Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

20 results about "Hydrothermal reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for making molecular sieves and novel molecular sieve compositions

Owner:ABB LUMMUS GLOBAL INC

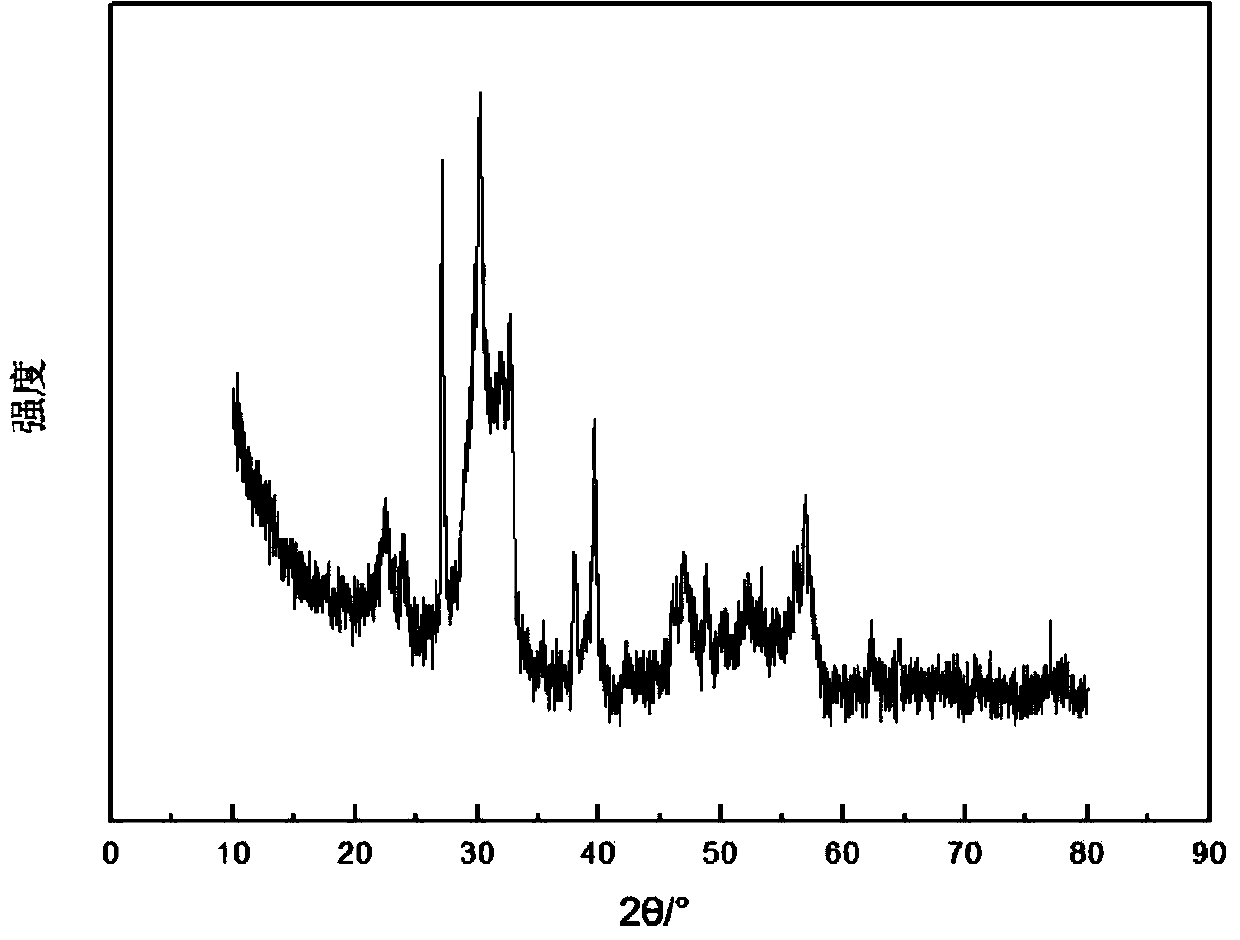

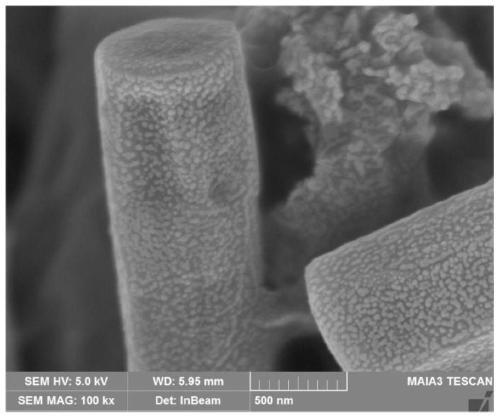

Method for preparing ZnWO4 nanorod photocatalysis material

InactiveCN102935360APhotocatalyticWith photocatalytic effectMetal/metal-oxides/metal-hydroxide catalystsTungsten compoundsHeat treatedNanorod

Owner:SHAANXI UNIV OF SCI & TECH

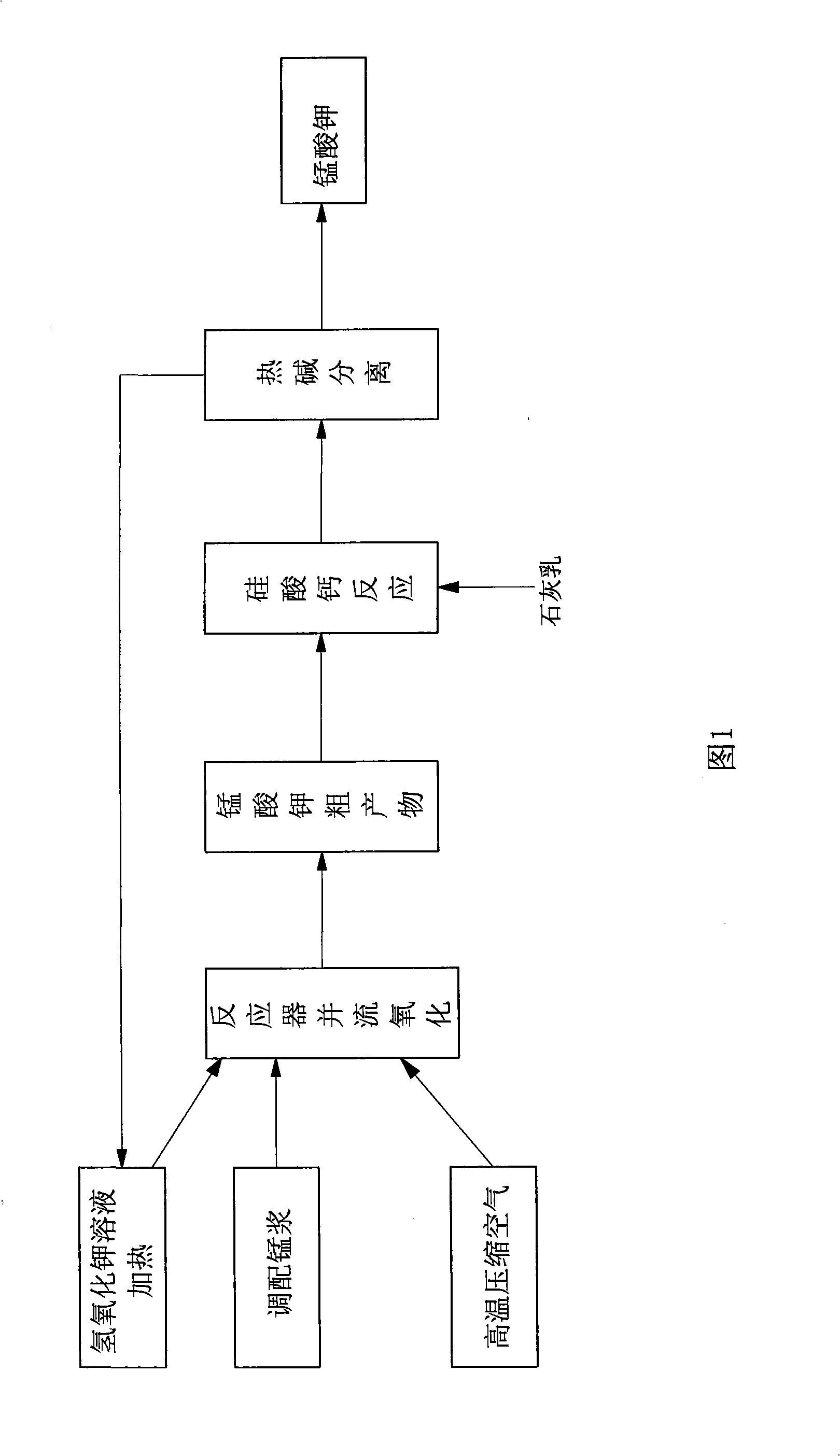

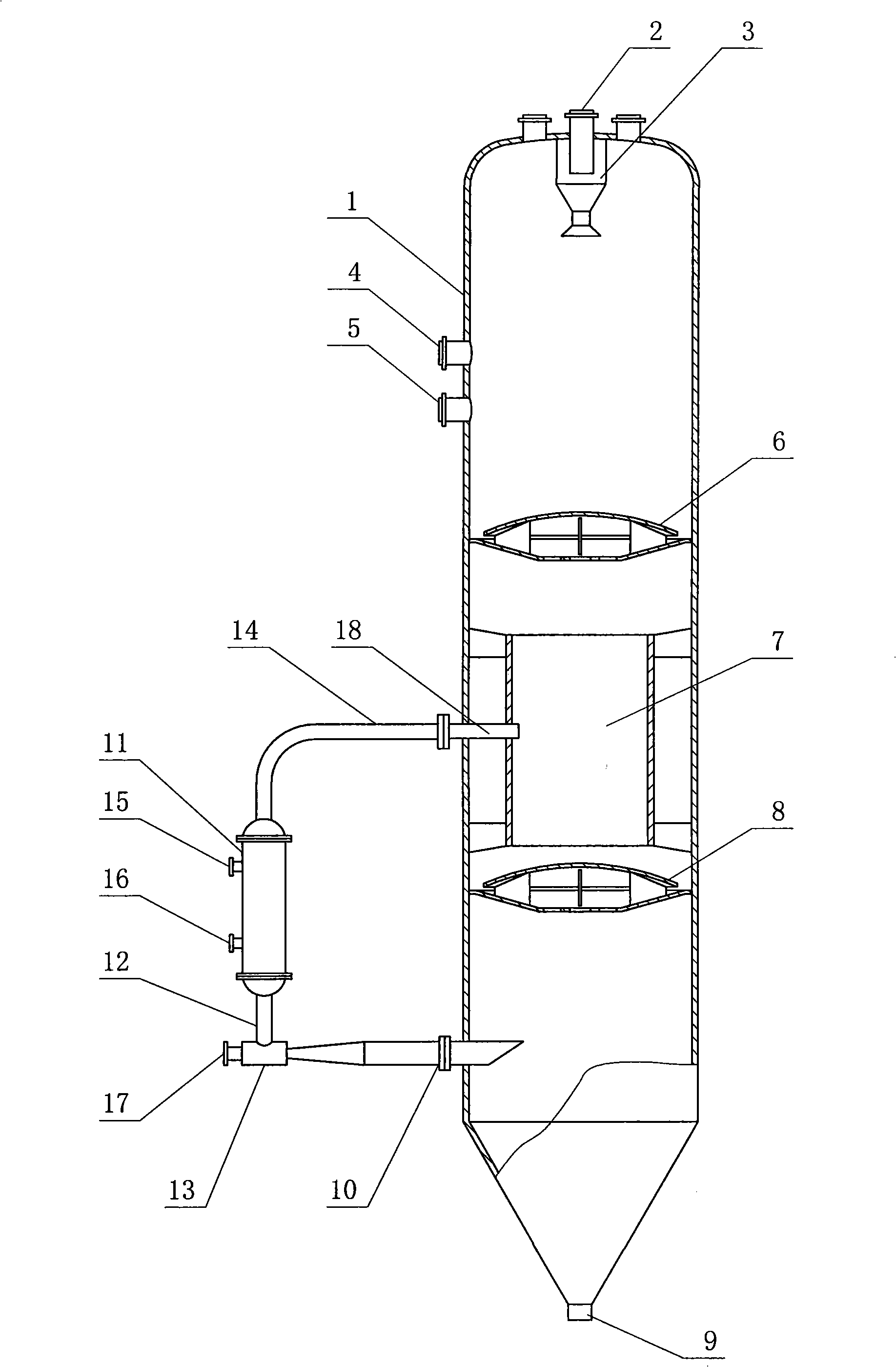

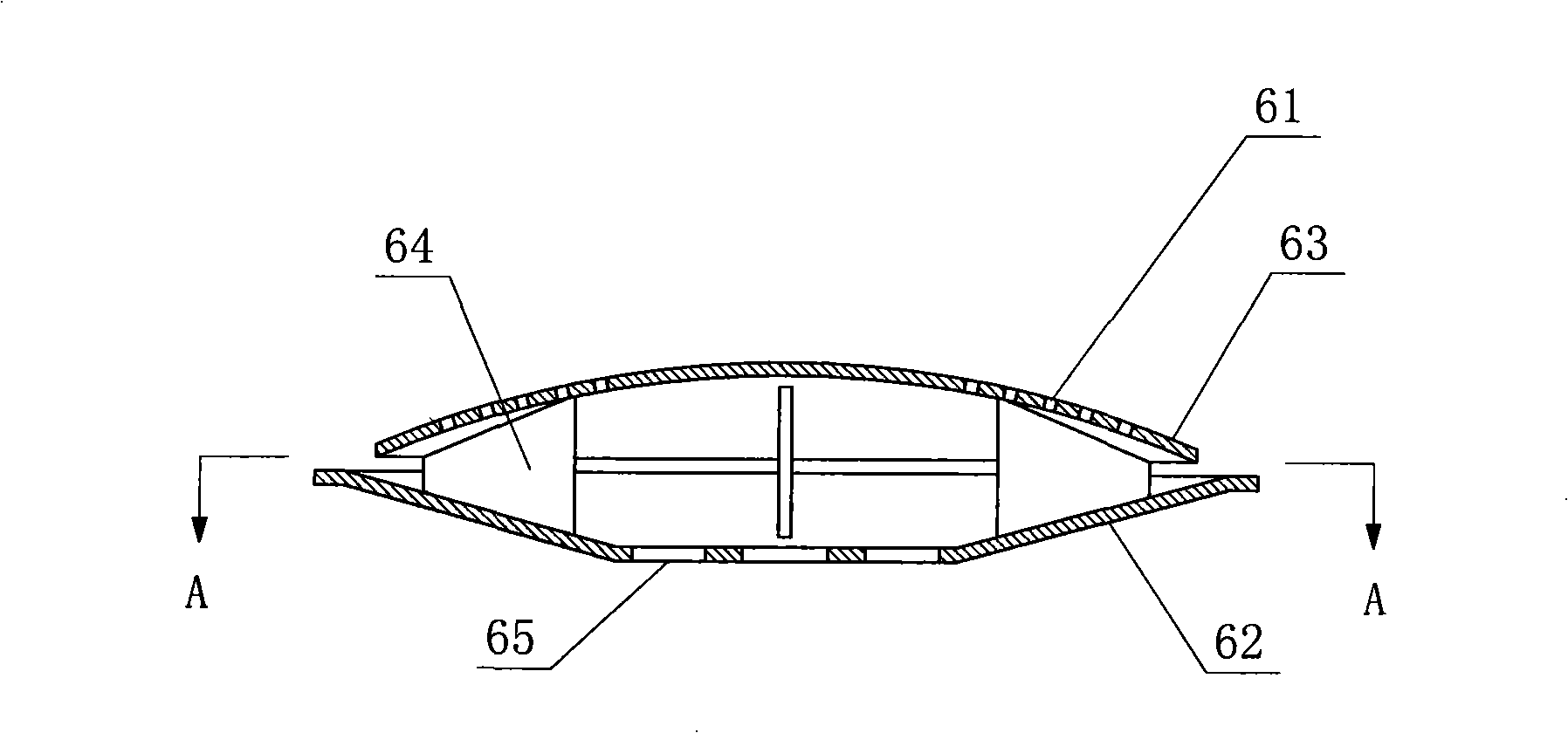

Method and equipment for manufacturing potassium manganate

InactiveCN101492182AWidely sourced and inexpensiveEfficient use ofEnergy inputManganates/permanganatesNatural resourceCalcium silicate

Owner:ZUNYI SHUANGYUAN CHEM IND GROUP

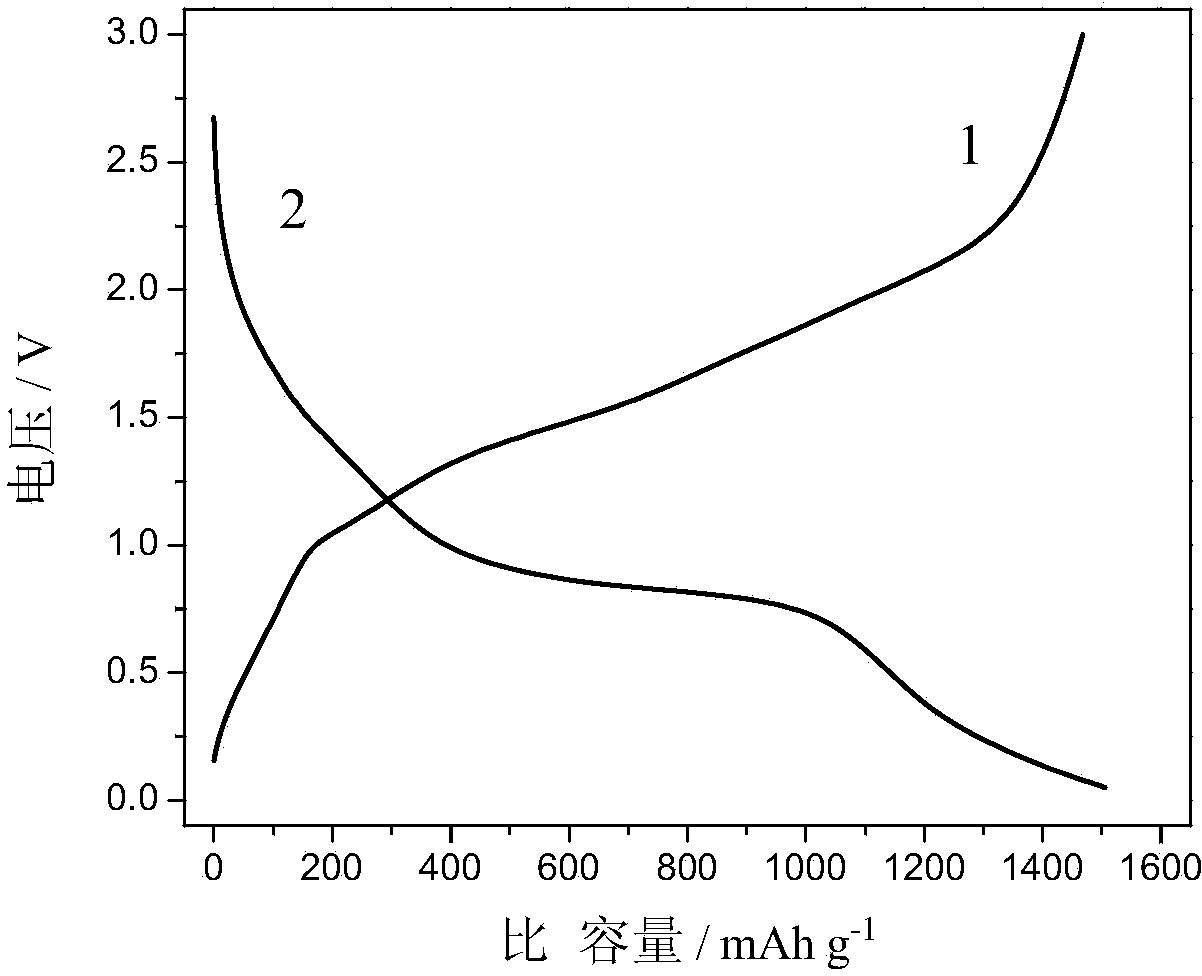

Ferrous carbonate/graphene composite material and preparation method and applications thereof

ActiveCN103840132AHigh specific capacityImprove cycle performanceNegative electrodesSecondary cellsMass ratioConcentration ratio

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

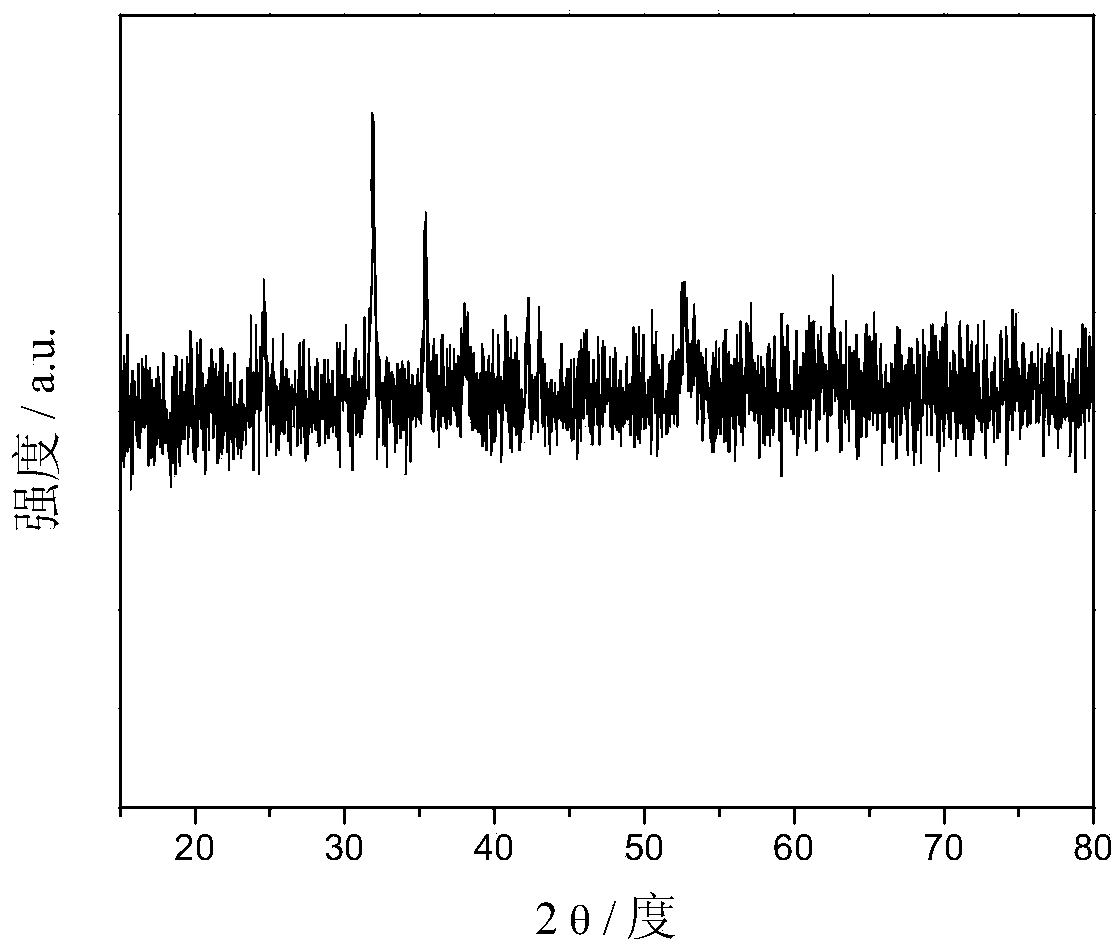

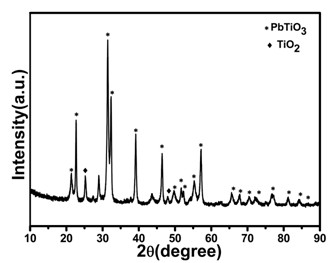

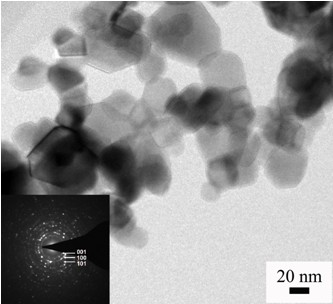

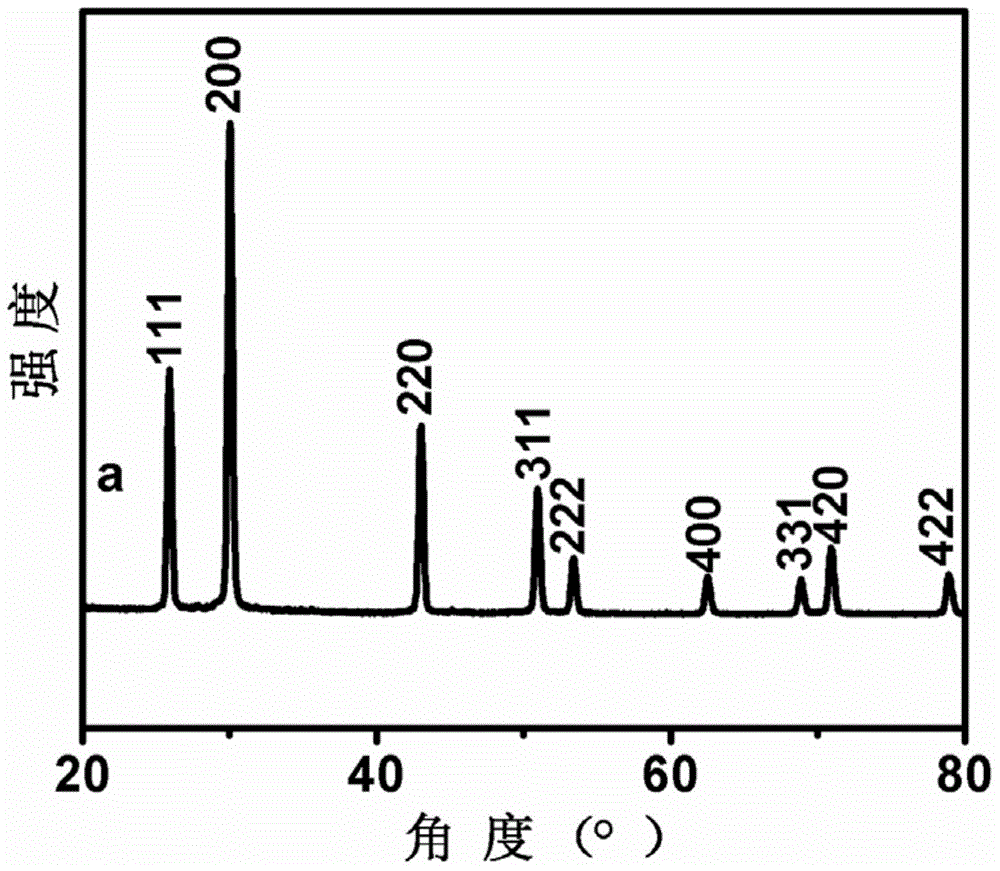

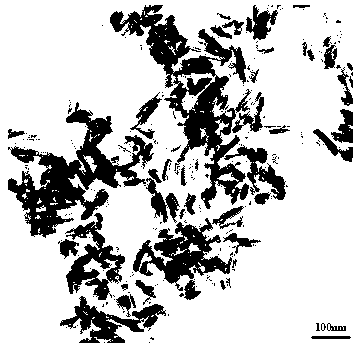

Preparation method of perovskite structure lead titanate single crystal nanoparticles

ActiveCN102677145AAchieve synthesisEasy to separatePolycrystalline material growthFrom normal temperature solutionsDispersityNanoparticle

Owner:ZHEJIANG UNIV

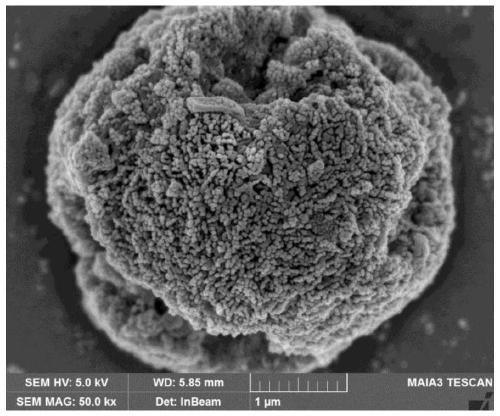

Preparation method of nano-magnesium hydroxide

ActiveCN107128962AHigh crystallinityImprove stabilityNanotechnologyCalcium/strontium/barium oxides/hydroxidesFiltrationPolyethylene glycol

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

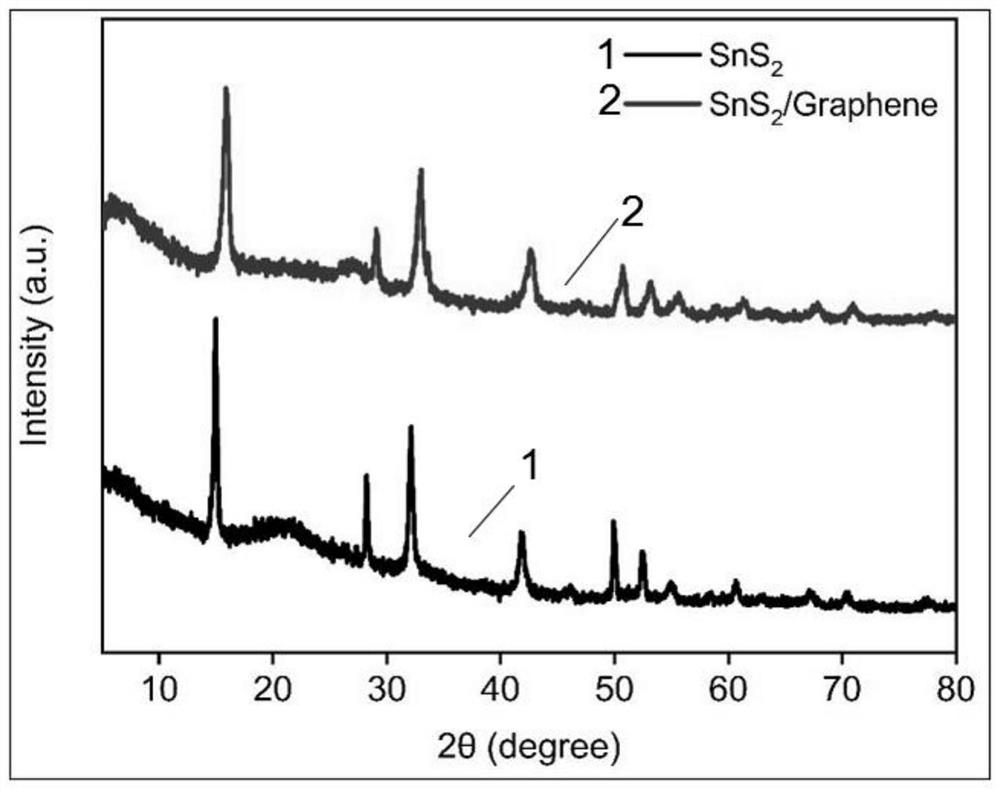

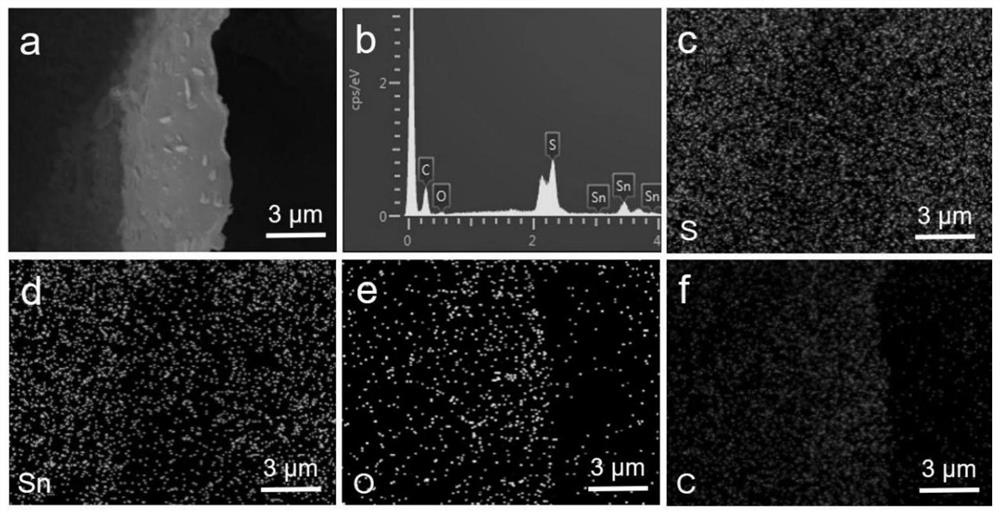

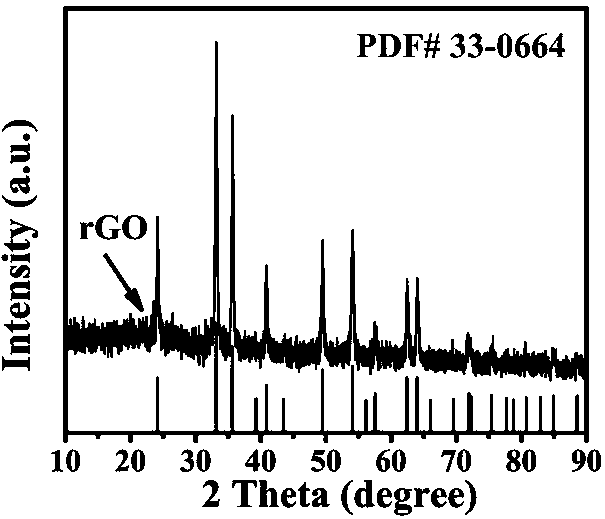

Preparation method of SnS2 nanosheet loaded graphene-based nanocomposite

Owner:安徽光特新材料科技有限公司

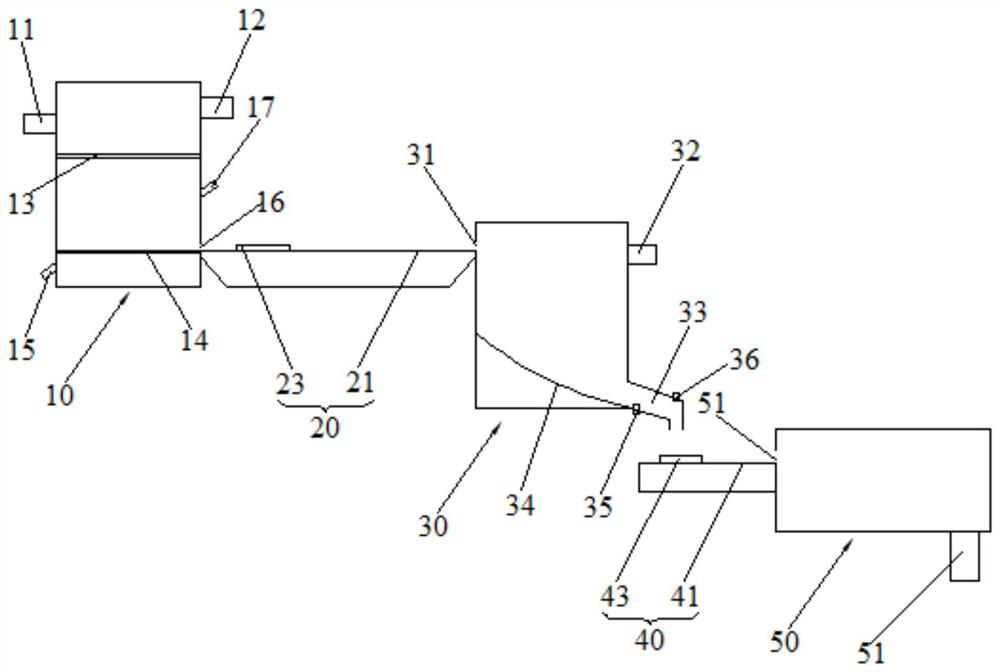

Recycling method and recycling equipment for positive electrode active material of lithium ion battery

PendingCN113764765AAvoid wastingAvoid pollutionElectrolyte/reactants regenerationPositive electrodesLithium electrodeHydrothermal reaction

The invention provides a recovery method and recovery equipment for a positive active material of a lithium ion battery, and the recovery method comprises the following steps: (1) soaking a scrapped positive plate in NMP (N-Methyl Pyrrolidone), heating to dissolve a binder in the positive plate in the NMP, and filtering and drying to obtain a positive waste material; and (2) adding LiNO3 and LiOH eutectic lithium salt into the positive electrode waste material, uniformly mixing, carrying out lithium supplement repair by adopting a solid phase method, and then carrying out high-temperature sintering. According to the method, the binder is dissolved through NMP, so that the positive electrode waste material can be separated from the current collector, then solid-phase lithium supplement repair is carried out on the positive electrode waste material and the eutectic lithium salt, and then high-temperature sintering is carried out, so that the positive electrode active material is obtained. The eutectic lithium salt is adopted, the sintering temperature of the eutectic lithium salt is low, the molten lithium salt can permeate into the surface and the interior of the positive electrode waste material at the low sintering temperature, and the sintered and repaired positive electrode active material can be more uniform. The solid-phase method is adopted for one-step sintering, the recovery rate is high, and the situation that an intermediate product needs to be prepared firstly and then cleaned and calcined in a hydrothermal reaction can be avoided.

Owner:DONGGUAN CHUANGMING BATTERY TECH

PbS nano-sheet preparation method

InactiveCN104609464APromote growthLow toxicityMaterial nanotechnologyLead sulfidesLead nitrateDecomposition

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

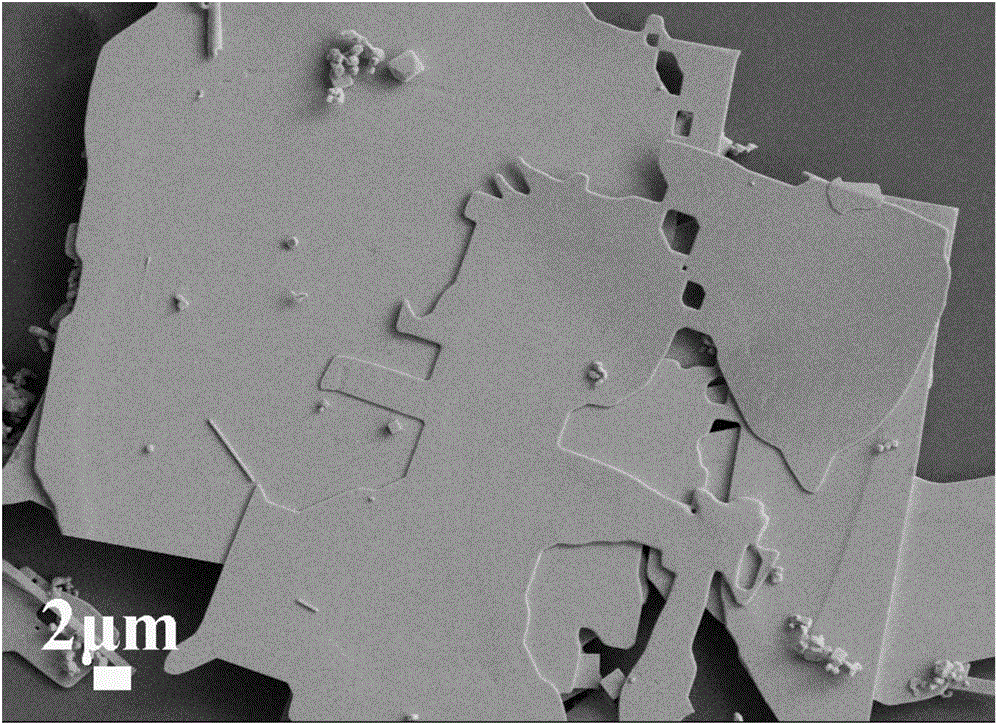

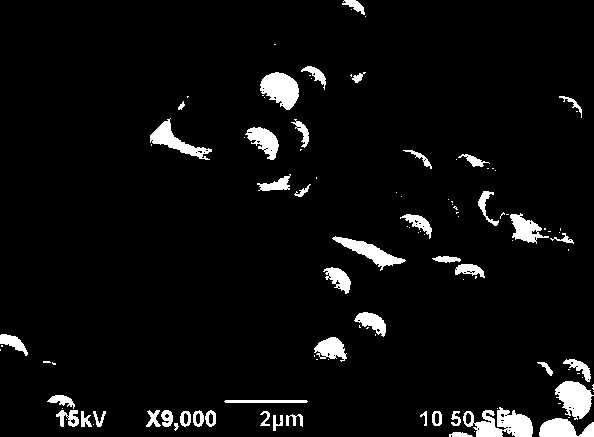

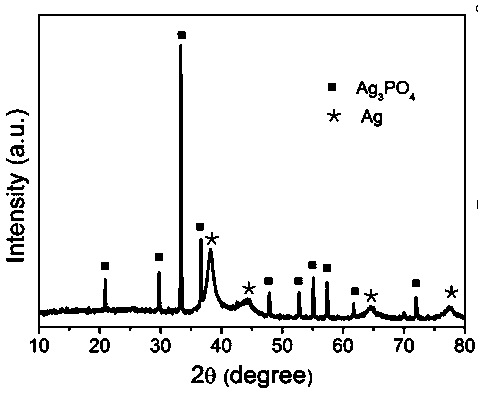

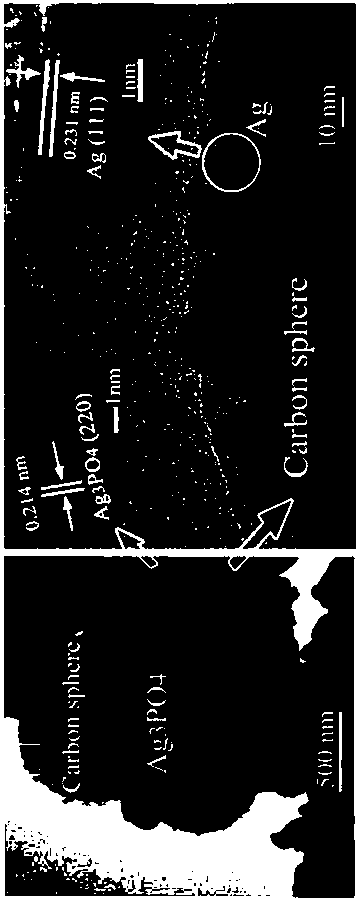

A preparing method of a Ag3PO4@Ag/carbon sphere ternary heterojunction composite material capable of selectively removing cationic dye

InactiveCN108906092AReduce coverageEasy transferPhysical/chemical process catalystsWater/sewage treatment by irradiationHeterojunctionCentrifugation

Owner:HENAN NORMAL UNIV

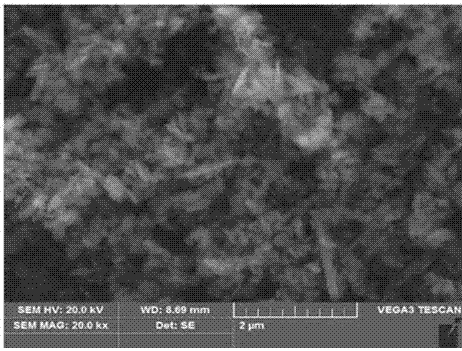

Preparation method of self-cleaning fibers

ActiveCN109382089ARetain high temperature resistanceRemain flexibleWater/sewage treatment by irradiationWater treatment compoundsFiberSodium bicarbonate

The invention provides a preparation method of self-cleaning fibers, and belongs to the field of water purification materials. The preparation method of the self-cleaning fibers comprises the following process steps: mixing deionized water, sodium metavanadate and ethylenediamine tetraacetic acid disodium, regulating pH of a solution with hydrochloric acid, and then adding a mixed solution of deionized water, bismuth nitrate pentahydrate, neodymium nitrate and sodium bicarbonate to prepare an active precursor solution; carrying out hydrothermal reaction on the active precursor solution and aluminium silicate fibers, and drying and calcining to obtain the self-cleaning fibers. The self-cleaning fibers consist of aluminium silicate fibers of which the surfaces are coated with bismuth neodymium vanadate, resist high temperature, are flexible, are high in strength, can float in water, and can degrade organic pollutants in water under the condition of illumination.

Owner:JIAXING RUYUN CONSTR TECH CO LTD

Preparation method and application of vanadium-doped gallium antimonate visible light photocatalyst

ActiveCN103920487AAvoid obstructionEnter fullyMaterial nanotechnologyWater/sewage treatment by irradiationVanadium dopingAmmonium metavanadate

Owner:FUJIAN NORMAL UNIV

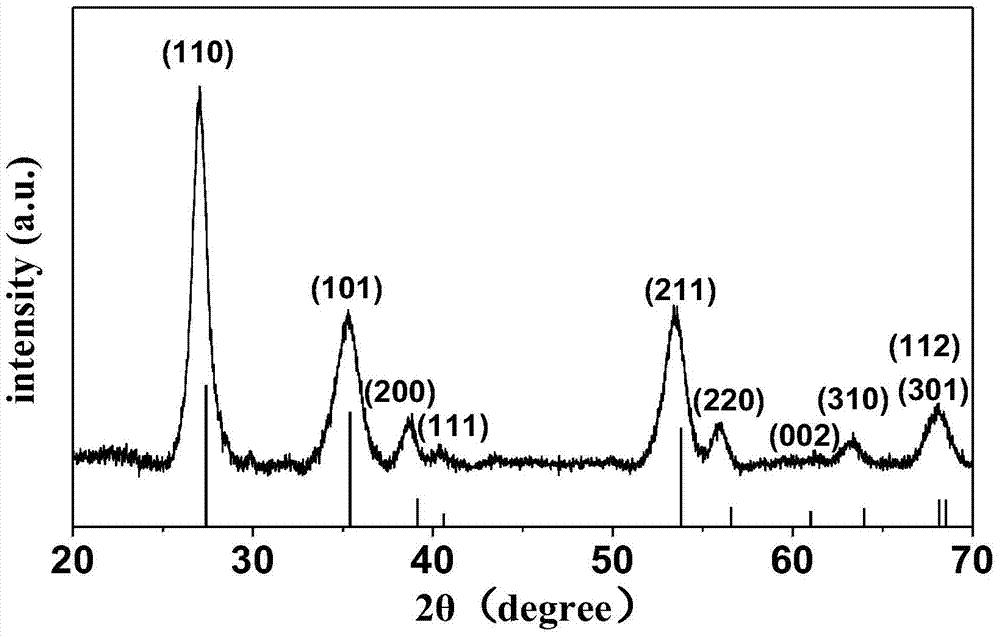

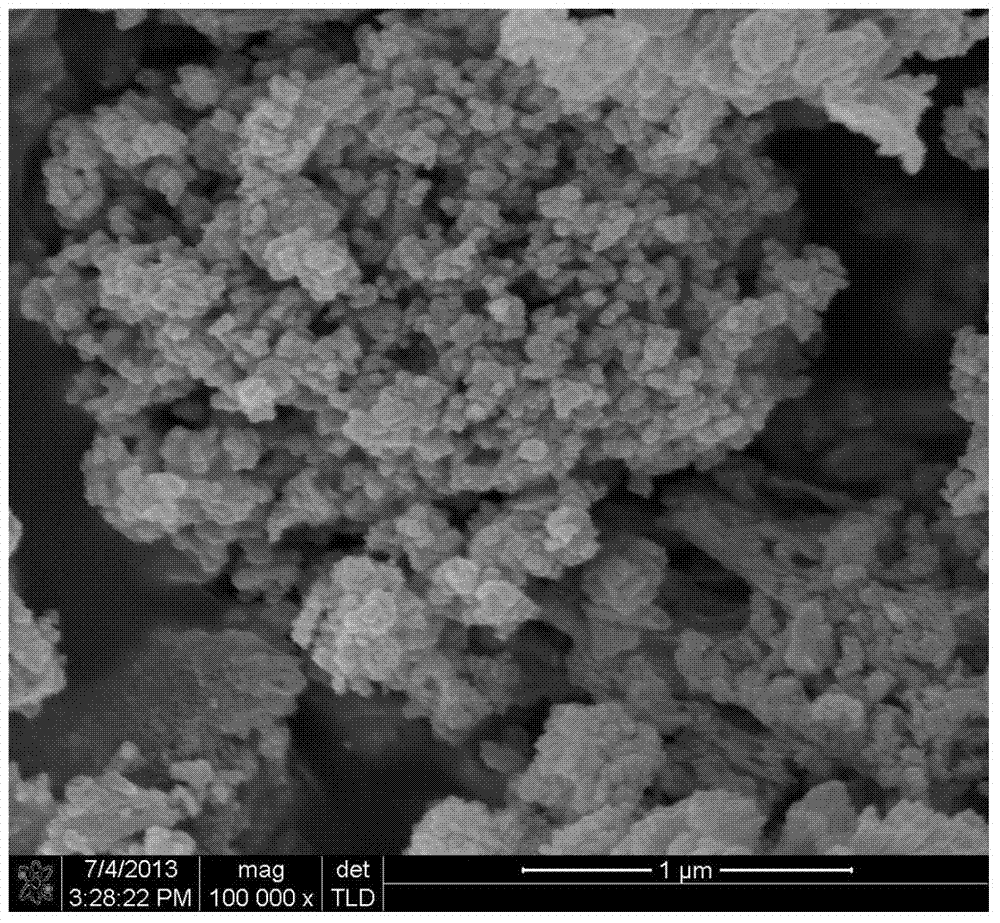

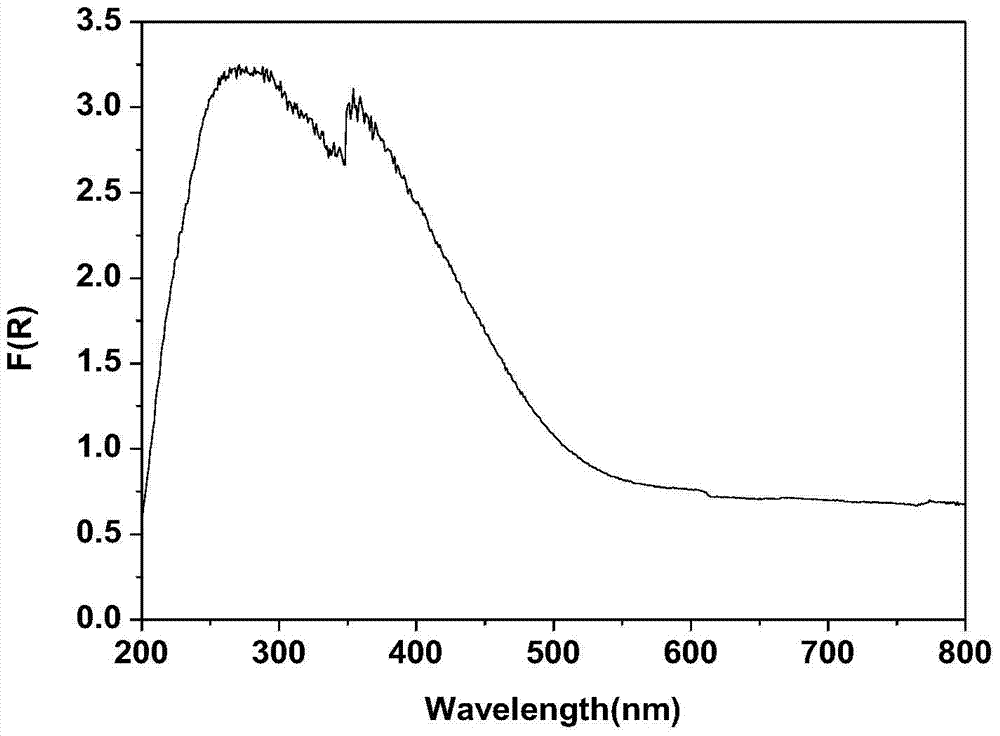

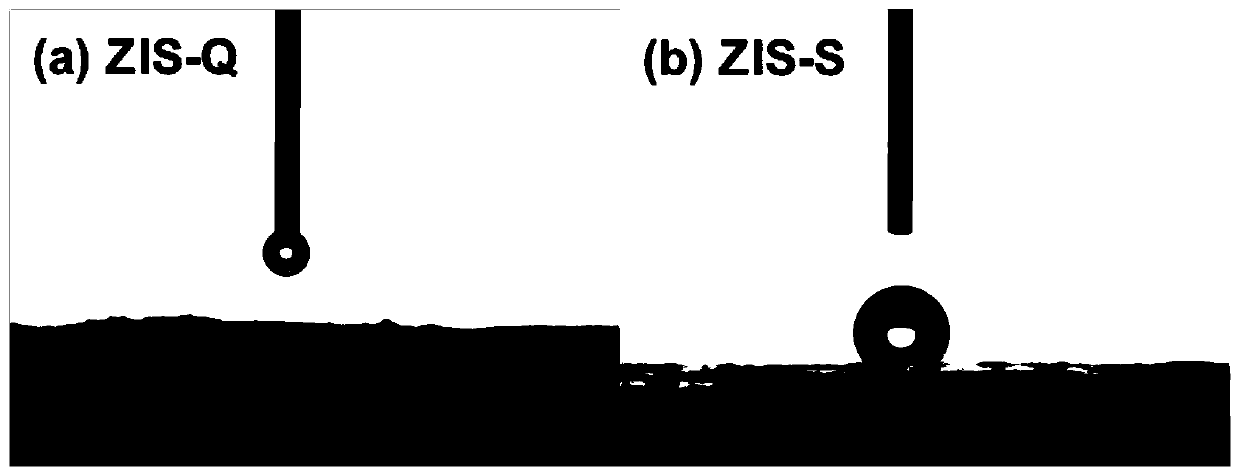

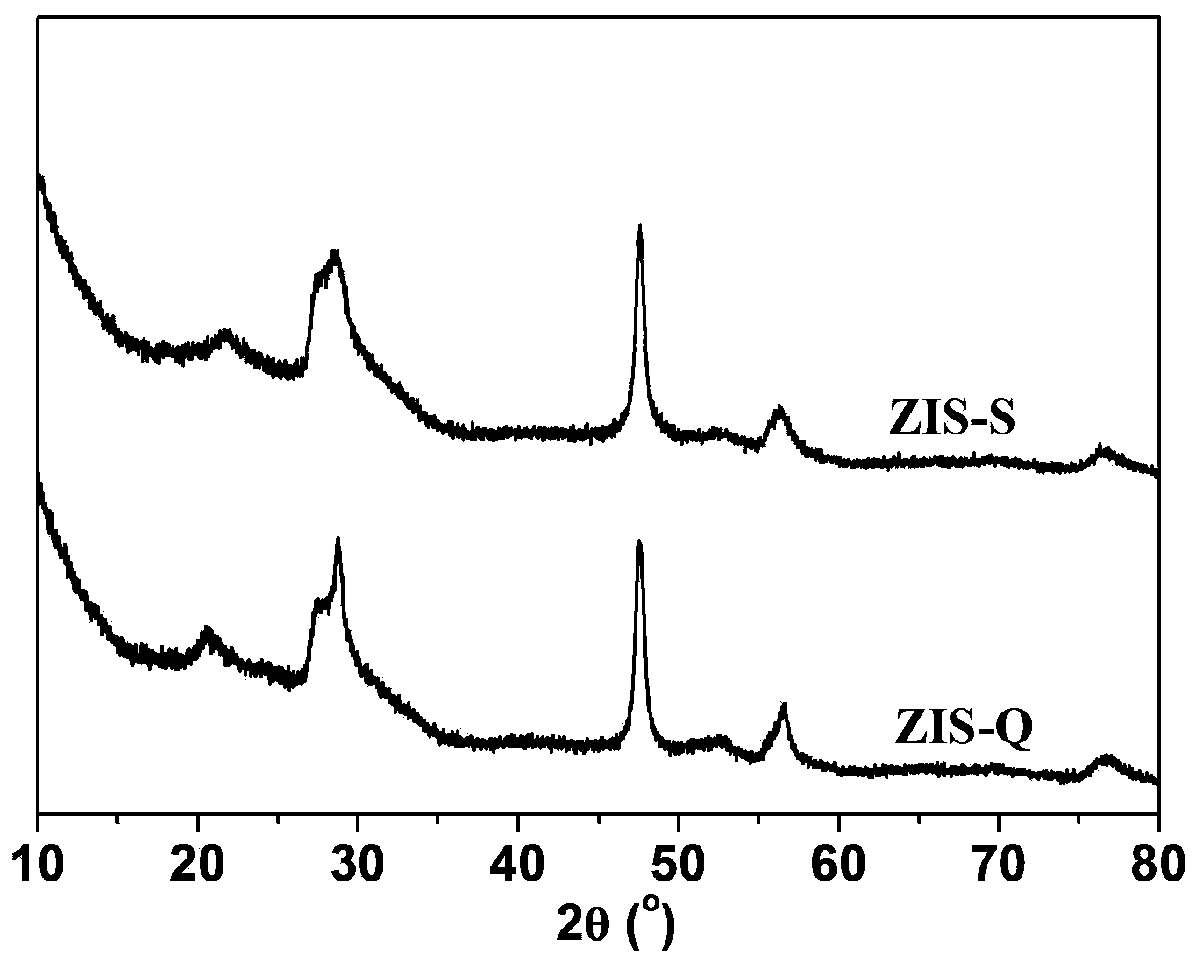

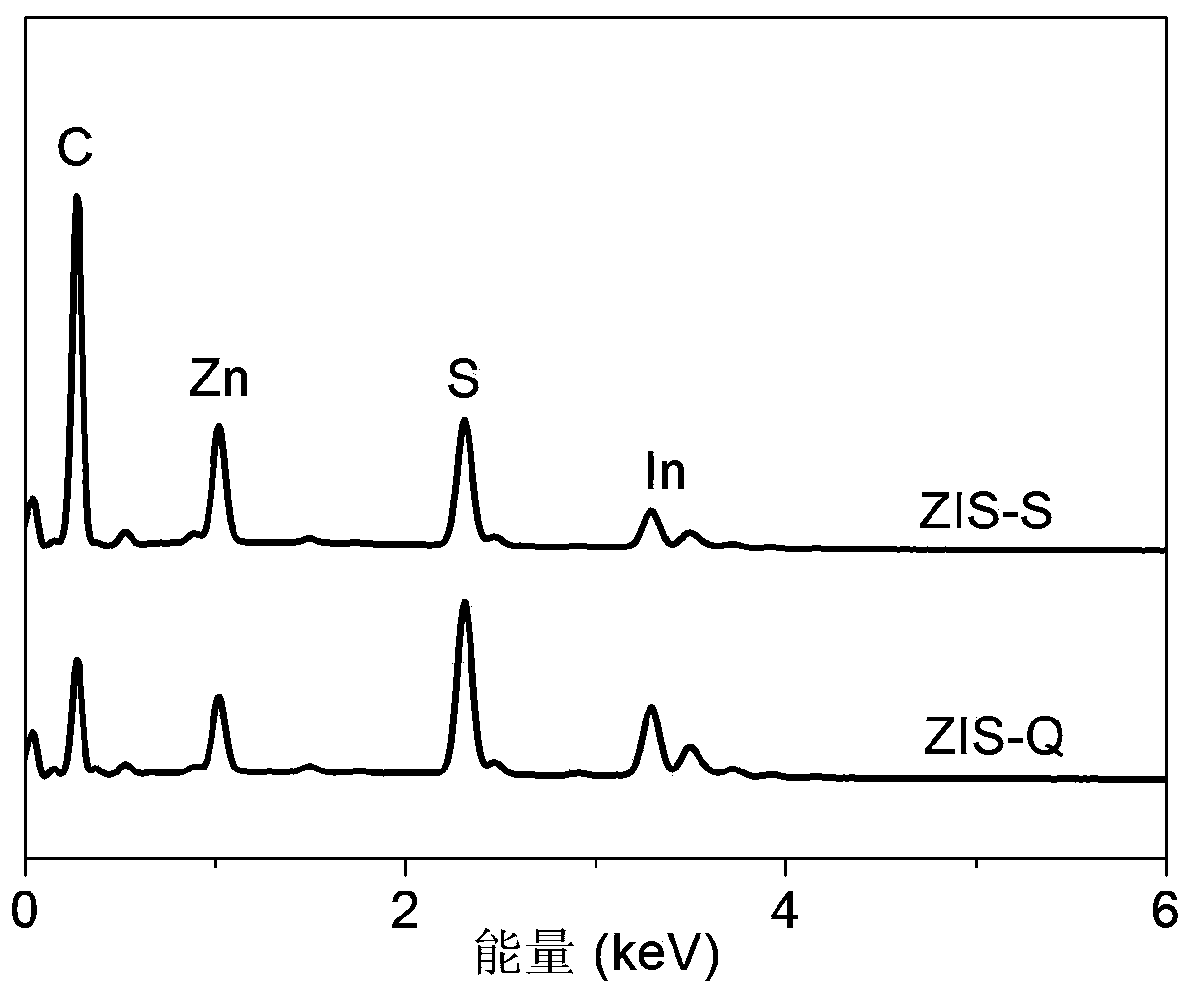

Preparation method of super-hydrophilic-super-hydrophobic controllable ZIS nano grading material and application thereof

PendingCN111233028AAchieve superphilic-hydrophobic regulationThe preparation method is simple and convenientMaterial nanotechnologyPhysical/chemical process catalystsMaterials scienceOrganic inorganic

Owner:HUAIBEI NORMAL UNIVERSITY

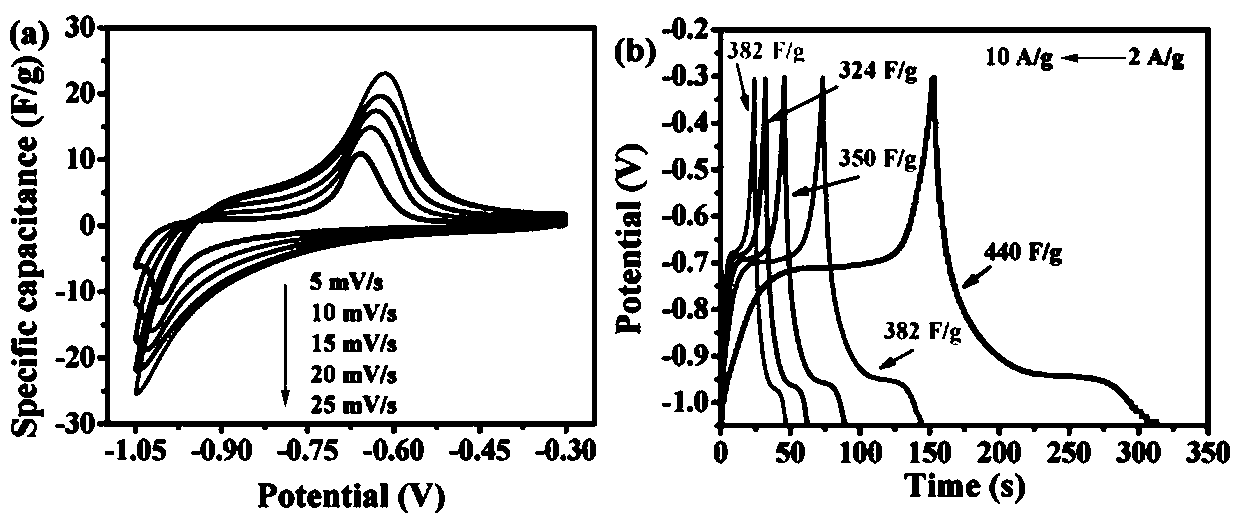

Reduced graphene/alpha-Fe2O3 supercapacitor material and preparation method and application thereof

ActiveCN110136978ALight in massQuality improvementHybrid capacitor electrodesHybrid/EDL manufactureThioureaSupercapacitor

Owner:ZHOUKOU NORMAL UNIV

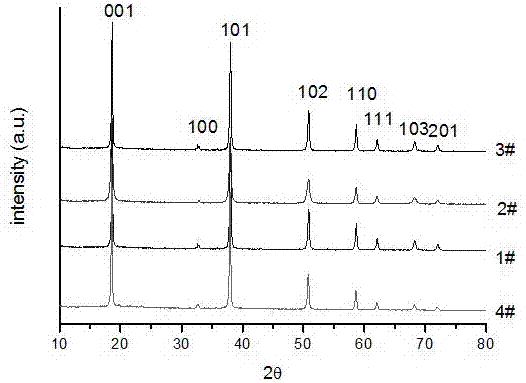

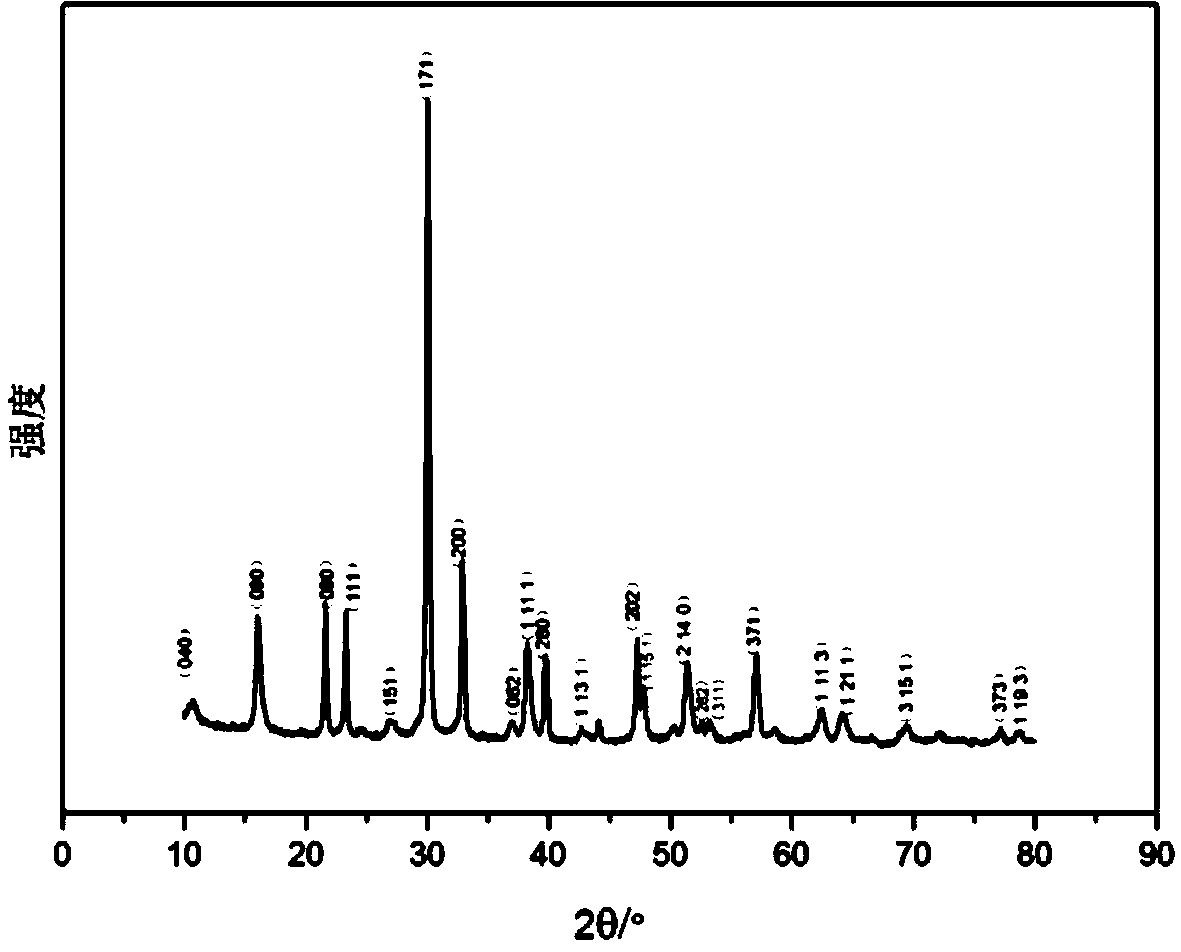

Preparation method and product of Bi4Ti3O12 micron sheets

InactiveCN104211118ABismuth compoundsHydrothermal reactionBismuth nitrate

Owner:ZHEJIANG UNIV

Graphene magnetic injection molding masterbatch for nylon electrical appliance plastics, and preparation method thereof

Owner:CHENDU NEW KELI CHEM SCI CO LTD

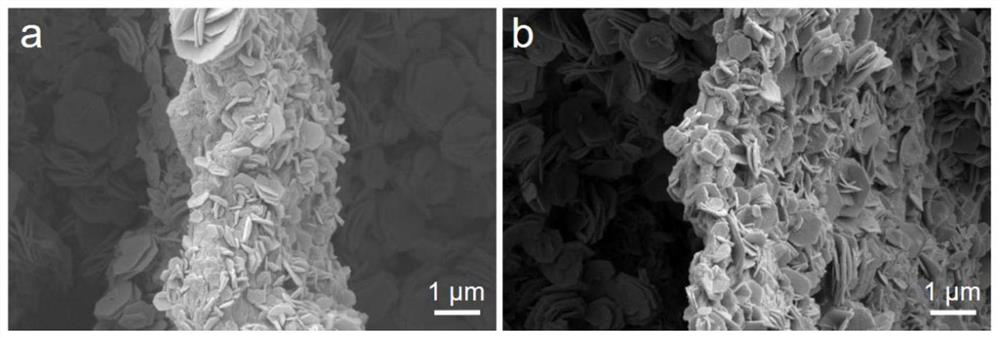

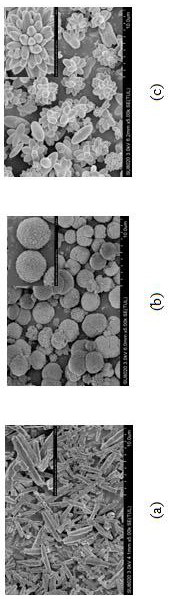

Preparation method of special-morphology micro nano structural lithium-rich manganese-based cathode material

ActiveCN110143619AAchieving controllable equipmentRealize controllable preparation of special morphologyMaterial nanotechnologyPositive electrodesNickel saltHigh energy

Owner:JISHOU UNIVERSITY

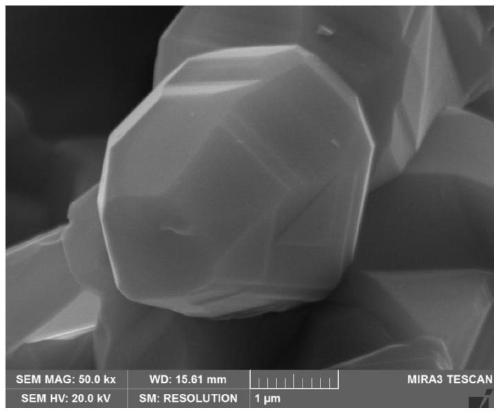

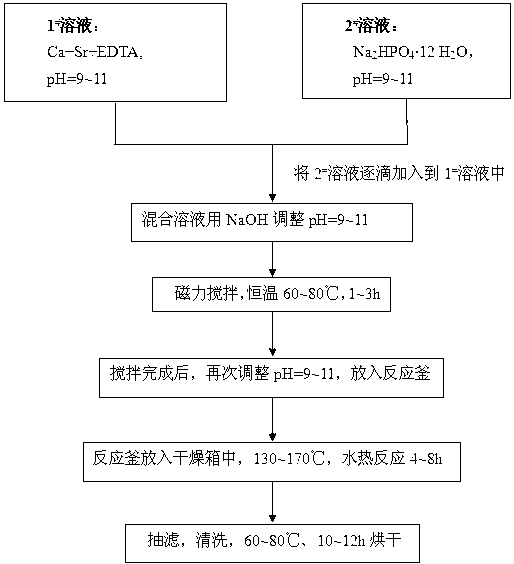

Preparation method of nanometer strontium-doped hydroxyapatite powder

InactiveCN102390823BThe experimental method is simpleThe experimental method is controllableMaterial nanotechnologyPhosphorus compoundsApatiteStrontium

Owner:CHONGQING UNIV

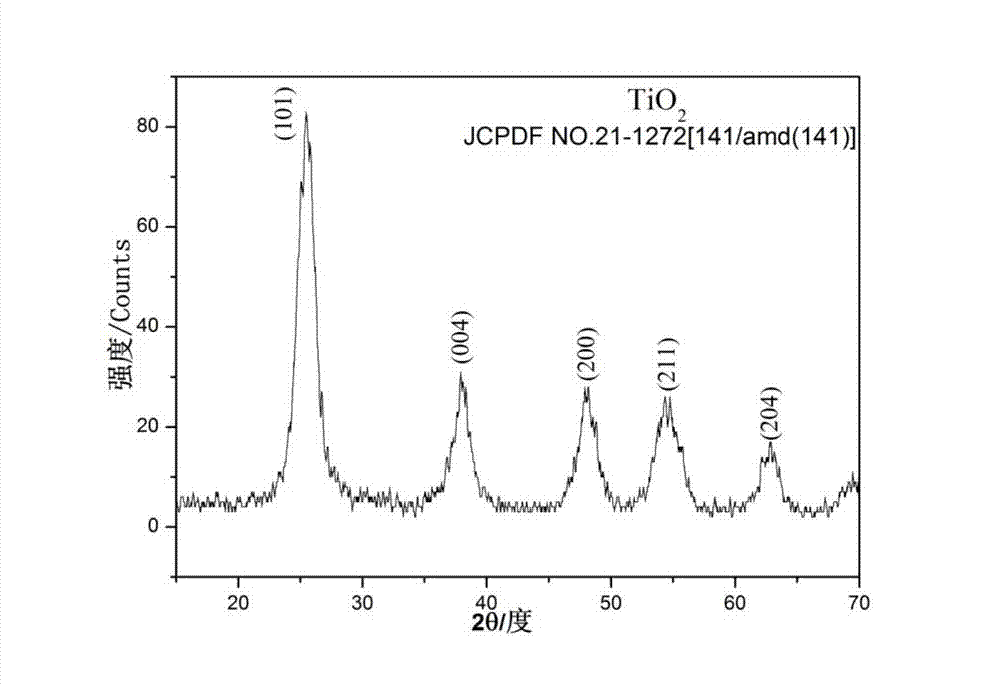

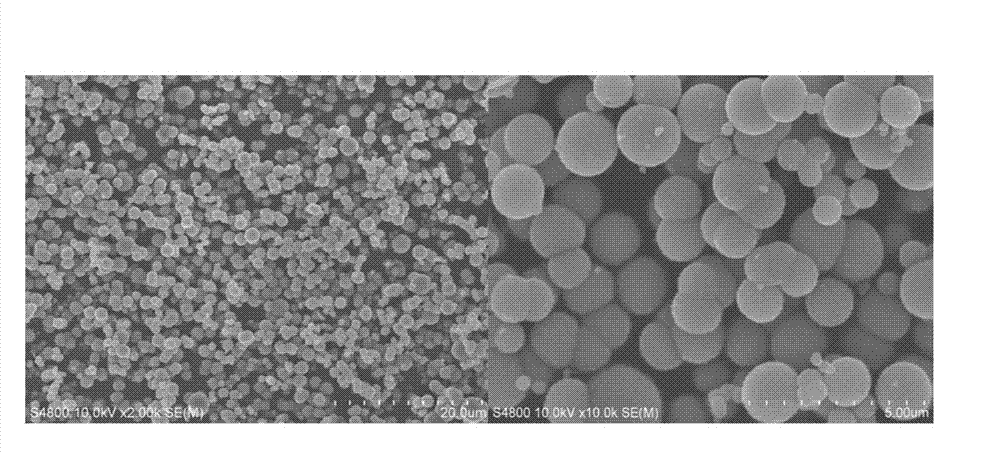

Method for preparing blue-shifting TiO2 microspheres

InactiveCN102923769AGood repeatabilityHigh temperature and high repeatabilityTitanium dioxideMicrosphereTemperature control mode

Owner:SHAANXI UNIV OF SCI & TECH

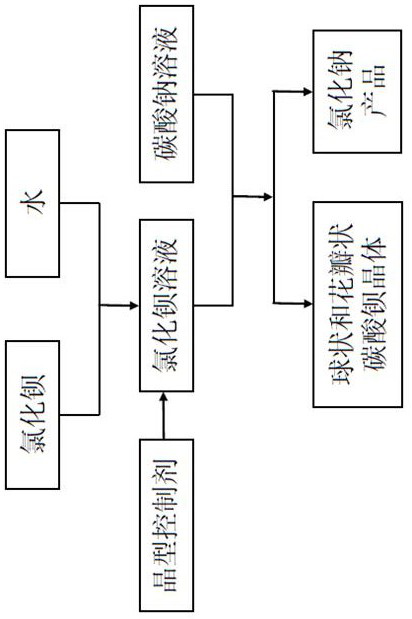

Preparation method of anhydrous barium carbonate crystals with special morphology

InactiveCN112194162ASolve the problem of high reaction temperatureHigh yieldBarium carbonatesBarium dichloridePhysical chemistry

Owner:NORTH CHINA INST OF SCI & TECH

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap