Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

18 results about "Polypropylene fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polypropylene Fiber. a synthetic fiber formed from a polypropylene melt. Polypropylene fiber is generally superior to polyamide fibers in elasticity and resiliency, but it has lower wear resistance. It displays good heat-insulating properties and is highly resistant to acids, alkalies, and organic solvents.

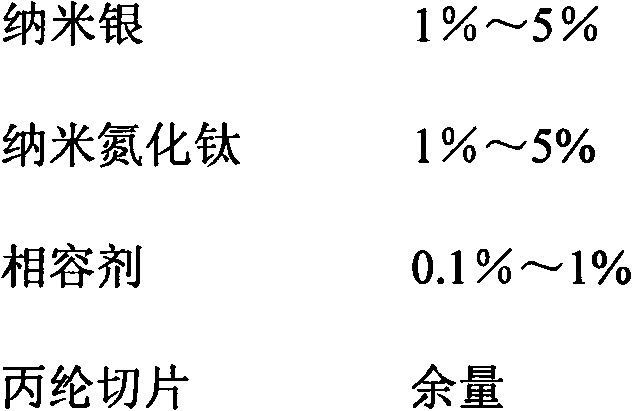

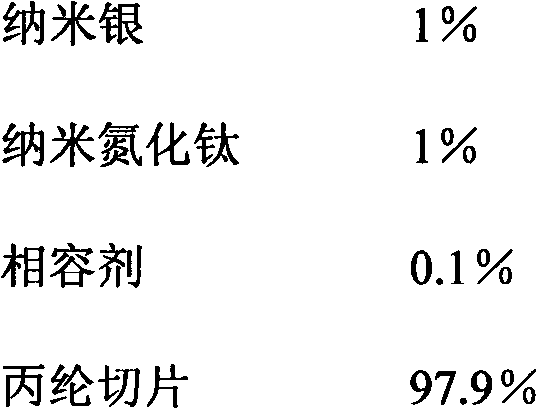

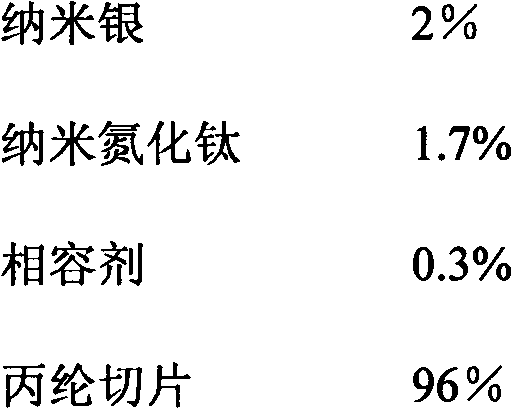

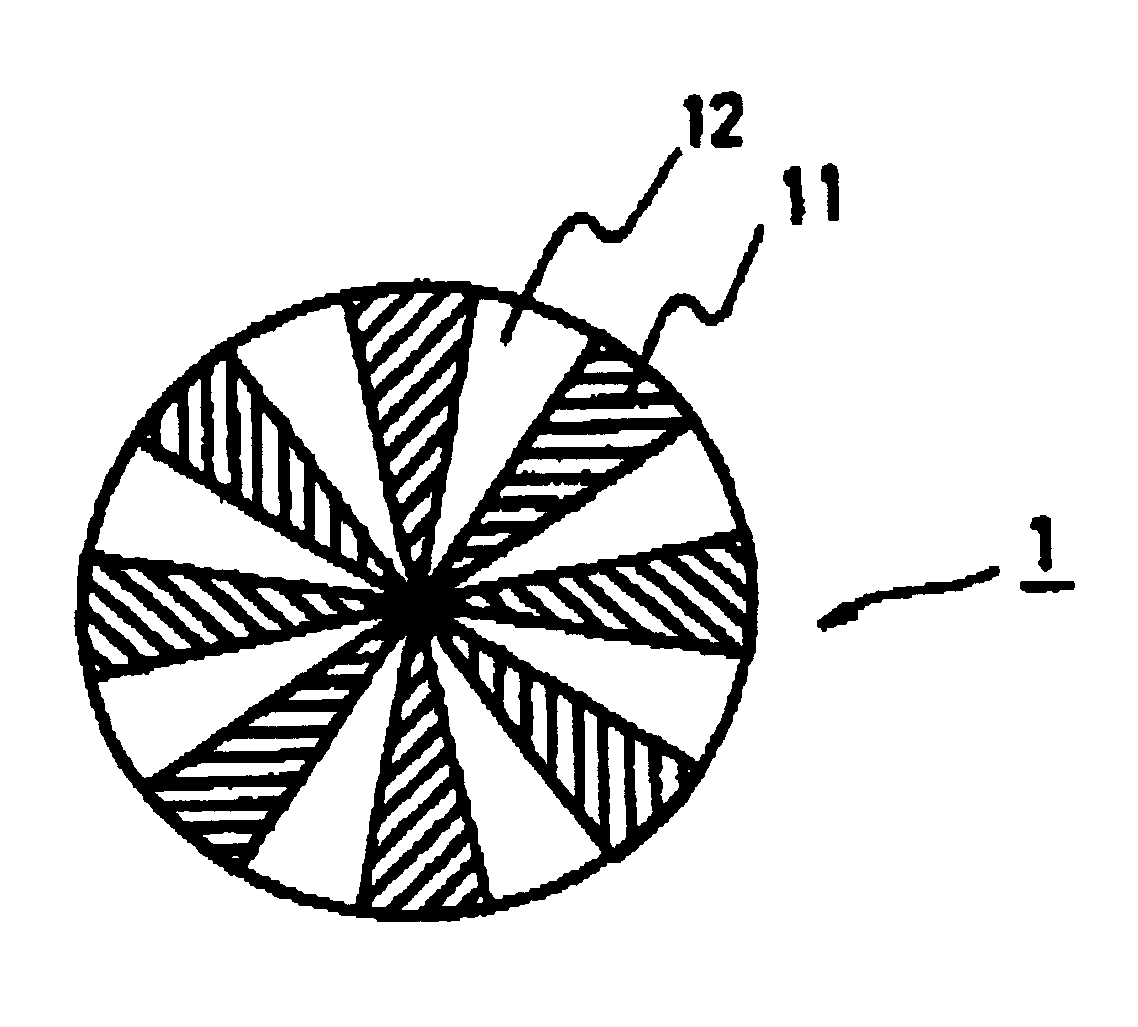

Antibacterial functional polypropylene fiber as well as preparation method and application thereof

InactiveCN102011206AImprove antibacterial propertiesImprove securityMonocomponent polyolefin artificial filamentArtifical filament manufactureMasterbatchTitanium nitride

Owner:上海歌灵新材料科技有限公司

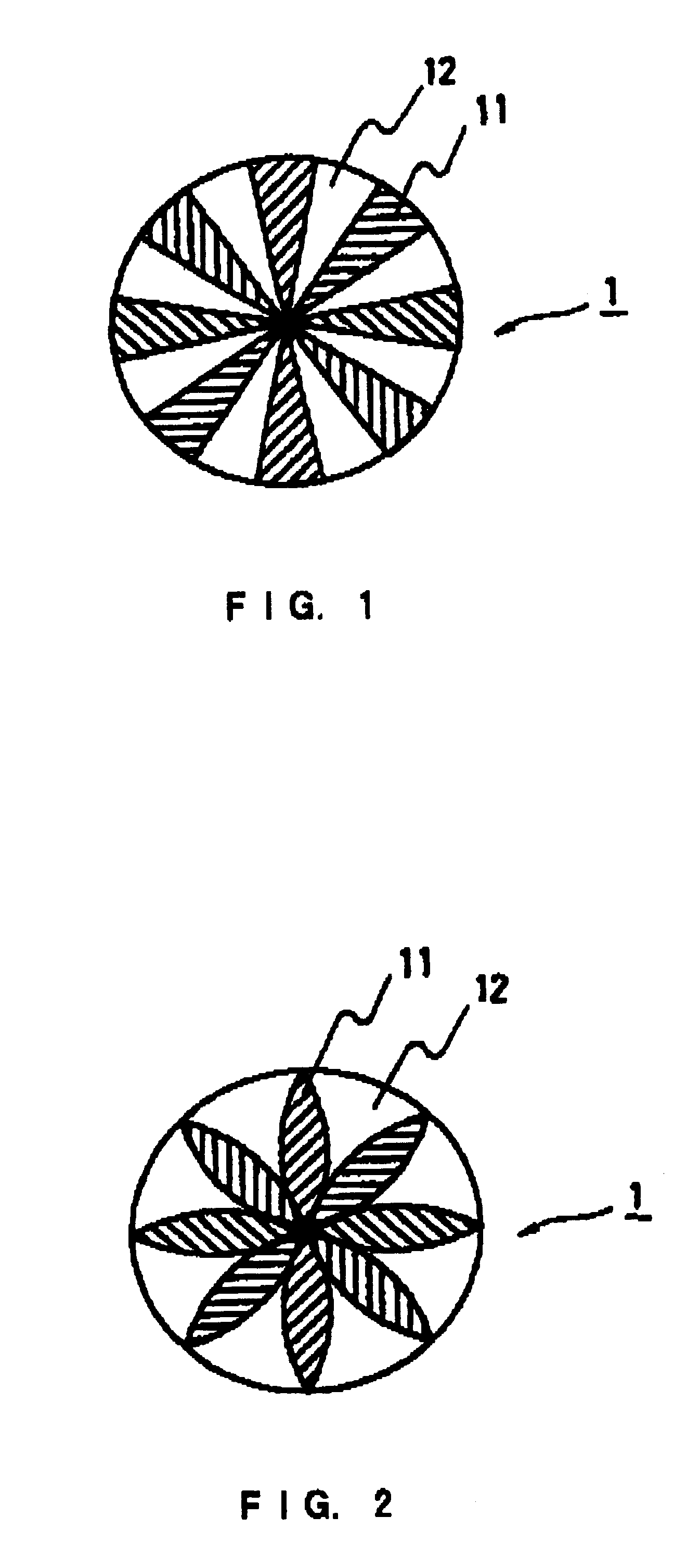

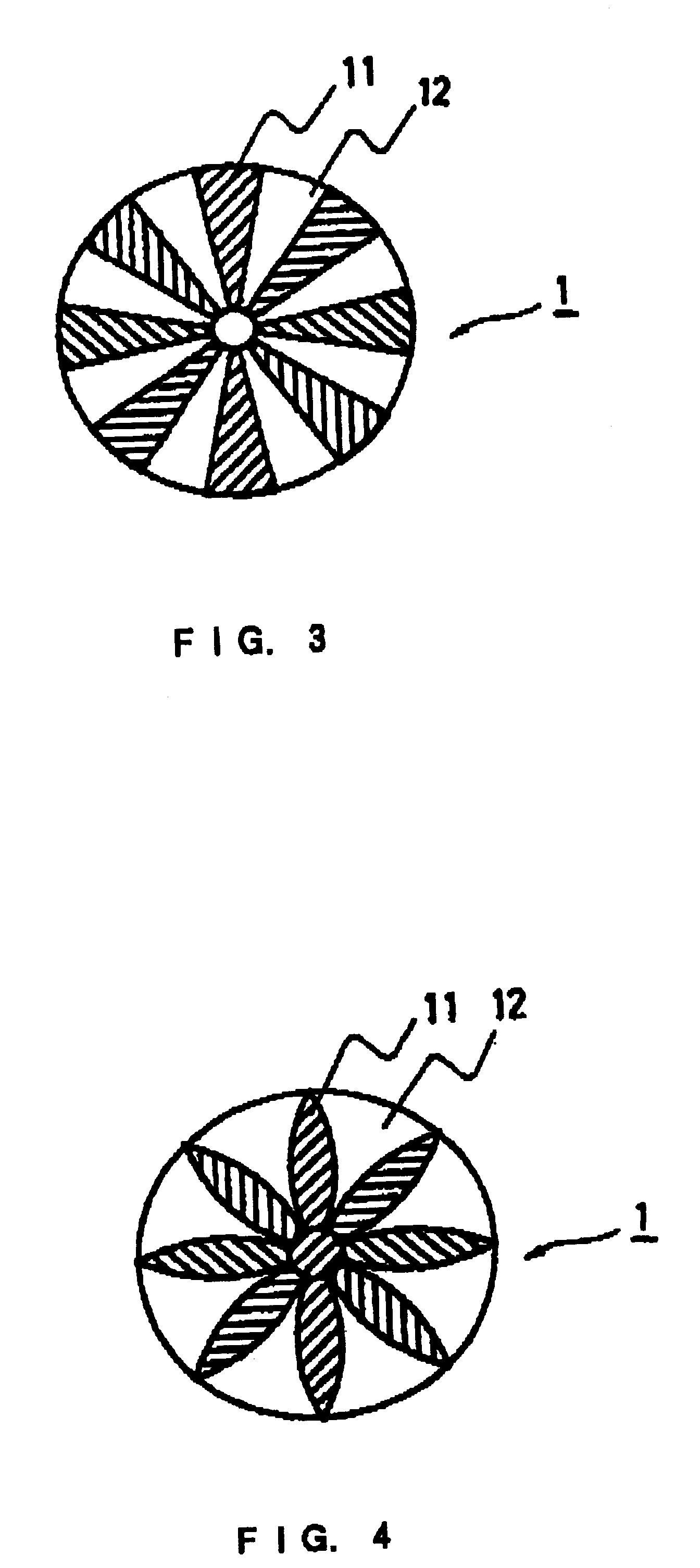

Battery separator

InactiveUS6586137B1Avoid breakingIncrease resistanceAlkaline accumulatorsCell component detailsYoung's modulusEngineering

Owner:NIPPON BAIRIIN

Automobile trim material combined with non-woven fabric and woven fabric

InactiveCN105034535ASignificant advantage effectLow priceSynthetic resin layered productsLaminationSodium bicarbonateWarm water

Owner:湖北南泽汽车复合材料有限公司

Concrete expansive agent

Owner:王嘉文

High-strength crack-resistant concrete and producing method thereof

Owner:南京加豪新型建筑材料有限公司

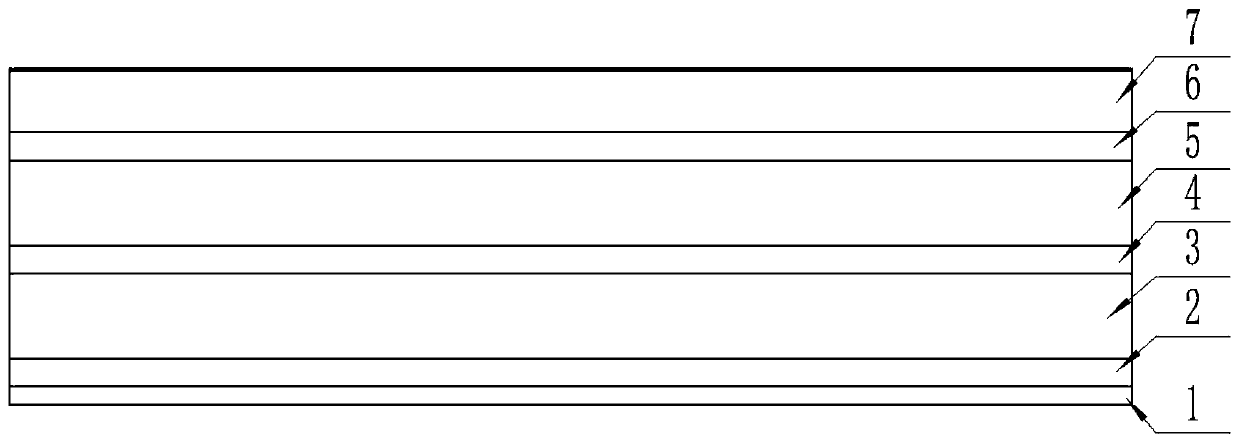

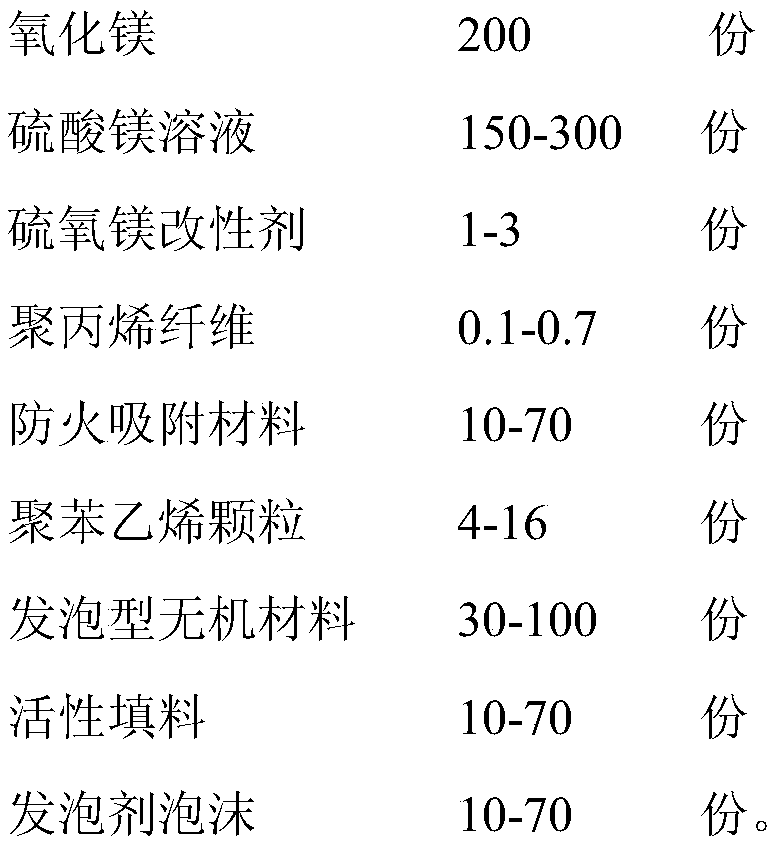

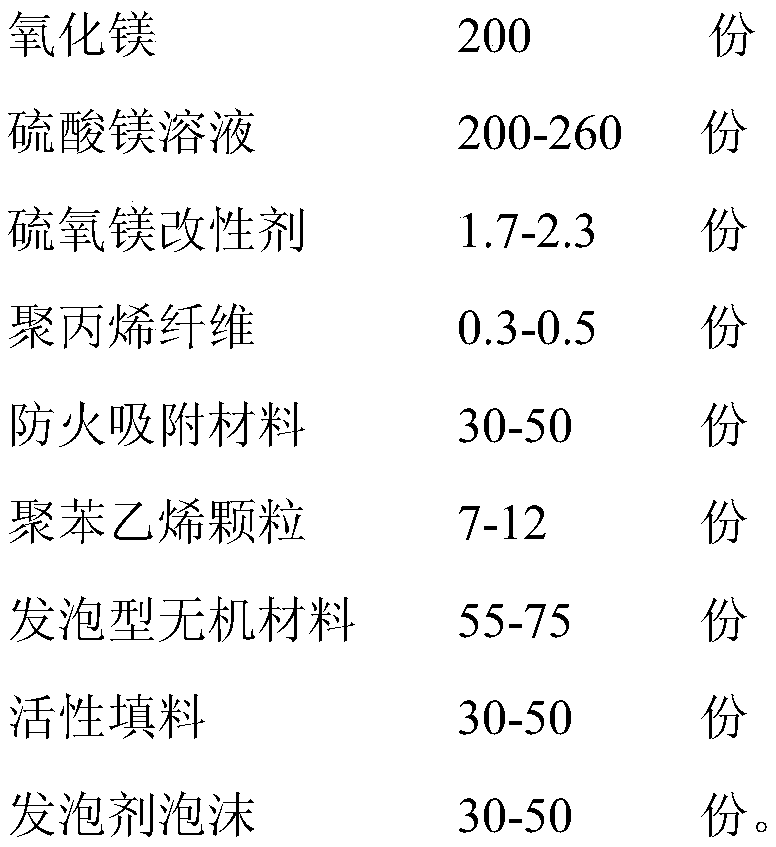

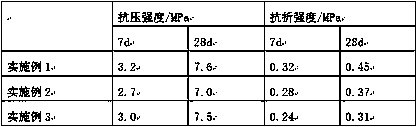

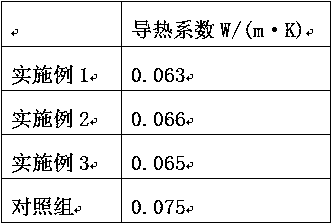

Heat-preservation sound-insulation magnesium oxysulfate fireproof material applied to wallboard and preparation method thereof

InactiveCN110294619ALow densityEasy to carryGlass/slag layered productsFoaming agentVolumetric Mass Density

Owner:常州布鲁科技有限公司

Preparation method of polyurethane heat preservation plate

InactiveCN106380828AGood dimensional stabilitySimple preparation stepsHeat proofingPolymer scienceSurface layer

Owner:CHANGZHOU YAHUAN ENVIRONMENTAL PROTECTION TECH

Preparation method of modified pitchstone-based thermal insulation mortar

InactiveCN110282929AImprove insulation effectImprove crack resistanceCrack resistanceThermal insulation

Owner:含山县领创新材料科技有限公司

Preparation method of porous graphene-based air purification agent

InactiveCN108772040AEfficient catalytic performanceReduce the precipitation ratePhysical/chemical process catalystsOther chemical processesPorous graphenePorous carbon

The invention relates to the technical field of vehicle purification agents, in particular to a preparation method of a porous graphene-based air purification agent. The preparation method of the porous graphene-based air purification agent includes the steps of: (1) adding a foaming agent into polypropylene resin and mixing the substances evenly, then conducting electrospinning to obtain polypropylene fiber, and performing calcining to obtain porous carbon fiber; (2) subjecting the porous carbon fiber, a soluble metal salt, a silane coupling agent and organic titanate to thermal reaction in asolvent to obtain modified porous carbon fiber; (3) modifying graphene oxide to obtain porous modified graphene oxide; and (4) mixing the modified porous carbon fiber with the porous modified graphene oxide to obtain the composite porous graphene-based air purification agent. The porous graphene-based air purification agent obtained by the method provided by the invention can adsorb harmful gasesin the air and catalyze harmful gases in situ at an adsorption point, and has the advantages of high catalytic efficiency and high removal rate.

Owner:ANHUI LEJIN ENVIRONMENT TECH CO LTD

Fireproof door core plate and production method thereof

InactiveCN106517989AImprove compatibilityImprove fire resistanceCeramicwarePhosphoric acidFire retardant

Owner:雅安市晶强板业有限公司

Non-flowable quick-setting phosphate cement repair material with strong cohesive forces and preparation method thereof

ActiveUS11339092B2Quick SetupImprove crack resistanceSolid waste managementCarboxylic acidP phosphate

The present invention belongs to the field of composite materials, and particularly to a non-flowable quick-setting phosphate cement repair material with strong cohesive forces and the preparation method thereof. The material comprises the following raw materials in percentage by weight: 20% to 40% of sand, 5% to 12% of ammonium dihydrogen phosphate, 10% to 25% of magnesium oxide, 2% to 8% of fly ash, 30% to 60% of rubber powder, 6% to 10% of silica fume, 0.35% to 0.6% of a polycarboxylate high efficiency water-reducing agent, 1% to 5% of sodium silicate, 1.5% to 2% of a polypropylene fiber, 0.5% to 2% of a retarder, and 8% to 10% of water. The material is used as the repair material for the special positions of bottom boards of bridges or facades of buildings which are damaged, and the repair effect thereof is remarkable.

Owner:YU JIAHUAN +1

Metal spray cleaning agent

InactiveCN111041500AResidue reductionReduce alkalinityMeth-Sodium phosphates

Owner:南京明仁光电科技有限公司

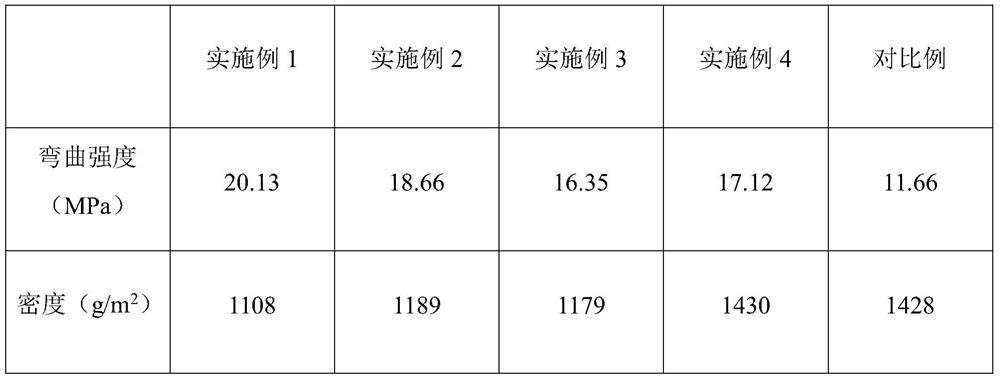

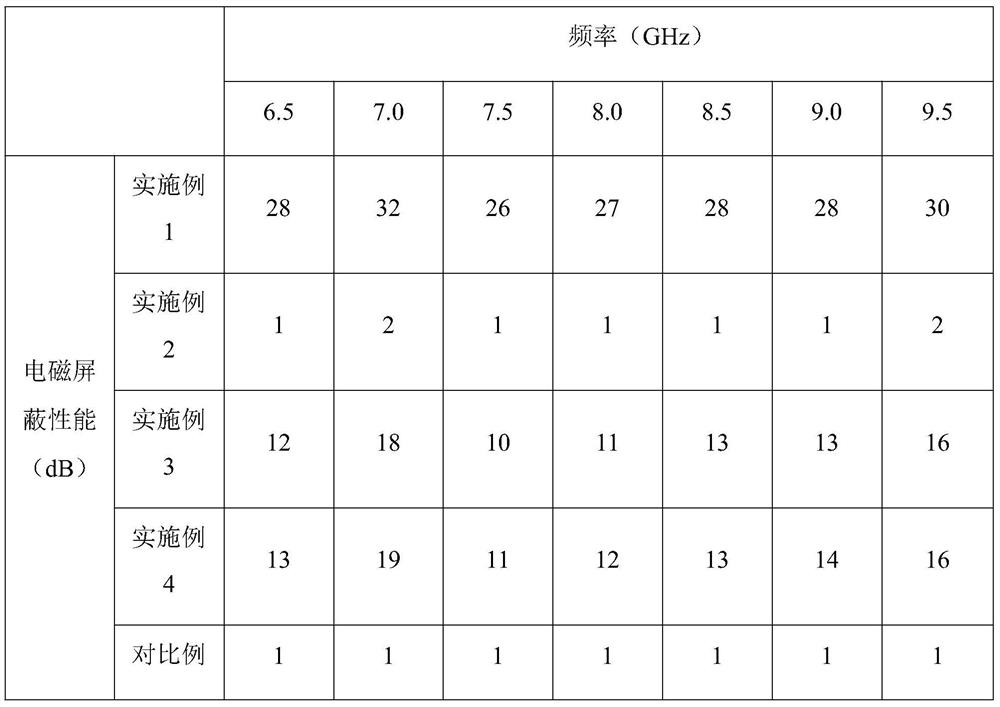

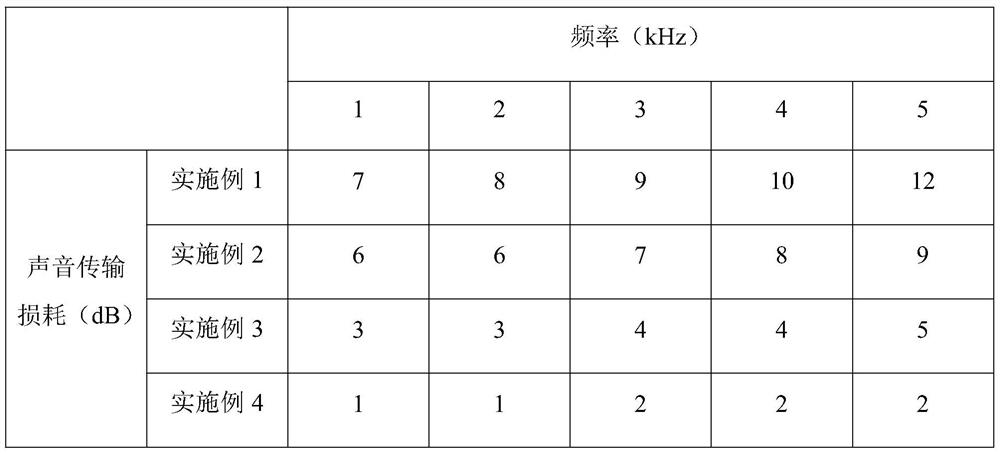

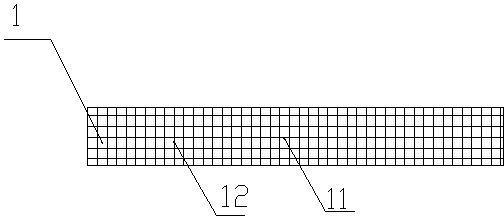

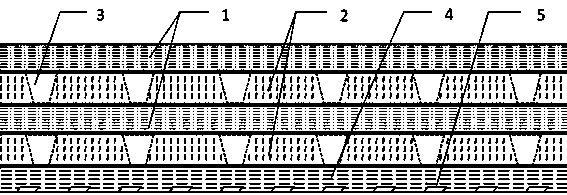

Composite board with electromagnetic shielding performance and preparation method thereof

ActiveCN113430713AImprove bindingImprove bending strengthNon-woven fabricsMonocomponent polyolefin artificial filamentPolyesterCellulose

Owner:SHENZHEN PENGHUI FUNCTIONAL MATERIAL CO LTD

Antibacterial medical fabric

InactiveCN104256977AEnhanced inhibitory effectGood killing effectWeft knittingWarp knittingEngineeringNatural fiber

Owner:JIANGYIN YASHUN GARMENT

High-dust and oil absorption electrostatic composite nonwoven wiping cloth

PendingCN110027288AImprove lipophilicityProne to adsorptionSynthetic resin layered productsSuction forceOptoelectronics

Owner:SHANDONG DERUN NEW MATERIAL TECH

Preparation method of high-moisture-retention dry-state essence mask with temperature-sensitive absorption-promoting function

InactiveCN114259425AExtended shelf lifePrevent oxidation failureCosmetic preparationsToilet preparationsPolyesterPolypropylene fiber

The invention relates to the field of cosmetics, and discloses a preparation method of a high-moisture-retention dry-state essence mask with a temperature-sensitive absorption-promoting function, and the preparation method comprises the following steps: (A) carrying out alkali decrement treatment on polypropylene fibers containing alkali-soluble polyester; (B) carrying out plasma treatment on the polypropylene fiber in an oxygen atmosphere; (C) dipping the polypropylene fiber into the essence; (D) spraying the finishing liquid on the polypropylene fiber, and carrying out heating crosslinking treatment to obtain the mask fiber with a skin-core structure; and (E) preparing the high-moisture-retention dry-state essence mask by taking the mask fiber as a raw material. The interior of the fiber in the mask is of a porous structure and can load essence substances, and meanwhile the surface of the fiber is provided with a temperature-sensitive gel skin layer. When the mask is stored in a dry state, the quality guarantee period can be effectively prolonged, and when warm water is added into the mask, the mask can quickly absorb water and promote release of essence substances after being applied to the skin surface.

Owner:贺文祯

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap