Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

19 results about "Calcium hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium hydroxide (traditionally called slaked lime) is an inorganic compound with the chemical formula Ca(OH)₂. It is a colorless crystal or white powder and is produced when quicklime (calcium oxide) is mixed, or slaked with water. It has many names including hydrated lime, caustic lime, builders' lime, slack lime, cal, or pickling lime. Calcium hydroxide is used in many applications, including food preparation, where it has been identified as E number E526. Limewater is the common name for a saturated solution of calcium hydroxide.

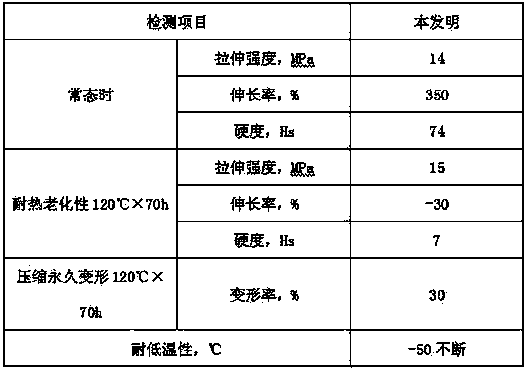

Rubber compositions for oil seal of rubber framework and method for manufacturing same

Owner:青岛茂林橡胶制品有限公司

Alkali metal ion source with moderate rate of ion release and methods of forming

ActiveUS20140345348A1Inhibition formationSafely raisedCalcareous fertilisersMagnesium fertilisersCalcium hydroxideAlkaline earth metal

An alkali metal ion source with a moderate rate of release of the ion (e.g. potassium) is formed by a method that includes: 1) combining an particulate ore that contains at least one of an alkali metal ion-bearing framework silicate (e.g. syenite ore) with at least one of an oxide and hydroxide of at least one of an alkali metal and alkaline earth metal such as calcium hydroxide; 2) milling the mixture of these two components optionally, with water, optionally, milling the dry components separately and blended thereafter, optionally, with water; 3) forming a mixture by adding water to the solid mixture after milling, if water was not added before milling; 4) exposing the mixture to an elevated temperature and pressure to form a gel that includes silica and the alkali metal of the framework silicate.

Owner:MASSACHUSETTS INST OF TECH

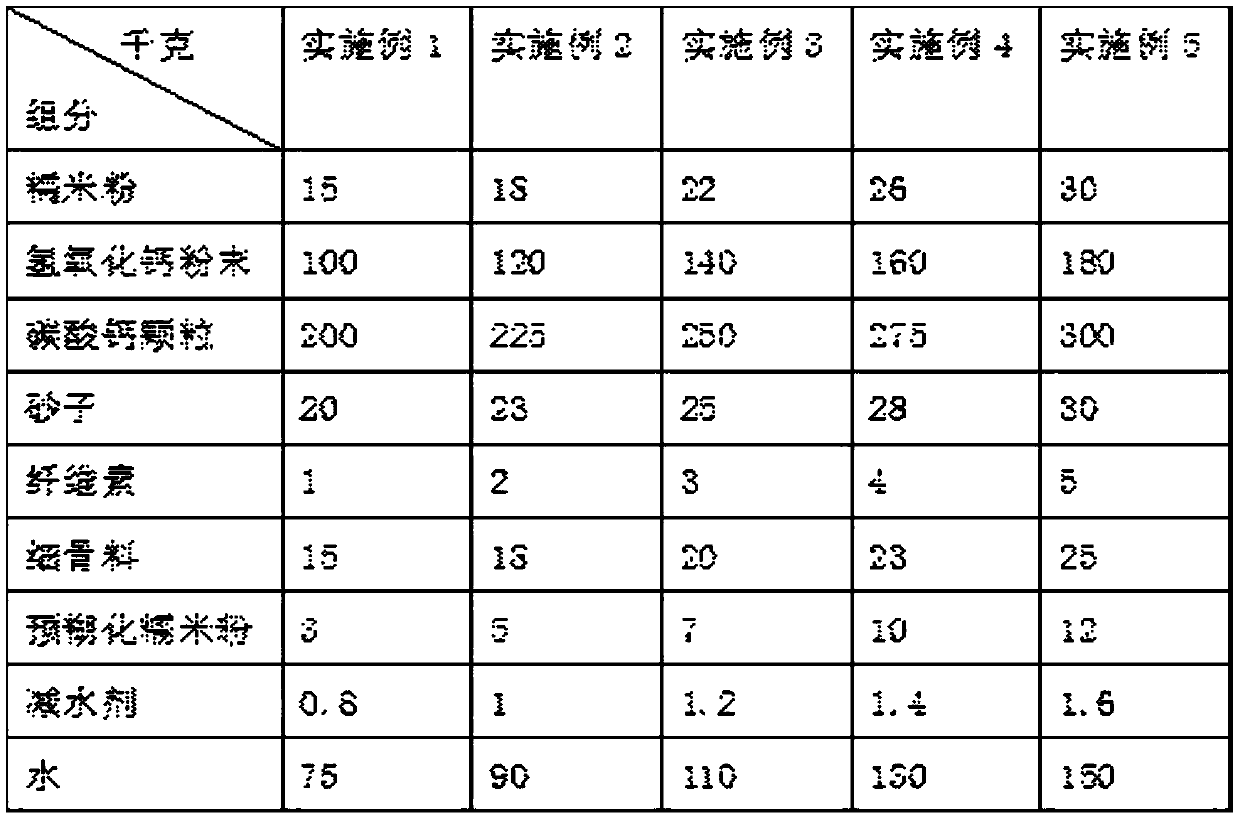

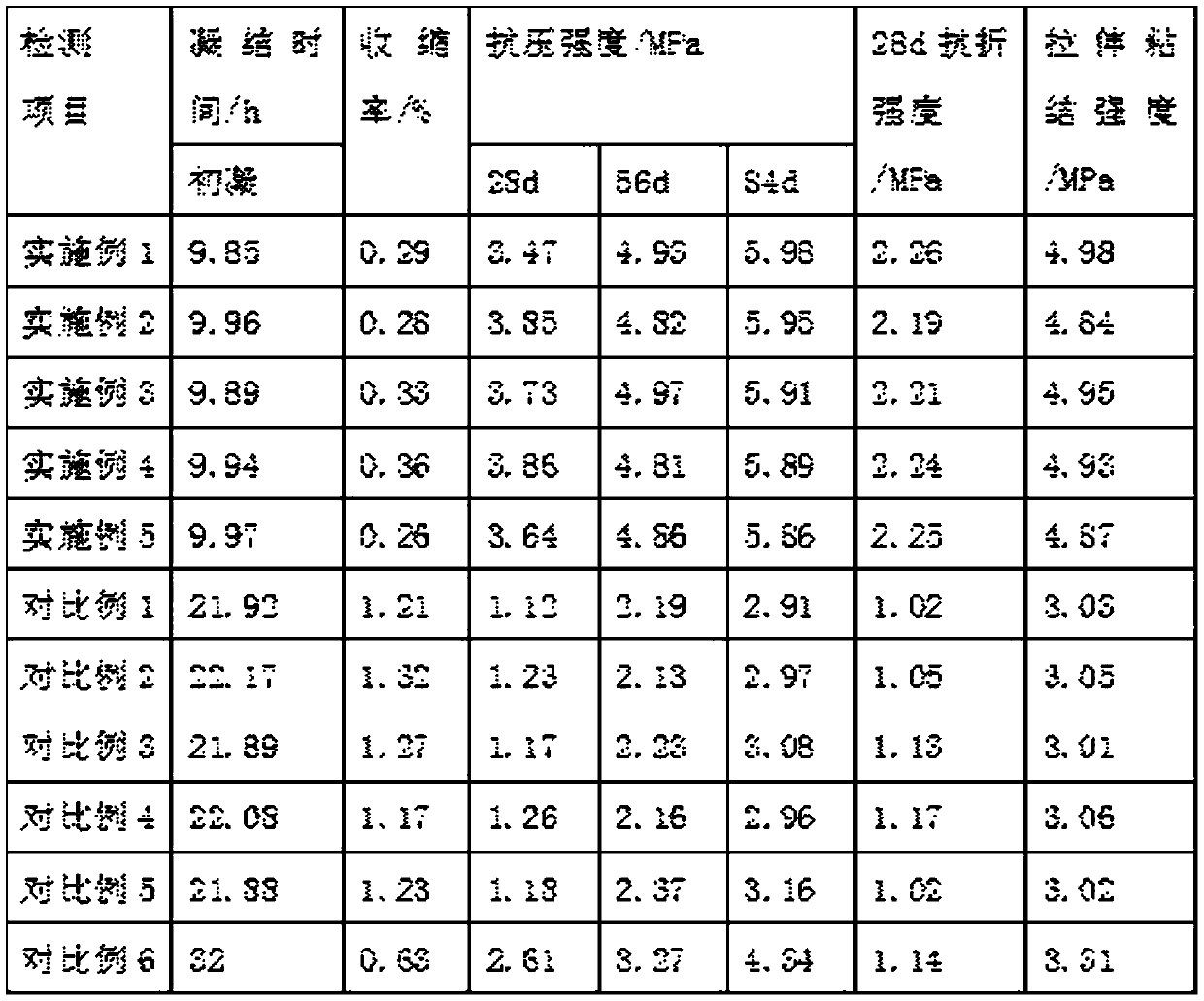

Sticky-rice mortar and preparation method thereof

Owner:中兴文建工程集团有限公司

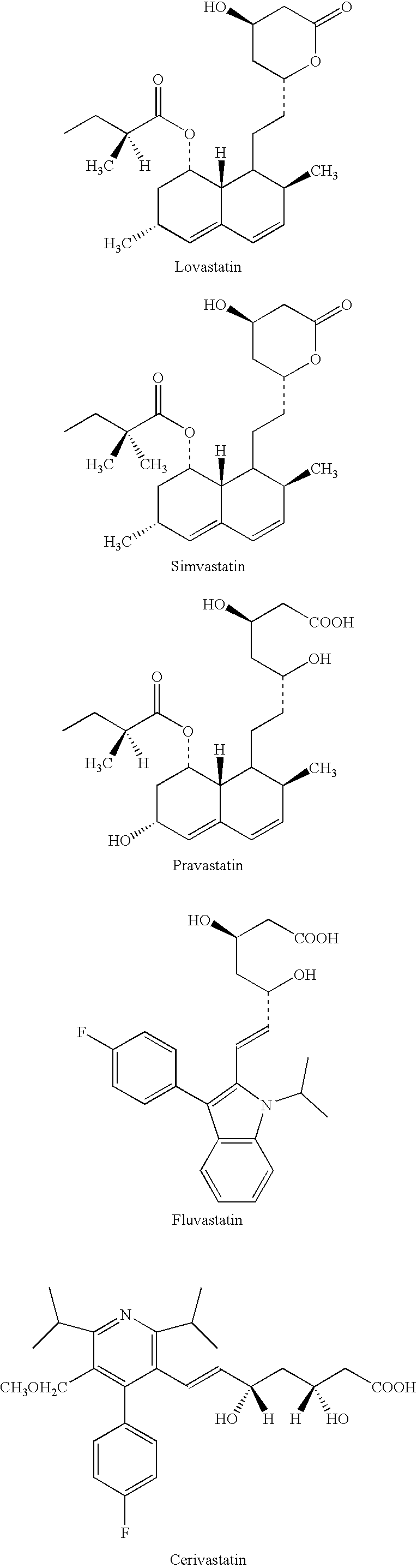

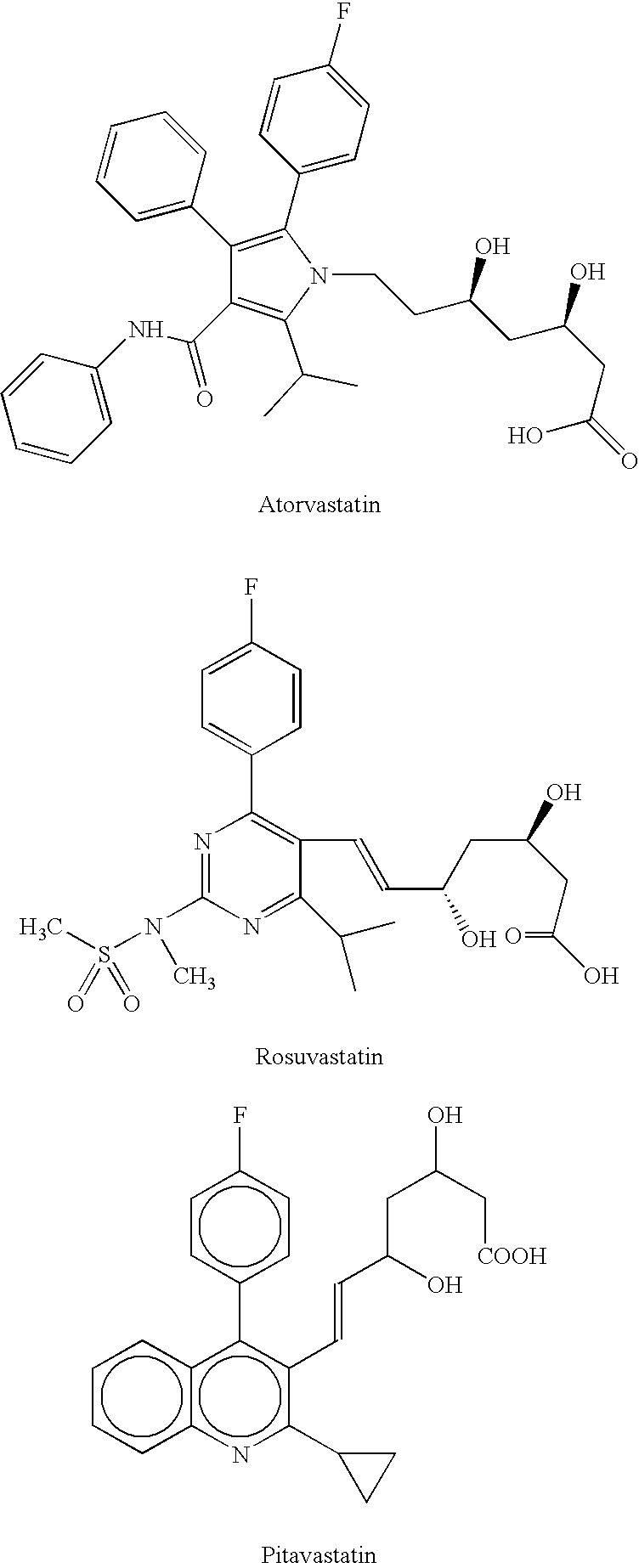

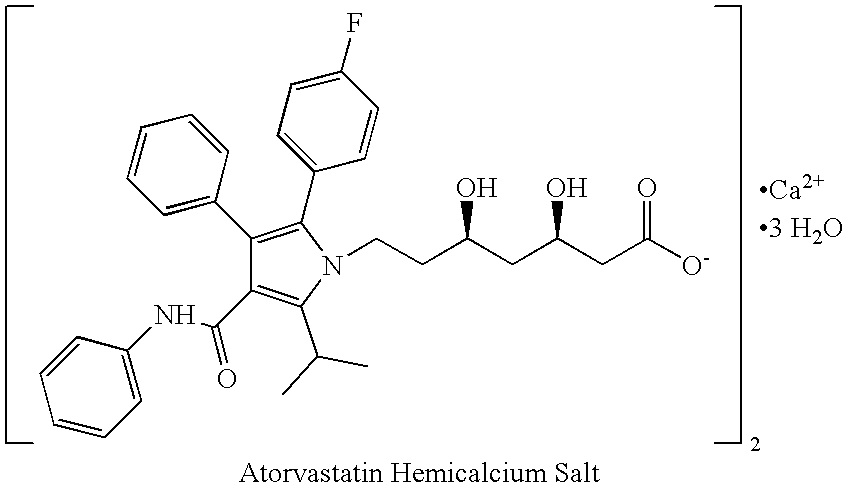

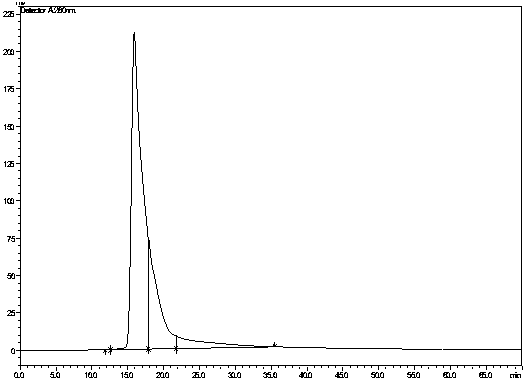

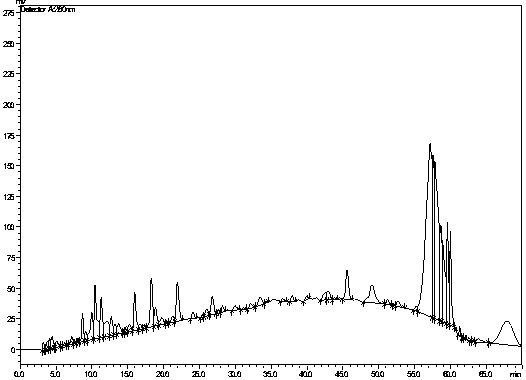

Processes for preparing calcium salt forms of statins

Owner:TEVA PHARMA IND LTD +1

Rubber tube and preparation method thereof

ActiveCN104072973AImprove high temperature resistanceImprove low temperature resistancePolymer scienceAntimony trioxide

Owner:LIUZHOU YINGHANG AUTO PARTS

Method for chemical degradation of polymer procyanidins by using lithium hydroxide

Owner:HARBIN INST OF TECH AT WEIHAI

Bleaching and dyeing sewage treatment water purification agent

InactiveCN101177316ALow costSave waterWater/sewage treatment by flocculation/precipitationCalcium hydroxideAcid water

Owner:梁代福 +1

Anti-corrosion acrylic acid epoxy resin powder paint for ceramic

ActiveCN104312235AWidely producedAnti-corrosive paintsPowdery paintsGlycidyl methacrylateDi-tert-butyl peroxide

Owner:SWANCOR JIANGSU NEW MATERIALS CO LTD

Mixed flocculating agent

InactiveCN102398981AReasonable formulaEasy to useWater/sewage treatment by flocculation/precipitationCalcium hydroxideChloride

Owner:苏晨曦

Soil improver and preparation method thereof

InactiveCN106010568AAlleviating povertyRaw materials are readily availableAgriculture tools and machinesOrganic fertilisersCalcium hydroxidePhosphate

Owner:覃福建

Preparation method of cobalt oxide coated nickel hydroxide composite material for alkaline rechargeable battery

InactiveCN108091845AHigh specific capacityExtended service lifeCell electrodesNickel accumulatorsAlkaline waterCalcium hydroxide

The invention discloses a preparation method of a cobalt oxide coated nickel hydroxide composite material for an alkaline rechargeable battery. The preparation method comprises the following steps: (1) preparing nickel chloride, cobalt sulfate and yttrium sulfate into nickel cobalt yttrium saline solution and injecting a potassium hydroxide solution and an ammonium hydroxide complexing agent intoa reaction kettle to perform chemical precipitation to obtain a yttrium doped spherical nickel hydroxide precursor; (2) weighing the defined amount of yttrium doped spherical nickel hydroxide precursor, putting into a sealed oxidizing reactor and inflating O2 to perform oxidization; (3) adding a Mg(OH)2 alkaline water solution into the oxidizing reactor after reaction finishes to perform thermal-insulation treatment. According to the alkaline rechargeable battery spherical nickel hydroxide material prepared by the preparation method disclosed by the invention, electrical conductivity and cycling stability of spherical nickel hydroxide are greatly improved; when the spherical nickel hydroxide material is applied to the alkaline rechargeable battery, the battery has the advantages of high specific capacity and longer service life.

Owner:NINGBO HIGH TECH ZONE JINZHONG INFORMATION TECH CO LTD

Powder coating

InactiveCN107418394AHigh hardnessWipe resistantPowdery paintsPolyester coatingsCelluloseCalcium hydroxide

Owner:RUGAO CITY LEHENG CHEM COMPANY

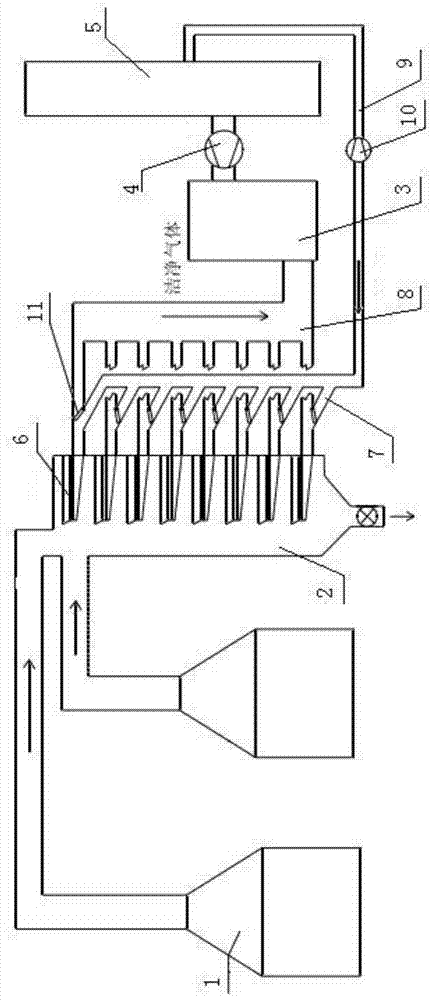

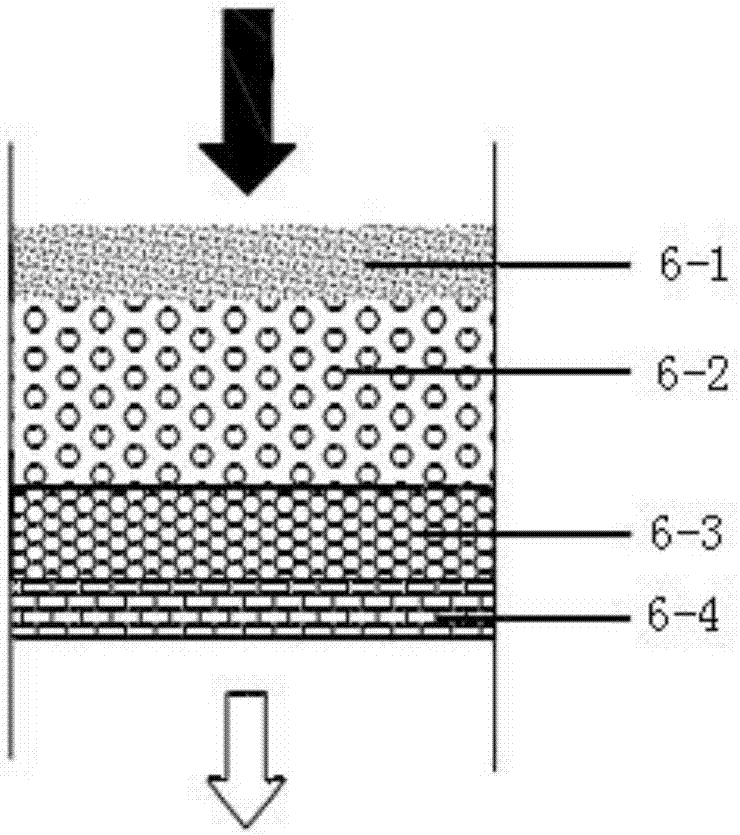

Emission technology of vapor containing nitrogen oxide and tar

ActiveCN108854458AImprove the efficiency of absorbing harmful components in exhaust gasPrevent control failure problems caused by errorsGas treatmentDispersed particle separationAtmospheric airExhaust gas emissions

The invention discloses an emission technology of vapor containing nitrogen oxide and tar. The emission technology comprises the following steps: opening a cutoff valve, a circulating water pump and an exhaust fan, wherein the circulating water pump starts a water circulation process; opening a discharging valve and releasing calcium hydroxide into water in a stepped overflow pool, and opening thedischarging valve when the pH value of the water in the stepped overflow pool is smaller than or equal to 8.0; closing the discharging valve when the pH value of the water in the stepped overflow pool is greater than or equal to 8.7; when an adjustment target is to prevent haze and the temperature of exhaust gas is greater than or equal to 90 DEG C, stopping the temperature-regulating operation;opening the temperature-regulating operation again when the temperature of the exhaust gas is smaller than 80 DEG C; stopping the temperature-regulating operation again when the adjustment target is to prevent thermal pollution and the difference value between the temperature of the exhaust gas and the atmospheric temperature is smaller than 3 DEG C; opening the temperature-regulating operation when the difference value between the temperature of the exhaust gas and the atmospheric temperature is greater than 6 DEG C. The emission technology disclosed by the invention can efficiently remove sulfur dioxide and nitrogen oxide from water, the weak alkalinity of water is maintained on the premise of ensuring safety and the emission temperature of the exhaust gas is correspondingly controlled according to different adjustment targets.

Owner:HENAN SONGYUE CARBON

Aluminum melting furnace flue gas dedusting and desulfurization system

Owner:HEFEI TIANXIANG ENVIROMENT PROJECT

Preparation process and formula of thermal insulation board special for refrigeration house

PendingCN111808381AImprove fire protectionImprove fire and flame retardant performanceCoatingsPolymer scienceThermal insulation

Owner:太仓幕阳节能科技有限公司

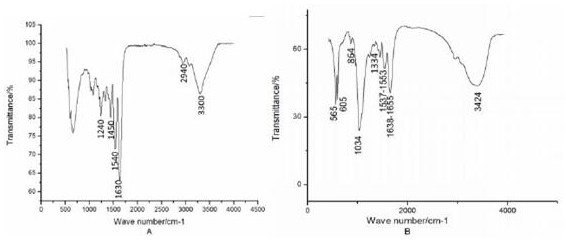

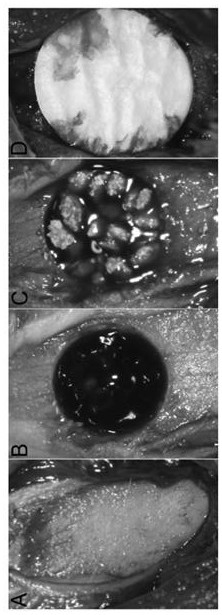

CHA gelatin stent

InactiveCN113521391AHigh mechanical strengthImprove mechanical propertiesTissue regenerationProsthesisCalcium hydroxideO-Phosphoric Acid

Owner:SECOND AFFILIATED HOSPITAL OF COLLEGE OF MEDICINEOF XIAN JIAOTONG UNIV

Environment-friendly architectural moisturizing material

InactiveCN103351814AGood moisturizing effectStrong resistance to combustionLignin material coatingsCalcium hydroxideGlass fiber

Owner:QINGDAO GUOQIANG ENVIRONMENTAL PROTECTION TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap