Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

28 results about "Gear drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Napier's compasses

ActiveCN104527272ANon-circular curve drawing instrumentsCircular curve drawing instrumentsMagnetGear drive

Owner:SUZHOU VOCATIONAL UNIV

Film cutting device

PendingCN107792707AReasonable and stable structureSimple system structureConveyorsArticle deliveryEngineeringGear drive

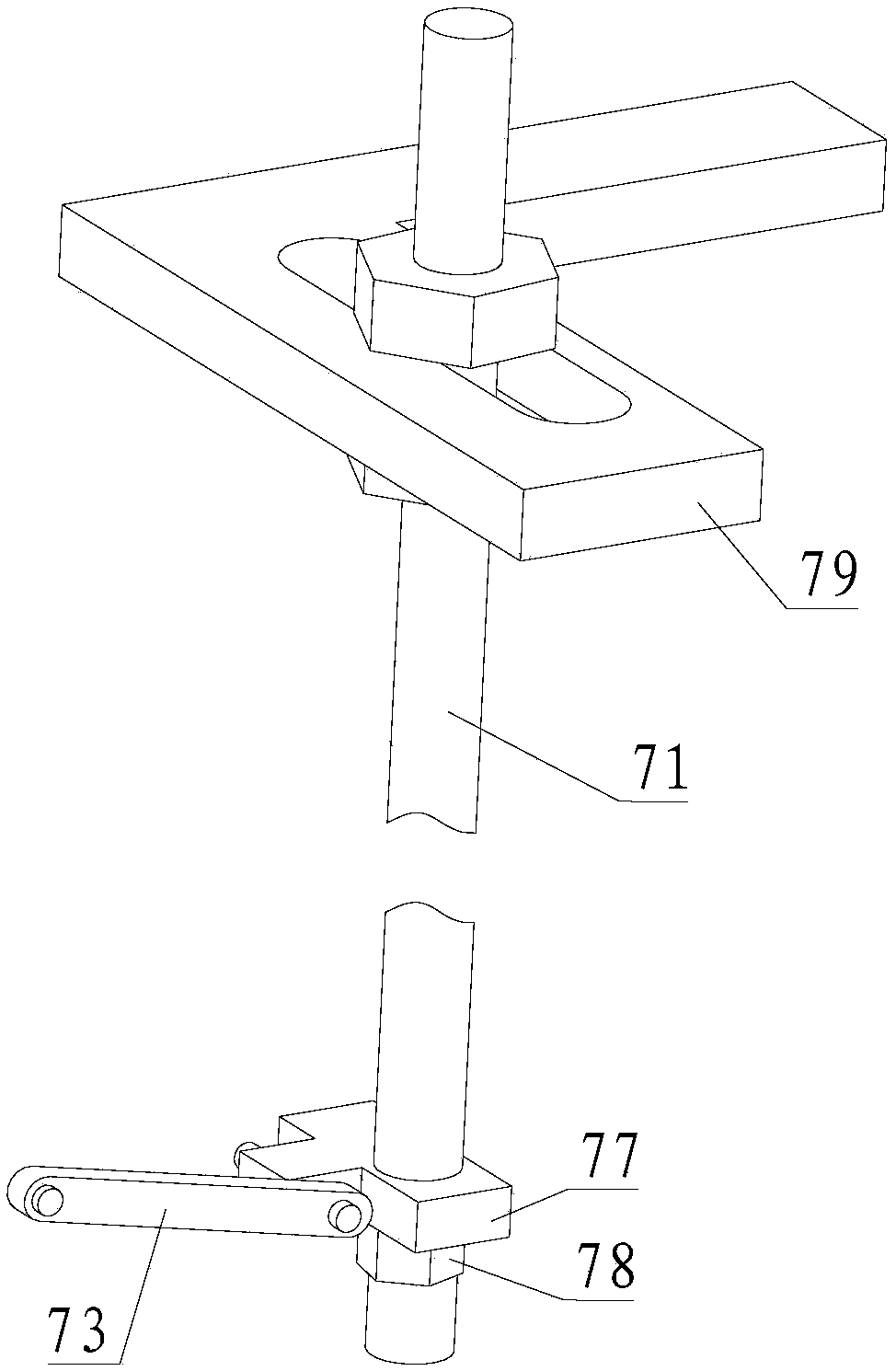

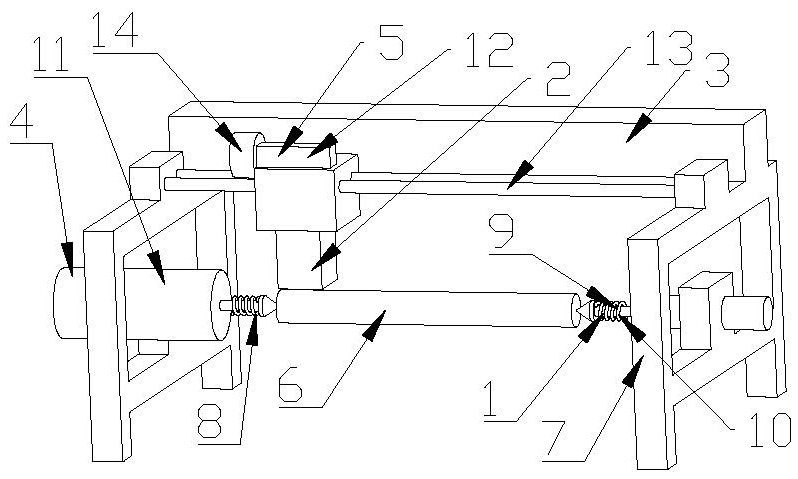

The invention provides a film cutting device comprising a machine frame and a conveyer belt assembly. The conveyer belt assembly comprises a first rolling shaft, a second rolling shaft and a conveyerbelt. The conveyer belt is connected to the first rolling shaft and the second rolling shaft in a sleeving manner. The film cutting device further comprises a motor, a gear transmission assembly, pullrods, a cutter, a connection rod mechanism and a one-way bearing. An output shaft of the motor is connected with the input end of the gear transmission assembly. One end of each pull rod is rotationally connected with the gear transmission assembly in an eccentric manner. The other end of each pull rod is rotationally connected with the upper end of the cutter. The cutter is located above the conveyer belt. The input end of the connection rod mechanism is connected with the upper end of the cutter. The output end is connected with the first rolling shaft through the one-way bearing. The motoris fixed to the machine frame. The motor drives the cutter to move up and down through the gear transmission assembly and the pull rods, the first rolling shaft is driven to conduct intermittent rotation through the connection rod mechanism and the one-way bearing, and the two actions of film cutting and feeding are achieved. The film cutting device is simple in system and saves energy.

Owner:王友炎

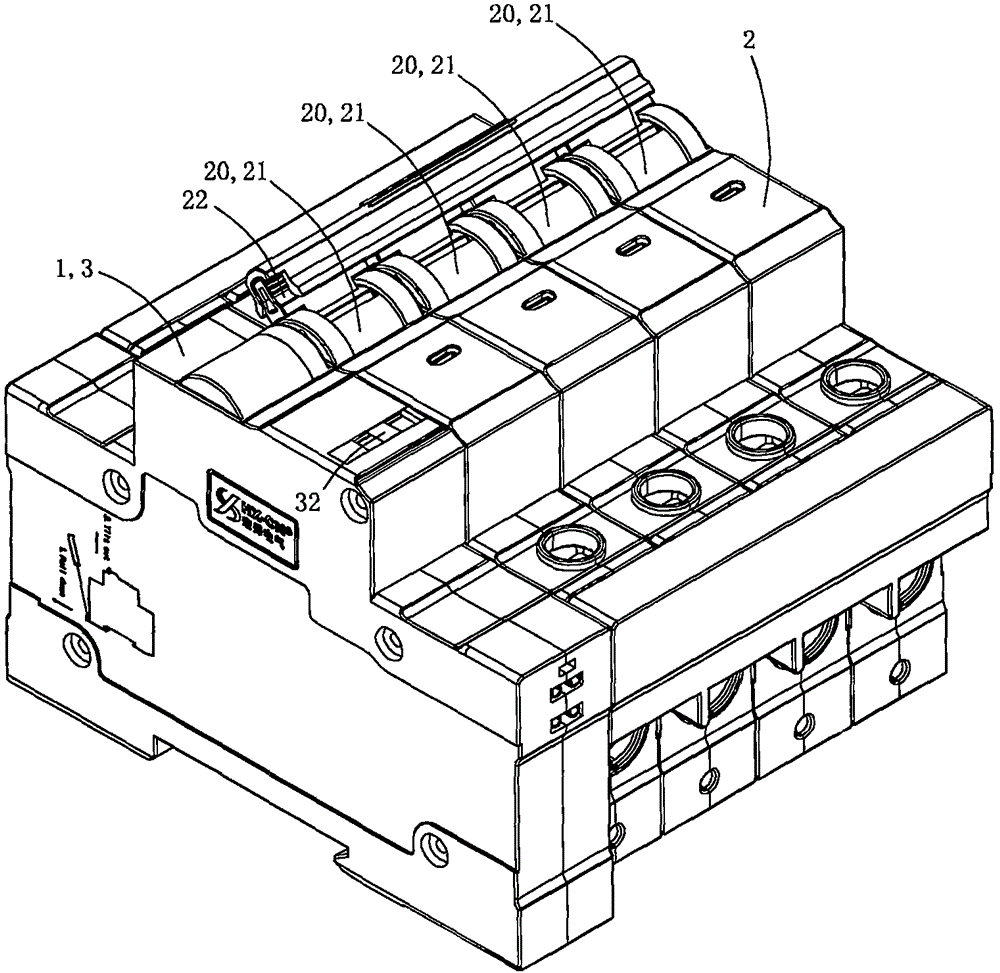

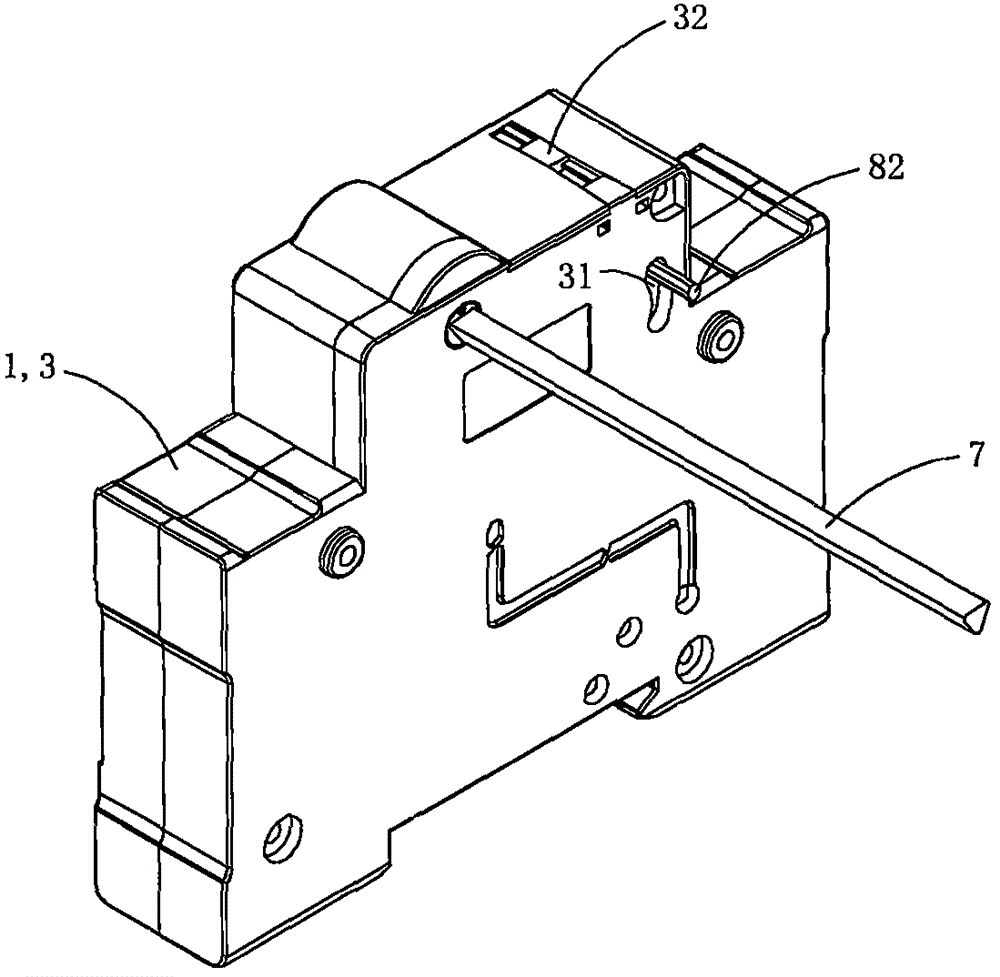

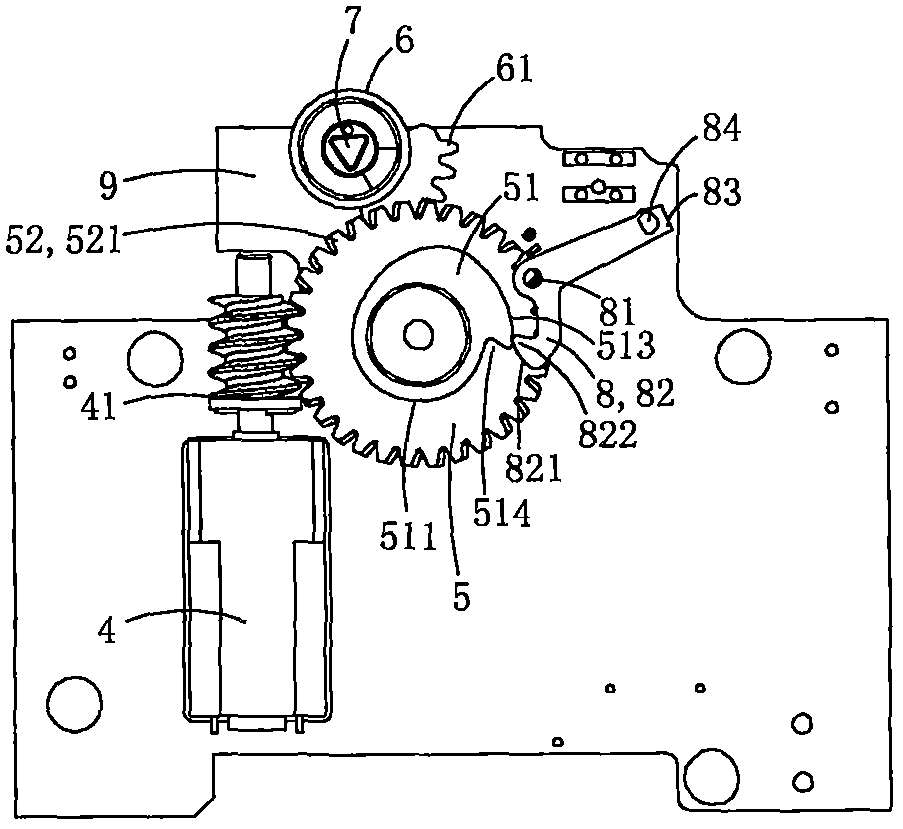

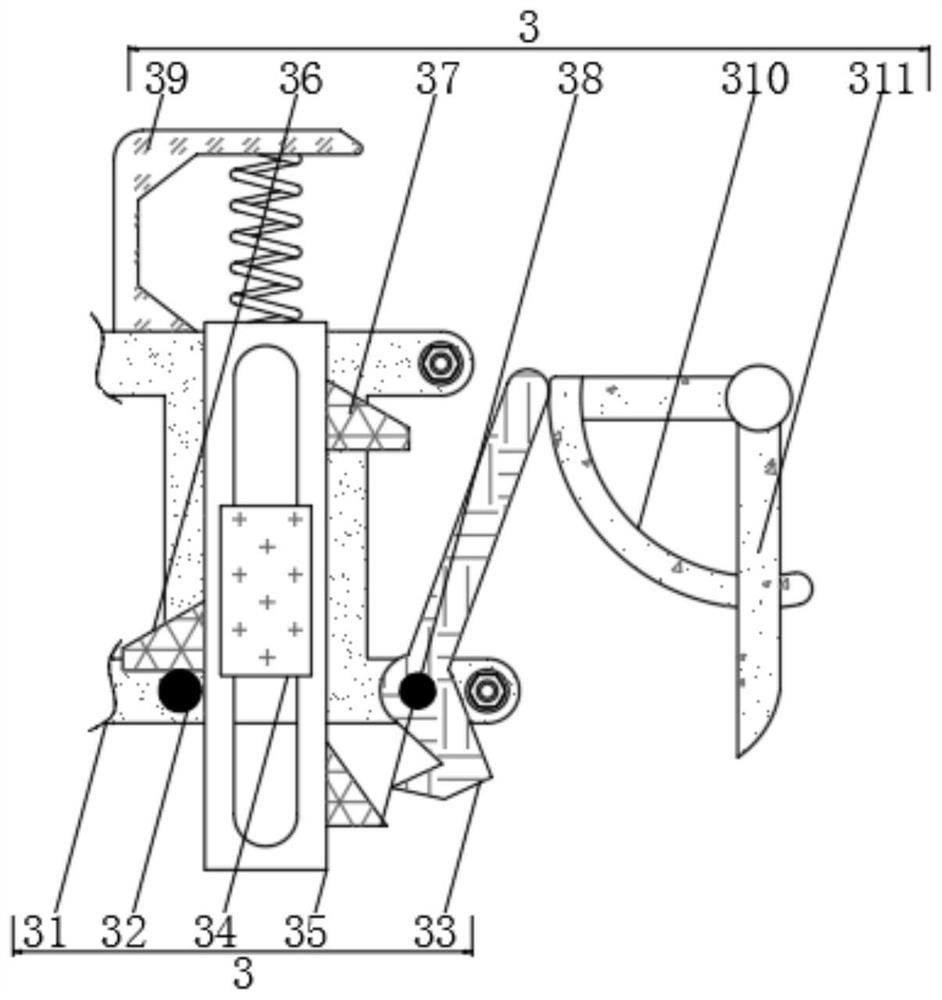

Automatic reclosing circuit breaker

InactiveCN106252172AComplianceSimplify electric controlProtective switch operating/release mechanismsGear driveEngineering

Owner:HONGXIU ELECTRIC

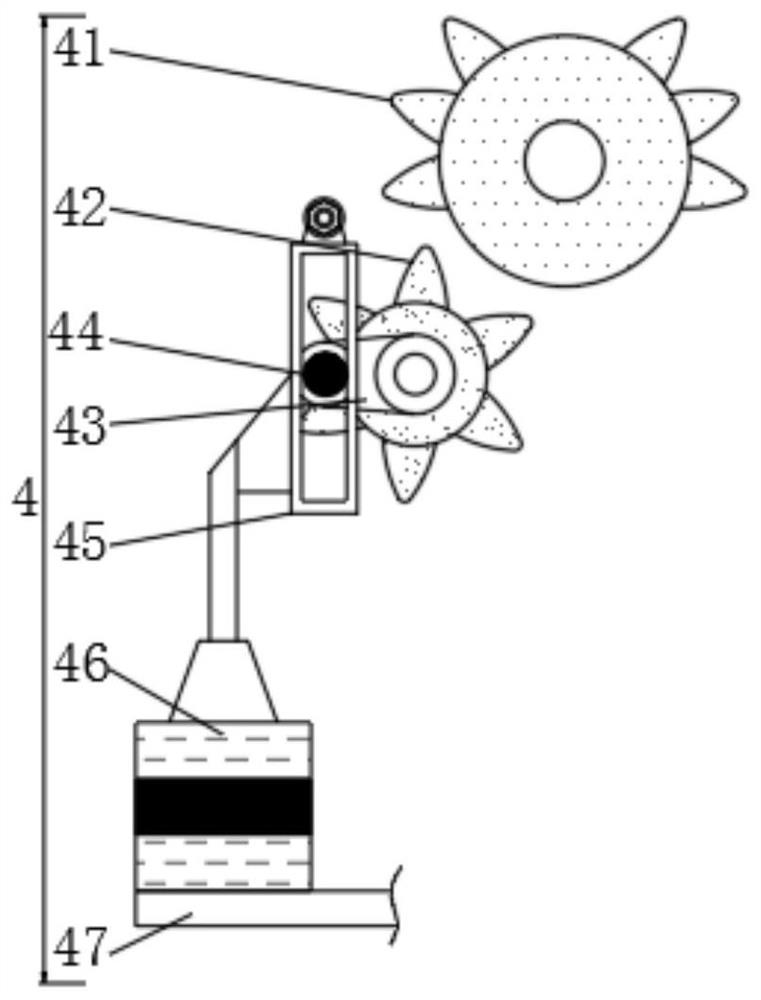

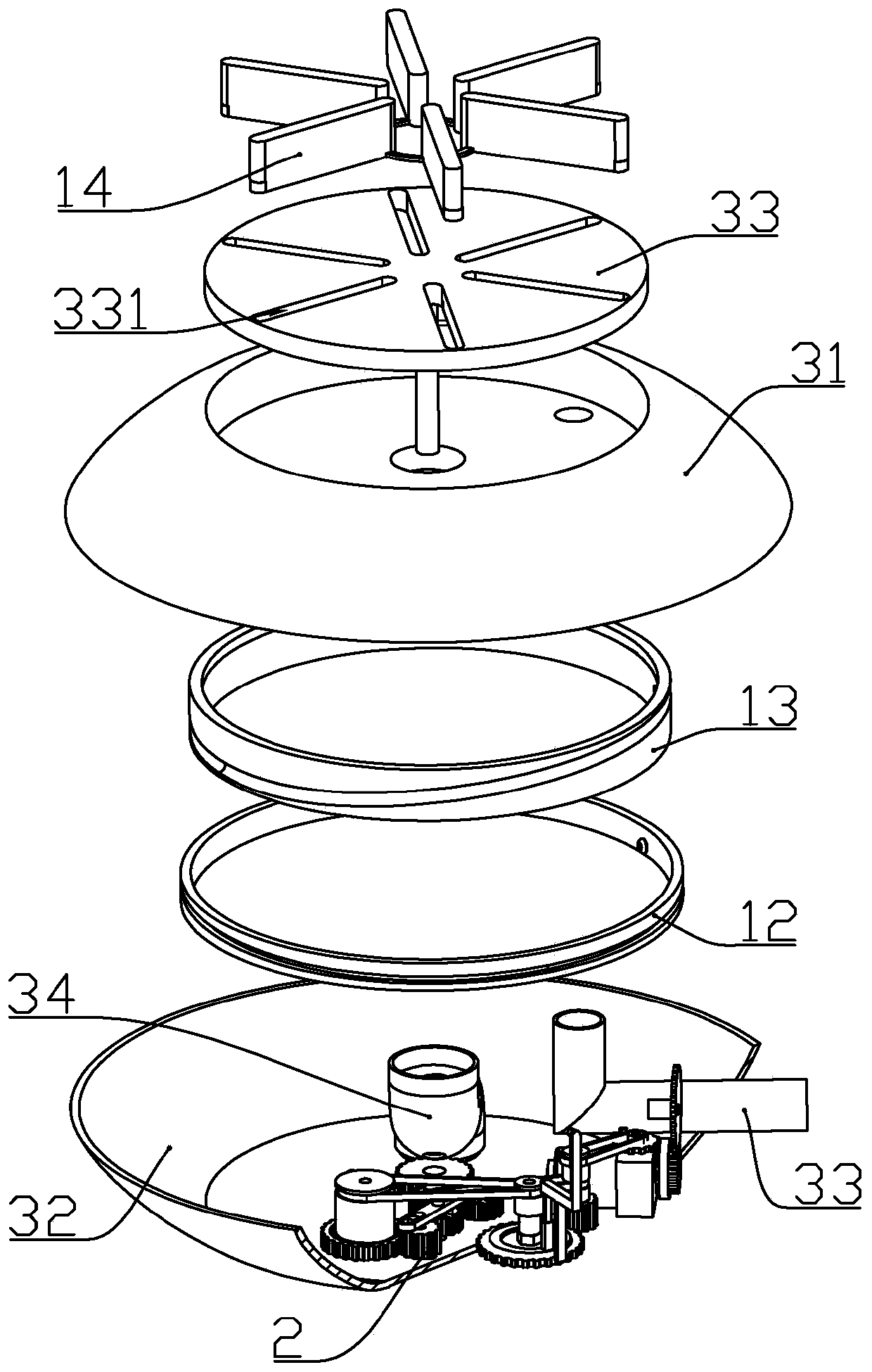

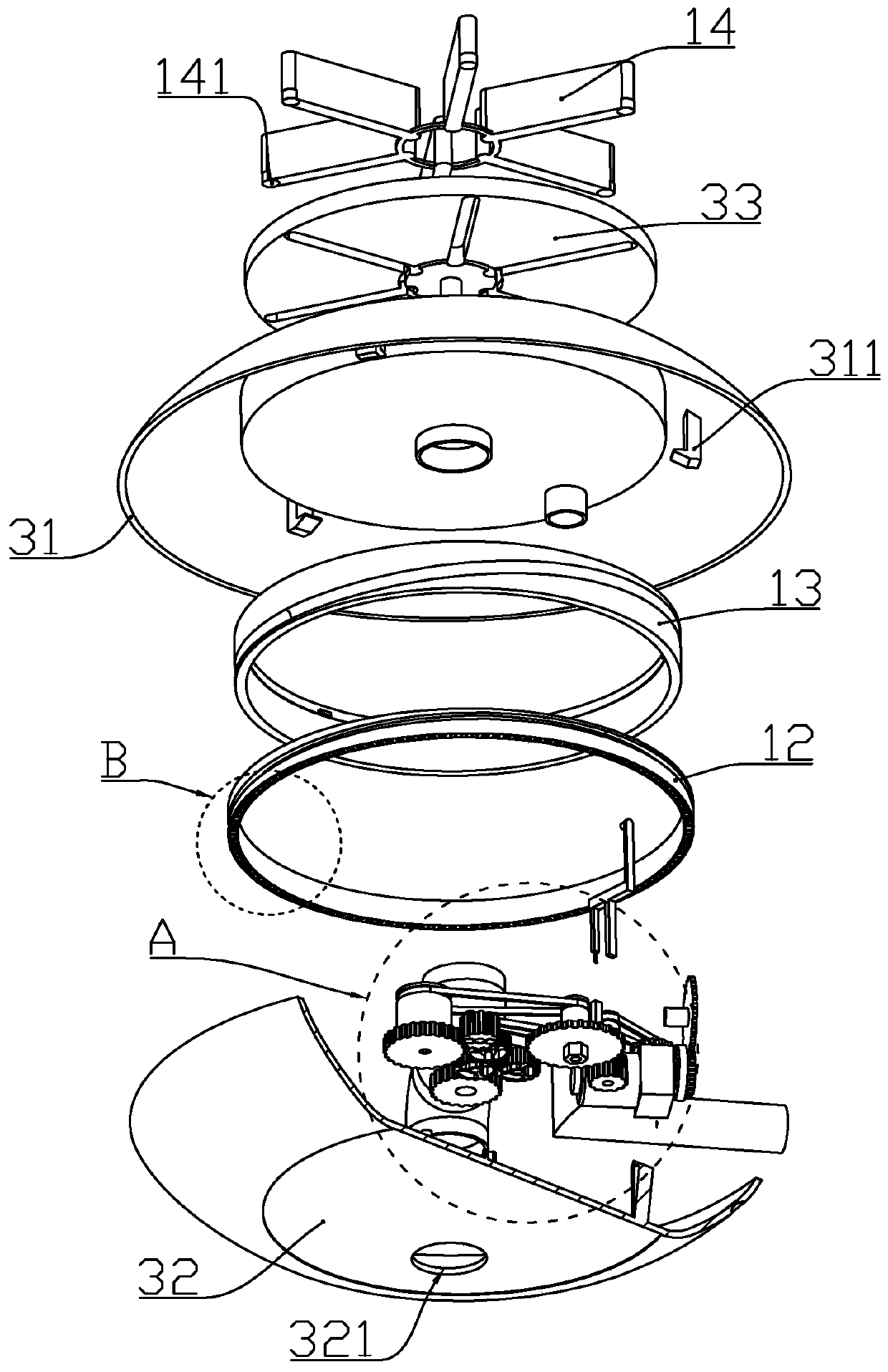

Rotor-type sprinkler with pressure regulator in outer case

ActiveUS20160136662A1Reduce water flowIncrease water flowWatering devicesMovable spraying apparatusGear driveWater source

Owner:HUNTER INDUSTRIES

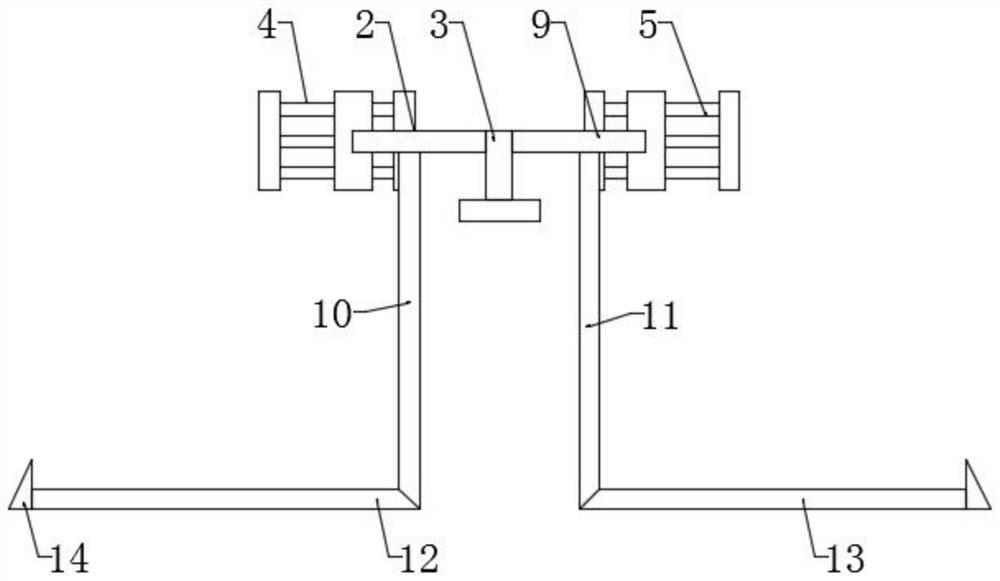

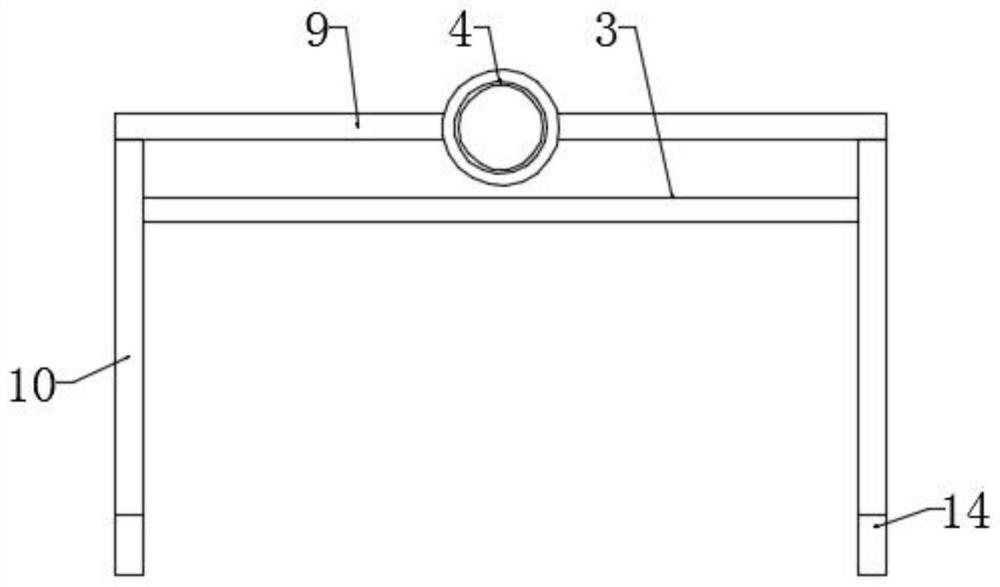

Automatic lifting protective guard used at highway-railway intersection

InactiveCN106956688AGuaranteed normal passageIncrease construction costsTraffic gates operationGear driveSlide plate

Owner:广西云厦建设有限公司

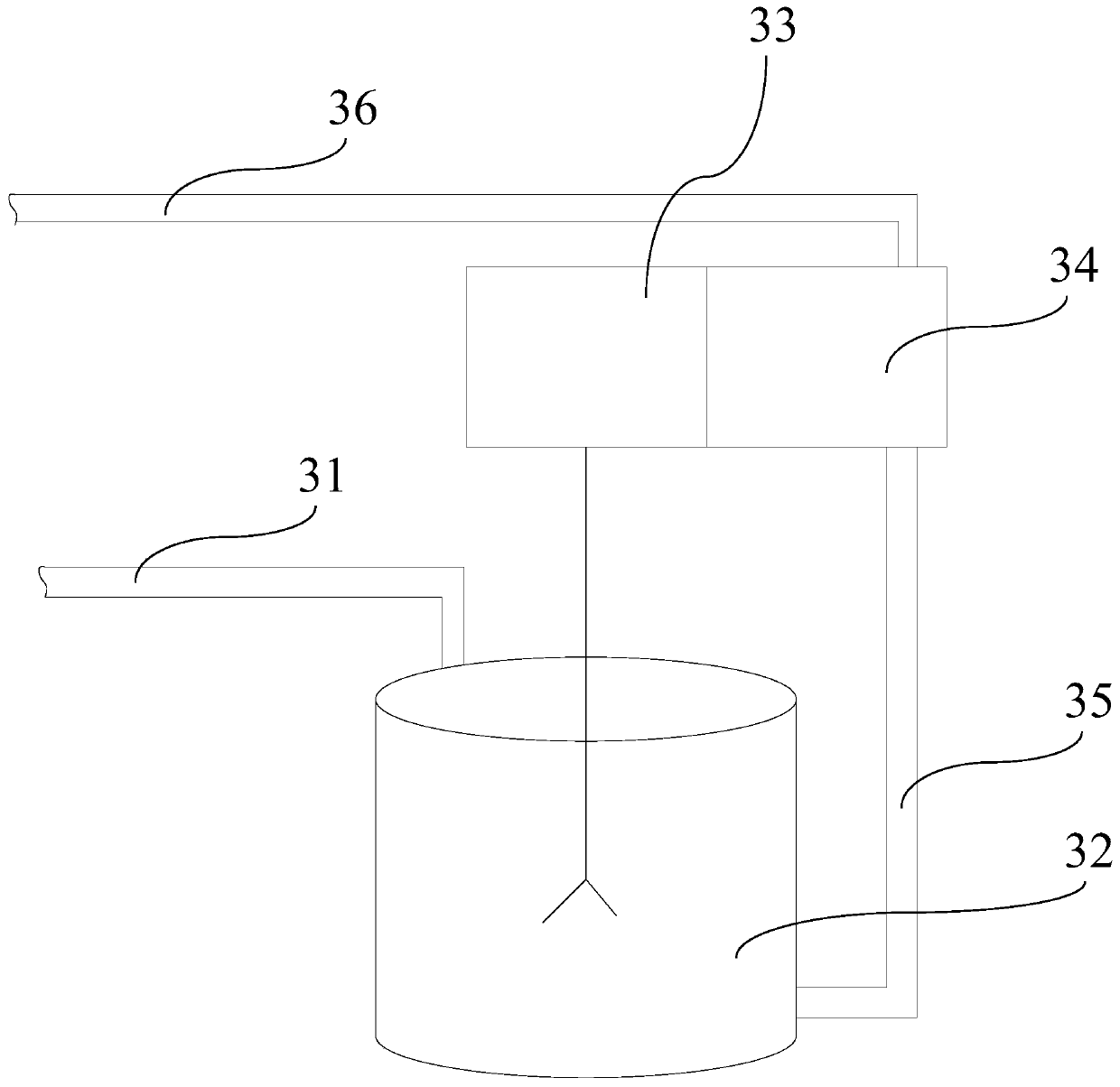

Flood early warning device in polder area

PendingCN110379133AKeep abreast ofImprove stabilityHuman health protectionClosed circuit television systemsGear driveWater flow

Owner:FARMLAND IRRIGATION RES INST CHINESE ACAD OF AGRI SCI

Novel sand making machine

ActiveCN104338577AReduce manufacturing costReduce energy lossGrain treatmentsHydraulic cylinderGear drive

Owner:上海申重矿机科技有限公司

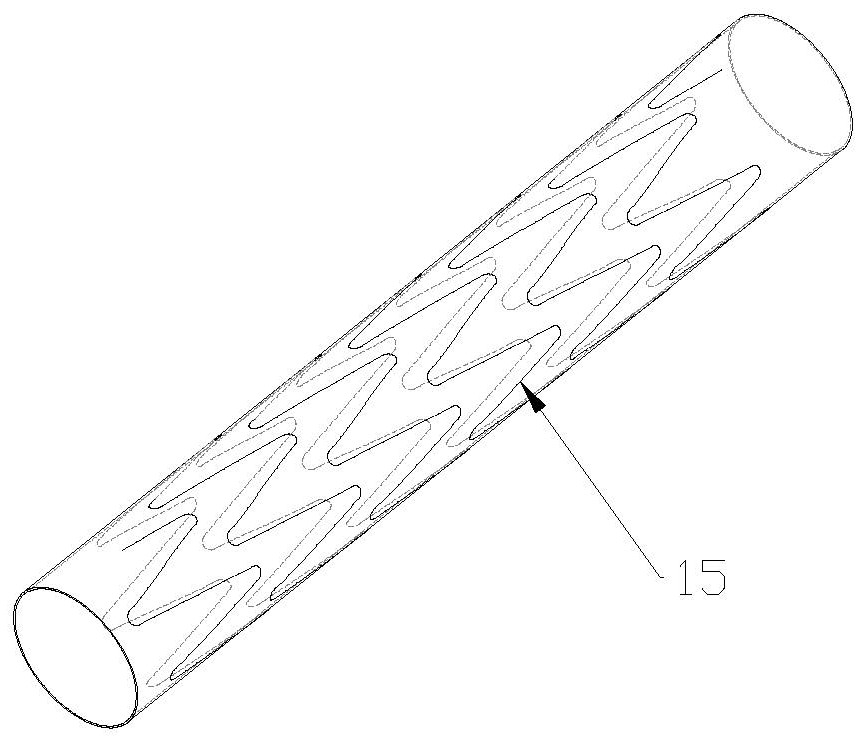

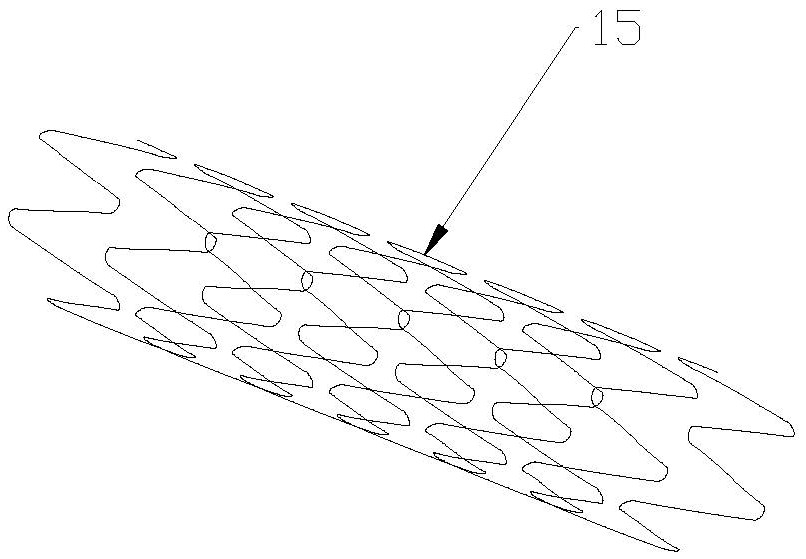

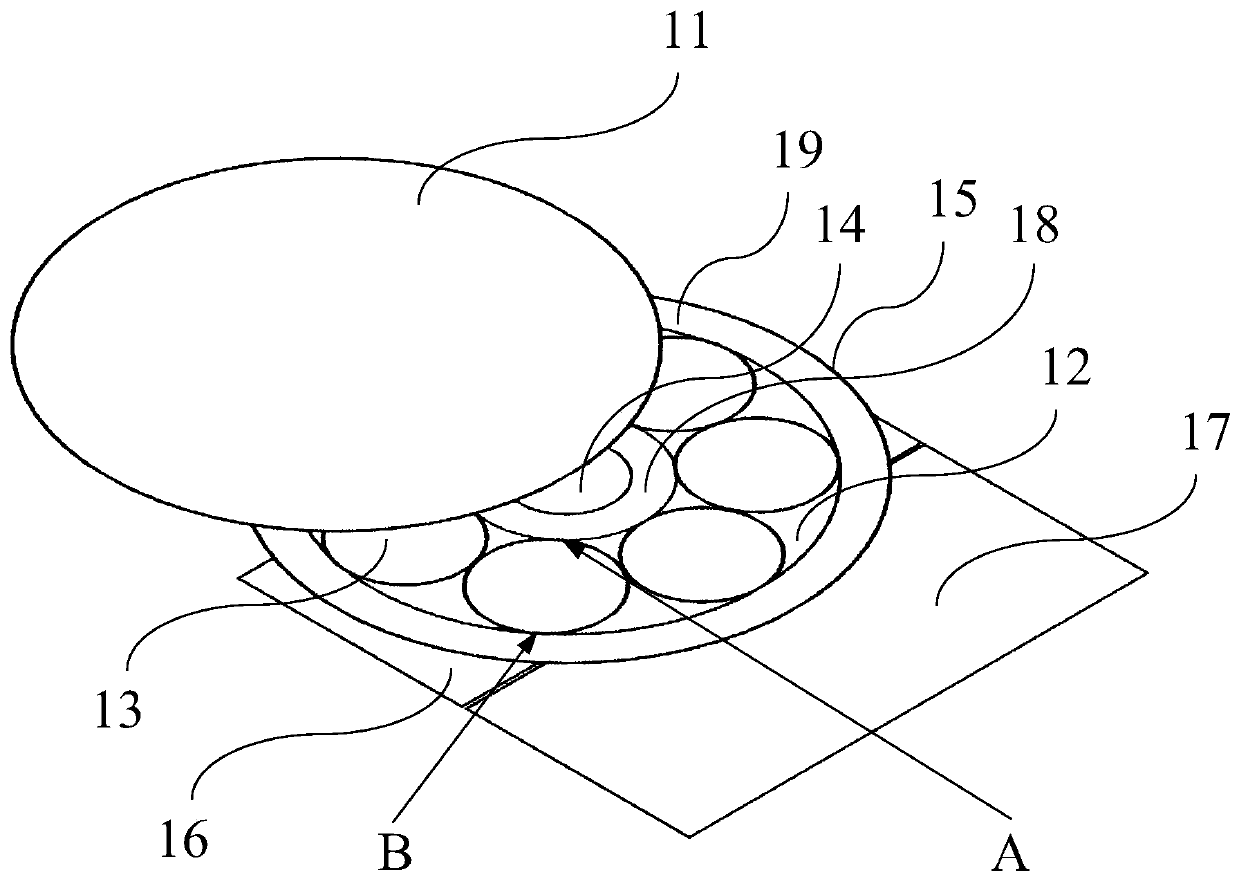

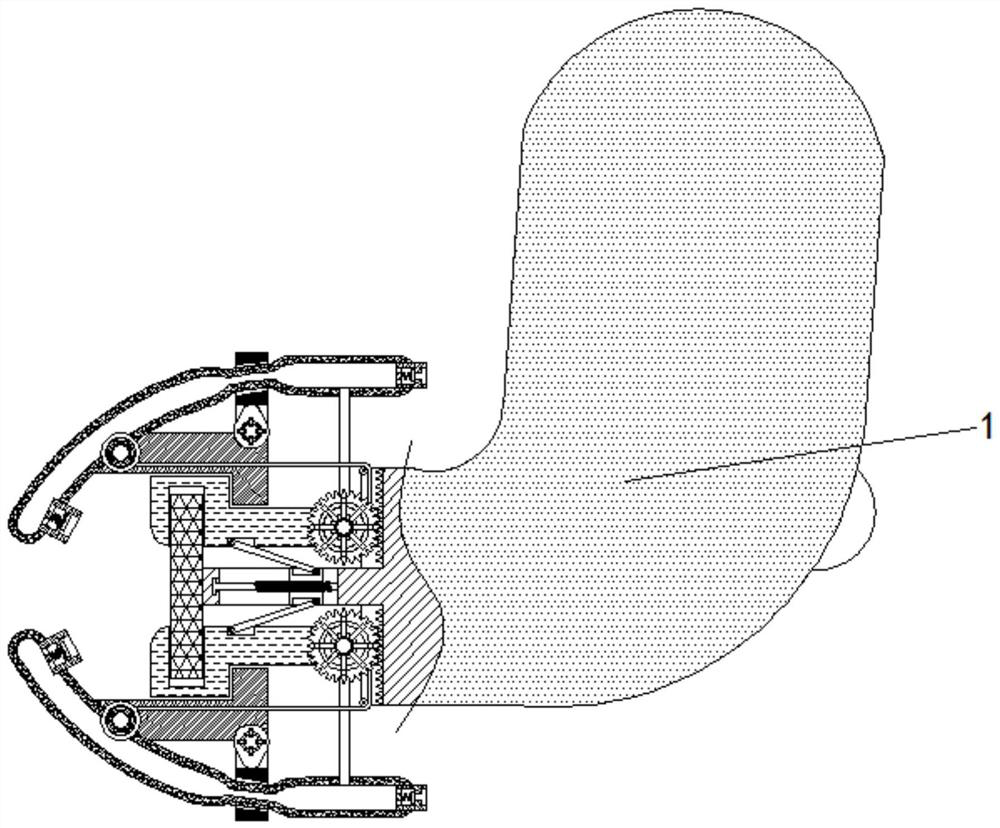

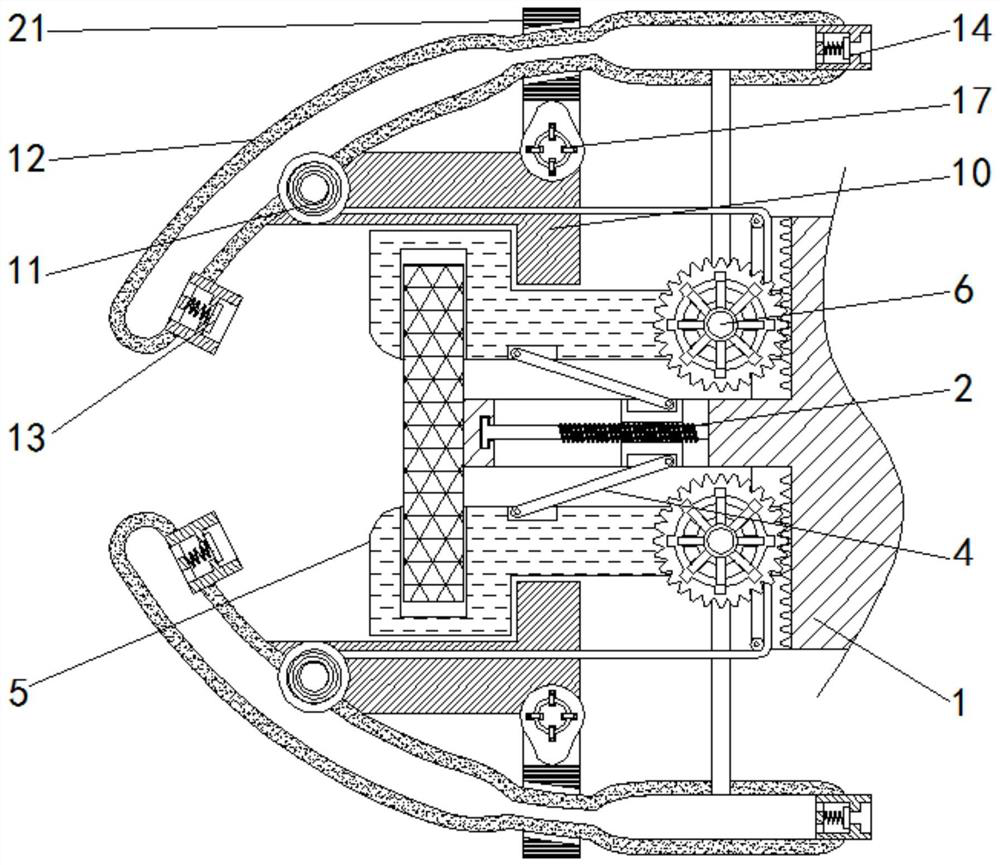

Low-temperature casing pressure device for taking out covered stent

ActiveCN114849929AI solve the problem that I took offLabor savingSpray boothsRadial motionMotor drive

Owner:深圳库珀医疗股份有限公司

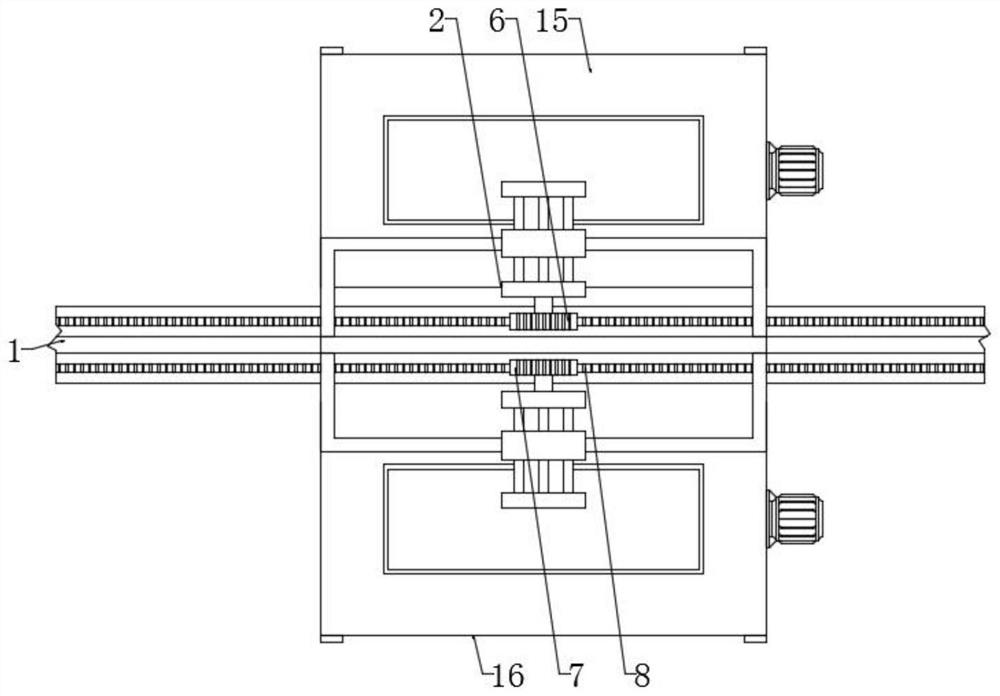

Two-sided grinding machine and two-sided grinding method

ActiveCN110640621AImprove machining accuracyImprove flatnessGrinding drivesLapping machinesGear driveGear wheel

Owner:HC SEMITEK ZHEJIANG CO LTD

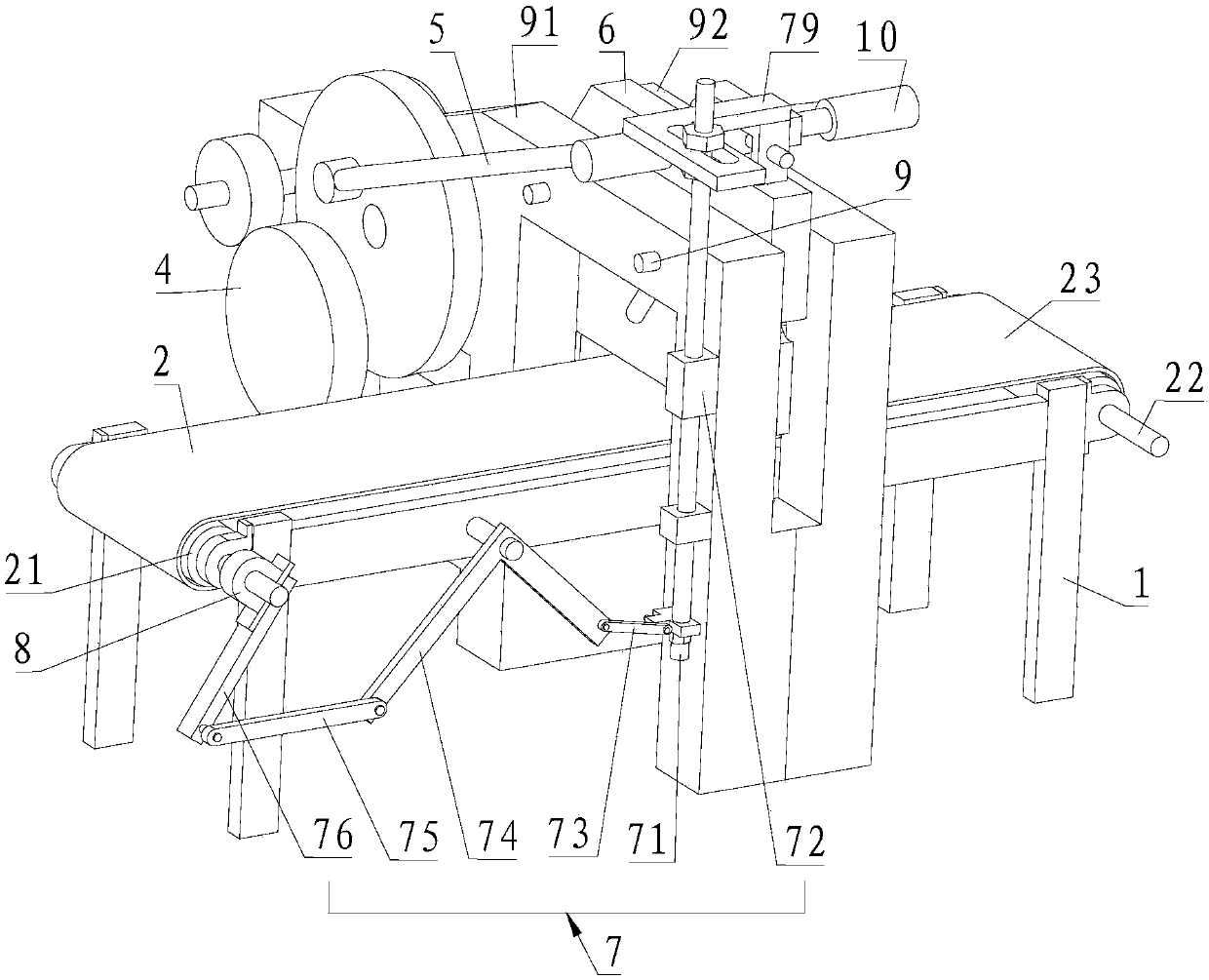

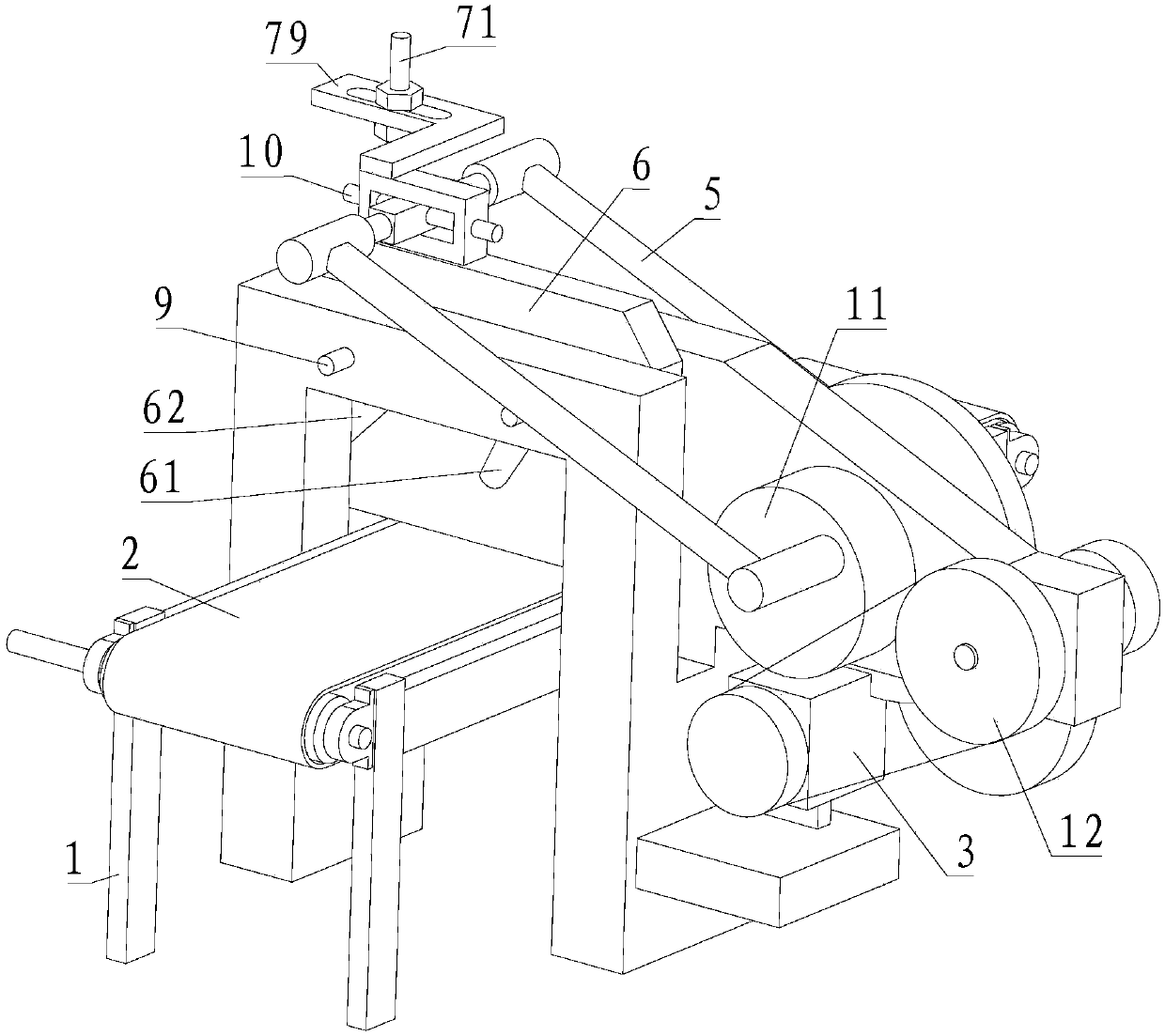

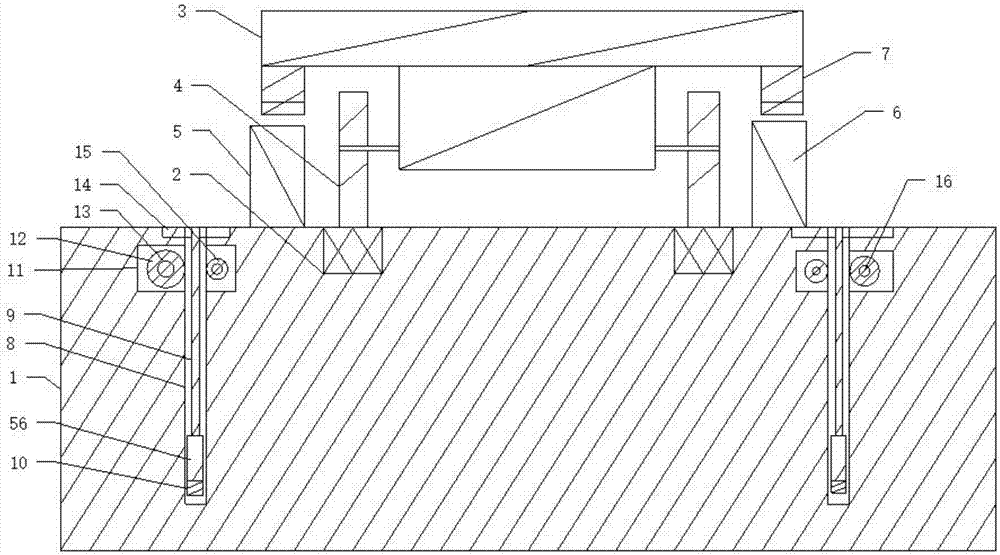

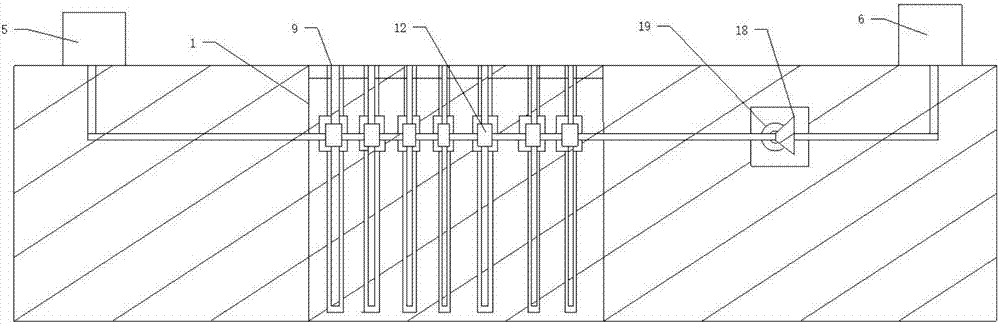

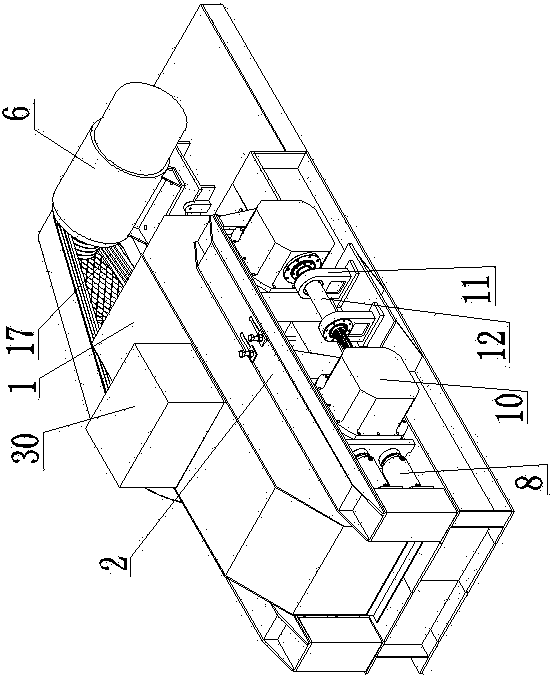

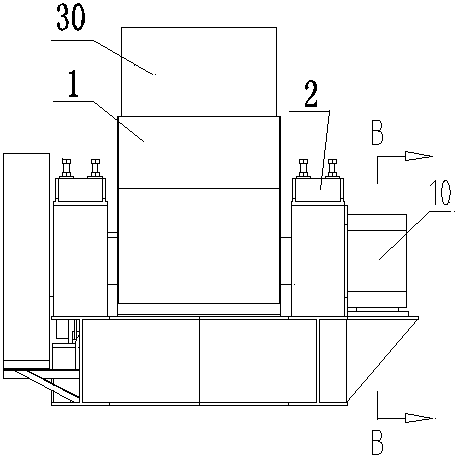

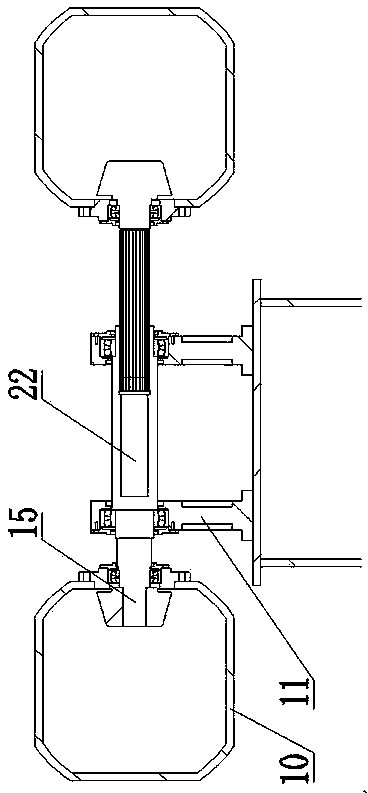

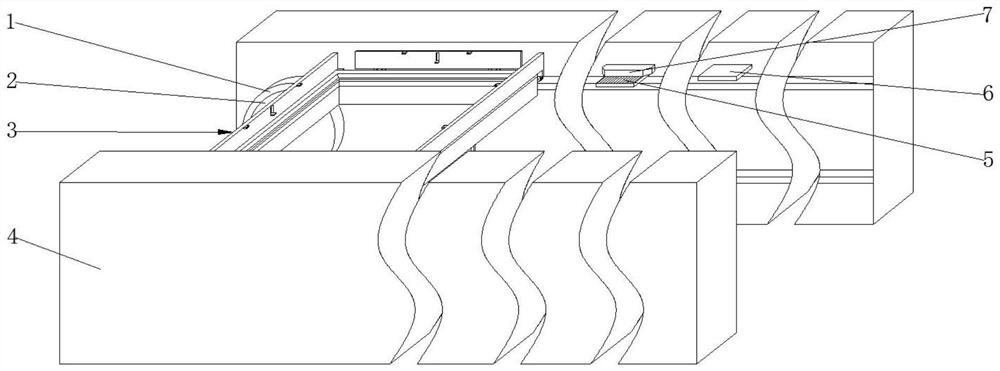

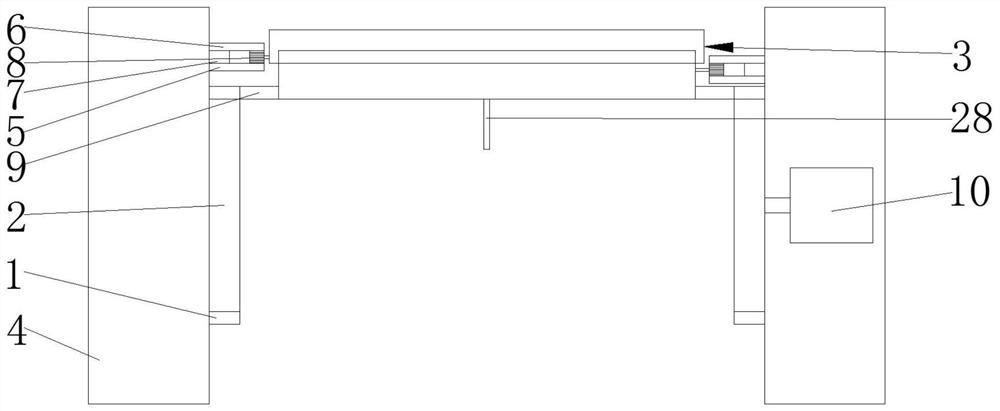

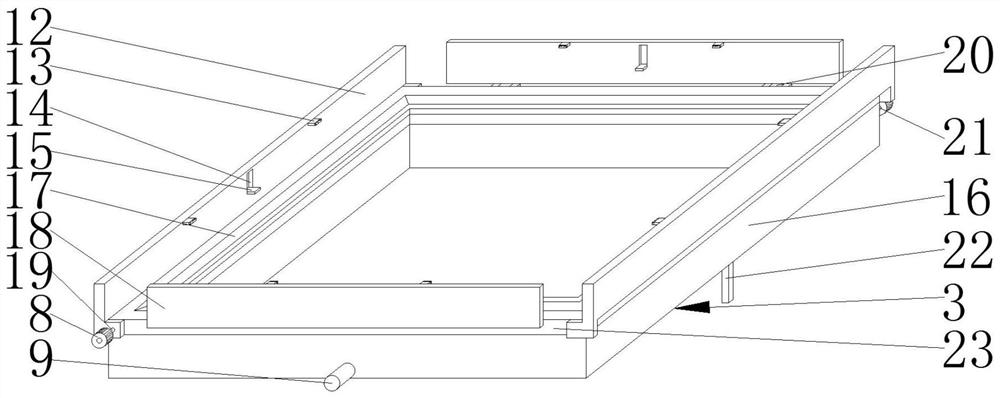

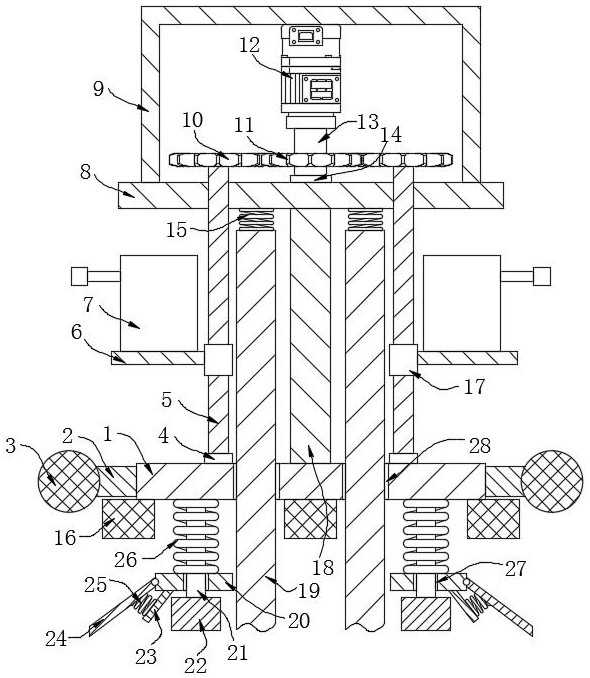

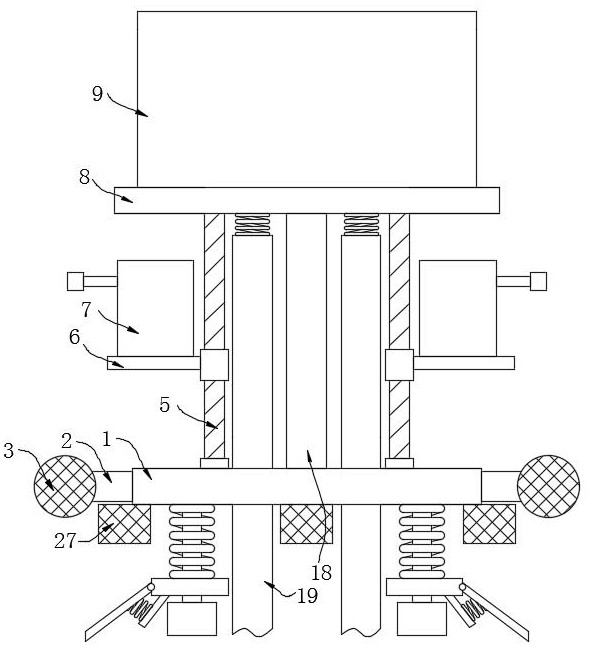

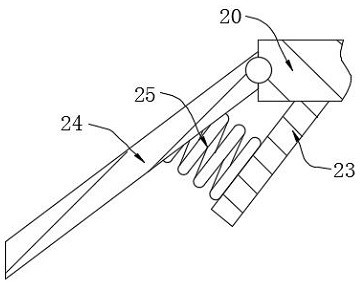

Automatic feeding and discharging device of hot press

PendingCN111618954AAdjustable distanceSuitable for retrofit and upgradeWood veneer joiningCleaning using gasesHydraulic motorGear drive

The invention provides an automatic feeding and discharging device of a hot press. The automatic feeding and discharging device comprises a movable supporting frame, a fixed frame and a power system.The movable supporting frame and the power system are arranged on the fixed frame. The movable supporting frame comprises an advancing and retreating screw transmission device and a bearing plate. Thepower system comprises a hydraulic motor and a lead screw. The hydraulic motor drives the lead screw to rotate through a first gear transmission mechanism. The lead screw is connected with the movable supporting frame and drives the movable supporting frame to move on the fixed frame. The advancing and retreating screw transmission device comprises a screw and a transmission nut. The lead screw drives the screw to rotate through a second gear transmission mechanism. The transmission nut is connected with the bearing plate. The distance between the automatic feeding and discharging device andthe hot press can be adjusted, and the problem of inaccuracy of repairing, maintaining, feeding, discharging and positioning is solved. Plate blanks of various thicknesses and curvatures can all be stably fed. The automatic feeding and discharging device is simple, easy to obtain, easy to operate, lower in construction cost and more suitable for transforming and upgrading of plywood manufacturingplants.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

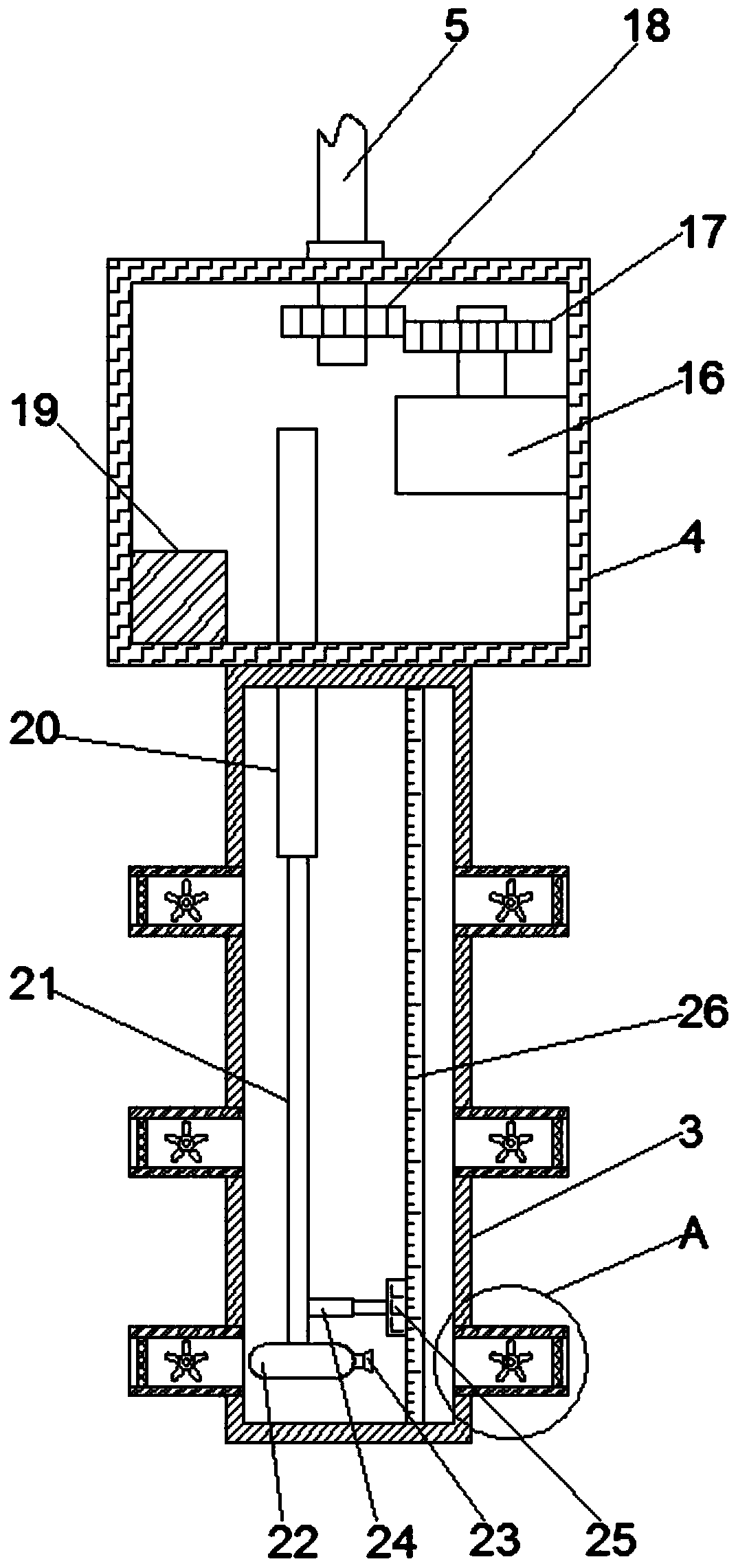

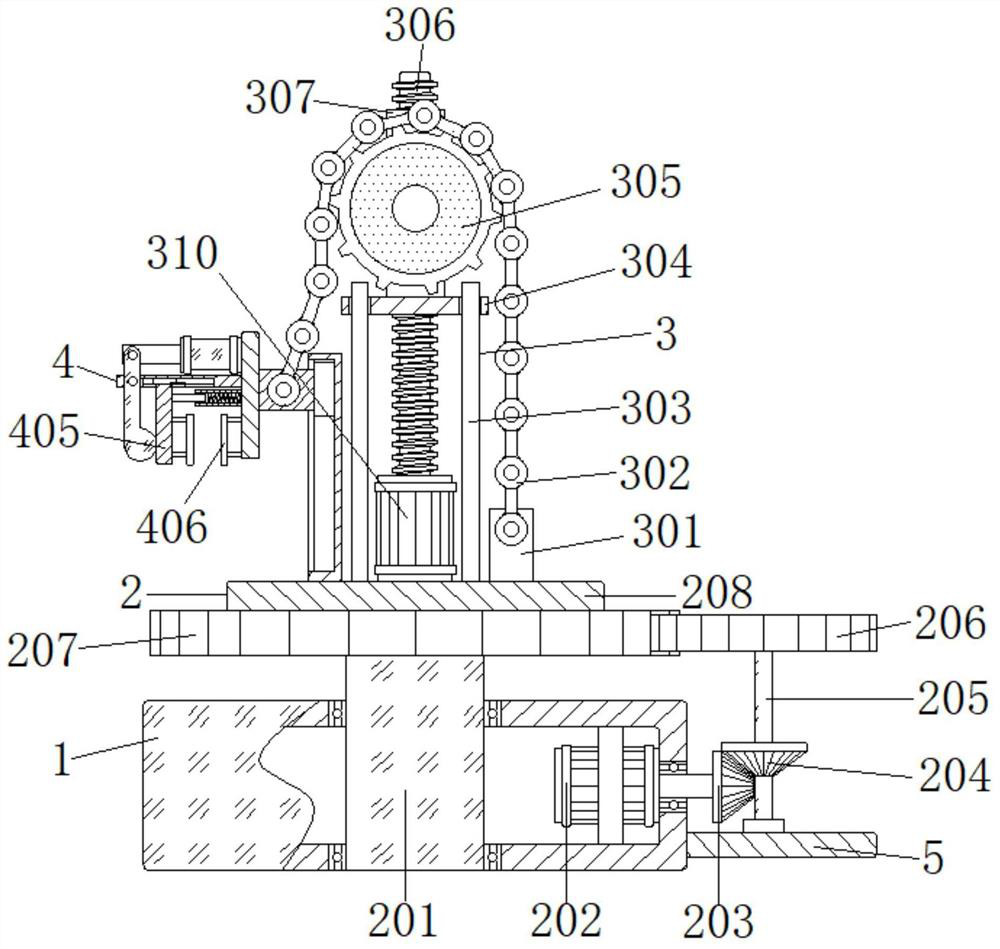

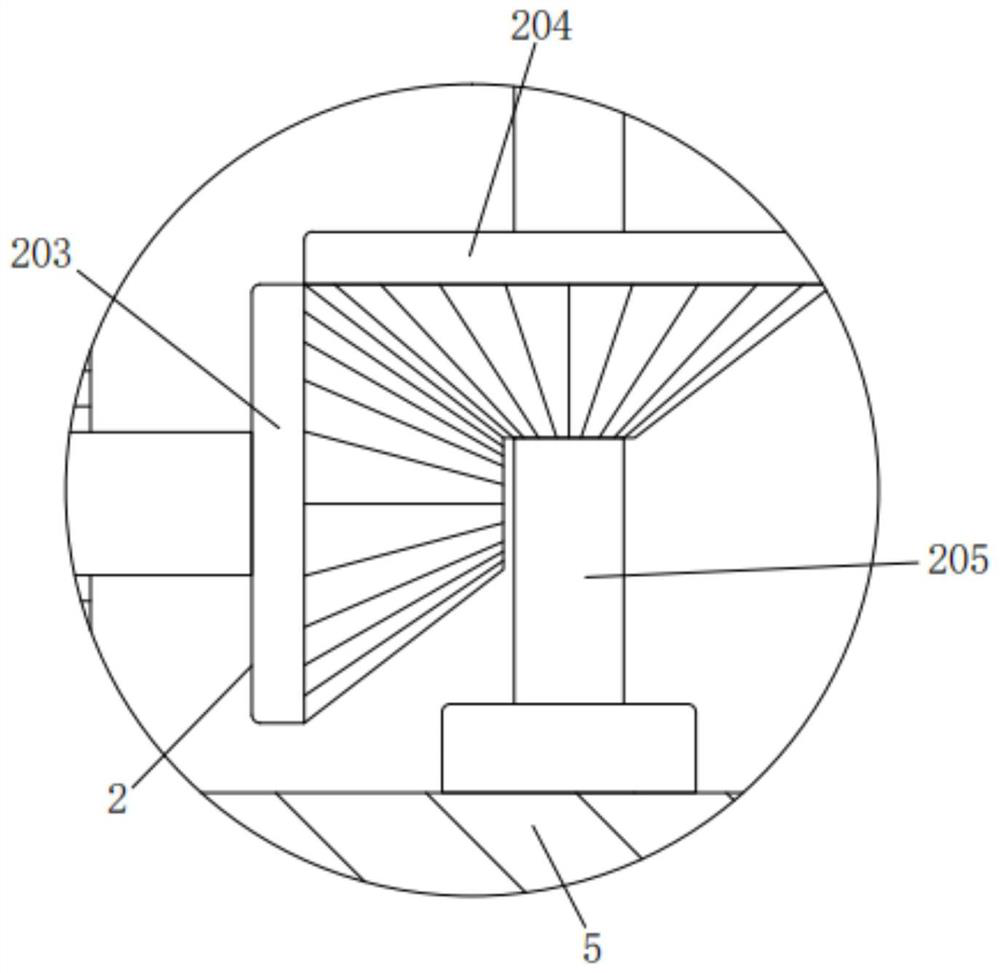

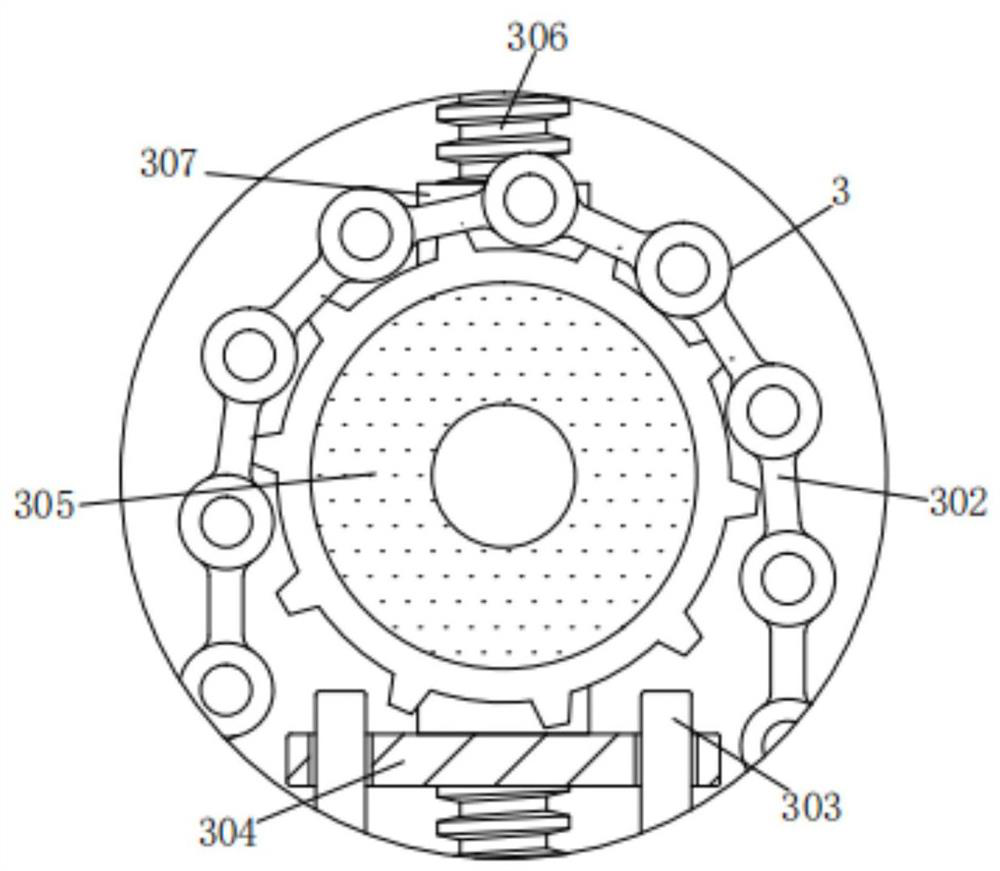

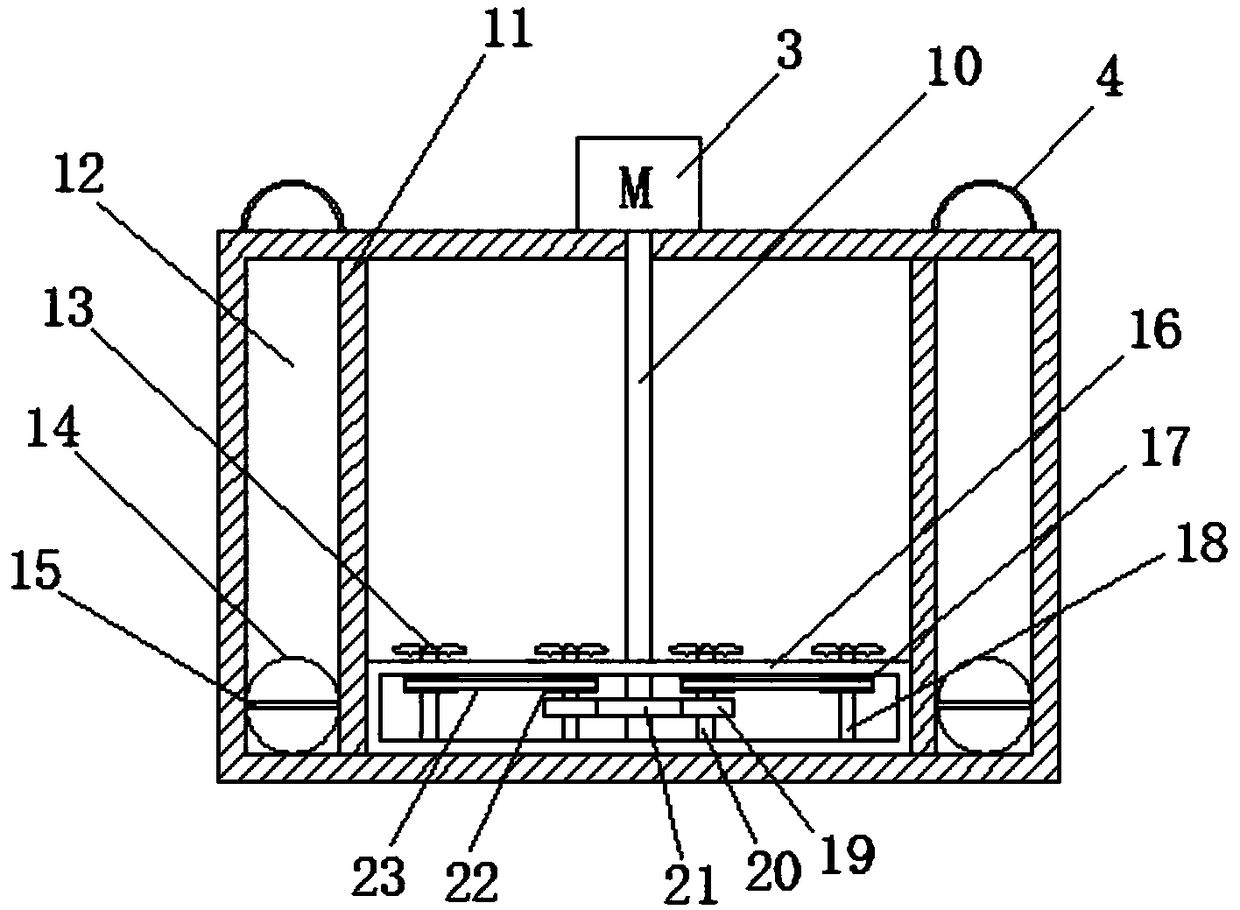

Automatic cleaner for inner wall of nonmetal container with small mouth and large cavity

The invention discloses an automatic cleaner for an inner wall of a nonmetal container with a small mouth and a large cavity. The automatic cleaner comprises a cleaning box, wherein a gear ring cavityis arranged in the cleaning box; a rotating rod penetrating through the top surface of the cleaning box is rotatably installed in the bottom wall of the gear ring cavity; a long rod drives a second gear to rotate; the second gear drives a rotating block to rotate through meshing with a second gear ring; the nonmetal container is placed between a cavity and a screw plate; the rotating rod is driven to rotate through a rotating knob, so that the screw plate moves up and down to adjust the distance between the screw plate and a supporting plate; the bottom surface of the screw plate is attachedto the top surface of the nonmetal container, and the nonmetal container does not shake when a cleaning mechanism cleans the nonmetal container; and a power mechanism drives a cleaning rod in the cleaning mechanism to move up and down and simultaneously rotate, and therefore the inner wall of the nonmetal container can be cleaned.

Owner:JIANGSU SHIFENG ENTERPRISE MANAGEMENT CONSULTING CO LTD

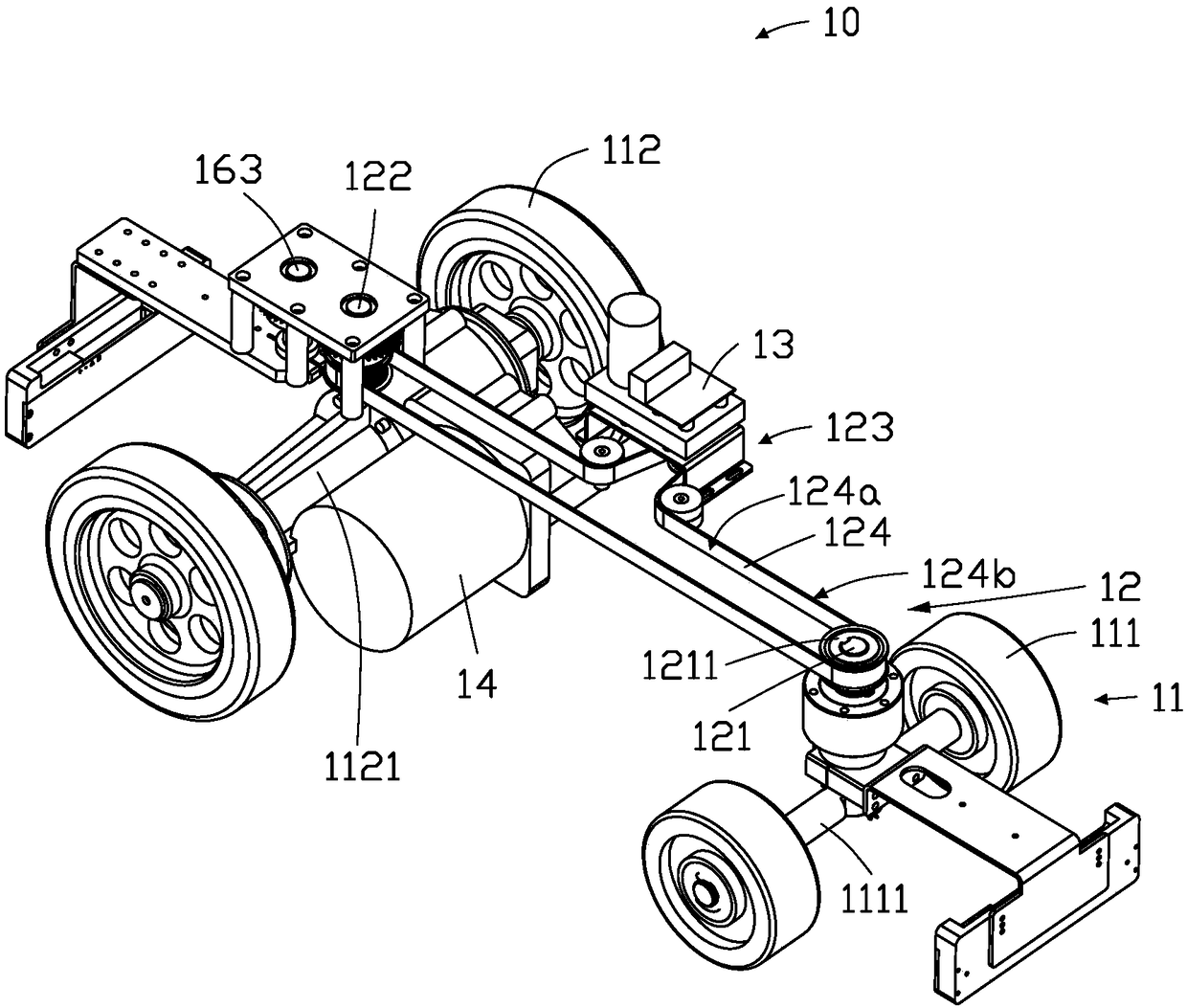

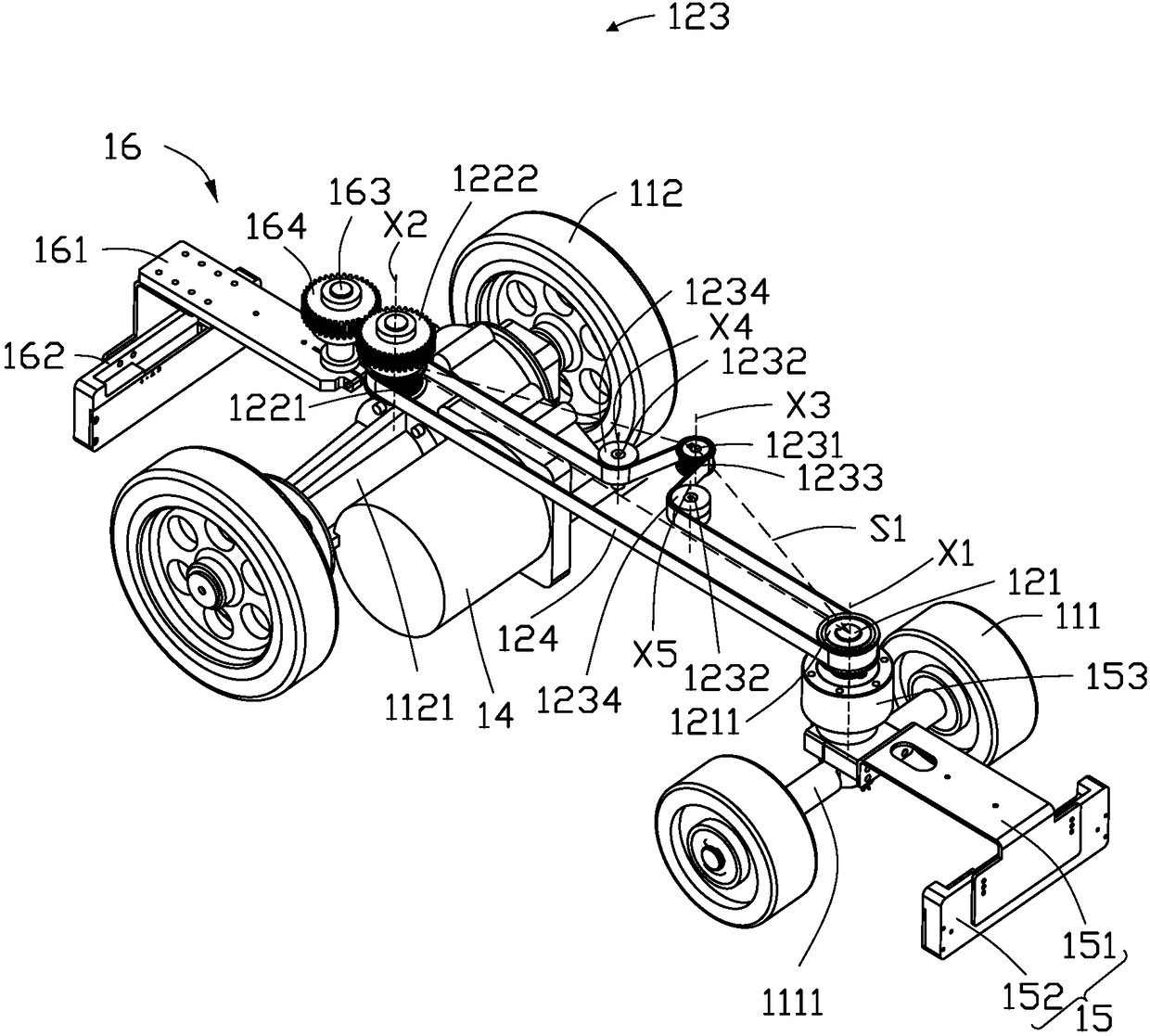

Automatic guided vehicle

InactiveCN109131632AFlexible steeringSteering linkagesDeflectable wheel steeringGear driveGear wheel

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

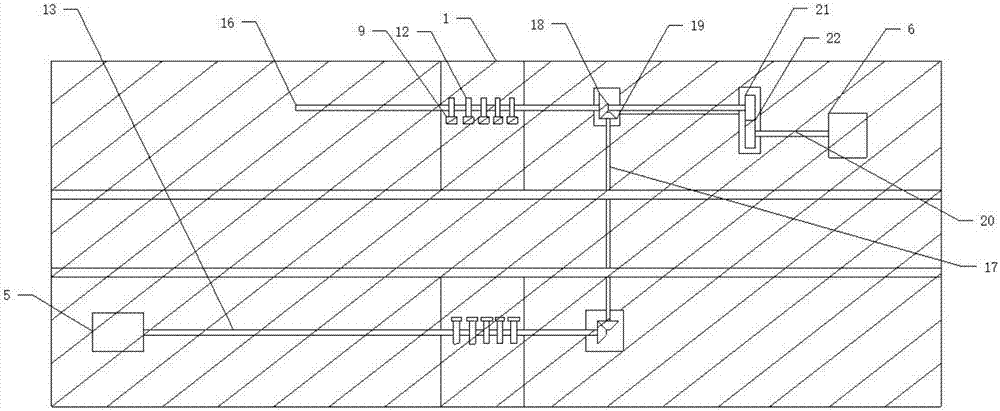

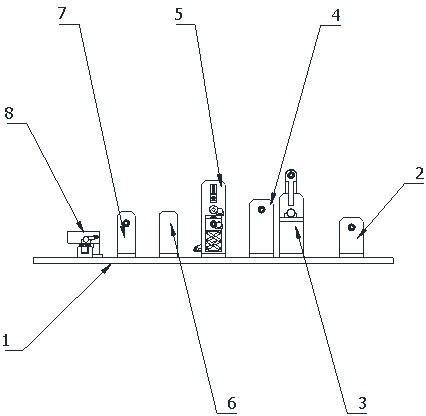

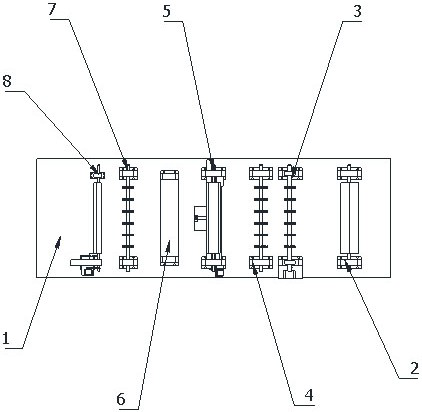

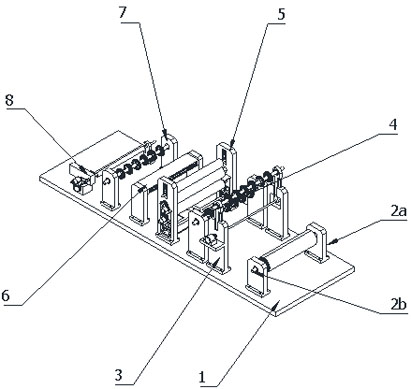

Cooling conveyor

ActiveCN111605999AAvoid wastingRapid coolingConveyorsDomestic cooling apparatusThermodynamicsGear drive

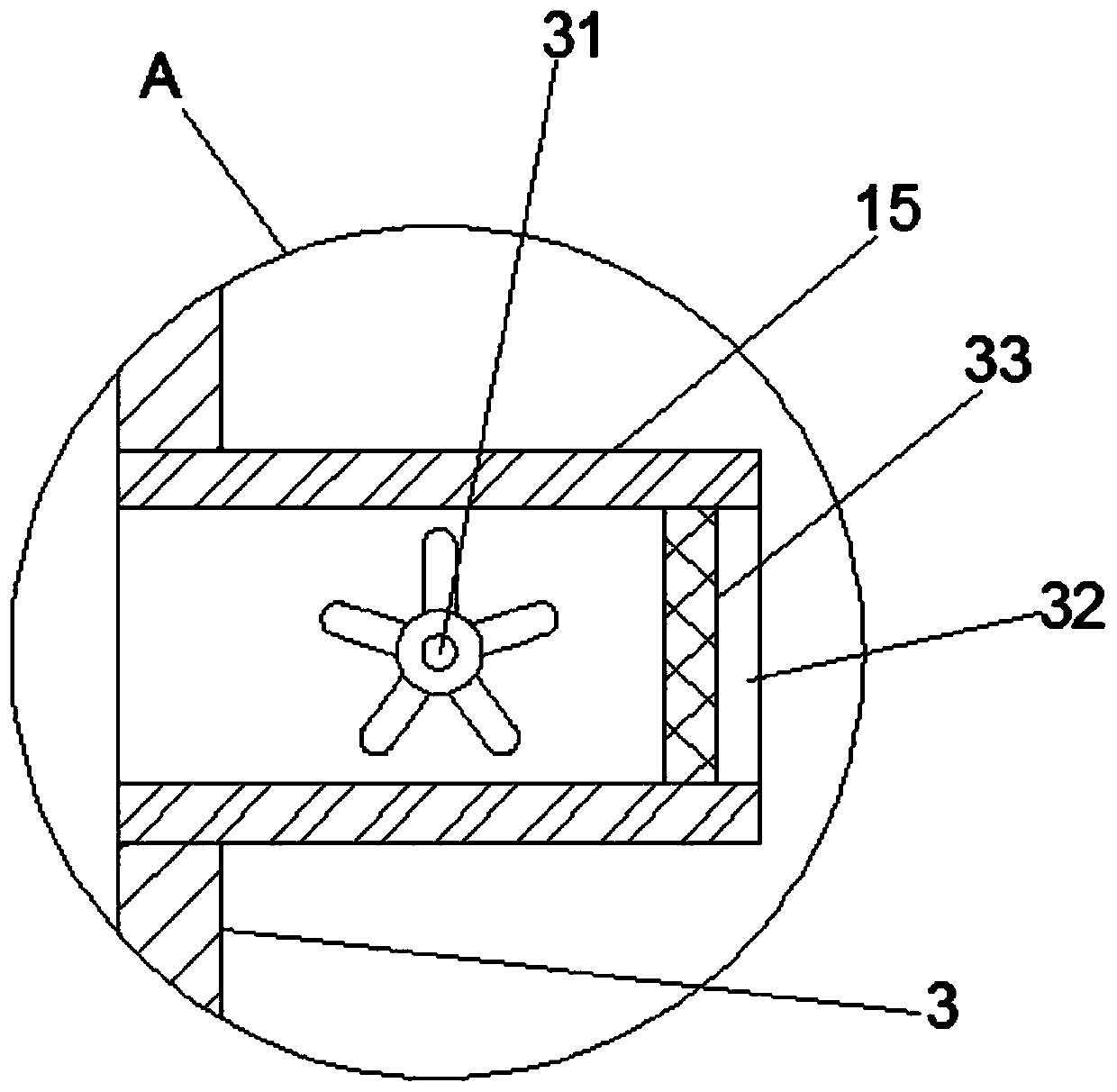

The invention discloses a cooling conveyor. The cooling conveyor structurally comprises a conveyor body, a driving device, universal guide wheels, an electric controller and a baffle plate, the conveyor body is composed of a machine body, a roller, a conveying belt, a driven air supply mechanism and an air inducing mechanism. According to the cooling conveyor, the conveyor body drives the driven air supply mechanism to work through cooperation of the conveying belt and a gear rack, a linkage gear drives a negative pressure fan to generate negative pressure wind power, and guiding the wind power is carried out through a wind shield, so that waste of the wind power is avoided; the wind power can be utilized to cool the interior and the exterior of the candy pot to the maximum degree throughthe air inducing mechanism, the cooling effect of objects on the conveying belt is improved; meanwhile, cooling equipment is not needed to be installed, so that the cost does not need to be increased;and a driving motor does not need to be additionally arranged, so that the electric energy is saved, and the working efficiency is improved.

Owner:JIANGSU HANYAO MEDICAL DEVICES CO LTD

Energy-saving filling machine based on Internet of Things and capable of realizing uniform filling

InactiveCN108996455AUniform densityImprove filling product qualityLiquid bottlingGear driveGear wheel

Owner:郑胜利

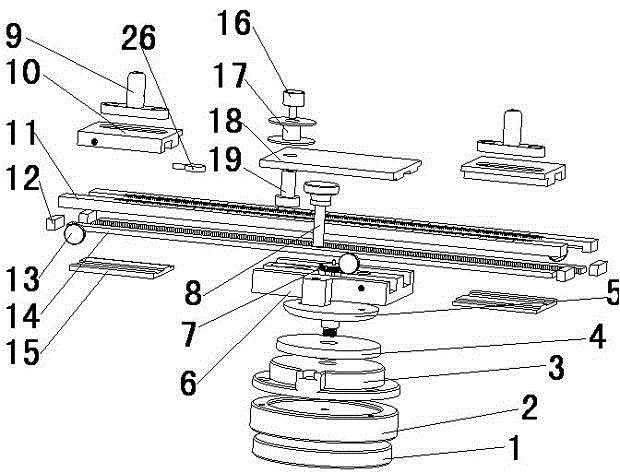

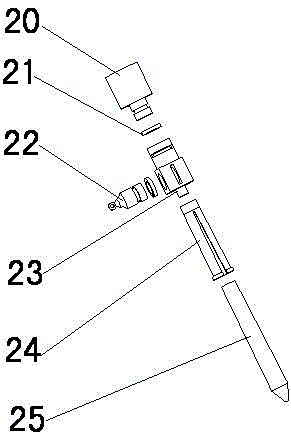

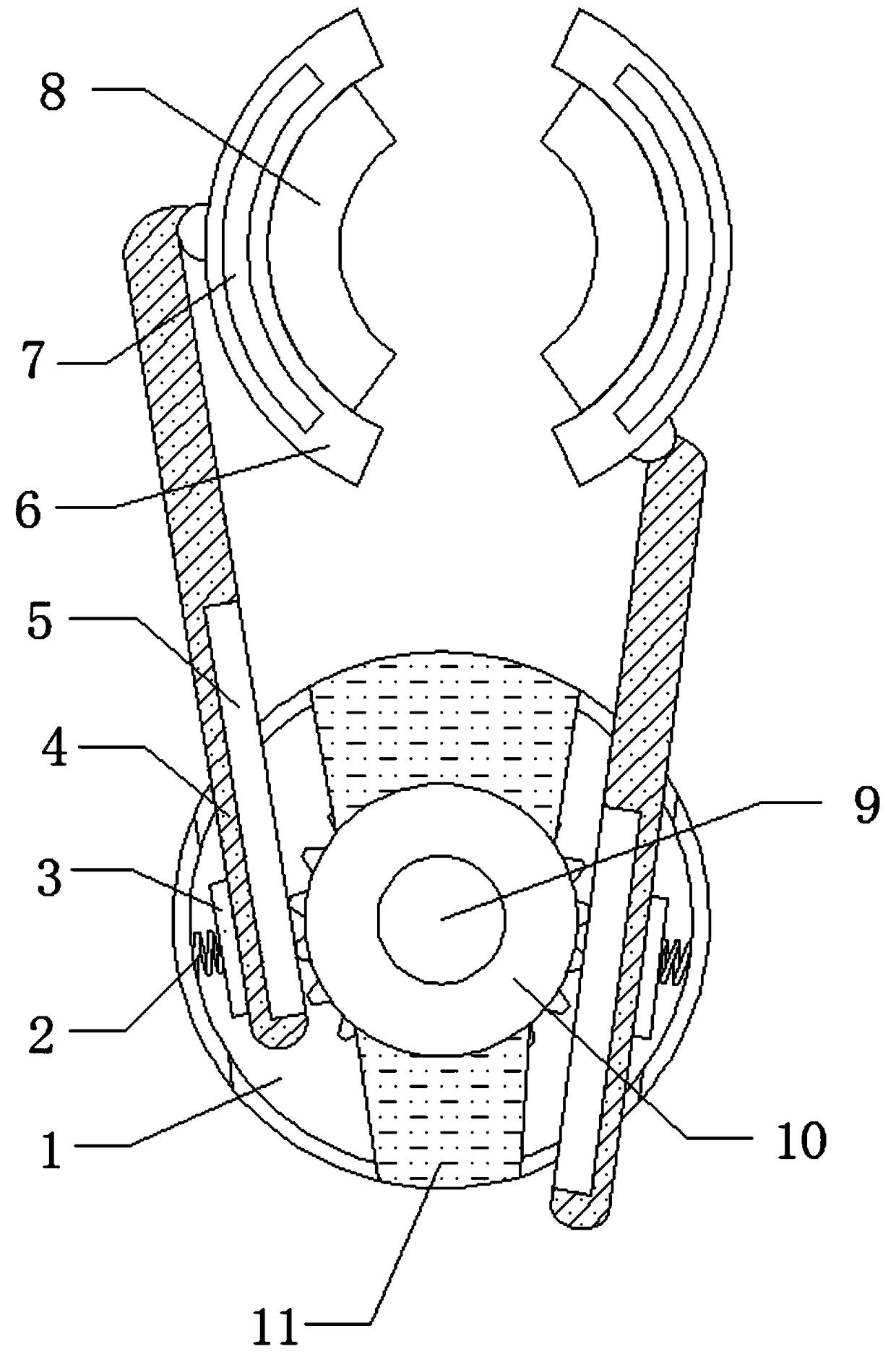

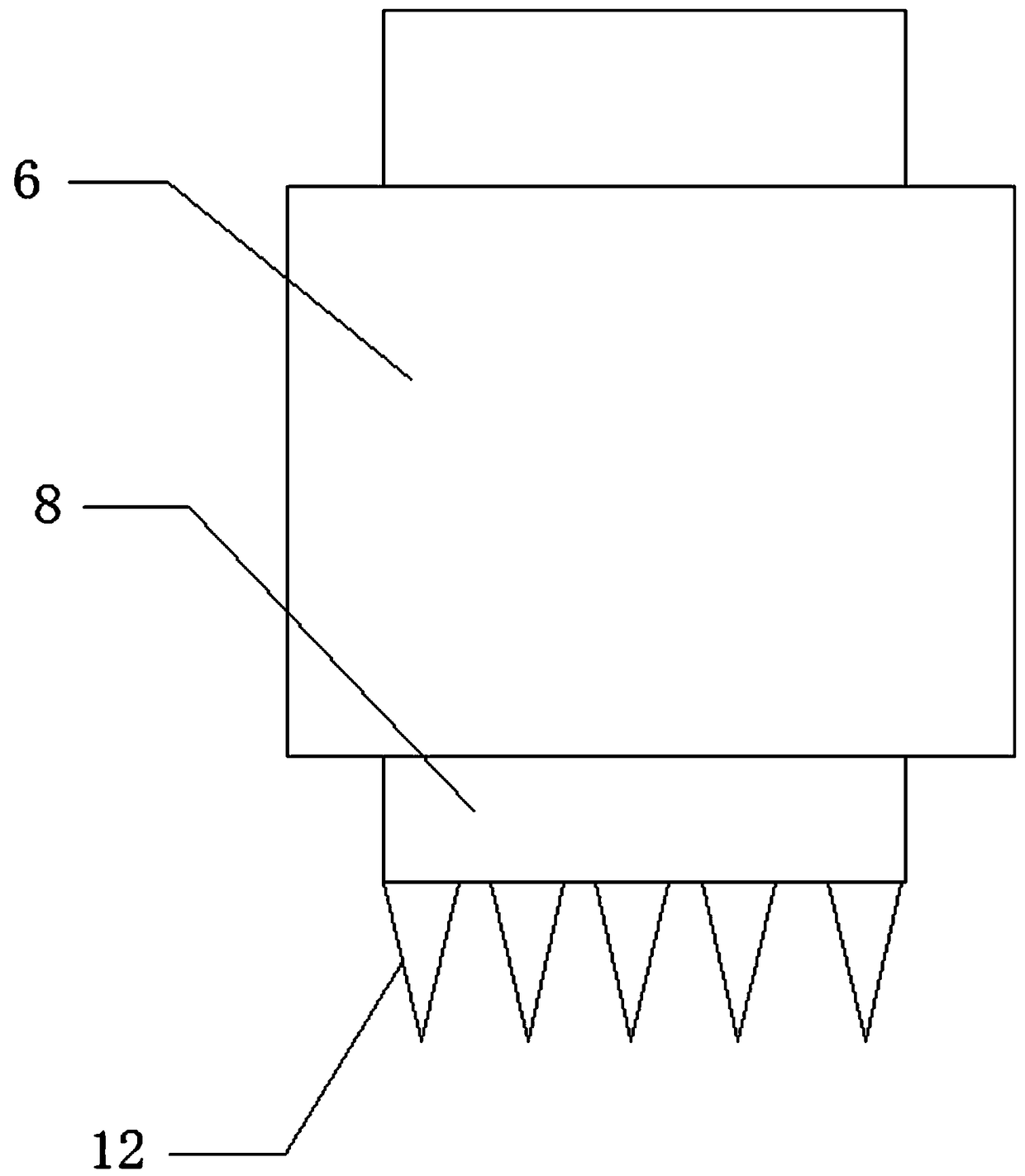

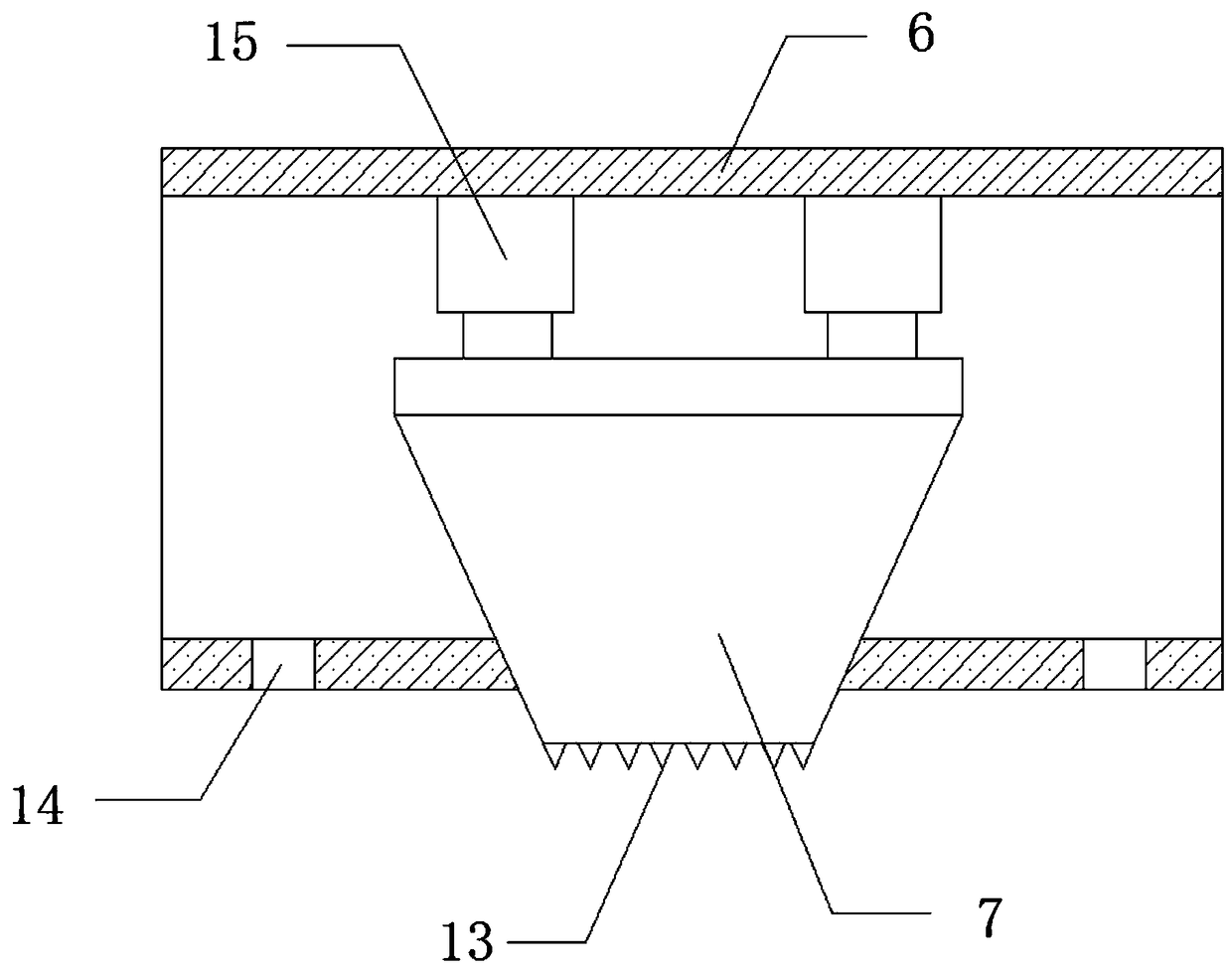

No-injury seedling transferring device for agricultural production

Owner:湖南省生源园林发展有限公司

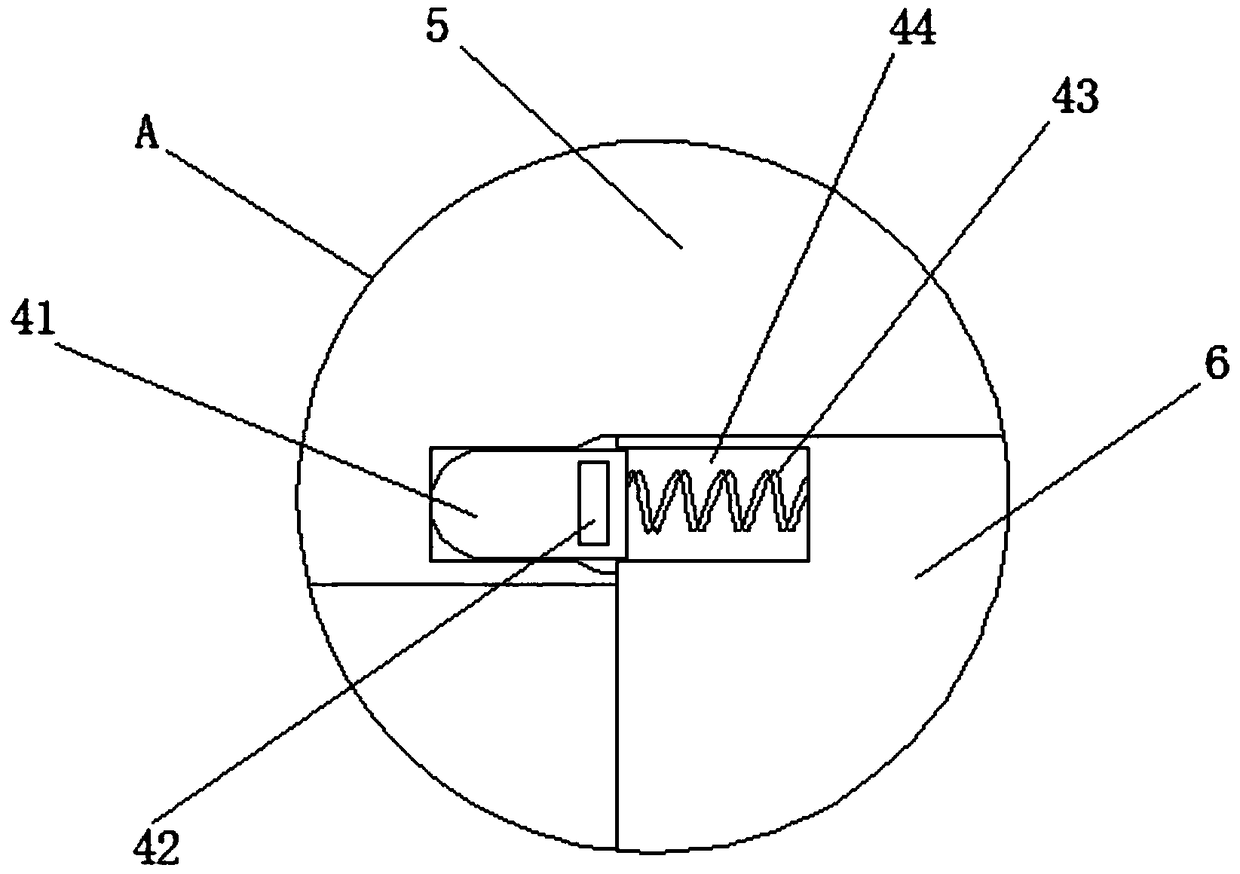

Gear-rack mechanism, door pushing device, refrigerator and door

PendingCN110397708AAchieve positioningTransmission stopped in timeFriction gearingsGear driveEngineering

The invention discloses a gear-rack mechanism, a door pushing device, a refrigerator and a door. The gear-rack mechanism comprises a floating return stroke device arranged at the end of a meshing tooth of a rack; when the floating return stroke device is in a first state, meshing between a gear and the rack is separated so as to achieve rack positioning; and when the floating return stroke deviceis in a second state, the upper end of the floating return stroke device at least partially abuts against the gear to push the gear to mesh with the rack again, and then the rack is driven to achievetransmission. According to the gear-rack mechanism, the floating return stroke device is arranged at the return stroke point of the rack stroke, therefore, the gear driven by a common motor also can be automatically separated from meshing with the rack at the return stroke point, rack transmission is stopped timely, the rack stops at the original position, and then accurate positioning is achieved. When the motor reversely rotates, the gear can be automatically separated from the positioning face and normally mesh with the rack to achieve transmission under the action of the floating return stroke device.

Owner:JIANGSU KIND ELECTRIC CO LTD

Remote data acquisition device for informatization improvement of offshore oil production platform

InactiveCN113594726ARealize automatic dockingEliminates screwing operationsLine/current collector detailsElectric connection structural associationsInformatizationGear drive

Owner:深圳市云帆自动化技术有限公司

Fixing device for computer mainboard production

Owner:NANJING VOCATIONAL UNIV OF IND TECH

Protruding and embossing device for textile fabric

InactiveCN114808337AImprove the effect of the finished productControlPattern makingWebs handlingGear driveGear wheel

Owner:南通佳之锦纺织有限公司

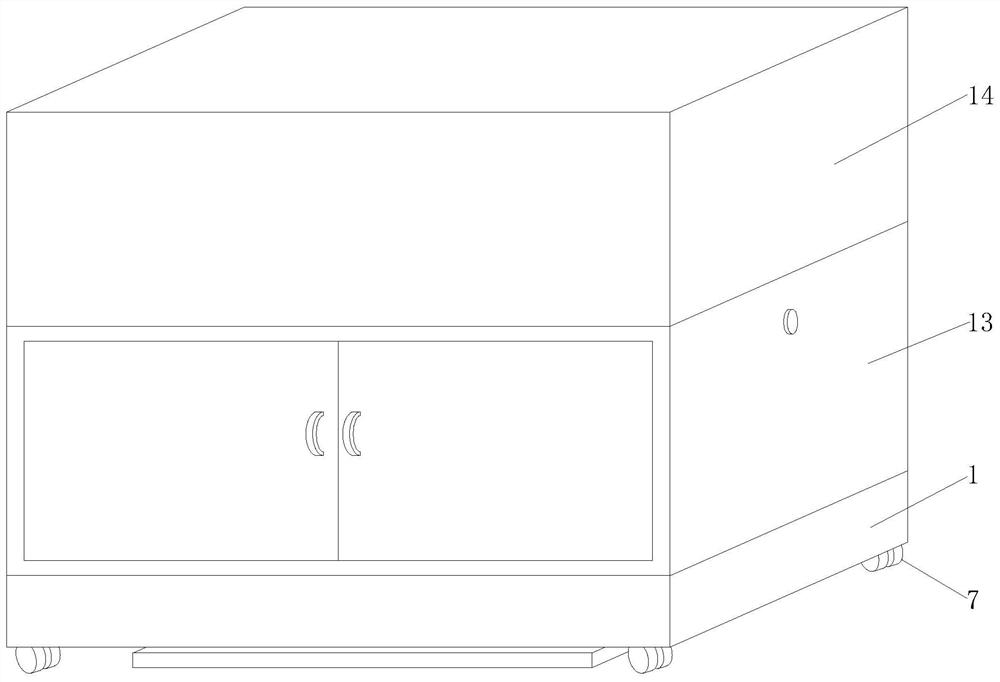

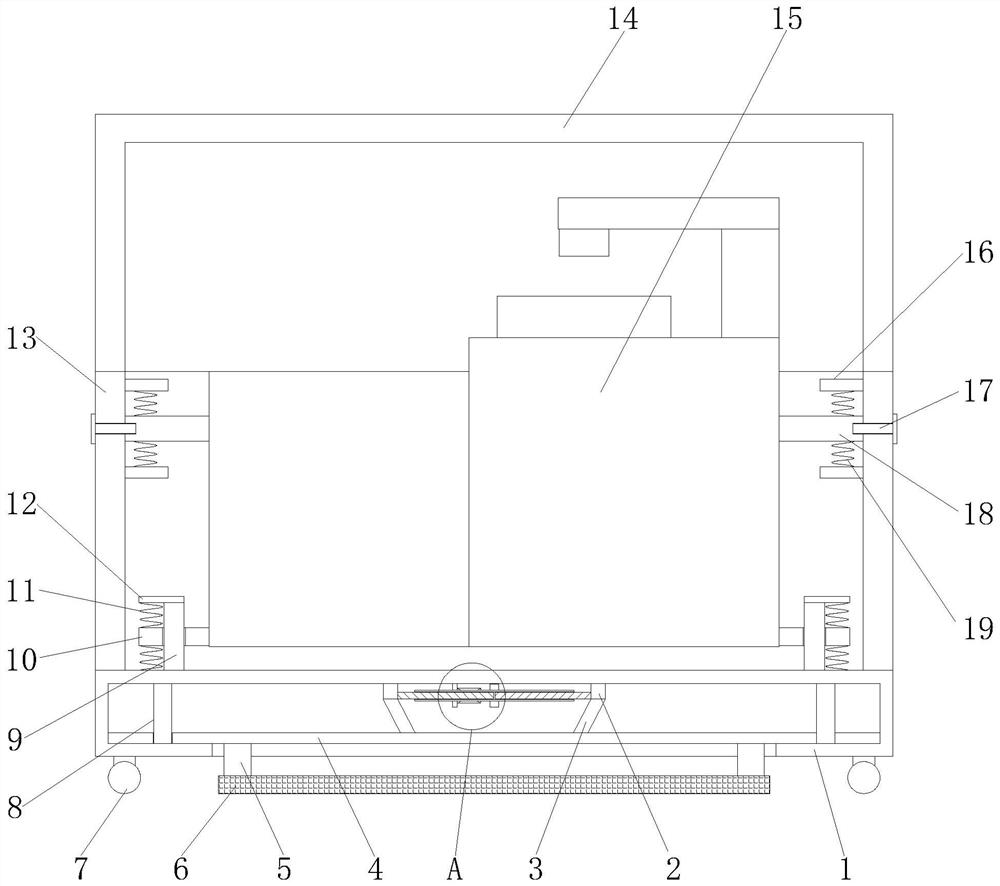

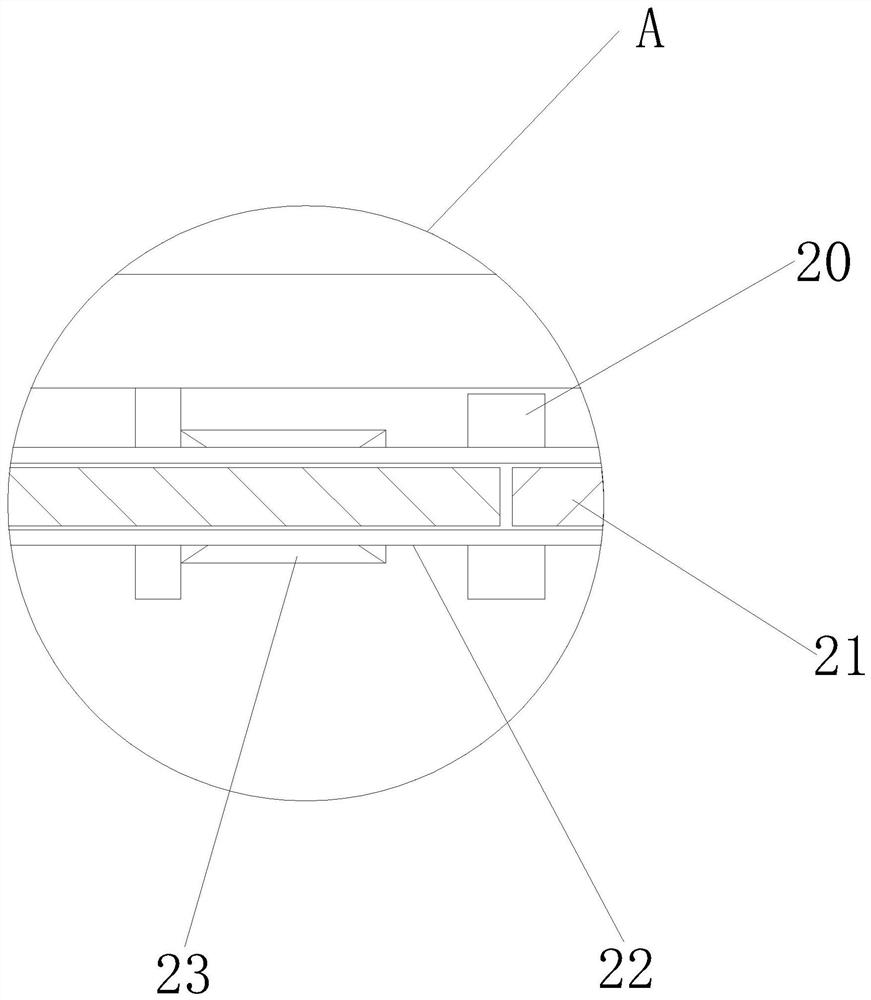

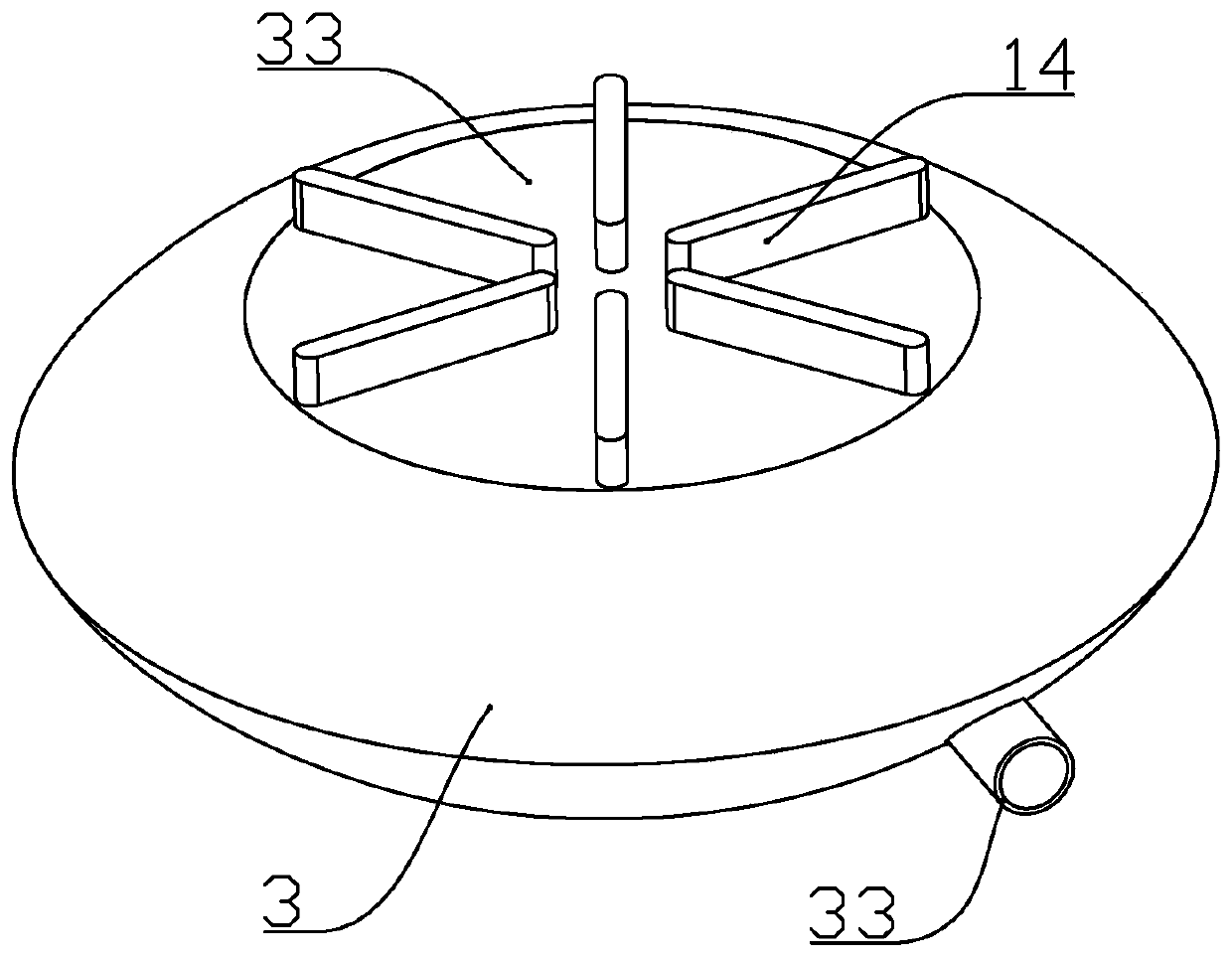

Water-cooling laser integrated welding cabinet

InactiveCN113275747ASolve the inconvenience of fixingFlexible moving processLaser beam welding apparatusGear driveElectric machine

Owner:武汉蓝晶优创激光科技有限公司

Portable washing machine

InactiveCN111188153ARealize reciprocating swingRealize the function of sewage dischargeWashing apparatusTextiles and paperLaundry washing machineGear drive

Owner:冷云祥

Horizontal milling machine power conversion machine head

InactiveCN107243669AImprove processing efficiencyIncrease output powerMilling equipment detailsGear driveMilling cutter

Owner:十堰西来工贸有限公司

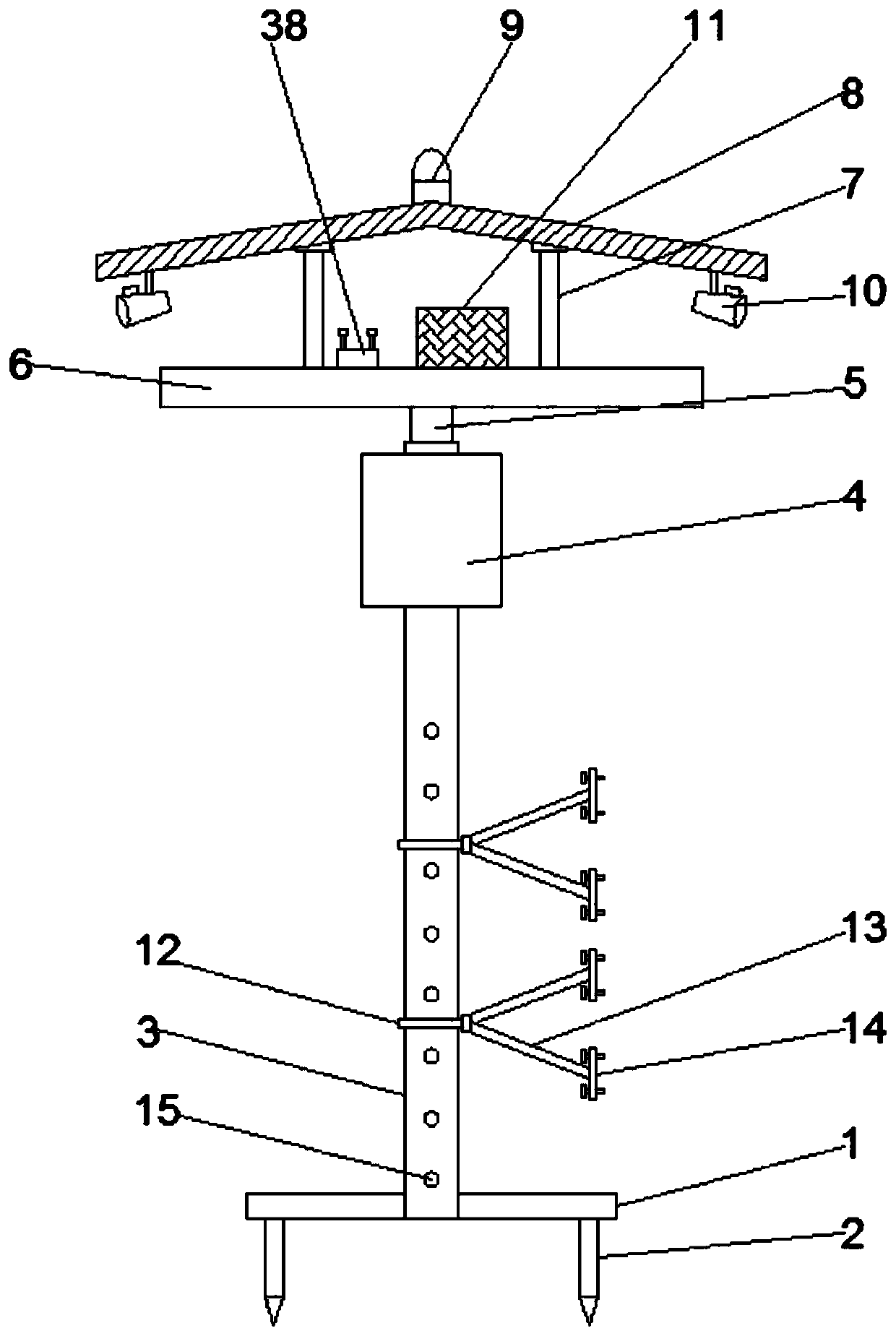

Overwater lifting type quick charging pile

PendingCN113246771AAvoid damageExtended service lifeVessel cleaningCharging stationsElectric machineryGear drive

The invention discloses an overwater lifting type quick charging pile which comprises a base, a supporting plate is welded to the upper surface of the base, a top plate is welded to the upper surface of the supporting plate, two limiting rods are symmetrically arranged on the upper surface of the base, and the bottoms of the two limiting rods penetrate through the upper surface of the base. A forward and reverse motor is arranged on the upper surface of the top plate, a rotating rod is welded to the output end of the forward and reverse motor, a second bearing is welded to the bottom of the rotating rod, the outer ring of the second bearing is welded to the upper surface of the top plate, and a second gear is welded to the outer side wall of the rotating rod; when the charging pile does not need to be used, the forward and reverse motor drives the rotating rod and the second gear to rotate, so that a first gear drives a lead screw to rotate, a sleeve drives a base plate and a power supply box to move up and down, the power supply box is far away from a base, the damage to the charging pile caused by collision between a ship and the base is avoided, and the service life of the charging pile is greatly prolonged.

Owner:上海贸迎新能源科技有限公司

Environment-friendly flour mixer based on cooking purpose

InactiveCN108541730AStir wellAvoid stickingMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsGear driveMotor drive

Owner:WUHU LE CHUANG ELECTRONICS TECH CO LTD

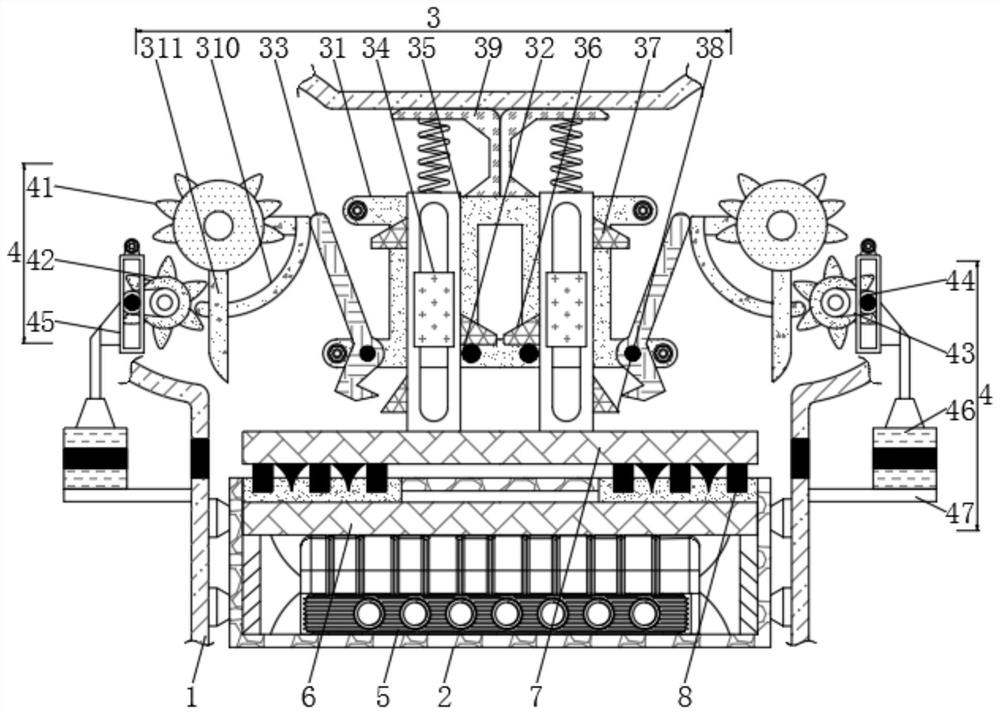

Automatic fertilizer applicator for sugarcane seedling cultivation

InactiveCN113056994AAvoid cloggingImprove stabilityFertiliser distributersAgricultural scienceGear drive

Owner:广州甘蔗糖业研究所湛江甘蔗研究中心

E-commerce Bluetooth earphone capable of adjusting size of receiver

Owner:广州正宏电子商务有限公司

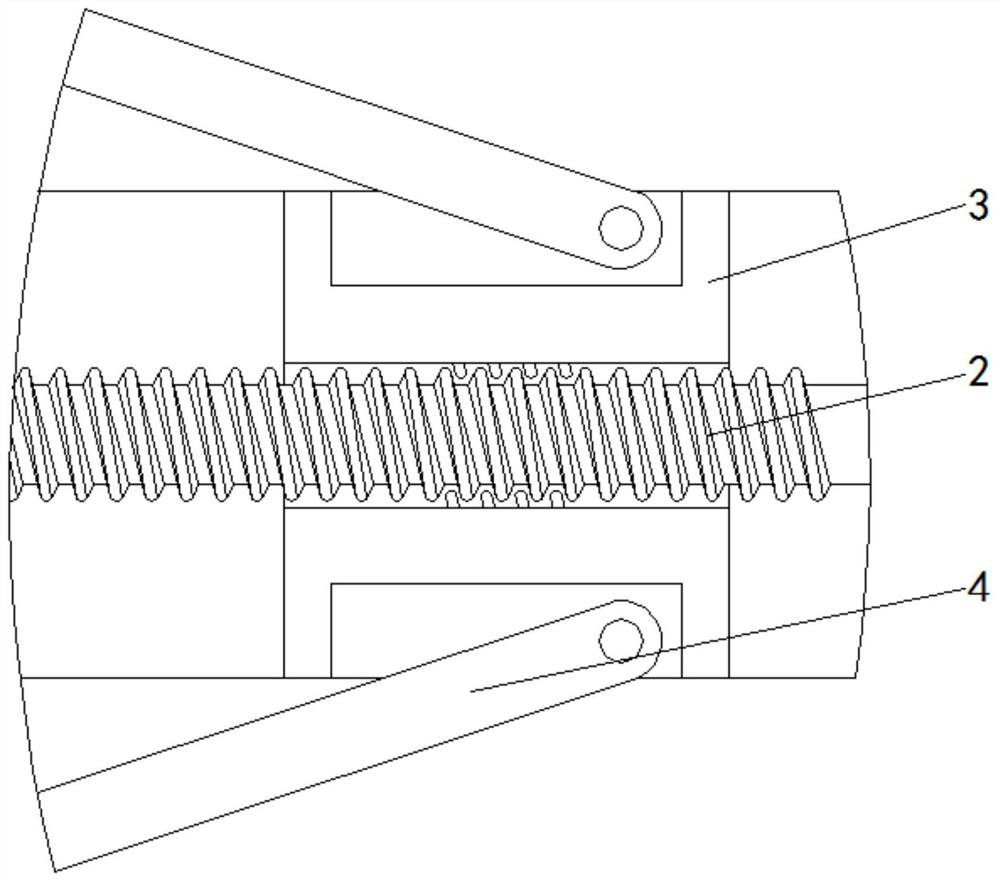

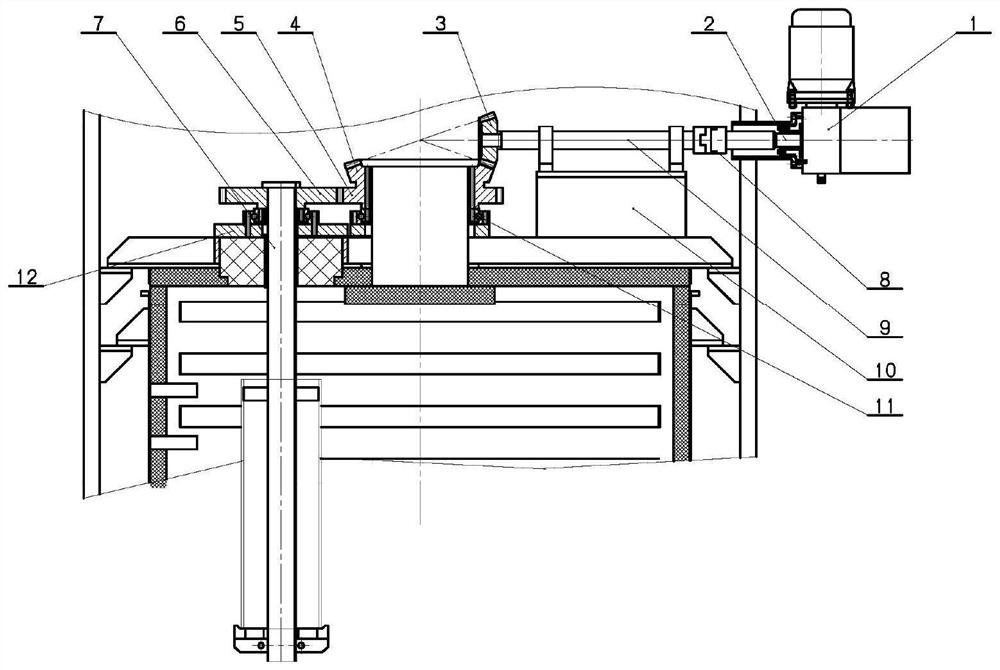

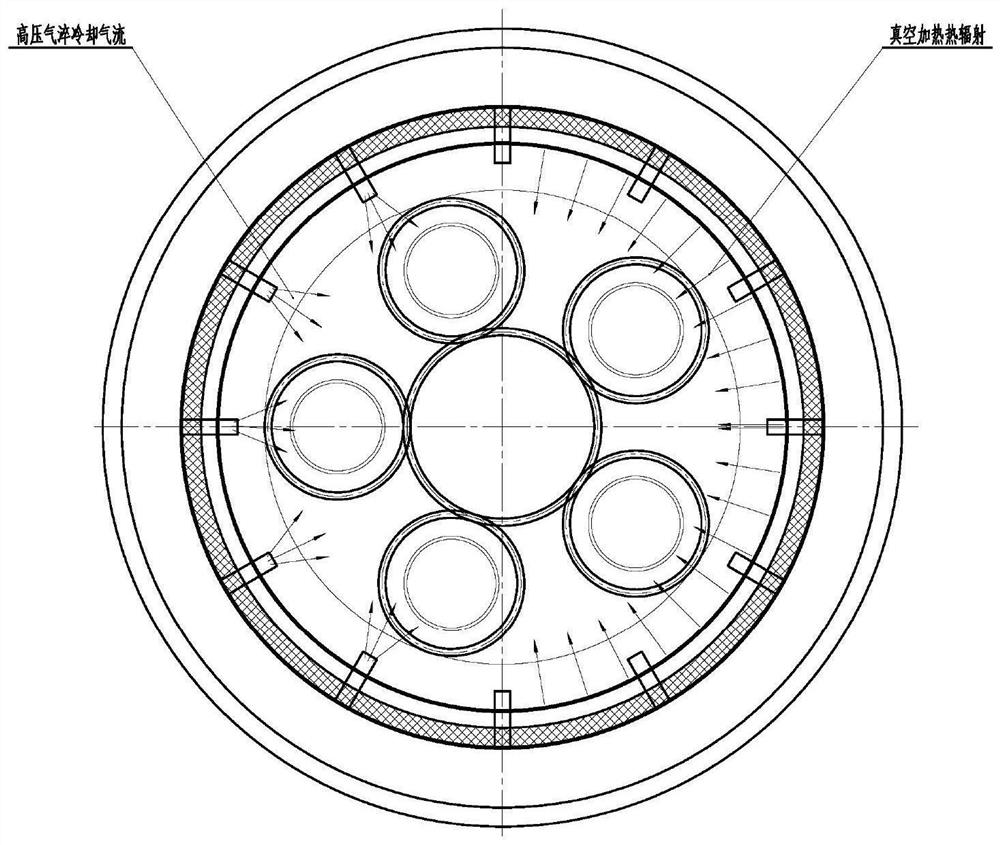

Transmission and clamping structure capable of realizing self-rotation of workpiece in vacuum furnace

ActiveCN112725596AImprove temperature uniformityImprove consistencyFurnace typesHeat treatment furnacesGear driveGear wheel

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap