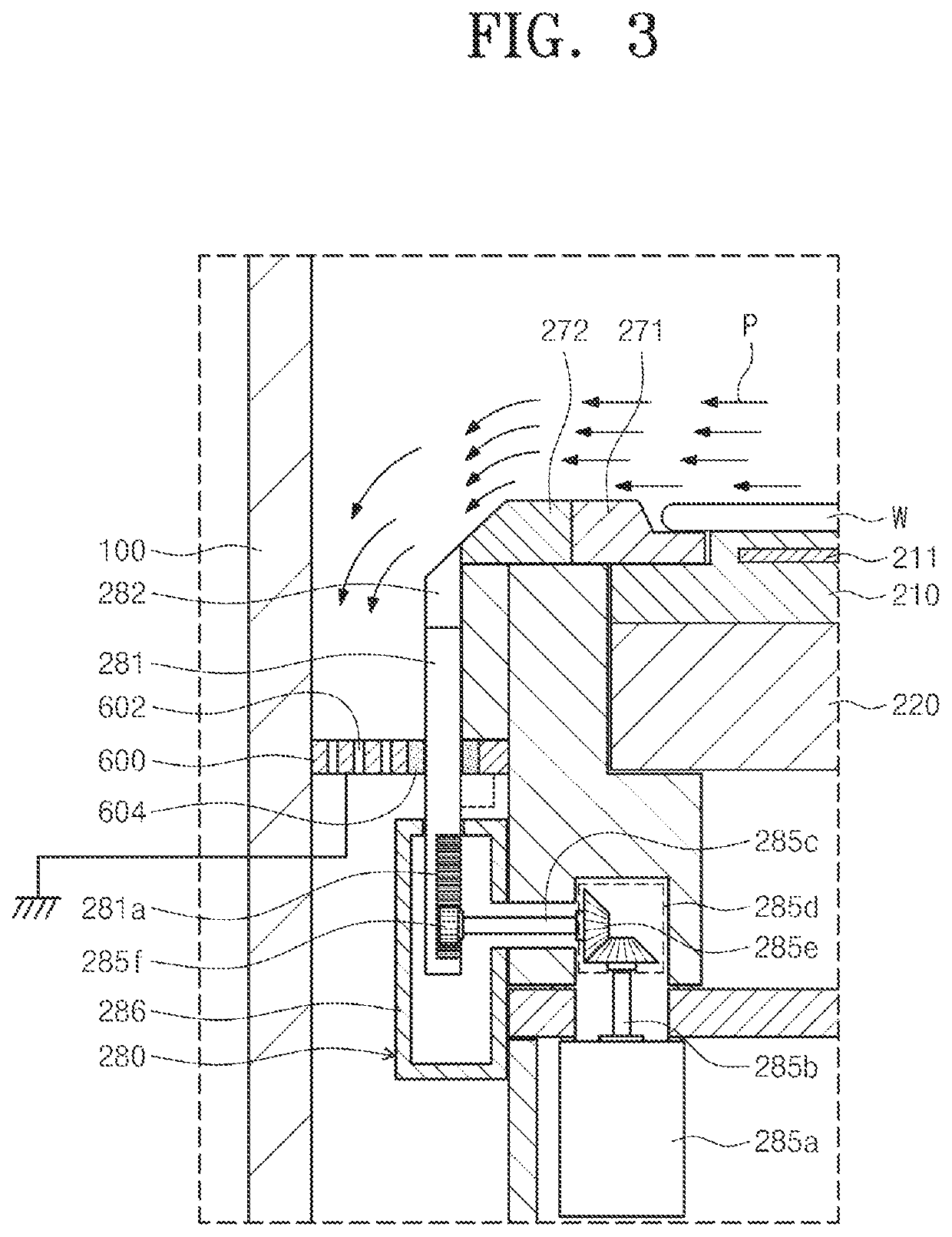

Support unit and apparatus for treating substrate

PendingUS20220199368A1Improve processing efficiencyEffective treatmentElectric discharge tubesSemiconductor/solid-state device manufacturingMechanical engineeringElectric power

Owner:SEMES CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap