Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Textile industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The textile industry is primarily concerned with the design, production and distribution of yarn, cloth and clothing. The raw material may be natural, or synthetic using products of the chemical industry.

Vinyl acetate-ethylene copolymer emulsion as electrostatic spinning adhesive and synthesis method thereof

ActiveCN102030857AGood adhesionImprove water resistanceMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsCross-linkPolymer science

The invention relates to a vinyl acetate-ethylene copolymer emulsion as an electrostatic spinning adhesive and a synthesis method thereof. Organic peroxides and zinc formaldehyde sulfate are taken as an initiator; vinyl acetate, ethylene, acrylic ester monomers and cross-linking monomer N-hydroxymethyl acrylamide are taken as comonomers; a nonionic emulsifier, and the synthetic emulsion and the protective colloid of an amphoteric emulsifier are matched to be taken as an emulsification system; and the copolymer emulsion is prepared through emulsion polymerization. Compared with the VAE (vinyl acetate-ethylene) emulsion prepared by the conventional preparation method, the product in the invention has the advantages of good water resistance, strong adhesion on low-surface-energy materials (polyethylene, polypropylene and the like), fine grain and the like. The vinyl acetate-ethylene copolymer emulsion is suitable for being as the adhesive to be applied to the field of the electrostatic spinning in textile industry and the fields of waterproofing and packaging.

Owner:CHINA PETROCHEMICAL CORP +1

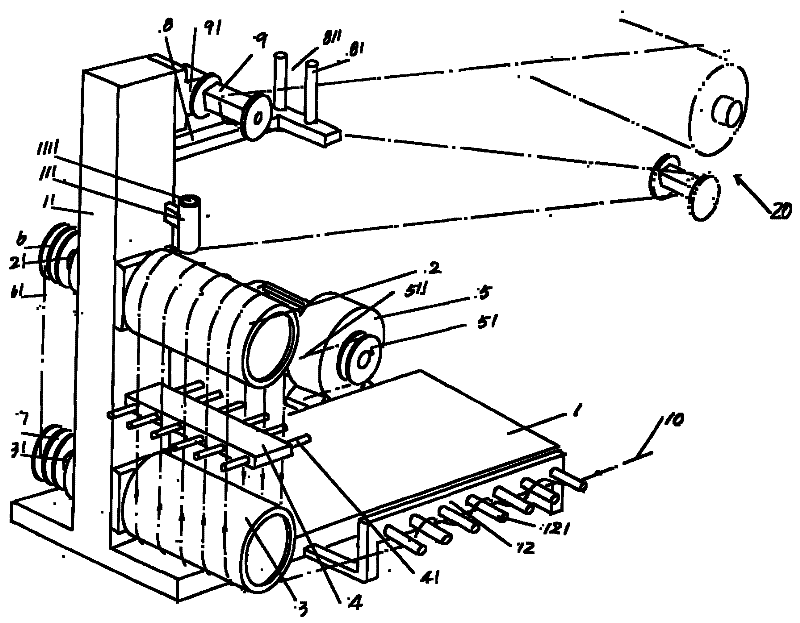

Yarn separating mechanism for yarn separating machine

Owner:常熟市荣伟纺织有限公司

Non-stick coating layer and coating process thereof

InactiveCN111171682ASmall coefficient of static frictionLower coefficient of dynamic frictionPretreated surfacesSpecial surfacesPolymer sciencePapermaking

The invention discloses a non-stick coating layer, which is prepared from the following raw materials in parts by weight: 40 to 50 parts of epoxy acrylate, 25 to 32 parts of polyacrylic acid fluorine-containing ester, 25 to 32 parts of poly (vinylidene fluoride-trifluoroethylene), 10 to 15 parts of polytetrafluoroethylene powder, 2.5 to 4 parts of a suspension dispersing agent, 1 to 1.4 parts of aleveling agent and 1.5 to 2 parts of a curing agent. The non-stick coating layer has excellent lubricating performance and excellent non-stick performance, can completely meet the use requirements ofvarious processing molds (such as various plastic demolding, baking molds and papermaking and textile industries), contains no demolding agent (the production efficiency can be improved), and has excellent durability; in addition, no silicone oil is contained, and the product is prevented from being polluted; the adhesive force with a base material is large, the loading capacity is large, the impact resistance is good, the flexibility is good, the comprehensive performance is good, and the service life is long.

Owner:CHENGRUN (JIAXING) NEW MATERIAL TECH CO LTD

Improved hank reeling machine

InactiveCN107164861AIncrease stranding efficiencyOther manufacturing equipments/toolsTextiles and paperYarnStructural engineering

The invention provides an improved hank reeling machine, belongs to the technical field of textile industries, and solves the problem on improvement of the hank reeling efficiency in the prior art. The improved hank reeling machine comprises a base and a rack fixed on the base, wherein a hank reeling mechanism capable of reeling yarn into a hank is arranged on the rack; the hank reeling mechanism comprises a long pipe I and a plurality of frame rods I parallel to the long rod I; the multiple frame rods I are arranged around the long pipe I in a surrounding manner; the hank reeling mechanism further comprises a long pipe II and a plurality of frame rods II parallel to the long pipe II; the multiple frame rods II are arranged around the long pipe II in a surrounding manner; the long pipe I and the long pipe II are arranged on the left and right sides; a driving structure capable of driving the long pipe I and the long pipe II to rotate is arranged between the long pipe I and the long pipe II; and an adjustment structure I capable of adjusting the frame rods I to get close to the long pipe I is arranged between the long pipe I and the frame rods I. The improved hank reeling machine has the advantage of improving the hank reeling efficiency.

Owner:HAINING YONGXIN TECH CONSULTING CO LTD

Nylon enhanced rubber conveyer belt

InactiveCN101879979AExtended service lifeOptimize the process routeConveyorsProduction lineNylon material

Owner:XIANGFAN ABSB AUTOMOBILE ABSORBER

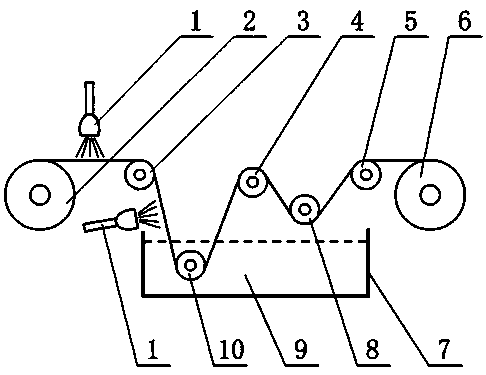

Cloth dyeing and drying device

InactiveCN111286891AReduce labor intensityImprove work efficiencyLiquid/gas/vapor removalLiquid/gas/vapor textile treatmentPolymer scienceEngineering

Owner:WENDENG JINXIU DRAWNWORK

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap