Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9 results about "Propylene oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Propylene oxide is an organic compound with the molecular formula CH₃CHCH₂O. This colourless volatile liquid with an odour resembling ether, is produced on a large scale industrially. Its major application is its use for the production of polyether polyols for use in making polyurethane plastics. It is a chiral epoxide, although it is commonly used as a racemic mixture.

Fused aza-heterocyclic aromatic hydrocarbon porous framework of two-dimensional lamellar structure, and preparation method and application thereof

ActiveCN105949443APromote complexationEasy to separateOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCycloadditionNitrogen

The invention specifically relates to a fused aza-heterocyclic aromatic hydrocarbon porous framework of a two-dimensional lamellar structure, and a preparation method and application thereof, belonging to the technical field of functional materials. According to the invention, aza-heteropolycyclic aromatic hydrocarbon is synthesized on the basiss of cyclization of a diamino group and a diketo group for formation of phenazine and is used as a monomer; and then aza-heteropolycyclic aromatic hydrocarbon is subjected to the Scholl reaction under the catalysis of a Lewis acid salt so as to allow aza-heteropolycyclic aromatic hydrocarbon to undergo homopolymerization at high temperature and low pressure, so a conjugated polymer material of a microporous structure and with two-dimensional lamellar layers for complex catalysis of metal is produced. The two-dimensional material has the characteristics of a high specific surface area, a full conjugate plane structure, heat stability, resistance to acid and alkali, excellent catalytic activity, high recovery rate, etc. The method provided by the invention is simple to operate and controllable in process; and the prepared material can be used for catalyzing a cycloaddition reaction of CO2 with epoxypropane compounds so as to immobilize CO2 and has good application prospects.

Owner:FUDAN UNIV

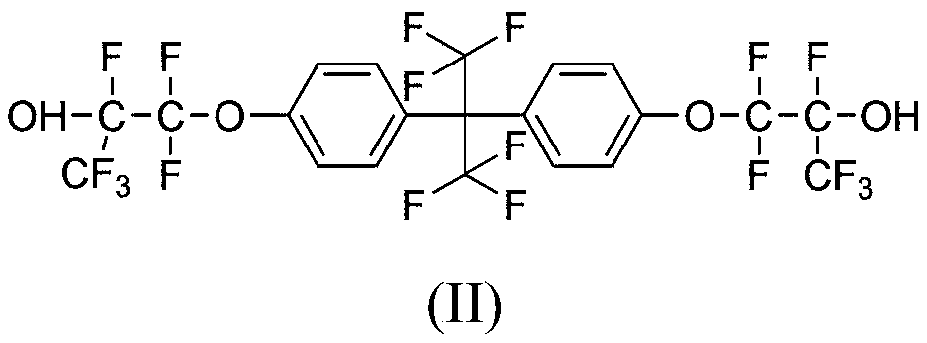

Preparation technology of perfluoropolyether for resin

Owner:XUZHOU ZENITH COATING

Continuous production equipment and process for hexafluoropropylene oxide oligomer

PendingCN111530383AContinuous operationReduce consumptionChemical recyclingCarboxylic acid halides preparationOligomerPtru catalyst

The invention provides continuous production equipment and a continuous production process for a hexafluoropropylene oxide oligomer. The continuous production equipment comprises a stirring kettle anda liquid phase separation kettle, wherein a stirrer is arranged in the stirring kettle; a discharge pipe is arranged at the bottom of the stirring kettle; a discharge pipe is arranged at the bottom of the liquid phase separation kettle; the discharging pipe is communicated with the discharge pipe through a feeding pipe; the feeding pipe is provided with a conveying pump; the top of the stirring kettle is communicated with the top of the liquid-phase separation kettle through a liquid-phase circulating pipe and a gas-phase circulating pipe respectively; the liquid-phase circulating pipe is provided with a circulating pump; the gas-phase circulating pipe is provided with a condenser; one end of the liquid-phase circulating pipe, which is positioned at the liquid-phase separation kettle, extends into the lower part of the liquid-phase separation kettle; and one end of the liquid-phase circulating pipe, which is positioned at the stirring kettle, is connected with a nozzle. The equipmentand the process have the advantages of continuous production, simplicity in operation, high production efficiency, stable product quality and the like, meanwhile, the catalyst, the solvent and byproducts can be recycled, and the process is low in cost and environmentally friendly.

Owner:JIUDING FLUORIN CHEM CO LTDZHANGPING FUJIAN

Preparation method and application of low-dielectric loss piezoelectric ceramic materials

InactiveCN107805072ALow dielectric lossImprove qualityPiezoelectric/electrostrictive/magnetostrictive devicesElectromechanical coupling coefficientZirconate

The invention discloses a preparation method and an application of low-dielectric loss piezoelectric ceramic materials. The method includes the steps: mixing silicon nitride, aluminum oxide and molybdenum disulfide, ball-milling mixture and placing the ball-milled mixture into ethylene glycol; adding bisphenol-A epoxy resin, strontium zirconate and polyether propylene oxide, and stirring and heating mixture to obtain thermal reaction mixed liquid; ageing the thermal reaction mixed liquid, adjusting pH (potential of hydrogen) of the mixed liquid, and drying the mixed liquid to obtain ceramic slurry; performing curing and demolding on the ceramic slurry in molds to obtain blanks; sintering the blanks to obtain the low-dielectric loss piezoelectric ceramic materials. The prepared low-dielectric loss piezoelectric ceramic materials are high in mechanical quality factor and electromechanical coupling coefficient and low in dielectric loss and have good application prospects in electronic device products.

Owner:SUZHOU KEMAO ELECTRONICS MATERIALS TECH

Purifying agent for compound containing aldehyde impurities and application of purifying agent

PendingCN113651776AEasy to makeHigh removal ratePreparation by isomerisationOrganic compound preparationAlcoholCombinatorial chemistry

Owner:CHINA CATALYST HLDG CO LTD

Process for production of propyline oxide

InactiveUS20050085647A1Long catalyst lifeImprove featuresOrganic compound preparationOrganic chemistry methodsOrganic acidAlcohol

Owner:SUMITOMO CHEM CO LTD

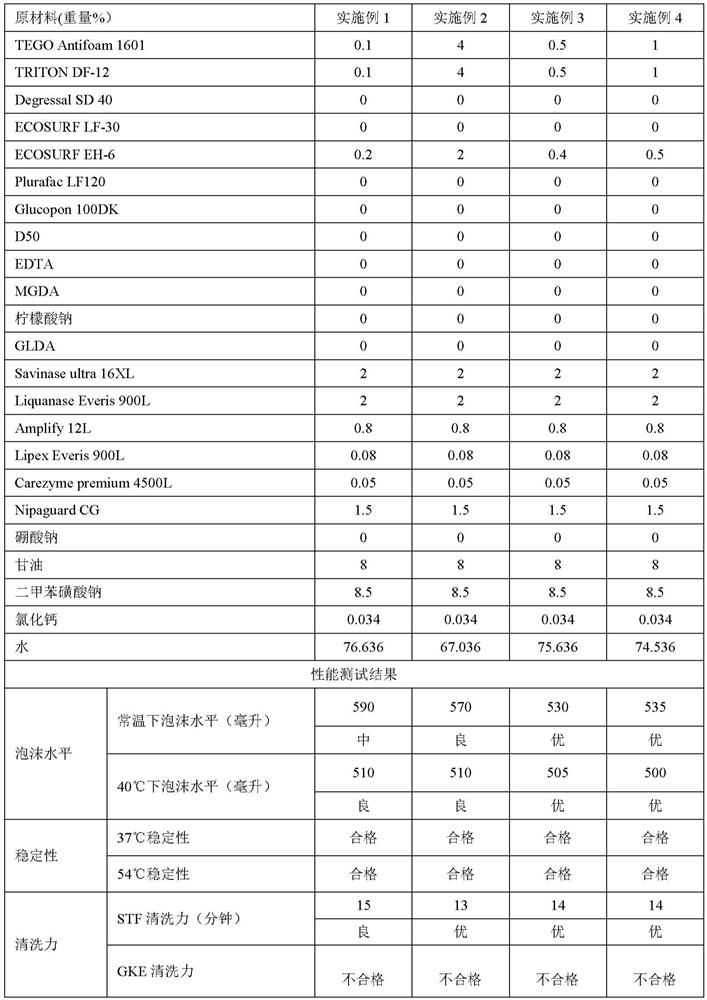

Liquid cleaning composition and preparation method thereof

ActiveCN113122395AImprove stabilityLow foam levelInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsActive agentSurface-active agents

Owner:3M INNOVATIVE PROPERTIES CO

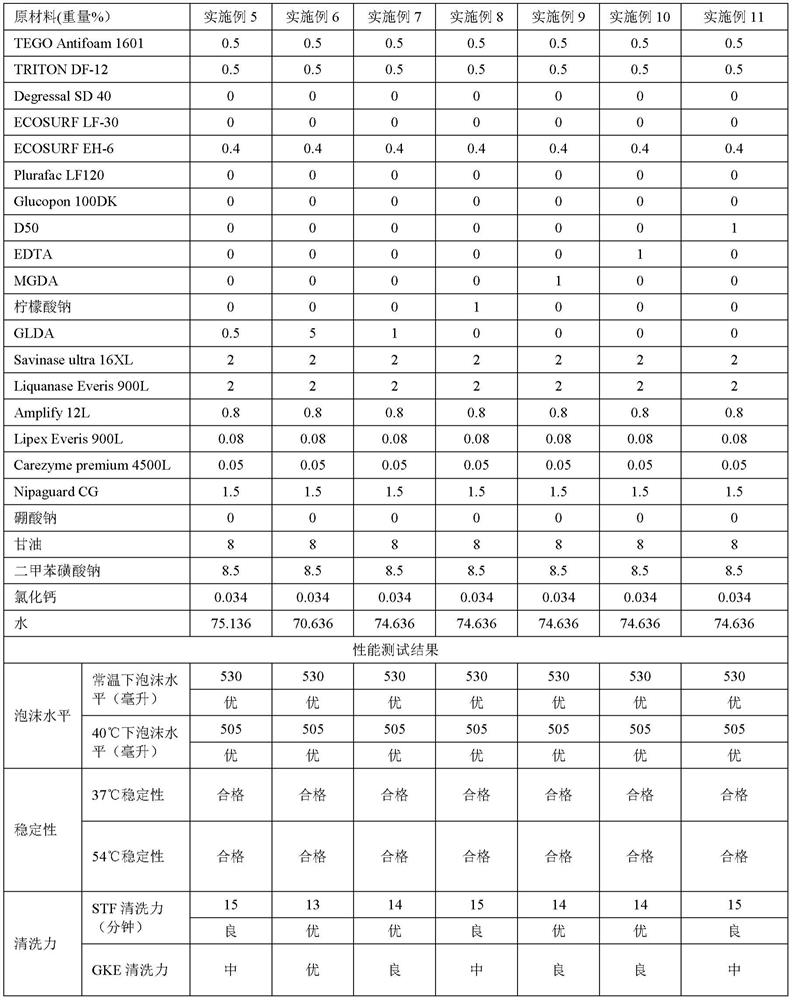

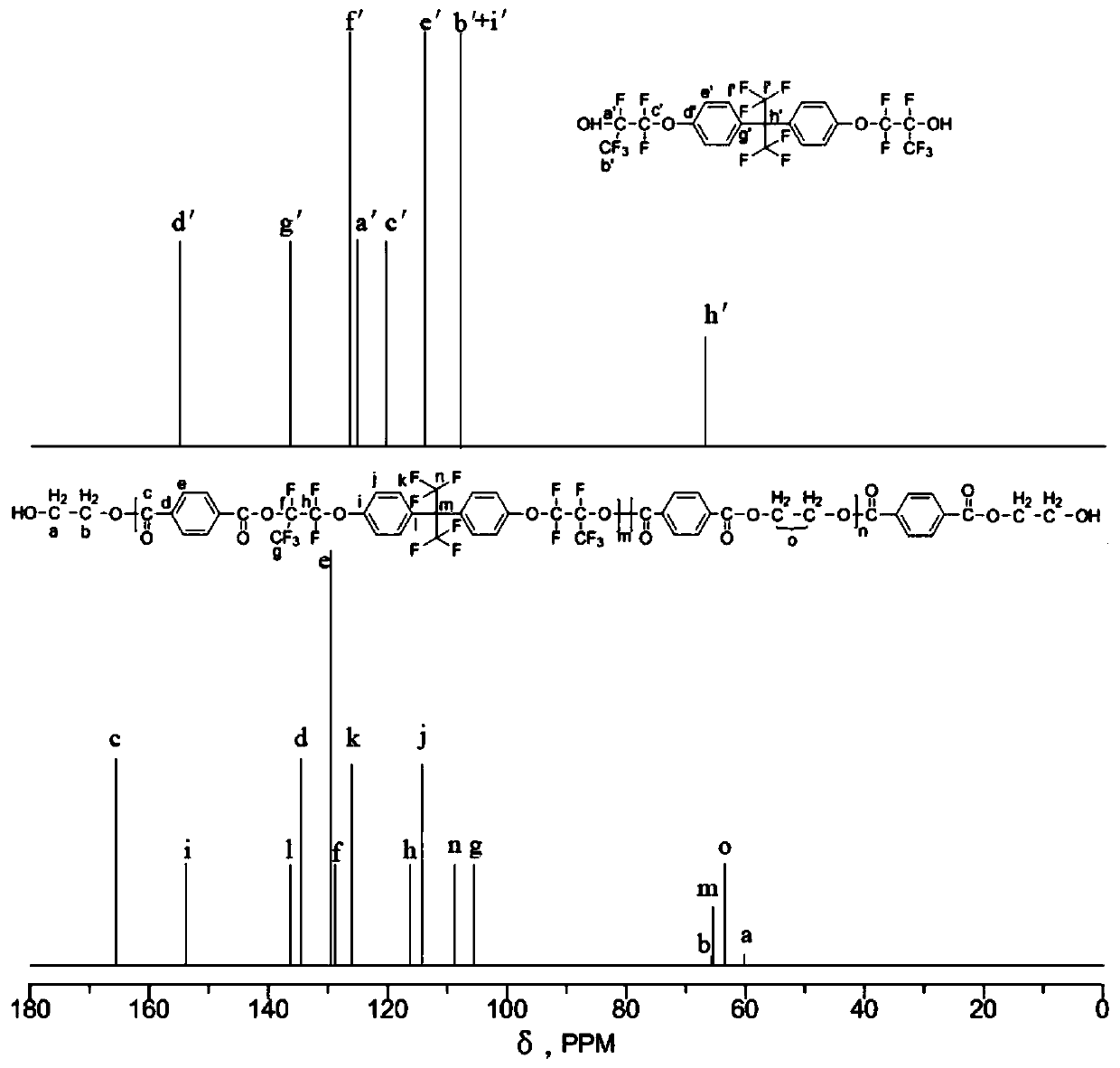

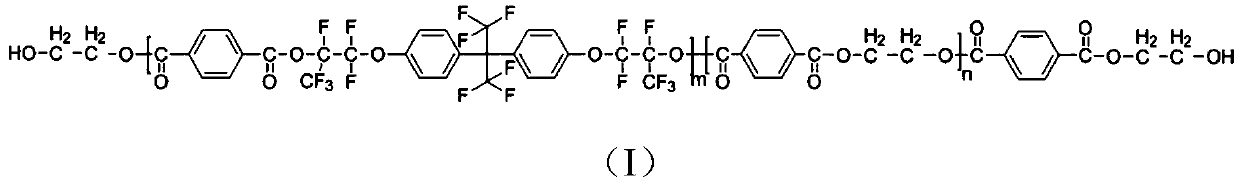

Anti-fouling flame-retardant fluorine-containing polyester fiber and preparation method thereof

InactiveCN111549389AViscosity is easy to controlImprove timelinessSpinning solution de-aeratingFilament/thread formingPolymer scienceHexafluoropropylene oxide

Owner:徐毓敏

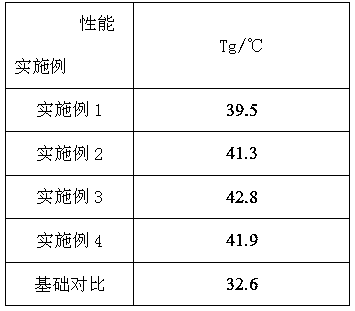

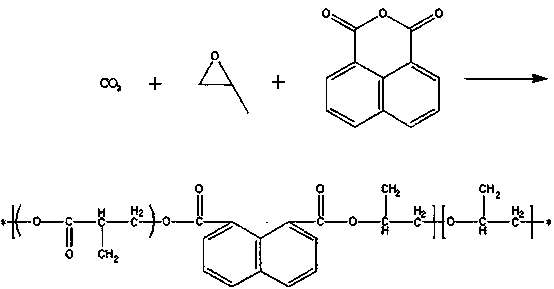

Preparation method of 1,8-naphthalic anhydride modified poly(propylene carbonate)

InactiveCN109721719AHigh glass transition temperatureImprove thermal efficiencyMolecular materialsRare earth

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap