Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15 results about "Calcium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium oxide (CaO), commonly known as quicklime or burnt lime, is a widely used chemical compound. It is a white, caustic, alkaline, crystalline solid at room temperature. The broadly used term "lime" connotes calcium-containing inorganic materials, in which carbonates, oxides and hydroxides of calcium, silicon, magnesium, aluminium, and iron predominate. By contrast, quicklime specifically applies to the single chemical compound calcium oxide. Calcium oxide that survives processing without reacting in building products such as cement is called free lime.

Method for desulphurizing, denitrating and decoking fire coal

The invention discloses a method for desulphurizing, denitrating and decoking fire coal. In the method, in a raw coal burning stage, a synergist is added in an amount of 0.2 to 0.3 weight percent based on the total weight of the raw coal into the fire coal, and a catalytic active agent is added in an amount of 0.002 to 0.008 weight percent based on the total weight of the raw coal into a slurry boax in a desulphurizing system at the same time. The synergist comprises 8 to 25 mass percent of calcium carbona, 5 to 15 mass percent of magnesium oxide, 5 to 10 mass percent of silicon dioxide, 5 to10 mass percent of zinc oxide, 8 to 10 mass percent of manganese dioxide, 15 to 40 mass percent of calcium oxide, 5 to 10 mass percent of barium hydroxide, 3 to 8 mass percent of aluminum oxide and 8to 15 mass percent of potassium permanganate; and the catalytic active agent comprises 0 to 40 mass percent of active calcium oxide, 20 to 30 mass percent of active carbon, 10 to 15 mass percent of calcium ammonium nitrate, 5 to 20 mass percent of ferric oxide and 2 to 10 percent of zinc oxide. Under the condition of not changing the conventional boiler equipment and process, the method can realize fire coal combustion-supporting and coal-saving functions at one time so as to perform desulphurization, denitration and decoking.

Owner:GUANGZHOU ZHONGKE GAOCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Dephosphorizing agent and application thereof

The invention relates to a dephosphorizing agent and application thereof, belonging to the technical field of ferrous metallurgy. The dephosphorizing agent solves the problems of low dephosphorizing efficiency, high residue consumption, environment pollution and difficulty in resource comprehensive utilization in the existing calcium-oxide-based molten iron pretreatment dephosphorizing agent. The dephosphorizing agent comprises the following components in percentage by mass: 25-50% of FeOt, 20-45% of CaO, 15-30% of SiO2, 2-10% of Na2O and 3-12% of Al2O3. After being molten, the molten iron dephosphorizing can form a solid-phase / liquid-phase coexistent multiphase residue system at 1300-1400 DEG C, wherein the solid phase is a 2CaO.SiO2 phase capable of providing a place for enriching oxidized phosphorus in molten iron, so that the dephosphorizing agent has the characteristics of favorable dephosphorizing effect, low slag consumption, no fluorine and small environmental pollution and is beneficial to comprehensive utilization of dephosphorizing slag.

Owner:CENT SOUTH UNIV

Full oil base drilling fluid with high dynamic shear force ratio

ActiveCN103146365AHigh ratio of dynamic plasticImprove rheologyDrilling compositionBase oilPotentiator

The invention discloses full oil base drilling fluid with high dynamic shear force ratio. The full oil base drilling fluid comprises base oil and other ingredients on the basis of the volume of the base oil: 1.5-2.5% of main emulsifying agent, 0.5-1.0% of auxiliary emulsifying agent, 0.8-1.0% of reverse wetting agent, 0.8-1.0% of shearing potentiator, 0.3-0.5% of thermoplastic flow type regulating agent, 2.0-3.0% of calcium oxide, 1.0-3.0% of organic soil, 1.5-2.0% of fluid loss additive and weighting material, and due to the addition amount of the weighting material, the density of the full oil base drilling fluid is 0.89-2.50g / cm<3>. The addition amount of the organic soil in the full oil base drilling fluid system is reduced by 1.0-3.0% through adding the thermoplastic fluid type regulating agent, the dynamic shear force ratio of the system is obviously improved and can achieve more than 0.45, the rheological property of the system can be improved, the comprehensive properties can be improved, and the production cost can be saved.

Owner:CHINA NAT PETROLEUM CORP +1

Composite high magnesia flux for sintering

InactiveCN101469365AAvoid negative effectsEliminate unfavorable situationsMaterials scienceWhite Spots

Owner:ANYANG IRON & STEEL GRP

Production raw material for preparing calcium oxide by using calcium carbide furnace gas purified ash and preparation process thereof

InactiveCN109179468AEasy to operateSave energyCalcium/strontium/barium oxides/hydroxidesCombustionCoal dust

Owner:石嘴山市鹏盛化工有限公司

Tire inner liner rubber and preparation method thereof

Owner:DEZHOU LINGLONG TIRE

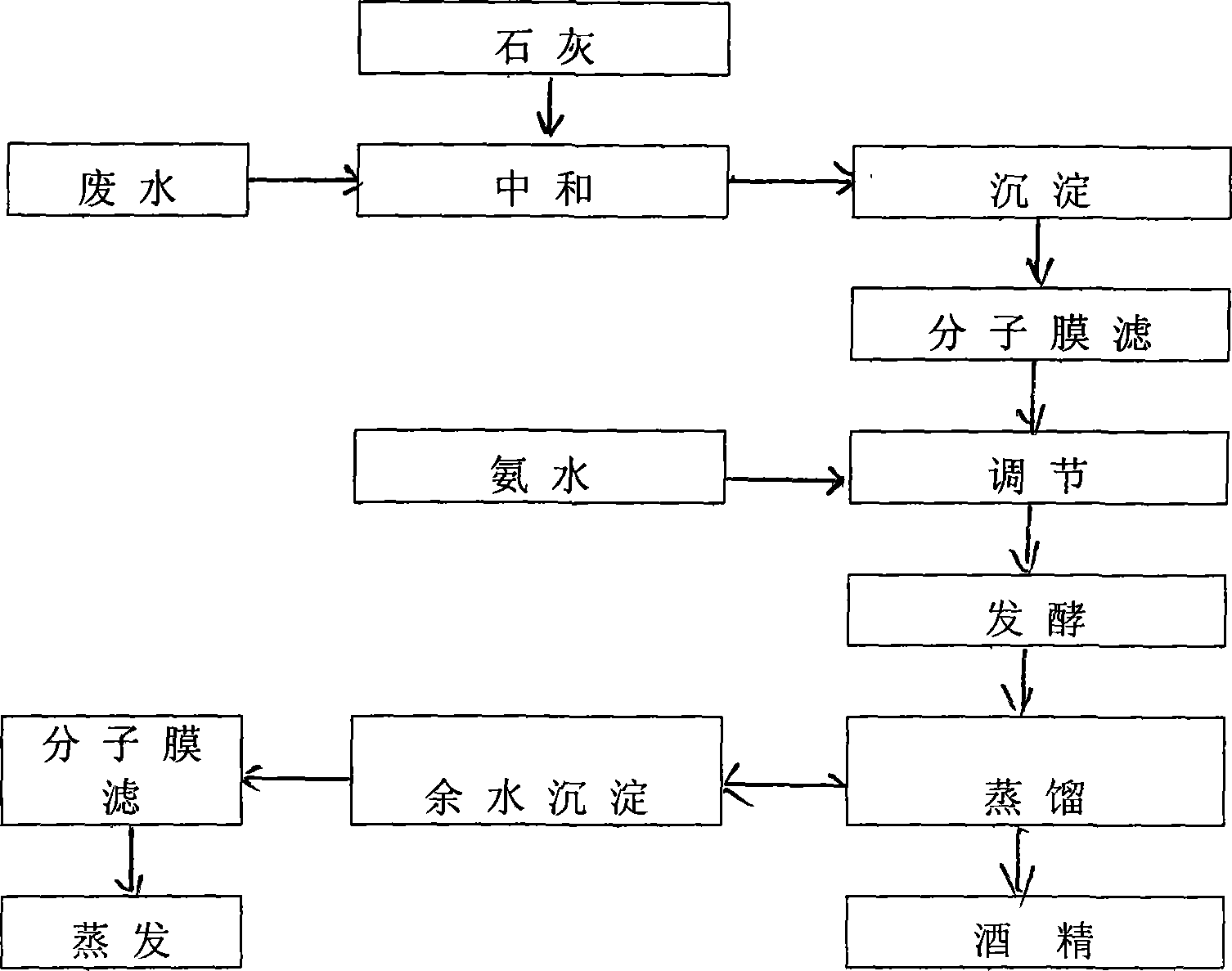

Method for treating and utilizing wastewater from process of extraction diosgenin of Dioscorea zingiberensis

InactiveCN101462807ANo pollution in the processSimple processBiofuelsWater/sewage treatment bu osmosis/dialysisFermentationPollution

Owner:LUOYANG DONGRUI BIOLOGICAL

Tailor's chalk

The invention discloses a tailor's chalk which comprises the following components in percentage by weight: 60-65% of calcium sulfate, 15-17% of salicylic acid, 15-16% of calcium oxide, 3.2-5.0% of zinc stearate, 2-5% of calcium stearate, 0-10% of palmitic acid, 0-1% of amino acid, 0.2-0.3% of a demolding agent and the balance of impurities. The tailor's chalk disclosed by the invention is improved on the basis of the existing invisible tailor's chalk, and is researched and developed with the main component of calcium sulfate by combining the conventional tailor's chalk; and when the tailor's chalk is applied to a dress material, calcium sulfate is attached to the dress material, and because calcium sulfate is matched with other auxiliary materials, the main component namely calcium sulfate can fall off only by beating forcibly for a while, so that the tailor's chalk is very easy to remove.

Owner:刘桂芹

Baking-free long water gap for large-plate-blank continuous casing low-carbon and low-silicon steel and preparation process of baking-free long water gap

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

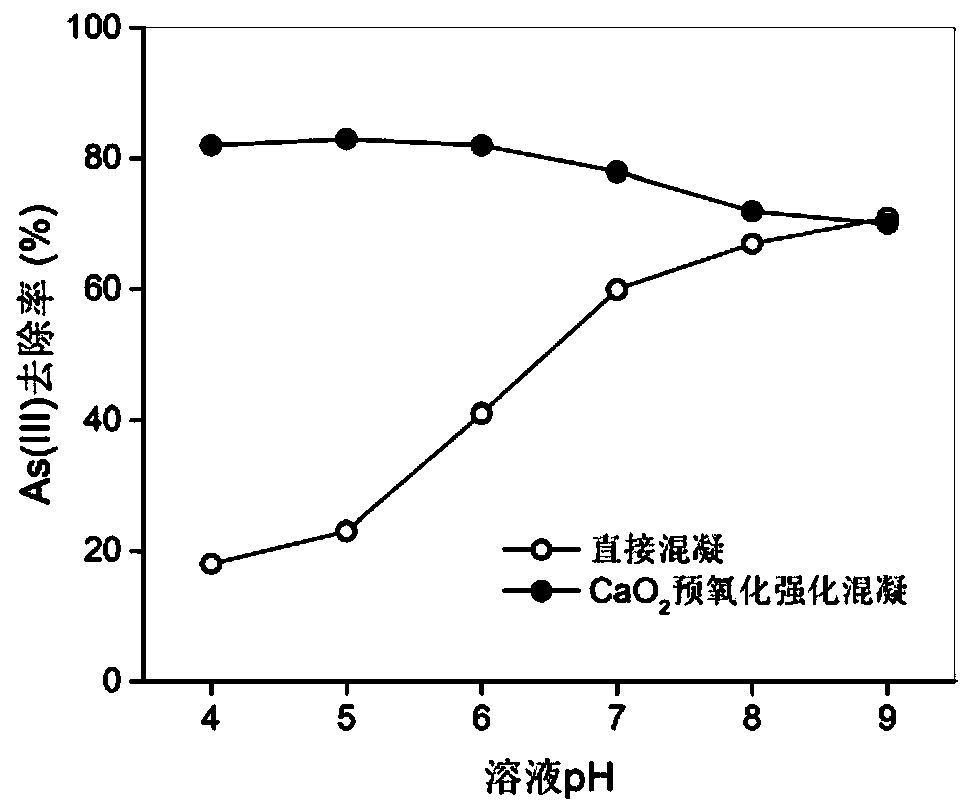

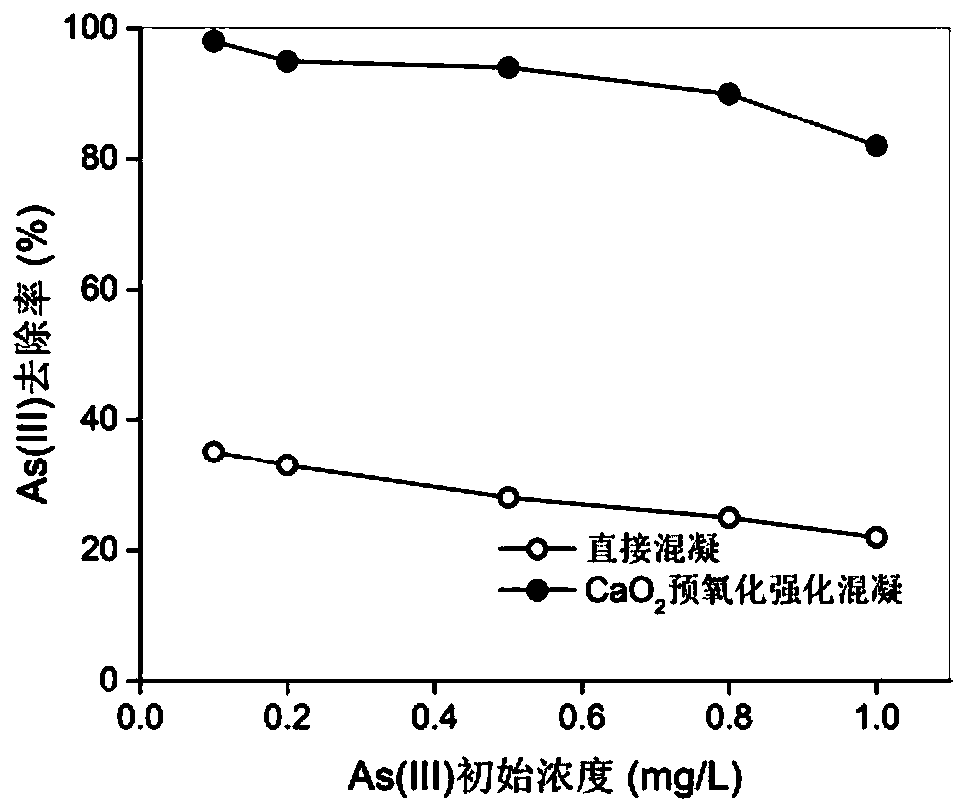

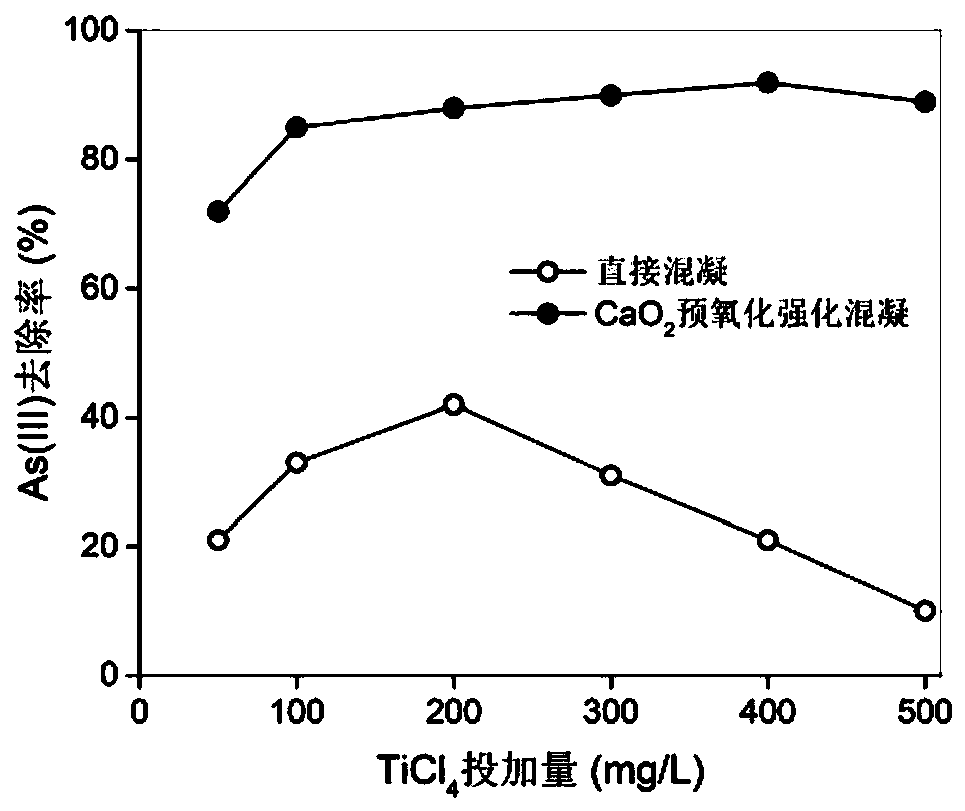

Method for removing As (III) in wastewater through enhanced coagulation

ActiveCN111348775AImprove pH environmentGood for alkaline levelsWater contaminantsEnergy based wastewater treatmentAlkaline waterIndustrial waste water

Owner:NANJING AGRICULTURAL UNIVERSITY

Preparation process and formula of thermal insulation board special for refrigeration house

PendingCN111808381AImprove fire protectionImprove fire and flame retardant performanceCoatingsPolymer scienceThermal insulation

Owner:太仓幕阳节能科技有限公司

Environmentally-friendly plastic cement

Environmentally-friendly plastic cement is disclosed. The plastic cement is composed of the following ingredients (by weight): 28-32% of epoxidized soybean oil, 13-15% of polyol benzoate, 7-13% of polyethylene resin, 11-14% of polyepichlorohydrin, 2-7% of white carbon black, 3-5% of calcium oxide, 1-4% of amide, 3-6% of barium stearate and the balance rubber particles. The invention has the following beneficial effects: the prepared product is environmentally-friendly, harmless, odorless, has flat surface, high compressive strength, good elasticity and long service life, and is not easy to age.

Owner:TIANJIN KANG ENVIRONMENTAL PROTECTION EQUIP CO LTD

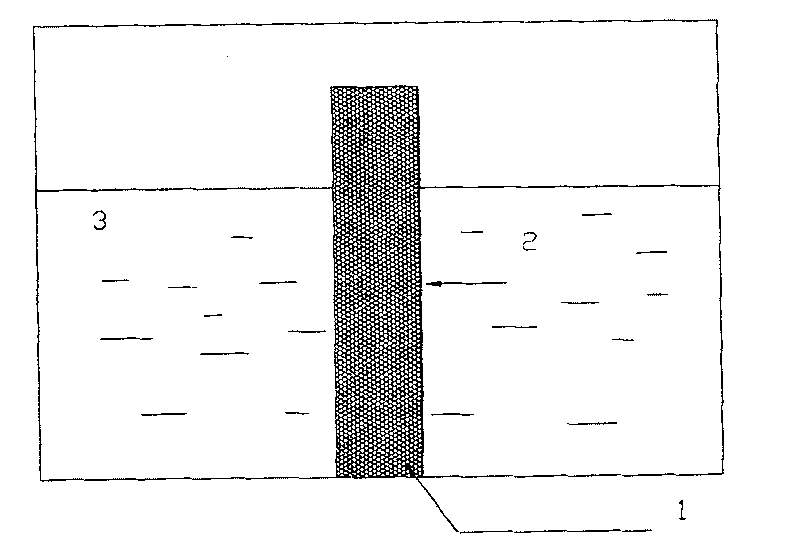

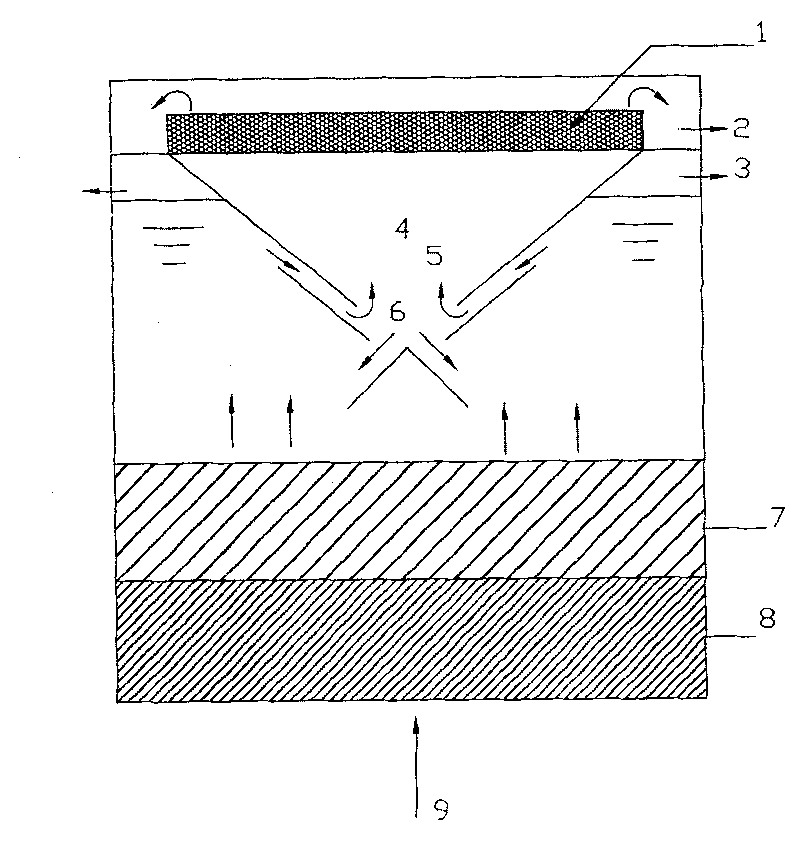

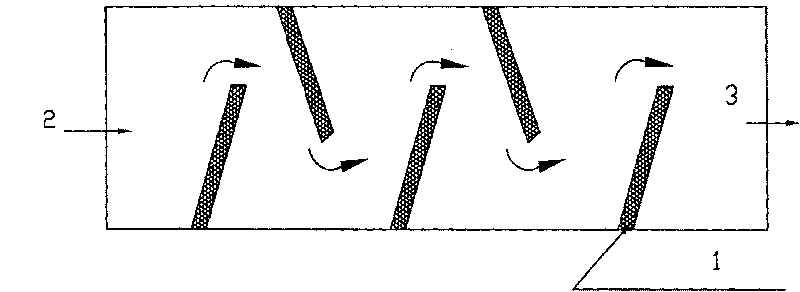

Composite immobilized enzyme material for repairing polluted water source and its preparing process

InactiveCN1986789BReduce resistanceThe geometric specific surface area is largeOn/in inorganic carrierBiological water/sewage treatmentWater sourceSewage

Owner:江苏晨翔环境科技股份有限公司

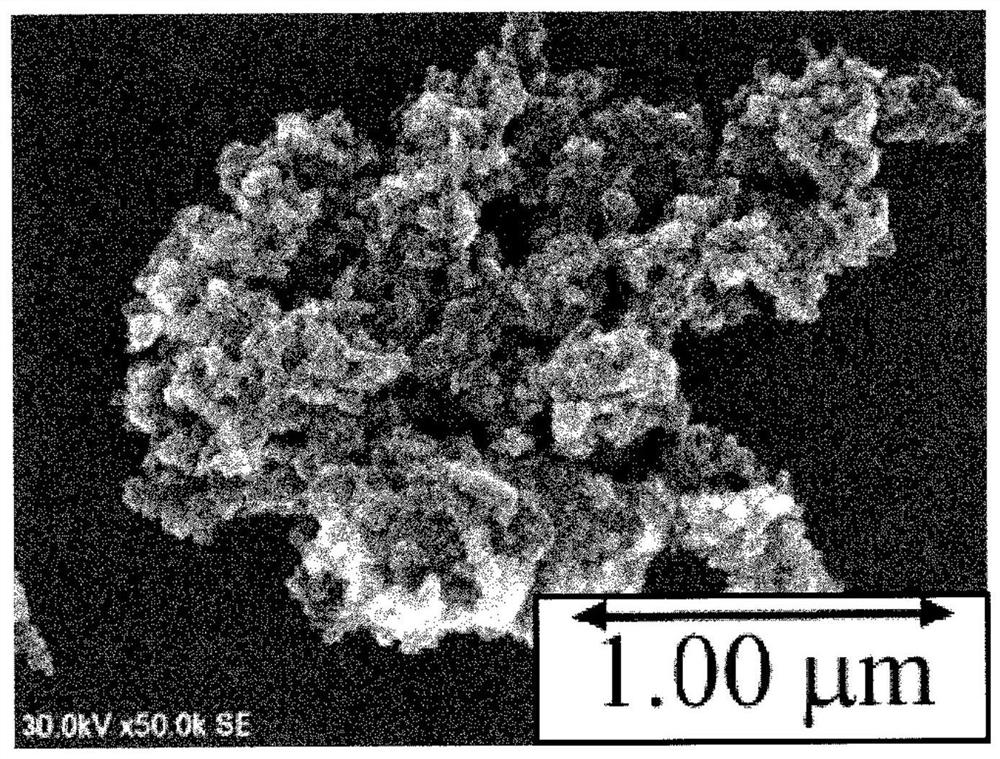

Chemical heat storage material and method for producing same

ActiveCN111918949AImprove repeat durabilityHeat-exchange elementsCalcium/strontium/barium oxides/hydroxidesCalcium silicatePhysical chemistry

Owner:SHIRAISHI CENT LAB +1

Cable with insect bite prevention effect

InactiveCN110577734AWith fire performanceHas insect repellent effectInsulated cablesInsulated conductorsParaffin oilsPhthalate

Owner:黄霞

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap