Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17 results about "Thermoplastic elastomer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic elastomers (TPE), sometimes referred to as thermoplastic rubbers, are a class of copolymers or a physical mix of polymers (usually a plastic and a rubber) that consist of materials with both thermoplastic and elastomeric properties. While most elastomers are thermosets, thermoplastics are in contrast relatively easy to use in manufacturing, for example, by injection molding. Thermoplastic elastomers show advantages typical of both rubbery materials and plastic materials. The benefit of using thermoplastic elastomers is the ability to stretch to moderate elongations and return to its near original shape creating a longer life and better physical range than other materials. The principal difference between thermoset elastomers and thermoplastic elastomers is the type of cross-linking bond in their structures. In fact, crosslinking is a critical structural factor which imparts high elastic properties.

Thermoplastic polymer composition and molded article

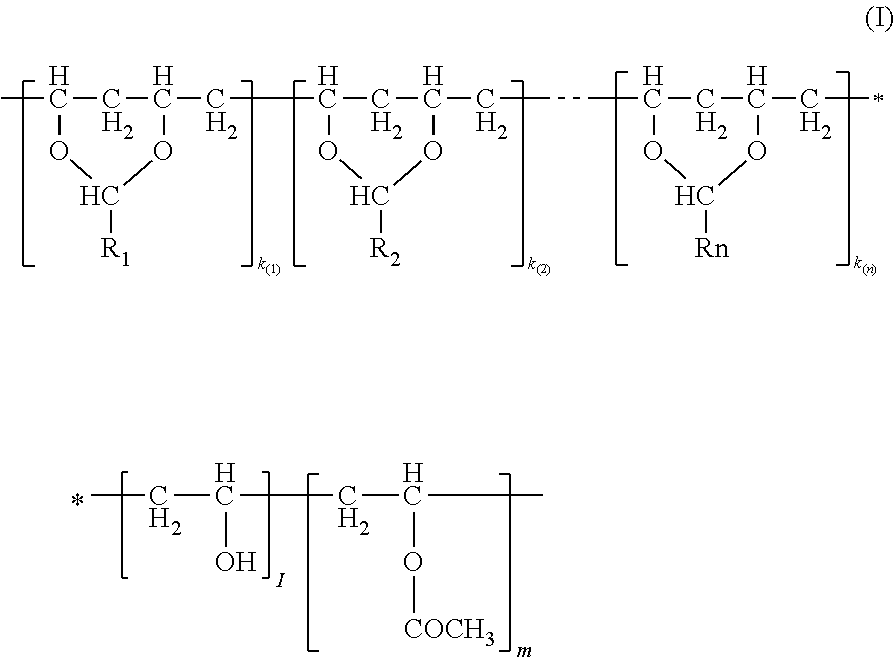

InactiveUS20130122289A1Excellent in flexibility propertyImprove mechanical propertiesNon-fibrous pulp additionNon-macromolecular adhesive additivesPolyvinyl alcoholGlass transition

Owner:KURARAY CO LTD

Thermoplastic Elastomer Compositions Comprising Intumescent Flame Retardants and Non-Phosphorous-Based Flame Retardant Synergists

ActiveUS20120125657A1Plastic/resin/waxes insulatorsInsulated cablesThermoplastic elastomerPolyphosphate

Owner:UNION CARBIDE CORP

Thermoplastic Elastomer Composition And Shaped Article

Owner:ZEON CORP

Thermoplastic elastomer composition

Owner:IDEMITSU KOSAN CO LTD

Toothbrush with Light Transmissive Handle

A toothbrush handle includes a support structure formed of clarified polypropylene and a body formed of thermoplastic elastomer disposed on the support structure. The support structure includes a web having a thickness in a first direction orthogonal to an axis of the toothbrush handle of less than 2 millimeters and at least one rib depending from the web and having a thickness in a second direction, orthogonal to the axis and angled relative to the first direction, of less than about 2 millimeters. The body at least partially covers the web and the at least one rib. The handle has a light transmissivity of greater than 40% through a portion of the handle at which the body covers the web and the at least one rib.

Owner:COLGATE PALMOLIVE CO

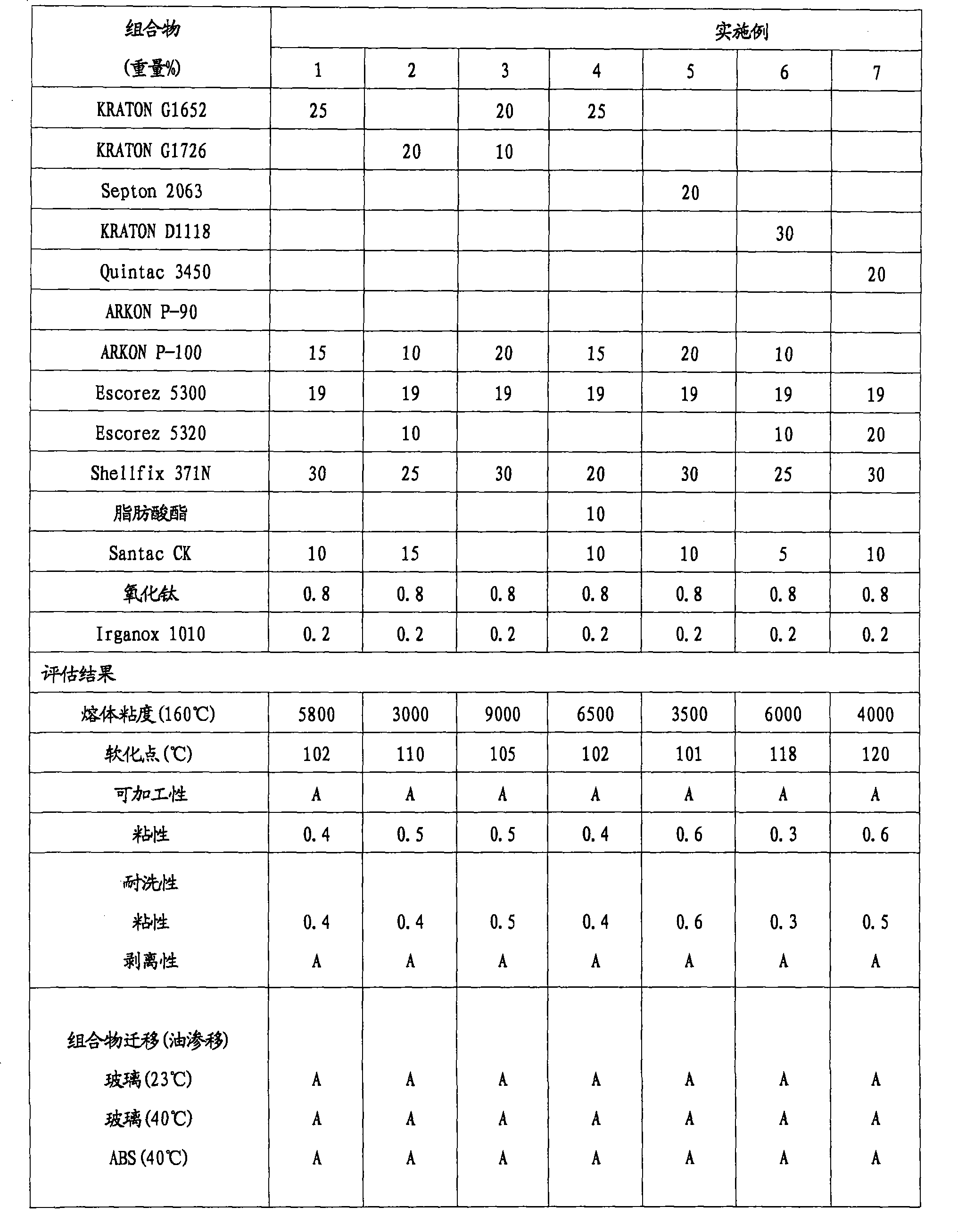

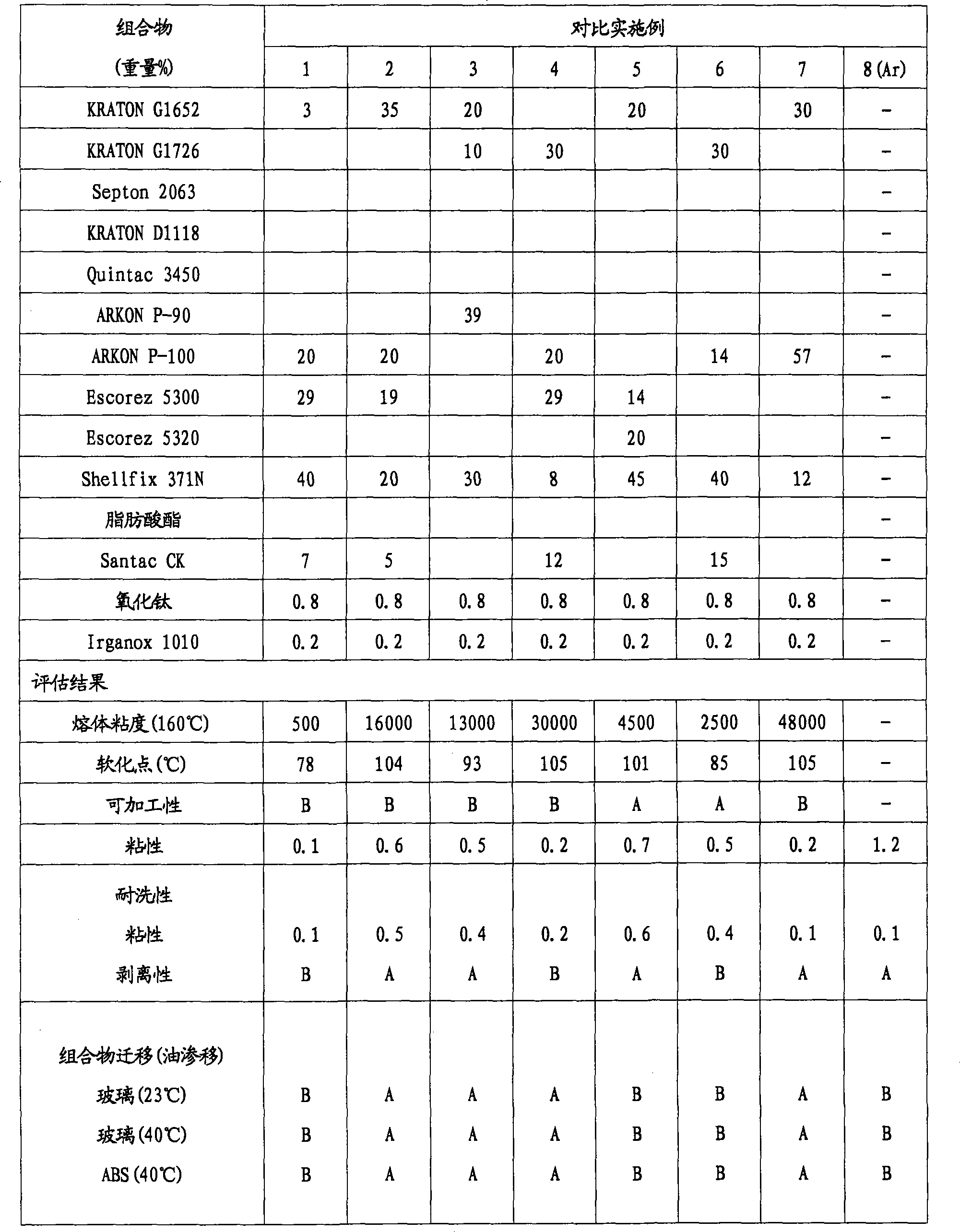

Hot melt composition for toilet seat sheet and toilet seat sheet

InactiveCN101381588AReduce manufacturing costIncrease productionBathroom coversAdhesivesPolyolefinEngineering

Owner:NISSHIN CHEM IND CO LTD

High-strength wear-resistant environmental-friendly plastic and preparing method thereof

Owner:ANHUI GUANGYUAN TECH DEV

Preparation method of high-polymer self-sealing hot melt adhesive powder for raising safety level of automobile tire

Owner:LUOYANG JUNTENG ENERGY TECH +1

Cement nanometer toughening agent for natural gas well cementation

Owner:CNPC BOHAI DRILLING ENG

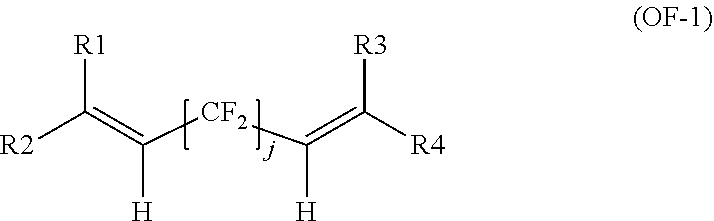

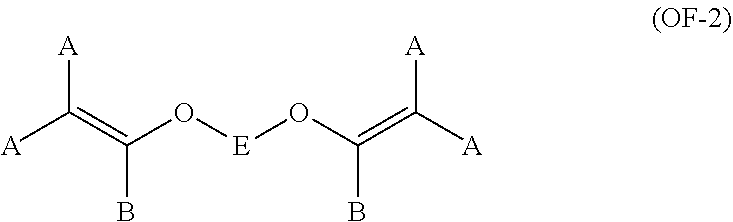

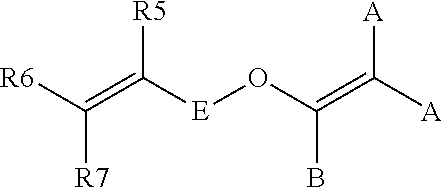

Composition comprising a semi-crystalline vdf polymer and a fluorinated thermoplastic elastomer block copolymer

InactiveUS20200095415A1Improved resistance to stainingEasy to adjustInsulatorsElastomerPolymer science

Owner:SOLVAY SOLEXIS

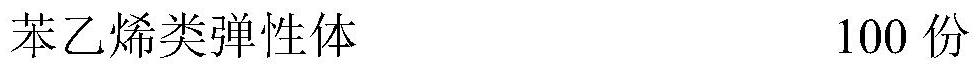

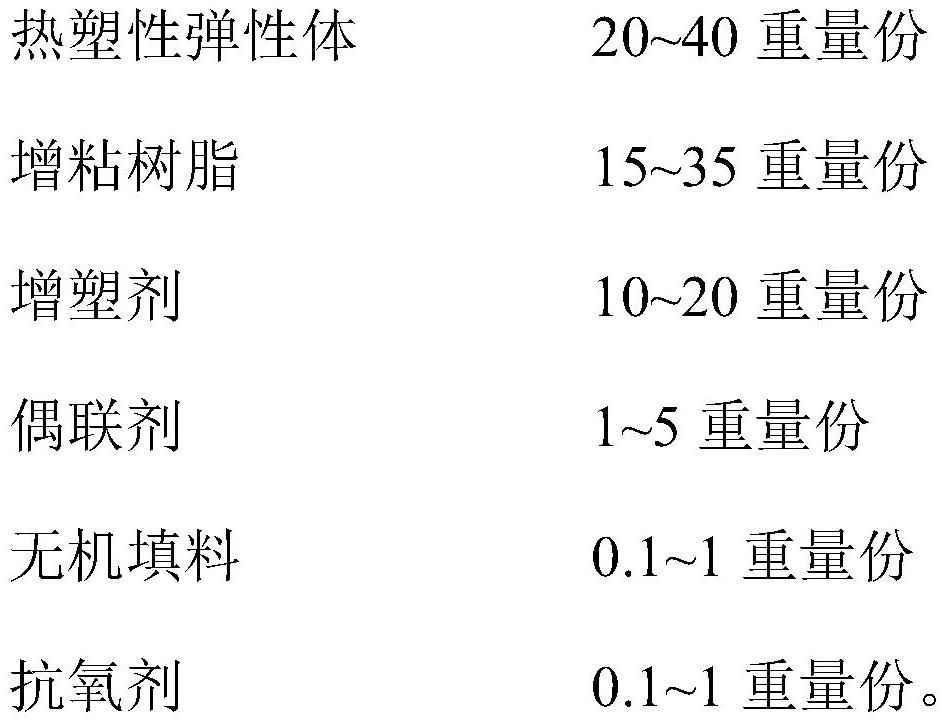

High-molecular hot melt glue with self-sealing function and production method of hot melt glue

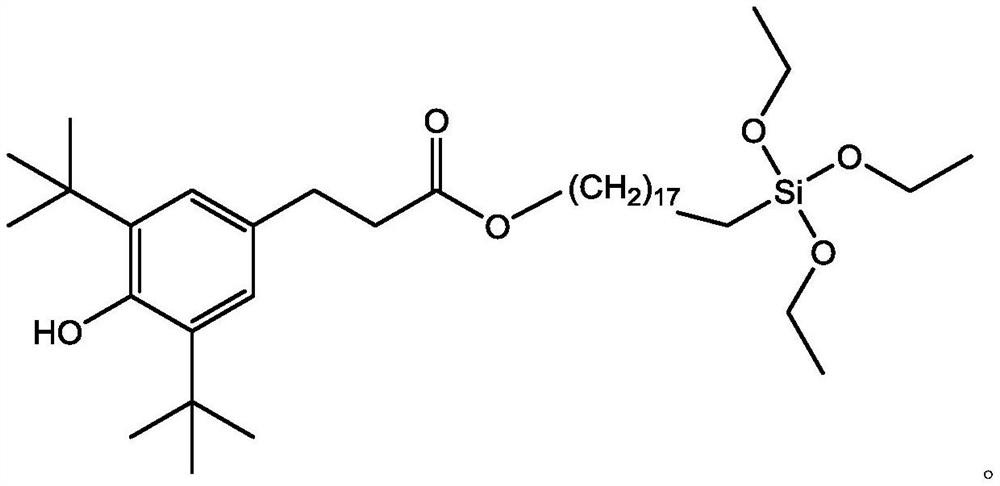

InactiveCN103849290AReduce the amount of vibrationNo change in dynamic balanceRosin coatingsPlasticizerThermoplastic elastomer

Owner:LUOYANG JUNTENG ENERGY TECH

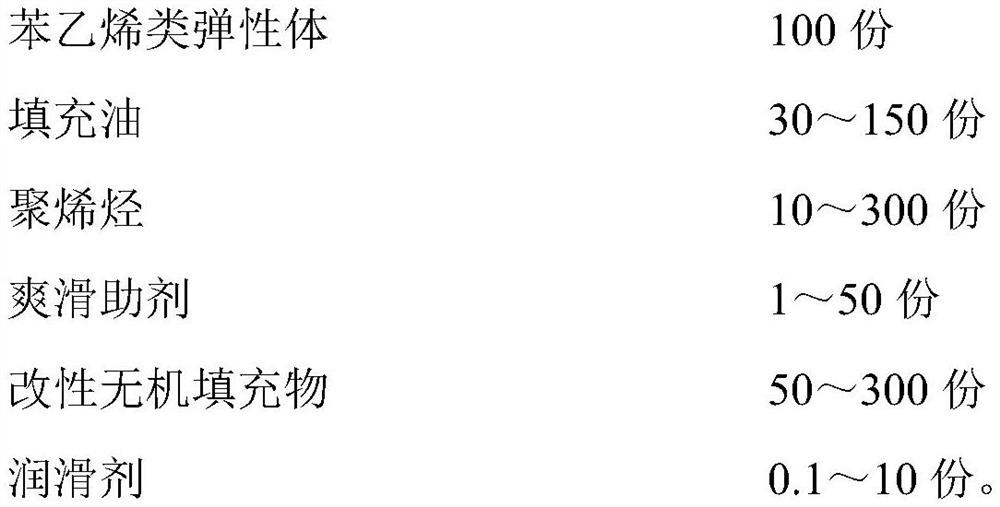

High-filling scratch-resistant extrusion-grade thermoplastic elastomer material and preparation method thereof

Owner:NANTONG POLYMAX ELASTOMER TECH

Multilayer natural fiber sheet and thermoplastic plastic composite material, and preparation method thereof

ActiveCN107057189AHigh mechanical strengthEasy to stretchOther domestic articlesThermoplasticThermoplastic elastomer

The invention discloses a multilayer natural fiber sheet and thermoplastic plastic composite material, and a preparation method thereof. The multilayer natural fiber sheet and thermoplastic plastic composite material is mainly formed by stacking and laminating natural fiber sheets and thermoplastic plastics, wherein the natural fiber sheets are made by mixing about 10 to 40 percent of natural fibers and about 2 to 5 percent of dispersing agents in percentage by volume, and the remaining are the thermoplastic plastics. The natural fibers are cut short, and after being blended, the dispersing agents and the natural fibers are added into distilled pure water and are ultrasonically dispersed to obtain suspension liquid; the water and the dispersing agents are filtered, and then the suspension liquid is dried to obtain the natural fiber sheets; thermoplastic plastic particles are pressed into plastic sheets, and the natural fiber sheets and the plastic sheets are stacked into a multilayer material which is placed into a mold frame and then pressed. The material is completely based on a green material and environment protection process, the mechanical performance of the material is associated with the number of layers of natural sheets and is maximized in case of four to five layers, the tensile strength, the bending strength and the impact strength can be more than two times those of raw materials, and the industrial application prospect is great.

Owner:THE UNIV OF NOTTINGHAM NINGBO CHINA

Solvent-free printing platen glue as well as preparation method and application thereof

PendingCN114561175AGood adhesionIncrease temperatureNon-macromolecular adhesive additivesOil/fat/wax adhesivesElastomerTextile printer

Owner:DONGGUAN CTL NEW MATERIAL TECH

High-temperature-resistant thermoplastic elastomer and preparation method thereof

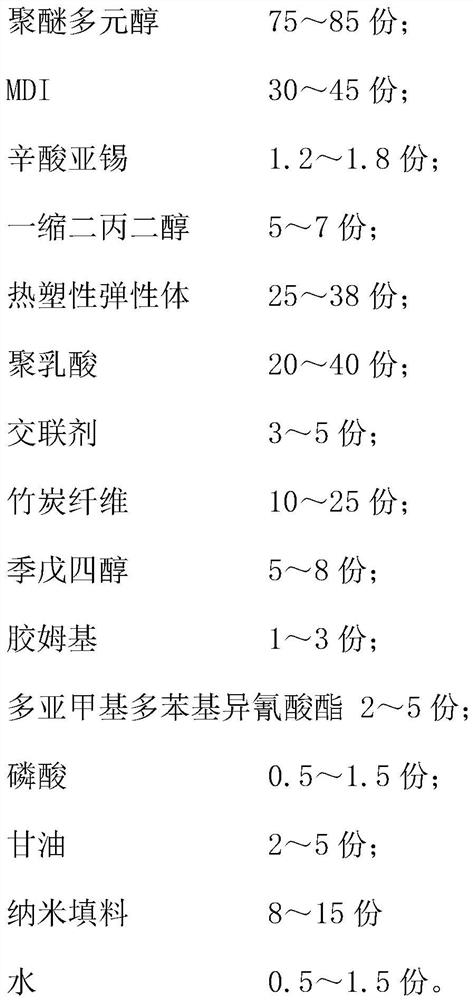

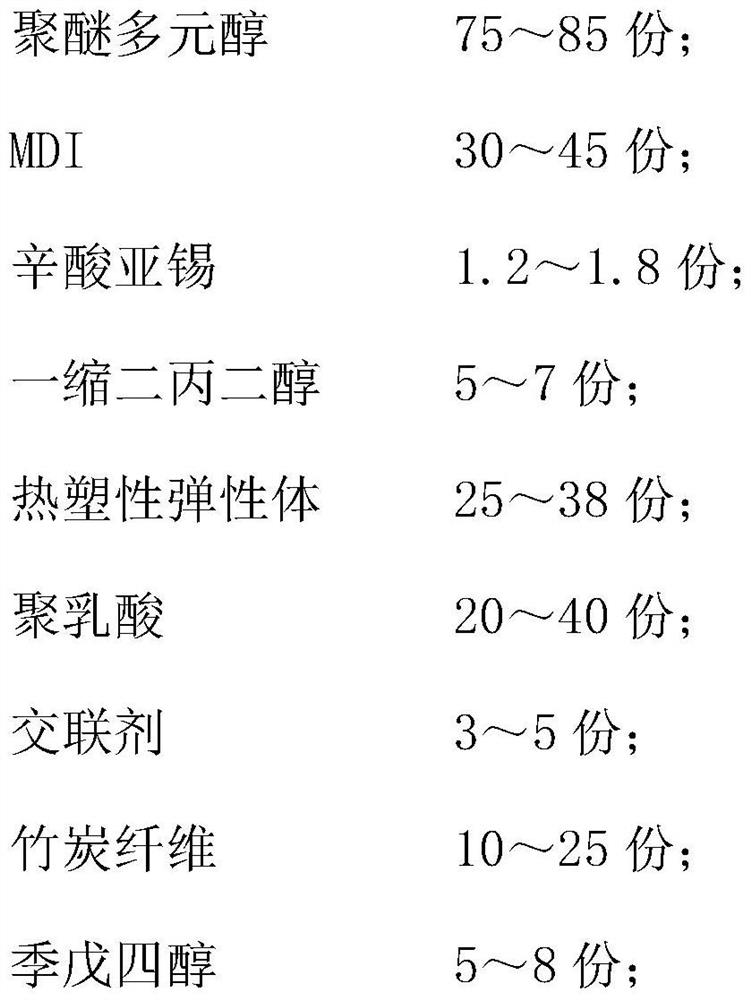

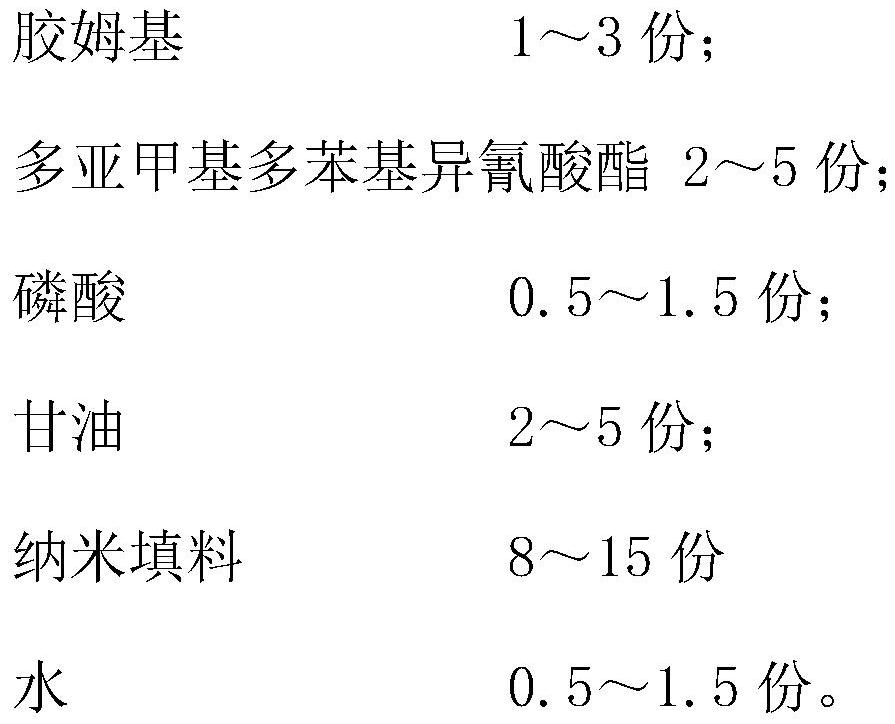

InactiveCN106674843AImprove aging resistanceImprove high temperature resistanceDiphenylmethaneElastomer

Owner:ANHUI TIANYUAN CABLE

Resin composition improved in low-temperature impact resistance

A resin composition of the invention includes a thermoplastic elastomer and a glycol or its derivative. Polyamide- or polyester-based thermoplastic elastomers, for example, can be used as the thermoplastic elastomer. The soft segment of the thermoplastic elastomer may be composed of a polyether or polyester. As the glycol or its derivative, for example, a compound represented by the following Formula (1):(wherein each of R<1 >and R<2 >is, identical to or different from each other, a hydrogen atom, an alkyl group or an acyl group; each of A<1>, A<2 >and A<3 >is, identical to or different from one another, an alkylene group having 2 or more carbon atoms; each of l, m and n is, identical to or different from one another, an integer of 0 or more, where l+m+n>0) can be used. This resin composition can substantially improve impact resistance at low temperatures while maintaining tensile properties, flexural properties and heat resistance properties.

Owner:DAICEL HULS

Nano high-resilience composite material for children's toys and preparation method thereof

Owner:广东乐的互动娱乐股份有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap