Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

21 results about "Photolithography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

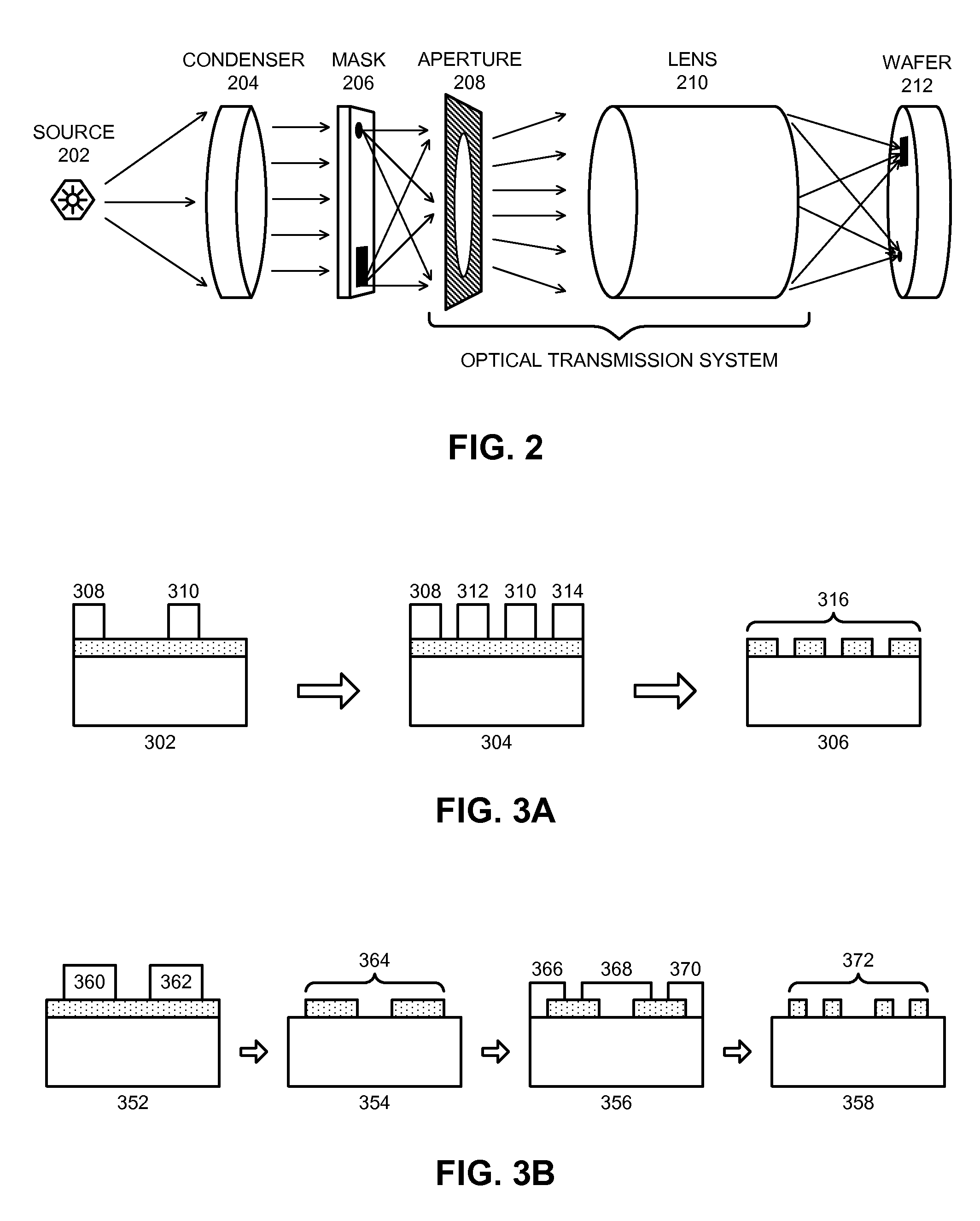

Photolithography, also called optical lithography or UV lithography, is a process used in microfabrication to pattern parts of a thin film or the bulk of a substrate (also called a wafer). It uses light to transfer a geometric pattern from a photomask (also called an optical mask) to a photosensitive (that is, light-sensitive) chemical photoresist on the substrate. A series of chemical treatments then either etches the exposure pattern into the material or enables deposition of a new material in the desired pattern upon the material underneath the photoresist. In complex integrated circuits, a CMOS wafer may go through the photolithographic cycle as many as 50 times.

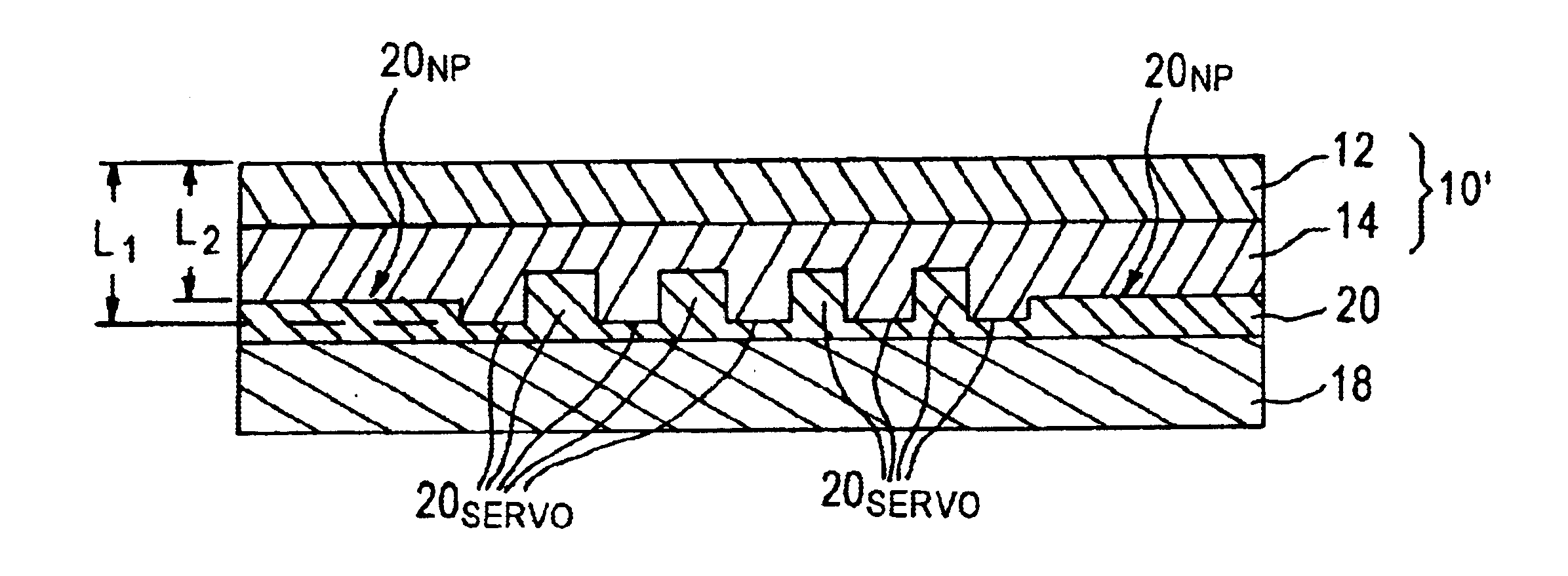

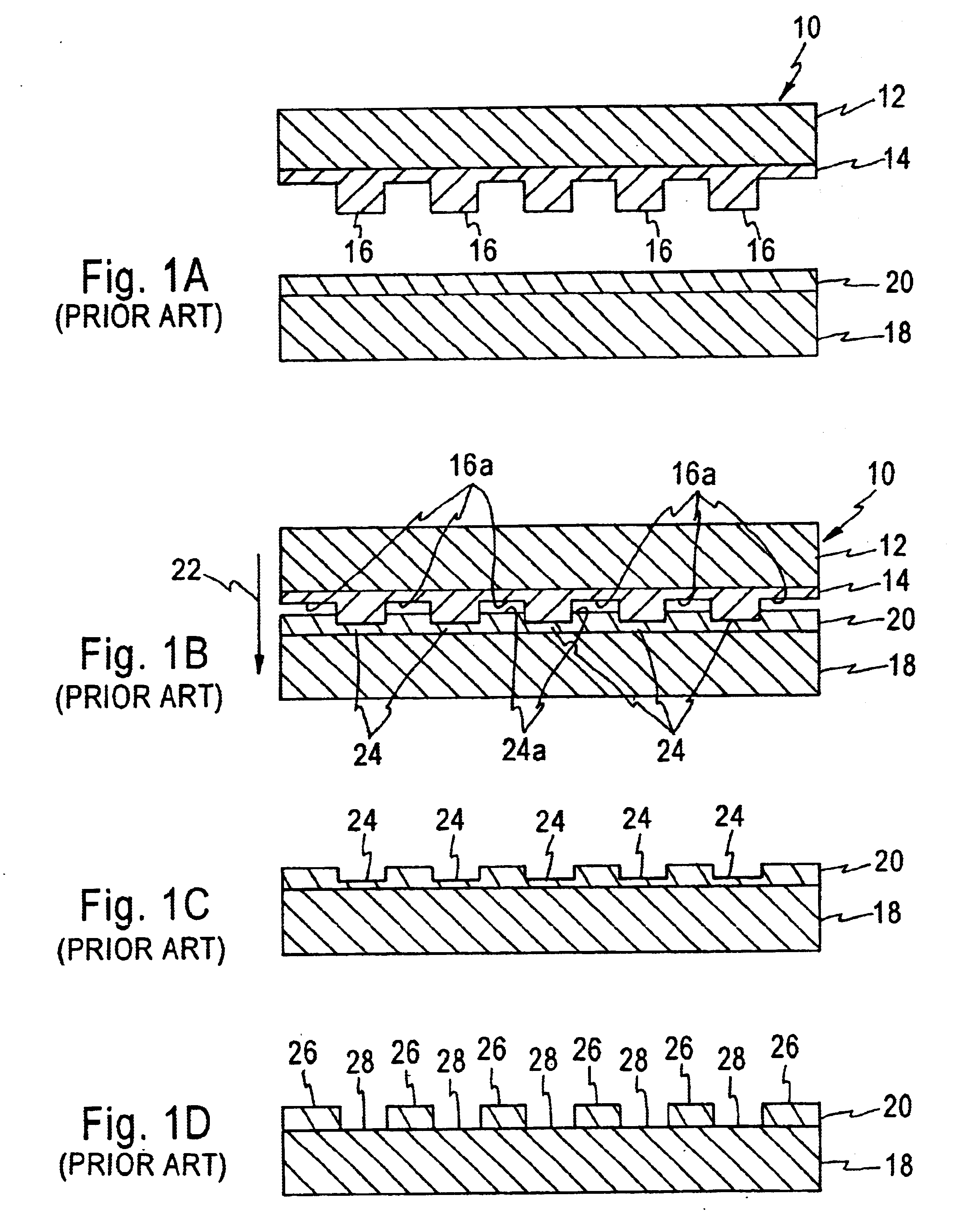

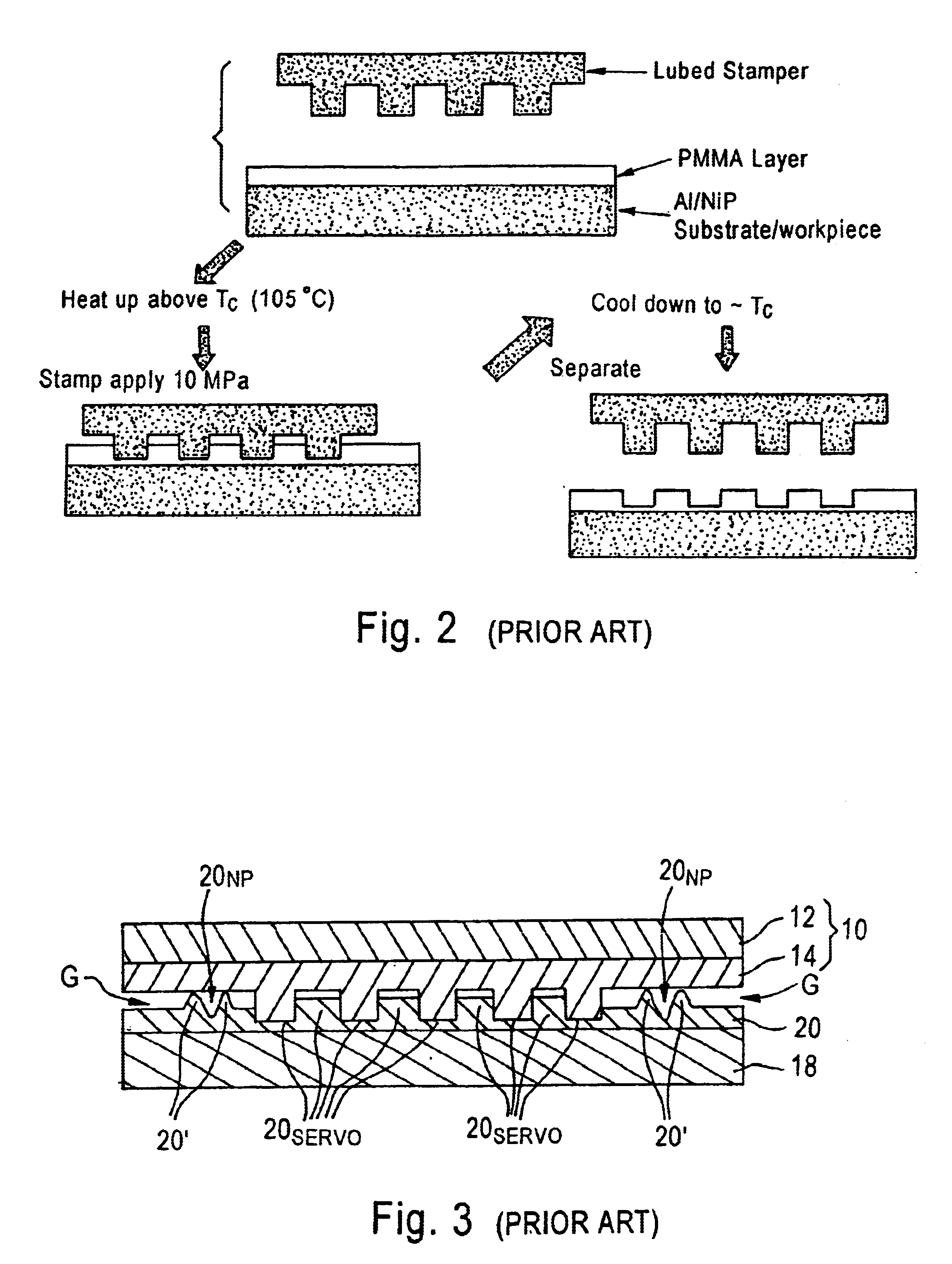

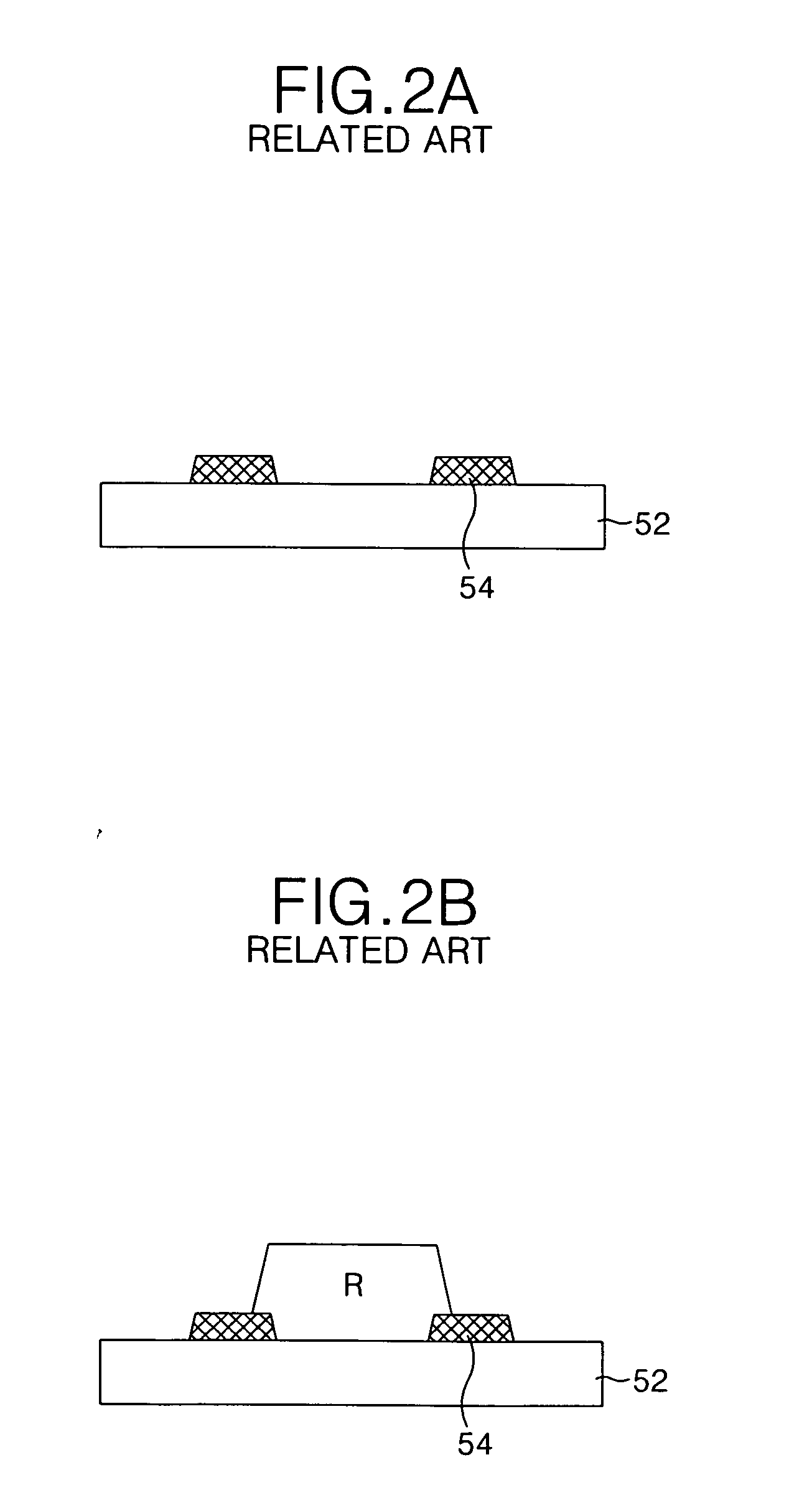

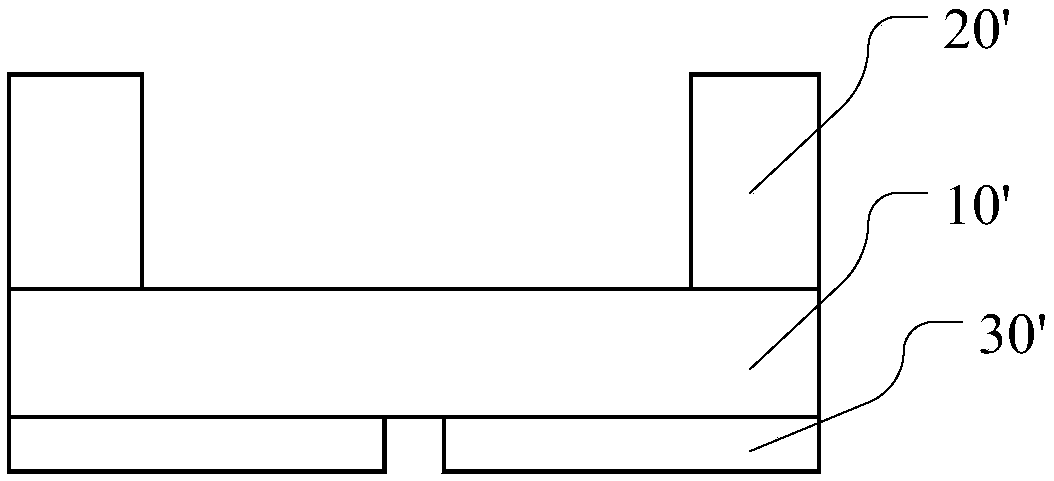

Multi-level stamper for improved thermal imprint lithography

InactiveUS6869557B1Avoid destructionPrevent gap formationRecord carriersNanoinformaticsPhotolithographyEngineering

A stamper / imprinter for use in performing thermal imprint lithography of a substrate / workpiece surface to form a pattern of features in first portions of the surface intended to receive the pattern, without incurring random formation of undesired, disordered features in second portions of the substrate / workpiece surface not intended to receive the pattern, comprising an imprinting surface configured to substantially prevent formation of gaps between the imprinting surface and the second portions of the surface during stamping / imprinting. Embodiments include stampers / imprinters with a multilevel imprinting surface comprises a first portion having a first level for forming the pattern of features in the first portions of the surface and a second portion having a second level for substantially preventing formation of gaps between the imprinting surface and the second portions of the surface during stamping / imprinting.

Owner:SEAGATE TECH LLC

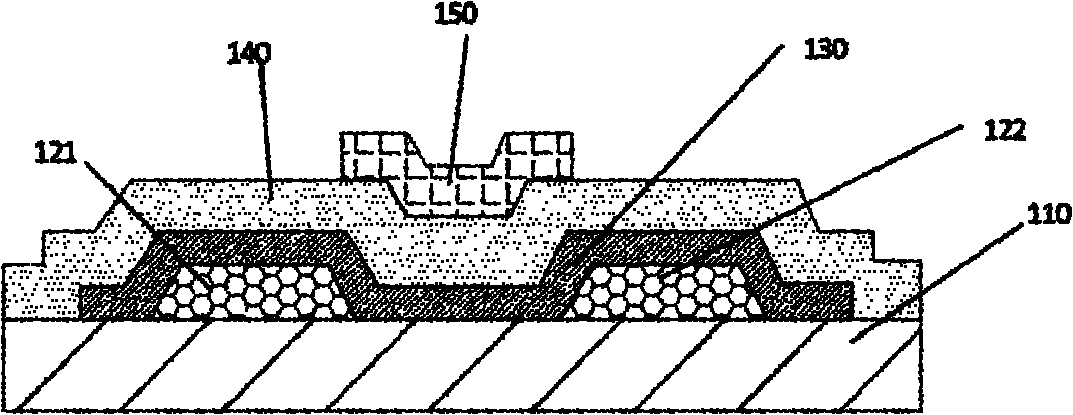

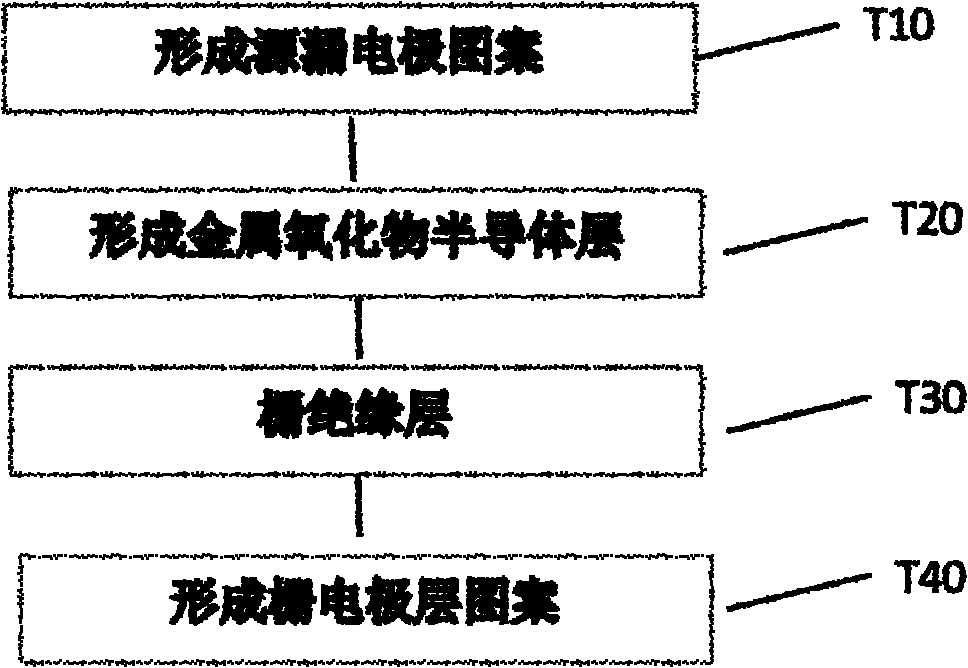

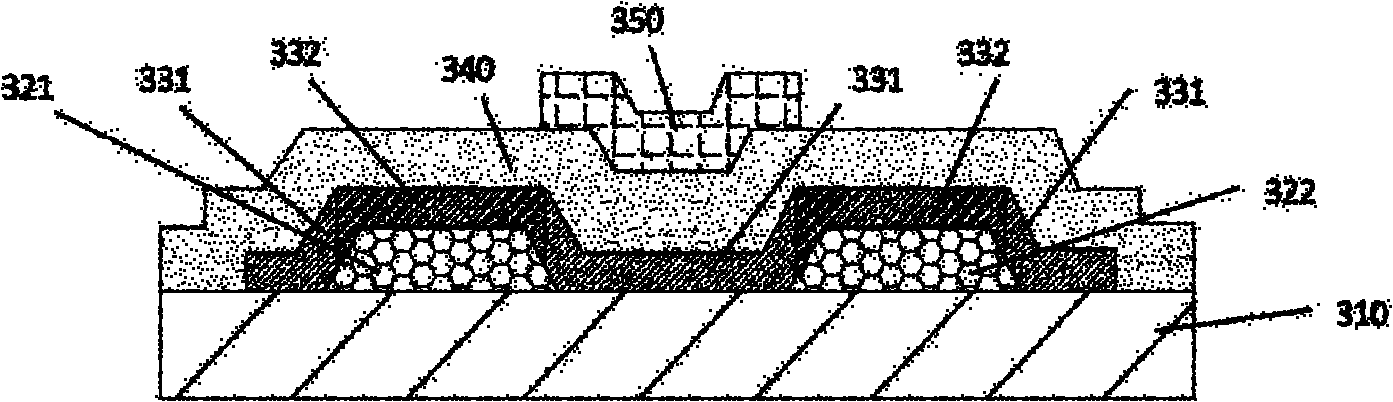

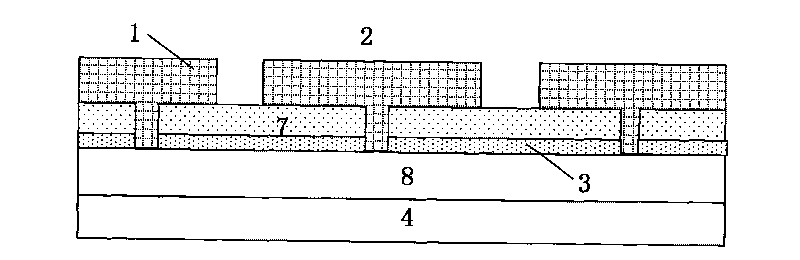

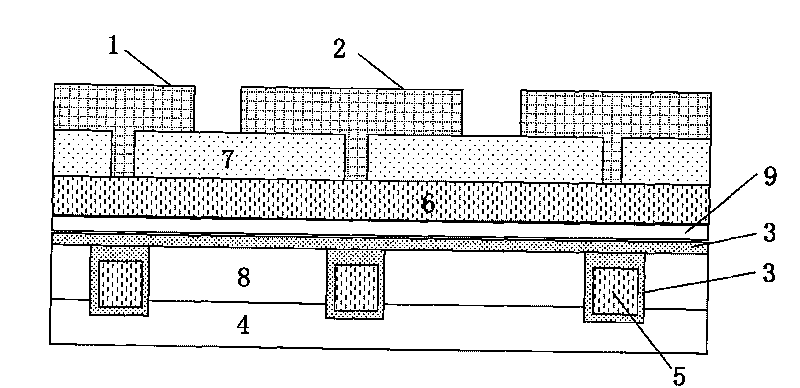

Preparation method of top gate metal oxide thin film transistor (TFT)

InactiveCN102157564ASolve the technical problem of insufficient chargingIncrease the on-state currentTransistorSemiconductor/solid-state device manufacturingEtchingElectrical conductor

Owner:SHANGHAI JIAO TONG UNIV

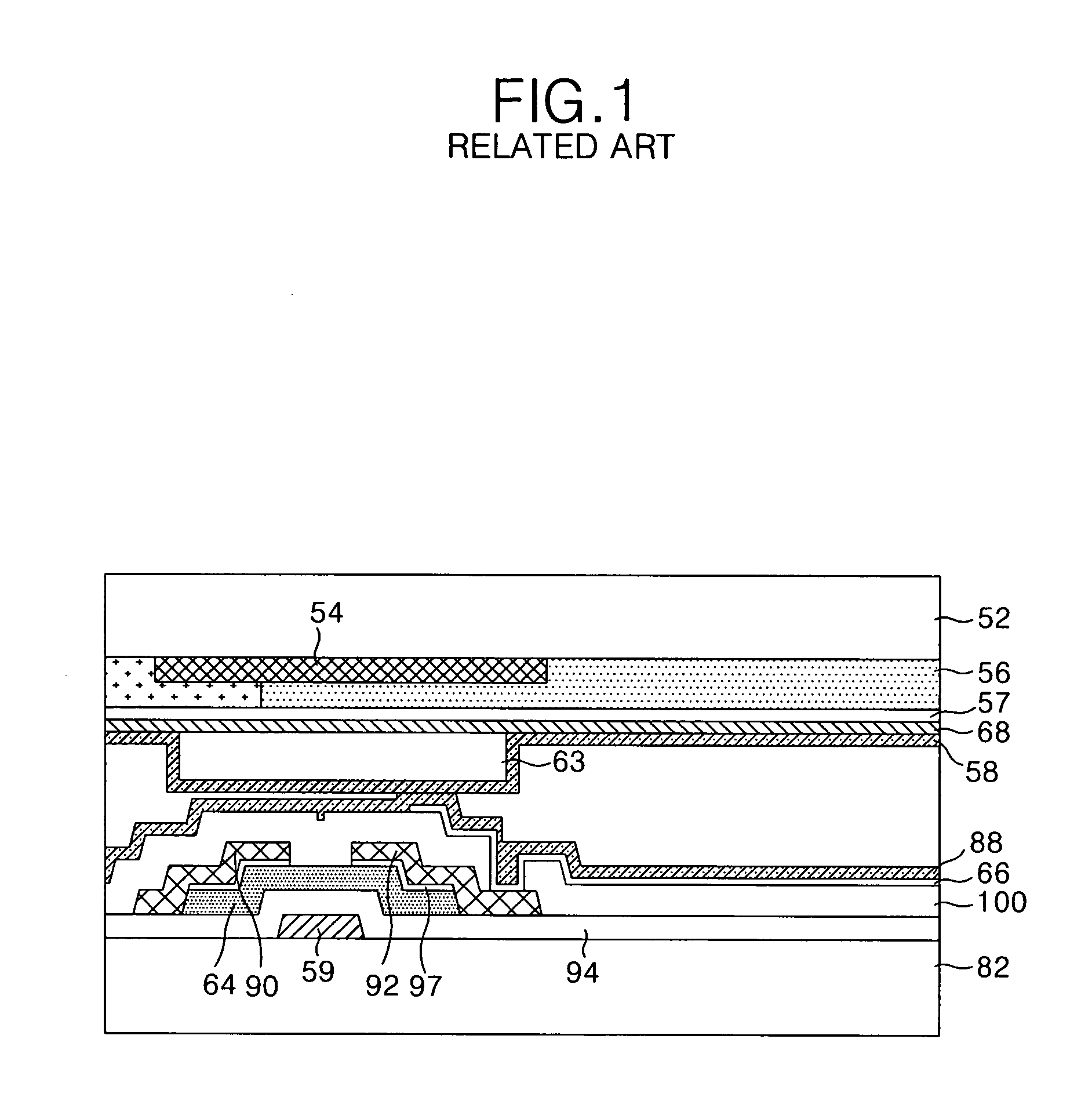

Liquid crystal display panel and method of fabricating the same

InactiveUS20060066777A1Simple processLow costStatic indicating devicesOptical filtersEngineeringLight filter

Owner:LG DISPLAY CO LTD

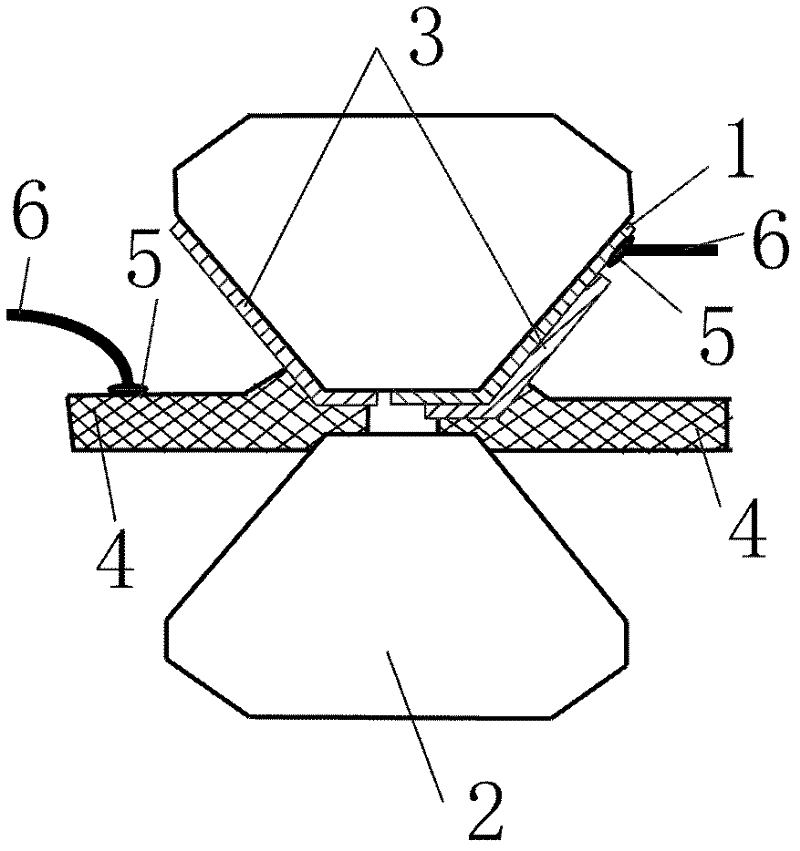

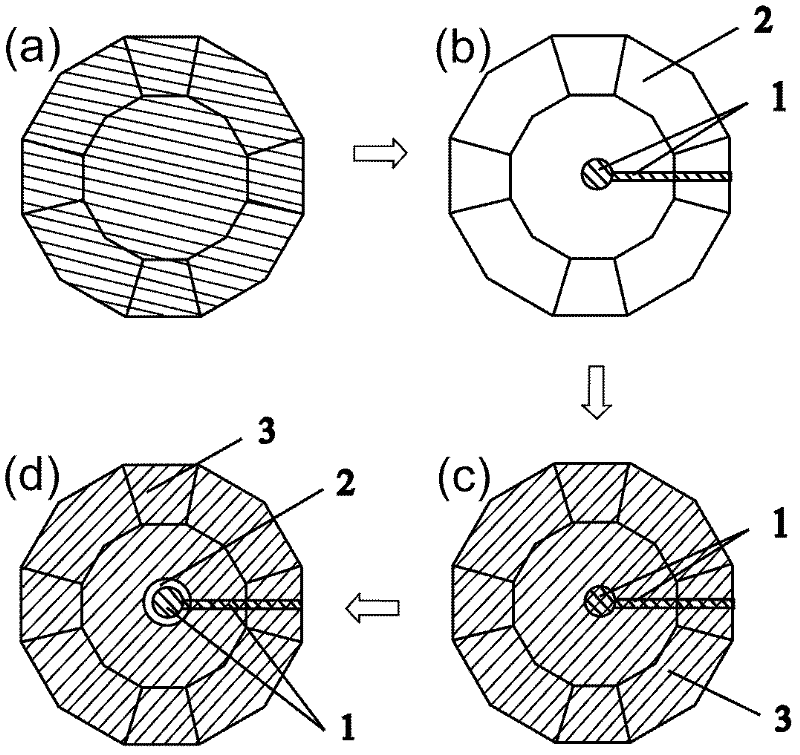

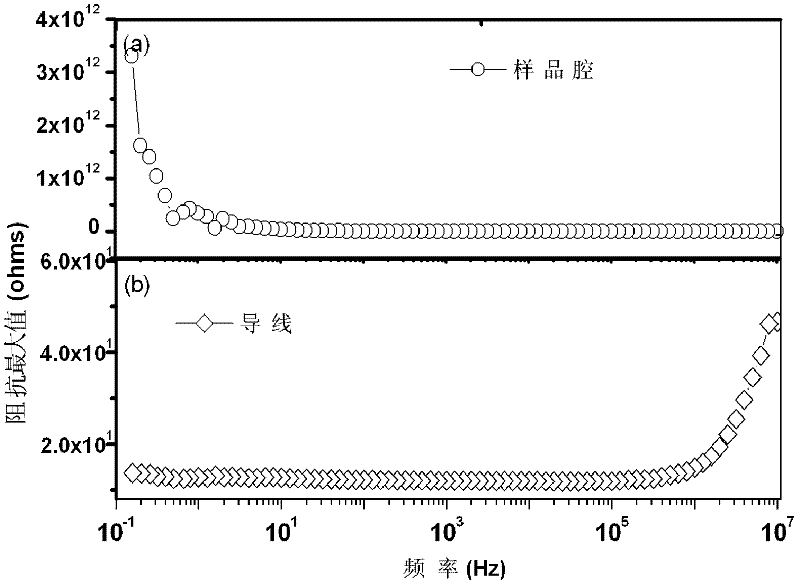

Electrode for high-voltage in-situ impedance spectroscopy measurement and its preparation method and application

InactiveCN102288824AFix fixitySolve insulation problemsResistance/reactance/impedenceEtchingInsulation Problem

Owner:JILIN UNIV

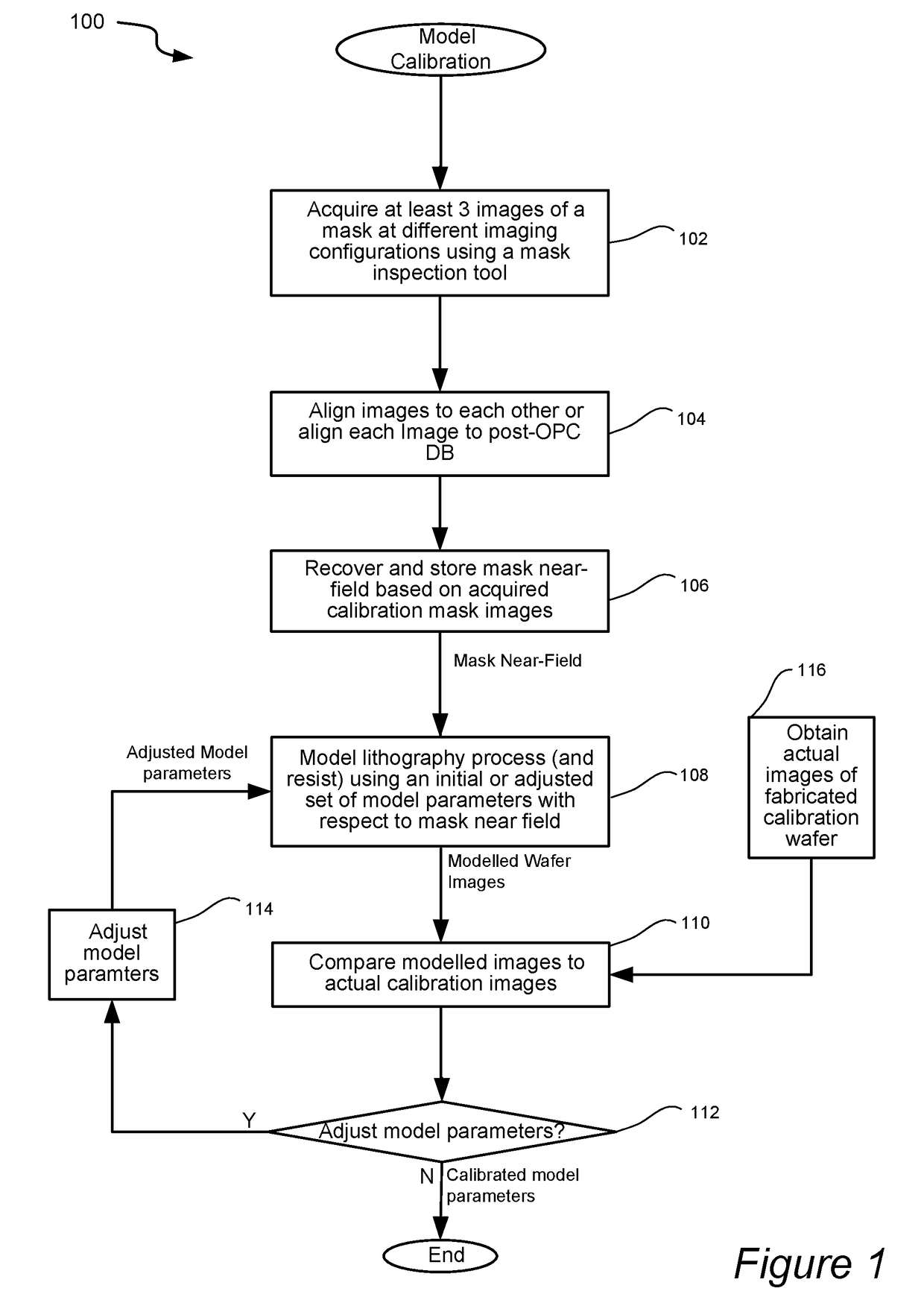

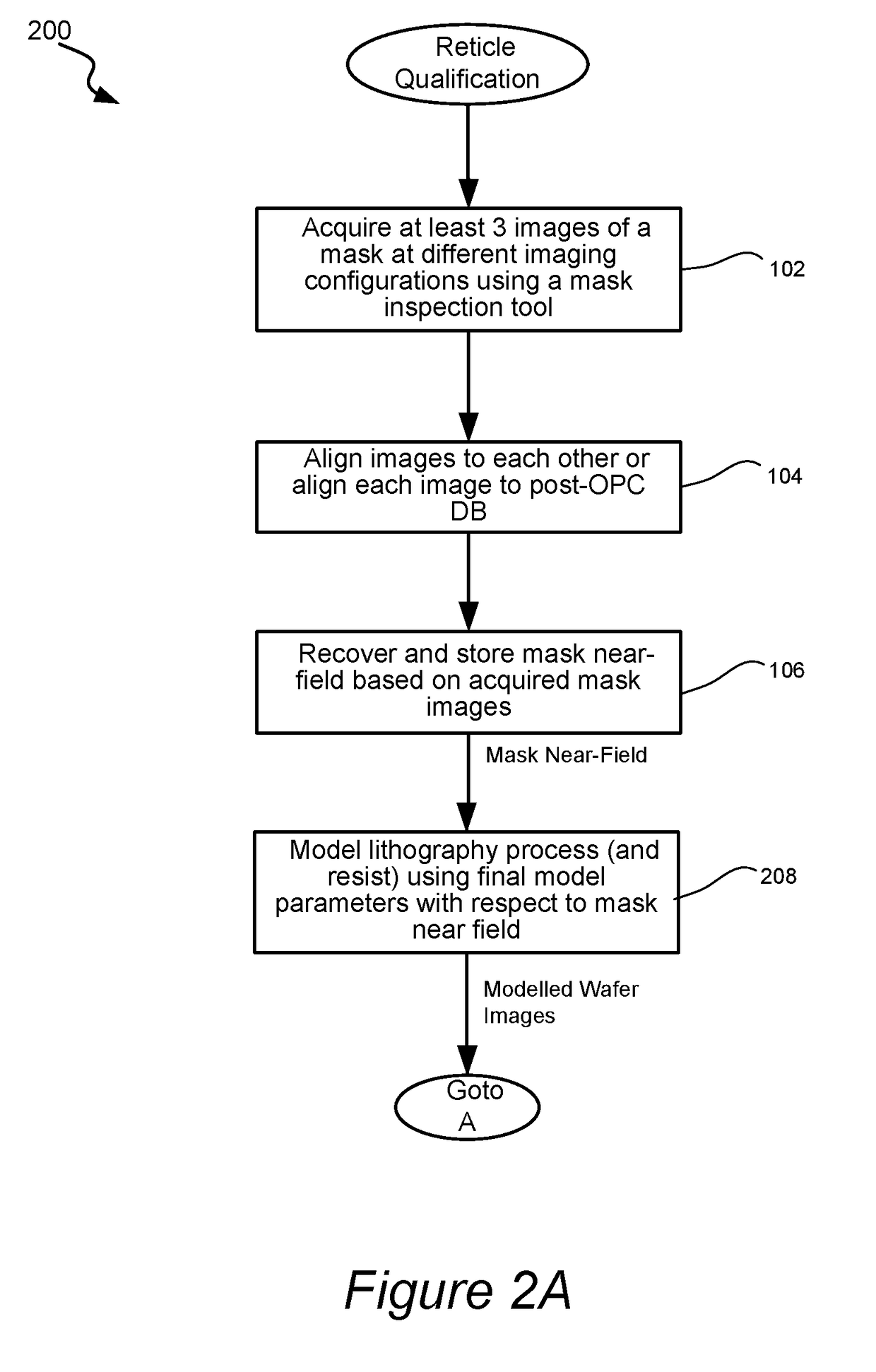

Apparatus and methods for predicting wafer-level defect printability

ActiveUS20170309008A1Minimize the differenceImage enhancementImage analysisPhotolithographyEngineering

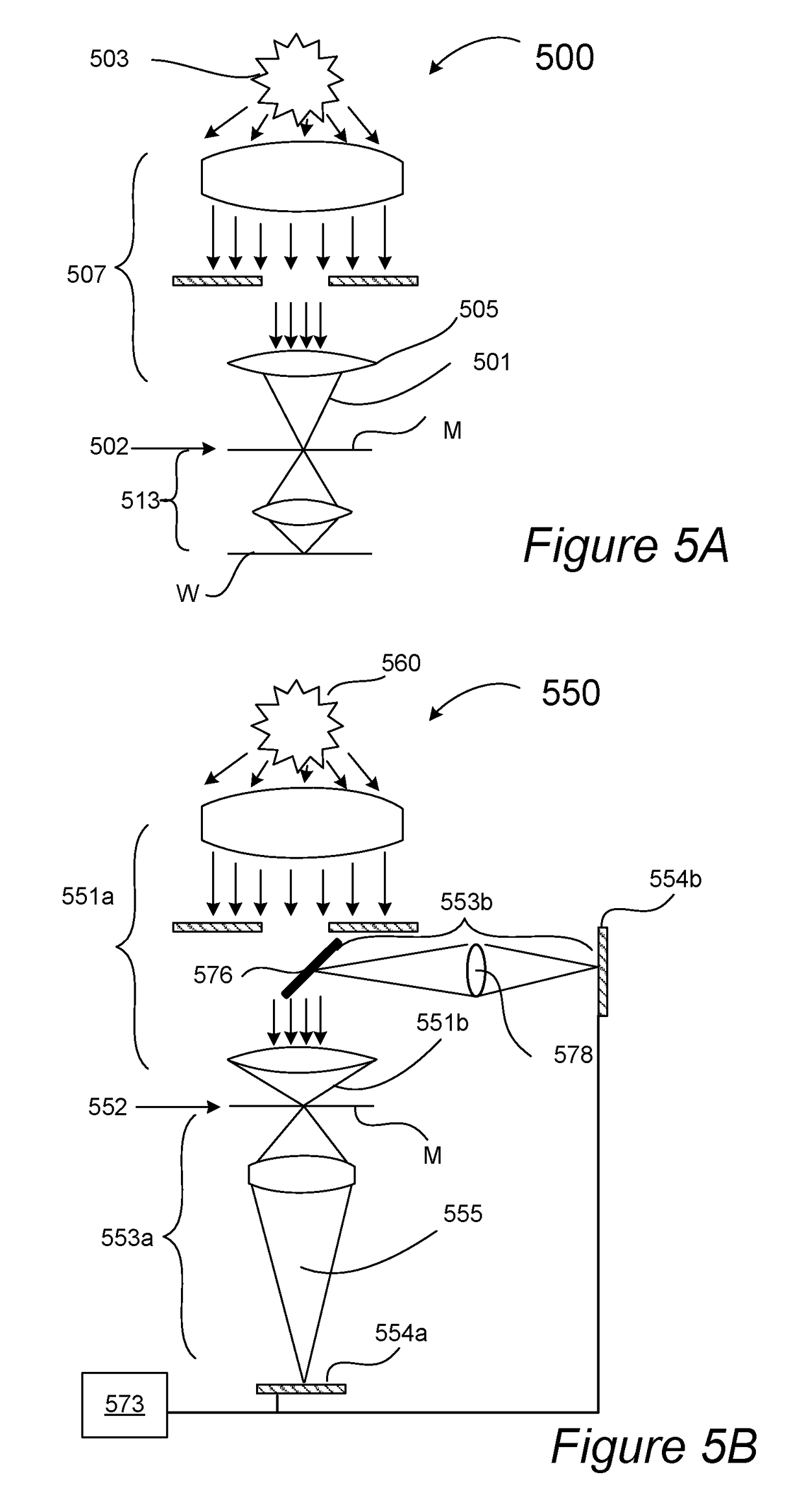

Disclosed are methods and apparatus for qualifying a photolithographic reticle. A reticle inspection tool is used to acquire images at different imaging configurations from each of a plurality of pattern areas of a test reticle. A reticle near field for each of the pattern areas of the test reticle is recovered based on the acquired images from each pattern area of the test reticle. A lithography model is applied to the reticle near field for the test reticle to simulate a plurality of test wafer images, and the simulated test wafer images are analyzed to determine whether the test reticle will likely result in an unstable or defective wafer.

Owner:KLA TENCOR CORP

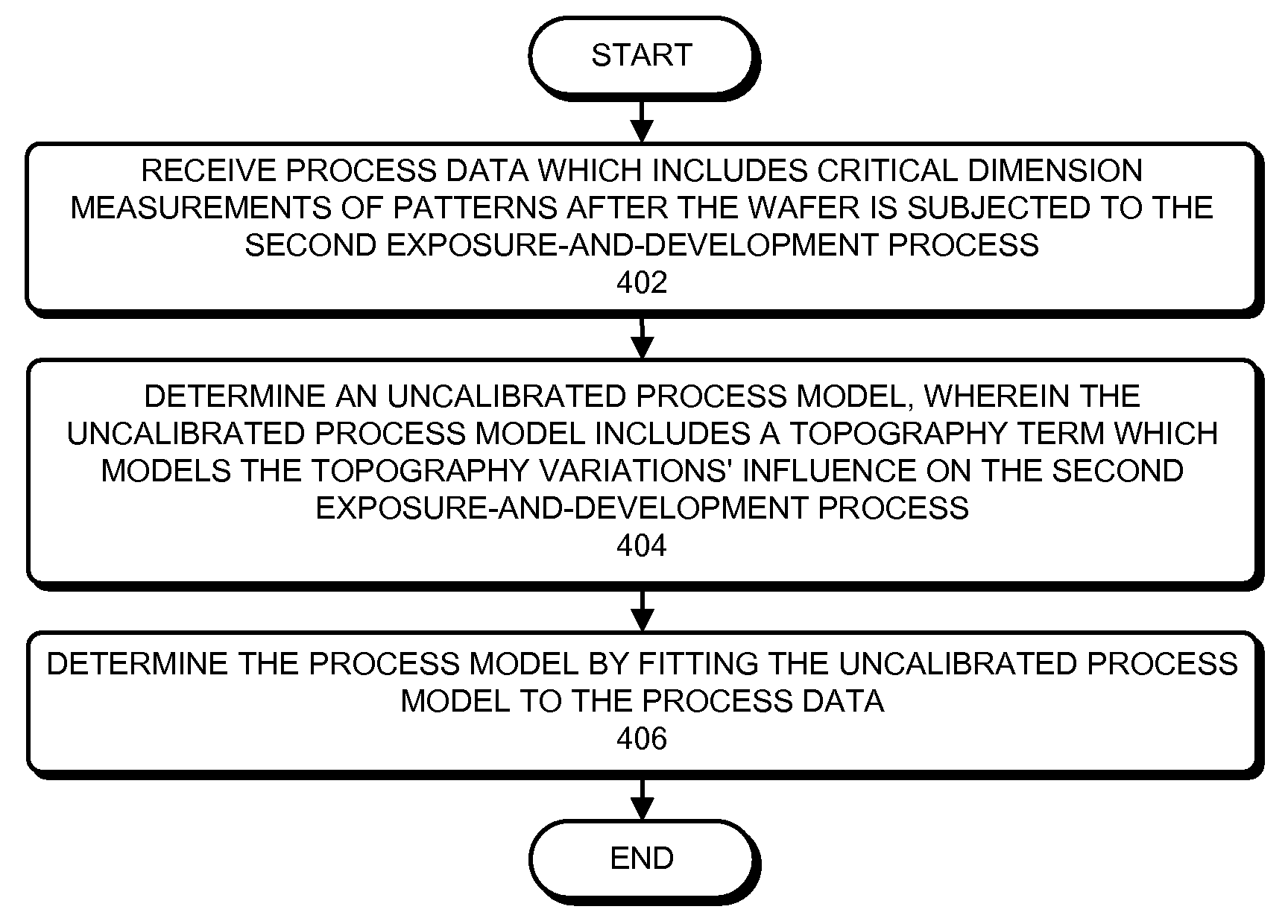

Method and apparatus for determining a photolithography process model which models the influence of topography variations

ActiveUS20100095264A1Accurate imagingImprove accuracyComputer programmed simultaneously with data introductionOriginals for photomechanical treatmentResistEngineering

Owner:SYNOPSYS INC

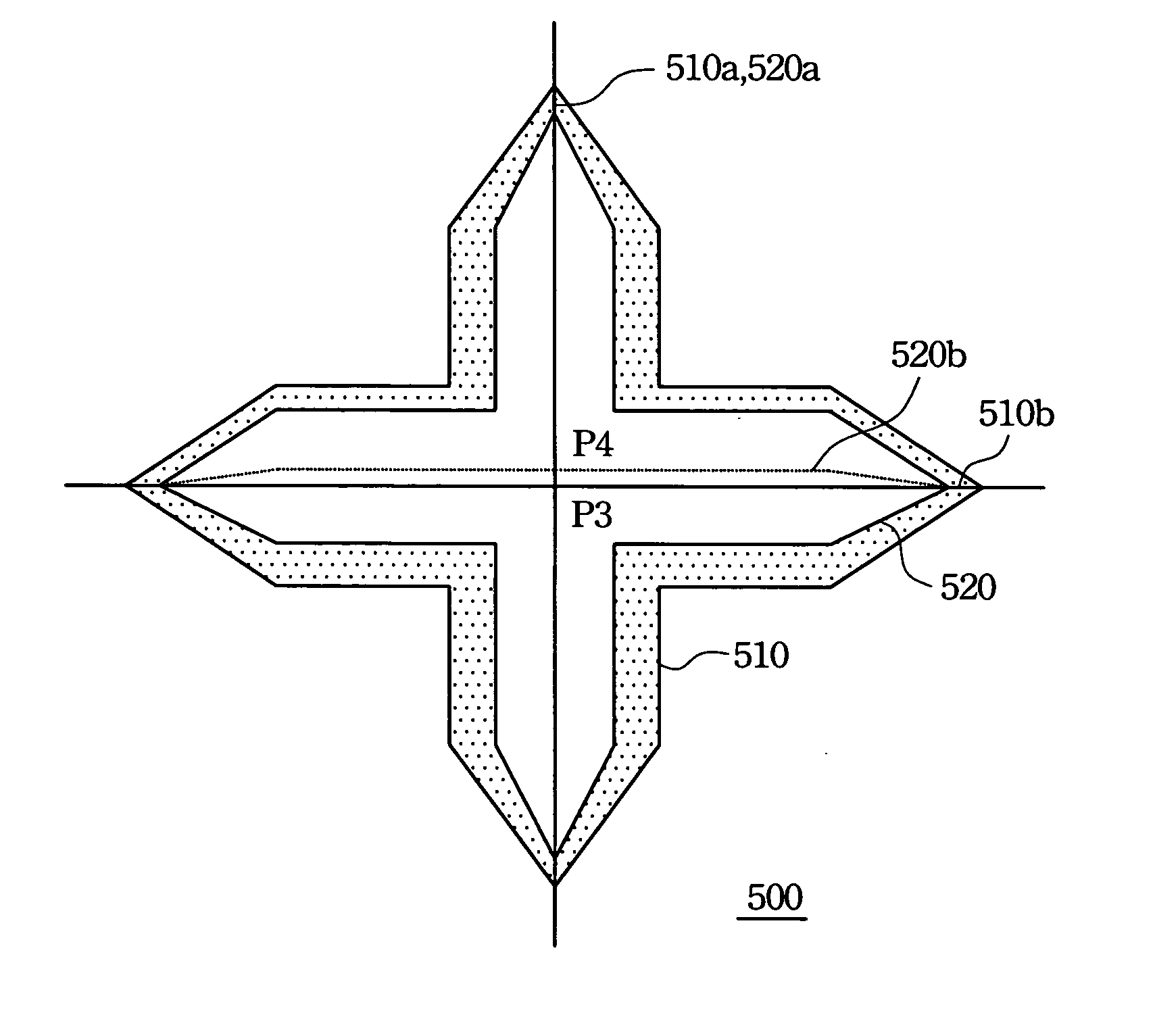

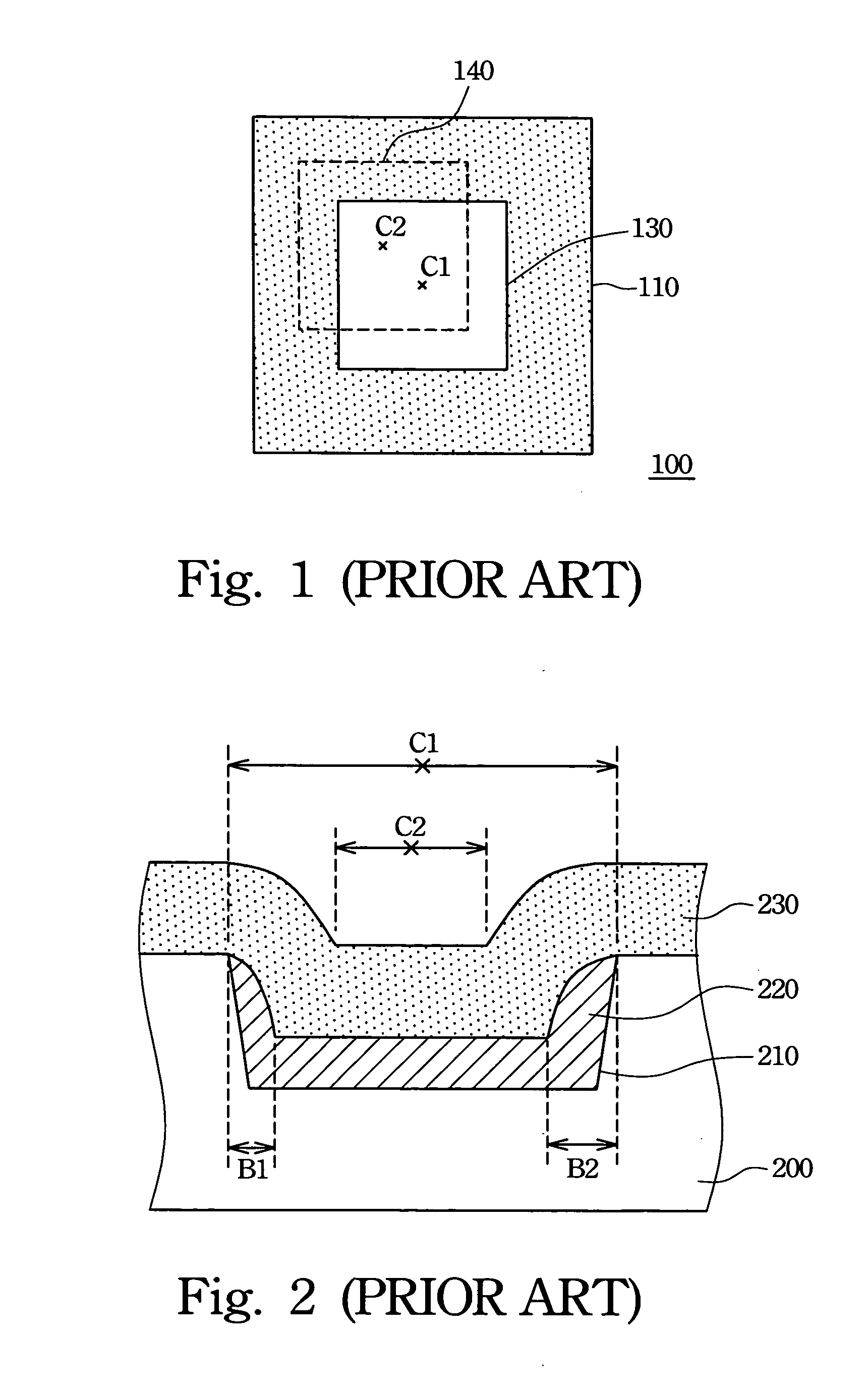

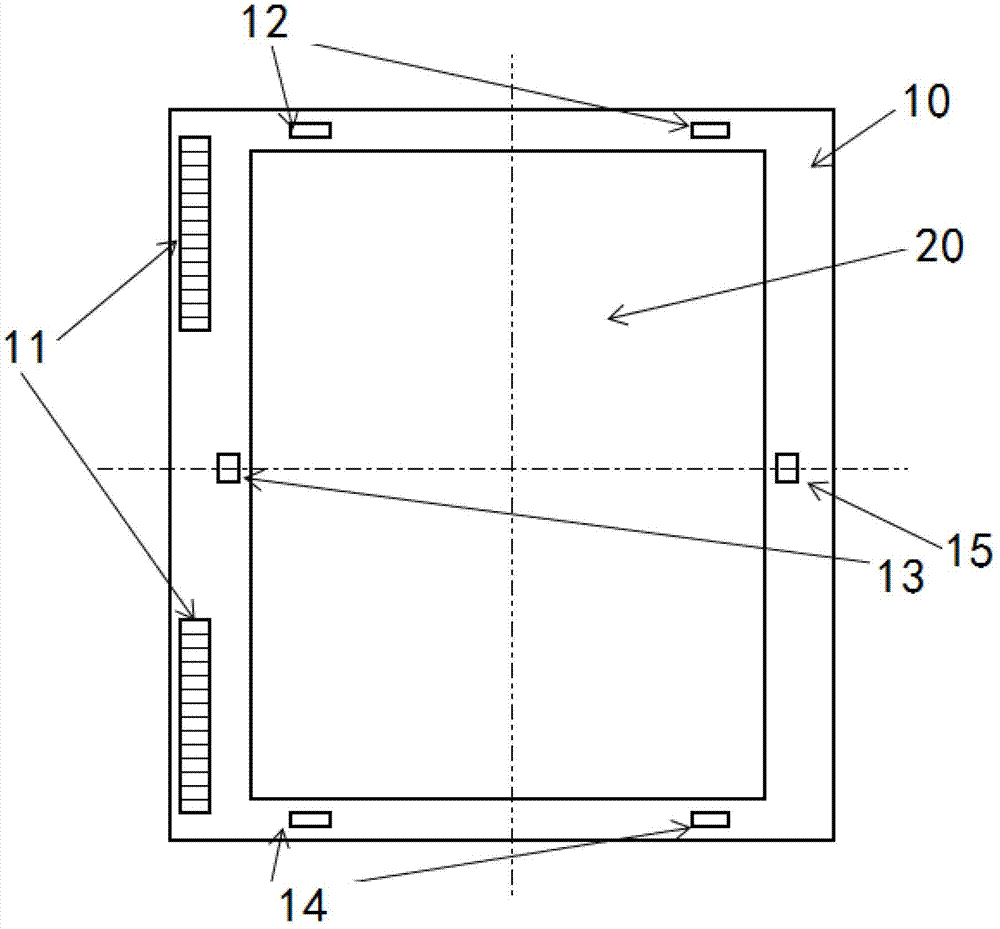

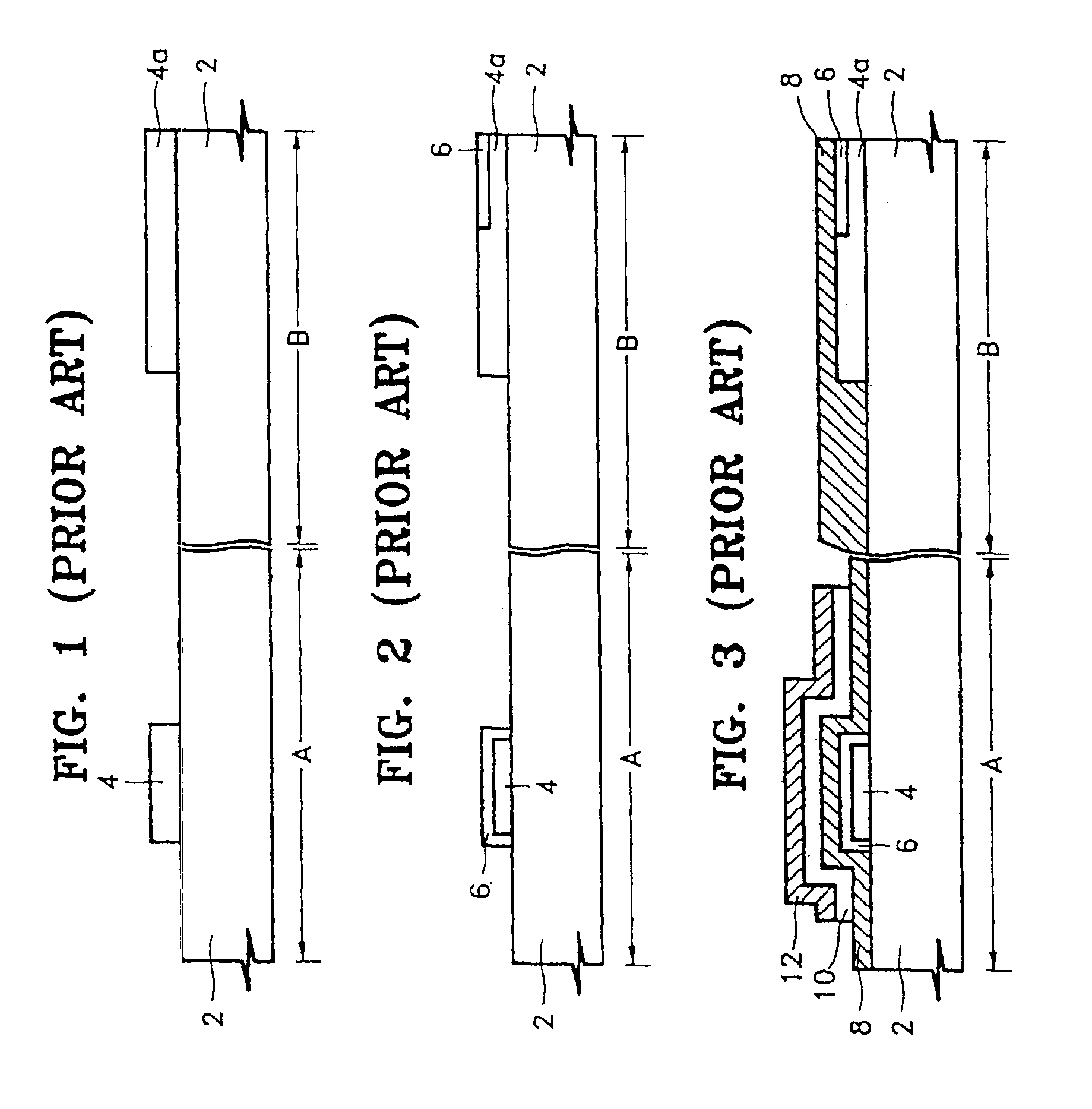

Alignment mark and alignment method using the same for photolithography to eliminating process bias error

InactiveUS20050023709A1Stable positionSemiconductor/solid-state device detailsSolid-state devicesPhysicsPhotolithography

Owner:PROMOS TECH INC

Novel design method for ESD protection

InactiveCN101692425ALow costIncrease lithographySemiconductor/solid-state device detailsSolid-state devicesPorous mediumGate oxide

Owner:GUANGDONG YUEJING HIGH TECH CO LTD

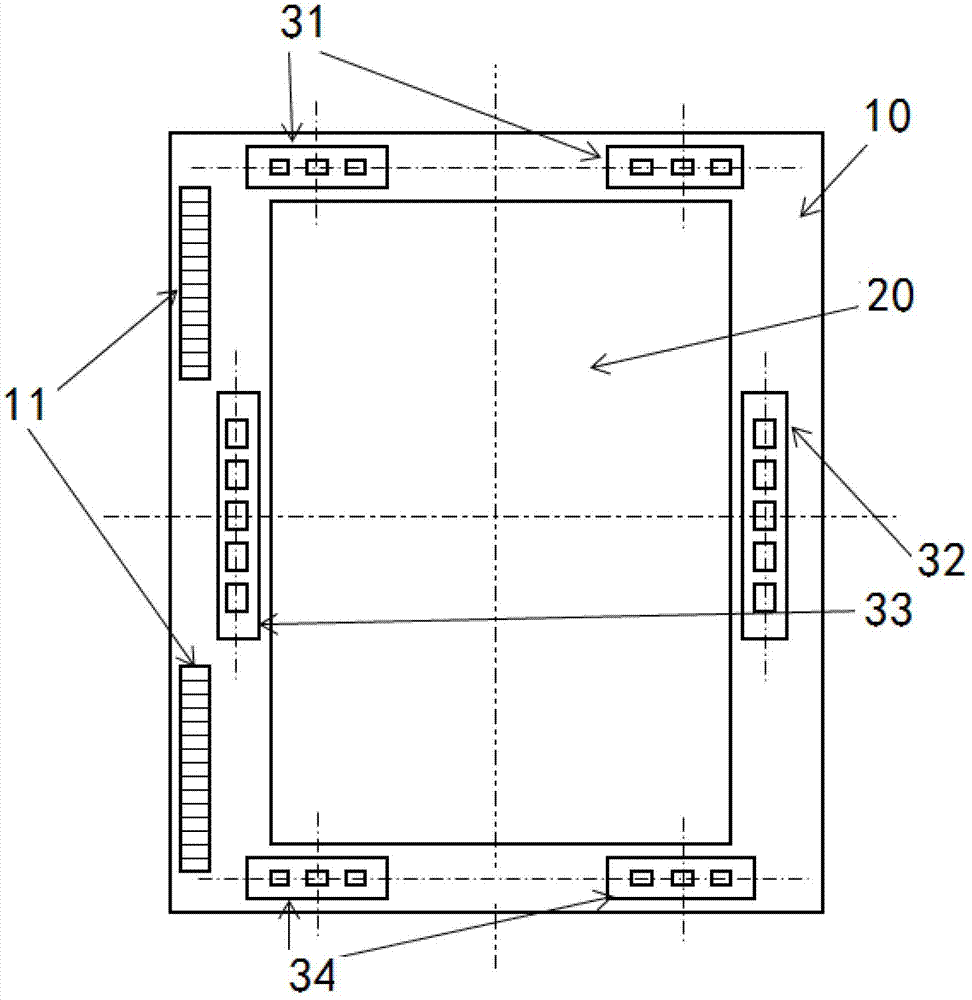

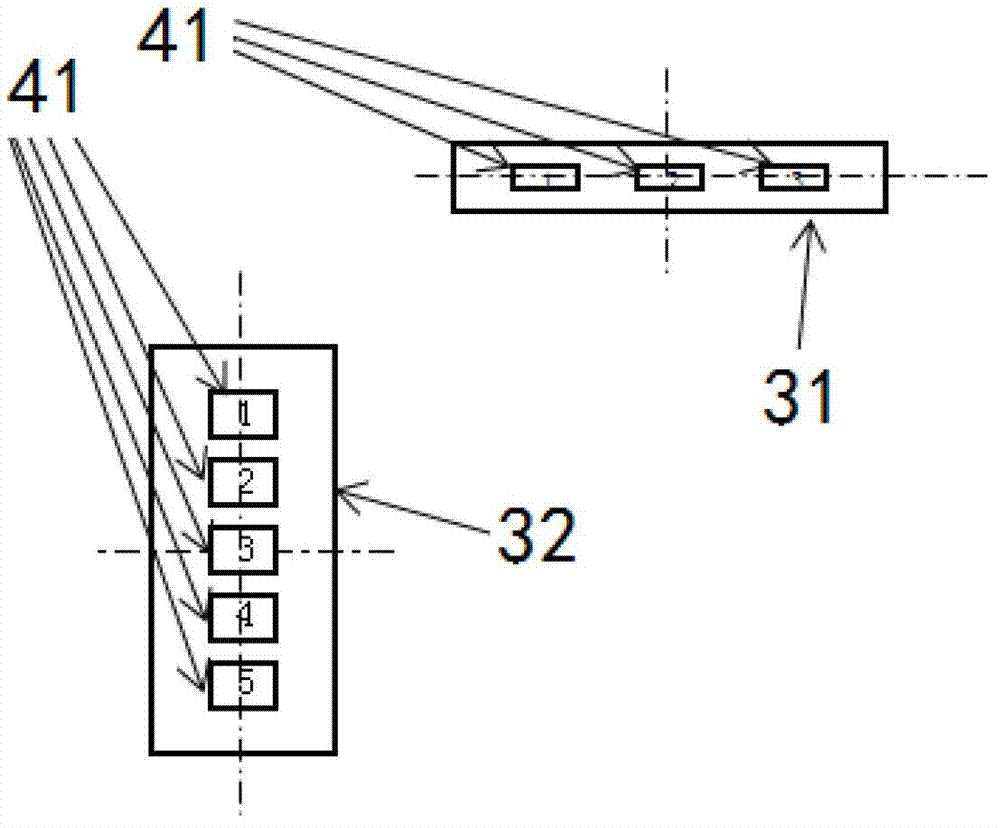

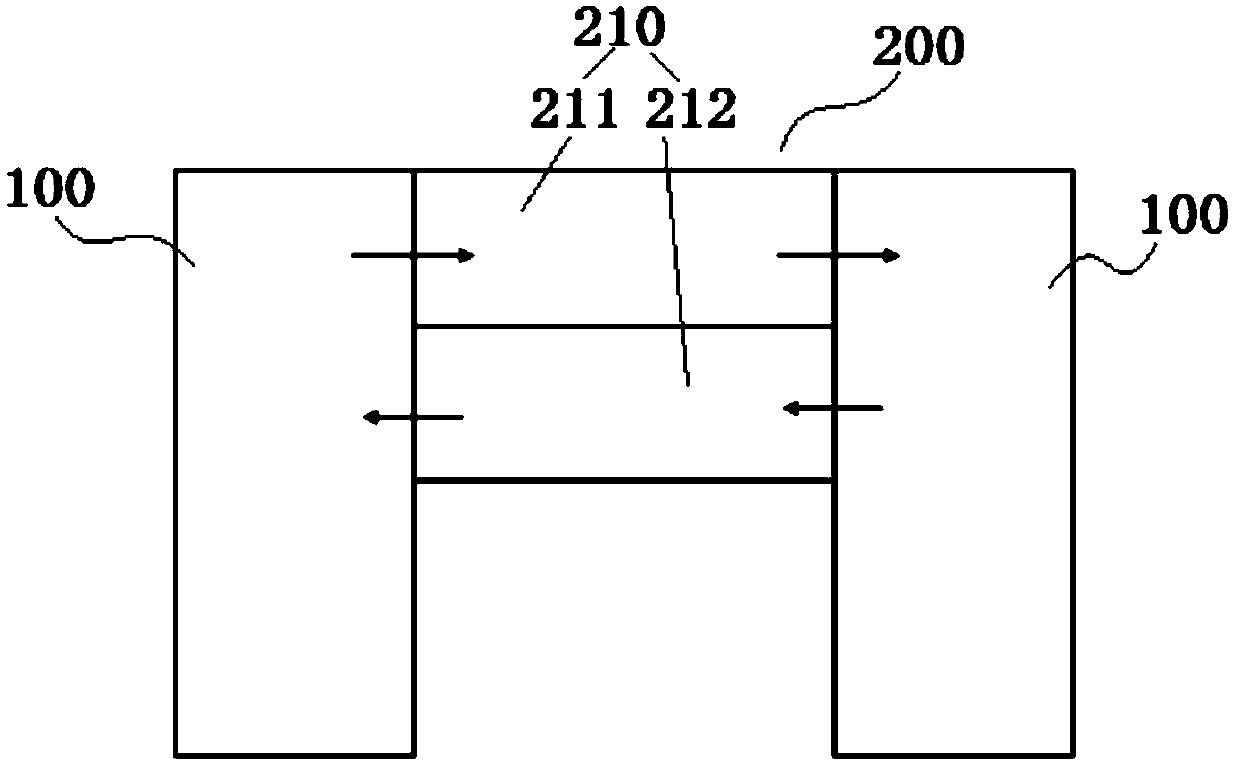

Photolithography mask structure

ActiveCN103091974ASolve the problem of marking conflicts in shared photolithography platesOriginals for photomechanical treatmentEngineeringIntegrated circuit layout

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

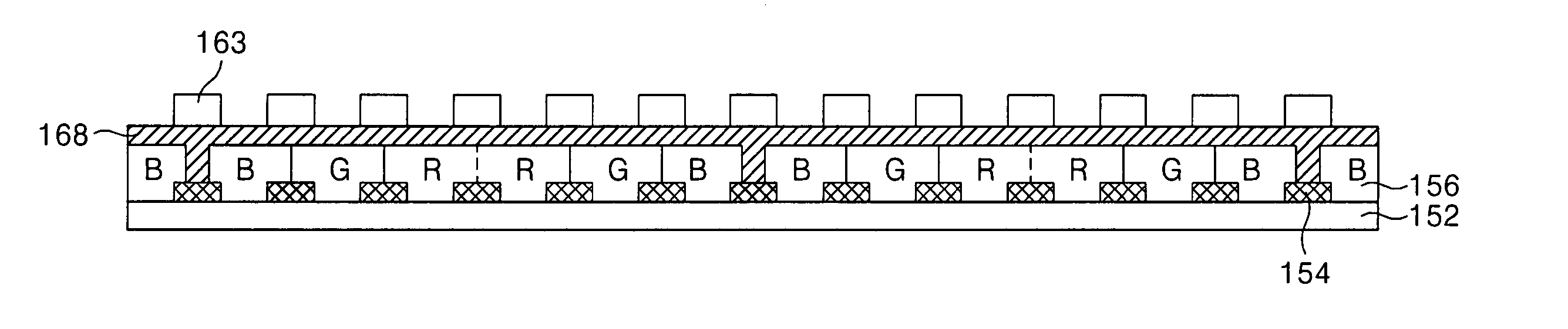

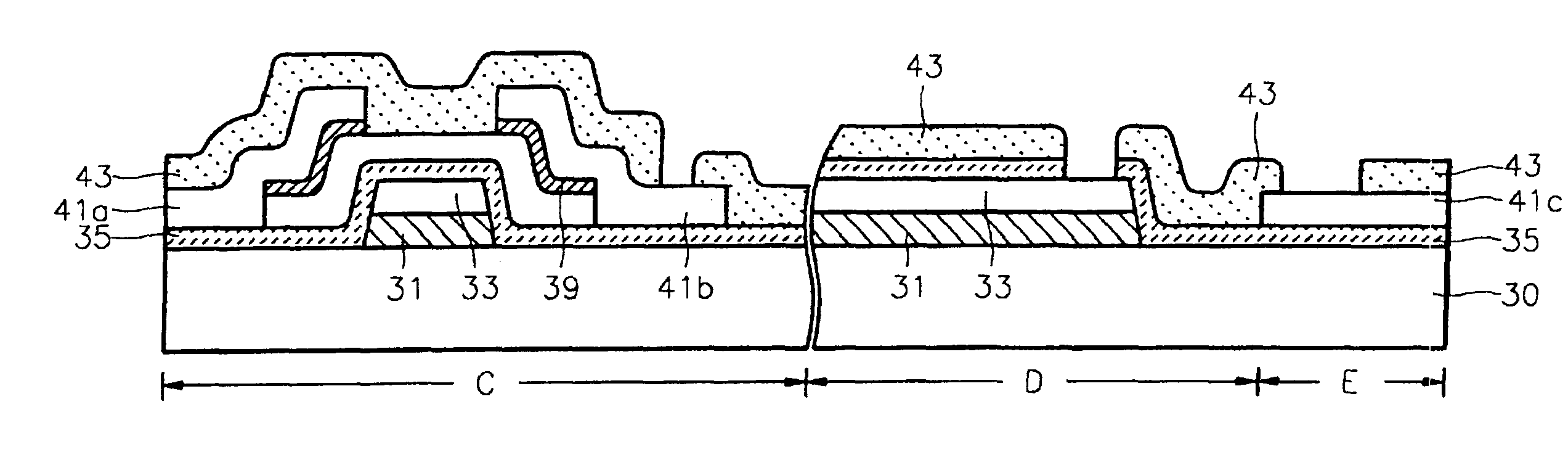

Method for manufacturing a liquid crystal display

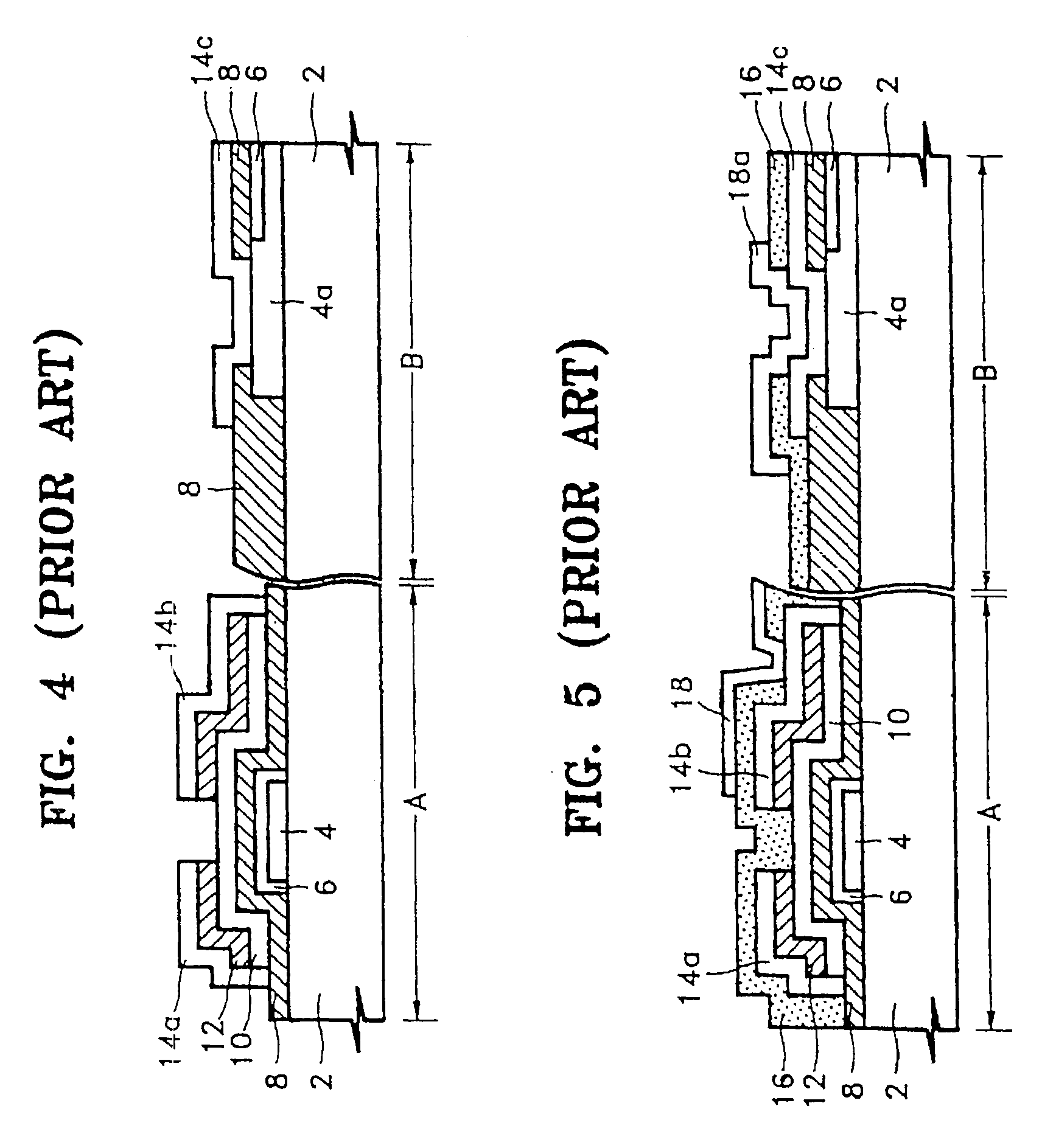

InactiveUSRE39211E1Reduce in quantitySharply reducing manufacturing costTransistorSemiconductor/solid-state device detailsLiquid-crystal displaySemiconductor

Owner:SAMSUNG DISPLAY CO LTD

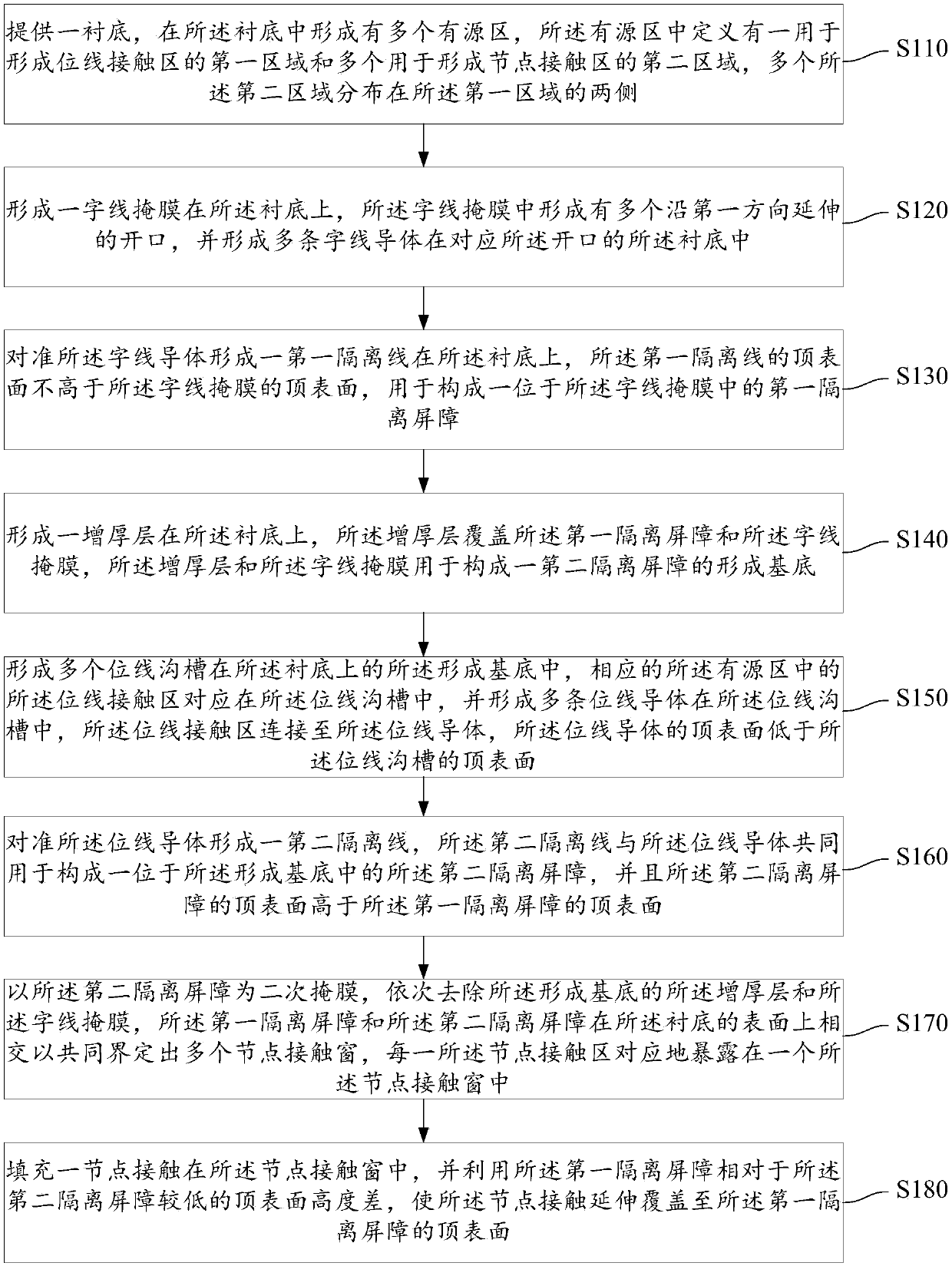

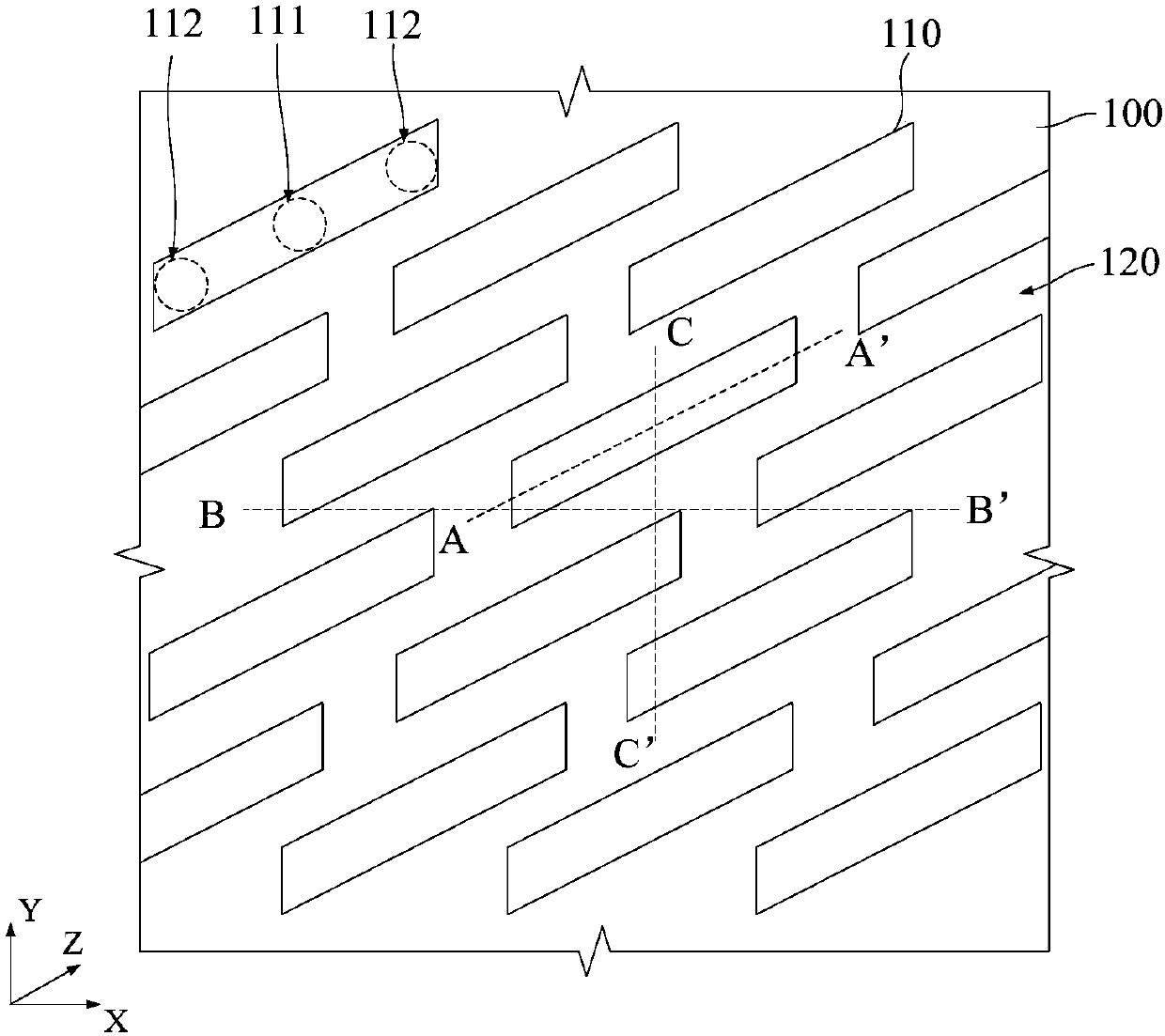

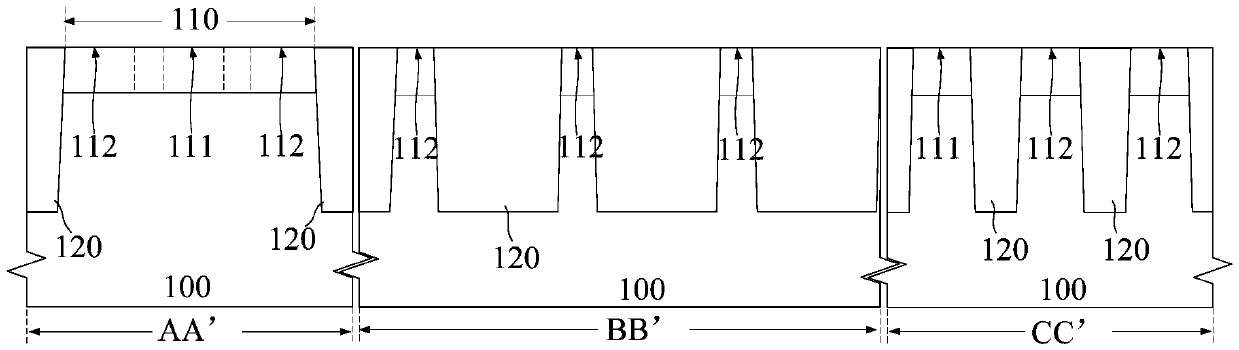

Storage, forming method thereof and semiconductor device

ActiveCN107611133ASolid-state devicesSemiconductor devicesPhotolithographyPower semiconductor device

Owner:CHANGXIN MEMORY TECH INC

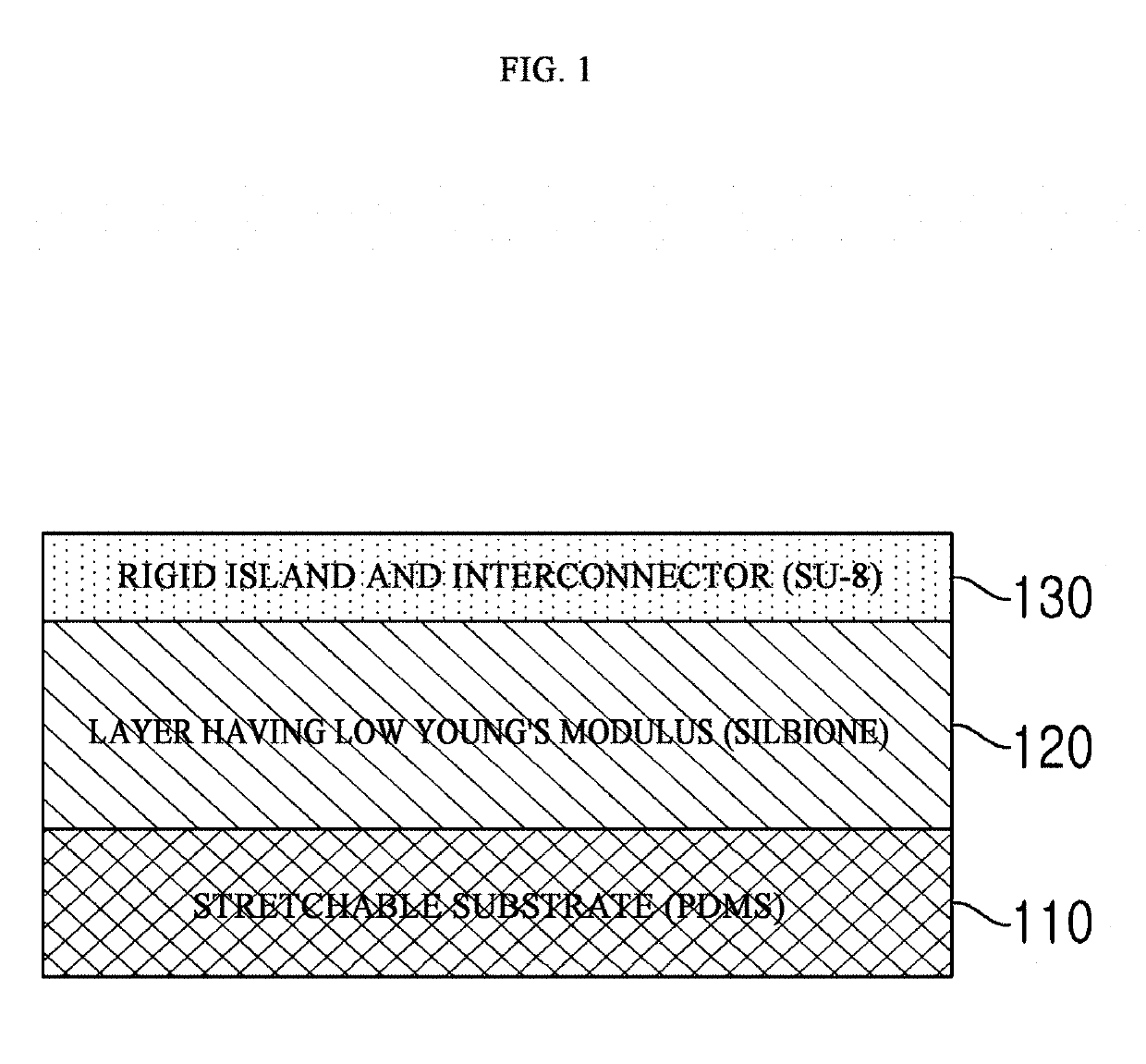

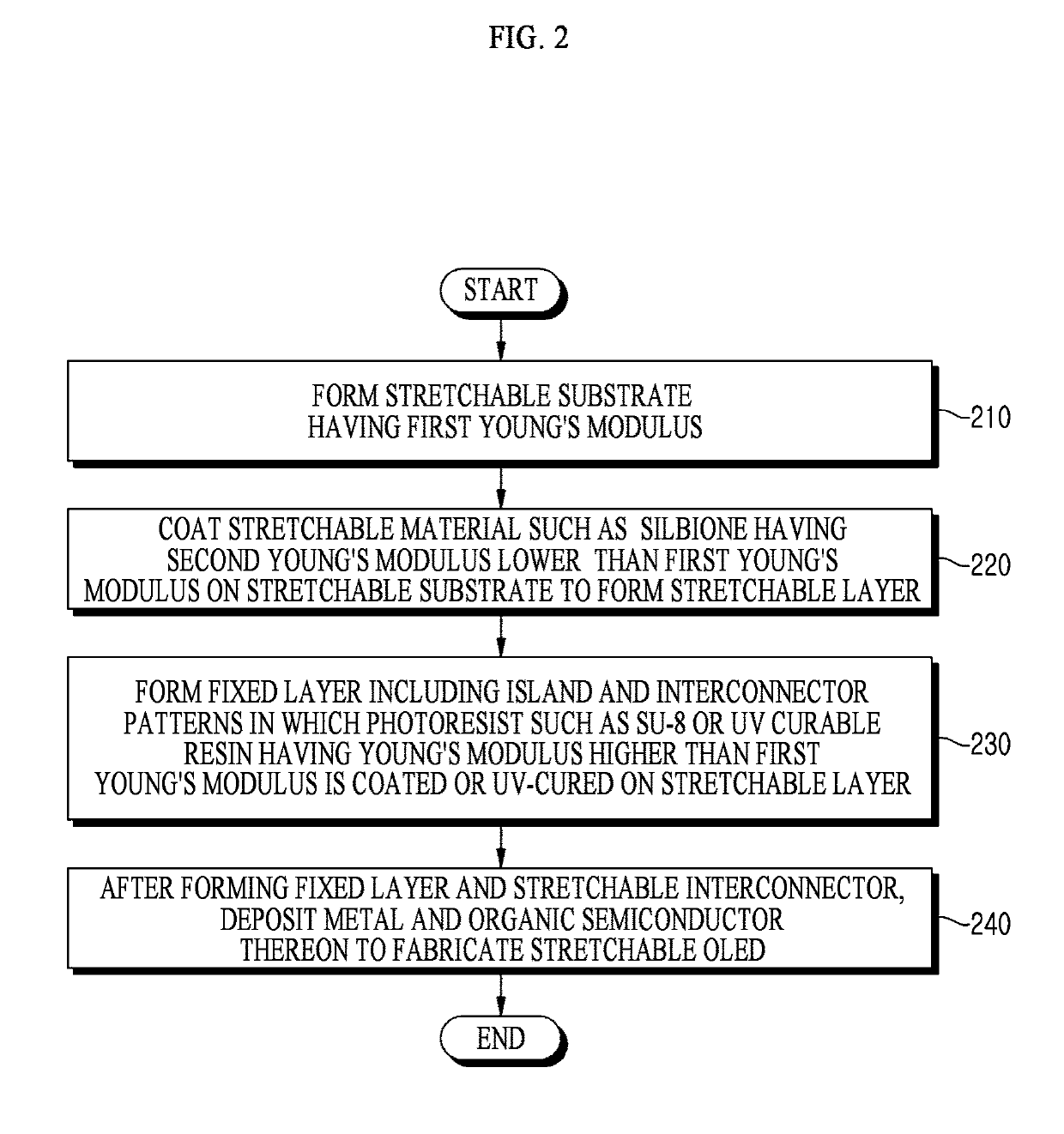

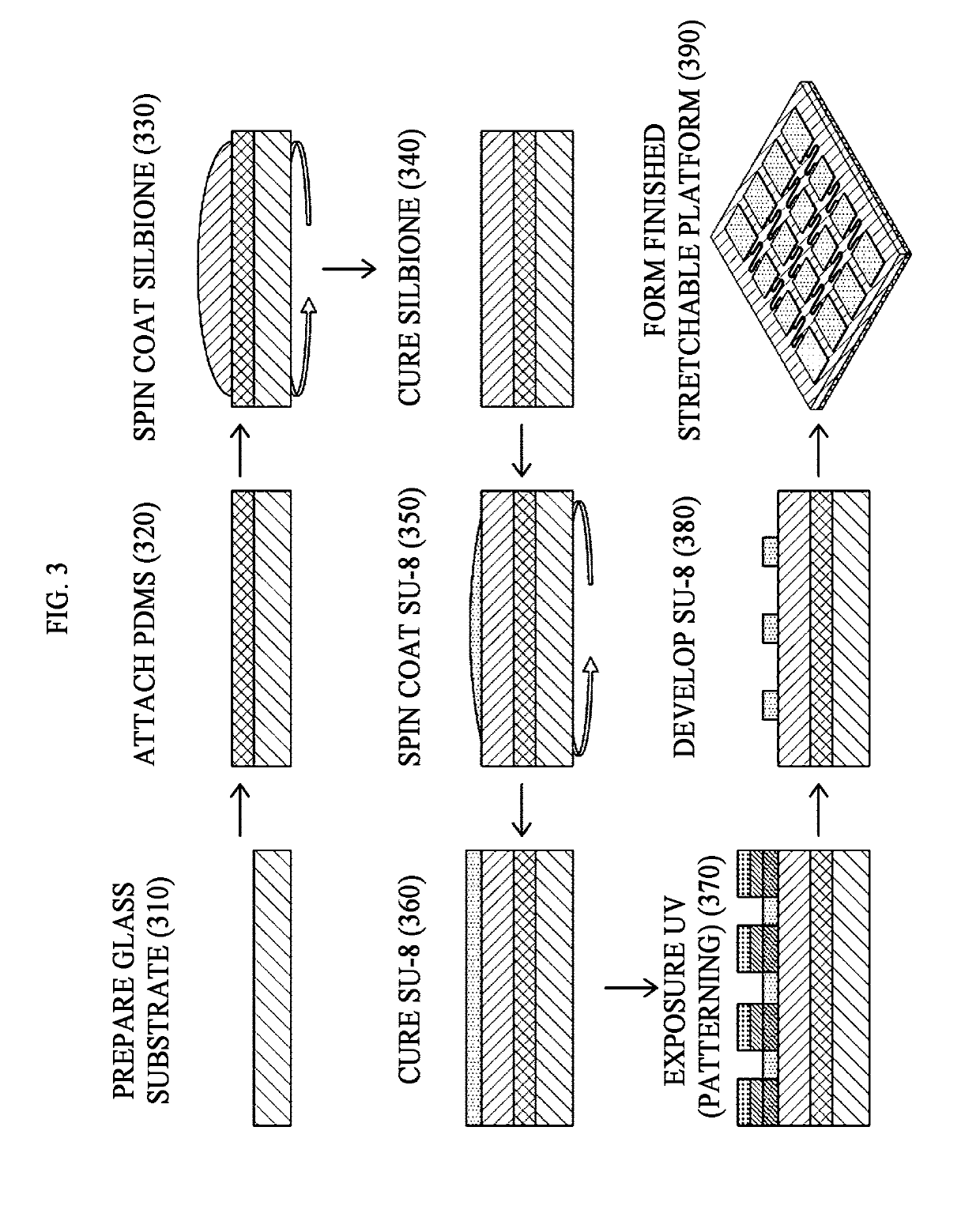

Method of fabricating rigid island pattern on stretchable layer with low young's modulus and stretchable electronic device platform using the same

ActiveUS20190305233A1Simplify the manufacturing processEnsuring stretchabilityCircuit bendability/stretchabilityFinal product manufactureStretchable electronicsResist

Owner:KOREA ADVANCED INST OF SCI & TECH

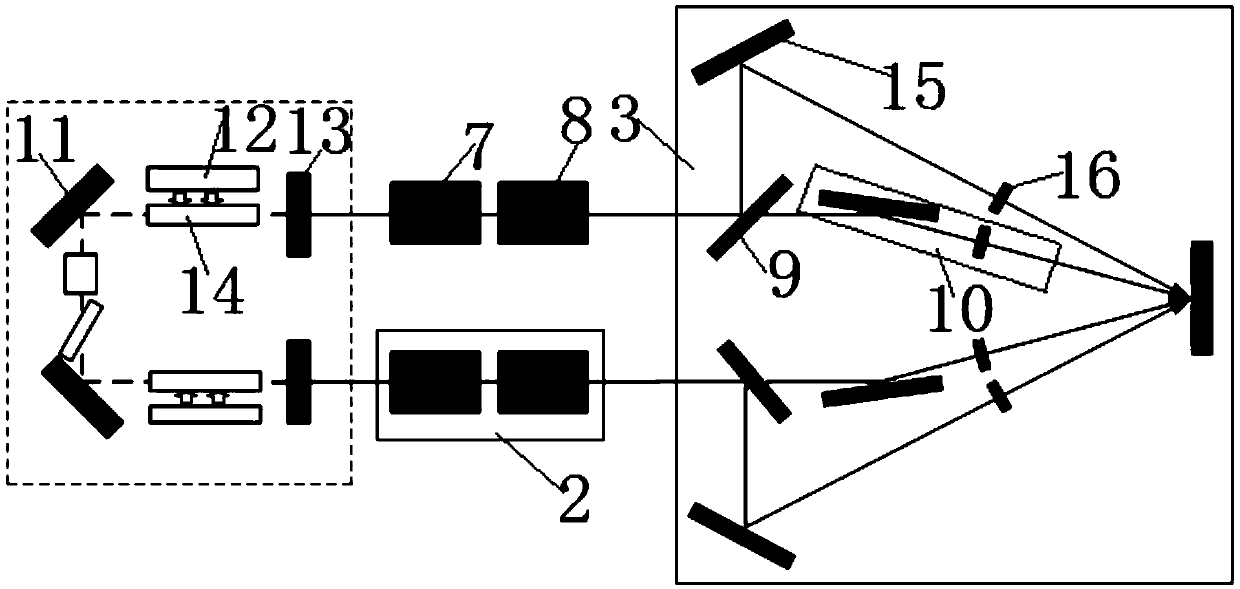

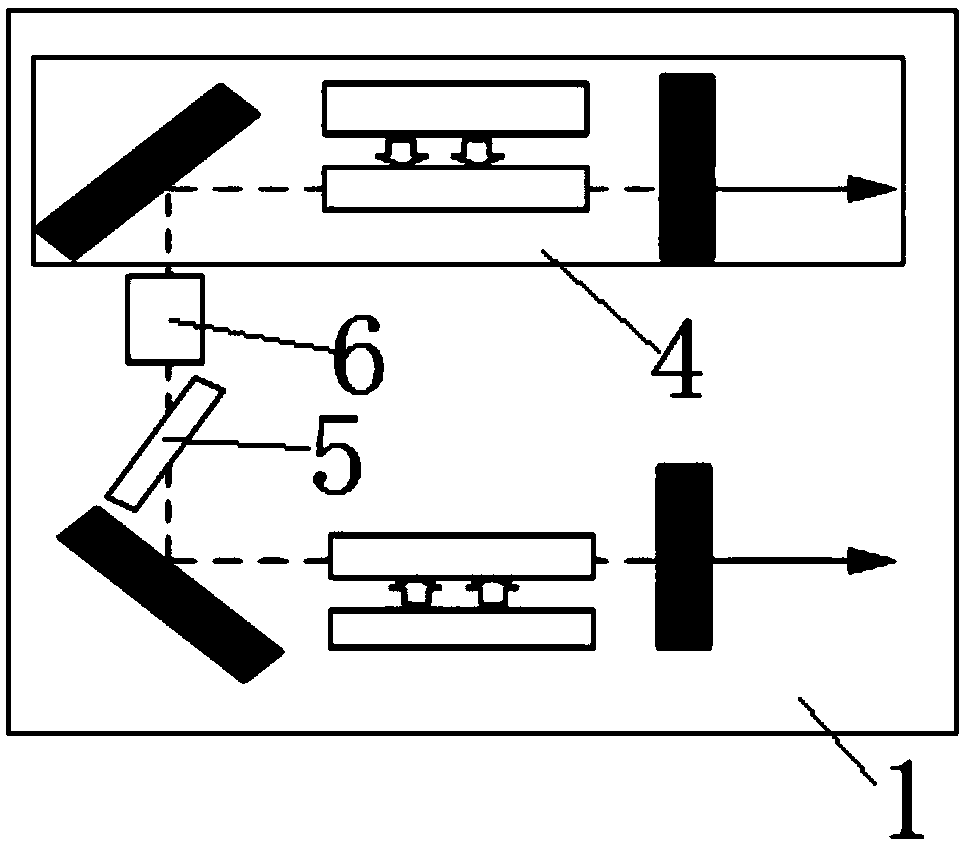

Laser interference photoetching system

ActiveCN109521651AGood stitchingEasy to adjustPhotomechanical exposure apparatusMicrolithography exposure apparatusLight beamLaser interference

Owner:JILIN UNIV

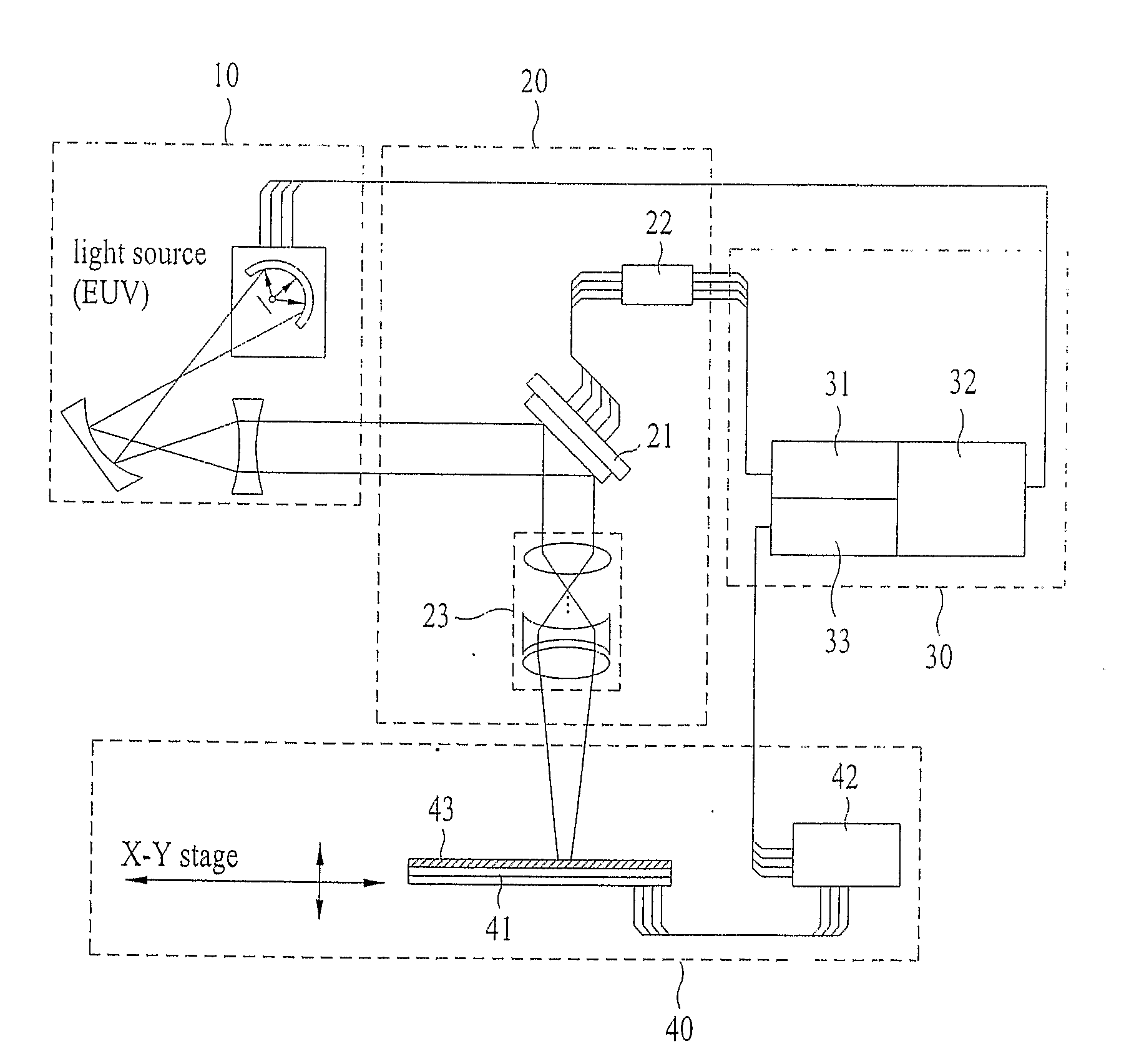

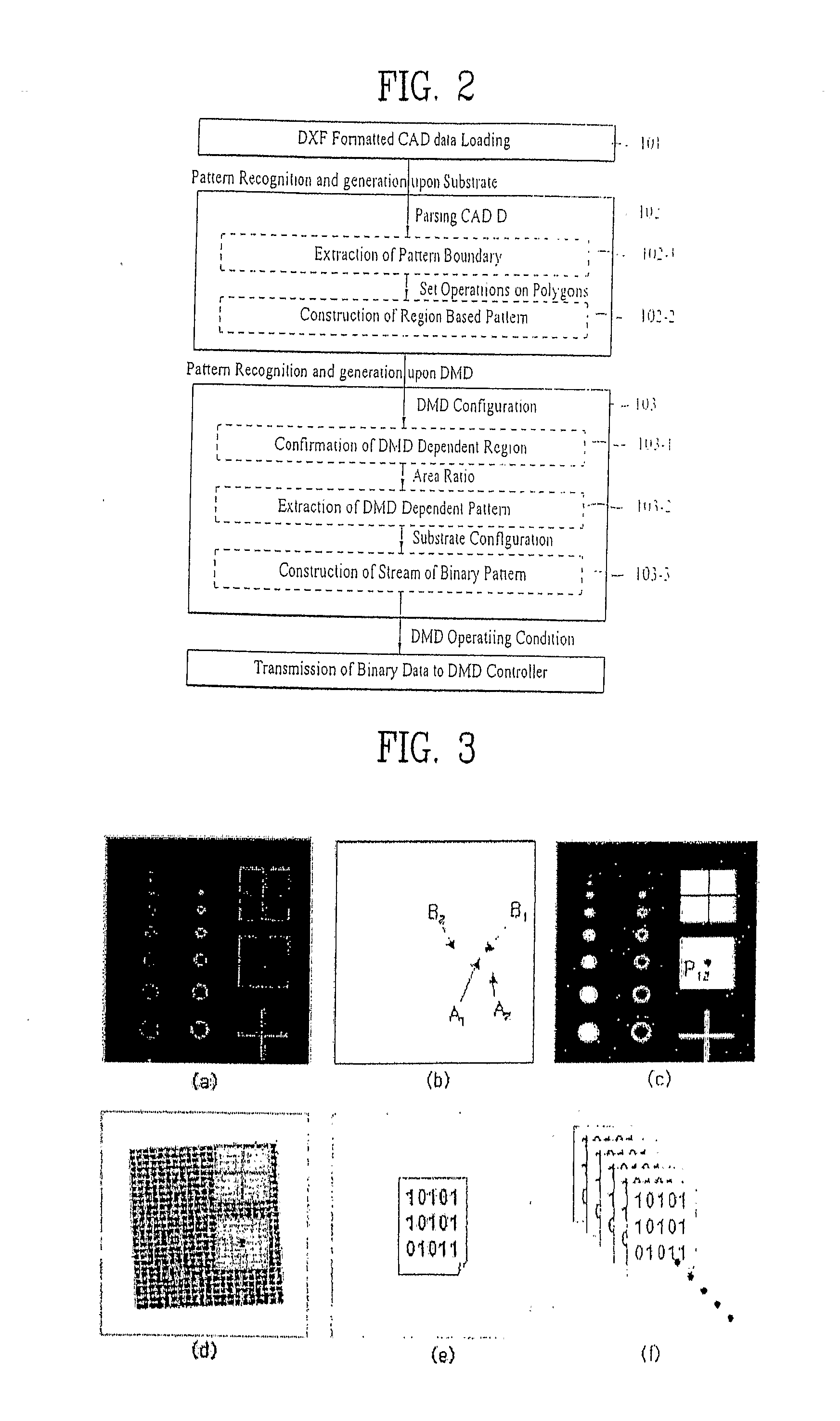

Occupancy Based on Pattern Generation Method For Maskless Lithography

InactiveUS20080313593A1Correctly and precisely and quickly generatedSmall sizePhotomechanical apparatusSpecial data processing applicationsEngineeringPattern generation

Owner:IAMTEN

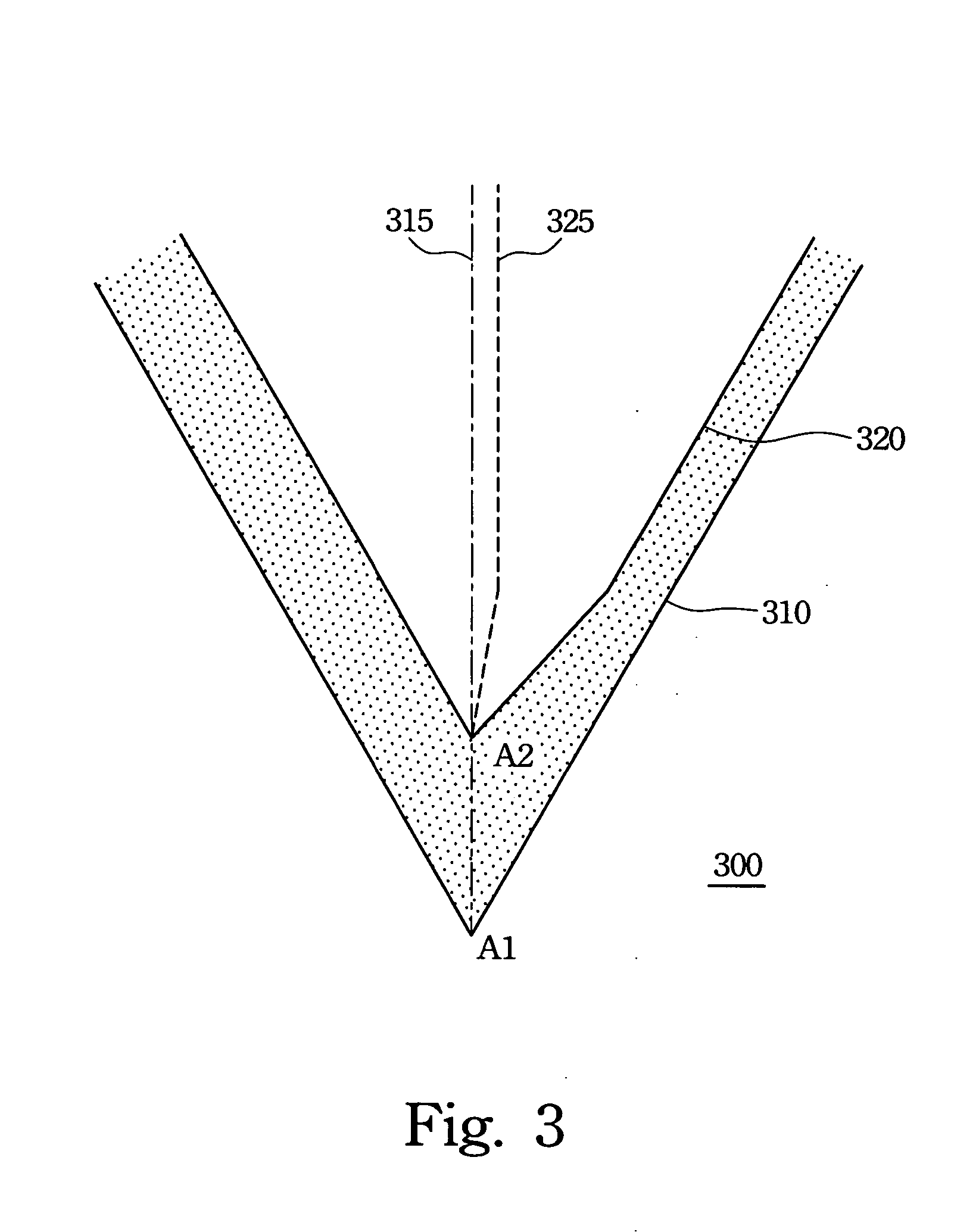

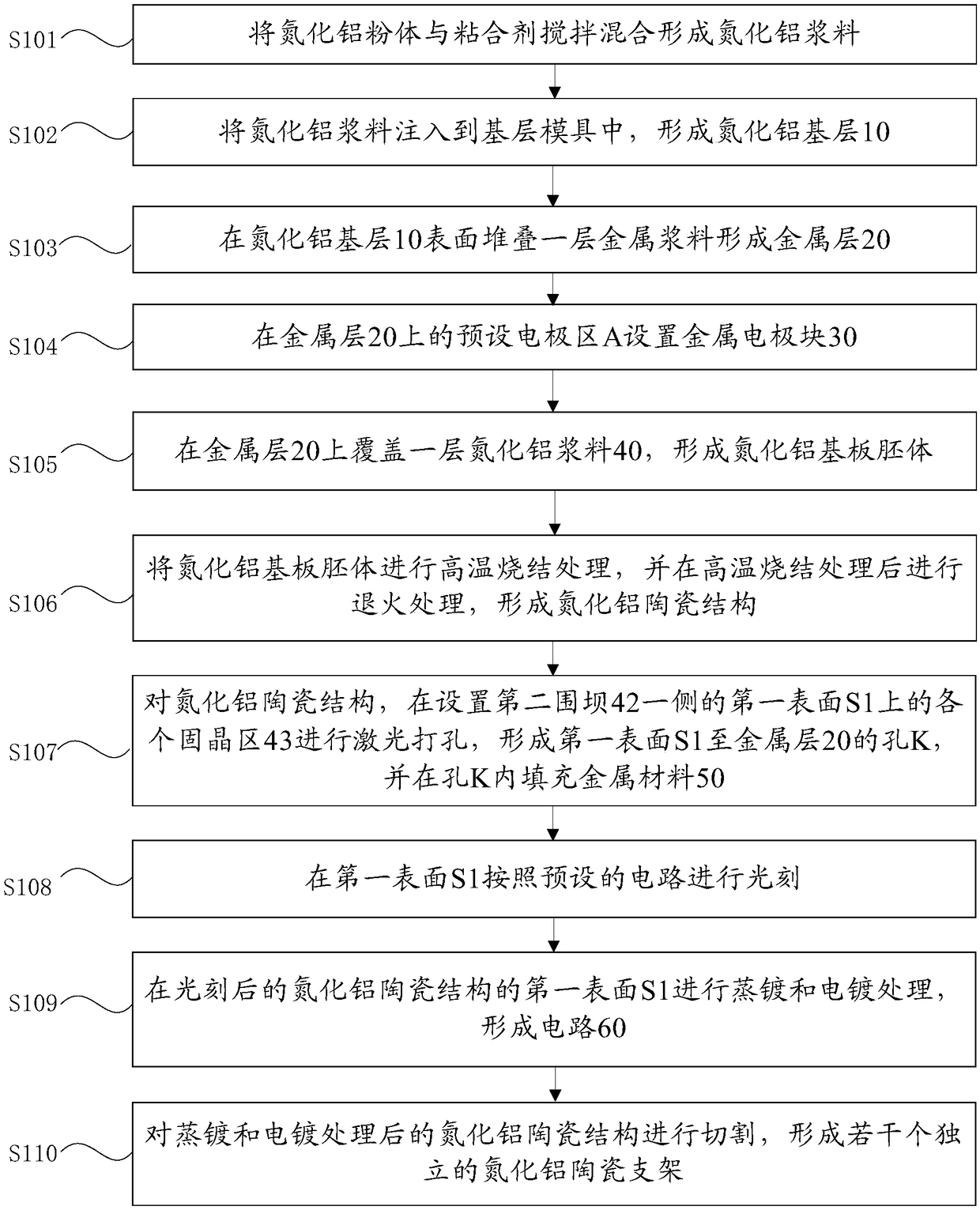

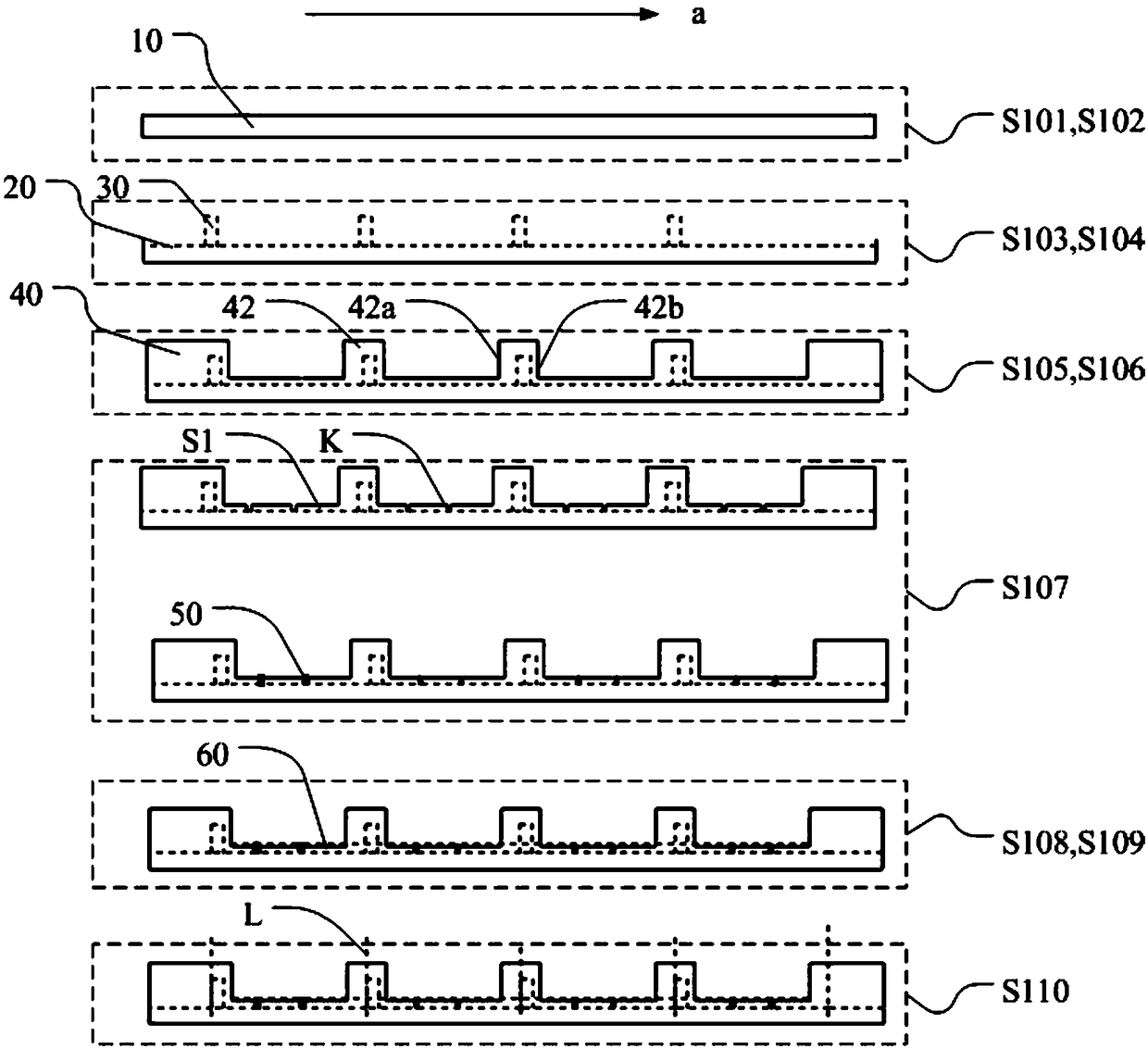

Side light-emitting deep-ultraviolet LED packaging bracket and production process thereof

ActiveCN109148671AAchieve side lightImprove thermal conductivitySemiconductor devicesUltravioletSlurry

Owner:江西力特康光学有限公司

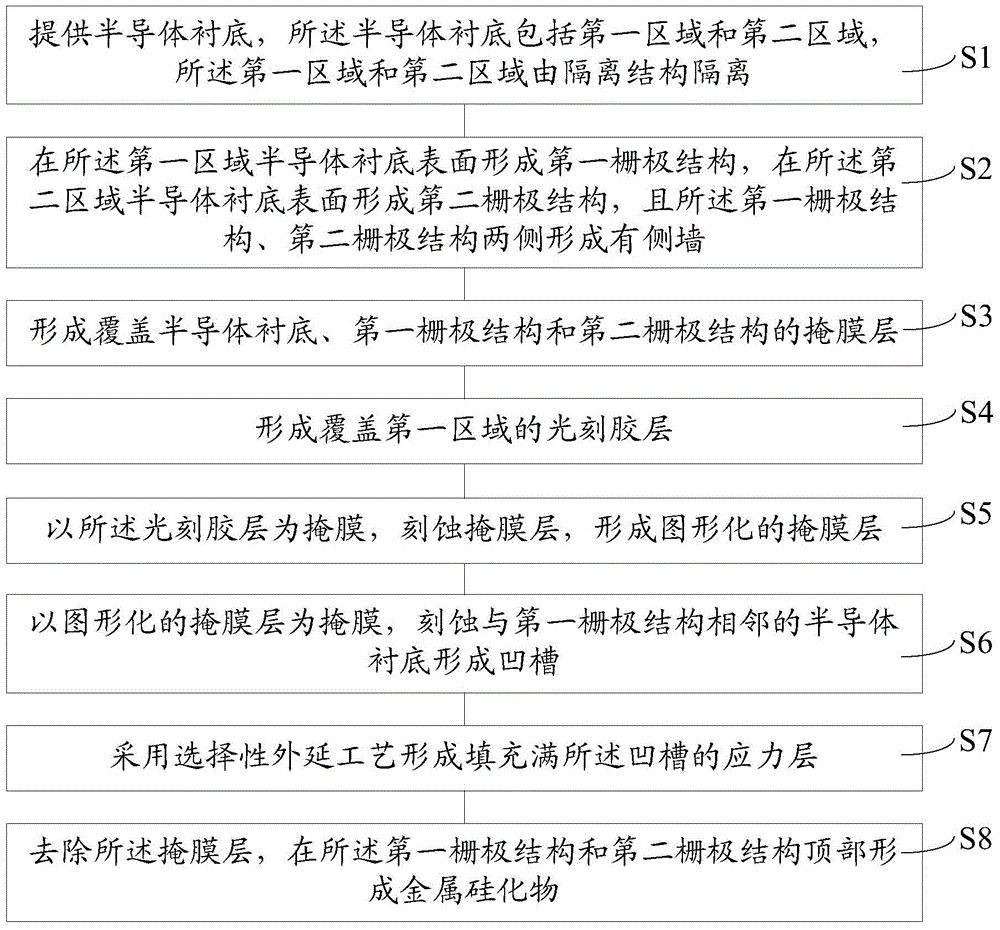

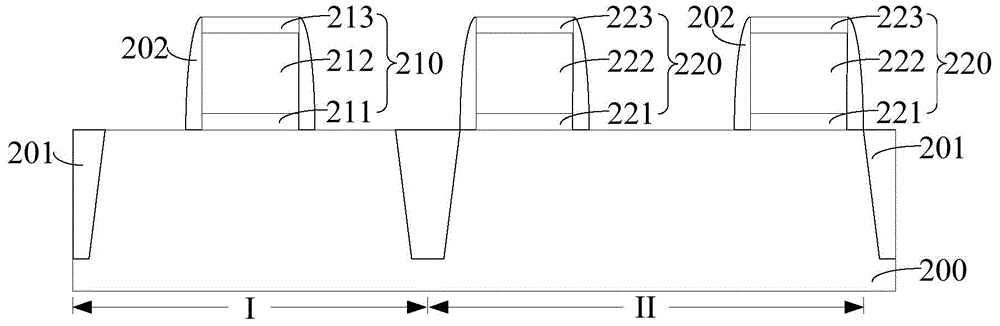

Semiconductor component forming method

ActiveCN104701166AAvoid damageGood choiceSemiconductor/solid-state device manufacturingDeposition processProtection layer

Owner:SEMICON MFG INT (SHANGHAI) CORP

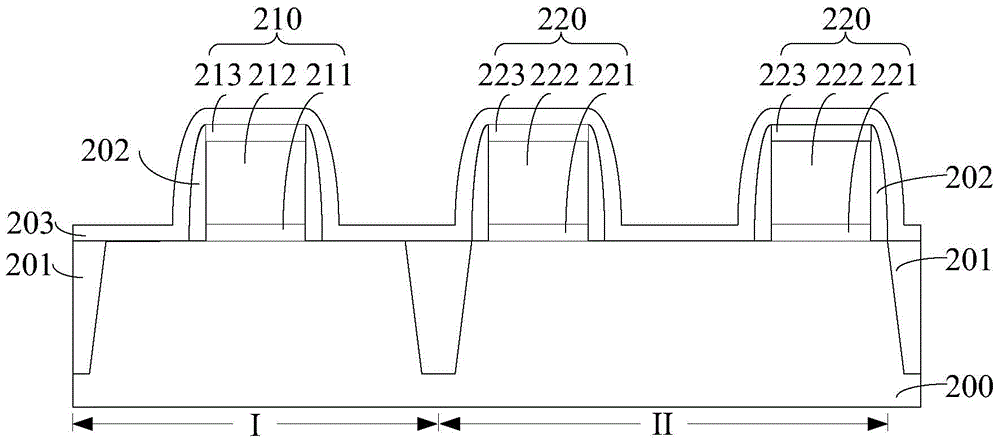

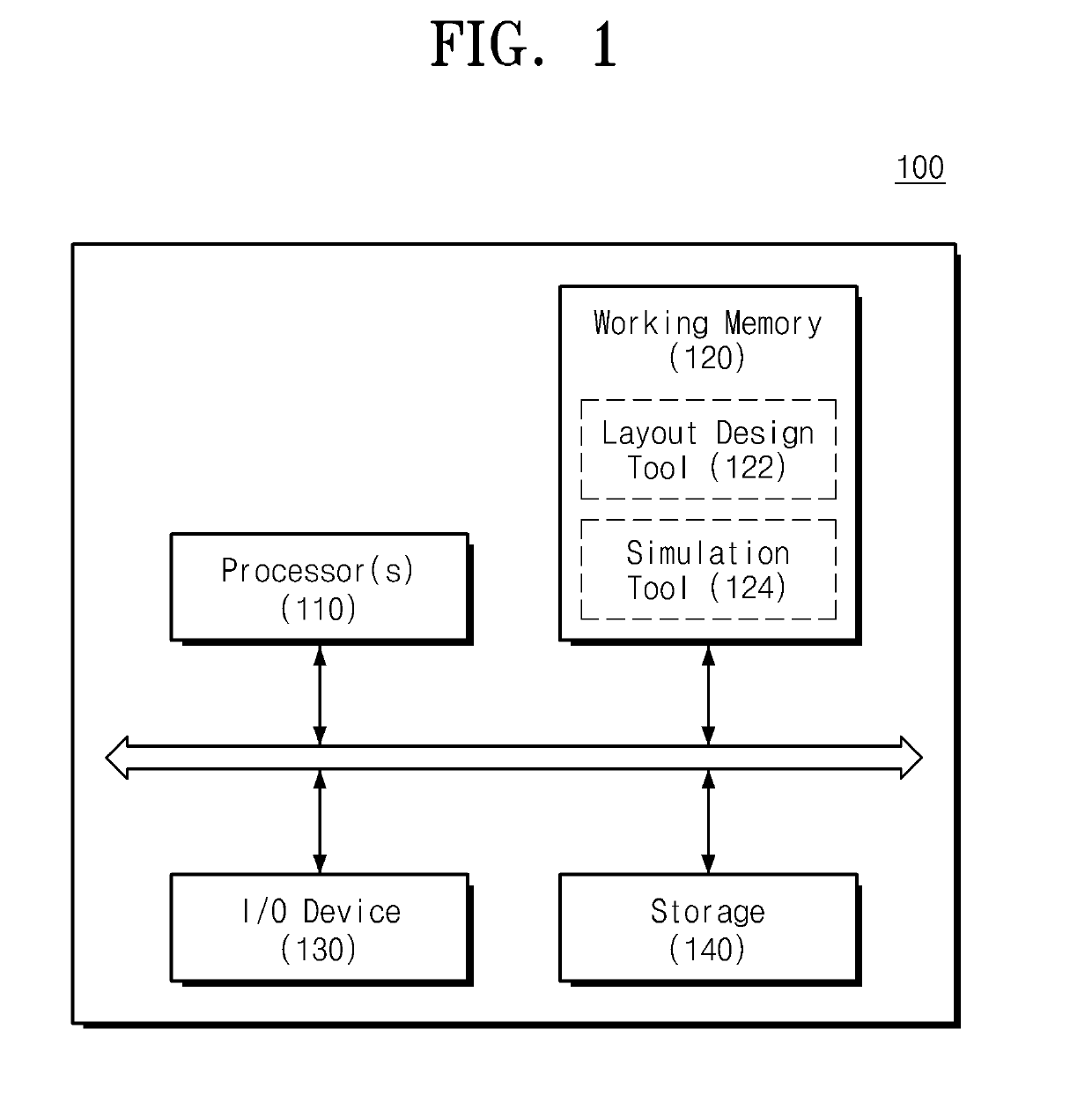

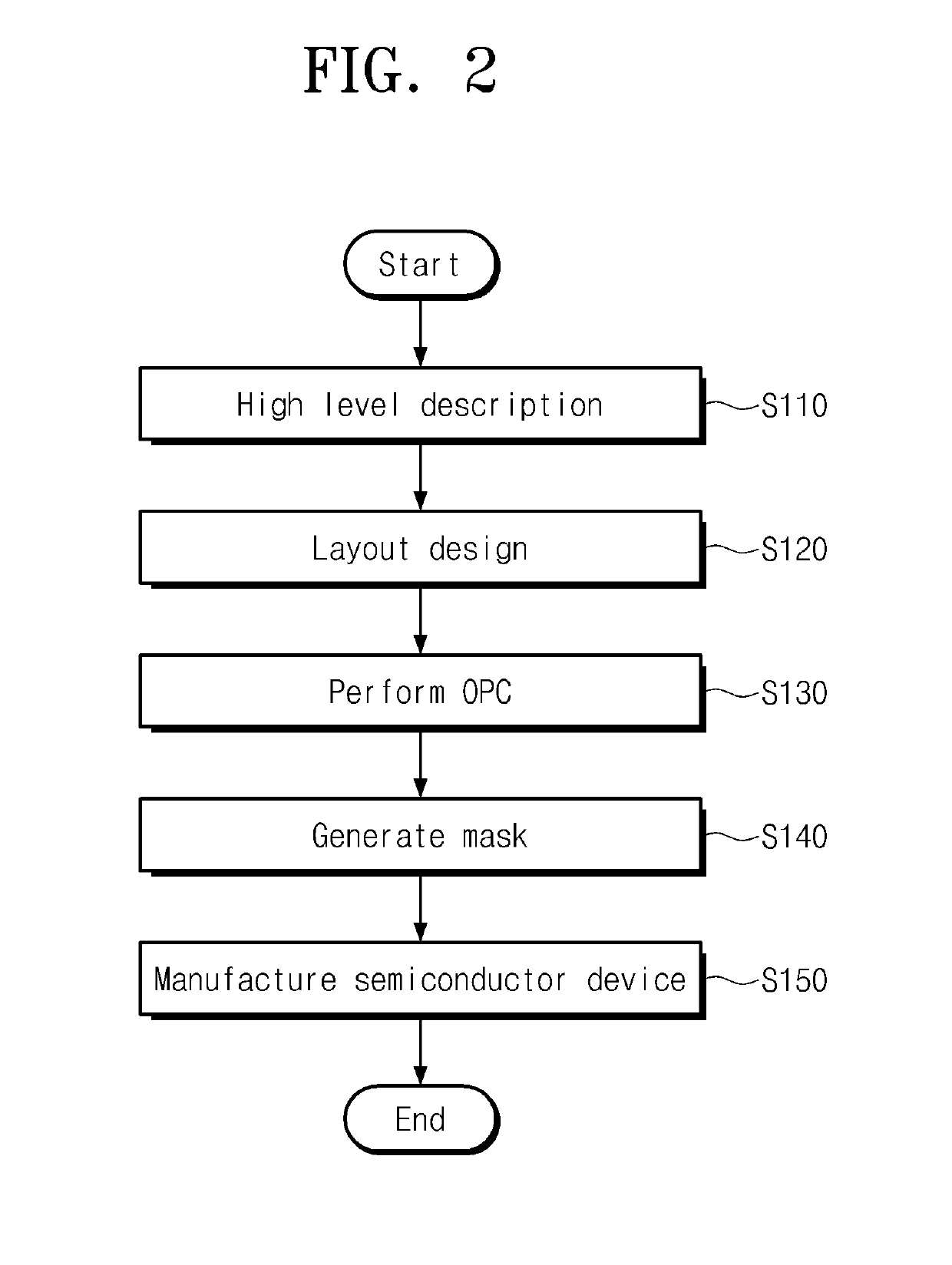

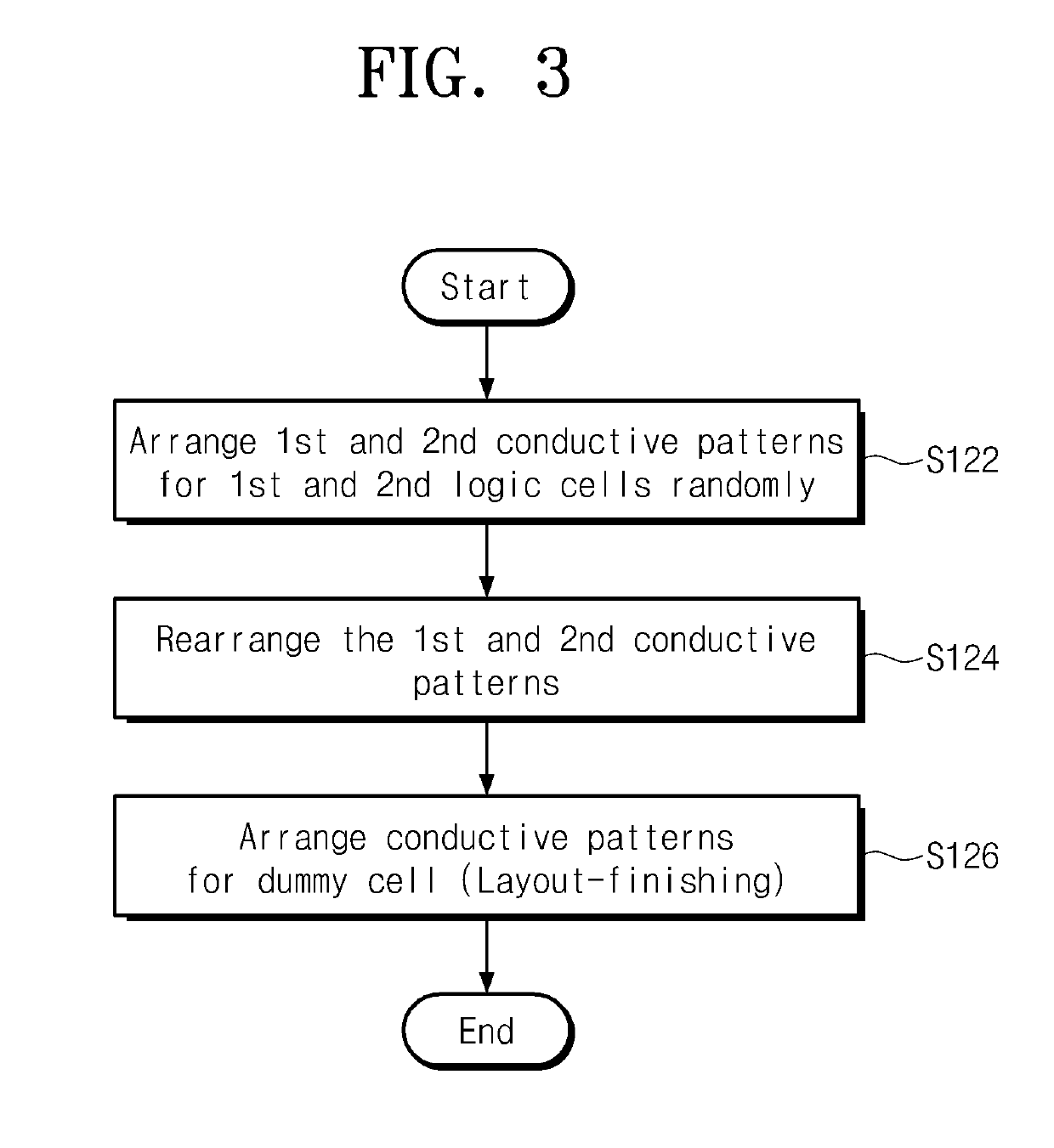

Method for designing layout of semiconductor device and method for manufacturing semiconductor device using the same

ActiveUS20190311954A1Shorten design timeTransistorSemiconductor/solid-state device detailsLogic cellEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

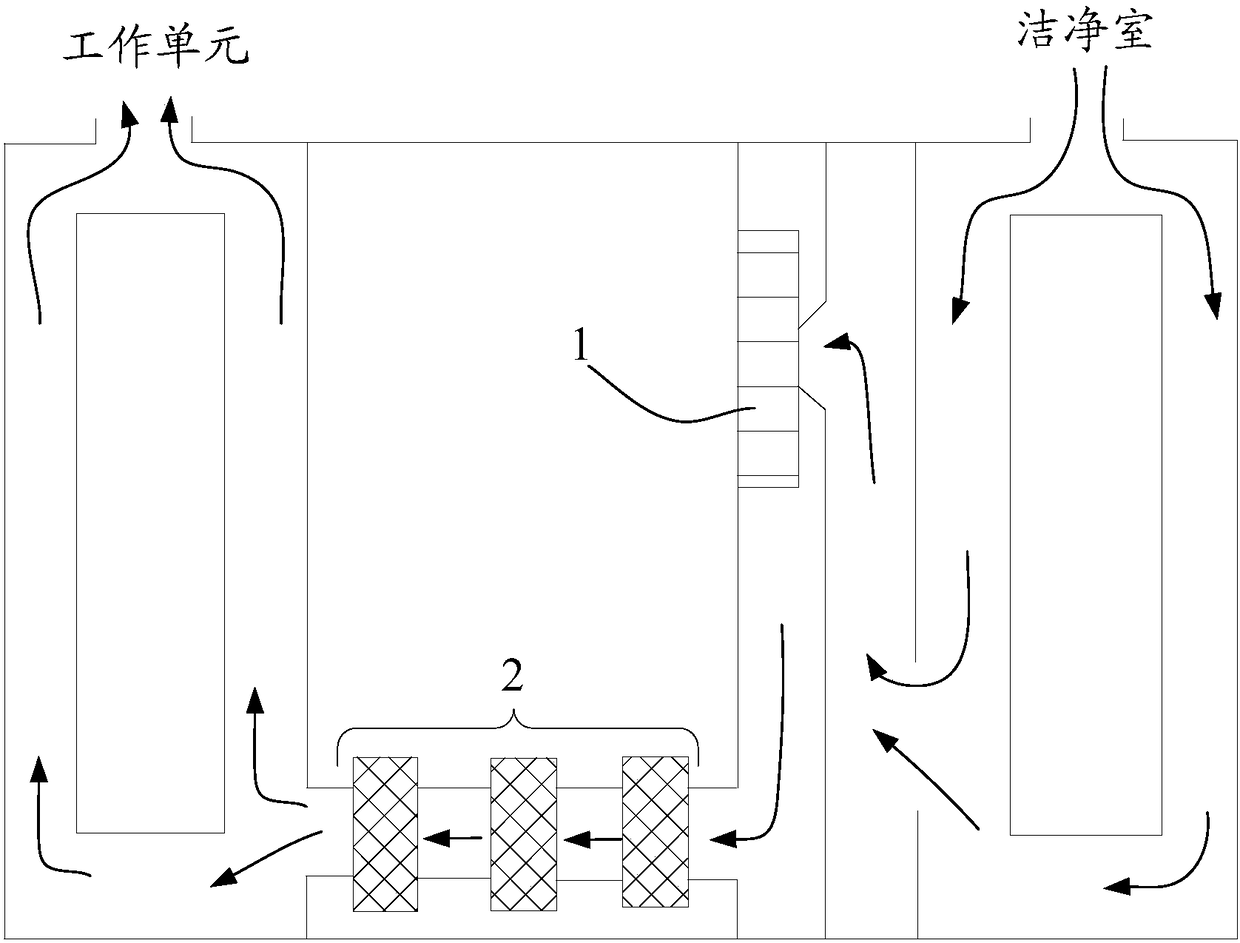

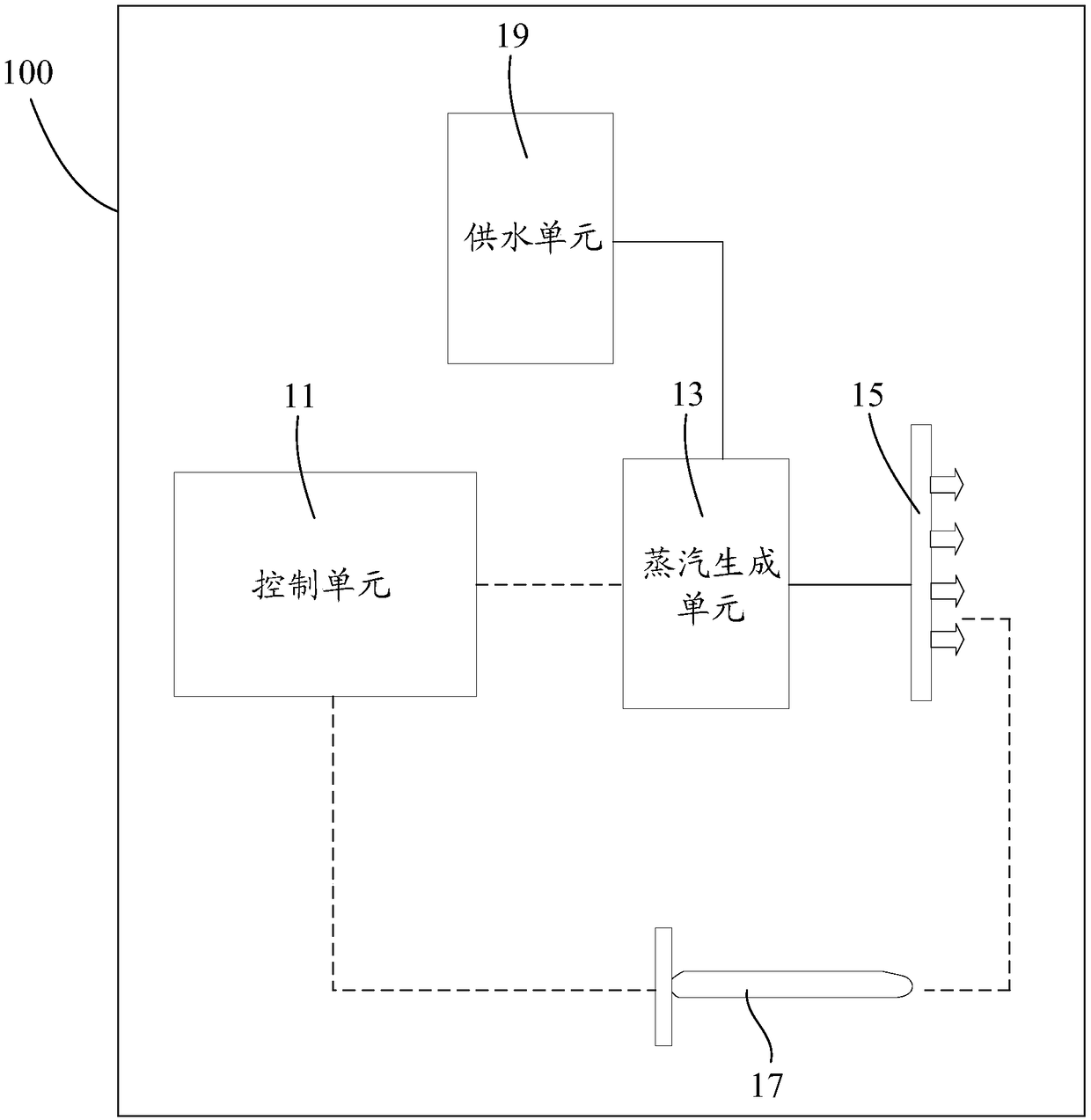

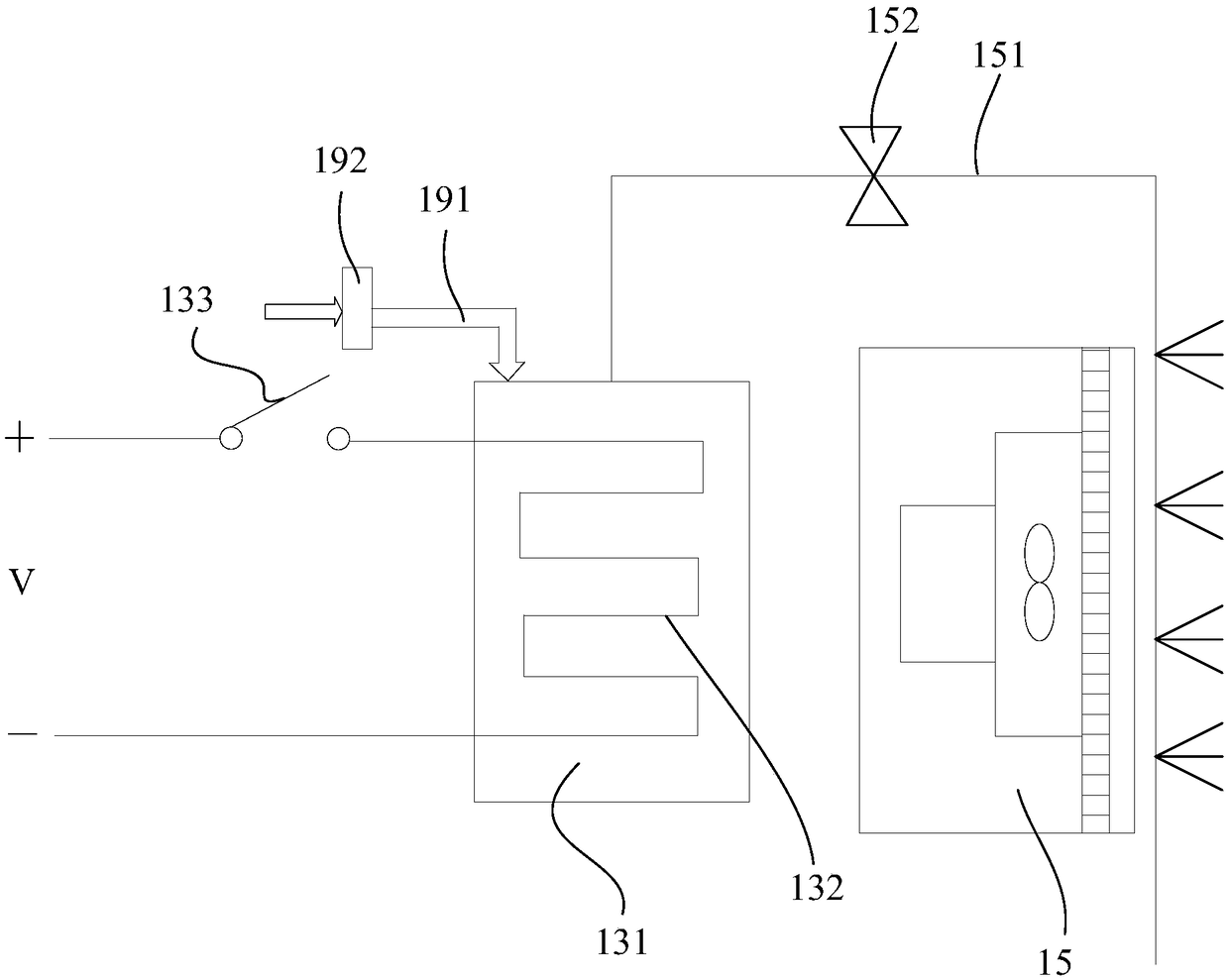

Humidity control device, temperature control system of humidity control device and photolithography cabinet

InactiveCN108240681AReduce adverse effectsImprove yieldMechanical apparatusLighting and heating apparatusTemperature controlControl system

Owner:HUAIAN IMAGING DEVICE MFGR CORP

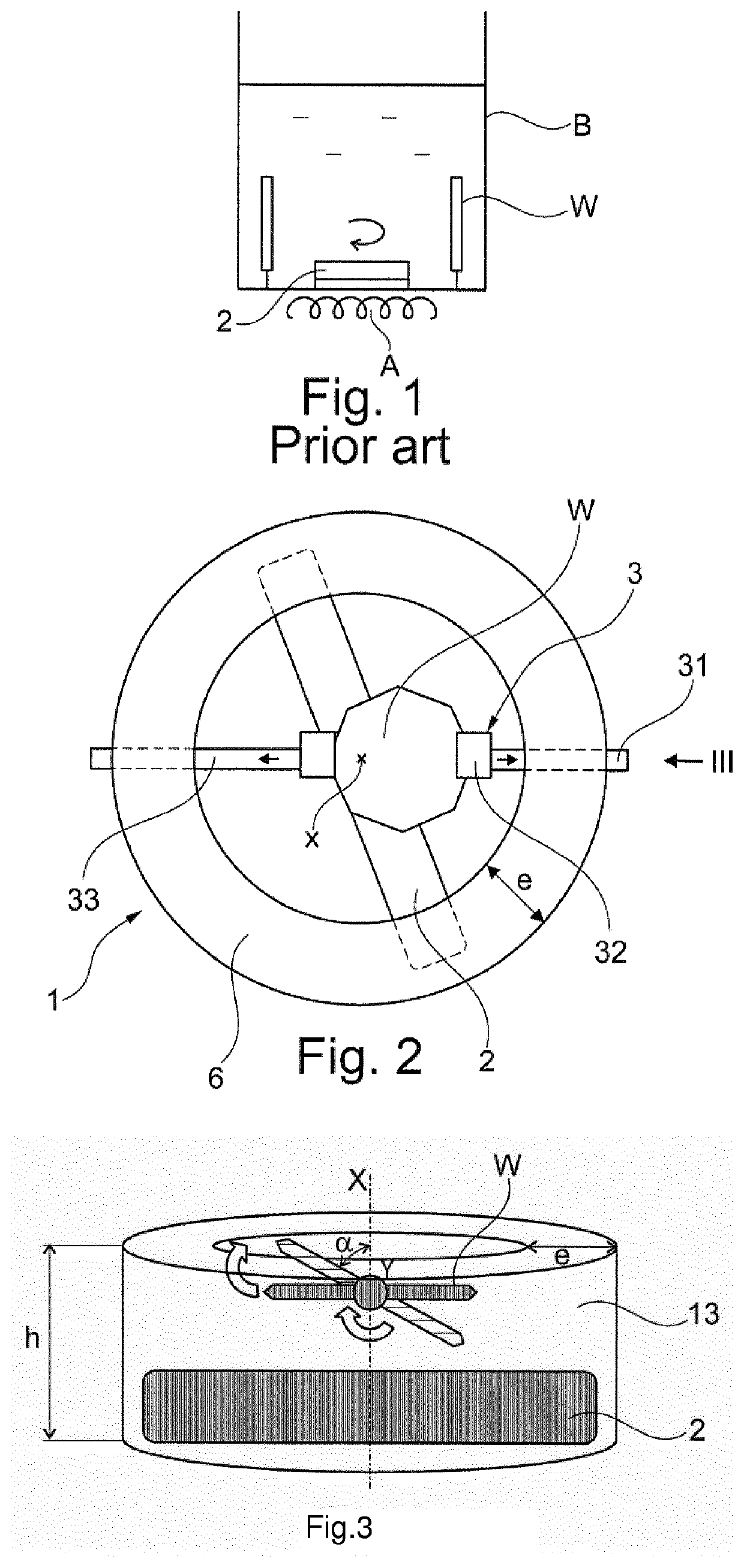

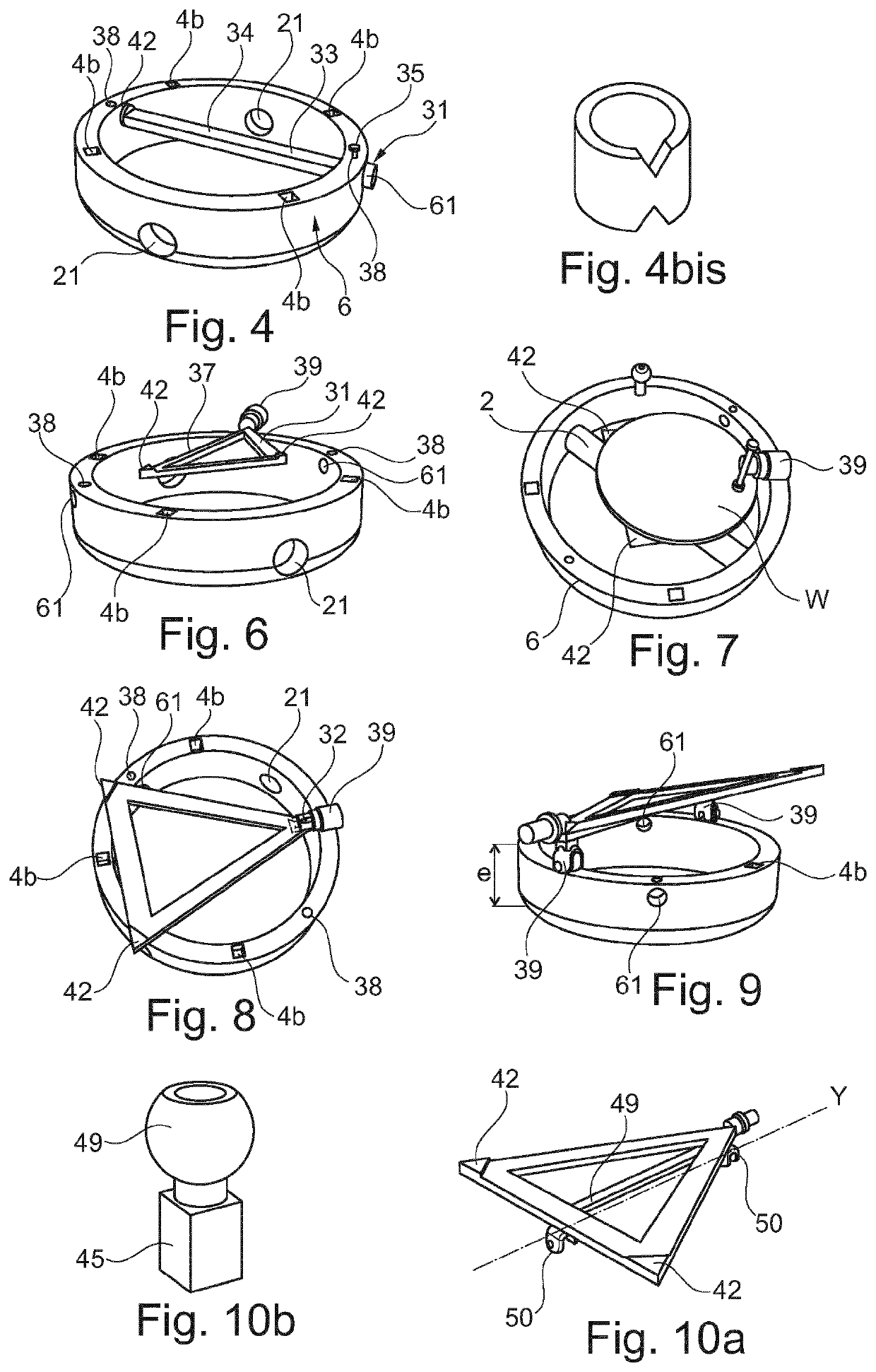

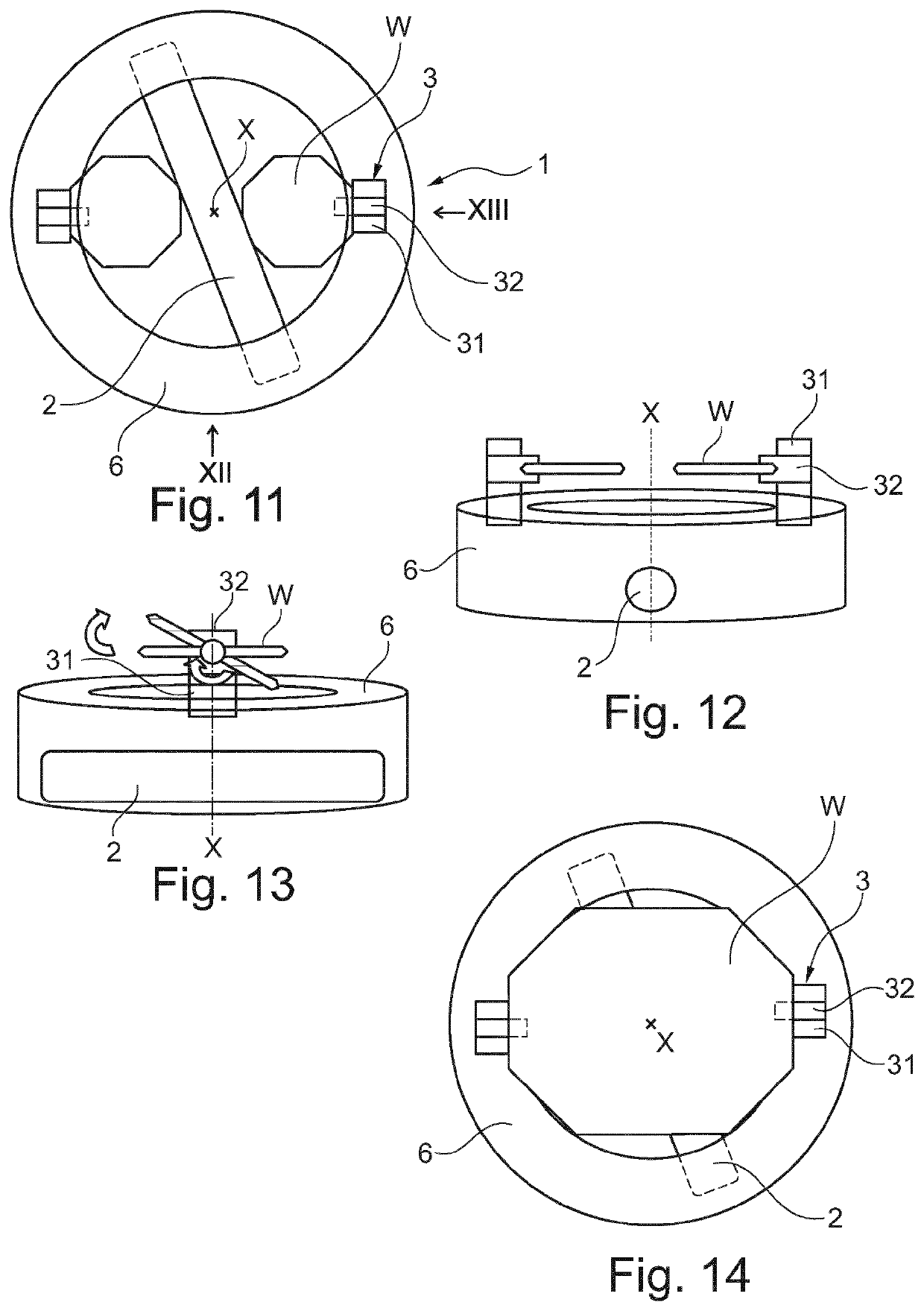

Method and apparatus for etching a substrate

InactiveUS20190359482A1Quality improvementDecorative surface effectsSemiconductor/solid-state device manufacturingMagnetic stirrerPhotolithography

Owner:INST NAT DE LA SANTE & DE LA RECHERCHE MEDICALE (INSERM) +2

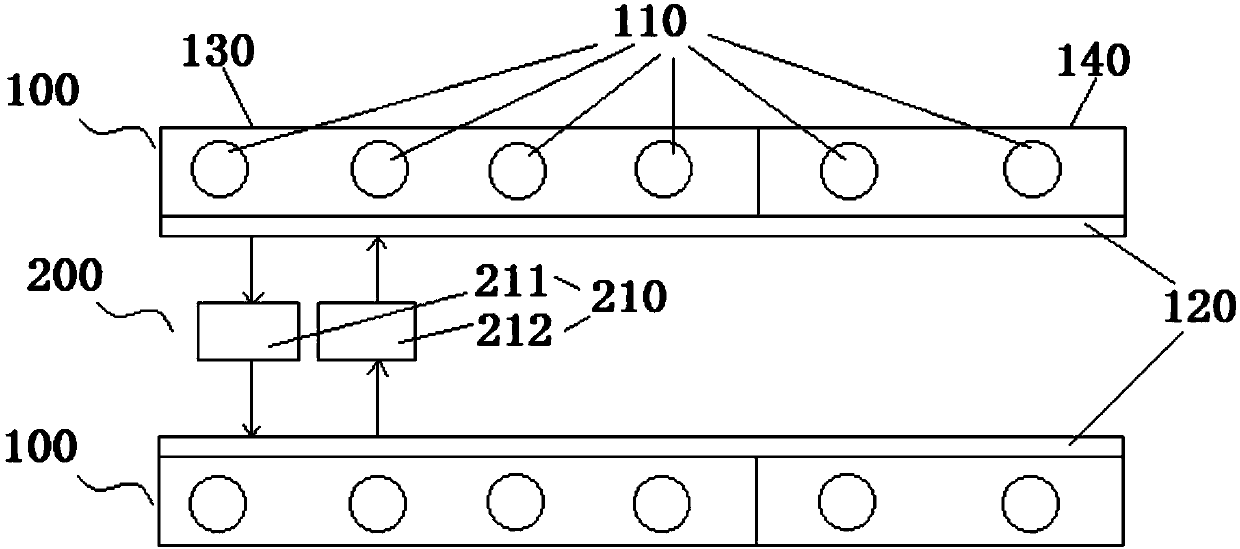

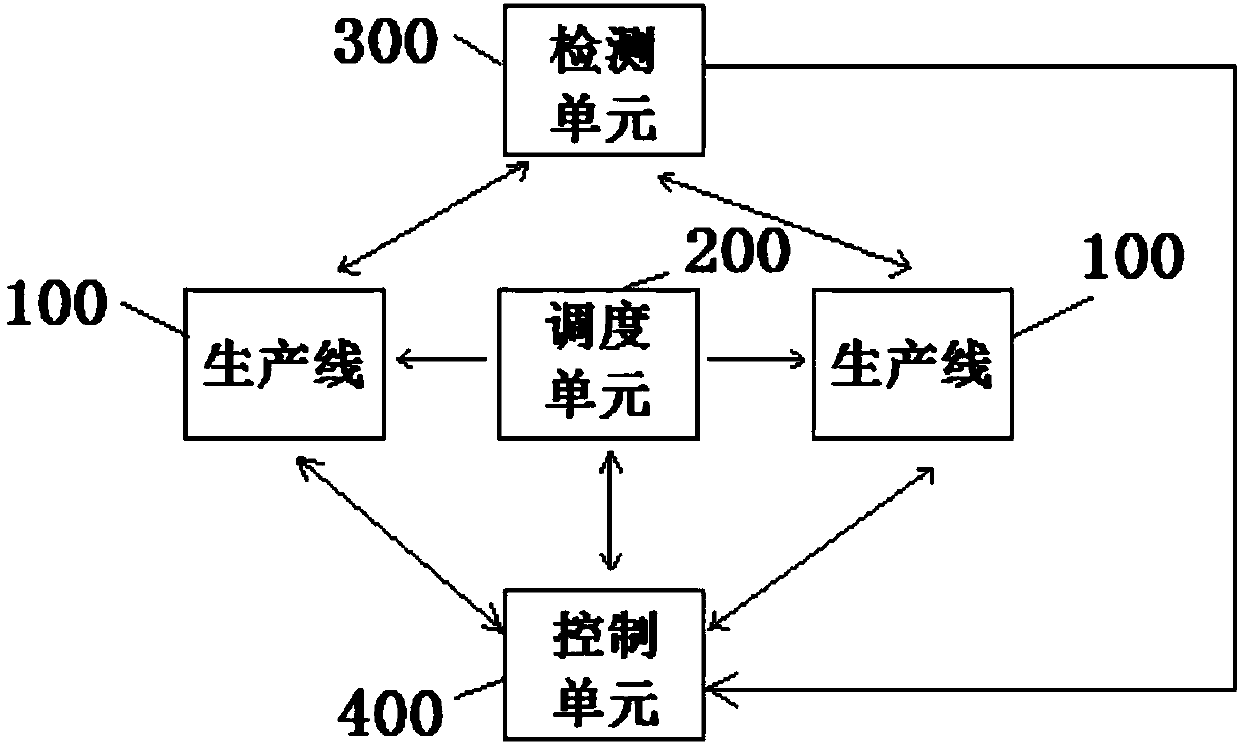

Photoetching system and photoetching method thereof

ActiveCN109976100AImprove fault toleranceAvoid discontinuationPhotomechanical exposure apparatusMicrolithography exposure apparatusProduction lineControl signal

Owner:CHANGXIN MEMORY TECH INC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap